Abstract

A bioflocculant with high flocculating activity, LC13-SF, produced by strain LC13T which was in a viable but nonculturable (VBNC) state, and which was woken up by Rpf (resuscitation promoting factor), was systematically investigated with regard to its fermentation conditions and flocculating activity. The key parameters influencing the bioflocculant LC13-SF were investigated through measuring the optical density at 660 (OD660) of the fermentation liquid and the optical density at 550 (OD550) of the centrifugal supernatant. The flocculating efficiency and the Zeta potentials were chosen as the response variables for the study of the flocculating activity. The results showed that the optimal conditions for bioflocculant LC13-SF production were a fermentation time of 72 h, an initial pH of 7.0, a fermentation temperature of 30°C and a shaking speed of 150 r/min. The optimized flocculating process was as follows: a final volume percentage of bioflocculant LC13-SF and 0.5% (w/w) CaCl2 were 1.5 and 5%, respectively in a 4 g/L Kaolin suspension, and the system pH was adjusted to 8.0. Under these conditions, the flocculating efficiency and the absolute value of the Zeta potential reached 94.83% and 4.37, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Soils may be the most challenging of natural environments to characterize microorganism. Through comparing the dilution plate counts of culturable microorganisms with direct microscopic counts of total microorganisms, it has been established that only 0.01–4% of microorganisms in soils can be cultured on organic growth media (Faegri et al. 1997; Olsen and Bakken 1987). Most soil bacteria are in a viable but nonculturable (VBNC) state, in which microbial cells are metabolically active but cannot be cultured by current techniques. Therefore, an important topic of research is how to wake up bacteria from such a non-growth state. A major breakthrough in the understanding of VBNC states has arisen from the study of the high G + C gram-positive bacterium, Micrococcus luteus, which secretes a small protein called Rpf (resuscitation-promoting factor). Rpf plays a very important role in studying unknown microorganisms, because it can resuscitate the large number of “non-culturable” bacterial groups to become cultivable (Mukamolova et al. 1998).

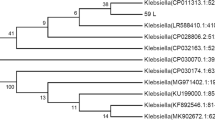

In our previous study, using MPN (most-probable-number) method (repeat the experiment three times, according to MPN table, can determine the total bacterial count of cultivable), Rpf was added as a component of culture system to investigate the VBNC state bacteria in response to Rpf. Through comparing the treatment group (with Rpf) with control group (without Rpf), many bacteria were confirmed inVBNC state, then were isolated by plate isolation method (Ding 2004; Ding et al. 2007, 2009; Li et al. 2007; Ding and Yokota 2010). Nowadays, it is highly anticipated to develop efficient microbial flocculants (MBFs) (Zhang et al. 2007; Huang and Chen 2004) that partly or even completely substitute for the traditional flocculants (Christopher et al. 2006; Tareke et al. 2002). So we selected some of strains which isolated from activated sludge or sewage treatment system to investigate their function of flocculation. Adopting Kaolin suspension as the active evaluation system, a flocculant producing strain LC13T which the flocculation efficiency was up to 80% was selected. The strain LC13T (CCTCC 206018T) was isolated using NY medium which was consisted of nutrient broth 1.6 g, yeast extract 0.5 g, cycloheximide 0.05 g, kabicidin 0.1 g and agar 15 g dissolved in 1 L distilled water with pH adjusted to 7.0, and was identified as a novel species of the genus Arthrobacter by its morphological, physiological and genotypic characteristics (Ding et al. 2009). In this study, attention was focused on its flocculating properties. We investigated its fermentation conditions and flocculating activity. Based on the experimental results, we optimized the flocculation characteristics of LC13T.

Materials and methods

Materials

Kaolin was of chemically pure grade (Sinopharm Chemical China), and its suspension was prepared at the concentration of 4 g/L. The analytically pure grade CaCl2 (Sinopharm Chemical China) was prepared at the concentration of 0.5% (w/w). The components of the culture and fermentation medium which were purchased from Sanpu Chemical Co. in China were of analytically pure grade.

Bacteria strain and culture media

A. albidus LC13T (CCTCC 206018T) was a flocculant-producing strain that was isolated from a filtration substrate made from volcanic rock from Niigata, Japan, using NY medium (Ding et al. 2009). Through comparing the treatment group (with Rpf) with control group (without Rpf), the strain LC13T was confirmed inVBNC state. The stock culture preserved in 20% (v/v) glycerol solution at −80°C was routinely used as a preinoculum to inoculate a 150-mL flask containing 50 mL of fermentation broth.

Assay of fermentation conditions

The fermentation medium consisted of peptone 5 g, yeast extract 0.5 g, glucose 5 g and NaCl 2.5 g dissolved in 1 L distilled water with the pH adjusted to 7.0 with NaOH (0.1 M) and HCl (0.1 M). All media solutions were sterilized at 121°C for 15 min. This fermentation cultivation process was divided into two stages. In the first stage, a 150-mL flask containing 50 mL fermentation medium was inoculated with 1.0 mL preculture of strain LC13T and incubated at 30°C in a rotary shaker at 160 r/min for 12 h. In the following stage, the pre-fermentation medium was inoculated into a 150-mL flask according to the same volume ratio used in the fermentation liquid in the first stage. Various conditions of fermentation time (24–120 h), the initial pH (5–9) of the fermentation medium, fermentation temperature (24–34°C) and shaking speed (130–180 r/min) were tested for bioflocculant LC13-SF production. In the meantime, the cell growth was monitored by measuring the optical density (OD) of the fermentation broth at 660 nm (OD660) with a spectrophotometer (UV-7504, Shanghai, China). At the end of the cultivation, the obtained fermentation broth was centrifuged (12,000×g, 10 min) to separate the cells. The centrifugal supernatant was the liquid bioflocculant LC13-SF, which was used for the analysis of flocculating efficiency. All experiments were performed in triplicate and the mean average was calculated.

Flocculation experiments

The flocculating efficiency (FE) was evaluated using a previous method with a slight modification, in which a Kaolin suspension was chosen (Zhang et al. 2007; Yokoi et al. 1995). In a 100-mL test tube, 0.5% (w/w) CaCl2 and bioflocculant LC13-SF were added to 100 mL of Kaolin suspension (4 g/L). The pH of the mixture was adjusted with NaOH (0.1 M) and HCl (0.1 M). After each addition, the reaction was allowed to proceed for 1 min with rapid mixing, then, gravity settlement was allowed to occur via letting the mixture stand for 5 min. The optical density (OD) of the upper phase was measured at 550 nm (OD550) with a spectrophotometer (UV-7504, Shanghai, China). A control experiment was prepared by the same procedure except that the bioflocculant LC13-SF was replaced by fresh fermentation medium. Flocculating activity was evaluated by the flocculating efficiency according to the Eq. (1) below. All experiments were performed in triplicate and the mean average was calculated.

where a, and b are the optical densities (OD) of the sample and control experiments, respectively, at 550 nm. The key parameters influencing the flocculation behavior, such as pH, the dose of bioflocculant LC13-SF and CaCl2 were systematically investigated by analyzing the Zeta potentials and FE of the flocculation systems.

Results and discussion

Effects of fermentation conditions on bioflocculant LC13-SF production

Bioflocculant production is affected by several factors, such as the constituents of the culture medium and culture conditions (Zhou et al. 2003). The key parameters of the fermentation conditions, such as fermentation time, initial pH, fermentation temperature and shaking speed were investigated with the aim of obtaining the maximum bioflocculant LC13-SF production as well as the optimal cost of cultivation.

Determination of the fermentation time

The initial pH of the fermentation medium, fermentation temperature and shaking speed were respectively fixed at 7.0, 30°C and 160 r/min, respectively. Then, the effect of fermentation time on the bioflocculant LC13-SF production was investigated by varying the time from 24 to 120 h. As can be seen from Fig. 1, the FE increased concomitantly with the increase of the fermentation time, and it went from 26.36% using a fermentation time of 24 h, to 83.16% when 72 h of fermentation time were tested. The fermentation time longer than 72 h did not result in a larger increase in the FE but conversely, it decreased slightly to 71.05% with a fermentation time of 120 h. The maximum production of bioflocculant LC13-SF was achieved at 72 h, but the cell growth reached its peak at 48 h. However, after 96 h, both the flocculating efficiency and the cell growth decreased. Therefore, 72 h was chosen as the optimal fermentation time.

These phenomena suggest that some LC13-SF bioflocculants were released in the post-fermentation period. In a previous study, bioflocculants produced by Bacillus licheniformis were also collected in the latter logarithmic growth phase and the early stationary phase (Shin et al. 2001). However, the results are discrepant with those of some other reports: for example, the bioflocculant production of Enterobacter aerogenes occurred in parallel with cell growth, concomitant with its maximum flocculating activity (Lu et al. 2005).

Determination of the initial pH of the fermentation medium

With other parameters fixed at the central level, the variation of the initial pH of the fermentation medium among 5.0, 6.0, 6.5, 7.0, 7.5, 8.0 and 9.0 was designed to measure the influence of initial pH on bioflocculant LC13-SF production. The terminal pH was also investigated. As shown in Table 1, the results showed that the FE of bioflocculant LC13-SF reached a peak when pH was 7.0. At higher pH levels, the FE in the system decreased, but the cell growth increased slightly until pH 7.5. The terminal pH increased when the initial pH of the fermentation medium was increased. Thus, when the initial fermentation pH was 9.0, the terminal pH reached 5.21.

The initial pH of the fermentation medium determines both the electric charge of the cells and the oxidation–reduction potential which, in turn, can affect nutrient absorption and enzymatic reaction. For the LC13T strain, bioflocculant LC13-SF was possibly produced at maximum levels under neutral conditions. Additionally, within a certain range, an initial alkaline condition can stimulate cell growth, and the terminal pH has a proportionally direct relationship with initial pH of the fermentation medium.

Determination of the fermentation temperature

The effect of the fermentation temperature on the FE and cell growth was investigated by fixing other parameters at the central level. As can be seen from Fig. 2, when the fermentation temperature was 30°C, the FE of bioflocculant LC13-SF rose to 90.1%, which was the optimal level. However, the cell growth continued to increase when the FE was already starting to decrease, at the temperature of 32°C, OD660 reached a maximum of 1.34. For the best FE, 30°C was used in the following studies.

The metabolism of microorganisms has a direct relationship with the culture temperature (Zhang et al. 2007; Salehizadeh and Shojaosadati 2002). A lower fermentation temperature might make the LC13T strain hibernate partially, and its enzyme system for bioflocculant LC13-SF production may not be activated completely. On the other hand, a higher fermentation temperature might have an adverse effect on the nucleic acid and the enzyme system of the LC13T strain, leading to the low flocculating efficiency.

Determination of the shaking speed

Various shaking speeds of 130, 140, 150, 160, 170 and 180 r/min were investigated by fixing the fermentation time, initial pH and fermentation temperature as 72 h, 7.0 and 30°C, respectively. The FE and cell growth change at the different shaking speeds were shown in Fig. 3. The maximum FE was obtained when a shaking speed of 150 r/min was used, but the cell growth continued to increase with the increase of the shaking speed until a shaking speed of 160 r/min was reached.

The shaking speed determines the concentration of dissolved oxygen, which can also affect the nutrient absorption and enzymatic reaction of microorganisms (Salehizadeh and Shojaosadati 2001). The results suggest that a shaking speed either higher or lower than the optimal speed caused a decrease of flocculating efficiency in the flocculation system.

On the basis of the above experimental results, the optimal conditions for bioflocculant LC13-SF production were: (a) a fermentation time of 72 h; (b) an initial pH of 7.0; (c) a fermentation temperature was 30°C; and (d) a shaking speed was 150 r/min. Under these conditions, the flocculating efficiency reached 90.60%.

Experimental results of flocculating activity

The effect of pH on the flocculation behavior

Volume percentage of bioflocculant LC13-SF and 0.5% (w/w) CaCl2 were 2 and 5%, respectively in a 4 g/L Kaolin suspension. Then, the system pH was adjusted to 5.0, 6.0, 7.0, 7.5, 8.0, 8.5 and 9.0, and the flocculating activity was determined by estimating the FE and Zeta potential. As shown in Fig. 4, when the pH was 8.0, the FE reached a peak (92.5%). Under the weak alkaline condition, the absolute value of the Zeta potential sharply decreased, and with the increasing of the pH, the Zeta potential grew close to zero. However, the flocculation of the system was changed only slightly and even deteriorated. Furthermore, the weak alkaline condition can save large amounts of acid and alkali used to adjust pH. Therefore, the optimal pH value was selected as 8.0.

These results were consistent with one previous report, which indicated that microbial flocculant TJ-F1 exhibited excellent flocculating efficiency at pH 7.5 (Zhang et al. 2010), but were discrepant with another previous report, which indicated that the biopolymer produced by Enterobacter cloacae WD7 had optimum pH for flocculating efficiency at pH 6 (Prasertsan et al. 2006). As a natural organic macromolecular flocculant, LC13-SF can strengthen its bridging ability under an alkaline condition because –COOH will be ionized into –COO−, and –OH will be increased, both of which can promote the flocculating activity of C13-SF, but under an acidic condition, this process will be blocked.

The effect of CaCl2 dose on the flocculation behavior

Two milliliters LC13-SF and various volume percentage of 0.5% (w/w) CaCl2 including 0, 2%, 4%, 5%, 6%, 8% and 10% were respectively added into a Kaolin suspension. Then the system pH was adjusted to 8.0 for the flocculating behavior test. The FE and Zeta potential changed at the different volume percentage of 0.5% (w/w) CaCl2 as shown in Fig. 5. The maximum FE was obtained when volume percentage was 6%, but the value of FE 93.3% was only slightly different from 92.94% when volume percentage was 5%. Therefore, 5% was fixed as the optimal volume percentage of 0.5% (w/w) CaCl2. The absolute value of Zeta decrease concomitantly with the increase of the volume percentage of 0.5% (w/w) CaCl2, after the volume percentage increased to 5%, the value of the Zeta potential decreased slightly, and when the volume percentage was 10%, the absolute value of Zeta decreased to 4.39.

The main role of CaCl2 in the flocculating process of bioflocculant LC13-SF to the Kaolin suspension was that Ca2+ efficiently neutralized the negative charges of the particles and decreased the absolute value of the Zeta potential in the flocculating process. With a deficient dose of CaCl2, not all of the suspended particles and the organic materials will be flocculated. On the other hand, an excessive concentration of CaCl2 makes the suspended particles and the organic materials stable again in their original states because of superfluous positive charges (Xia et al. 2008). In addition, excessive CaCl2 debased the floc size, because excessive Ca2+ might occupy the absorption sites with negative charge on MBFGA1 molecules (Yang et al. 2009).

The effect of bioflocculant LC13-SF dose on the flocculation behavior

Volume percentage of bioflocculant LC13-SF varying from 0.5 to 3.5% were investigated by adding 5% volume percentage of 0.5% (w/w) CaCl2 to a Kaolin suspension. Then the system pH was adjusted to 8.0 for the flocculating behavior test. As can be seen from Fig. 6, the dose of LC13-SF had an obvious effect on the FE as well as the Zeta potential. The FE initially increased with increasing LC13-SF dose, but then decreased. The optimal FE was obtained when the volume percentage of LC13-SF was 1.5%, and the absolute value of the Zeta potential reached its lowest value of 4.37. With a lower dose of LC13-SF, not all of the suspension particles were flocculated to flocs, but an excessive concentration may prevent the small flocs from growing into large flocs because the small flocs carry the same charges. Therefore, only the proper dose of LC13-SF resulted in excellent flocculating efficiency. These phenomena observed in Fig. 6 are consistent with most reports (Yu et al. 2008; Lian et al. 2003).

The bioflocculant LC13-SF was especially effective in terms of the flocculating behavior at a low concentration, because the adsorption of excessive flocculants restabilized the particles in the flocculation system. When excessive flocculants were used, only particles around them participated in the flocculating reaction, because of incomplete dispersion of the excesses. Therefore, other particles did not participate in the reaction, which may have lead to a decrease of the FE (Suh et al. 1997). Thus, these results suggested that the bioflocculant LC13-SF held some advantages which were favorable for the flocculating effects.

Based on our results, the optimal conditions for flocculating efficiency were found to be as follows: a final volume percentage of bioflocculant LC13-SF and 0.5% (w/w) CaCl2 were 1.5 and 5%, respectively in a 4 g/L Kaolin suspension. Then the system pH was adjusted to 8.0, and after each addition, the reaction occurred for 1 min with rapid mixing, then gravity settlement was allowed to occur for 5 min. Under these conditions, the flocculating efficiency and the absolute value of the Zeta potential reached 94.83% and 4.37, respectively.

Conclusions

LC13T was demonstrated to be an effective flocculant-producing strain. The fermentation conditions and flocculating activity of bioflocculant LC13-SF were systematically investigated in this paper. The results showed that the optimal conditions for bioflocculant LC13-SF production were: (a) a fermentation time of 72 h; (b) an initial pH of 7.0; (c) a fermentation temperature was 30°C; and (d) a shaking speed was 150 r/min. Under these conditions, the flocculating efficiency reached 90.60%. The optimized flocculating process was as follows: a final volume percentage of bioflocculant LC13-SF and 0.5% (w/w) CaCl2 were 1.5% and 5%, respectively in a 4 g/L Kaolin suspension. Then the system pH was adjusted to 8.0. Under these conditions, the flocculating efficiency and the absolute value of the Zeta potential reached 94.83% and 4.37, respectively.

The activity of LC13-SF under optimal conditions was determined and found that it was highly efficient for flocculating activity, which may find possible application in wastewater treatment as well as in the dewatering of waste sludge. Therefore, we believe that many of these VBNC-state bacteria which are, in fact, culturable using special techniques, may be very useful in the application of microbial resources. Further studies should focus on cultivating bacteria that belong to these uncultured groups, as well as exploring their application value.

References

Christopher E, Olga K, Deborah J, Stanisiav S, Anthony P, Peter C (2006) Non-invasive therapy to reduce the body burden of aluminium in Alzheimer’s disease. J Alzheimers Dis 10:17–24

Ding LX (2004) Studies on the isolation of viable but non-culturable bacteria and the phylogenetic analysis of the genus Aquaspirillum. PhD Thesis, The University of Tokyo

Ding LX, Yokota A (2010) Curvibacter fontana sp. nov., a microaerobic bacteria isolated from well water. J Gen Appl Microbiol 3:267–271

Ding LX, Hirose T, Yokota A (2007) Amycolatopsis echigonensis sp. nov. and Amycolatopsis niigatensis sp. nov., novel actinomycetes isolated from a filtration substrate. Int J Syst Evol Microbiol 57:1747–1751

Ding LX, Hirose T, Yokota A (2009) Four novel Arthrobacter species isolated from filtration substrate. Int J Syst Evol Microbiol 59:856–862

Faegri A, Torsvik V, Goksoyr J (1997) Bacterial and fungal activities in soil: separation of bacteria and fungi by a rapid fractionated centrifugation technique. Soil Biol Biochem 9:105–112

Huang XW, Chen J (2004) Screening of flocculant-producing strains by NTG mutagenesis. J Environ Sci-China 17:494–498

Li B, Furihata K, Ding LX, Yokota A (2007) Rhodococcus kyotonensis sp. nov., a novel actinomycete isolated from soil. Int J Syst Evol Microbiol 57:1956–1959

Lian B, Chen Y, Yuan S, Zhu L, Liu CQ (2003) Study on the flocculability of metal ions by Bacillus mucilaginosus GY03 strain. Chin J Geochem 23:380–386

Lu WY, Zhang T, Zhang DY, Li CH, Wen JP, Du LX (2005) A novel bioflocculant produced by Enterobacter aerogenes and its use in defecating the trona suspension. Biochem Eng J 27:1–7

Mukamolova GV, Kaprelyants AS, Young DI, Young M, Kell DB (1998) A bacterial cytokine. Proc Natl Acad Sci USA 95:8916–8921

Olsen RA, Bakken LR (1987) Viability of soil bacteria: optimization of plate-counting technique and comparison between total counts and plate counts within different size groups. Microb Ecol 13:59–74

Prasertsan P, Dermlim W, Doelle H, Kennedy JF (2006) Screening, characterization and flocculating property of carbohydrate polymer from newly isolated Enterobacter cloacae WD7. Carbohyd Polym 66:289–297

Salehizadeh H, Shojaosadati SA (2001) Extracellular biopolymeric flocculants: recent trends and biotechnological importance. Biotechnol Adv 19:371–385

Salehizadeh H, Shojaosadati SA (2002) Isolation and characterization of a bioflocculant produced by Bacillus firmus. Biotechnol Lett 24:35–40

Shin IL, Van YT, Yeh LC, Lin HG, Chang YN (2001) Productiong of a biopolymer flocculant from Bacillus licheniformis and its flocculation properties. Bioresour Technol 78:267–272

Suh HH, Kwon GS, Lee CH, Kim HS, Oh HM, Yoon BD (1997) Characterization of bioflocculant produced by Bacillus sp. DP-152. J Ferment Bioeng 84:108–112

Tareke E, Rydberg P, Kalesson P, Eriksson S, Tornqvist M (2002) Analysis of acrylamide, a carcinogen formed in heated foodstuffs. J Agric Food Chem 50:4998–5006

Xia SQ, Zhang ZQ, Wang XJ, Yang A, Chen L, Zhao JF, Leonard D, Jaffrezic-Renault N (2008) Production and characterization of a bioflocculant by Proteus mirabilis TJ-1. Bioresour Technol 99:6520–6527

Yang ZH, Huang J, Zeng GM, Ruan M, Zhou CS, Li L, Rong ZG (2009) Optimization of flocculation conditions for Kaolin suspension using the composite flocculant of MBFGA1 and PAC by response surface methodology. Bioresour Technol 100:4233–4239

Yokoi H, Natsuda O, Hirose J, Hayashi S, Takasaki Y (1995) Characteristics of a biopolymer flocculant produced by Bacillus sp. PY-90. J Ferment Bioeng 79:378–380

Yu GH, He PJ, Shao LM, He PP (2008) Statification structure of sludge flocs with implications to dewaterability. Environ Sci Technol 42:7944–7949

Zhang ZQ, Lin B, Xia SQ, Wang XJ, Yang AM (2007) Production and application of a novel bioflocculant by multiple-microorganism consortia using brewery wastewater as carbon source. J Environ Sci-China 19:667–673

Zhang ZQ, Xia SQ, Zhao JF, Zhang J (2010) Characterization and flocculation mechanism of high efficiency microbial flocculant TJ-F1 from Proteus mirabilis. Coll Surf B 75:247–251

Zhou X, Wang J, Zhou JT (2003) Studies on properties of a bioflocculant produced by Pseudomonas sp. GX4-1 in fish meal wastewater. J Environ Sci-China 16:31–34

Acknowledgments

We are grateful to HIROSE Co., Ltd., Japan for providing us the filter material as the source of isolated bacteria. We also thank Zhejiang Normal University for providing the “Professor Scientific Research Foundation, Grant No. ZC304009160”, so that this research could be conducted smoothly.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Su, X., Shen, X., Ding, L. et al. Study on the flocculability of the Arthrobacter sp., an actinomycete resuscitated from the VBNC state. World J Microbiol Biotechnol 28, 91–97 (2012). https://doi.org/10.1007/s11274-011-0795-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11274-011-0795-2