Abstract

When Bacillus subtilis NB-NUC1 associated with Cheonggukjang fermentation was aerobically grown in a synthetic medium containing 1 to 2% glycine (w/v), cell growth was inhibited in a dose-dependent manner. Subsequently, different concentrations of glycine (0, 1, and 2%) were used in Cheonggukjang fermentation for 96 h at 40 °C. Supplementation of 1% glycine increased extracellular γ-glutamyl transpeptidase (γ-GTPase), responsible for the production of viscous substance. Based on correlation studies, we conclude that the production of viscous substance is correlated with viscous extension (r = 0.867), extracellular proteins contents (r = 0.821), and γ-GTPase activity (r = 0.807). The molecular weight of the viscous substance obtained during Cheonggukjang fermentation by B. subtilis NB-NUC1 was also affected by glycine supplementation. Our results demonstrate that glycine supplementation before solid-state fermentation may increase the mass production of mucilage in food industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

A number of health products containing Bacillus species are available worldwide (Jang et al., 2007). Cheonggukjang is a non-salty fermented soybean food produced using Bacillus subtilis as a starter, and is similar to Natto, which is a popular fermented soybean product grown in Japan. Cheonggukjang is rich in protein and easy to manufacture. Various metabolites including soy protein hydrolysates, glucoside isoflavones, enzymes, and viscous substances are produced during Cheonggukjang fermentation. These metabolites are under great scrutiny as food supplements to prevent hypertension (Shin et al., 1995), cancer (Hara et al., 1992), atherosclerosis (Kwon et al., 2004), and obesity (Na et al., 2019).

Among the different metabolites of Cheonggukjang, the viscous substance is composed of levan and poly gamma glutamate (γ-PGA), and its composition varies according to the type of starter used in fermentation and aging processes (Lee and Hahm, 2005; Son and Lee, 2011). In Cheonggukjang fermentation, B. subtilis is responsible for the production of levan and γ-PGA. Levan is a homopolymer composed of D-fructofuranosyl residue connected by β-(2,6) and β-(2,1) linkages (Han and Clarke, 1990). γ-PGA is a polypeptide composed of glutamic acid residues joined by linkages between the α-amino and γ-carboxylic acid groups (Jang et al., 2007). Levan and γ-PGA are produced by levansucrase (EC 2.4.1.10) and γ-glutamyl transpeptidase (γ-GTPase, EC 2.3.2.2), respectively (Lee et al., 2007; Steinmetz et al., 1985; Xu and Strauch, 1996). Levansucrase and γ-GTPase are localized in the cell wall or as extracellular proteins (Jang et al., 1999; Steinmetz et al., 1985; Xu and Strauch, 1996). According to Jang et al. (1999), levansucrase is synthesized as a cytoplasmic protein in Escherichia coli. It is secreted into culture medium following addition of glycine. Hammes et al. (1973) suggested that when Gram-positive cells are grown in the presence of high dose of glycine, glycine replaces alanine in the cell wall, weakening the peptidoglycan structure. However, the effect of glycine on cell growth of B. subtilis and production of viscous substance during Cheonggukjang fermentation is unknown. In order to understand role of glycine, it is also important to measure the extracellular protein content in Cheonggukjang. The objective of the present study was to investigate the effect of glycine supplementation on the growth of B. subtilis and to optimize glycine concentration for the production of viscous substance in Cheonggukjang.

Materials and methods

Bacterial cultures and fermentation

B. subtilis NB-NUC1 was purchased from NUC (Daegu, Korea). Tryptic Soy Broth (TSB) (Difco, St. Louis, MO, USA) was used for the cultivation of B. subtilis NB-NUC1. The purity of glycine was 99% and was purchased from Sigma-Aldrich (St. Louis, MO, USA). To test the effect of glycine on the growth of B. subtilis NB-NUC1, cells were inoculated using 4% inoculum into 100 mL quantities of TSB broth supplemented with 0, 1 and 2% (w/v) of glycine, with an initial absorbance of 0.2 to 0.3 at 600 nm (A600nm), and incubated (SI-4000R, Jeio Tech, Daejeon, Korea) at 40 °C without agitation.

The cell growth rates of B. subtilis NB-NUC1 were compared by measuring the μ value (specific cell growth rate, 1/h) and the duration of lag phase. When A600nm exceed 0.8, the cultures were diluted in TSB and A600nm was recorded against TSB. The μ values of the B. subtilis NB-NUC1 were expressed as the percentage relative to the growth in the TSB without glycine. For calculation of the μ value, the samples were withdrawn at hourly intervals and the optical density was measured at A600nm with a UV–visible spectrophotometer (UV-1650, Shimadzu, Kyoto, Japan). The doubling time was measured during the exponential growth period from the slope of the curve obtained by plotting the logarithm of Abs600nm against time. The cell-specific growth rate was calculated as follows: Cell specific growth rate (μ, 1/h) = 0.693/doubling time (h).

Cheonggukjang preparation

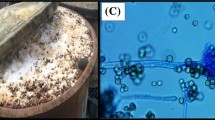

Cells of B. subtilis NB-NUC1 were incubated (SI-4000R, Jeio Tech) at 40 °C for 24 h in TSB without agitation and used as a starter. Soybean, produced in Samcheok in 2018, was used for Cheonggukjang fermentation. Soybeans were washed and soaked in water containing 0% glycine (for the preparation of Control Cheonggukjang), 1% glycine (for the preparation of GLC 1 Cheonggukjang) and 2% glycine (for the preparation of GLC 2 Cheonggukjang) for 24 h at room temperature. The control Cheonggukjang contained no glycine. After autoclaving at 121 °C for 40 min and cooling down to room temperature, cells of the freshly prepared B. subtilis NB-NUC1were inoculated using 1% inoculum into 100 g of soybeans and cultured in an incubator (SI-4000R, Jeio Tech) at 40 °C for 48, 72 and 96 h. All the experiments involving Cheonggukjang preparation were carried out in triplicate.

Chemical analysis

Distilled water (20 mL) was added to 5 g of three Cheonggukjang samples (Control, GLC 1, and GLC 2) and vortexed for 2 min followed by filtration through a filter paper (Whatman No2, Buckinghamshire, England). The filtrate was used as the source of either proteins or γ-GTPase activity. Protein concentration was estimated using a Bio-Rad protein assay kit (Bio-Rad Lab, Inc., Hercules, CA, USA) based on Bradford assay (Bradford, 1976). To 1 mL of the dye reagent, 20 μL of standard (bovine serum albumin, BSA, Sigma-Aldrich) or samples were added, and the mixture was allowed to stand at room temperature for 20 min. The absorbance of the mixture was measured at 595 nm for quantification of protein concentration. The γ-GTPase was assayed as described by Kim and Lee (1995). Three Cheonggukjang samples (Control, GLC 1, and GLC 2) were washed with 4 volumes of water, filtered and then centrifuged at 10,000×g for 10 min. The supernatant was used as a source of γ-GTPase. The reaction was initiated by adding 0.25 μL of crude enzyme solution to 5 mL of 50 mM Tris·Cl buffer (pH 8.0) containing 1.0 mM γ-glutamyl-p-nitroanilide and 1.0 mM glycylglycine followed by incubation at 37 °C for 10 min with gentle shaking. The reaction was terminated by the addition of 0.5 mL of 3.5 M acetic acid. The absorbance of the mixture was measured at 405 nm to determine γ-GTPase activity.

Viscous extension and viscous content

The viscous extension was measured using a ruler. After transferring Cheonggukjang to a petridish, a spoon was dipped in it and pulled. The length of the extended viscous substance before cutting was measured using a ruler. The average values of viscous extension in 25 repeated measurements were obtained. The contents of the viscous substance were measured as described by Jang et al. (2007). To extract the viscous substance, 60 mL of distilled water were added to 10 g of Cheonggukjang, mixed for 1 h, filtered and then centrifuged at 1811×g for 30 min. The supernatant was lyophilized and weighed to measure the dry weight (%) of the sample.

Determination of molecular weight (MW) of viscous substance of Cheonggukjang

To measure the molecular weight (MW) of the viscous substance of Cheonggukjang, 60 mL of distilled water was added to 10 g of Cheonggukjang, including Control, GLC 1 and GLC2, mixed for 1 h and filtered. The filtrate was injected into a high-performance size exclusion chromatography column equipped with UV, multi-angle laser light scattering and refractive index detection system (HPSEC-UV-MALLS-RI). The HPSEC-UV-MALLS-RI system consisted of a pump (model Gilson, Middleton, WI, USA), an injector valve with 100 μL sample loop and SEC columns (TSK G5000PW, and G2500 PWX1, TosoBiosep, Mongomeryville, PA, USA). The aqueous solution of 0.15 M NaNO3 and 0.02% NaN3 was used as a mobile phase at a flow rate of 0.4 mL/min. The normalization of MALLS detector and the determination of volume delay between MALLS and RI detectors were carried out with BSA. The MW and radius of gyration (Rg) were calculated using ASTRA version 6.0 software (Wyatt Technology Corp. Dernbach, Germany).

Statistical analysis

Data were analyzed using the SPSS 23.0 statistical program (SPSS Inc., Chicago, IL, USA). One-way ANOVA (analysis of variation) was performed at a p < 0.05 level and the differences were analyzed by Duncan’s multiple range test. The extracellular protein content, γ-GTPase activity, viscous extension, and the content of viscous substance were correlated using Pearson`s correlation coefficient. All experiments were carried out in triplicate and the results were obtained as a mean of three observations ± standard deviations (SD).

Results and discussion

Effects of glycine on the growth of B. subtilis NB-NUC1

The effect of glycine on the growth of B. subtilis NB-NUC1 is shown in Fig. 1 and Table 1. The growth rate of B. subtilis NB-NUC1 decreased with increasing glycine concentration between 0 and 2%. The specific cell growth rate (% μ value) was inhibited by 23.1% in the presence of 1% glycine and by 63.4% in the presence of 2% glycine (Table 1). In case of cells grown in liquid media without glycine, the cell growth started after a short lag phase (4 h). At 1% glycine, the cell growth curve showed a similar pattern, but the values of Abs600nm at each point were lower than those of the control (0% glycine). At 2% glycine, the cell growth occurred after a long lag phase (18 h) and the cell density attainable at the stationary phase was reduced by 90%, compared with the cells grown in the absence of glycine (Fig. 1, Table 1). Among the different cell growth phases including lag phase, log phase, stationary phase, and death phase, addition of 1% glycine affected the growth of B. subtilis NB-NUC1 and extended the lag phase, decreased the specific growth rate during the log phase, and resulted in maximum specific growth rate (μmax). At levels exceeding 2% glycine in the growth medium, no cell growth was seen (data not shown). Based on this work, the concentration of glycine required to inhibit the cell growth of B. subtilis NB-NUC1 was 1.0–2.0%, which was similar to that of Corynebacterium gluctamicum (Best and Britz, 1986) and Lactobacillus plantarum (Jang et al., 2009).

Effects of glycine on extracelluar secretion of protein and γ-GTPase activity

Effects of glycine on extracellular secretion of proteins in B. subtilis NB-NUC1 during solid-state fermentation are listed in Table 2. Extracellular proteins contents at 48, 72 and 96 h, were 1.93 ± 1.00, 2.96 ± 0.66 and 3.23 ± 0.64 mg/g, respectively for Control Cheonggukjang; 2.25 ± 0.31, 2.95 ± 0.24 and 3.84 ± 0.33 mg/g, respectively for GLC 1 Cheonggukjang; and 3.57 ± 0.25, 3.46 ± 0.45 and 3.92 ± 0.17 mg/g, respectively for GLC 2 Cheonggukjang. At 48 and 72 h, the amounts of extracelluar secretory proteins in GLC 2 Cheonggukjang was the highest among the 3 samples of Cheonggukjang (p < 0.05). However, at 96 h, there was no significant difference. In addition, in case of GLC 2 Cheonggukjang, most of the extracellular proteins were secreted into culture fluids at 48 h in solid-state fermentation. However, the amounts of extracellular proteins in Control- and GLC 1 Cheonggukjang significantly increased as the time increased from 48 to 96 h (p < 0.05). A previous study of Cheonggukjang obtained from glutamate indicated that most of the extracellular proteins content increased significantly within the initial fermentation time for 24 h (Oh et al., 2007). However, our study of Cheonggukjang showed that glycine reduced the secretion of proteins within the initial fermentation time but increased continuously during the whole fermentation period. Based on these results, we believe that the presence of glycine accelerated the secretion of proteins related to viscous substance formation during Cheonggukjang fermentation. According to Tjalsma et al. (2004), the extracellular secretion of proteins in B. subtilis 168 are mediated by either signal peptide-dependent (76%) or signal peptide-independent (24%) mechanism.

Effects of glycine on γ-GTPase activity of B. subtilis NB-NUC1 are presented in Table 2. In control Cheonggukjang, the γ-GTPase activity increased significantly with increased duration of fermentation (p < 0.05), suggesting a remarkable increase between 48 and 72 h of fermentation time. Compared with γ-GTPase activity of Control Cheonggukjang at 48 h of fermentation showed that the activity of Control Cheonggukjang at 72 h and 96 h was 220% and 230%, respectively. The γ-GTPase activity of GLC 1 Cheonggukjang at 48 h, 72 h and 96 h was 72%, 143% and 215%, respectively, and that of GLC 2 Cheonggukjang at 48 h, 72 h and 96 h was 15%, 137% and 207%, respectively. Comparison of γ-GTPase activity at 48 and 72 h of fermentation time showed the highest levels in the control Cheonggukjang, followed by GLC 1 Cheonggukjang, and GLC 2 Cheonggukjang with the lowest level. It is interesting to note that the presence of 1% glycine in solid-fermentation reduced the γ-GTPase activity at 48 h of fermentation time, but the enzyme activities of the three Cheonggukjang samples were almost similar at 96 h of fermentation time. γ-GTPase catalyzes synthesis of γ-PGA from glutamate (Jang et al., 2007). γ-PGA is a highly water-soluble and biodegradable enzyme, and is an anionic homo-polyamide (Jang et al., 2007). According to Tjalsma et al. (2004), γ-GTPase of B. subtilis is secreted into the culture fluids via signal peptide-dependent pathway.

Effects of glycine on viscous extension and viscous substance production

The viscous extension in control Cheonggukjang at 48, 72 and 96 h was 29.74 ± 1.31, 44.23 ± 4.60 and 36.47 ± 3.53 cm, respectively; in GLC1 Cheonggukjang, 33.57 ± 1.78, 50.20 ± 3.35 and 53.16 ± 4.37 cm, respectively; and for GLC2 Cheonggukjang, 27.34 ± 1.58, 40.90 ± 4.18 and 45.31 ± 2.87 cm, respectively (Table 3). At 48 h of fermentation, GLC 1 Cheonggukjang showed the highest degree of extension, followed by the control Cheonggukjang and the GLC 2 Cheonggukjang had the least extension. These results indicated that the characteristics of viscous substance in Cheonggukjang can be altered by the presence of glycine. It is interesting to note that the viscous extension of GLC1 Cheonggukjang measured at 96 h of fermentation time was almost 146% higher than that of the control Cheonggukjang.

The viscous substance produced via solid-state fermentation of soybean soaked in 0–2% glycine by B. subtilis NB-NUC1 was characterized using Control, GLC 1, and GLC 2 Cheonggukjang (Table 3). The amounts of viscous substance of Cheonggukjang at 48 h, 72 h and 96 h were 6.67 ± 0.69, 8.41 ± 0.00 and 7.60 ± 1.39 g/100 g Cheonggukjang, respectively in the case of control Cheonggukjang. The concentrations of viscous substance were 6.98 ± 0.00, 12.00 ± 2.08 and 12.40 ± 0.69 g/100 g Cheonggukjang, respectively, for GLC1 Cheonggukjang; and 9.35 ± 0.00, 10.00 ± 0.69 and 11.20 ± 0.69 g/100 g Cheonggukjang, respectively, for GLC2 Cheonggukjang. Compared with the concentration of viscous substance of control Cheonggukjang at 48 h of fermentation, the levels in GLC1 Cheonggukjang at 72 and 96 h were increased to 180% and 187%, respectively.

Under optimum solid-state fermentation conditions, the concentrations of the viscous substance ranged from 9.50 to 28.7% (Kim et al., 2008; Oh et al., 2006). Viscous substance levels increased slightly under solid-state fermentation using a mixture of barley and soybean, but increased twofold under solid-state fermentation using a mixture of brown rice and soybean (Son and Lee, 2011). Viscous substance production was dependent upon glutamate levels, fermentation time, and type of Bacillus sp. (Jang et al., 2007; Oh et al., 2007). According to Kim et al. (2008), the viscous substance contents were 28.7% including 2.15 to 6.03% of γ-PGA from the solid-state fermentation of soybean grits. Jang et al. (2007) reported that extension in fermentation time to 72 h reduced the viscosity levels particularly during levan production. In terms of sensory characteristics, viscosity decreased the bitter taste (Park, 2006).

Correlation between proteins, γ-GTPase activity, viscous extension, and viscous content in Cheonggukjang

The correlation coefficients of proteins, γ-GTPase activity, viscous extension, and viscous content in Cheonggukjang are presented in Table 4. The viscous content showed a significant correlation between viscous extension (r = 0.867), extracellular proteins content (r = 0.821), and the γ-GTPase activity (r = 0.807). These results demonstrate that viscous content is directly correlated with viscous extension, extracellular proteins content, and the γ-GTPase activity. The amino acid sequences of B. subtilis-derived and mammalian γ-GTPase showed a low degree of match (Hara et al., 1992; Suzuki et al., 1989). In B. subtilis (natto), the γ-PGA production is mediated by more than two enzyme systems (Hara et al., 1992). Therefore, the relatively low correlation between viscous content and the γ-GTPase activity may be explained by the presence of other enzyme(s) responsible for γ-PGA production. However, we have not characterized these additional enzymes.

Determination of molecular weight of viscous substance

To establish the effects of glycine content on viscosity, we determined the molecular weight of the viscous samples (Table 5). The molecular weights of the viscous substances obtained from solid-state fermentation using B. subtilis NB-NUC1, ranged from 1.07 × 105 to 1.36 × 106 Da. Other studies reported molecular weights of viscous substances ranging from 1.4 × 106 to 1.5 × 106 Da (Jang et al., 2007; Oh et al., 2007). The culture conditions determine the production of viscous substance in a liquid culture and soli-state fermentation (Oh et al., 2007), which is consistent with our results. The presence of glycine decreased the molecular weight of viscous substance.

In conclusion, the supplementation of glycine to soybean ranging between 1.0 and 2.0% decreased the growth of B. subtilis NB-NUC1 associated with Cheonggukjang fermentation but increased the secretory production of proteins including γ-GTPase, responsible for the production of viscous substance. The production and molecular weight of viscous substance during the Cheonggukjang fermentation by B. subtilis NB-NUC1 was significantly affected by glycine supplementation. Soybean containing 1% glycine was efficiently transformed into various metabolites including 12.4% viscous substance. As far as we know, this is the first report of glycine-induced increase of mucilage production via increased cell-wall permeability of B. subtilis. In order to produce the viscous substance, levansucrase and γ-GTPase need to travel from cytoplasm to extracellular fluids. We believe that the presence of appropriate concentrations of glycine reduce the cell surface barrier to protein secretion. Our results demonstrate that glycine supplementation prior to solid-state fermentation may facilitate the increased mass production of mucilage in the food industry.

References

Best GR, Britz ML. Facilitated protoplasting in certain auxotrophic mutants of Corynebacterium glutamicum. Appl. Microbiol. Biotechnol. 23: 288-293 (1986)

Bradford MM. A rapid and sensitive method for quantification of microgram quantities of protein using the principle of protein-dye binding. Anal. Biochem. 72: 248-254 (1976)

Hammes W, Schleifer KH, Kandler O. Mode of action of glycine on the biosynthesis of peptidoglycan. J. Bacteriol. 116: 1029-1053 (1973)

Han YW, Clarke MA. Production and characterization of microbial levan. J. Agric. Food Chem. 38: 393-396 (1990)

Hara T, Nagatomo S, Ogata S, Ueda S. The DNA sequence of γ-glutamyltranspeptidase gene of Bacillus subtilis (natto) plasmid pUH1. Appl. Microbiol. Biotechnol. 37: 211-215 (1992)

Jang KH, Seo JW, Song KB, Kim CH, Rhee SK. Extracellular secretion of levansucrase from Zymomonas mobilis in Escherichia coli. Bioproc. Eng. 21: 453-458 (1999)

Jang EK, Seo JH, Park SC, Yoo BS, Lee SP. Characterization of mucilage produced from the solid-state fermentation of soybean grit by Bacillus firmus. Food Sci. Biotechnol. 16: 722-727 (2007)

Jang KH, Han WC, Ji SH, Kang SA, Shah NP. Effect of glycine on the growth of Leuconostoc mesenteroides and Lactobacillus plantarum in Kimchi fermentation. Food Sci. Biotechnol. 18: 1180-1185 (2009)

Kim BN, Lee SY. Nattokinase, γ-GTP, protease activity and sensory evaluation of natto added with spice. J. Korean Soc. Food Nutr. 24: 228-233 (1995)

Kim HJ, Lee SG, Ji YJ, Hwangbo MH, Lee EJ, Lee SP, Lee IS. Quality characteristics of defatted soybean grits fermented by Bacillus subtilis NUC 1. J. Korean. Soc. Food Sci. Nutr. 37: 1479-1484 (2008)

Kwon HY, Kim YS, Kwon GS, Kwon CS, Sohn HY. Isolation of immune stimulating strain Bacillus pumilus JB-1 from Chunggukjang and fermentational characteristics of JB-1. Kor. J. Microbiol. Biotechnol. 32: 291-296 (2004)

Lee NK, Hahm YT. Antioxidative characteristics of browning reaction products of glucose poly-γ-glutamate(Glu-PGA) obtained from amino-carbonyl reaction. Korean J. Food Sci. Technol. 37: 812-825 (2005)

Lee TE, Yoon MH, Choi WY. γ-Glutamyltranspeptidase gene from Bacillus subtilis BS-62. J. Agric. Sci. 34: 161-170 (2007)

Na HG, Park YN, Kim MA, Lee JW, So GS, Kim SH, Jang KH, Kim MJ, Namkoong S, Koo HJ, Lee SR, Sohn EH. Secondary fermented extract of Chaga-Cheonggukjang attenuates the effects of obesity and suppresses inflammatory response in the liver and spleen of high-fat diet-induced obese mice. J. Microbiol. Biotechnol. 29: 739-748 (2019)

Oh SM, Kim CS, Lee SP. Functional properties of soybean curd residue fermented by Bacillus sp. J. Korean. Soc. Food Sci. Nutr. 35: 115-120 (2006)

Oh SM, Jang EK, Seo JH, Ryu MJ, Lee SP. Characterization of γ-polyglutamic acid produced from the solid-state fermentation of soybean milk cake using Bacillus sp. Food Sci. Biotechnol. 16: 509-514 (2007)

Park SI. Preparation of natto (unripe Chungkukjang) using small soybeans and Bacillus subtilis KCCM 11315. Korean J. Culinary Res. 12: 225-235 (2006)

Shin ZI, Ahn CW, Nam HS, Lee HJ, Lee HJ, Moon TH. Fractionation of angiotensin converting enzyme (ACE) inhibitory peptidases from soybean paste. Korean J. Food Sci. Technol. 27: 230-234 (1995)

Son SJ, Lee SP. Evaluation of rheological and functional properties of roasted soybean flour and mixed cereals fermented by Bacillus sp. J. Korean Soc. Food Sci. Nutr. 40: 450-457 (2011)

Steinmetz M, Le Coq D, Aymerich S, Gonzy-Treboul G, Gay P. The DNA sequence of the gene for the secreted Bacillus subtilis enzyme levansucrase and its genetic control sites. Mol. Gen. Genet. 200: 220-228 (1985)

Suzuki H, Kumagai H, Echigo T, Tochikura T. DNA sequence of the Escherichia coli K-12 γ-glutamyltranspeptidase gene, ggt. J. Bacteriol. 171: 5169-5172 (1989)

Tjalsma H, Antelmann H, Jongbloed JDH, Brayn PG, Darmon E, Dorenbos R, Dubois JYF, Westers H, Zanen G, Quax WJ, Kuipers OP, Bron S, Hecker M, van Diji JM. Proteomics of protein secretion by Bacillus subtilis: separating the “secrets” of the secretome. Microbiol. Mol. Biol. Rev. 68: 207-233 (2004)

Xu K, Strauch MA. Identification, sequence and expression of the gene encoding γ-glutamyltranspeptidase in Bacillus subtilis. J. Bacteriol. 178: 4319-4322 (1996)

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) Grant funded by the Korea government (MSIP) (No. NRF-2017R1D1A3B03034313).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have declared no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Na, H.G., Kim, MA., Shin, J.W. et al. Improvement of viscous substance production during Cheonggukjang fermentation added with glycine. Food Sci Biotechnol 29, 953–959 (2020). https://doi.org/10.1007/s10068-020-00743-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-020-00743-5