Abstract

The compressive stress–strain behavior and mechanical properties of clay brick masonry and its constituents clay bricks and mortar, have been studied by several laboratory tests. Using linear regression analysis, a analytical model has been proposed for obtaining the stress–strain curves for masonry that can be used in the analysis and design procedures. The model requires only the compressive strengths of bricks and mortar as input data, which can be easily obtained experimentally. Development of analytical model from the obtained experimental results of Young’s modulus and compressive strength. Simple relationships have been identified for obtaining the modulus of elasticity of bricks, mortar, and masonry from their corresponding compressive strengths. It was observed that the proposed analytical model clearly demonstrates a reasonably good prediction of the stress–strain curves when compared with the experimental curves.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Masonry walls are used due to low cost material, good sound and heat insulation properties, easy availability and locally available material. Analytical modeling of masonry prism requires the properties and interrelationships of brick and mortar; it is not easily available because of limitation of experimental tests and variation in properties and proportion of material. In this experimental study, tests were performed on clay brick specimens manufactured at Kasat brick kiln plant Paldhi, group of each 27 mortar cube specimens for 3, 7 and 28 days of 1:4 grade for replacement of sand with clay brick waste (CB0, CB10, CB20, CB30, CB40) and group of each 27 masonry prisms combination of four bricks and three mortars joint (CBP0, CBP10, CBP20, CBP30, CBP40).

From the experimental data of compressive strengths, it has been calculated modulus of elasticity of bricks, mortar, and masonry prism. A simple analytical model has been proposed for obtaining the nonlinear stress–strain curves of masonry, which is a function of only the compressive strengths of bricks and mortar cubes.

Review Literture

Kaushik et al. [1] developed a simple analytical equation by regression analysis of the experimental data to estimate the modulus of elasticity and to plot the stress–strain curves for masonry. A significant improvement in ductility of masonry was observed because of the presence of lime in the mortar without any considerable reduction in its compressive strength. This showed that lime in the mortar offered distinct structural advantages. The compressive strength of masonry was found to increase with the compressive strength of bricks and mortar. The trend was more prominent in case of masonry constructed with weaker mortar.

Based on an experimental study, it has been reported that modulus of elasticity of soft bricks 500 MPa were responsible for development of triaxial compression in bricks and axial compression with lateral tension in mortar joints of masonry prism [2]. This behavior is contradictory to the generally accepted behavior of the masonry constructed with stiff bricks and softer mortar [3].

Various researchers have suggested that masonry is very weak in tension because it is composed of two different materials distributed at regular intervals and the bond between them is weak [4–6]. Therefore, masonry is normally provided and expected to resist only the compressive forces, during compression of masonry prisms constructed with stronger and stiffer bricks, mortar of the bed joint has a tendency to expand laterally more than the bricks because of lesser stiffness. Shear stresses at the brick–mortar interface result in an internal state of stress which consists of triaxial compression in mortar and bilateral tension coupled with axial compression in bricks. This state of stress initiates vertical splitting cracks in bricks that lead to the failure of the prisms [4].

Earlier, the investigators have conducted several uniaxial, biaxial, and triaxial tests on clay bricks, mortar, and masonry to validate an analytical model describing the failure criteria of masonry prisms, which considers the nonlinear behavior of confined mortar between bricks and splitting strengths of bricks [4]. It was observed that the failure of masonry prisms took place because of lateral tensile splitting of bricks, which was induced in the bricks by the mortar. Several relations were proposed for the analytical determination of compressive strengths of bricks, mortar, and masonry, which depend upon their compressive and tensile strengths [4].

The researchers have suggested several analytical relations for estimation of strength and deformation characteristics of masonry, which depend upon the compressive and tensile strengths of bricks and mortar along with several other factors [5, 7–9].

Experimental Program

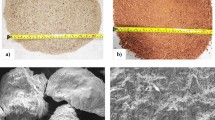

Compressive strength and modulus of elasticity is main parameters for determines the bearing capacity and deformation of the mortar and masonry prism under loading. Several tests were carried out in order to evaluate the uniaxial compressive stress–strain curves of brick units, mortar cubes, and masonry prisms constructed with mortar grade 1:4. This work presents an investigation of various blended mortars produced by 0, 10, 20, 30, and 40 % replacement of sand with a clay brick waste. The experimental result of replacement mortar compared with the controlled mortar (0 % replacement). The compressive strength of cement mortar cubes (size 7.07 cm × 7.07 cm × 7.07 cm) of 1:4 proportions, as specified by IS: 650 (1966) as shown in Fig. 1a.

Clay Brick Prism (CBP) of size 210 × 95 × 340 mm were prepared using clay brick of size 210 × 95 × 60 mm 1:4 cement mortars with 0, 10, 20, 30, and 40 % replacement of sand with a clay brick waste as shown in Fig. 1b. Mortar joint thickness of 10 mm was used for all the prism specimens. The Bureau of Indian Standards IS: 1905 (1987) suggest to use brick masonry prisms having the dimensions of 40 cm height with aspect ratios (height/thickness) between 2 and 5 in order to determine the axial strength of the brick masonry [10]. In this experimental study axial compression test was conducted on the brick masonry prisms with the ratio (h/t) of 3.58.

After casting of mortar cube and prism they are cured in water for 3, 7 and 28 days. Mortar and masonry prism specimen was placed on the computerized universal testing machine and the axial compressive load was applied and the deformation was recorded by a sensor available in the computer based data acquisition system. The specimens were subjected to an axial load up to failure of the test specimen as shown in Fig. 1c, d.

From obtained result a graph is plotted in between Young’s modulus and compressive stress. Modulus of elasticity is calculated from stress–strain curves by measuring the slope of a secant between ordinates corresponding to 5 and 33 % of the ultimate strength of the specimens [11].

Results and Discussion

Stress–strain characteristics of brick masonry prism were examined through prism test as per IS 1905 (1987) [10]. From the stress strain behavior of prism, the compressive strength of clay brick masonry prism in 1:4 cement mortars with 20 % replacement of fine aggregate with clay brick waste exhibited higher compressive strength due to the effect of clay brick waste on brick masonry attributed its pozzolanic activity, by which the pozzolans chemically convert the weak CH crystals to strong CSH fibrous gel. The pozzolanic activity depends mainly on the chemical composition, fineness and percentage of the pozzolans. The pozzolanic reaction of clay brick waste was reported to have a significant effect on long-term strength development. The clay brick masonry prisms were damaged with visible vertical cracks along the entire surface as shown in Fig. 2.

Some investigators have reported that the mortar joints can develop lateral compression while brick develops lateral tension in brick masonry [12]. The compressive strength of clay brick prism varies in the range of 4.6–5.53 MPa for 28 days, with partial replacement of fine aggregate in the mortar with the clay brick waste, the compressive strength (load carrying capacity) was increased. From the above results, it was found that the construction cost is reduced, because of clay brick waste is naturally and easily available at construction sites and brick manufacturing plants and its crushing cost is very less than naturally available standard sand in nearby rivers. The stress, strain and young’s modulus of mortar and clay brick masonry prism are given in Tables 1 and 2.

In this experimental study, the compressive strength of the clay brick masonry prism was predicted from the obtained results of brick and mortar compressive strength. Earlier, some of the investigators have given a relationship between the strength of the brick masonry with the strength of the brick and the mortar as [1],

Based on regression analysis of data obtained in an experimental study, Dayaratnam [13] proposed different values of the constants K, α, and β as per the following equation [13]

The equation proposed by Dayaratnam gives almost equal weight age to the compressive strength of the brick and the mortar. It has been reported earlier that, in such cases, the errors in the estimation of masonry compressive strength may be higher [1].

The generalized equation is proposed for estimating the axial strength of the brick masonry as K, α and β are constants. Based on present experimental results, by trial and error method the value of, K = 0.7, α = 0.57 and β = 0.35

Therefore, the relation between compressive stresses of brick, mortar and brick masonry prism.

It indicates that if the compressive stress of any brick and mortar of 1:4 proportions is known then the compressive stress of brick masonry can be found out by using above relation. f ′ m is the intrinsic property of masonry which can be used in the design of a variety of masonry elements, particularly the walls. f ′ m is also used to estimate E m and for plotting the masonry stress strain curves. The relation between Young’s modulus and compressive strength of standard mortar and replaced mortar present in Table 3.

In general, the brick strength is usually greater than the mortar strength, hence ‘α’ must be greater than ‘β’ as reported by the previous researchers [1]. However, the axial strength of brick masonry is calculated based on the experimental results of the present study, the value of ‘k’ is obtained by least square methods of regression analysis.

Fitness of Proposed Analytical Model

The proposed analytical model for compressive stress–strain curves is examined for its fitness by comparing it with: (1) experimental curves obtained in the present study, (2) experimental curves obtained in research study [2] of analytical relations for estimating f ′ m have been proposed by the researchers [1]. Therefore for better comparison among the three analytical models, stress–strain curves are generated using: analytical f ′ m and experimentally obtained f ′ m . A comparison of past experimental results on masonry prisms with analytical predictions is shown in Table 3, which show a very close match between the analytical and experimental curves. The proposed analytical model clearly demonstrates a reasonably good prediction of the stress–strain curves when compared with the experimental curves. The proposed model successfully predicts prism strengths and corresponding peak strain values fairly accurately. In most of the cases, failure strains predicted by the proposed model are significantly greater than the corresponding experimental values. The researchers have used very soft and weak bricks in their experimental study, therefore prism strength reported in their study is also much les [2].

Based on experimental result, graph is plotted in between Young’s modulus and compressive stress. An angle bisector is drawn in between two extreme lines which show maximum and minimum value with origin and its equation is found. The equation of that angle bisector gives the average relation between young’s modulus and compressive stress of masonry mortar. Finally found the exact relationship in between the equation of replacement mortar and controlled mortar (Table 4). The relation between young’s modulus and compressive strength of controlled and replaced mortar as shown in Fig. 2 and clay brick masonry Prism as shown in Fig. 3.

Conclusion

-

The mortar with the ratio of 1:4 cement mortars with 20 % replacement of fine aggregate with clay brick waste exhibited a higher compressive strength than the controlled mortar after 28 days of curing. Based on experimental results, compressive strength is more than controlled mortar for replacement ratio of sand with clay brick waste up to around 35 % for a curing period of 3 and 28 days and 25 % for curing period of 7 days. For higher replacement ratio, parameters decreased. This was the combination of some degree of pozzolanic effect of these brick waste with filler effect.

-

In prism test, it is seen that compressive strength of replaced brick waste masonry prism is more than the compressive strength of standard brick masonry prism. The value of constant factor ‘C’ is more in replaced mortar than standard mortar for each and every curing period. It indicates that the sand replacement with brick waste gives better strength than standard mortar without brick waste.

-

A comparison of past experimental results on masonry prisms with analytical predictions, which show a very close match between the analytical and experimental curves. The proposed analytical model clearly demonstrates a reasonably good prediction of the stress–strain curves when compared with the experimental curves.

-

The elastic modulus of the brick masonry (Epm) was determined with the prism strength (fpm). The equivalent homogenized elastic property of the masonry was derived with the elastic properties of brick and mortar.

References

H.B. Kaushik, D.C. Rai, S.K. Jain, Stress–strain characteristics of clay brick masonry under uniaxial compression. J. Mater. Civ. Eng. (ASCE) 19(9), 728–739 (2007)

G. Sarangpani, B.V.V. Reddy, K.S. Jagadish, Structural characteristics of bricks, mortar and masonry. J. Struct. Eng. 29(2), 101–107 (2002)

G. Sarangpani, B.V.V. Reddy, K.S. Jagadish, Brick mortar bond and masonry compressive strength. J. Mater. Civ. Eng. 17(2), 229–237 (2005)

M.C. Nary, D.P. Abrams, Mechanics of masonry in compression. J. Struct. Eng. 111(4), 857–870 (1985)

M.J. Priestley, D.M. Elder, Stress–strain curves for unconfined and confined concrete masonry. Am. Concr. Inst. J. 80(3), 192–201 (1983)

R.G. Drysdale, A.A. Hamid, L.R. Baker, Masonry structures: behavior and design (Prentice-Hall, Englewood Cliffs, 1994)

C.T. Grimm, Strength and related properties of brick masonry. J. Struct. Div. 101(1), 217–232 (1975)

Indian Standards, Indian standard methods of test of burn clay building bricks—part 1: determination of compressive strength, IS 3495, 3rd Rev., Bureau of Indian Standards, New Delhi, India (1992a)

L. Binda, A. Fontana, G. Frigerio, Mechanical behavior of brick masonries derived from unit and mortar characteristics, in Proceedings, 8th International Brick and Block Masonry Conference, vol. 1, Dublin, Ireland, (1988), pp. 205–216

Indian Standards Indian standard code of practice for structural use of unreinforced masonry, IS1905, 3rd Rev., Bureau of Indian Standards, New Delhi, India (1987)

Masonry Standards Joint Committee (MSJC), Building code requirements for masonry structures, ACI 530-02/ASCE 5-02/TMS 402-02, American Concrete Institute, Structural Engineering Institute of the American Society of Civil Engineers, The Masonry Society, Detroit (2002)

D. Lenczer, Elements of load bearing brickwork (Pergamon Press, Oxford, 1972)

P. Dayaratnam, Brick and reinforced brick structures (Oxford and IBH, New Delhi, 1987)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumavat, H.R. An Experimental Investigation of Mechanical Properties in Clay Brick Masonry by Partial Replacement of Fine Aggregate with Clay Brick Waste. J. Inst. Eng. India Ser. A 97, 199–204 (2016). https://doi.org/10.1007/s40030-016-0178-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40030-016-0178-7