Abstract

The aim of this study was to investigate the essential aspects of Conocarpus erectus as a potential fuel wood. The results show that the tree can produce acceptable biomass (13.5 MT ha−1) with relatively low water consumption (approximately 44 m3 ha−1). Conocarpus erectus is completely compatible with the climate of Khuzestan and can be planted in the desert areas of the province to deal with desertification. The appropriate proximate and ultimate properties of the tree wood such as heating value (18 MJ kg−1), fresh and dry bulk density (943 and 592 kg m−3, respectively), moisture content and moisture loss behavior, compatible wood and ash elemental contents, which are comparable to those of some common energy crops such as Paulownia, Populus, and Switch-grass, make the tree a potential for bioelectricity generation. The results of the LCA study showed that the environmental impacts of Conocarpus-based electricity are significantly improved in almost all studied categories. Also, compared to the environmental effects of natural gas-based electricity, the environmental damages of Conocarpus-based electricity are improved in all three impact categories of “Human Health”, “Ecosystem”, and “Resources” by 97, 97 and 98%, respectively. If the deserts of Khuzestan are used for the construction of farms and the urban wastewater is used for irrigation, not only this situation will improve even more, but also obvious environmental benefits will follow, including the fight against desertification.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Biomass is probably the first type of human-inhibited energy carrier (Demirbas 2004). Fuelwood has traditionally been burned directly in an unstable, inefficient, and uncontrolled manner for heating and cooking (Goldemberg and Coelho 2004). Combustion or burning of biomass in air, releases chemical energy of biomass as heat (Mckendry 2002). This technology has evolved over time to become more effective technic of energy conversion by implementing advanced boilers (Rajh et al. 2016; Trojanowski and Fthenakis 2019), converting heat to electricity in modern more efficient CHP plants (Li et al. 2019), controlling emissions (Trojanowski and Fthenakis 2019) and so on. Bioenergy and biomass will inevitably play an important role in ensuring future energy security even in a region with very rich fossil energy resources, such as the Middle East. The sustainability of biomass use for energy security and reduction of carbon emissions for climate adaptation is a matter of concern (Dasgupta et al. 2022). Sustainable production of high-quality biomass, with the proper composition is of great importance. Factors affecting biomass as an energy source are including: moisture content, calorific value, properties of volatile matters, and ash and alkali content (Jenkins et al. 1998; Villanueva et al. 2011; Bilandzija et al. 2018). Actual and bulk density not only affects the transportation and maintenance process but also the combustion properties, such as thermal conductivity (Villanueva et al. 2011). Calorific value plays a decisive role in the use of any substance as fuel (Khan et al. 2009; Demirbas 2010; Bilandzija et al. 2018). Particle size and specific gravity, ash content and its fusion point, and moisture content, which are given by proximate analysis and element (C, H, O and N) content, which is given by ultimate analysis are among the most important affecting characteristics of wood combustion (Obernberger et al. 2006; Khan et al. 2009; Demirbas 2010; Bilandzija et al. 2018). Ash content can directly affect heating value, so that the higher the ash content of a fuel, the less desirable that fuel is (Demirbas 2010, p. 129). Cl and S can lead to deposit formation and corrosion, and are therefore relevant for plant availability and its lifetime (Obernberger et al. 2006). On the other hand, analyzing the major ash elemental composition (Al, Ca, Fe, K, Mg, Na, P, Si, Ti) (Obernberger et al. 2006) in addition to help studying the ash melting behavior and its technical problems in combustion systems, such as deposit formation, corrosion, fouling and slagging, and accumulation, is useful for determining the possibility of using ash as fertilizer (Jenkins et al. 1998).

Khuzestan, a vast province located in the southwest of Iran, in recent years has been grappling with environmental problems especially desertification and micro dust crisis (Asakereh et al. 2017). Increasing vegetation cover is definitely among the most effective and environmentally friendly methods of combating desertification (Asakereh et al. 2017). Desert areas, such as those found in Khuzestan Province, are in fact marginal lands (Gelfand et al. 2013), and are not suitable for agricultural crops due to their innate low crop productivity, environmental climatic conditions or risk of exposure to erosion or other environmental risks if cultivated, but are suitable for short-rotation tree crops or other perennial vegetation, which has persistent roots to adapt to low-nutrient, erodible or droughty soils (Gelfand et al. 2013; Testa et al. 2022). Thus, allocating these type of lands to energy farms may not increase the “food vs. energy” challenge (Gerwin et al. 2018) and land use competition (Zheng et al. 2022). The tree species that are planted in these lands must be chosen very consciously in order to have the most compatibility with the weather and environmental conditions, as well as to have the most effectiveness and productivity.

Tree species selected for planting in these deserts, in addition to the minimum water and care needs, must be compatible with the ambient climate. Conocarpus erectus is the most dominant tree species planted in the green space of Ahvaz, the capital and the most populous city of Khuzestan province. This tree is also planted almost all over the province and is completely adapted to the climatic conditions of the province. The number of these trees in the campus of Shahid Chamran University of Ahvaz is also impressive. Water is the only input provided to these trees. The irrigation period of these trees is very different depending on their location and distance or proximity to the main boulevards of the university and varies from three to ten and even twenty days. Even some trees that are far from the main views of the university are rarely watered. The continuation of growth of these trees with the least amount of water consumption shows their resistance and adaptation to the climatic conditions of Khuzestan and therefore are considered suitable trees for afforestation and the fight against desertification. Some other great features including tolerating extreme environmental conditions, contributing to temperature stability, improving photosynthesis rate, and especially holding off dust, are made it fully compatible with Khuzestan climate. This tree can tolerate air pollution and water shortage (Rehman et al. 2019) and has good experience in soil remediation in the deserts of Saudi Arabia, United Arab Emirates and Kuwait, after the Persian Gulf War in 1911 (Al-Surrayai et al. 2009). Conocarpus erectus can not only grow in urban sewage, it also removes some heavy metals, nitrate, ammonium and phosphate from wastewater (Alsihany et al. 2019; Sayadi et al. 2019). So, the water needed for this tree can be supplied from urban sewage. These characteristics along with high biomass yield, have convinced some researchers to consider the tree as a potential bioenergy crop (Hegazy et al. 2008; Tauqeer et al. 2019; Asakereh and Firouzi 2022).

Moreover, evaluating the environmental performances of the proposed bioenergy system is of particular importance. In this context, the life cycle assessment (LCA), is a cradle-to-grave perspective (Guenther 2021; Zhao et al. 2022) provides a comprehensive view by taking into account all environmental impacts of a system in its entire life from the extraction of resources (cradle) through manufacturing, transportation, assembly, exploitation and recycling or final disposal (grave) (Faleh et al. 2022). LCA has been used for the evaluation of various bioenergy systems such as biohythane production from food waste (Dangol et al. 2022), H2 production from sheep tallow (Faleh et al. 2022), biogas (Hijazi et al. 2016; Izzah et al. 2019), bioethanol (Ingrao et al. 2021; Kumar et al. 2022; Santoyo and Luengas 2022), etc.

Accordingly, to evaluate the Conocarpus erectus as a potential bioenergy crop can be planted to combat desertification, this study was conducted with the aims of measuring the inputs required for the tree growth and the amount of biomass produced, studying thermochemical and physicochemical properties of the wood, and finally assessing the environmental impacts of the whole life cycle in generating 1 kWh electricity from burning the wood.

Materials and methods

LCA

LCA is a “cradle-to-grave” perspective that can compare the environmental burden of products or services over their entire life cycle, from raw material extraction to end-of-life waste disposal (Saraiva 2016). According to the definition reported in the ISO 14040 (ISO 2006), any LCA is performed in the following four steps:

-

Goal and scope definition

-

Inventory analysis

-

Impact assessment

-

Interpretation

Goal and scope definition

The main objective of this LCA study was to analyze the environmental damage of electricity generated from Conocarpus biomass and compare its damages with that’s of conventional natural gas-based electricity. The functional unit for this research is the production of 1 kWh electricity. Figure 1 shows the hypothetical boundaries of the LCA system. The figure also shows all the detailed inputs and outputs to and from the system.

Inventory analysis

SimaPro® V8.4.00 software was used to perform LCA. A large part of the data required was background data available in databases or found in the literature. The specific data required for this particular LCA study are the amount of water, land, and electricity used to produce biomass, the fuel required to cut wood, and the emissions from burning biomass to produce heat, which were collected as follows.

Water consumption and biomass yield

As mentioned before, water is the only input that is supplied to Conocarpus trees in the green spaces of “Shahid Chamran University of Ahvaz” campus. To measure water consumption, nine different locations in the university campus were chosen based on the irrigation interval (three locations on the main boulevard that were irrigated weekly, three on the side streets that were irrigated every two weeks, and three out of the main views that were irrigated monthly). In each place, eight trees were considered for this purpose and piped so that these trees were irrigated only with water passing through the pipe. A water meter was placed along the water pipe in the middle of eight trees to measure the amount of water passing through the pipe (Fig. 2). The irrigation period continued according to the previous routine and exactly like the program that was common in the green space of the university in previous years. At different intervals, the amount of water coming out of each meter was recorded. After one year, the total water consumption of the trees was obtained and the annual consumption of the trees was calculated on a scale of one hectare.

Pruning of trees and pruning periods continued as before, with the same previous green space workers. The amount of pruned biomass in each period for each tree was weighed and recorded separately. The frequency of pruning is two to three times per year, depending on the irrigation period and, of course, the rate of biomass growth. Normally, in addition to the usual annual pruning, the trees are heavily pruned once every three years. This pruning is so severe that almost all parts of the tree are cut down except part of the main trunk. Fortunately, during the study period, the trees were severely pruned once and the pruned biomass was weighed and recorded. Biomass recorded in total conventional pruning and one-third of the amount recorded in severe pruning were calculated as annual production biomass.

Electricity

Equation (1) was used to calculate power requirement to pump water for irrigation (Kitani 1999).

where E is electricity (J ha−1), γ is water density (1000 kg m−3), g is gravity of earth (9.8 m s−2), Q is total required water, H is dynamic head (The height difference between the water supply location and the farm, 15 m), is the pump efficiency (80%) and is the overall efficiency of the power device (0.2). Since Khuzestan province is a flat area, there is not much difference in height between different areas, so it was assumed that the difference in height between the point of consumption and water supply is 15 m.

Wood processing and transportation

It is assumed that the result of every 5 min of sawing is the production of 4 MT of wood. Also to reduce transmission costs, it is assumed that the heat generating plant will be located in the center of the energy field. Therefore, it is assumed that the cut wood after being dried is transported up to 5 km on average (or 6.25 (t)*5 (km) = 31.25 tkm). The transport and sawing process documented in the SimaPro database was used to model the impacts of these two processes. Also, since the average ambient temperature in Khuzestan region in 6, 7 and 9 months of the year is above 40, 35 and 30℃, respectively (Anonymous 2013), it was assumed that all biomass naturally dries, below the appropriate moisture content for combustion. The actual thermal efficiency of a modern thermal power plant is usually between 35 and 49% (Soto and Vergara 2014; Zhang 2020; Shajahan et al. 2022). Accordingly, the thermal efficiency of the hypothetical power plant was considered to be the middle of this range, i.e., 42%. A loader with a capacity of loading 14 MT h−1 is used to load biomass and a lorry with a capacity of 16–32 MT is used to transport biomass from field to power plant (Goedkoop et al. 2014).

Emissions

The documented database in SimaPro was used to take into account the emissions related to water, electricity, transportation, sowing and so on. Emission related to biomass combustion was acquired from the literature as in Table 1.

Impact assessment

The SimaPro model was used to perform LCA of the electricity generated by the combustion of Conocarpus erectus wood. To perform an LCA, it is first necessary to consider all inputs, outputs, processes and emissions from all stages of planting, growing, cutting, transporting, drying, combustion and managing waste streams. For this purpose, a hypothetical energy field and a power plant are modeled. Almost all of the data needed to perform an LCA is background data (data on the production of generic materials, energy, transportation, etc., which can be acquired from SimaPro databases and literature) (Goedkoop et al. 2016). The ReCiPe 2016 Endpoint (I) V1.00 method was used to compare the environmental life cycle impacts of natural gas-based electricity and Conocarpus biomass electricity. This method assigns different life cycle emissions (according to the substances’ ability to contribute to different environmental problems (Goedkoop et al. 2016) to 21 different impact assessment subcategories. These 21 subcategories are “Global warming, Human health”, “Global warming, Terrestrial ecosystems”, “Global warming, Freshwater ecosystems”, “Stratospheric ozone depletion”, “Ionizing radiation”, “Ozone formation, Human health”, “Fine particulate matter formation”, “Ozone formation, Terrestrial ecosystems”, “Terrestrial acidification”, “Freshwater eutrophication”, “Terrestrial ecotoxicity”, “Freshwater ecotoxicity”, “Marine ecotoxicity”, “Human carcinogenic toxicity”, “Human non-carcinogenic toxicity”, “Land use”, “Mineral resource scarcity”, “Fossil resource scarcity”, “Water consumption, Human health”, “Water consumption, Terrestrial ecosystems”, and “Water consumption, Aquatic ecosystems”. The final score of each sub-category is the sum of the product of the amount of each emission multiplied by its own characterization factor (Goedkoop et al. 2016). Then according to the weight of each sub-category, they are combined into three main categories of Human Health”, “Ecosystem”, and “Resources.

The proximate and ultimate analysis of Conocarpus wood

Sampling and preparation the samples

Almost all samples were taken from Conocarpus Erectus trees on the campus of Shahid Chamran University of Ahvaz (UC samples). Samples were taken in November 2020, and in this period ambient temperature and relative humidity was 39 °C and 48%, respectively. To compare biomass elemental content in contaminated areas, some samples were also taken from trees in a boulevard adjacent to the Khuzestan Steel Company Complex (KSC samples). Samples were taken from all aerial parts of the tree including leaf, branch, trunk, skin, and a mixed sample from all organs. All samples were prepared according to the guidelines of standards shown in Table 2.

Moisture content

50 g of each sample was put in a covered crucible and after weighing (Wi) was oven-dried for 24 h at 105 °C. Then the crucible was taken out, cooled in a desiccator, and weighed again (Wf). The average moisture content of the sample was the mean of 3 replications based on Eq. (2):

where MC, is the moisture content (%, wet basis); Wi, is the weight of crucible and undried sample (gr); Wf , is the weight of crucible and dried sample (gr) and Wc, is the weight of crucible (gr).

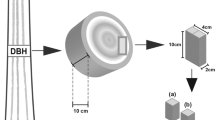

Bulk density

Five small cubic pieces of wood with dimensions (3*3*3 cm) were prepared and weighted accurately. The bulk density of each piece was measured according to Eq. (3) and (4) (Gendek et al. 2016):

where ,BDar is the bulk density of fresh wood (gr cm−3); BDd, is the bulk density of dry wood (gr cm−3), MC is the weight of wood piece (gr); MC, is the moisture content (%, wet basis); and V , is the volume of wood piece (cm3).

Moreover, to study the rate of weight loss in a controlled environment like what is done by (Villanueva et al. 2011), two samples of Conocarpus Erectus wood, each with 1000 gr, were oven dried for 10 days at 35 and 50 °C, respectively. The samples were weighted daily and the diagram of weight loss was plotted.

Ash content

Like the moisture content measuring process, 50 g of each sample was oven-dried. Samples after cooling completely in a desiccator were placed in electrical furnace and maintained at 550 °C, for 4 h. The remained ash (Fig. 3) was weighted after cooling completely in the desiccator. The ash content was measured according to Eq. (5):

where AC, is the ash content (%, dry basis); Wa, is the weight of crucible and ash (gr); Wf, is the weight of crucible and dried sample (gr) and Wc , is the weight of crucible (gr).

Heating value

25 g of each sample was oven-dried for 48 h at 60 °C. Then after cooling completely in a desiccator, the samples were completely crushed and passed through 80 mesh sieves. So they were ready to transfer into DA-TE10-Bomb Calorimeter- DeghatAzma® to determine their calorific value.

Ultimate elemental (C, H, N and O)

25 g of each sample was oven-dried for 48 h at 60 °C (to dry at a low temperature but at relatively long time). Then the samples were completely crushed and passed through an 80 mesh sieve, then transferred into the Vario EL III -CHNSO Elementar®, using a Falcon.

Ash elemental analysis

In order to prepare the samples for measuring the ash elementals of k, Ca, Mg, Na, P, Cl, Fe, Al and Ti, 10 ml of 2 molar hydrochloric acid (HCl) was added to one gram of ash in a beaker. After two hours of storage at room temperature, the beaker was placed on a heater until the temperature reached 80 °C, while white fumes escaped from the samples. At the end, beaker contents were transferred to a 100-ml balloon. Then deionized double distilled water was added to reach the volume to 50 ml and finally it was filtered through Whatman® Grade 42 filter paper, to be ready for ICP-OES.

Results and discussion

Water and electricity consumption

Figure 4 shows the relationship between water consumption and biomass production based on the data collected over the studied time period. According to this figure, with the increase in water consumption, the amount of biomass production increases quadratically (R2 = 0.96). Considering this relationship, the optimal annual biomass production is 13.5 MT per hectare, which is obtained with an annual consumption of approximately 44 m3 of water. To pump this amount of water, according to Eq. (1), 11.3 kWh of electricity is needed. This is a significant biomass yield compared to that of some proposed energy crops such as Nordic Poplar (11 MT ha−1 (Adler et al. 2022)), Paulownia (18.3–20.3 MT ha−1 (Testa et al. 2022)), Willow and Poplar (9.7 DM t ha−1 (Haberzettl et al. 2021)), Miscanthus, Poplar or Willow (11.9 DM t ha−1 (Haberzettl et al. 2021)), and Miscanthus (9.6 DM t ha−1 (Haberzettl et al. 2021)).

Conocarpus is a fast-growing tree and the time interval between two harvest periods can be shortened to 3–4 years. This time interval for Paulownia, Eucalyptus, Pine and Poplar trees is 5–7, 15–20, 15–20 and about 10 years, respectively (Villanueva et al. 2011). Therefore, a comparable biomass can be harvested from a Conocarpus field in a shorter period of time.

Result of proximate and ultimate analysis

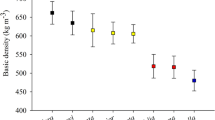

Bulk density

Knowing the actual density of raw materials is essential to avoid cost increases in the transportation system and to design proper transportation and logistics. Density is one of the most important physical properties of wood, which greatly affects its mechanical properties. The higher the density, the higher the mechanical properties, especially the hardness of the wood (Villanueva et al. 2011). The amount of heat produced by burning wood also depends on its density. The bulk density of fast-growing species is usually lower than that of slow-growing species (Villanueva et al. 2011). Amounts of bulk density and moisture content in aerial parts of Conocarpus erectus for both UC and KSC and some related woods are shown in Table 3. The fresh and dry bulk density of Conocarpus erectus is about 943 and 592 kg.m−3, respectively which according to Table 3 is among the dense species. Although Conocarpus erectus is relatively a fast-growing tree, its moisture content and density is comparable to that of Poplar and Pine which are relatively slow-growing species.

Moisture content

Moisture is a key indicator in determining the lower heating value (LHV) of a fuel (NúÔez-Regueira et al. 2005). The higher the moisture content of a fuel, the lower the amount of its LHV. As a result, less energy is available for the boiler (Clarke and Preto 2011). As shown in Table 3, the moisture content of KSC is slightly higher than that of UC. This is due to shorter intervals and more amount of irrigation inside the university than inside the city. Also as shown in Table 3, the moisture content of leaves and branches is typically higher than that of the trunk. But the trunk, as the densest part, is the most important organ whose moisture is important for burning in the furnace. The moisture content of Conocarpus erectus wood is comparable to that of Populus, Eucalyptus and Pine (Table 3).

Biomass combustion and water evaporation are two reactions with different thermodynamic behavior, the first of which is exothermic and the second is endothermic. Moisture contents, up to 65% (Jenkins et al. 1998; McNulty and Grace 2009) does not prevent autothermal combustion (self-supporting combustion). At high moistures, available energy in biomass, does not meet the energy required to evaporate fuel moisture. The moisture content of Conocarpus erectus trunk is around 45%

Table 3 which must be dried to a lower amount for more efficient burning. The high ambient temperature in Khuzestan province provides an excellent opportunity for natural drying with the sun without using an external source of energy. However, a solution must also be found to eliminate the effect of high relative humidity, which in most cases is more than 30%, and fuelwood is prone to moisture absorption under these conditions (Deng et al. 2019).

Figure 5 shows that Conocarpus erectus wood loses about 30 percent of its weight after 10 days at 35℃, which is the most common temperature in Khuzestan region. The amount of weight loss at the temperatures of 50℃ and above (Fig. 5), which is sometimes available in the summers of Khuzestan, can reach 42% and more. The moisture loss behavior of Conocarpus erectus is similar to that of Populus (Villanueva et al. 2011), which has the same density and initial moisture content (Table 3).

Elemental composition of aerial parts

Table 4 shows the elemental analysis of aerial parts of Conocarpus erectus. As shown in this table, KSC samples have relatively higher values of these elements. Higher carbon and hydrogen content can result in higher heating value (Clarke and Preto 2011). The amounts of sulfur, nitrogen and chlorine in most types of biomass are rarely more than 1% dry matter (Jenkins et al. 1998). Relatively higher levels of sulfur and nitrogen in the composition of Conocarpus erectus organs (Table 5) are probably due to the polluted air of Khuzestan, affected by oil and gas facilities and other polluting industries, such as steel, sugarcane, etc. As previously proven, (Yateem et al. 2008; Al-Surrayai et al. 2009; Ali and Ali 2014) the tree is prone to absorb elements such as nitrogen and sulfur in contaminated areas. However, this property makes Conocarpus erectus suitable for the treatment of polluted air in cities, high levels of nitrogen, sulfur and chlorine in these conditions, if used as fuel, can lead to the release of NOx, SO2 and HCl (Jenkins et al. 1998; Clarke and Preto 2011; Bilandzija et al. 2018). Sulfur is also involved in certain ash reactions that lead to fouling and slagging (Jenkins et al. 1998). On the other hand, nitrogen and sulfur oxides participate in reactions leading to acid rain (Jenkins et al. 1998). The promising point, according to Table 4, is that the highest amount of nitrogen and sulfur is in the leaves, shoots and bark, and by removing these parts, the content of these two elements can be reduced to a great extent.

Heating value

The heating value of wood and elemental analysis of Conocarpus erectus and some reference trees are shown in Table 5. The heating value of KSC wood is slightly higher than that of UC. This is probably due to the carbon and hydrogen content of KSC, which is slightly higher than that of UC (Clarke and Preto 2011). Conocarpus erectus generally has a higher oxygen content than reference trees. Although oxygen is partly responsible for the relatively lower LHV of biomass (Demirbas 2004; Ilari et al. 2022), its presence in the fuel composition contributes to more complete combustion of the fuel, resulting in the release of less carbon dioxide and carbon monoxide (Carraretto et al. 2004; Ushakov et al. 2013). The heating value of Conocarpus erectus is comparable to that of Paulownia, Populus and Switch-grass, but slightly lower than that of Eucalyptus, Pine, Willow and Poplar. The carbon and hydrogen content of Conocarpus erectus, which play a decisive role in determining the heating value based on the Dulong equation (Demirbas 2004), is comparable to that of Paulownia, Populus, Eucalyptus and Switch-grass. Sulfur and nitrogen content of Conocarpus erectus is overally higher than that’s of other biomass types. This is most likely due to oil pollution in Khuzestan, as it is observed that the S and N content in KSC is higher than that of UC.

Ash and ash elemental composition

A proper fuelwood should have a high heating value and fixed carbon and, in contrast, low ash and moisture content. Also, to prevent the release of NOx, SO2, and HCl, it is better for wood to have a lower share of nitrogen, sulfur and chlorine (Bilandzija et al. 2018). Waste management in the combustion process of a biomass with lower ash content is easier and less expensive. Also, lower ash content leads to fewer problems in heaters (Demirbas 2002; Villanueva et al. 2011). The ash content of different biomass has been reported from less than 1–20%. This factor is generally lower in forest wood, compared to crop residues and farm removals (Anonymous 2018, p. 31). The average ash content of bark in selected trees is typically higher than that of the trunk (Demirbas 2002, 2004; Obernberger et al. 2006; Clarke and Preto 2011), so it is recommended to peel the wood to reduce the ash content under 5% (Hazeltine and Bull 2003).

In the case of Conocarpus erectus, as shown in Table 6, the ash content of trunk wood is remarkably lower than that of leaves, shoots, and bark. Therefore, as recommended, removal of leaves, bark and shoots can help reduce ash waste management problems, although it increases the cost. Like density and moisture content, the ash content of Conocarpus erectus is comparable to that of Populus.

The content of Cl, K, Si and Ti is almost the same in both KSC and UC. But Fe, Al, Mn and Ca content in KSC are higher than in UC. In contrast, the sodium content in UC is higher than in KSC, most likely due to sodium in irrigation water. The higher content of some elements, especially Fe in KSC, obtained from trees near Khuzestan Steel Company, shows the high ability of this tree to absorb airborne elements. Ash content and the type of ash elements in biomass depends on many factors including age (Kumar et al. 2010; Zając et al. 2018), plant type and species (Bakker and Elbersen 2005; Zając et al. 2018), plant parts (Bakker and Elbersen 2005; Zając et al. 2018), growing process conditions (Bakker and Elbersen 2005; Zając et al. 2018), quantity and quality of fertilization application (Zając et al. 2018), harvest time and techniques (Zając et al. 2018), transport and storage conditions, processing methods, as well as the process of combustion itself (Zając et al. 2018). Slagging, sintering, deposition, erosion, corrosion and fouling are among the major ash related problems in furnaces, boilers and heat exchanging surfaces (Jenkins et al. 1998; Khan et al. 2009; Clarke and Preto 2011; James et al. 2012; Mancini et al. 2018; Zając et al. 2018). In general, a higher content of calcium and magnesium increases the melting point of ash, while a higher content of potassium, chlorides and aluminosilicates lowers it (Jenkins et al. 1998; Obernberger et al. 2006; Clarke and Preto 2011; Zając et al. 2018; Sefidari et al. 2020). On the other hand, the formation of hydrochloric acid as a result of high chloride content can lead to corrosion in boiler tubes and water leakage in the boiler (Clarke and Preto 2011).

The amount of potassium in Conocarpus erectus ash, especially in relatively clean areas (UC samples in Tables 6 and 7) is very low, compared to this amount in energy crops (Table 7). But the chloride content in Conocarpus erectus organs is higher than that of common energy products (Table 7). This condition is more likely to be affected by pollution from oil-related industries in Khuzestan Province because it is observed that the potassium and chloride content in KSC are higher than those of UC (Tables 6 and Table 7). Planting trees in remote areas and, if possible, away from polluting industries can alleviate this problem.

Ash is generally free of toxic metals and other contaminants and can be used as soil fertilizer. Although potassium plays a major role in fouling and slagging, as a macronutrient it enhances the fertilizer value of ash. Based on Nieminen et al. (2005) (Nieminen et al. 2005) potassium (K), sodium (Na), boron (B) and sulfur (S) in wood ash are easily releasing but heavy metals are not. The amount of K, and Na in the ash of Conocarpus erectus is much lower than the ash of some reference woods in Table 7. However, the nutritional value of biomass ash is certainly commensurate with the nutritional needs of the source plant. The use of ash as fertilizer in places of biomass origin can increase sustainability by returning nutrients to their original soil. Other options are to use it as a raw material for building materials (Pels et al. 2005). However, it is recommended that the fertilizer value of Conocarpus erectus wood ash be investigated in another study.

Results of LCA of one kWh of Conocarpus-based electricity

Table 8 shows all the inputs, outputs, processes and key points in the life cycle of power generation from the Conocarpus biomass in a hypothetical energy farm and a related power plant. Based on this table, it is possible to produce 13,125 kWh ha−1 of electricity assuming an average thermal efficiency of 42% for the assumed power plant. If a useful use is found for the rejected heat (65,250 MJ), it can greatly contribute to the stability of the system.

Table 9 represents the characterized values of the whole life cycle of natural gas-based and Conocarpu-based electricity in the 21 impact categories studied. As shown in the table in bold, the environmental impacts of the life cycle of Conocarpus-based electricity are significantly improved in almost all studied categories. The results are somewhat similar to the results of the study (Quek et al. 2019), which stated that in the transition to renewable electricity, “Human Toxicity Potential” and “Acidification” (rows 9, 14, and 15 in Table 9) are expected to increase, while “Global Warming Potential” (first three rows of Table 9), and “Fossil Energy Used” (row 18 in Table 9) could be decreased. In another study (Beagle and Belmont 2019) it was shown that greenhouse gases emissions, mainly classified under the category of “Global Warming”, are reduced by 76% over the life cycle of biomass used for electricity generation compared to that of coal-based electricity (first three rows of Table 9, which are reduced by 97%).

Figure 6 shows the comparison diagram of final impact categories for both types of electricity. According to this figure, the environmental damage of Conocarpus-based electricity has been improved in every three categories of “Human Health”, “Ecosystems” and “Resources” by 97%, 97% % and 98%, respectively. If the marginal lands and deserts of Khuzestan province are cultivated with Conocarpus and the waste water of the cities of Khuzestan (with a population of more than 4 million people) is used to irrigate these trees, this situation will improve even more.

Conclusion

The special properties of Conocarpus erectus tree, including high biomass production in a short period of time, relatively low water consumption, and resistance to drought conditions, along with the appropriate proximate and ultimate properties of the tree's wood, make it a potential species for planting in the desert areas of Khuzestan province with the aim of combating desertification and at the same time using its biomass as bioenergy. On the other hand, since this tree is prone to absorbing elements such as nitrogen, sulfur and chlorine, which are undesirable elements for biomass-burning furnaces, it is recommended to build bioenergy farms away from polluting industries such as oil, gas, petrochemical, and steel. Also, by removing the foliage and peeling the bark of the trunk, in addition to reducing the content of nitrogen and sulfur, the amount of biomass ash is also reduced to a great extent. Moreover, the results of the LCA study showed that the environmental impacts of Conocarpus-based electricity are significantly improved in 19 of the 21 studied impact categories.

Challenges and future prospects

For the sustainable development of energy farms, multi-purpose use of these farms should be considered. Therefore, it is recommended to investigate the possibility of expanding vegetation between trees in order to combine animal husbandry with trees, the possibility of producing medicinal, edible and industrial substances from the organs of this tree, the degree of coexistence of this tree with other useful trees such as Ziziphus spina-christi in order to expand beekeeping or camel farming, and the possibility of producing energy carriers such as biogas and bioethanol, especially from lignocellulosic residues.

References

Adler A, Kumaniaev I, Karacic A et al (2022) Lignin-first biorefining of Nordic poplar to produce cellulose fibers could displace cotton production on agricultural lands Lignin-first biorefining of Nordic poplar to produce cellulose fibers could displace cotton production on agricultural lan. Jule 6:1845–1858. https://doi.org/10.1016/j.joule.2022.06.021

Ali B, Ali H (2014) Possibility of using Conocarpus lancifolius Engl in remediation of some Iraqi soils polluted by crude oil. Adv Bio Res. https://doi.org/10.15515/abr.0976-4585.5.185-190

Alsihany MM, Ghoneim AM, Bukhari NA (2019) Transfer and accumulation of some heavy metals in native vegetation plants. Int J Plant Soil Sci 28:1–10. https://doi.org/10.9734/ijpss/2019/v28i430113

Al-Surrayai T, Yateem A, Al-Kandari R et al (2009) The use of Conocarpus lancifolius trees for the remediation of oil-contaminated soils. Soil Sediment Contam an Int J 18:354–368. https://doi.org/10.1080/15320380902772661

Amaral SS, de Carvalho JA, Costa MAM, Pinheiro C (2016) Particulate matter emission factors for biomass combustion. Atmosphere (basel) 7:1–25. https://doi.org/10.3390/atmos7110141

Anonymous (2013) Ahwaz metropolitan statistics (in Farsi)

Anonymous (2018) Biomass from agricultural pruning and plantation removals a feasible practice promoted by the up-running project

Asakereh AHWA, Firouzi AF (2022) Biochar and bioenergy production by pyrolysis of Conocarpus and Eucalyptus wastes : a case study, Khuzestan province. Iran Int J Environ Sci Technol 19:5839–5848. https://doi.org/10.1007/s13762-021-03765-6

Asakereh A, Soleymani M, Sheikhdavoodi MJ (2017) A GIS-based Fuzzy-AHP method for the evaluation of solar farms locations: case study in Khuzestan province. Iran Sol Energy 155:342–353. https://doi.org/10.1016/j.solener.2017.05.075

Bakker R, Elbersen H (2005) Managing ash content and quality in herbaceous biomass: an analysis from plant to product. 14th European Biomass Conference, Paris

Beagle E, Belmont E (2019) Comparative life cycle assessment of biomass utilization for electricity generation in the European Union and the United States. Energy Policy 128:267–275. https://doi.org/10.1016/j.enpol.2019.01.006

Bilandzija N, Voca N, Jelcic B et al (2018) Evaluation of Croatian agricultural solid biomass energy potential. Renew Sustain Energy Rev 93:225–230. https://doi.org/10.1016/j.rser.2018.05.040

Bond TC, Club CC, Principal C, No C (2006) Emission factors and real-time optical properties of particles emitted from traditional wood burning cookstoves. Environ Sci Technol 40:6750–6757

Carraretto C, Macor A, Mirandola A et al (2004) Biodiesel as alternative fuel: experimental analysis and energetic evaluations. Energy 29:2195–2211. https://doi.org/10.1016/j.energy.2004.03.042

Clarke S, Preto F (2011) Biomass burn characteristics. Ministry of Agriculture; Food and Rural Affairs, Ontario

Dangol S, Ghimire A, Tuladhar S et al (2022) Biohythane and organic acid production from food waste by two–stage anaerobic digestion: a review within biorefinery framework. Int J Environ Sci Technol. https://doi.org/10.1007/s13762-022-03937-y

Dasgupta S, Badola R, Ali SZ, Tariyal P (2022) Bioresource, energy and forest sustainability: a case study from Indian Himalayan region. J Clean Prod 337:130497. https://doi.org/10.1016/J.JCLEPRO.2022.130497

Delmas R, Lacaux JP, Brocard D (1995) Determination of biomass burning emission factors: methods and results. Environ Monit Assess 38:181–204

Demirbas A (2002) Relationships between heating value and lignin, moisture, ash and extractive contents of biomass fuels. Energy Explor Exploit 20:105–111. https://doi.org/10.1260/014459802760170420

Demirbas A (2004) Combustion characteristics of different biomass fuels. Prog Energy Combust Sci 30:219–230. https://doi.org/10.1016/j.pecs.2003.10.004

Demirbas A (2010) Biorefineries: For biomass upgrading facilities

Deng T, Alzahrani AM, Bradley MS (2019) Influences of environmental humidity on physical properties and attrition of wood pellets. Fuel Process Technol 185:126–138. https://doi.org/10.1016/j.fuproc.2018.12.010

Faleh NE, Ben HK, Hajjaji ZKN (2022) Sustainability evaluation of H2 production from sheep tallow by combining emergy and environmental life cycle assessment. Int J Environ Sci Technol. https://doi.org/10.1007/s13762-022-04271-z

Gelfand I, Sahajpal R, Zhang X et al (2013) Sustainable bioenergy production from marginal lands in the US Midwest. Nature 493:514–517. https://doi.org/10.1038/nature11811

Gendek A, Aniszewska M, Chwedoruk K (2016) Bulk density of forest energy chips. Agriculture 67:101–116

Gerwin W, Repmann F, Galatsidas S et al (2018) Assessment and quantification of marginal lands for biomass production in Europe using soil-quality indicators. Soil 4:267–290. https://doi.org/10.5194/soil-4-267-2018

Goedkoop M, Oele M, Vieira M, et al (2014) SimaPro Tutorial. 1–89

Goedkoop M, Oele M, Leijting J, et al (2016) Introduction to LCA with SimaPro. 1–80

Goldemberg J, Coelho ST (2004) Renewable energy — traditional biomass vs. modern biomass. Energy Policy 32:711–714. https://doi.org/10.1016/S0301-4215(02)00340-3

Guenther SLPSE (2021) Discounting and life cycle assessment : a distorting measure in assessments, a reasonable instrument for decisions. Int J Environ Sci Technol. https://doi.org/10.1007/s13762-021-03426-8

Haberzettl J, Hilgert P, Von CM (2021) a critical review on lignocellulosic biomass yield modeling and the bioenergy potential from marginal land. Agronomy 11:1–39

Hazeltine B, Bull C (2003) Field guide to appropriate technology. Elsevier

Hegazy SS, Aref IM, Al-mefarrej H, El-juhany LI (2008) Effect of spacing on the biomass production and allocation in Conocarpus erectus L.trees grown in Riyadh Saudi Arabia. Saudi J Biol Sci 15:315–322

Hijazi O, Munro S, Zerhusen B, Effenberger M (2016) Review of life cycle assessment for biogas production in Europe. Renew Sustain Energy Rev 54:1291–1300. https://doi.org/10.1016/j.rser.2015.10.013

Ilari A, Duca D, Boakye-Yiadom KA et al (2022) Carbon footprint and feedstock quality of a real biomass power plant fed with forestry and agricultural residues. Resources. https://doi.org/10.3390/resources11020007

Ingrao C, Matarazzo A, Gorjian S et al (2021) Wheat-straw derived bioethanol production: A review of Life Cycle Assessments. Sci Total Environ 781:146751. https://doi.org/10.1016/j.scitotenv.2021.146751

ISO (2006) ISO 14040:2006(en) Environmental management — Life cycle assessment — Principles and framework

Izzah N, Aziz HA, Hana MM, Gheewala SH (2019) A review on life cycle assessment of biogas production: challenges and future perspectives in Malaysia. Biomass Bioenergy 122:361–374. https://doi.org/10.1016/j.biombioe.2019.01.047

James AK, Thring RW, Helle S, Ghuman HS (2012) Ash management review-applications of biomass bottom ash. Energies 5:3856–3873. https://doi.org/10.3390/en5103856

Jenkins B, Baxter L, Miles T Jr, Miles T (1998) Combustion properties of biomass. Fuel Process Technol 54:17–46. https://doi.org/10.1016/S0378-3820(97)00059-3

Khan AA, de Jong W, Jansens PJ, Spliethoff H (2009) Biomass combustion in fluidized bed boilers: potential problems and remedies. Fuel Process Technol 90:21–50. https://doi.org/10.1016/j.fuproc.2008.07.012

Kitani O, Thomas J, Robert MP, Abdellah R (1999) CIGR handbook of agricultural engineering. Energy Biomass Eng 5:330

Kumar R, Pandey KK, Chandrashekar N, Mohan S (2010) Effect of tree-age on calorific value and other fuel properties of Eucalyptus hybrid. J for Res 21:514–516

Kumar P, Latha M, Prem N, Pabbathi P (2022) Second-generation bioethanol production from corncob: a comprehensive review on pretreatment and bioconversion strategies, including techno-economic and lifecycle perspective. Ind Crop Prod 186:115245. https://doi.org/10.1016/j.indcrop.2022.115245

Li H, Wang B, Yan J et al (2019) Performance of flue gas quench and its in influence on biomass fueled CHP. Energy 180:934–945. https://doi.org/10.1016/j.energy.2019.05.078

Mancini M, Rinnan PA, Toscano G (2018) Prediction of gross calorific value and ash content of woodchip samples by means of FT-NIR spectroscopy. Fuel Process Technol 169:77–83. https://doi.org/10.1016/j.fuproc.2017.09.021

Mckendry P (2002) Energy production from biomass (part 2): conversion technologies. Bioresour Technol 83:47–54

Mcnulty P, Grace PM (2009) Agricultural mechanization and automation. EOLSS Publications, pp 1–489

Nieminen M, Piirainen S, Moilanen M (2005) Release of mineral nutrients and heavy metals from wood and peat ash fertilizers: field studies in Finnish forest soils. Scand J for Res 20:146–153. https://doi.org/10.1080/02827580510008293

NúÔez-Regueira L, Rodríguez-AÔón JA, Proupín J et al (2005) Energetic characterization of forest biomass by calorimetry and thermal analysis. J ofThermal Anal Calorim 80:457–464

Obernberger I, Brunner T, Bärnthaler G (2006) Chemical properties of solid biofuels-significance and impact. Biomass Bioenerg 30:973–982. https://doi.org/10.1016/j.biombioe.2006.06.011

Pels JR, Nie DS De, Jacob HAK (2005) Utilization of ashes from biomass combustion and gasification. In: 14th European Biomass Conference & Exhibition. Paris, pp 1–17

Quek TYA, Ee WLA, Chen W, Ng TSA (2019) Environmental impacts of transitioning to renewable electricity for Singapore and the surrounding region : a life cycle assessment. J Clean Prod 214:1–11. https://doi.org/10.1016/j.jclepro.2018.12.263

Rajh B, Yin C, Samec N (2016) Advanced modelling and testing of a 13 MWth waste wood-fired grate boiler with recycled flue gas. Energy Convers Manag J 125:230–241. https://doi.org/10.1016/j.enconman.2016.02.036

Rehman S, Zam F, Rehman SU et al (2019) A Review on botanical, phytochemical and pharmacological reports of Conocarpus Erectus. Pakistan J Agric Res 32:212–217

Santoyo E, Luengas DAC (2022) Life cycle assessment of bioethanol production from sugarcane bagasse using a gasification conversion process: bibliometric analysis, systematic literature review and a case study. Appl Therm Eng. https://doi.org/10.1016/j.applthermaleng.2022.119414

Saraiva AB (2016) System boundary setting in life cycle assessment of biorefineries : a review. Int J Environ Sci Technol. https://doi.org/10.1007/s13762-016-1138-5

Sayadi M, Farasati M, Mahmoodloo M, Rostami F (2019) Removal of nitrate, ammonium and phosphate from water using Conocarpus and Paulownia plant biochar. Iran J Chem Chem Eng 39(4):205–222

Sefidari H, Ma C, Fredriksson C et al (2020) The effect of co-firing coal and woody biomass upon the slagging / deposition tendency in iron-ore pelletizing grate-kiln plants. Fuel Process Technol. https://doi.org/10.1016/j.fuproc.2019.106254

Shajahan MSM, Jamal DN, Mathew J et al (2022) Case Studies in Thermal Engineering Improvement in efficiency of thermal power plant using optimization and robust controller. Case Stud Therm Eng 33:101891. https://doi.org/10.1016/j.csite.2022.101891

Soto R, Vergara J (2014) Thermal power plant efficiency enhancement with ocean thermal energy conversion. Appl Therm Eng 62:105–112. https://doi.org/10.1016/j.applthermaleng.2013.09.025

Tauqeer HM, Ur-Rehman M, Hussain S et al (2019) The potential of an energy crop “ Conocarpus erectus “ for lead phytoextraction and phytostabilization of chromium, nickel, and cadmium: an excellent option for the management of multi-metal contaminated soils. Ecotoxicol Environ Saf 173:273–284. https://doi.org/10.1016/j.ecoenv.2019.01.119

Testa R, Schifani G, Rizzo G, Migliore G (2022) Assessing the economic profitability of as a biomass crop in Southern Mediterranean area. J Clean Prod 336:130426. https://doi.org/10.1016/J.JCLEPRO.2022.130426

Trojanowski R, Fthenakis V (2019) Nanoparticle emissions from residential wood combustion : a critical literature review, characterization, and recommendations. Renew Sustain Energy Rev 103:515–528. https://doi.org/10.1016/j.rser.2019.01.007

Ushakov S, Valland H, Æsoy V (2013) Combustion and emissions characteristics of fish oil fuel in a heavy-duty diesel engine. Energy Convers Manag 65:228–238. https://doi.org/10.1016/j.enconman.2012.08.009

Villanueva M, Proupín J, Rodríguez-Añón JA et al (2011) Energetic characterization of forest biomass by calorimetry and thermal analysis. J Therm Anal Calorim 104:61–67. https://doi.org/10.1007/s10973-010-1177-y

Yateem A, Al-Sharrah T, Bin-Haji A (2008) Investigation of microbes in the rhizosphere of selected trees for the rhizoremediation of hydrocarbon-contaminated soils. Int J Phytoremediation 10:311–324

Yuntenwi EAT, MacCarty N, Still D, Ertel J (2008) Laboratory study of the effects of moisture content on heat transfer and combustion efficiency of three biomass cook stoves. Energy Sustain Dev 12:66–77. https://doi.org/10.1016/S0973-0826(08)60430-5

Zając G, Szyszlak-Bargłowicz J, Gołębiowski W, Szczepanik M (2018) Chemical characteristics of biomass ashes. Energies 11:1–15. https://doi.org/10.3390/en11112885

Zhang T (2020) Methods of improving the efficiency of thermal power plants. J Phys Conf Ser 1449:012001

Zhao Y, Zhao C, Wen T, Markides CN (2022) High temperature sensible storage — industrial applications. Encycl Energy Storage 1:424–432. https://doi.org/10.1016/B978-0-12-819723-3.00070-6

Zheng Z, Ji L, Xie Y et al (2022) Synergic management of crop planting structure and biomass utilization pathways under a food-energy-water nexus perspective. J Clean Prod 335:130314. https://doi.org/10.1016/J.JCLEPRO.2021.130314

Acknowledgements

The authors would like to thank Shahid Chamran University of Ahvaz and the financial support of the Vice Chancellor for Research and Technology of Shahid Chamran University of Ahvaz in the form of a fund (97/3/02/26247).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Editorial responsibility: Samareh Mirkia.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Soleymani, M., Shokrpoor, S. & Jaafarzadeh, N. A comprehensive study of essential properties of Conocarpus Erectus as a potential bioenergy crop. Int. J. Environ. Sci. Technol. 20, 6147–6160 (2023). https://doi.org/10.1007/s13762-023-04878-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-023-04878-w