Abstract

The article describes the results achieved in 5 years of monitoring of a large wastewater treatment plant (700,000 PE) in Southern Italy, which has a conventional activated sludge process scheme and electricity as exclusive energy source. The monitoring involved a preliminary phase ("static" monitoring) for the analysis of historical data on the main process-related variables, using the approach of normalization techniques. In the second monitoring phase ("dynamic" monitoring) the theoretical distribution of the energy load among the electromechanical units of the plant was first studied; then, an energy monitoring system was implemented on the most energy-consuming unit of the plant, a 500 kW turbo-blower, with the aim of analysing in detail its real-time performance and investigating potential correlations with other process parameters (wastewater flow rates and associated pollutant load). Results of the static monitoring suggest good overall performances, both from an energy and environmental point of view, even if the plant works close to the maximum hydraulic capacity due to the massive infiltrations. In particular, focusing on the energy performances, the plant consumes on average 0.17 kWh/m3, 28 kWh/PE/year and 0.66 kWh/kgCODremoved. The results of dynamic monitoring, on the other hand, indicate that the turbo-blower consumes 30% less energy than what initially estimated through the theoretical model, but its functioning does not seem to be influenced by the other process parameters; this latter result reveals an inadequate energy management of the most power-absorbing electromechanical units of the plant and the consequent need to adopt effective strategies for energy optimization.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the present day, issues such as water availability and energy demand are becoming increasingly hot and urgent topics, especially given the rapid growth in world population over the last few decades. By 2050, the UN Observatory estimates world population to reach 9.7 billion (DESA 2019), 240 million people will no longer have access to clean water, while 1.4 billion people will no longer have access to basic sanitation (OECD 2015b). In such context, one of the problems is the maintenance status of existing infrastructures, many of which are becoming increasingly obsolete and with governance systems which are unable to deal with increasing demand, environmental challenges, relentless urbanization, climate change and water-related disasters.

Renewing and modernizing such infrastructures in the water sector requires significant financial investments, the value of which could reach $6.7 trillion by 2050 (OECD 2015a). In the absence of such measures, responding to growing demand by ensuring the same performances is only possible through an increase in energy consumptions.

A significant share of the energy used in the water sector can be attributed to wastewater treatment, which accounts for 25% of this energy on a global scale (IEA 2016) and plays the fundamental role of protecting water bodies by reducing the amount of carbon, nutrients, and pathogens discharged into the environment (Tang et al. 2019). Projections of IEA (2016) indicate that the energy demand of wastewater sector will increase over 60% by 2040, caused by the increase in polluted water needing remediation. At present, most existing wastewater treatment plants (WWTPs) rely on well-established activated sludge processes and anaerobic digestion of the sewage sludge (Metcalf and Eddy 2014). These systems are relatively simple from a design point of view and allow to achieve high purification yields while at the same time giving the opportunity to recover energy through the production of biogas from anaerobic digestion (dos Santos et al. 2016). Within these Conventional Active Sludge (CAS) systems, energy is used more abundantly to fulfil two main functions: lifting and mixing of sewage. Lifting is used to overcome or create gravitational gradients, so its energy consumption depends on the volumes handled. Mixing can be mechanical or by aeration and is necessary to provide an adequate supply of oxygen to the slurry and thereby ensure the degradation of pollutants, so its energy consumption is related to the concentration of contaminants to be removed (Luo et al. 2019). The electricity usage in CAS-type plants therefore follows rather typical trends: sewage lifting and aeration units are responsible for about 40–60% of the total electricity consumption, while 15–25% is mainly related to the sludge treatment, and finally another 15% is attributed to secondary sedimentation and recirculation pumps (inter alia Campanelli et al. 2013; Gu et al. 2017; Metcalf and Eddy 2014).

To reduce energy usage in this sector, the first option considered from the stakeholders would be upgrading the old units in existing facilities. In order to be effective and long-lasting, such measures should involve all the most energy intensive equipment of a plant, thus requiring conspicuous investments. To avoid expensive upgrading measures and together reduce energy usage and Green House Gases (GHG) emissions, in recent years alternative approaches are being explored. Ferrentino et al. (2018) reported that the implementation of intermittent aeration in the secondary treatment, coupled with a proper control strategy, can lead to a reduction in energy consumption, chemicals used for phosphorous removal and sludge production of about 15%, 23% and 12%, respectively. Tang et al. (2019) suggested that a reduction in the GHG emissions and an energy recovery, enough to ensure the self-sufficiency of the system, can be reached through the implementation in existing CAS WWTPs of bio-electrochemical technologies, which convert organic matter contained in wastewater into electricity or other valuable products. Through a thorough review, Grando et al. (2017) has explored the immense potential for biogas production across Europe coming from sludge digestion, demonstrating its importance not only for energy production, but also as a true by-product of wastewater treatment, which would be promoted as a valuable resource. Nevertheless, a topic that has been increasingly discussed in depth in recent years is the use of algal cultures or microbial communities in wastewater treatment, with the aim of recovering nutrients from the slurry and to achieve in a single step both effluent depuration and biomass production, which could eventually be used for the production of energy (inter alia Jankowska et al. 2017; Johnson et al. 2018; Nagy et al. 2018; Petrini et al. 2018; Tchinda et al. 2019).

In the process of selecting the most suitable measure to be carried out in a WWTP, a starting-point to support institutions in the decision-making process is the accurate energetic-environmental audit of the plant, i.e. the collection and analysis of all the data coming from the system. These data are both qualitative (e.g. process layout, technical data on the electromechanical equipment in place, maintenance operations reports, data concerning the meteorological context) and quantitative (e.g. volumetric flow rates, input and output of pollutant load, amount of sludge generated by the process, overall or single-unit energy consumptions), and—at the moment—there is not an univocal data collection protocol to be applied in all contexts. Furthermore, WWTPs are highly heterogeneous systems and the data that can be collected from them are not simple to analyse due to their multidimensional, complex and nonlinear nature (Li et al. 2019). In order for WWTPs to operate safely and maintain high levels of performance, while taking into account time dynamics related to climate or human activities (e.g. tourism flows), the optimal solution would be the online real-time monitoring of process parameters; however, this would require the use of specialized and constantly functioning sensors, being monitored by well-trained technical staff (Mamandipoor et al. 2020). As a matter of fact, in many contexts data are not collected and recorded with the same frequency and the same scientific thoroughness, precisely due to the high operational costs of equipment and human resources, so that the available data are often fragmented and can lead to erroneous evaluations (Doherty et al. 2017). As a consequence, a major problem for the scientific community is not only the availability, but especially the accuracy of data from WWTPs, which can negatively impact the meaningfulness of predictive analysis (Borzooei et al. 2019).

Over the last few years efforts have been made to invest in the use of sensors and monitoring techniques, making it possible to collect a large amount of accurate data, so that now the real challenge is how to effectively manage these data in a way that they can be correctly used by stakeholders (Mauricio-Iglesias et al. 2020). Up to now, many studies focused on the definition an effective know-how for the analysis of data from WWTPs (inter alia Balmer and Hellstrom 2012; Benedetti et al. 2008; Brandt 2011; Foladori et al. 2015; Gallego et al. 2008; Longo et al. 2016; Panepinto et al. 2016; Quadros et al. 2010; Silva and Rosa 2015; Thurlimann et al. 2015; Torregrossa et al. 2016; Vaccari et al. 2018). For instance, Campanelli et al. (2013) published a compendium of relevant background information, data, methods of analysis and intervention on energy-environmental performance within WWTPs, as well as a comprehensive overview of the current regulatory framework. Foladori et al. (2015) analysed 5 small WWTPs (< 10,000 PE) and developed a methodology for the identification of the performance indicators most suitable to the specific case and their benchmarking, focusing on the removal efficiency of BOD5, COD, TKN and NH4-N and on the energy consumption of the single electromechanical units installed in the systems. Yet, a broad and exhaustive overview of the available literature on the energy characterization of WWTPs has been carried out by Longo et al. (2016), who provided a thorough analysis of possible approaches, lessons learned and challenges still open. Their study identifies three main data benchmarking methodologies: normalization, which is useful to compare similar contexts both from a geographical and process point of view; statistical techniques, such as ordinary least squares regression, whose limit is represented by the statistical data set that must be sufficiently representative and robust; programming techniques, such as data envelopment analysis, whose limit is represented by the correct selection of input and output variables. Longo et al. (2016) conclude that these methodologies are not universally valid and applicable, but they must be chosen according to the specific purposes; in any case, these methodologies should be considered only as diagnostic tools that do not enable to univocally identify the most effective energy optimization strategy. Starting from the key energy performance indicators and the removal efficiency of pollutant loads, Di Fraia et al. (2018) have instead defined and proposed both new energy performance indicators (called EPIs) and new efficiency classes according to which a WWTP can be labelled; the various efficiency classes have been determined on the basis of an extensive database of about 300 WWTPs. In this context, however, one of the key research initiatives pursued in these last few years is the European project ENERWATER, which started in 2015 and aims to create a standardized and common methodology for the definition of the energy performance of WWTPs (Doherty et al. 2017). ENERWATER proposal is based on the use of a composite index, called WTEI, which can be easily understood by stakeholders and then replicated in different international contexts; the index could offer an accurate representation of the energy efficiency level of a WWTP, enabling the continuous monitoring of the system and an effective comparison with all other contexts involved in the international network (Longo et al. 2019; Mauricio-Iglesias et al. 2020).

Narrowing down to the Italian context, in compliance with European Directive 2012/27/EC on energy efficiency, Article 8 of Legislative Decree No. 102 of 2014 introduced the obligation to perform energy audits "within production sites located throughout the national territory by the 5th December 2015 and every 4 years thereafter…" (D.Lgs 102/2014 as amended). In this framework, from the joint work between the technical tables of UTILITALIA group and ENEA agency, in 2018 Guidelines were published for the execution of energy diagnosis of the companies in the Integrated Water Service sector, in compliance with the current regulations. For the WWTPs, these Guidelines restrict the field to three main activities, each with its own energy performance indicator. The indicators are specific electricity consumption, obtained through the normalization of the energy usage (kWh) versus a parameter which is representative of the activity being considered: volume of wastewater for the pre-treatment (kWh/m3), amount of COD removed (kWh/kgCOD) for the biological sector, and amount of sludge being produced with the corresponding dry matter concentration for the sludge treatment line (kWh/kgsludge). All the information provided in the document represents minimum criteria that can be observed on a voluntary basis; hence the use of alternative methods for energy analysis is not excluded, as long as the relevant regulations are observed (Utilitalia 2018).

Within the above-mentioned context, the present article shows the progress of the results obtained in the energy-environmental monitoring of a large WWTP during the period 2014–2018 (5 years), which is part of a research and development project between the DiSTABiF Department of the University of Campania Luigi Vanvitelli and the company Salerno Sistemi S.p.A.-Salerno Energia Group. The investigations started in 2016 and are still ongoing; the research has been carried out both in situ and at the Environmental Physics and Energy Laboratory of DiSTABiF. Taking into account what has been learned from the relevant literature mentioned above, the monitoring activities performed to date have involved (i) the analysis of historical data on the main process parameters, provided by the company and collected through on-site inspections, and (ii) the analysis of the real-time energy consumption of the electromechanical unit with the highest energy demand of the plant, obtained through the implementation of an on-site monitoring system.

The overall purposes of this work are to demonstrate that integrated methodologies can be adapted and used for the interpretation of the phenomena occurring within a WWTP, and—through the discussion of the main findings—characterize the energy-environmental performances of the system and identify possible critical aspects of the process where improvements can be pursued. The article promotes research in the field of energy efficiency for the wastewater sector and offers useful data for benchmarking with the international context.

Material and methods

The WWTP managed by the company Salerno Sistemi S.p.A. is located in Campania region (Southern Italy), and it was conceived and built 32 years ago (in 1988) to collect and purify urban wastewater coming from the city of Salerno and surrounding communities situated along the Amalfi coast and inland areas. The plant is served by a 85 km sewerage network (Fig. 1a) and, because of the geomorphological characteristics of the territory, most of the flow is gravitational, except for 10 sewer lifting stations located along the coastline.

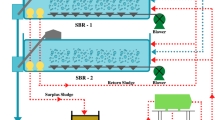

a The WWTP (circled) and the district sewer network. b WWTP configuration, from 1 to 12, respectively: coarse grid, Archimedes’ screws, fine grid, grease and grit removal with primary aeration, primary clarifiers, oxidation tanks, secondary clarifiers, chlorination, sludge thickeners, anaerobic digesters, sludge dewatering centrifuges, torch for excess biogas

Originally, the WWTP was designed to sustain a population equivalent (PE) of 700,000 users, on the basis of a water supply of 280 L PE−1 day−1 and a Return Coefficient (Metcalf and Eddy 2014) into the sewer estimated at 80%; under these assumptions, the WWTP could handle an average wastewater flowrate of about 157,000 m3 day−1, corresponding to 1.82 m3 s−1. Latest water service data indicate that the water supply has increased by at least 14% and currently stands at 320 L PE−1 day−1, with still the 80% being discharged as wastewater. In this regard, it is worth recalling that WWTPs can easily deal with such changes in the flowrates entering the plant because, especially in those areas exposed to seasonal fluctuations (due, for example, to tourism) and in order to avoid extra operational costs deriving from these fluctuations (Sala-Garrido et al. 2012), the WWTPs are designed taking into account extreme operating conditions and using specific safety coefficients to reduce the uncertainty associated with wastewater flowrates (Torregrossa et al. 2019). For the technological services of the facility, the WWTP only uses electrical energy, coming from non-renewable sources; note that electric power consumption (kWh) still remains the most common energy source used in WWTPs, both on the Italian and international context (Belloir et al. 2015; Luo et al. 2019; Utilitalia 2018). The plant is in a conventional configuration with activated sludge oxidation tanks in the wastewater treatment line and anaerobic digestion of the sludge fraction in the sludge treatment line; the layout of the WWTP with the list of the plant sectors is reported in Fig. 1b.

In order to assess the performance of the system and identify critical aspects and potential opportunities of energy improvement, the monitoring campaign was divided in two monitoring phases: static and dynamic monitoring.

Static data collection and processing

The aim of the static monitoring phase was to further explore in detail the energetic and environmental performances of the WWTP through the analysis of the time trends and the possible correlations between the many control variables of the depuration process. Therefore, all the data regarding the most important parameters were collected, namely: electric energy consumptions; total incoming wastewater flowrate; total amount of sludge generated by the process; pollutants load entering and leaving the system, specifically chemical oxygen demand (COD), biochemical oxygen demand (BOD5), total suspended solids (TSS), ammonium (NH4+) and total phosphorus (Ptot). The static data collected, organized on a monthly basis, refer to a 5-year timeframe (from January 2014 to December 2018), and they were acquired through documentation provided by the company (e.g., electric bills, sewage environmental analysis reports, etc.) and field inspections with the technical staff. The oil equivalent consumption and the CO2 equivalent emissions have been derived indirectly from the electricity consumption of the plant, according to the following factors: 0.187 tonnes of oil equivalent and 0.411 tonnes of CO2 equivalent for each MWh due to the electricity consumption in Italy, as reported, respectively, in D.Lgs 102/2014 as amended and ECAM tool software, the latter being described in Fighir et al. (2019).

To fulfil the purposes of static monitoring, the collected data were used for the calculation of those operational indicators and key performance indexes (KPIs) more thoroughly described in the literature. First, as operational indicators, population equivalent effectively served by the plant (PEserved), load factor (LF), dilution factor (DF) and COD/BOD5 ratio were used (Longo et al. 2016; Papadopoulos et al. 2001; Samudro and Mangkoedihardjo 2010). These indicators play an important role in understanding the processes that occur in the WWTP, because their combined analysis provides information useful for identifying whether the wastewater intake is more concentrated or diluted. Very often, in fact, the slurry conveyed through the sewer system captures large quantities of "white" wastewater, such as rainwater, groundwater and runoff; such waters would not require the intervention of purification treatments, so they are often referred to as "parasitic inflow" because of their undesirable presence. A more diluted sewage is a problem, as the effectiveness and the kinetics of most wastewater treatment processes (e.g. activated sludge) depend on the high concentration of nutrients and micro-organisms in the biological compartment (Metcalf and Eddy 2014). Therefore, in order to get more information about the impact of parasitic inflows, it was introduced a distinction between organic and hydraulic load in the calculation of both the population equivalent and the load factor. More specifically, while the organic load is based on the amount of BOD5 in the wastewater, the hydraulic load relies on the possibility of evaluating the per capita wastewater yield as a product of water supply and return coefficient (di Cicco et al. 2019). Concerning, instead, the KPIs, it was decided to use specific energy consumptions evaluated with respect of treated flow rate (KPI1), population equivalent served (KPI2) and removed amount of COD (KPI3) (Benedetti et al. 2008; Campanelli et al. 2013; Quadros et al. 2010). KPIs are part of the normalization techniques already described by Longo et al. (2016) and are recognized as an efficient mechanism for energy performance evaluation (Torregrossa et al. 2016). Table 1 summarizes all the indicators and KPIs previously reported, with a brief description of their meaning and their related equations.

Dynamic energy monitoring

The analysis of static data provides an overview of the WWTP working condition. In order to use this information effectively and design an optimal use of energy resources in the system, goal of the dynamic energy monitoring is to know in detail: (i) the distribution of energy consumption within the structure, (ii) how do the most energy intensive apparatuses work, and which factors could affect at any level their functioning.

Theoretical energy model

Since the WWTP is a highly heterogeneous system, a prior step was the theoretical analysis of the energy distribution between the individual treatment lines of the plant. In order to do this, it was first drawn up a detailed list of the plant equipment, rated power of each apparatus, its estimated duty cycle and other general operational characteristics (e.g., machinery condition, location inside the facility, etc.). Afterwards, the values of rated power and operating time were used to deduce an estimation on an annual basis of the energy consumption of each individual apparatus (\(E_{i}\)), according to the following equation:

where \(P_{i}\) is the rated power of the apparatus \(i\) and \(t_{i}\) are the estimated operating hours in a single year; the equation also takes into account the utilization factor (\(K_{u}\)), which is function of the rated power of the i-apparatus and represents the ratio between the power that the consumer device is expected to absorb in ordinary operation and the maximum power that the consumer device can absorb (CEI 2007).

Starting from the previous Eq. (1), the percentage contribution of each apparatus \(i\) to the total consumption of the plant (\(E_{\% }^{i}\)) can be obtained as:

The results obtained from these theoretical models (1, 2) and all the generic information about the process layout (Fig. 1b) were used to subdivide the apparatuses into categories and quantify the energy demand of each one. As previously mentioned in "Introduction" section, from a macroscopic point of view the electromechanical units installed within a WWTP basically accomplish two tasks: sewage lifting and mixing, with the latter occurring through aeration or mechanical mixing (Luo et al. 2019). For this reason, the subdivision into categories did not refer to plant sectors (as described in Fig. 1b), but rather to equipment typologies. In particular, the following categories have been identified: screens; belt conveyors; Archimedes screws; grease removal bridge; grit pumps; pre-treatment compressors; sludge scrapers; pumps; comminutors; turbo-blowers; sludge thickeners; centrifuges.

EMS and dynamic data processing

Considering the results obtained from the theoretical model, it was decided to develop an energy monitoring system (EMS) on an apparatus sufficiently energy demanding and representative of the depuration process. The EMS has been used to obtain information about the real-time functioning of the apparatus and, with the aim of understanding whether theoretical models are reliable or not, to make a comparison with the results obtained from the static data analysis.

For the first trial of the EMS, the decision was to focus on the electromechanical unit that required most of the energy consumed in the entire WWTP. From the application of the theoretical model described above, it was found that the highest consumption derived from the biological treatments (Fig. 1b–sector 6), specifically from the primary turbo-blower operating in the oxidation tanks; the unit in question has a rated power of 500 kW and a duty cycle estimated to be continuous (24 h/7d). Other 2 turbo-blowers with the same characteristics as the main one are installed in the facility, but they are used as spare equipment. The EMS consists of a multifunction meter (Schneider Electric-mod. PM5110), which measures energy consumption and power absorbed by the machine each minute, and a data logger (Schneider Electrics-mod. Com'X 510) connected to the meter, which collects and sends data to a web platform (david.energreenup.it). The measurements shown in this work refer to a period of 17 months, from August 2017 to December 2018, with some interruptions due to maintenance operations. In total, the EMS recorded 701,340 measurements, corresponding to a period of 487 days.

The recovered data were used to evaluate the following statistical quantities: average value of daily energy consumption, average value of absorbed power, standard deviation of power measurements, frequency distribution of recorded power measurements, comparison between real energy consumptions and estimated values. In addition, it was investigated a possible correlation between the power absorbed by the turbo-blower and the variables of the process. In doing that, a limiting factor was the different nature of the available data. In fact, while for the turbo-blower the absorbed power data were available minute by minute, for almost all the other relevant environmental parameters (COD, BOD5, TSS) only the monthly average values were available. The only parameter with a higher level of detail was the volumetric flowrates; for these, the technical staff of the WWTP had the average values recorded every month at the following hours: 2.00, 6.00, 10.00, 14.00, 18.00, and 22.00 (every 4 h). So, in order to analyse the possible connections between the power absorbed by the turbo-blower and the other variables, it was necessary to align the level of detail; in particular, it was necessary to use the monthly average power for the comparison with COD, BOD5, and TSS, and the average power recorded every 4 h, month by month, for the comparison with the volumetric flowrates. The significance of the correlations was evaluated using Pearson's index.

Results and discussion

Static data analysis

Table 2 provides, for each one of the 5 years of monitoring, detailed information regarding: the energy consumptions of the system, the emissions associated with these consumptions, the wastewater flow rates with their relative pollutant load, the pollutants removal level and the results obtained for each operational indicator and KPI used in this study. The entire WWTP shows an average annual energy consumption of about 7.88 GWh year−1 (Table 2), with the corresponding oil equivalent consumption and CO2 equivalent emissions averagely being 1829 and 3238 tonnes, respectively. As regards the wastewater incoming flowrates, the analysis of the monthly values allows the identification of seasonal fluctuations, especially in the rainiest months, and overall a reduction of the average monthly value of about 27% throughout the 5 years of observations.

The study of the chemical composition of the wastewaters points up the presence of inorganic inflows/infiltrations diluting sewages, included in the definition “parasitic inflow” previously given in "Static data collection and processing" section. Figure 2 shows that the distribution of BOD5, COD and TSS remains quite stable for all the years and, in addition, COD and TSS account for about 80–90% of the polluting load, in terms of the 3 above-mentioned parameters. Moreover, Fig. 3 states a mean value for the COD/BOD5 ratio of about 2.3. When the value of the ratio is included in the range between 1.5 and 3.0, urban wastewater shall be classified as medium degradable (Abdallaa and Hammamb 2014; Samudro and Mangkoedihardjo 2010; Weiß et al. 2002). Despite the abundant inorganic fraction, the plant still ensures an efficient pollutant removal level (Table 2), which fulfils the minimum threshold values of the national legislation: 80% for BOD5, 75% for COD, 90% for TSS.

Further considerations about the volumetric load entering the system and the energy performances of the plant can be obtained from the study of operational indicators and KPIs. Values obtained for PEserved, LF and DF reveal that the plant receives a significant amount of parasite inflows. Indeed, assuming infiltration being 0% and the 80% of the water supply be discharged as wastewater (return coefficient), for a water supply of 320 L PE−1 day−1 the dilution factor should approximately stay within the range of 256 L PE−1 day−1; actually, results show a mean value for the wastewater collected by the sewerage and entering the WWTP of 443 L PE−1 day−1 over the entire survey period (Table 2), which is almost double the theoretical value.

The comparison between organic and hydraulic load factors clearly shows that the amount of pollutants to be removed accounts for less than 50% of the total, while the plant works in condition close to the maximum hydraulic capacity (Table 2); in fact, although the data in Table 2 indicate that the plant operates at an average annual level of 71%, the month-by-month specific data reveal that on 12 of the 60 months of survey (i.e. 20% of the time) the WWTP sustained a hydraulic load ranging from 80 to 112%, thereby exceeding the threshold value. The difference between the population equivalent served interpreted from an organic and hydraulic point of view is evident when comparing the average values obtained for the PEserved and reported in Table 2, in which the difference between the two parameters is a signal of the contribution of inflows/infiltrations to the total wastewater flowrates. The diluted nature of the wastewater is also noticeable in the results obtained for KPI1, which shows an average value over the entire period of 0.17 kWh m−3. This result is not fully aligned with the data coming from the literature: for WWTPs with an organic load factor around 50%, Silva and Rosa (2015) indicate that the typical values of KPI1 are in the range of 0.32–0.60 kWh m−3; WRF and EPRI (2013) report a value for this index in the range 0.41–0.87 kWh m−3, depending on the size of the plant; Awe et al. (2016), on the other hand, base this index on the daily flow rate of a WWTP and show average consumptions of 0.591 kWh m−3 and 0.272 kWh m−3 for WWTPs dealing with 4000 and 378,500 m3 day−1, respectively. In the literature it is known that the result of KPI1 is affected by 2 problems: the first is a scale effect, i.e. as the size of the plant increases, the KPI value decreases (Campanelli et al. 2013; Longo et al. 2016); the second is that it does not take into account the dilution degree of the wastewater, but only the amount of wastewater treated by the WWTP, so that if the incoming flowrates are higher due to the presence of inflows/infiltrations, and the energy consumption does not vary significantly during this time, the KPI1 will then show a lower numerical value and the WWTP will finally seem more efficient.

Regarding the other KPIs, the average results of 28 kWh PE−1 year−1 and 0.66 kWh kgCODremoved−1 obtained for the WWTP under consideration are consistent with the results found in the literature for plants of the same size, purification process and country, as described in the thorough review of Gandiglio et al. (2017) and as reported in the ENERWATER project database (available at: https://www.enerwater.eu/); in particular, combining the databases from both sources gives a range between 24 and 65 kWh PE−1 year−1 for the KPI2, and between 0.4 and 1.6 kWh kgCODremoved−1 for the KPI3. In this perspective, the WWTP qualifies as an energy-efficient plant. A more in-depth analysis reveals a correlation between KPI3 and the dilution of sewage caused by inflows and infiltrations: when the dilution factor is higher, the removal process of a unit quantity of COD requires more energy (Fig. 4a). On the other hand, when the biodegradable pollutant concentration (LForganic) is higher, KPI3 rapidly reduces (Fig. 4b), and this attests that the WWTP consumes energy more efficiently when the pollutant content is quantitatively closer to the design value (100%). The regression attained in the two graphs (Fig. 4a, b) is also in line with what has been described in previous publications (inter alia Campanelli et al. 2013; Longo et al. 2016).

Theoretical energy distribution

With the aim of effectively compare theoretical and experimental behaviour and at the same time to choose the equipment most energy-demanding and where a real-time dynamic monitoring system could be installed, the first step was to characterize the theoretical energy consumption within the system. Figure 5 shows the energy share of the different facility apparatuses, which has been obtained applying the theoretical model discussed in "Theoretical energy model" section. Among all the categories which have been identified, turbo-blowers and Archimedes screws account, respectively, for 36% and 33% of the energy demand of the entire WWTP; following, pumps (18%) and centrifuges (8%) are the main categories, while all the other apparatuses account for less than 2% of the total power supply, each. These proportions are aligned with the data reported in the literature about power distribution in WWTPs. In particular, Luo et al. (2019) indicate that aeration of activated sludge accounts for 50–75% of a WWTP total energy demand, while in Metcalf and Eddy (2014) it is responsible for the 55.5% of the total consumptions.; Gu et al. (2017) organized the electromechanical units according to categories that are more similar to those adopted in this study, thus facilitating their comparison; more specifically, the study gives the following energy consumption distribution: 60% for the aeration, 12% for wastewater pumping, 11% for the grits, 6% for lighting and buildings (not included in the present study), 3% for belt press, 3% for the clarifiers and the other categories (screens, thickening, chlorination, etc.) accounting for less than 2% each.

Dynamic data analysis

The 500-kW turbo-blower selected for the dynamic monitoring is estimated to work 24 h day−1 and, since the rated power is above 10 kW, its Ku factor is 0.80 (CEI 2007); based on this, the average energy consumption of the turbo-blower should not exceed 3,500,000 kWh per year.

With the support of the EMS, real-time data were then analysed, and it has been possible to draw the real-time pattern of the power absorbed by the turbo-blower (Fig. 6) and acquire important information. First, the apparatus works in a power range of 220 to 460 kW, with an average value over the entire monitoring campaign of 338 kW (Fig. 6) and there is evidence of the continuous duty cycle of the blower, which proves the significant theoretical contribution shown in Fig. 5 for the blower sector (42%).

The data provided by the technical staff of the WWTP indicate the selected turbo-blower as responsible for at least 90% of the energy spent in its sector, being the only one to have a working cycle of 24/7, and the other two blowers a spare function, as mentioned in "EMS and dynamic data processing" section. Its actual energy consumption obtained from real-time data is in the range of about 2,500,000 kWh per year, which is almost 30% lower than the theorized value (3,504,000 kWh) and covers the 32% of the total energy demand of the WWTP. According to this, the real energy share of the entire turbo-blower sector will also be about 30% lower than the theoretical value (42%-Fig. 5). Actually, this result should not be surprising; it is well known, in fact, that devices which use electrical energy do not necessarily absorb the maximum power for which they have been designed, even considering the approximation with the utilization factor Ku. With regard to the specific case of the turbo-blower being monitored during this study, it is responsible alone for approximately the entire consumption of its sector, whereas in other sectors the energy share is due to the contribution of several units (for example, the Archimedes screws are 6 and all regularly operating). For this reason, the result obtained assumes even greater importance: implementing the appropriate measures to reduce the energy consumption of this single turbo-blower could lead to a not negligible reduction in the overall consumptions of the WWTP.

Change of operating setting and correlation of power with static data

To reduce the continuous power variations during the day, the company decided to modify the operating settings of the turbo-blower, increasing from 1 to 10 min the time interval with which the blower adjusts the air supply in relation to the level of dissolved oxygen in the oxidation tank. Figure 7 shows how the power time trend has changed (a), with a zoom on the daily operation before and after the intervention (b, c).

The only visible effect of the intervention was the one originally foreseen, i.e. a mitigation of the variations of absorbed power over time. Alongside that, there was no significant effect on the blower energy consumption, which remained averagely constant over time. Moreover, from the analysis of potential correlations with other variables, these consumptions appear to be independent of the process parameters. Specifically, Pearson correlation index between the average monthly power absorbed by the turbo-blower and the average monthly values of COD, BOD5 and TSS shows the following values: 0.37, 0.39 and 0.21, respectively, and the correlation can be classified as weak and not significant. The only parameter with a higher resolution dataset was the wastewater flowrate. For this variable, as an example, Fig. 8 shows the comparison between the wastewater levels and the power absorbed by the turbo-blower recorded every 4 h over the entire survey period, as mentioned in "EMS and dynamic data processing" section; as can be easily observed, also in this case the two datasets are significantly not correlated (Pearson correlation index equals − 0.03).

With regard to this latter aspect, namely the link between pumping units and volumes to be treated, Torregrossa et al. (2019) remarked that, if the pump systems are set to operate with a specific wastewater flowrate (often over-estimated), their energy cost may increase because they are forced to operate far from their best efficiency point. The adoption of automatic controls and inverters throughout the WWTP could lead to a concrete reduction in these energy extra-costs, along with the switching from a continuous to an intermittent operating regime (Foladori et al. 2015). Nevertheless, since yearly aggregated data are not truly representative of the phenomena that occur within a WWTP (Longo et al. 2016), all these solutions are not feasible unless real-time online monitoring systems are first adopted, to allow the daily data benchmarking and the application of effective solutions to the different problems that may occur in the system.

Conclusion

The main purpose of this research is to show the possibility of applying integrated approaches when exploring the aspects which most affect the energy demand of the WWTP under investigation. This task has been pursued through (i) the analysis of historical data provided by the company about the main variables of the process (pollutant levels, wastewater flow rates, electricity consumption, etc.) using normalization techniques, and (ii) the study of real-time energy consumptions of the most power-intensive apparatus of the WWTP by means of an energy monitoring system.

The key conclusions which can be obtained from the study are therefore summarized below.

As a general comment, the WWTP fulfils completely its remediation role and can guarantee high levels of pollutants removal, in full compliance with the threshold values imposed by current legislation. From the energy perspective, meanwhile, the results obtained for the specific consumptions (KPIs) are consistent with those reported in previous relevant studies. In particular, the following average results were obtained: 0.17 kWh/m3 (dev.st 0.03) for KPI1, 28 kWh/PE/year (dev.st 8) for KPI2 and 0.66 kWh/kgCODremoved (dev.st 0.26) for KPI3; according to these results, the WWTP is considered as energy efficient. One parameter that appears to be less reliable and accurate is the KPI1, because it does not allow to exclude from the analysis of performances the contribution to the wastewater volumes due to inflows and infiltrations. In fact, the volume of “parasitic” inflows captured by the sewerage network is considerable, and the high level of these inflows leads the plant to operate under conditions close to the hydraulic peak, with an inevitable negative impact on energy demand. In particular, the plant uses more power to remove the pollutant load (e.g. COD) as efficiently as possible. The choice to differentiate population equivalent served and load factor from an organic and hydraulic perspective turned out to be a valuable way to better identify parasite inflows.

Using an EMS allowed to study more in depth the working conditions of the most “energivorous” unit of the facility, namely the turbo blower for the oxidation process. Real-time data reveal that the actual consumption of the blower is 30% lower than the theoretical estimated value. Moreover, the power absorbed by the turbo-blower was found to be unaffected by the fluctuations of the process variables, suggesting that the unit is set to work according to a predetermined flowrate and, most important, that the use of energy resources by energy-intensive machinery is not efficiently managed.

The study of real-time and daily data allows for more accurate information to be obtained and allows to define with higher resolution the critical aspects and the opportunities for improving a specific issue. For these reasons, real-time online monitoring is confirmed to be the irreplaceable tool for planning effective interventions aimed at optimising the energy efficiency of a plant.

References

Abdallaa KZ, Hammamb G (2014) Correlation between biochemical oxygen demand and chemical oxygen demand for various wastewater treatment plants in Egypt to obtain the biodegradability indices. Int J Sci: Basic Appl Res (IJSBAR) 13:42–48

Awe OW, Liu R, Zhao Y (2016) Analysis of energy consumption and saving in wastewater treatment plant: case study from Ireland. J Water Sustain 6:63–76. https://doi.org/10.11912/jws.2016.6.2.63-76

Balmer P, Hellstrom D (2012) Performance indicators for wastewater treatment plants. Water Sci Technol 65:1304–1310. https://doi.org/10.2166/wst.2012.014

Belloir C, Stanford C, Soares A (2015) Energy benchmarking in wastewater treatment plants: the importance of site operation and layout. Environ Technol 36:260–269. https://doi.org/10.1080/09593330.2014.951403

Benedetti L, Dirckx G, Bixio D, Thoeye C, Vanrolleghem PA (2008) Environmental and economic performance assessment of the integrated urban wastewater system. J Environ Manag 88:1262–1272. https://doi.org/10.1016/j.jenvman.2007.06.020

Borzooei S et al (2019) Data scarcity in modelling and simulation of a large-scale WWTP: Stop sign or a challenge. J Water Process Eng 28:10–20. https://doi.org/10.1016/j.jwpe.2018.12.010

Brandt M (2011) Energy efficiency in the water industry, a global research project. Water Pract Technol 6:1–2. https://doi.org/10.2166/wpt.2011.028

Campanelli M, Foladori P, Vaccari M (2013) Consumi elettrici ed efficienza energetica nel trattaento delle acque reflue. Maggioli Editore

CEI (2007) Norma CEI 64-8 per impianti elettrici utilizzatori. Criteri di applicabilità. Prescrizioni di progettazione ed esecuzione. Legge 46/90 e decreti ministeriali attuativi. Guida alle novità contenute nella nuova edizione. CEI, Milan, Italy

D.Lgs 102/2014 as amended Decreto Legislativo n.102 del 4 luglio 2014. Attuazione della direttiva 2012/27/UE sull'efficienza energetica, che modifica le direttive 2009/125/CE e 2010/30/UE e abroga le direttive 2004/8/CE e 2006/32/CE. (14G00113). Gazzetta Ufficiale

D.Lgs 152/2006 as amended Decreto Legislativo n.152 del 3 aprile 2006. "Norme in materia ambientale". Gazzetta Ufficiale

DESA (2019) Ten key findings world population prospects 2019: highlights

di Cicco MR, Spagnuolo A, Masiello A, Vetromile C, Nappa M, Corbo G, Lubritto C (2019) Assessing energy performance and critical issues of a large wastewater treatment plant through full-scale data benchmarking. Water Sci Technol 80:1421–1429. https://doi.org/10.2166/wst.2019.392

Di Fraia S, Massarotti N, Vanoli L (2018) A novel energy assessment of urban wastewater treatment plants. Energy Convers Manag 163:304–313. https://doi.org/10.1016/j.enconman.2018.02.058

Doherty E, McNamara G, Fitzsimons L, Clifford E (2017) Design and implementation of a performance assessment methodology cognisant of data accuracy for Irish wastewater treatment plants. J Clean Prod 165:1529–1541. https://doi.org/10.1016/j.jclepro.2017.07.083

dos Santos IFS, Barros RM, Tiago Filho GL (2016) Electricity generation from biogas of anaerobic wastewater treatment plants in Brazil: an assessment of feasibility and potential. J Clean Prod 126:504–514. https://doi.org/10.1016/j.jclepro.2016.03.072

Ferrentino R, Langone M, Vian M, Andreottola G (2018) Application of real-time nitrogen measurement for intermittent aeration implementation in a biological nitrogen removal system: performances and efficiencies. Environ Technol. https://doi.org/10.1080/09593330.2018.1444102

Fighir D, Teodosiu C, Fiore S (2019) Environmental and energy assessment of municipal wastewater treatment plants in Italy and Romania: a comparative study. Water 11:1611. https://doi.org/10.3390/w11081611

Foladori P, Vaccari M, Vitali F (2015) Energy audit in small wastewater treatment plants: methodology, energy consumption indicators, and lessons learned. Water Sci Technol 72:1007–1015. https://doi.org/10.2166/wst.2015.306

Gallego A, Hospido A, Moreira MT, Feijoo G (2008) Environmental performance of wastewater treatment plants for small populations. Resour Conserv Recycl 52:931–940. https://doi.org/10.1016/j.resconrec.2008.02.001

Gandiglio M, Lanzini A, Soto A, Leone P, Santarelli M (2017) Enhancing the energy efficiency of wastewater treatment plants through co-digestion and fuel cell systems. Front Environ Sci. https://doi.org/10.3389/fenvs.2017.00070

Grando RL, de Souza Antune AM, da Fonseca FV, Sánchez A, Barrena R, Font X (2017) Technology overview of biogas production in anaerobic digestion plants: a European evaluation of research and development. Renew Sustain Energy Rev 80:44–53. https://doi.org/10.1016/j.rser.2017.05.079

Gu Y et al (2017) The feasibility and challenges of energy self-sufficient wastewater treatment plants. Appl Energy 204:1463–1475. https://doi.org/10.1016/j.apenergy.2017.02.069

IEA (2016) World energy outlook. Organisation for economic co-operation and development / international energy agency

Jankowska E, Sahu AK, Oleskowicz-Popiel P (2017) Biogas from microalgae: review on microalgae's cultivation, harvesting and pretreatment for anaerobic digestion. Renew Sustain Energy Rev 75:692–709. https://doi.org/10.1016/j.rser.2016.11.045

Johnson DB, Schideman LC, Canam T, Hudson RJM (2018) Pilot-scale demonstration of efficient ammonia removal from a high-strength municipal wastewater treatment sidestream by algal-bacterial biofilms affixed to rotating contactors. Algal Res 34:143–153. https://doi.org/10.1016/j.algal.2018.07.009

Li Z, Zou Z, Wang L (2019) Analysis and forecasting of the energy consumption in wastewater treatment plant. Math Probl Eng 2019:1–8. https://doi.org/10.1155/2019/8690898

Longo S et al (2016) Monitoring and diagnosis of energy consumption in wastewater treatment plants. A state of the art and proposals for improvement Appl Energ 179:1251–1268. https://doi.org/10.1016/j.apenergy.2016.07.043

Longo S et al (2019) ENERWATER—A standard method for assessing and improving the energy efficiency of wastewater treatment plants. Appl Energy 242:897–910. https://doi.org/10.1016/j.apenergy.2019.03.130

Luo L, Dzakpasu M, Yang B, Zhang W, Yang Y, Wang XC (2019) A novel index of total oxygen demand for the comprehensive evaluation of energy consumption for urban wastewater treatment. Appl Energ 236:253–261. https://doi.org/10.1016/j.apenergy.2018.11.101

Mamandipoor B, Majd M, Sheikhalishahi S, Modena C, Osmani V (2020) Monitoring and detecting faults in wastewater treatment plants using deep learning. Environ Monit Assess 192:148. https://doi.org/10.1007/s10661-020-8064-1

Mauricio-Iglesias M, Longo S, Hospido A (2020) Designing a robust index for WWTP energy efficiency: the ENERWATER water treatment energy index. Sci Total Environ 713:136642. https://doi.org/10.1016/j.scitotenv.2020.136642

Metcalf and Eddy (2014) Wastewater engineering, treatment and reuse, 4th edn. McGraw Hill, New York

Nagy BJ et al (2018) MAB2.0 project: integrating algae production into wastewater treatment. EuroBiotech J 2:10–23. https://doi.org/10.2478/ebtj-2018-0003

OECD (2015a) The governance of water regulators

OECD (2015b) OECD principles on water governance

Panepinto D, Fiore S, Zappone M, Genon G, Meucci L (2016) Evaluation of the energy efficiency of a large wastewater treatment plant in Italy Appl. Energy 161:404–411. https://doi.org/10.1016/j.apenergy.2015.10.027

Papadopoulos A, Parissopoulos G, Papadopoulos F, Karteris A (2001) Variations of COD/BOD5 ratio at different units of a wastewater stabilization pond pilot treatment facility. In: Proceeding of 7th international conference on environmental science and technology ermoupolis, pp 16–19

Petrini S, Foladori P, Andreottola G (2018) Laboratory-scale investigation on the role of microalgae towards a sustainable treatment of real municipal wastewater. Water Sci Technol 78:1726–1732. https://doi.org/10.2166/wst.2018.453

Quadros S, Joao Rosa M, Alegre H, Silva C (2010) A performance indicators system for urban wastewater treatment plants. Water Sci Technol 62:2398–2407. https://doi.org/10.2166/wst.2010.526

Sala-Garrido R, Molinos-Senante M, Hernández-Sancho F (2012) How does seasonality affect water reuse possibilities? An efficiency and cost analysis. Resour Conser Recycl 58:125–131. https://doi.org/10.1016/j.resconrec.2011.11.002

Samudro G, Mangkoedihardjo S (2010) Review on BOD COD, and BOD/COD ratio: a triangle zone for toxic, biodegradable and stable levels Internation. J Acad Res 2:235–239

Silva C, Rosa MJ (2015) Energy performance indicators of wastewater treatment: a field study with 17 Portuguese plants. Water Sci Technol 72:510–519. https://doi.org/10.2166/wst.2015.189

Tang J, Zhang C, Shi X, Sun J, Cunningham JA (2019) Municipal wastewater treatment plants coupled with electrochemical, biological and bio-electrochemical technologies: opportunities and challenge toward energy self-sufficiency. J Environ Manag 234:396–403. https://doi.org/10.1016/j.jenvman.2018.12.097

Tchinda D, Henkanatte-Gedera SM, Abeysiriwardana-Arachchige ISA, Delanka-Pedige HMK, Munasinghe-Arachchige SP, Zhang Y, Nirmalakhandan N (2019) Single-step treatment of primary effluent by Galdieria sulphuraria: removal of biochemical oxygen demand, nutrients, and pathogens. Algal Res 42:101578. https://doi.org/10.1016/j.algal.2019.101578

Thurlimann CM, Durrenmatt DJ, Villez K (2015) Energy and process data processing and visualisation for optimising wastewater treatment plants. Water Pract Technol 10:10–18. https://doi.org/10.2166/wpt.2015.002

Torregrossa D, Castellet-Viciano L, Hernández-Sancho F (2019) A data analysis approach to evaluate the impact of the capacity utilization on the energy consumption of wastewater treatment plants. Sustain Cities Soc 45:307–313. https://doi.org/10.1016/j.scs.2018.11.036

Torregrossa D, Schutz G, Cornelissen A, Hernandez-Sancho F, Hansen J (2016) Energy saving in WWTP: daily benchmarking under uncertainty and data availability limitations. Environ Res 148:330–337. https://doi.org/10.1016/j.envres.2016.04.010

Utilitalia (2018) Linea Guida per l’Esecuzione della Diagnosi Energetica ai sensi dell'articolo 8 del d.lgs 102/2014 - Servizio Idrico Integrato. Transl. Guideline for the execution of the Energy diagnosis according to article 8 of the legislative decree no. 102/2014 - Integrated Water Service, 6/2018 edn. Utilitalia-imprese acqua ambiente energia, Rome, IT

Vaccari M, Foladori P, Nembrini S, Vitali F (2018) Benchmarking of energy consumption in municipal wastewater treatment plants—a survey of over 200 plants in Italy. Water Sci Technol 77:2242–2252. https://doi.org/10.2166/wst.2018.035

Weiß G, Brombach H, Haller B (2002) Infiltration and inflow in combined sewer systems: long-term analysis. Water Sci Technol 45:11–19

WRF and EPRI (2013) Electricity use and management in the municipal water supply and wastewater industries. Palo Alto, California

Acknowledgements

The authors declare that the study is part of a research collaboration agreement between the DiSTABiF Department of the University of Campania Luigi Vanvitelli and Salerno Sistemi S.p.A. as the managing authority of the wastewater treatment plant. The authors received no financial support for the research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Editorial responsibility: M.Abbaspour.

Rights and permissions

About this article

Cite this article

di Cicco, M.R., Spagnuolo, A., Masiello, A. et al. Energetic and environmental analysis of a wastewater treatment plant through static and dynamic monitoring activities. Int. J. Environ. Sci. Technol. 17, 4299–4312 (2020). https://doi.org/10.1007/s13762-020-02775-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-020-02775-0