Abstract

This article presents an environmental and energy analysis of a wastewater treatment plant operating on sequential batch reactor technology. The analysis of energy consumption shows that the electrical, mechanical, chemical, and human energy consumption works out to 0.26 kW h/m3 of the treated wastewater. The overall share of electrical energy consumption is 84%, and 15% share is of mechanical energy. Nearly 78% of the electrical energy is consumed in the aeration process. The biological oxygen demand, chemical oxygen demand, total suspended solids, total nitrogen, and total phosphorous are measured for the influent and effluent of the treatment plant. A reduction of 76–97% occurs in these parameters due to wastewater treatment. The greenhouse gas emissions arising directly from the treatment processes and indirectly from the electricity and diesel usage are estimated. The direct and indirect emissions from the wastewater treatment plant amount to 105 tCO2e/year and 1316 tCO2e/year, respectively. A projection of methane accumulation in the atmosphere from this plant till the year 2041 is also made. The contribution of this plant to the atmospheric accumulation of CH4 is projected to reach 8679 kg in 2029. The projection for 2030 and thereafter is 9468 kg. Analysis of the energy, environment, and wastewater treatment nexus is of significance to have a holistic view for the sustainable development.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The world is expected to add nearly 2 billion people in the next 30 years raising, the global population to 9.7 billion by the year 2050 (UN 2019). As urbanization is rising at a rapid pace, 68% of the population will live in urban areas. In India also, this trend has an impact on the population distribution, and according to a projection for the next 30 years, nearly 416 million people will add to the urban areas (UN 2018). Around 2027, India will overtake China to become the most populous country (UN 2019). Growing population, unplanned urbanization, and fluctuating economic growth pose unprecedented challenges for water management in rural and urban India (Sahasranaman and Ganguly 2018; Shah 2016).

The freshwater resources are depleting at an alarming rate due to the increase in water consumption, and accordingly, the volume of wastewater discharge is rising substantially. The freshwater scarcity together with the wastewater treatment is among the prominent environmental challenges of this century (MoEF 2010). India ranked 13 among the world’s 17 “extremely water-stressed” counties (WRI 2019). The water crisis is not only the problem of India but also of other developing countries (Sharawat et al. 2019). Reuse of treated wastewater could help to mitigate the water stress (Gulati and Banerjee 2018). Because of the water scarcity in India, new stringent standards were implemented in 2019. These standards have prescribed norms to achieve non-potable reuse of the wastewater treated effluent (NGT 2019). Earlier nutrient removal was not mandatory in India, but now stringent limits are also prescribed for nitrogen and phosphorous removal. To achieve this, the electricity consumption required at the wastewater treatment plants will increase.

A sizeable gap exists between the wastewater discharge and its treatment in our country. The estimated volume of the wastewater generation in urban areas is 62,000 million litres per day (MLD), while the treatment capacity is 23,277 MLD. In practice, 18,883 MLD of the wastewater was actually treated in the year 2015 (CBCP 2015). This was because out of total 816 treatment plant, only 522 were operational. It means 70% of the wastewater generated in urban India was not treated and simply discharged into the rivers causing contamination of the freshwater bodies. Therefore, a massive infrastructure related to the wastewater treatment is expected to be administered to combat the environmental degradation caused by the untreated wastewater discharge (Chakraborti et al. 2019). So far, the decision making of such projects is based on factors like capital costs, operating costs, and adaptability of technology under local conditions (Mahgoub et al. 2010). However, to develop sustainable wastewater treatment, it is required to view the treatment systems using a holistic approach (Jenssen et al. 2007). Therefore, besides the factors mentioned above, energy and environmental aspects are also essential to consider when deciding a treatment system.

A wastewater treatment plant primarily uses electrical, mechanical, manual, and chemical energy. Most of the studies on the energy estimation of a treatment plant have taken into account only the electrical energy (Vera et al. 2013; Merlin and Lissolo 2010; Mizuta and Shimada 2010; Devi et al. 2007; Jonasson 2007). There are limited data available in the literature about the breakup of total energy consumption in the wastewater treatment plants. Tao and Chengwen (2011) indicated that the electrical energy share is only 50% of the total energy consumption, and the human energy also presented a significant share (32%). Singh et al. (2012) also pointed out that 50% share is of electrical energy in the total energy consumed at the wastewater treatment plant. However, Belloir et al. (2014) have done a benchmarking exercise of two wastewater treatment plants based on oxidation ditch and concluded that 90% of the energy utilized in both wastewater treatment plants is electrical energy, and the other forms of energy represent a smaller proportion of the total energy consumption. Aeration process in the oxidation ditches consumed the maximum energy.

The conventional treatment systems are facing severe challenges to comply with the new environmental regulations. The sequential batch reactor (SBR)-based treatment plants can achieve the standards due to their operational flexibility and excellent process control possibilities (Dutta and Sarkar 2015). An SBR plant has small footprints because the flow equalization, biological treatment, and secondary clarification occur in a single tank (Showkat and Najar 2019). In India, the total installed capacity of the SBR technology is 2175.1 MLD at 57 treatment plants, which is nearly 12% of the total installed capacity. Most of the treatment plants were commissioned in 2013–2014 (CPCB 2015).

The objective of the present study is to carry out the environmental and energy analysis of an SBR-based wastewater treatment technology. The sequential batch reactor technology is selected because this technology is gaining immense popularity in the recent years and no such study is available for this technology in the literature. In the past, most of the studies for the wastewater treatment plants have considered merely electrical energy consumption. A comprehensive analysis of different forms of energy usage at the treatment plants is required for assessing the options for energy substitution and enhancing the energy efficiency. Such an analysis is carried out in this paper by including the concept of energy intensity and by taking into the account electrical energy, human energy, mechanical energy, and chemical energy used at an SBR-based wastewater treatment plant. Studies on GHG accumulation in atmosphere due to the wastewater treatment plants are not available in the literature. An effort has also, therefore, been made to investigate the GHG emissions due to the wastewater treatment plant and thereby the GHG accumulation in the atmosphere.

Reproduction of similar studies and production of data in this area will suggest directions for decision making on the selection of treatment technology from the considerations of climate change mitigation and energy usage. It will also help in improving the sustainability of the wastewater treatment systems.

Description of study site

The wastewater treatment plant selected for the present investigation is located at Pandit Bhagwat Dayal Sharma Post Graduate Institute of Medical Sciences (PGIMS), Rohtak, Haryana, India. Figure 1 shows the flow diagram of SBR-based wastewater treatment plant. Capacity of the treatment plant is 19 MLD. The plant is based on the sequential batch reactor technology. It uses the physico-chemical and biological treatment methods. Primary treatment includes screening and grit removal. The secondary treatment is based on SBR in which the whole process takes place in one reactor, within which all the biological treatment steps take place sequentially. The plant completes six cycles a day. One cycle is of 244 min and comprises fill and aeration for 123 min, settling for 44 min, and decanting for 77 min. The effluent from the SBR flows to the chlorine contact tank and then to the drainage, which ultimately flows through a public drain to Yamuna river. The sludge from the SBR basin is collected in a sludge sump and then transferred to the centrifuge unit for dewatering. The sludge is not reused and the treated water is discharged from the plant. The sludge after treatment is disposed of to a designated place (outside the compound of the treatment plant). Most of it is collected by the local farmers to be used as fertilizer in the agriculture farms. Unit-wise description of the SBR-based wastewater treatment plant is described below:

-

Inlet chamber One reinforced cement concrete (RCC) chamber of 3.0 × 2.5 × 2 m3. Raw water flows in this chamber.

-

Screen chamber One chamber of size of 6.0 × 1.1 × 0.5 m3 with mechanically operated screens and one standby chamber of size 6.0 × 1.5 × 0.5 m3 with manually operated screens.

-

Grit chamber One working and one standby mechanical grit chambers each having size of 6.7 × 6.7 × 1.0 m3 are provided after the fine screen. Reciprocating rake mechanism is used to remove the grit. Bypass arrangement with sluice gates is provided to bypass either of the grit chambers for maintenance.

-

SBR reactor An RCC channel conveys sewage from grit the chambers into two SBR reactors with dimensions of 38.5 m dia × 5.5 m. Oxygen required in the reactor is supplied through diffused aeration system with auto-control of oxygen level in the tank.

-

Chlorine contact tank The decanted treated water from the SBR process is taken to a chlorine mixing tank through RCC channel. From the mixing tank, the treated water is passed on to the chlorine contact tank of size 18.6 × 18.6 × 2 m3. Baffles are also provided in the tank to achieve proper mixing and disinfection.

-

Sludge thickener The excess sludge from the SBR reactors is pumped by SAS pumps into the sludge thickener having dimensions of 13.75 m dia × 3.0 m.

-

Sludge sump From the thickener, the sludge comes to the sump which is equipped with coarse bubble air grid made from stainless steel pipes to facilitate mixing of the contents of sludge sump. Dimensions of sump are 8.0 × 2.5 × 1.5 m3.

-

Centrifuge The sludge from the sump is pumped to a solid bowl centrifuge for dewatering of sludge. The sludge in the form of wet cake from the centrifuges is collected on a sludge platform. Dimensions of the centrifuge building are 8.0 × 8.0 m2.

-

Filtrate sump Filtrate from the centrifuge units is passed into the filtrate sump and then recycled back to the SBR reactors. Dimensions of the filtrate sump are 3.75 × 3.75 × 1.5 m3.

Materials and methods

A wastewater treatment plant based on the SBR technology is investigated for its total energy consumption and the resulting impact on the environment. The energy usage at the plant in the form of electrical, mechanical, human, and chemical energy is analysed. For analysing the environmental impact of the wastewater treatment plant, the effluent quality, the GHG emissions, and their accumulation in the atmosphere are taken into account. A system dynamics model is developed to give temporal projection of the methane accumulation in the atmosphere.

Total energy consumption

For the operation of a wastewater treatment plant, the energy in various forms, i.e. electrical, mechanical, chemical, and human energy is used. Bulk of it is the electrical energy, human energy is considered as renewable energy, chemical energy is an indirect form of energy and the mechanical energy as non-renewable energy. The electrical energy is also considered non-renewable because the treatment plant uses the electricity, which comes from a coal-based thermal power station. The amount of energy utilized per cubic metre of the treated wastewater is analysed. Primary data, like type and total number of equipment used, working units and their rated power, total hours of working, quantity of the chemicals, and diesel used, that were required to calculate the total energy consumption are collected by making visits to the site and monitoring the data. For evaluating the human energy required at the treatment plant, the number of people engaged as labour force and the time taken by them for various activities were discussed with the plant operators and labours. Records of the material consumptions, various transactions, and logbooks were also referred to the data validation. The equations used in calculating the total energy consumption are given below:

The methodology followed for evaluating the amount of energy consumption in various forms at the wastewater treatment plant is described below:

The electrical energy consumed for pumping the wastewater is obtained using the equation given by

where Ee is the electrical energy in kW h/m3, Pr is the rated power of the pump/motor in kW, T in hours (h) is time the pump operates in a day and Q in m3/day is the daily flow of wastewater.

Regular cuts of the electrical power supplied by the utility grid are usual in the region where the wastewater treatment plant being analysed, in the present investigations, is located. In the event of electrical power cuts, a standby diesel-powered electrical generator is operated to run the plant. For the present analysis, this is considered as mechanical energy since the diesel engine produces mechanical power to run the generator. The mechanical energy or the fuel energy represents the total amount of oil or diesel used in the treatment plant daily for running the generator in the case of power supply failure. It is estimated using Eq. 2.

where Me is the mechanical energy in kW h/m3, D is the diesel consumption in L/day and 10 is the unit power density value of diesel in kW h/L and shows the amount of power stored in 1 L of diesel (Ginley and Cahen 2010; Belloir et al. 2014). The diesel consumed in the wastewater treatment was found to be approximately 70 L/day for running the generators.

Human energy is required for various activities on the field, like collection and transportation of sludge cakes from the sludge handling unit to the endpoint, cleaning of tank walls, monitoring of the centrifuge unit for clogging, maintaining logbook, and monitoring the panel control room. Human energy consumption is based on the gender of the worker and the type of activity, as shown in Table 1. Human activities are classified as heavy, medium, and low, based on manual input. On the basis on these considerations, the human energy is estimated. In the wastewater treatment plant studied, there was no female employee engaged. Hence, the male power equivalent was used given in Table 1.

where He is the human energy in kW h/m3, n is the number of type of activities characterized as heavy, moderate, and light (Table 1), m is the gender number (female, male), N is the number of people occupied in an activity, E is the human power equivalent in kW and T is the time of activity in h/day.

Chemical energy is evaluated from the change of standard enthalpy (\(\Delta H\)) during a reaction. The chemical energy in kW h/m3 is, therefore, estimated using Eq. 4.

where Ce is the chemical energy kW h/m3, m is the number of moles used/day, \(\Delta H_{{{\text{product}}}}\) is the heat of evolution of product (kJ/mol) and \(\Delta H_{{{\text{reactant}}}}\) is the heat of evolution of reactant (kJ/mol).

The effluent quality

The wastewater samples were collected from the treatment plant, and laboratory tests were performed to check the influent and effluent water quality. The water quality parameters selected for the tests are biological oxidation demand (BOD), chemical oxidation demand (COD), total suspended solids (TSS), pH, total phosphorous (TP), and total nitrogen. Standard methods (APHA 2012) were used for testing the samples.

Estimation of GHG emissions

The methodology followed for calculating GHG emissions from the wastewater treatment plant is based on 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories (IPCC 2019). Direct and indirect GHG emissions are calculated. In direct emissions, CH4 (methane) and N2O (nitrous oxide) emissions are estimated for the treatment plant, and emissions due to the utility grid electrical power consumption and those because of the diesel generator are estimated as indirect emissions. Direct CO2 emission from the treatment system is not considered in the IPCC guidelines because of their biogenic origin. It means carbon present in the wastewater is derived from modern (biogenic) organic matter in human excreta or food waste, and they do not represent a transfer of carbon from the lithosphere to the atmosphere. Therefore, it should not be included in the total national emissions (IPCC 2019). The equations used in calculating GHG emissions (CH4 and N2O) are given below:

where \({\text{CH}}_{4} \;{\text{Emissions}}_{ j}\) is methane emissions from a treatment pathway or system, j, in kg/CH4/year, TOWj is total degradable organics in domestic wastewater of a treatment pathway or system, j, in kg BOD/year, \(S_{j}\) is organic component removed in kg BOD/year, j represents each system or treatment pathway, EFj is emission factor, and \(R_{j}\) is the amount of methane recovered. Methane is not recovered from the respective treatment plant (value of \(R_{j}\) is 0).

where EFj is the emission factor in kg CH4/kg BOD, MCFj is methane correction factor, j represents each discharge pathway/treatment, and \(B_{0}\) is maximum methane producing capacity, kgCH4/kg BOD. According to IPCC guidelines, MCFj value of aerobic treatment plants is within the range of 0.003–0.09 (average value is 0.03). The respective treatment plant has MCFj value of 0.035. Default value for \(B_{0} \) is 0.6 kg CH4/kg BOD.

where TOW is the total degradable organics in domestic wastewater, kg BOD/year, P is the population served by treatment pathway, BOD is area specific per capita BOD in grams/day/person, country-specific data are provided in the guidelines, for India it is within the range of 21–41 g/person/day (average value is 34 g/person/day), but the regional data were also available at the respective treatment plant and the value taken is 38 g/person/day, and 0.001 is the conversion factor for grams to kilograms.

where TOWj is the total organics in wastewater, kg BOD/year, for income group i and treatment pathway, j. \(U_{i }\) is the fraction of population in i income group, \(T_{i,j}\) is the degree of utilization of system or treatment pathway, j, for each fraction of income group i, and I is the correction factor for BOD discharged into sewer by industries (1.25 for collected or 1.00 for uncollected). For \(U_{i }\) and \(T_{i,j}\), country-specific data are provided. For India, the values of \(U_{i }\) for each income group, rural, urban high, and urban low, are 0.71, 0.06, and 0.23, respectively. The \(T_{i,j,}\) values for rural, urban high, and urban low are 0.10, 0.07, and 0.03, respectively.

where \({\text{N}}_{2} {\text{O}}\;{\text{Plants}}_{{{\text{dom}}}}\) is N2O emissions from domestic treatment plants, kg N2O/year, TNdom is the total nitrogen in domestic wastewater, kg N/year, \(U_{i}\) is the fraction of population in income group i, \(T_{ij}\) is degree of utilization of treatment pathway j, for each income group fraction i, EFj is the emission factor for treatment pathway or system j, kg N2O–N/kg N. In guidelines, it is given that EFj value for aerobic treatment plants is 0.016 kg N2O–N/kg N and \(\frac{44}{{28}}\) = conversion of kg N2O–N into kg N2O.

where \({\text{TN}}_{{{\text{dom}}\_ j}}\) is the total amount of nitrogen in domestic wastewater for treatment pathway j, kgN/year, \(P_{j}\) is population served by treatment pathway j, protein is the per capita consumption of protein in kg protein/person/year, Fnpr is the nitrogen fraction in protein, 0.16 kg N/kg protein is the default value, Fnon-con is the factor for non-consumption of protein disposed in sewer system, kg N/kg N, Find-com is the factor for commercial and industrial co-discharged protein into the sewer system in kg N/kg N, 1.25 is the default value and Nhh is the additional nitrogen from household products added to the wastewater. Country-specific data are provided for Fnon-con and Nhh. For India, the value for Fnon-con and Nhh is 1.02 and 1.13, respectively.

where \({\text{Protein}}_{{{\text{supply}}}}\) is the annual per capita protein supply, kg protein/person/year and protein supply in India is 0.06533 kg per person day (FAO 2017), or FPC = fraction of protein consumed. Country-specific data are given for FPC (value for India is 0.96).

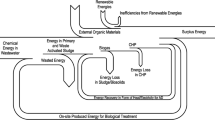

Estimation of CH4 accumulation in the atmosphere

System dynamics (SD) is a policy-based methodology that evaluates the effect of policy changes on a system (Sharawat et al. 2014). A SD model is used to calculate the CH4 accumulation in the atmosphere. The main building blocks for the SD model are stocks, flows, converter, and connectors. In Fig. 2, the stock variable is shown as rectangle represent accumulations—physical and non-physical. They start with some initial value and thereafter are changed only by flows into and out of them. A flow is the rate of change in a stock which is represented by a double-lined arrow with valves. Converters are represented by circles and they serve utilitarian role in the model. They define external inputs to the model, hold values for constants, and act as repository for graphical functions. The job of the connector is to connect model elements, represented by red lines in Fig. 2. The modelling is done using STELLA 9.0.1 software. The modelling is done using STELLA 9.0.1 software. Figure 2 shows the system dynamic stock and flow diagram of CH4 accumulation in the atmosphere from the wastewater treatment plant. Equations used in the system dynamic model are as follows:

Inflows:

CH4 = methane released from the wastewater treatment plant (the value calculated from Eq. 5)

Outflows:

A dynamic balance exists between the inflow and outflow rate of the CH4 concentration. Whatever quantity of CH4 enters into the atmosphere, the same amount is removed or decays but with a delay period of 12 years because the life span of CH4 in the atmosphere is 12 years. In the present study, a “delay function” in the system dynamic model is used for estimating CH4 accumulation in the atmosphere. The CH4 emission from the wastewater treatment plant is taken as a CH4 accumulation rate. The initial concentration of CH4 in the atmosphere is taken as 0. Thus, the 12 years back generation rate of CH4 was equal to its decay rate. The delay function is based on the following equation (Kumari et al. 2016).

where \(A_{t}\) = CH4 accumulation in time t, \(k_{{\text{a}}}\) = CH4 accumulation rate, \(k_{{\text{d}}}\) = CH4 decay rate, T = delay time (12 years) and \(E_{0}\) = initial concentration of CH4 in the atmosphere.

Results and discussion

Total energy consumption

The electrical energy consumption evaluated for different sections of the SBR-based wastewater treatment plant is given in Table 2. The sum total of all the sections works out to 0.22 kW h/m3. Figure 3 shows the share of different forms of energy utilized at the treatment plant. Obviously, as evident from Fig. 3a, the maximum share is of electrical energy and it is 84% of the total energy consumed. The electrical energy consumption in the SBR-based technology is less than that in other treatment technologies. The values for other technologies range from 0.24 to 2.32 kW h/m3 (Belloir et al. 2014; Pan et al. 2011; Venkatesh and Brattebo 2011; Mizuta and Shimada 2010). Among the treatment processes, primary and secondary treatment in the SBR reactor comes out to be the most energy-demanding processes. They consume 82% of the electrical energy. Out of this, the air blowers used for the aeration process consume 78% followed by return activated sludge (RAS) pump that consumes 2.7% of the electrical energy. The sludge handling unit consisting of sludge thickener, sludge sump, and centrifuge unit accounts for 13% of the electrical energy consumption. The complete picture of the electrical energy used in different treatment units and processes is shown in Fig. 3b, c.

The share of mechanical energy in the total energy consumption works out to 15% (0.04 kW h/m3). Daily 70 L diesel was consumed at the wastewater treatment plant site for running the standby generator. Table 3 gives the detailed aspects for the human energy spent for the different operations at the plant. The human energy works out to merely 1% of the total energy consumption. This is low because most of the manual activities, like opening and closing of valves or gates, handling of chemicals, etc., are automated. It was found that 34% of the human energy was spent for scrubbing off the sludge from the walls in the reactor zone of the SBR reactor. Figure 4 shows the process-wise distribution of human energy. Obviously, the bulk of it (82%) is used in the primary and secondary processes followed by the sludge handling (13%).

Chlorine gas utilized in the disinfection tank accounts for the chemical energy. The study made for the SBR-based wastewater treatment plant showed that this energy component was just 0.07% (0.0002 kW h/m3) of the total energy consumption. The overall energy consumption at the treatment plant worked out to 0.2612 kW h/m3 by talking into account all the energy aspects. However, the literature does not have the sufficient data to compare values with the same technology treatment plant. Few studies on other treatment technologies have reported values which differ significantly due to dissimilarity in scale, automation, and selection of treatment technology. Total energy consumption ranges from 2.07 to 2.32 kW h/m3 for oxidation ditches and 1.07 kW h/m3 for rotating biological contractor (Belloir et al. 2014; Singh et al. 2012).

As mentioned earlier, a comprehensive assessment of different forms of energy utilized during the wastewater treatment is important to analyse opportunities for energy substitution. Though the share of human energy in the wastewater treatment process was quite low, it is important in energy analysis studies. It provides an opportunity to look for alternatives at various stages of the treatment processes, e.g. the cleaning of preliminary treatment units (screening and grit removal) and chemical dosing. These processes can be done mechanically or manually (human). The manual process is worth considering where the labour charges are low, and the electrical energy is scarce. However, the health hazard and human safety are vital for utilizing the labour force while handling the wastewater flow in the treatment units. The investigations of the breakup of energy consumption can thus be helpful in choosing the energy resource and the extent of automation at the wastewater treatment plants.

It could be observed that the wastewater treatment plants are energy intensive and the energy required at the treatment plants is expected to rise considerably because of more stringent limits for water quality parameters and inclusion of nutrient removal parameters in the prescribed standards of effluent discharge. As mentioned earlier, a few studies are available in the literature on the total energy assessment for the wastewater treatment plants and no such study was available for the SBR-based technology. To meet the new standards, the existing wastewater treatment plants will require retrofitting. For these and new plants fulfilling the requirements of updated standards, the overall energy analysis will be beneficial to evolve techno-economic energy-efficient strategies. Such types of generalizations are needed for different categories of the wastewater treatment plants in order to have a holistic view on energy and wastewater treatment nexus. It will also help in deciding the size of treatment plant, level of automation, and choice of the treatment technology based on the available resources.

Investigation of effluent quality

Samples of influent and effluent collected from the wastewater treatment plant under investigations were analysed to determine six water quality parameters, i.e. BOD, TSS, COD, pH, TN, and TP. The test results along with the new (prescribed in the year 2019) and old standards for the wastewater effluent discharge are given in Table 4. Earlier removal of nutrients was not mandatory in India to meet the quality standards for the effluent discharge in rivers. But in the year 2019, stringent limits are added to the newly prescribed standards for the discharge of TN and TP. From the results, it is clear that the effluent quality discharged from the treatment plant, comply with the new standards of all the six parameters. The percentage reduction in the values of BOD, COD, TSS, TN, and TP is 97%, 87%, 97%, 78%, and 76%, respectively. The treated effluent quality of the SBR-based treatment plant satisfies the EPA guidelines to be reused for non-potable purposes, like landscaping, horticulture, gardening, toilet flushing, etc. (EPA 2012). Therefore, SBR technology is an efficient technology in terms of treated wastewater quality.

Estimation of GHG emissions

The greenhouse gases (CH4 and N2O) emitted from the wastewater depends on its biodegradable organic matter and the wastewater treatment technology. Following the IPCC guidelines, Eqs. (5) to (11) were used to evaluate the quantity of CH4 and N2O emissions from the treatment plant. The data collected from the treatment plant, emission factors used for the evaluation, and GHG emissions are given in Tables 5 and 6. As given in Table 5, the annual emissions of CH4 and N2O from the plant are estimated to be 19 tCO2e/year and 86 tCO2e/year, respectively. Therefore, annually in total 105 tCO2e/year of GHGs are emitted from the wastewater treatment plant. The plant is also responsible for indirect emissions of GHGs due to the electricity used from the utility grid and the captive power produced by the standby generator at the plant site. Total emissions of these so-called indirectly emitted GHGs because of the electrical power used by the treatment plant work out to 1316.47 tCO2e/year. Out of this, the emissions due to the electrical power drawn from the utility grid amount to 1251.32 tCO2e/year and from the standby power generator at the plant site are 65.15 tCO2e/year. The details are given in Table 6. Taking both the direct and indirect emissions arising due to the SBR-based wastewater treatment plant with the treatment capacity of 19 MLD, the overall GHG emissions work out to 1421.47 tCO2e/year.

In India, according to an estimate, nearly 62,000 MLD wastewater was generated 5 years ago from urban areas, while the treatment capacity was only 23,277 MLD (CPCB 2015). It means nearly 62% of wastewater was discharged untreated, causing pollution of water bodies. With the increasing population and growth of GDP the water usage and, as a consequence, wastewater discharge also increases. Substantial enhancement in the capacity of wastewater treatment and reuse of the treated water is required to circumvent the continuously growing water scarcity and the problem of water pollution. According to the present analysis, if all the untreated wastewater is treated using the SBR technology, 2,897,031 tCO2e/year of GHGs will emit from such sites. However, for a holistic view, such studies on different types of treatment processes in various parts of the world would be required.

Estimation of CH4 accumulation in the atmosphere

The system dynamics approach described in methodology is adopted to estimate the CH4 accumulation in the atmosphere with projection till the year 2041 starting from 2018. The N2O accumulations are not considered since the N2O life span in atmosphere is quite long, i.e. 110 years. The CH4 emitted from the treatment plant is neither recovered nor reused for any purpose; it simply goes to the atmosphere. Figure 5 (generated from SD model) shows the accumulation of CH4 in the atmosphere over the years due to its emission from the wastewater treatment plant under investigation. The initial concentration of CH4 is taken as 0 in the base year 2018. From the year 2018 to 2029, the concentration increases; however, its decomposition and decay start from 2029 onwards. Nevertheless, the decay and accumulation balance from 2030 onwards. The red line in Fig. 5 represents the CH4 accumulation rate, which is constant at 789 kg CH4/year (estimated in the previous section). The rate is constant because the treatment capacity of the wastewater treatment plant is expected to remain unchanged at 19 MLD till the year 2041. The pink line shows the decay rate and the CH4 decay starts after 12 years of its existence in the atmosphere (from the year 2030 in this case) as the CH4 life span is 12 years. Since the treatment capacity of the plant will remain unchanged, the CH4 decay after 2030 will be equal to its accumulation. The blue line shows the CH4 accumulation in the atmosphere. In the base year 2018, the initial value of CH4 emission from the plant was taken 0 kg for the present system dynamic analysis. By 2023, the contribution of this plant to the atmospheric accumulation of CH4 is projected to reach 3945 kg and further on 8679 kg in 2029. The projection for 2030 and thereafter is 9468 kg. In its life span of 12 years, the accumulated CH4 arising from the wastewater treatment plants can have substantial impact on the global warming. It is well realized that CH4 being a greenhouse gas its accumulation in the atmosphere poses serious environmental risk. The studies like the present one will have significant implications in understanding and improving the wastewater treatment technologies from the energy and environment viewpoint.

Conclusion

A sequential batch reactor-based wastewater treatment plant has been investigated for the energy utilized in running the plant, quality of the effluent discharged from it, and the greenhouse gas emissions due to its operation. The analysis showed that 0.26 kW h energy was consumed for every cubic metre of the wastewater treated at an urban plant. Out of this, 84% share was of electrical energy followed by 15% mechanical and the remaining 1% distributed between the human and chemical energy. Motors powering the blowers consumed the maximum, 78%, of the electrical energy. For the environmental analysis, effluent quality and the GHG emissions are considered. During the wastewater treatment, the BOD, COD, TSS, TN, and TP values redubbed by 97%, 87%, 97%, 78%, and 76%, respectively. With this, the effluent quality was found to be well within the prescribed standards for reuse in non-potable applications. Primarily CH4 and N2O greenhouse gases are emitted due to the wastewater treatment plant and the annual contribution of the investigated plant to the GHGs worked out to 1421.47 tCO2e. Temporal projection of CH4 accumulation in the atmosphere arising from the treatment of wastewater at the plant, taking 2018 as base year, projected 9468 kg of CH4 accumulation by the year 2030 and beyond. The present study is useful for analysing the energy use, effluent quality, and GHG emissions in respect of different wastewater treatment technologies to have the holistic view of the energy, environment, and water nexus. It will also help in improving the sustainability of the wastewater treatment systems.

References

APHA (2012) Standard methods for the examination of water and wastewater. American Public Health Association, Washington DC

Belloir C, Stanford C, Soares A (2014) Energy benchmarking in wastewater treatment plants: the importance of site operation and layout. Environ Technol 36:260–269. https://doi.org/10.1080/09593330.2014.951403

CEA (2014) CO2 baseline database for the Indian power sector. Central Electricity Authority. Ministry of power, India https://cea.nic.in/reports/others/thermal/tpece/cdm_co2/user_guide_ver10.pdf. Accessed 07 June 2020

Chakraborti R, Kaur J, Kaur H (2019) Water shortage challenges and a way forward in India. J Am Water Work Assoc 111:42–49. https://doi.org/10.1002/awwa.1289

CPCB (2015) Inventorization of sewage treatment plant. Central pollution control board, Ministry of Environment and Forest, India. https://nrcd.nic.in/writereaddata/FileUpload/NewItem_210_Inventorization_of_Sewage-Treatment_Plant.pdf. Accessed 25 May 2020

Devi R, Dahiya RP, Kumar A, Singh V (2007) Meeting energy requirement of wastewater treatment in rural sector. Energy Policy 35:3891–3897. https://doi.org/10.1016/j.enpol.2007.01.017

Dutta A, Sarkar S (2015) Sequencing batch reactor for wastewater treatment: recent advances. Curr Pollut Rep 1:177–190. https://doi.org/10.1007/s40726-015-0016-y

EPA (2012) Water reuse guidance manual factsheet. Environmental Protection Agency, USA. EPA/600/R-12/618

FAO (2017) The State of Food Security and Nutrition in the World. United Nations, Rome. https://www.fao.org/3/a-I7695e.pdf. Accessed 01 June 2020

Ginley DS, Cahen D (2010) Fundamentals of materials for energy and environmental sustainability. Cambridge University Press, Cambridge

Gulati A, Banerjee P (2018) Emerging water crisis in India: key issues and way forward. Indian J Econ 383:681–704

IPCC (2006) Guidelines for national greenhouse gas inventories. IGES, Japan, pp 4.1–4.77

IPCC (2019) 2019 Refinement to the 2006 IPCC Guidelines for national greenhouse gas inventories. IPCC, Switzerland, pp 6.1–6.72

Jenssen PD, Vrale L, Lindholm O (2007) Sustainable wastewater treatment. In: International conference on natural resources and environmental management and environmental safety and health. Kuching, Malaysia, November 27–29 (proceeding)

Jonasson M (2007) Energy benchmark for wastewater treatment process—a comparison between Sweden and Austria. Dissertation, Lund University

Kumari S, Dahiya R, Naik SN, Hiloidhari M, Thakur IS, Sharawat I, Kumari N (2016) Projection of methane emissions from livestock through enteric fermentation: a case study from India. Environ Dev 20:31–44. https://doi.org/10.1016/j.envdev.2016.08.001

Mahgoub MESM, Steen NPVD, Zeid KA, Vairavamoorthy K (2010) Towards sustainability in urban water: a life cycle analysis of the urban water system of Alexandria City Egypt. J Clean Prod 18:1100–1106. https://doi.org/10.1016/j.jclepro.2010.02.009

Merlin G, Lissolo T (2010) Energy and emergy analysis to evaluate sustainability of small wastewater treatment plants: application to a constructed wetland and a sequencing batch reactor. J Water Resour Prot 2:997–1009. https://doi.org/10.4236/jwarp.2010.212120

Mizuta K, Shimada M (2010) Benchmarking energy consumption in municipal wastewater treatment plants in Japan. Water Sci Technol 62:2256–2262. https://doi.org/10.2166/wst.2010.510

MoEF (2010) Sewage treatment in class I towns: recommendations and guidelines. Ministry of Environment and Forest, India. https://www.moef.nic.in/sites/default/files/ngrba/003_EQP_S&R_02.pdf. Accessed 30 May 2020

NGT (2019) Ministry of Environment and Forest. National Green Tribunal, India. https://www.indiaenvironmentportal.org.in/files/file/revised-standards-STPs-NGT-Order.pdf. Accessed 30 May 2020

Pan T, Zhu XD, Ye YP (2011) Estimate of life-cycle greenhouse gas emissions from a vertical subsurface flow constructed wetland and conventional wastewater treatment plants: a case study in China. Ecol Eng 37:248–254. https://doi.org/10.1016/j.ecoleng.2010.11.014

Sahasranaman M, Ganguly A (2018) Wastewater treatment for water security in India. Institute for Resource Analysis and Policy (No. 13-0418). https://irapindia.org/images/irap-Occasional-Paper/Wastewater-Water-Security-India.pdf. Accessed 27 May 2020

Shah M (2016) Urban water systems in India: a way forward. Indian council for research on international economic relations, New Delhi. https://icrier.org/pdf/Working_Paper_323.pdf. Accessed 27 May 2020

Sharawat I, Dahiya RP, Dahiya R, Kumari S (2014) System dynamics approach: a novel water resource management tool. Int J Environ Res Dev 4:297–302

Sharawat I, Dahiya RP, Krishnan TR, Dahiya R, Kumari S (2019) Policy options for managing the water resources in rapidly expanding cities: a system dynamics approach. Sustain Water Resour Manag 5:1201–1215. https://doi.org/10.1007/s40899-018-0296-7

Showkat U, Najar IA (2019) Study on the efficiency of sequential batch reactor (SBR)-based sewage treatment plant. Appl Water Sci 9:2. https://doi.org/10.1007/s13201-018-0882-8

Singh P, Marquet CC, Kansal A (2012) Energy pattern analysis of a wastewater treatment plant. Appl Water Sci 2:221–226. https://doi.org/10.1007/s13201-012-0040-7

Tao X, Chengwen W (2011) Impact of different factors on greenhouse as generation by wastewater treatment plants in China. In: International symposium on resource and environmental protection, China, vol 2, pp 1448–1451

UN (2018) World urbanization prospects: the 2018 revision. Department of Economic and Social Affairs, Population Division. United Nations. https://population.un.org/wup/Publications/Files/WUP2018-Report.pdf. Accessed 27 May 2020

UN (2019) World population prospects 2019: highlights. Department of Economic and Social Affairs, Population Division. (ST/ESA/SER.A/423). United Nations. https://population.un.org/wpp/Publications/Files/WPP2019_Highlights.pdf. Accessed 27 May 2020

Venkatesh G, Brattebo H (2011) Energy consumption, costs and environmental impacts for urban water cycle services: case study of Oslo (Norway). Energy 36:792–800. https://doi.org/10.1016/j.energy.2010.12.040

Vera I, Saez K, Vidal G (2013) Performance of 14 full-scale sewage treatment plants: comparison between four aerobic technologies regarding effluent quality, sludge production and energy consumption. J Environ Technol 34:2267–2273. https://doi.org/10.1080/09593330.2013.765921

WHO (1985) Energy sand protein requirements report of Joint FAO/WHO/UNU expert consultation and WHO technical report series no. 724. World Health Organization and United Nations University, Geneva

WRI (2019) Aqueduct water risk atlas 2019. World Resources Institute. https://www.wri.org/resources/data-sets/aqueduct-30-country-rankings. Accessed 14 may 2020

Acknowledgements

Isha Sharawat is grateful to the University Grant Commission, Government of India for providing UGC-SRF Fellowship (No. F.10-18/07 (SA-I)). The authors are also thankful to the officials and operators of the wastewater treatment plant for their cooperation and assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

Editorial responsibility: Q. Aguilar-Virgen.

Rights and permissions

About this article

Cite this article

Sharawat, I., Dahiya, R. & Dahiya, R.P. Analysis of a wastewater treatment plant for energy consumption and greenhouse gas emissions. Int. J. Environ. Sci. Technol. 18, 871–884 (2021). https://doi.org/10.1007/s13762-020-02893-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-020-02893-9