Abstract

An efficient protocol for C–C coupling has been developed using three iodo-bridged copper(I) complexes as catalysts. Complexes [CuI(bpy)]2 (1), [CuI(phen)]2·DMF (2), and [CuI(Mephen)]2 (3) were successfully synthesized via solvothermal method (bpy = 2,2′-dipyridyl, phen = 1,10-phenanthroline, and Mephen = 2,9-dimethylphenanthroline). The self-coupling reaction of phenylboronic acid was selected as a model reaction to evaluate the catalytic property of the complexes. Moreover, this method tolerates various substituents on the arylboronic acids such as halogens, carbonyls, and nitro groups. It shows that the iodo-bridged Cu(I) center serves as the active site to activate molecular oxygen during the catalytic process. The result illustrates that these complexes were found to be excellent catalysts for self-coupling of arylboronic acids under mild conditions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

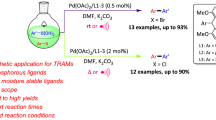

C–C bond-formation reactions are important organic synthesis method for construction of important building block [1,2,3]. Palladium-based catalysts are most frequently used for the homocoupling of aryboronic acids [4]. However, the high cost of Pd and the air-sensitive experimental conditions of homogeneous reactions limit their wider application [5,6,7,8,9]. In addition, noble metal-catalyzed directly C–C bond construction requires strong bases [10,11,12,13,14] and higher temperature and appropriate ligands [15, 16]. For instance, the Jürgen Schatz’s group [17] and Vivek Polshettiwar’s group [18] reported Suzuki coupling reactions with boronic acid as a nucleophilic coupling partner with Pd(OAc)2 in both pure water and aqueous media [19]. Developing the environmentally friendly reactions for the preparation of biaryls will be of great importance [20]. Therefore, transition-metal-catalyzed homocoupling of arylboronic acids is an excellent method to obtain symmetrical biaryls from a single aryl precursor. Great progresses have been made in the construction of biaryls by transition-metal-catalyzed couplings such as Suzuki reaction [21,22,23,24], Ullmann reaction [25], and Kumada–Corriu–Tamao reaction [26]. Until now, copper-mediated catalyzed C–C bond construction is a powerful method in providing multifunctional materials [27,28,29,30]. Copper has multiple oxidation states, such as Cu0, CuI, CuII and CuIII, which will display different electron (one-electron or two-electron) processes [31, 32]. The different oxidation states of copper can associate well with numerous functional groups via Lewis acid interactions [33, 34]. These features confer a remarkably broad range of activities allowing copper to tolerate many substrates [35, 36]. Recently, copper acts as a low-cost and benign metal catalysis for a sustainable approach to prepare functional organic molecule. CuI-catalyzed coupling of alkylboron reagents with aryl and heteroaryl iodides affords coupled products in good yield [37]. Nowadays, encouraged by the economical and environmental viewpoints [38], the relatively low toxicity, ease of handing, and low cost of copper catalysts make them attractive for the elaboration of new synthesis methodologies [39].

Efforts in our laboratory are focused on the synthesis of metal organic complexes and exploration of their application on catalytic organic synthesis [40,41,42,43]. We obtained three dinuclear Cu(I) complexes with copper salt and cheap bpy or phen ligand. Each Cu(I) atom in 1–3 is coordinated by two nitrogen atoms from the ligands and two iodo atoms (Fig. 1). Generally, the dinuclear Cu(I) complexes which bridged by halogen-metal bonds can be viewed as the typical catalyst to activate molecular oxygen [44]. In this way, the ligands like phen or bpy can stabilize the intermediate with mixed valence, which serves the significant role in the catalytic process [45,46,47]. Therefore, it can be suggested that the copper(I) center in complexes 1–3 might serve as potent active site to activate molecular oxygen [38]. Based on above fact and deduction as well as our continuing interest in catalytic characters study of metal organic complexes, we envisioned that whether the aerobic homocoupling reaction could occur with complexes 1–3 as catalysts. Importantly, we find herein that the homocoupling of arylboronic acids could be catalytically conducted by 1–3 under mind condition, which is hard to be implemented in reported Cu-based catalyst system [48].

Experimental

Materials and measurements

All reagents and starting materials were purchased from commercial resources and used without further purification. Elemental analysis (C, H, and N) was performed on Perkin-Elmer 2400 II elemental analyzer. IR spectroscopy was carried out on an FTIR spectrometer 6700 instrument in the range 4000–400 cm−1 using KBr pellets. Thermogravimetric analysis (TGA) experiments were carried on Perkin-Elmer SAT-6000 instrument heated from 25 to 900 °C under constant N2 flow (10 mL/min) at a heating rate of 10 °C/min. Gas chromatography (GC) was performed using the Agilent 7890A GC with flame ionization detector. 1H NMR (400 MHz) and 13C NMR (100 MHz) spectra were recorded in DMSO-d6 solutions on a Bruker AVANCE III HD600 spectrometer.

General procedure for the synthesis of complexes 1–3

Complex 1 CuI (0.0286 g, 1.50 mmol), bpy (0.0156 g, 1.00 mmol), DMAC (dimethylacetamide) (2 mL), EtOH (3 mL), and H2O (3 mL) were placed into a Teflon-lined stainless vessel (15 mL). Then, the mixture was sealed and heated to 120 °C for 12 h, and the reaction system was cooled to room temperature at a rate of 15 °C/h. Red block-shaped crystals were obtained after filtering, washing with ethanol, and drying in vacuum. Yield 71% (based on bpy). Elemental analysis calcd (%) for C20H16Cu2I2N4: C, 34.65; H, 2.33; N, 8.08; found: C, 34.08; H, 2.65; N, 7.92. IR data (KBr pellet) ν (cm−1): 3054, 1592, 1564, 1464, 1432, 1309, 1277, 1246, 1150, 1004, 763.

Complex 2 CuI (0.0286 g, 1.50 mmol), phen (0.0198 g, 1.00 mmol), DMF (2 mL), EtOH (3 mL), and MeCN (10 mL) were added to a Teflon-lined stainless steel vessel (25 mL). Then, the mixture was sealed and heated to 120 °C for 12 h, and the reaction system was cooled to room temperature at a rate of 15 °C/h. Dark red block-shaped crystals were obtained after filtering, washing with ethanol, and drying in vacuum. Yield 60% (based on phen). Elemental analysis calcd (%) for C27H23Cu2I2N5O: C, 39.82; H, 2.85; N, 8.60; found: C, 39.25; H, 2.95; N, 8.17. IR data (KBr pellet) ν (cm−1): 2371, 1621, 1573, 1506, 1421, 1226, 1140, 1023, 843, 763, 717.

Complex 3 CuI (0.0286 g, 1.50 mmol), Mephen (0.2083 g, 1.00 mmol), DMAC (2 mL), EtOH (3 mL), and H2O (10 mL) were placed into a Teflon-lined stainless vessel (25 mL). Then, the mixture was sealed and heated to 120 °C for 12 h, and the reaction system was cooled to room temperature at a rate of 15 °C/h. Red block-shaped crystals were obtained after filtering, washing with ethanol, and drying in vacuum. Yield 53% (based on dimethyl-phen). Elemental analysis calcd (%) for C28H24Cu2I2N4: C, 42.17; H, 3.03; N, 7.03; found: C, 41.87; H, 3.49; N, 6.78. IR data (KBr pellet) ν (cm−1): 1962, 1592, 1498, 1359, 1203, 1156, 853, 735.

General procedure for the self-coupling reaction of various arylboronic acids

A dry 10-mL vial was charged sequentially with the arylboronic acid (0.2 mmol), K2CO3 (0.20 mmol, 0.138 g), and i-PrOH (2 mL). The mixture was stirred at RT for 6 h in air until complete disappearance of arylboronic acid (monitored by TLC). After complete reaction, the product was extracted three times with ethyl acetate (5 mL). The combined organic extract was dried with anhydrous sodium sulfate. The product was analyzed by GC. The product was further purified by column chromatography with petroleum ether-EtOAc (20:1) as eluent.

1,1′-biphenyl [49]

m.p. 70–71 °C. 1H NMR (600 MHz, DMSO-d6, ppm) δ 7.66 (d, 4H, J = 7.5 Hz), 7.47 (d, 4H, J = 7.5 Hz), 7.35 (t, 2H). 13C NMR (150 MHz, DMSO-d6, ppm) δ 140.43, 129.18, 127.67, 126.94. LC–MS (EI): m/z, [M + 1]+ = 155.1.

4,4′-dimethyl-1,1′-biphenyl [49]

m.p. 122–123 °C. 1H NMR (600 MHz, DMSO-d6, ppm) δ 7.53 (d, J = 7.5 Hz, 2H), 7.25 (d, J = 7.5 Hz, 2H), 2.34 (s, 3H); 13C NMR (150 MHz, DMSO-d6, ppm) δ 136.73, 135.86, 128.99, 125.73, 20.16. LC–MS (EI): m/z, [M + 1]+ = 183.0.

4,4′-diethyl-1,1′-biphenyl [50]

m.p. 78–80 °C. 1H NMR (600 MHz, DMSO-d6, ppm) δ 7.54 (d, 4H, J = 5.6 Hz), 7.27 (d, 4H, J = 5.6 Hz), 2.66 (s, 4H), 1.22 (s, 6H); 13C NMR (150 MHz, DMSO-d6, ppm) δ 142.80, 137.68, 128.39, 126.50, 27.91, 15.72. LC–MS (EI): m/z, [M + 1]+ = 211.1.

4,4′-dichloro-1,1′-biphenyl [48]

m.p. 142–143 °C. 1HNMR (600 MHz, DMSO-d6, ppm) δ 7.72–7.68 (m, 4H, J = 8.4 Hz), 7.54 (s, 4H, J = 8.4 Hz); 13C NMR (150 MHz, DMSO-d6, ppm) δ 138.04, 133.11, 129.37, 128.83. LC–MS (EI): m/z, [M + 1]+ = 223.0.

4,4′-dibromo-1,1′-biphenyl [49]

m.p. 164–165 °C. 1H NMR (400 MHz, CDCl3, ppm) δ 7.73 (d, 4H, J = 8.4 Hz), 7.58–7.51 (d, 4H, J = 8.4 Hz); 13C NMR (100 MHz, CDCl3, ppm) δ 138.68, 131.82, 128.30, 121.77. LC–MS (EI): m/z, [M + 1]+ = 310.9.

4,4′-dinitro-1,1′-biphenyl [39]

m.p. 240–242 °C. 1H NMR (400 MHz, DMSO-d6, ppm) δ 8.04 (d, 4H, J = 8.2 Hz), 8.01–7.94 (d, 4H, J = 8.2 Hz). 13C NMR (100 MHz, DMSO-d6, ppm) δ 147.77, 139.17, 125.40, 104.93. LC–MS (EI): m/z, [M + 1]+ = 245.1.

4,4′-bipyridine [48]

m.p. 110–112 °C. 1H NMR (400 MHz, DMSO-d6, ppm) δ 8.73 (d, 4H, J = 5 Hz), 7.84 (d, 4H, J = 5 Hz). 13C NMR (100 MHz, DMSO-d6, ppm) δ 150.82, 144.55, 121.54. LC–MS (EI): m/z, [M + 1]+ = 157.1.

3,3′-bithiophene [51]

m.p. 130–131 °C. 1H NMR (400 MHz, DMSO-d6, ppm) δ 7.77 (s, 2H), 7.59 (d, J = 1.4 Hz, 2H), 7.52 (s, 2H). 13C NMR (100 MHz, DMSO-d6, ppm) δ 136.67, 126.32, 120.12. LC–MS (EI): m/z, [M + 1]+ = 167.0.

X-ray crystallography

Crystallographic data for complexes 1–3 were collected on a Bruker SMART CCD diffractometer using graphite monochromated MoKα radiation (λ = 0.71073 Å) at room temperature. Data were corrected for absorption effected using the multiscan technique (SADABS) [52]. The structures were solved by direct method, and all non-hydrogen atoms were refined with anisotropic displacement parameters by full-matrix least squares using the SHELXTL program [53]. All hydrogen atoms were placed at a geometrically calculated position and refined using the riding model approximation. The details of the crystal parameters and structure refinements for complexes 1–3 are listed in Table S1.

Results and discussion

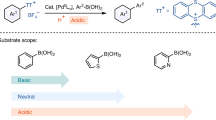

Compounds 1–3 are stable in air or conventional solvent. The elemental analyses were consistent with the chemical formulas of complexes 1–3. The IR spectra of complexes 1–3 showed the characteristic bands from 1430 to 1600 cm−1 may be attributed to the vC=C and vC=N stretching vibration of the pyridine rings. The decomposition temperature of complexes 1–3 was reached to 210 °C. Initially, study commenced with the self-coupling reaction of phenylboronic acid for optimization. Employing phenylboronic acid (0.2 mmol) with 2 mL i-PrOH, almost no trace conversion was detected by GC after 4 h in the presence of complexes 1–3 or inorganic copper (I) salts (CuI, CuBr, CuCl) (Table 1, entry 1–6). To our delight, product was obtained with a K2CO3 as a base, which indicated that the self-coupling yield was achieved in the need of basic condition. The catalytic activities of complexes 1–3 are markedly better than inorganic salts (Table 1, entry 7–12). Control reactions prolonging per hour were carried out via adjusting time from 2 to 9 h, and the results demonstrated that the corresponding yield was prone to slight improvement after 6 h at room temperature (Fig. 2c, Table 1, entry 10, 13–19).

a Effect of different solvents on the self-coupling reaction catalyzed by complex 1. b The effect of different bases on the self-coupling reaction catalyzed by complex 1. c The effect of time on the self-coupling reaction catalyzed by complex 1. d The effect of different substituent groups on the self-coupling reaction catalyzed by complexes 1–3

Further optimization for investigation utilizing K2CO3 as the limiting base, a variety of organic solvents were used to participate in the reaction. The yields of biphenyl were ordered as: i-PrOH (72.95%), MeCN (70.98%), DMF (70.73%), PhCH3 (66.35%), MeOH (62.59%), THF (57.53%), CHCl3 (31.29%) (Fig. 2a, Table 1, entry 16, 20–25). Unfortunately, using pure water as solvent resulted in low yield of 8.78% (Table 1, entry 26). The i-PrOH could be the best solvent owing to that the copper center atom is oxidated to CuII species in air and i-PrOH is necessary to reduce CuII species back to CuI precursors. The inorganic base except Na2CO3 is superior to organic base in such catalytic process although the organic base was easily soluble in the organic phase. The result indicated that the solubility of bases had no dominated effect on the self-coupling reaction (Figure 2b, Table 1, entry 16, 27–32, in 1.44–72.95% yield).

Based on these results, we choose the following parameters as optimal conditions: copper(I) complexes (5 mol%), K2CO3 as a base and i-PrOH as solvent, with a reaction time of 6 h. With the optimal conditions in hand, the scope of the reaction was briefly explored. Further study of the reaction scope demonstrated that the conditions were tolerant of both arylboronic acids and heteroaryl boronic acids, and the results are summarized in Fig. 2d and Table 2.

Both electron-donating and electron-withdrawing substituents are well tolerated at para position of the phenylboronic acid. Electron-donating substituents at the benzene ring of arylboronic acids increase the electron density at the active site during the formation of transition state [54, 55]. From Table 2 (2a1–2a6), it can be seen that the yields of biphenyls containing electron-donating groups (–CH2CH3, –CH3, –Br, –Cl) were higher than 4,4′-dinitrobiphenyl containing electron-withdrawing groups (–NO2). The reaction can also successfully accommodate heterocycle boronic acids, giving 4,4′-bipyridine and 3,3′-bithiophene in the range of 57.69%-73.27% and 26.74%-54.98% yield, respectively (Table 2, 2a7-2a8). As shown in Fig. 2d,the catalytic activity of 1 is superior to other two complexes. The results are comparable with the other copper catalysts and palladium catalysts reported recently (Table S2, table S3).

The single-crystal analysis shows that the center copper atom of three complexes takes up identical geometrical configuration which is in shape with four coordination number and has vacant sites [56]. The precise structure can give more information to study the mechanism of the coupling reaction. Scheme 1 outlines a plausible mechanism for the Cu-catalyzed homocoupling reaction. We speculate that the reaction proceeds according to the following steps. Firstly, the binuclear copper compounds are activated by molecular oxygen ion and quickly forming catalytically active (µ-hydroxide)copper(II) complex A. Then, the hydroxide A attacks the oxyphilic boron center to obtain bimetallic aryl copper(II) intermediates B. Afterward, it undergoes a series of reductive elimination to produce the symmetrical biaryl compound [4, 35, 38, 39, 49, 57,58,59,60]. It showed that the yield was very low when the reaction carried out under inert atmosphere. Therefore, the oxygen plays an important role in the catalytic process which referred to the valence variation of Cu ions [44].

Conclusion

In summary, we have synthesized three binuclear copper(I) compounds by a hydrothermal method. The compounds were characterized by elemental analysis, IR spectra, thermogravimetric analyses (TGA), and single-crystal X-ray diffraction. These binuclear copper(I) compounds exhibited good catalytic performance toward the homocoupling reaction. The result showed that the binuclear Cu(I) unit played an important role during the catalytic process. To some extent, the structural study of the dinuclear Cu(I) compound constructed a catalytic model toward the homocoupling reaction, which will guide the similar homocoupling reaction in the future.

Supplementary material

The crystallographic data of the complexes 1–3 were deposited to the Cambridge Crystallographic Data center as supplementary publication (CCDC No. 1440313, 1516188 and 1440312 for 1–3, respectively. Copies of the data can be obtained free of charge on application to CHGC, 12 Union Road, Cambridge CB2 1EZ, UK (Fax: +44-1223-336033 or Email: deposit@ccdc.cam.ac.uk).

References

N. Miyaura, A. Suzuki, Chem. Rev. 95, 2457 (1995)

D.A. Horton, G.T. Bourne, M.L. Smythe, Chem. Rev. 103, 893 (2003)

P. Lloyd-Williams, E. Giralt, Chem. Soc. Rev. 30, 145 (2001)

A.S. Demir, Ӧ. Reis, M. Emrullahoglu, J. Org. Chem. 68, 10130 (2003)

A. Suzuki, Angew. Chem. Int. Ed. Engl. 50, 6722 (2011)

C.E. Knappke, A.J. von Wangelin, Chem. Soc. Rev. 40, 4948 (2011)

Y. Nakao, T. Hiyama, Chem. Soc. Rev. 40, 4893 (2011)

A.H. Cherney, N.T. Kadunce, S.E. Reisman, Chem. Rev. 115, 9587 (2015)

E. Mohammadi, B. Movassagh, J. Organomet. Chem. 822, 62 (2016)

D.M. Kaphan, M.D. Levin, R.G. Bergman, K.N. Raymond, F.D. Toste, Science 350, 1235 (2015)

S. Si, C. Wang, N. Zhang, G. Zou, J. Org. Chem. 81, 4364 (2016)

F. De Schouwer, L. Claes, N. Claes, S. Bals, J. Degrève, D.E. De Vos, Green Chem. 17, 2263 (2015)

G. Aragay, J. Pons, V. Branchadell, J. Garcíaantón, X. Solans, M. Font-Bardía, J. Ros, Aust. J. Chem. 63, 257 (2010)

A.D. Leon, J. Pons, J. García-Antón, X. Solans, M. Font-Bardía, J. Ros, Inorg. Chim. Acta 360, 2071 (2007)

M.B. Ibrahim, S.M. Shakil Hussain, A. Fazal, M. Fettouhi, B. El Ali, J. Coord. Chem. 68, 432 (2015)

O.Y. Poimanova, S.V. Radio, K.Y. Bilousova, V.N. Baumer, G.M. Rozantsev, J. Coord. Chem. 68, 1 (2014)

J. Schatz, S. Dommer, S.O.N. Thumann, B. Blumenröder, I. Hoffmann, Green Chem. 17, 3844 (2015)

V. Polshettiwar, C. Len, A. Fihri, Coord. Chem. Rev. 253, 2599 (2009)

A. Fihri, D. Luart, C. Len, A. Solhy, C. Chevrin, V. Polshettiwar, Dalton Trans. 40, 3116 (2011)

A. Monopoli, A. Afzal, C. di Franco, N. Ditaranto, N. Cioffi, A. Nacci, P. Cotugno, L. Torsi, J. Mol. Catal. A Chem. 386, 101 (2014)

N. Marion, O. Navarro, J. Mei, E.D. Stevens, N.M. Scott, S.P. Nolan, J. Am. Chem. Soc. 128, 4101 (2006)

N. Miyaura, K. Yamada, A. Suzuki, Tetrahedron Lett. 20, 3437 (1979)

V. Montoya, J. Pons, V. Branchadell, J. Garciaantón, X. Solans, M. Font-Bardía, J. Ros, Organometallics 27, 1084 (2008)

M. Guerrero, J. Pons, M. Font-Bardía, T. Calvet, J. Ros, Aust. J. Chem. 63, 958 (2010)

J. Hassan, M. Sévignon, C. Gozzi, E. Schulz, M. Lemaire, Chem. Rev. 102, 1359 (2002)

J.P. Corbet, G. Mignani, Chem. Rev. 106, 2651 (2006)

S.I. Son, W.K. Lee, J. Choi, H.-J. Ha, Green Chem. 17, 3306 (2015)

A. Das, D. Wang, M.C. Belhomme, K.J. Szabo, Org. Lett. 17, 4754 (2015)

K. Hirano, M. Miura, Chem. Commun. 48, 10704 (2012)

V.P. Mehta, E.V. Van der Eycken, Chem. Soc. Rev. 40, 4925 (2011)

S.E. Allen, R.R. Walvoord, R. Padillasalinas, M.C. Kozlowski, Chem. Rev. 113, 6234 (2013)

N. Hussain, P. Gogoi, V.K. Azhaganand, M.V. Shelke, M.R. Das, Catal. Sci. Technol. 5, 1251 (2015)

M. Zhao, X. Zhao, P. Zheng, Y. Tian, J. Fluor. Chem. 194, 73 (2017)

Y. Lin, M. Cai, Z. Fang, H. Zhao, Tetrahedron 72, 3335 (2016)

P. Puthiaraj, P. Suresh, K. Pitchumani, Green Chem. 16, 2865 (2014)

K. Inamoto, K. Nozawa, J. Kadokawa, Y. Kondo, Tetrahedron 68, 7794 (2012)

P. Basnet, S. Thapa, D.A. Dickie, R. Giri, Chem. Commun. 52, 11072 (2016)

Y.-H. Wang, M.-C. Xu, J. Liu, L.-J. Zhang, X.-M. Zhang, Tetrahedron 71, 9598 (2015)

N. Kirai, Y. Yamamoto, Eur. J. Org. Chem. 2009, 1864 (2009)

F. Hu, H. Zou, X. Zhao, Y. Mi, C. Luo, Y. Wang, CrystEngComm 15, 1068 (2013)

F.-L. Hu, Y. Mi, Y.-Q. Gu, L.-G. Zhu, S.-L. Yang, H. Wei, J.-P. Lang, CrystEngComm 15, 9553 (2013)

F.-L. Hu, S.-L. Wang, B.F. Abrahams, J.-P. Lang, CrystEngComm 17, 4903 (2015)

F.-L. Hu, S.-L. Wang, B. Wu, H. Yu, F. Wang, J.-P. Lang, CrystEngComm 16, 6354 (2014)

E.A. Lewis, W.B. Tolman, Chem. Rev. 104, 1047 (2004)

J.-H. Yu, Z.-L. Lü, J.-Q. Xu, H.-Y. Bie, J. Liu, X. Zhang, New J. Chem. 28, 940 (2004)

B.W. Skelton, A.F. Waters, A.H. White, Aust. J. Chem. 44, 1207 (1991)

P.C. Healy, C. Pakawatchai, A.H. White, J. Chem. Soc. Dalton Trans. 12, 2531 (1985)

B.A. Dar, S. Singh, N. Pandey, A.P. Singh, P. Sharma, A. Lazar, M. Sharma, R.A. Vishwakarma, B. Singh, Appl. Catal. A 470, 232 (2014)

G. Cheng, M. Luo, Eur. J. Org. Chem. 2011, 2519 (2011)

P.K. Raul, A. Mahanta, U. Bora, A.J. Thakur, V. Veer, Tetrahedron Lett. 56, 7069 (2015)

G.I. Dzhardimalieva, I.E. Uflyand, J. Coord. Chem. 70, 1468 (2017)

G.M. Sheldrick, SHELXS-97, Program for Refinement of Crystal Structures (University of Göttingen, Göttingen, Germany, 1997)

G.M. Sheldrick, SHELXS-97, Program for Solution of Crystal Structures (University of Göttingen, Göttingen, Germany, 1997)

J.-J. Ning, J.-F. Wang, Z.-G. Ren, D.J. Young, J.-P. Lang, Tetrahedron 71, 4000 (2015)

Q. Li, L.-M. Zhang, J.-J. Bao, H.-X. Li, J.-B. Xie, J.-P. Lang, Appl. Organomet. Chem. 28, 861 (2014)

S. Roy, M.J. Sarma, B. Kashyap, P. Phukan, Chem. Commun. 52, 1170 (2016)

B. Agrahari, S. Layek, S. Kumari, Anuradha, R. Ganguly, D.D. Pathak, J. Mol. Struct. 1134, 85 (2017)

B. Kaboudin, T. Haruki, T. Yokomatsu, Synthesis 1, 91 (2011)

B. Kaboudin, Y. Abedi, T. Yokomatsu, Eur. J. Org. Chem. 2011, 6656 (2011)

B. Kaboudin, R. Mostafalu, T. Yokomatsu, Green Chem. 15, 2266 (2013)

Acknowledgements

The authors thank the financial supports from the National Natural Science Foundation of China (21701035, 21761004), Guangxi Natural Science Foundation (2018GXNSFAA138129, 2018GXNSFBA281085), and Specific research Project of Guangxi for research bases and talents (AD18126005, AD18126002).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

All of the authors declare no completing conflict.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Long, BF., Qin, GF., Huang, Q. et al. Homocoupling of arylboronic acids catalyzed by dinuclear copper(I) complexes under mild conditions. J IRAN CHEM SOC 16, 2639–2646 (2019). https://doi.org/10.1007/s13738-019-01728-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-019-01728-w