Abstract

In this paper, 2-hydroxyethylammonium acetate (2-HEAA) was used as the first functionalized ionic liquid for the facile, economical and environmentally friendly synthesis of Fe3O4 nanoparticles by a co-precipitation method. The synthesized Fe3O4 nanoparticles were used as solid material for supporting 2-HEAA (Fe3O4-2-HEAA). The newly prepared Fe3O4-2-HEAA was characterized by TEM, XRD, FT-IR, TGA and elemental analysis and successfully applied as a magnetically recyclable heterogeneous catalyst for the efficient one-pot, three-component synthesis of 2-amino-3,5-dicarbonitrile-6-thio-pyridines. The catalyst was easily separated by an external magnet and reused at least five times without significant degradation in the activity.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Ionic liquids (ILs) possess unique physicochemical properties including negligible vapor pressure, intrinsic ionic conductivity, supramolecular network acceptable electrochemical stability and tunable solubility for inorganic and organic molecules [1,2,3]. They have aroused increasing interest worldwide as new class of compounds for a potentially effective green replacement of conventional organic solvents [4, 5]. They have been used as a promising catalytic media for the synthesis of organic compounds [6]. Moreover, ILs have many advantages that make them useful media for the synthesis of nanomaterials such as metals, alloys, oxides and sulfides [7,8,9,10]. They act as nanosynthetic template to stabilize, and control the size and shape of nanostructured materials [11, 12]. In recent years, by introducing certain functional groups into the cation or/and anion of traditional ionic liquids a great number of functionalized ILs have been designed for different purposes ranging from synthetic and catalytic chemistry to biotechnology, electrochemistry, and materials science [13,14,15,16,17]. However, the widespread use of ILs is still troubled by the following practical shortcomings such as isolation of the product; recovery of the catalyst which leads to economical and environmental problems; difficult in handling and the use of relatively large amounts of ILs which is costly and may cause toxicological concerns [18]. To solve these problems, a concept of supported ILs has recently been established to combine the advantages of ILs with those of heterogeneous supporting materials. It was also claimed that immobilized ILs can enhance the reactivity and selectivity when they are involved in catalytic reactions [19]. Along this line, a variety of matrices have been introduced for the immobilization of ILs [20]. Within these supporting materials, magnetic nanoparticles (MNPs) have attracted increasing attention because of their facile separation from the reaction mixture using an external magnet [21,22,23]. Magnetic separation of MNPs is easy, economical, and saves time and energy. Furthermore, MNPs such as iron oxide have excellent thermal and chemical stability, surface modification ability, a high surface area, and low toxicity and cost [24,25,26].

Densely substituted pyridine derivatives are one of the most important classes of compounds as they widely occur as key structural subunits in numerous natural products that exhibit many interesting biological and physiological activities [27,28,29]. Among them, 2-amino-3,5-dicarbonitrile-6-thio-pyridine ring systems are known as interesting compounds in the pharmaceutical industry due to their various therapeutic applications [28, 30, 31]. One of the most significant routes for the synthesis of these compounds involves the cyclocondensation of aldehyde, malononitrile and thiol. Generally, this condensation has been carried out under acidic or basic conditions [32, 33], microporous molecular sieves [34], nanocatalysts such as ZnO [35], CuI [36], MgO [37] and SiO2 [38], and ionic liquids including [bmIm]Br [39] and [bmIm]OH [40]. However, the reported protocols suffer from one or more of the following drawbacks such as low yields, prolonged reaction time, harsh reaction conditions, formation of inevitable side products, time consuming methods for catalyst recovery, tedious workup, and use of expensive, unrecyclable and environmentally toxic catalysts and solvents. Therefore, introducing a simple synthetic method for the preparation of a range of 2-amino-3,5-dicarbonitrile-6-thio-pyridines using a recoverable non-hazardous catalyst is highly desirable.

In continuation of our works towards the introduction of new heterogeneous catalysts, recently we have focused our attention on the synthesis of new magnetically heterogeneous catalysts [41,42,43,44,45,46,47,48,49]. Along this line and to benefit the valuable applications of ILs in the synthesis of MNPs, herein, at first part of our studies, we report 2-hydroxyethylammonium acetate (2-HEAA) as a cost-effective and the first functionalized ILs for the synthesis of uniform Fe3O4 MNPs by the co-precipitation of Fe2+ and Fe3+ ions. 2-HEAA has been reported as a functionalized ILs for different types of reactions such as Knoevenagel condensation reaction, and synthesis of β-phosphonomalonates, 4-substituted 2-amino-4H-chromenes and bis(pyrazolyl)methanes [50,51,52]. In the second part of our studies, we have used the prepared Fe3O4 for the immobilization of 2-HEAA to synthesis a new supported IL (Scheme 1). We have also investigated the applicability of this newly synthesized catalyst with dual mode of activation as a magnetically heterogeneous catalyst for the one-pot three-component synthesis of 2-amino-3,5-dicarbonitrile-6-thio-pyridines.

Experimental section

General information

Chemicals were purchased from Merck Chemical Companies. NMR spectra were recorded in ppm in DMSO on a Bruker Avance DPX-400 instrument using TMS as internal standard. Elemental analyses for C, H and N were obtained using Elementar, Vario EL III. The purity of the products and the progress of the reactions were accomplished by TLC on silica gel polygram SILG/UV254 plates. TEM analysis was performed using TEM microscope (Philips CM10). FT-IR spectra were recorded on a Shimadzu Fourier Transform Infrared Spectrophotometer (FT-IR-8300). IR spectra were run on a Perkin Elmer 780 instrument. Thermogravimetric analysis (TGA) was performed using a Shimadzu thermogravimetric analyser (TG-50). Power X-ray diffraction (XRD) was performed on a Bruker D8-advance X-ray diffractometer with Cu Kα (λ = 0.154 nm) radiation.

Synthesis of Fe3O4 MNPs

In a typical procedure, aqueous solutions of FeCl2.4H2O (5 mL, 0.4 M) and FeCl3 (7.5 mL, 0.4 M) were added drop wise to 2-HEAA (32 mL) with vigorous stirring under N2 atmosphere at room temperature. A NaOH solution (1 M) was then added drop wise to the stirring mixture at room temperature to reach the reaction pH to 11. The resulting black dispersion was refluxed for 1 h at 90 °C. After cooling the black suspension to room temperature, MNPs were separated by an external magnet and washed several times with deionized water and ethanol. It was then dried under vacuum at 50 °C overnight to furnish Fe3O4 MNPs.

Synthesis of chloro-functionalized Fe3O4

The prepared Fe3O4 (1 g) was sonicated in dry toluene (15 mL) for 30 min. 3-Chloropropyltrimethoxysilane (1 mL) was added to the dispersed Fe3O4 in toluene, slowly heated to 105 °C and stirred at this temperature for 24 h. The resulting chloro-functionalized Fe3O4 was separated by an external magnet and washed with toluene, methanol and deionized water in turn, and dried under vacuum.

Synthesis of Fe3O4 supported with 2-hydroxyethylammonium chloride (Fe3O4-2-HEAC)

Ethanolamine (1 mL) was added to a magnetically stirred mixture of chloro-functionalized Fe3O4 (1 g) in dry toluene (15 mL). After refluxing for 24 h, the mixture was cooled to room temperature. The resulting Fe3O4-2-HEAC was separated by an external magnet, washed with toluene, ethanol and methanol and dried in oven under vacuum.

Synthesis of 2-hydroxyethylammonium acetate supported on Fe3O4 (Fe3O4-2-HEAA)

NaOAc (2 mmol) was added to a mixture of Fe3O4-2-HEAC (1 g) in water (20 mL) and vigorously stirred at room temperature for 24 h. Fe3O4-2-HEAA was separated from the mixture by an external magnet. It was washed with water until impurities of sodium chloride were removed (the absence of chloride ions was tested by AgNO3 solution). It was dried under reduced pressure to give Fe3O4-2-HEAA.

General procedure for the synthesis of 2-amino-3,5-dicarbonitrile-6-thio-pyridines in the presence of Fe3O4-2-HEAA

Fe3O4-2-HEAA (1 mol%, 0.016 g) was added to a stirred mixture of aldehyde (1 mmol), malononitrile (2 mmol) and thiol (1 mmol). The reaction mixture was stirred at 70 °C for the appropriate time (Table 2). EtOAc (10 mL) was added to the cooled reaction mixture. The catalyst was separated by an external magnet, washed with EtOAc, dried and reused for a consecutive run under the same reaction conditions. Evaporation of the solvent of the filtrate under reduced pressure gave the crude products. Pure product was obtained by recrystallization in aqueous EtOH.

Spectral data for 2-amino-3,5-dicarbonitrile-6-thio-pyridines

2-Amino-4-phenyl-6-phenylsulfanyl-pyridine-3,5-dicarbonitrile (1)

White solid, 1H NMR: δH 7.84 (2H, br, NH2), 7.63–7.59 (7H, m, Ar), 7.53–7.51 (3H, m, Ar) ppm; IR (KBr) (νmax/cm−1): 3471 (NH), 3349 (NH), 2196 (CN).

2-Amino-4-(4-chloro-phenyl)-6-phenylsulfanyl-pyridine-3,5-dicarbonitrile (2)

White solid, 1H NMR: δH 7.88 (2H, br, NH2), 7.68 (2H, d, J = 8.4 Hz, Ar), 7.61 (4H, d, J = 8.4 Hz, Ar), 7.53–7.50 (3H, m, Ar) ppm; IR (KBr) (νmax/cm−1): 3470 (NH), 3331 (NH), 2200 (CN).

2-Amino-4-(4-methyl-phenyl)-6-phenylsulfanyl-pyridine-3,5-dicarbonitrile (3)

White solid, 1H NMR: δH 7.81 (2H, br, NH2), 7.62–7.60 (2H, m, Ar), 7.52–7.50 (3H, m, Ar), 7.45 (2H, d, J = 7.6 Hz, Ar), 7.39 (2H, d, J = 8.0 Hz, Ar), 2.42 (3H, s, CH3) ppm; IR (KBr) (νmax/cm−1): 3460 (NH), 3318 (NH), 2200 (CN).

2-Amino-6-(4-chloro-phenylsulfanyl)-4-phenyl-pyridine-3,5-dicarbonitrile (4)

White solid, 1H NMR: δH 7.89 (2H, br, NH2), 7.63 (3H, d, J = 8.4 Hz, Ar), 7.60–7.56 (6H, m, Ar) ppm; IR (KBr) (νmax/cm−1): 3438 (NH), 3315 (NH), 2203 (CN).

2-Amino-6-(4-methoxy-phenylsulfanyl)-4-phenyl-pyridine-3,5-dicarbonitrile (5)

White solid, 1H NMR: δH 7.79 (2H, br, NH2), 7.59–7.55 (5H, m, Ar), 7.52 (2H, d, J = 8.4 Hz, Ar), 7.07 (2H, d, J = 8.4 H, Ar), 3.83 (3H, s, OCH3) ppm; IR (KBr) (νmax/cm−1): 3427 (NH), 3322 (NH), 2100 (CN).

2-Amino-6-(4-methyl-phenylsulfanyl)-4-phenyl-pyridine-3,5-dicarbonitrile (6)

Light-yellow solid, 1H NMR: δH 7.84 (2H, br, NH2), 7.63–7.57 (6H, m, Ar), 7.52–7.50 (3H, m, Ar), 2.51 (3H, s, CH3) ppm; IR (KBr) (νmax/cm−1): 3467 (NH), 3348 (NH), 2195 (CN).

2-Amino-4-(2-naphthyl)-6-phenylsulfanyl-pyridine-3,5-dicarbonitrile (7)

Light-yellow solid, 1H NMR: δH 8.18 (1H, s, Ar), 8.13 (1H, d, J = 8.8 Hz, Ar), 8.09–8.05 (2H, m, Ar), 7.89 (2H, br, NH2), 7.71–7.64 (5H, m, Ar), 7.54–7.52 (3H, m, Ar) ppm; IR (KBr) (νmax/cm−1): 3431 (NH), 3301 (NH), 2170 (CN).

2-Amino-4-(3-pyridinyl)-6-phenylsulfanyl-pyridine-3,5-dicarbonitrile (8)

White solid, 1H NMR: δH 8.80–8.78 (2H, m, Ar), 8.07 (1H, d, J = 7.6 Hz, Ar), 7.94 (2H, br, NH2), 7.67–7.61 (3H, m, Ar), 7.53–7.52 (3H, m, Ar) ppm; IR (KBr) (νmax/cm−1): 3360 (NH), 3290 (NH), 2200 (CN).

2-Amino-4-phenethyl-6-phenylsulfanyl-pyridine-3,5-dicarbonitrile (9)

White solid, 1H NMR: δH 7.77 (2H, br, NH2), 7.59–7.57 (2H, m, Ar), 7.50–7.47 (3H, m, Ar), 7.35 (2H, t, J = 7.2 Hz, Ar), 7.28–7.22 (3H, m, Ar), 3.03–2.99 (2H, m, CH2), 2.92–2.89 (2H, m, CH2) ppm; IR (KBr) (νmax/cm−1): 3442 (NH), 3344 (NH), 2215 (CN). 13C NMR (100.6 MHz, DMSO-d6): δC (ppm) 166.3, 160.4, 160.1, 139.9, 135.2, 130.1, 129.9, 129.1, 128.7, 127.6, 127.1, 115.4, 115.0, 93.9, 87.6, 36.1, 35.1.

2-Amino-4-methyl-6-phenylsulfanyl-pyridine-3,5-dicarbonitrile (10)

White solid, 1H NMR: δH 7.71 (2H, br, NH2), 7.58–7.56 (2H, m, Ar), 7.50–7.47 (3H, m, Ar), 2.46 (3H, s, CH3) ppm; IR (KBr) (νmax/cm−1): 3396 (NH), 3310 (NH), 2202 (CN).

2-Amino-4-phenyl-6-(n-butylsulfanyl)-pyridine-3,5-dicarbonitrile (11)

White solid, 1H NMR: δH (ppm) 8.04 (2H, br, NH2), 7.58–7.53 (5H, m, Ar), 3.25 (2H, t, J = 7.2 Hz, CH2), 1.69–1.62 (2H, m, CH2), 1.48–1.39 (2H, m, CH2), 0.93 (3H, t, J = 7.2 Hz, CH3) ppm; IR (KBr) (νmax/cm−1): 3452 (NH), 3313 (NH), 2200 (CN).

1,4-bis(2-amino-6-phenylsufanyl-4-pyridyl-3,5-dicarbonitrile)benzene (12)

White solid, 1H NMR: δH 7.90 (4H, br, NH2), 7.80 (4H, s, Ar), 7.64–7.62 (4H, m, Ar), 7.54–7.51 (6H, m, Ar) ppm; IR (KBr) (νmax/cm−1): 3407 (NH), 3325 (NH), 2216 (CN). 13C NMR (100.6 MHz, DMSO-d6): δC (ppm) 166.8, 160.2, 158.2, 139.5, 136.1, 135.3, 129.9, 129.4, 127.5, 115.7, 115.4, 93.7, 87.5.

Results and discussion

Characterization of Fe3O4-2-HEAA

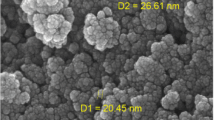

At first, Fe3O4 MNPs were synthesized by a chemical co-precipitation technique of ferric and ferrous ions in alkali solution in the presence of 2-HEAA as a functionalized and cost-effective ionic liquid. The size and structure of Fe3O4 MNPs were evaluated using transmission electron microscopy (TEM). TEM image demonstrated spherical-like shape for Fe3O4 MNPs with a narrow size distribution (2–7 nm) and an average diameter of about 5 nm (Fig. 1a). To show the role of ILs in the synthesis of MNPs, a similar reaction was studied in the absence of ILs. TEM image showed the influence of ILs on the morphology of Fe3O4 MNPs. The obtained MNPs were not uniform in shape and contain a mixture of spherical and rod-like shapes (Fig. 1b). When the reaction was performed in the presence of ethylammonium acetate (EAA), Fe3O4 MNPs with uniform spherical-like shape and sizes between 6 and 12 nm were obtained (Fig. 1c). These results showed the role of hydroxyl group in 2-HEAA on the size of MNPs and indicates that 2-HEAA can act as a functionalized ionic liquid in this method. It is worth to mention that this is the first report for the synthesis of Fe3O4 MNPs via a co-precipitation method using a functionalized ILs. Moreover, the most popular ILs which have been used for the synthesis of Fe3O4 MNPs incorporate expensive cations, such as alkyl methyl imidazolium or dialkyl imidazolium, and expensive anions, such as tetrafluoroborate or hexafluorophosphate [9, 53, 54]. The existing methods also suffer from one or more of these drawbacks such as requiring additives, microwave or co-solvents [9, 53,54,55,56,57].

The synthesized Fe3O4 MNPs mostly exist in cubic structure using XRD pattern (Fig. 2). All the diffraction peaks in the XRD pattern were indexed to the structure known for the Fe3O4 crystal and no other peaks were detected. In addition, the average particle size of Fe3O4 MNPs calculated using Debye–Scherrer’s formula and was 10 nm.

Fe3O4 MNPs were then allowed to react with an appropriate concentration of 3-chloropropyl trimethoxysilane to give chloro-functionalized Fe3O4. The obtained chloro-functionalized Fe3O4 was reacted with ethanolamine to produce Fe3O4 supported with 2-hydroxyethylammonium chloride (Fe3O4-2-HEAC). To this end, the reaction of Fe3O4-2-HEAC with NaOAc in water led to the formation of 2-hydroxyethylammonium acetate supported on Fe3O4 MNPs (Fe3O4-2-HEAA) (Scheme 1).

TEM images of Fe3O4-2-HEAA (Fig. 3) demonstrated that supporting of ILs leads to a small increase of the average particle size to ~ 6–7 nm, but the nanoparticles morphology remain unchanged.

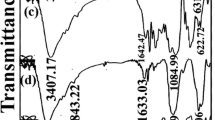

FT-IR spectra of Fe3O4 and Fe3O4-2-HEAA were shown in Fig. 4. The band at around 557–690 cm−1 was assigned to the stretching vibrations of Fe–O bond in these compounds. The peaks positioned at 2910, 2930 and 1480 cm−1 in the FT-IR spectrum of Fe3O4-2-HEAA were related to the stretching and bending of the CH2 bonds, respectively. Si–O stretching bond was observed in the range of 1000–1110 cm−1. The anchoring of 2-HEAA on Fe3O4 was evidenced by the presence of bands at 1580 and 1615 cm−1 corresponding to stretching vibrations of C=O and C–N+ bonds which overlaps with OH vibration of adsorbed water (1635 cm−1).

Thermogravimetric analysis (TGA) was used to study the thermal behavior of the catalyst. TGA of Fe3O4-2-HEAA showed two weight losses at different temperatures (Fig. 5). The first weight loss observed below 207 °C was attributed to adsorbed water and solvents from the catalyst. The second and main weight loss was about 13.9 wt%, which could be attributed to the loss of organic components attached to the surface of Fe3O4 and verified the high thermal stability of the Fe3O4-2-HEAA. According to the TGA, the amount of organic components functionalized on Fe3O4 was calculated to be 0.68 mmol g−1. These results are in good agreement with the elemental analysis data (N = 0.86% and C = 3.56%).

In continuation of our recent research programs on the development of novel methods for the synthesis of 2-amino-3,5-dicarbonitrile-6-thio-pyridines [41, 42], in this paper, we have studied the applicability of Fe3O4-2-HEAA as a new magnetically recyclable catalyst for the one-pot synthesis of 2-amino-3,5-dicarbonitrile-6-thio-pyridines directly from aldehydes, malononitrile and thiols.

Catalytic activity of Fe3O4-2-HEAA in the synthesis of 2-amino-3,5-dicarbonitrile-6-thio-pyridines

In the preliminary stage of investigation, one-pot reaction of benzaldehyde, malononitrile and thiophenol was chosen as a model reaction to optimize the reaction conditions. The model reaction was studied in different conditions (Table 1). We found that in the presence of 1 mol% of Fe3O4-2-HEAA, the desired product 1 was obtained in the best yield at 70 °C under solvent-free conditions (entry 1). When 0.5, 0.25 and 0.1 mol% of the catalyst was used, the yield of the desired product was decreased (entries 2–4). The importance of the catalyst was indicated by performing the reaction in the presence of Fe3O4 and in the absence of the catalyst. The results of these studies showed that any quantity of the desired product was not formed even after 24 h, and α, β-unsaturated malonate was detected as the only product (entries 12, 13). A similar reaction in the presence of 2-HEAA as a non-supported IL gave the desired product in moderate yield (41%) due to the formation of by-products (entry 14). This result indicated that the catalytic efficiency of IL was increased by immobilization onto Fe3O4.

The reaction of different aldehydes and thiols with malononitrile was then investigated to confirm the generality of the present method (Table 2). As shown in Table 2, the reaction of various aldehydes and thiols containing electron-donating and electron-withdrawing groups with malononitrile in the presence of Fe3O4-2-HEAA afforded the corresponding pyridines in good to high yields (entries 2–6). The reaction of polyaromatic and heteroaromatic aldehydes underwent the condensation reaction to produce the desired products in good yields (entries 7 and 8). This method is also applicable for the synthesis of 2-amino-3,5-dicarbonitrile-6-thio-pyridines using aliphatic aldehydes and thiols in 80–85% yields (entries 9–11). Interestingly, Fe3O4-2-HEAA efficiently catalyzed the reaction of both carbonyl groups in terephthalaldehyde with malononitrile and thiophenol to give a structurally complex pyridine derivative 12 in 93% yield after 15 min (Scheme 2).

The recyclability of Fe3O4-2-HEAA was investigated in a model reaction of benzaldehyde, thiophenol and malononitrile under optimized reaction conditions. After the reaction was completed, EtOAc was added to the reaction mixture and the catalyst was separated using an external magnet (Fig. 6), washed with EtOAc, dried 30 min at 100 °C and reused in subsequent runs. The catalyst was found to retain its activity for a minimum of five reaction cycles and displayed almost high catalytic performance with over 85% yields (Fig. 7).

The recovered catalyst after five reaction cycle was analyzed by TEM and FT-IR. The TEM image of used Fe3O4-2-HEAA was illustrated a uniform and regular morphology of the catalyst (Fig. 8). Moreover, the comparison of FT-IR spectrum of used Fe3O4-2-HEAA (Fig. 9) with the fresh catalyst showed the fact that the structure of Fe3O4-2-HEAA remained intact after five recoveries.

We have proposed a mechanism for the synthesis of 2-amino-3,5-dicarbonitrile-6-thio-pyridine derivatives in the presence of Fe3O4_2-HEAA in Scheme 3. The first step of the process involves the Knoevenagel condensation of an aldehyde with malononitrile to form the corresponding Knoevenagel product. The reaction proceeds through thiolate addition to nitrile of the Knoevenagel product followed by Michael addition of the second molecule of malononitrile to the adduct and produces dihydropyridine. Aromatization of dihydropyridine under the reaction conditions gives pyridine 1–12. In this three-component reaction, it is supposed that dual activation of substrates by Fe3O4-2-HEAA has taken place. The Lewis base moiety of the catalyst (OH) activates the malononitrile and thiol, and its acidic functional group (ammonium ion) activates the aldehyde and nitrile of the Knoevenagel product.

Finally, the efficiency of Fe3O4-2-HEAA was compared with reported reagents or catalysts in the synthesis of 1 (Table 3). As demonstrated in Table 3, Fe3O4-2-HEAA is the most efficient catalyst for the synthesis of 2-amino-3,5-dicarbonitrile-6-thio-pyridines in terms of turnover number (TON) and turnover frequency (TOF).

Conclusion

In summary, we have reported a facile, economical and environmentally friendly method for the synthesis of uniform Fe3O4 magnetic nanoparticles via a co-precipitation method in the presence of 2-hydroxyethylammonium acetate (2-HEAA) as a cost-effective ILs. This is the first report for the synthesis of iron oxide using a functionalized ILs. The synthesized nanoparticles were used as a solid material for supporting 2-HEAA. The newly synthesized Fe3O4-2-HEAA was then successfully applied as a magnetically recyclable heterogeneous catalyst with dual mode of activation for the one-pot synthesis of 2-amino-3,5-dicarbonitrile-6-thio-pyridine derivatives. The catalyst was easily separated from the reaction media by an external magnet and reused five times without any obvious loss in activity. Using a cost-effective and reusable catalyst with high TON and TOF, being amenable for both aromatic and aliphatic aldehydes/thiols and short reaction time (5–15 min) are the other advantages of this protocol.

References

A. Kumar, S.S. Pawar, J. Org. Chem. 69, 1419 (2004)

R.A. Brown, P. Pollet, E. McKoon, C.A. Eckert, C.L. Liotta, P.G. Jessop, J. Am. Chem. Soc. 123, 1254 (2001)

W. Leitner, Nature. 423, 930 (2003)

B.C. Ranu, R. Jana, J. Org. Chem. 70, 8621 (2005)

T. Zhu, D. Jiang, B. Wang, L. Han, J. Liu, J. Huang, D. Zhang, Sun, Green Chem. 7, 514 (2005)

J.P. Hallett, T. Welton, Chem. Rev. 111, 3508 (2011)

C. Vollmer, Janiak, Coord. Chem. Rev. 255, 2039 (2011)

Z. Li, Z. Jia, Y. Luan, T. Mu, Curr. Opin. Solid State Mater. Sci. 12, 1 (2008)

Y. Wang, H. Yang, Chem. Eng. J. 147, 71 (2009)

S.-W. Cao, Y.-J. Zhu, G.-F. Cheng, Y.-H. Huang, J. Hazard. Mater. 171, 431 (2009)

Z. Ma, J. Yu, S. Dai, Adv. Mater. 22, 261 (2010)

J. Dupont, J.D. Scholten, Chem. Soc. Rev. 39, 1780 (2010)

V.I. Parvulescu, C. Hardacre, Chem. Rev. 107, 2615 (2007)

S.W. Tang, A.M. Scurto, B. Subramaniam, J. Catal. 268, 243 (2009)

N. Yan, Y. Yuan, R. Dykeman, Y. Kou, P.J. Dyson, Angew. Chem. 122, 5681 (2010)

S. Sobhani, M. Honarmand, J. Iran. Chem. Soc. 9, 661 (2012)

S. Sobhani, M. Honarmand, Synlett. 24, 236 (2013)

T. Selvam, A. Machoke, W. Schwieger, Appl. Catal. A 445, 92 (2012)

Y.-H. Kim, S. Shin, H.-J. Yoon, J.W. Kim, J.K. Cho, Y.-S. Lee, Catal. Commun. 40, 18 (2013)

J. Miao, H. Wan, Y. Shao, G. Guan, B. Xu, J. Mol. Catal. A Chem. 348, 77 (2011)

X. Zheng, S. Luo, L. Zhang, J.-P. Cheng, Green Chem. 11, 455 (2009)

S. Azad, B.B.F. Mirjalili, RSC Adv. 6, 96928 (2016)

M.B. Gawande, P.S. Branco, R.S. Varma, Chem. Soc. Rev. 42, 3371 (2013)

J. Li, F. Wang, H. Chen, Jing, RSC Adv. 7, 4237 (2017)

X. Zheng, L. Zhang, J. Li, S. Luo, J.-P. Cheng, Chem. Commun. 47, 12325 (2011)

R. Mrówczyński, A. Nan, J. Liebscher, RSC Adv. 4, 5927 (2014)

K. Guo, R. Mutter, W. Heal, T.R. Reddy, H. Cope, S. Pratt, M.J. Thompson, B. Chen, Eur. J. Med. Chem. 43, 93 (2008)

B.C. May, J.A. Zorn, J. Witkop, J. Sherrill, A.C. Wallace, G. Legname, S.B. Prusiner, F.E. Cohen, J. Med. Chem. 50, 65 (2007)

M.T. Cocco, C. Congiu, V. Lilliu, V. Onnis, Eur. J. Med. Chem. 40, 1365 (2005)

S. Ray, P. Das, A. Bhaumik, M. Pramanik, C. Mukhopadhyay, Recycl. Catal. 1, 34 (2012)

M.N. Khan, S. Pal, T. Parvin, L.H. Choudhury, RSC Adv. 2, 12305 (2012)

M. Sridhar, B.C. Ramanaiah, C. Narsaiah, B. Mahesh, M. Kumaraswamy, K.K. Mallu, V.M. Ankathi, P.S. Rao, Tetrahedron Lett. 50, 3897 (2009)

S. Mishra, R. Ghosh, Synth. Commun. 42, 2229 (2012)

P.V. Shinde, V.B. Labade, B.B. Shingate, M.S. Shingare, J. Mol. Catal. A Chem. 336, 100 (2011)

M.A. Ghasemzadeh, Acta Chim. Slov. 59, 697 (2012)

J. Safaei-Ghomi, M.A. Ghasemzadeh, J. Sulfur Chem. 34, 233 (2013)

M.L. Kantam, K. Mahendar, S. Bhargava, J. Chem. Sci. 122, 63 (2010)

S. Banerjee, G. Sereda, Tetrahedron Lett. 50, 6959 (2009)

P. Davoodnia, H. Attar, A. Eshghi, N. Morsali, A. Tavakoli-Hoseini, Tavakoli-Nishaburi, Asian J. Chem. 23, 1273 (2011)

B.C. Ranu, R. Jana, S. Sowmiah, J. Org. Chem. 72, 3152 (2007)

S. Sobhani, M. Honarmand, C. R. Chim. 16, 279 (2013)

S. Sobhani, M. Honarmand, Appl. Catal. A 467, 456 (2013)

S. Sobhani, Z. Pakdin-Parizi, R. Nasseri, J. Chem. Sci. 125, 975 (2013)

S. Sobhani, M.S. Ghasemzadeh, M. Honarmand, F. Zarifi, RSC Adv. 4, 44166 (2014)

S. Sobhani, F. Zarifi, RSC Adv. 5, 96532 (2015)

S. Sobhani, F. Zarifi, J. Skibsted, ChemistrySelect. 1, 2945 (2016)

S. Sobhani, F. Zarifi, J. Skibsted, New J. Chem. 41, 6219 (2017)

S. Sobhani, F. Zarifi, J. Skibsted, ACS Sustain. Chem. Eng. 5, 4598 (2017)

S. Sobhani, F. Khakzad, Appl. Organomet. Chem. 31, e3877 (2017)

A. Yue, Y. Mao, M. Wei, Lü, Catal. Commun. 9, 1571 (2008)

S. Sobhani, M. Honarmand, Catal. Lett. 143, 476 (2013)

S. Sobhani, M. Honarmand, Can. J. Chem. 90, 798 (2012)

C.-M. Lee, H.-J. Jeong, S.T. Lim, M.-H. Sohn, D.W. Kim, ACS Appl. Mater. Interfaces. 2, 756 (2010)

Y. Wang, S. Maksimuk, R. Shen, H. Yang, Green Chem. 9, 1051 (2007)

J. Hu, X. Hu, A. Chen, S. Zhao, J. Alloys Compd. 603, 1 (2014)

F.C. Oliveira, L.M. Rossi, R.F. Jardim, J.C. Rubim, J. Phys. Chem. C 113, 8566 (2009)

S.-W. Cao, Y.-J. Zhu, Acta Mater. 57, 2154 (2009)

K.N. Singh, S.K. Singh, Arkivoc. xiii, 153 (2009)

R. Mamgain, R. Singh, D.S. Rawat, J. Heterocycl. Chem. 46, 69 (2009)

N.M. Evdokimov, A.S. Kireev, A.A. Yakovenko, M.Y. Antipin, I.V. Magedov, A. Kornienko, J. Org. Chem. 72, 3443 (2007)

N.M. Evdokimov, I.V. Magedov, A.S. Kireev, A. Kornienko, Org. Lett. 8, 899 (2006)

Z.Q. Wang, Z.M. Ge, T.M. Cheng, R.T. Li, Synlett 2009, 2020 (2009)

A. Shaikh, G. Shaikh, Nazeruddin, J. Chem. Pharm. Res. 4, 4953 (2012)

V. Kamble, S. Atkore, P. Pisal, M. Sadaf, R.V. Thakre, Iran. Chem. Commun. 4, 186 (2016)

M.S. Su, X.J. Ji, B.B. Zhao, M. Tian, J.J. Ma, J. Chem. Soc. Pak. 37, 1130 (2015)

U.V. Desai, M.A. Kulkarni, K.S. Pandit, A.M. Kulkarni, P.P. Wadgaonkar, Green Chem. Lett. Rev. 7, 228 (2014)

M. Thimmaiah, P. Li, S. Regati, B. Chen, J.C.-G. Zhao, Tetrahedron Lett. 53, 4870 (2012)

S. Takale, J. Patil, V. Padalkar, R. Pisal, A. Chaskar, J. Braz. Chem. Soc. 23, 966 (2012)

M.R.P. Heravi, F. Fakhr, Tetrahedron Lett. 52, 6779 (2011)

J.B. Gujar, M.A. Chaudhari, D.S. Kawade, M.S. Shingare, Tetrahedron Lett. 55, 6939 (2014)

P.V. Shinde, B.B. Shingate, M.S. Shingare, Chin. J. Chem. 29, 1049 (2011)

Acknowledgements

Financial support of this project by University of Birjand Research Council is appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sobhani, S., Nasseri, F. & Zarifi, F. Unique role of 2-hydroxyethylammonium acetate as an ionic liquid in the synthesis of Fe3O4 magnetic nanoparticles and preparation of pyridine derivatives in the presence of a new magnetically recyclable heterogeneous catalyst. J IRAN CHEM SOC 15, 2721–2732 (2018). https://doi.org/10.1007/s13738-018-1460-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-018-1460-6