Abstract

Hybrid hydrogels based on pre-gelatinized starch were synthesized by inverse emulsion polymerization through modifying the starch with a glycidyl-crosslinked microgel. Glycidyl-crosslinked microgel is a special latex with high ability to impart hydrophilic characteristics to various substrates. Glycidyl-crosslinked microgel latexes with various structures were synthesized, and the effect of latex type on swelling capacity of the hybrid hydrogels based on pre-gelatinized starch was investigated. The highest swelling capacity was achieved for a pre-gelatinized starch modified with a glycidyl-crosslinked microgel latex based on poly(acrylic acid, sodium acrylate, acrylamide, 2-acrylamide-2 methyl propane sulfonic acid) (AA–SA–AM–AMPS). The swelling values of this hybrid hydrogel in distilled water and saline solution were 52.4 and 28.8 g/g, respectively. A key advantage of these hybrid hydrogels is that starch constitutes 64% of their structure. Given the fact that such hybrid hydrogels display low absorbency under load (AUL), they were surface crosslinked using microwave heating instead of conventional heating. Ethylene glycol diglycidyl ether was used as surface crosslinker. The AUL of the surface crosslinked hybrid hydrogels was increased by 85%. The hydrogels were characterized using FTIR, thermogravimetric analysis, scanning electron microscopy, and rheological measurements.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Starch is the second most readily available natural polymer [1]. As a polysaccharide, it consists of repeating d-glucopyranose units, linked together with α-1,4 and α-1,6 glycosidic bonds [2]. Pre-gelatinized starch is a modified starch that, in addition to its solubility in cold water, it possesses a high water holding capacity. It is a preferred starch, which is used in industry to avoid highly viscous gels [3]. The potential advantages of using starch in its gelatinized state have been extensively reviewed [4].

Superabsorbent hydrogels are hydrophilic polymer networks that can absorb and retain large amount of water and aqueous solutions [5, 6], and have been used in both hygienic and non-hygienic applications extensively [7]. Superabsorbent hydrogel structures can be synthetic, natural, or synthetic-natural hybrid [5]. Hybrid hydrogels are mostly prepared through graft polymerization of acrylic monomers such as acrylic acid and acrylamide, 2-acrylamido-2-methyl propane sulphonic acid (AMPS) onto natural polymers [5, 6]. Although hybrid hydrogels can be prepared based on proteins or polysaccharides, those based on polysaccharides are being extensively used due to their variety and accessibility, low price, and remarkable rheological properties in aqueous media [8,9,10].

Preparation of hybrid hydrogels through graft polymerization has several shortages such as low grafting efficiency, homopolymerization of acrylic monomers, low content of natural component, and low absorbency under load (AUL). A lot of work has been done on hybrid hydrogels containing natural polymers such as collagen [11], starch [12], carrageenan [13], agarose [14], and chitosan [15].

Glycidyl-crosslinked microgels have been recently prepared using inverse emulsion polymerization of acrylic monomers and diglycidyl chemicals as crosslinker. These glycidyl-crosslinked microgels possess considerably higher thickening properties than microgels crosslinked with the conventional multifunctional acrylic crosslinkers such as methylene bisacrylamide or poly(ethylene glycol) diacrylate [16]. Moreover, glycidyl-crosslinked microgel latex has the ability to induce absorbency to different substrates. The promotion of high water absorbency to polyester fiber was reported using glycidyl-crosslinked microgel, where swelling capacity of the polyester fiber was increased to 75 g/g [17].

Due to their low AUL, the conventional hybrid hydrogels based on starch cannot be used in hygiene or agricultural applications. Therefore, as a common practice to increase AUL of synthetic superabsorbent materials, such hydrogels need to be crosslinked at their surface to achieve desirable mechanical and swelling properties [18]. The AUL enhancement after surface modification depends on several parameters including surface crosslinker type, surface crosslinker concentration, surface treatment temperature, and surface treatment time. Surface crosslinking reaction is carried out between acrylic acid of SAP and surface crosslinking agents, i.e., ethylene glycol diglycidyl ether, polyethylene glycol diglycidyl ether, and epoxy silanes for AUL enhancement in full acrylic superabsorbents [18,19,20].

In this research, glycidyl-crosslinked microgel latex was used to induce absorbency to pre-gelatinized starch in preparation of starch-based hybrid hydrogels. We first prepared glycidyl-crosslinked microgels by inverse emulsion polymerization of 1,4-butandiol diglycidyl ether or poly(ethylene glycol) diglycidyl ether, and then modified the pre-gelatinized starch with the prepared glycidyl-crosslinked microgel to induce absorbency to its hybrid hydrogel. Finally, the surface of the hydrogel was crosslinked to enhance its AUL. Surface crosslinking of superabsorbent hydrogels is carried out mostly through the conventional heating at high temperature for long period of time [18]. In this research, the surface crosslinking was achieved using a more efficient microwave process.

Experimental

Materials

Acrylic acid (AA, Merck), acrylamide (AM, Merck), and 2-acrylamide-2-methyl propane sulfonic acid (AMPS, Fluka) as monomers, and 2,2′-azobis-isobutyronitrile (AIBN, Fluka, recrystallized in ethanol) as initiator were used. Pre-gelatinized starch from Glucozan Co., Iran, was used. Poly(ethylene glycol) diglycidyl ether (PEGDGE), 1,4-butan-diol-diglycidyl-ether (1,4-BDDGE), and ethylene glycol diglycidyl ether (EGDGE) (Sigma-Aldrich) as crosslinker were used as received. Sorbitan monooleate (Span 80, HLB 4.3) and poly(ethylene glycol) sorbitan monooleate (Tween 80, HLB 15) were purchased from Merck and used as emulsifier. Liquid paraffin (ρ = 0.85 g/cm3) from Farshid Shahrza Co., (LP140) was used as continuous phase in inverse emulsion polymerization.

Synthesis

Synthesis of glycidyl-crosslinked microgel through inverse emulsion polymerization

Synthesis of microgel latex was performed in a 250 mL four-neck glass reactor equipped with an agitator, a condenser, a nitrogen inlet gas, and an injection inlet pump. The continuous phase was composed of paraffin, Span 80, and Tween 80 was stirred for 15 min using a magnetic stirrer, and then transferred into the reactor. The aqueous phase including monomers, crosslinker, and water were mixed and added dropwise to the continuous phase for 30 min. The mixture under nitrogen blanket was kept under mixing at 350 rpm for 30 min. The slurry was then heated to 70 °C, kept at this temperature, the initiator was added into, and the reaction was continued for 4 h. The formulation for the synthesized latexes is shown in Table 1.

Preparation of the hybrid hydrogel

A certain amount of the glycidyl-crosslinked microgel was added to a certain amount of pre-gelatinized starch to carry out a chemical reaction on starch surface for achieving superabsorbency. After mixing, the mixture was placed in an oven at 70 °C for 2 h, and then washed several times with acetone to remove paraffin, impurities and unreacted polymer latex. Finally, the product was dried out in an oven at 50 °C for 3 h.

Surface crosslinking of pre-gelatinized starch hybrid hydrogel

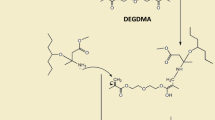

EGDGE was used as a crosslinker in surface modification of the hybrid hydrogel. Given amounts of water and acetone (10:90) and crosslinker were added to 1.5 g of hybrid hydrogel prepared in the previous step. Surface treatment was carried out using both conventional heating and microwaving for a given time and temperature. Figure 1 shows a general outline of the steps involved in the reaction.

Characterization

Viscosity measurements

The apparent viscosity of the synthesized latex powder in distilled water (1 g sample in 100 mL solvent) was measured at room temperature with a digital rotational viscometer (model Brookfield, Selecta, Spain).

FTIR spectroscopy

A model EQUINOX55 spectrophotometer (Germany) was used to obtain FTIR spectrum of the plates containing the sample with KBr matrix.

Microstructural and elemental analysis

A scanning electron microscope (model S360, Cambridge Company) equipped with an energy-dispersive X-ray spectrometer (EDX, INCA model, Ofordinst) was used to perform a microstructural study on the samples. A thin layer of palladium–gold alloy was used to coat the samples.

TGA thermogram

Thermogravimetric analysis (TGA) was performed on powder samples using a TGA-PL (PL1500, England) under nitrogen at a heating rate of 10 °C/min. Samples used in FTIR, TGA, and SEM–EDX tests were immersed in distilled water to remove their sol content before analysis.

Swelling measurements

A tea bag method [21] was used to measure the swelling capacity of the hydrogel samples. Thus, 0.2 g of the hydrogel was added into 100 mL distilled water and allowed to fully swell at room temperature. The swelling capacity was calculated using the following equation:

where ws and wd are the weights of the swollen and dried gels, respectively.

Absorbency under load (AUL) measurements

A weighed dried SAP sample (0.5 g) was uniformly dispersed on the surface of polyester gauze, which had been located on a macro-porous sintered glass filter plate placed in a Petri dish. A cylindrical solid load (Teflon, d = 60 mm) was put on the dry SAP particles, while it could be freely slipped in a glass cylinder. The desired load of 0.3 psi was applied on each sample. Then, a 0.9% saline solution was placed in a Petri dish. After 30 min, the maximally swollen particles were removed and re-weighed [20]. AUL value was calculated by Eq. (1).

Rheology

The rheological measurement was performed on the swollen samples with the concentration of 10% (1 g sample in 10 g distilled water). A para-physical vibrational device (model MCR 300 with parallel pages at 25 °C) was used where the page diameter and distance were 25 and 3 mm, respectively [22].

Results and discussion

Glycidyl-crosslinked microgel synthesis

Glycidyl-crosslinked microgel latexes with different structures were synthesized. The products displayed high thickening properties which made them suitable for imparting hydrophilic properties to substrate.

Figure 2 shows the apparent viscosity of synthesized latexes versus shear rate. According to this figure, viscosity decreases with increasing shear rate. This behavior can be seen in all the microgels swollen in water. Such observation refers to the pseudoplastic behavior of the synthesized microgels [23, 24]. At low shear rates, the relaxation time was long, while at high shear rates, the microgels were deformed easily and apparent viscosity was reduced. Poly(acrylic acid, sodium acrylate, acrylamide, 2-acrylamide-2-methyl propane sulfonic acid) (AA–SA–AM–AMPS) having 0.2 g of PEGDGE crosslinker shows the highest apparent viscosity.

Effect of latex type on swelling capacity of the modified pre-gelatinized starch

Table 2 shows the swelling capacity of the modified pre-gelatinized starch with different latexes. The swelling capacities of pure sample in distilled water and saline solution (NaCl 0.9% solution) are 9.2 and 6.1 g/g, respectively. Swelling of modified pre-gelatinized starch was considerably increased after treatment with the acrylic latex. For the pre-gelatinized starch modified by poly(AA–SA–AM–AMPS) latex, the highest swelling capacities in distilled water and saline solution are 52.3 and 28.8 g/g, respectively.

The higher absorbency of poly (AA–SA–AM–AMPS)-based hydrogel in saline solution can be attributed to the ionizing part of polymer latex. The increased ionic contribution in a hydrogel increased ionic mobility inside the gel phase, which led to swelling enhancement. Furthermore, the presence of AMPS in hydrogel structure generally causes increased salt absorbency [25].

Modification of the pre-gelatinized starch by poly(AA–SA–AM–AMPS) and addition of 0.2 g of crosslinker was carried out more efficiently than other latexes, and enhanced the swelling capacity. Therefore, the hybrid hydrogel prepared using the above latex was chosen for further study, including other analyses and surface crosslinking.

FTIR analysis

Figure 3 shows the FTIR spectrum of the unmodified pre-gelatinized starch, poly(AA–SA–AM–AMPS) and the pre-gelatinized starch modified by poly(AA–SA–AM–AMPS) latices.

In poly(AA–SA–AM–AMPS) FTIR spectrum, the peak at 1569.8 cm−1 corresponds to the asymmetrical tension of CO group of carboxylate ions. In addition, the medium intensity peak at 1455.6 cm−1 is due to the symmetrical tension of CO group of carboxylate ions. The absorption peaks at 1045.6 cm−1 which were observed for AMPS revealed the existence of SO group [26,27,28].

Considering the spectrum obtained for pre-gelatinized starch, the peak at 3433 cm−1 could be related to OH group. The band at 2922.6 cm−1 was attributed to the C–H tension vibration and the band at 1054.2 cm−1 was due to the tension of CH2–O–CH2 [21, 29]. Considering the spectrum of the unmodified and modified pre-gelatinized starch, the high intensive peak at 1735 cm−1 disappeared after the modification of pre-gelatinized starch by poly(AA–SA–AM–AMPS), confirming that a chemical reaction was carried out between the acrylic latex and pre-gelatinized starch.

The peak related to carboxamide which appeared in poly(AA–SA–AM–AMPS) spectral absorption at 1670.1 cm−1 disappeared after the modification reaction with pre-gelatinized starch, indicating that a reaction occurred between the carboxamide and functional groups on the pre-gelatinized starch.

Morphology

The images from scanning electron microscopy (SEM) taken for pre-gelatinized starch, pre-gelatinized starch modified by poly(AA–SA–AM–AMPS), and surface crosslinked hydrogel are demonstrated in Fig. 4. The pre-gelatinized starch particles have smooth surface with no porosity. A new morphology was observed for the samples modified by glycidyl-crosslinked microgel latex. The latex has uniformly covered the starch surface. After the modification reaction, the surface area between the pre-gelatinized starch and poly(AA–SA–AM–AMPS) was increased.

Figure 5 demonstrates the elemental map of the elements including Na, S, and N (Na map, S map, and N map) obtained from the surface of the hydrogel synthesized from pre-gelatinized starch modified by poly(AA–SA–AM–AMPS) polymer latexes. This figure confirms the presence of sulfur and sodium elements in the sample modified by glycidyl-crosslinked microgel latex. Since these elements are not present in the pre-gelatinized starch, they certainly originated from poly(AA–SA–AM–AMPS). In addition, the image revealed a uniform dispersion of these elements on the surface of the pre-gelatinized starch, which could be attributed to the uniform reaction between the starch and glycidyl-crosslinked microgel latex.

Contribution of different atoms in the structure of two samples of poly(AA–SA–AM–AMPS) and pre-gelatinized starch modified by poly(AA–SA–AM–AMPS), shown in Table 3, was obtained by SEM–EDX. By the substitution of the data in Table 3 into Eq. (2), the percentages of natural and synthetic components present in the basic hydrogels of pre-gelatinized starch were calculated as follows:

In this equation, w2 is the atomic percentage of the elements Na, S, or N in the synthesized hydrogel and w1 is the atomic percentage of the above-mentioned elements in poly(AA–SA–AM–AMPS). After performing the above calculations, the percentage of natural component in the hydrogel synthesized from the pre-gelatinized starch was found to be almost 64% and the percentage of synthetic component in these products was about 36. This result shows that the contribution of natural part in the hybrid hydrogel is significantly high, and it is much higher than that in those prepared by grafting method. Table 4 shows the natural part contribution in hybrid hydrogels reported in the literature previously. Natural parts of the hybrid hydrogels based on starch [30], tara gum [31], chitosan [32], and sodium alginate [33] have been already reported (15, 2, 1, and 6), respectively. The results for other natural-based hybrid hydrogels are also seen in this table [34,35,36]. The results indicate that this new method has great potential in the economic production of environmentally friendly hybrid hydrogels based on glycidyl-crosslinked microgel latex due to high contribution of natural part in the structure of these hydrogels.

TGA analysis

Figure 6 shows the thermogravimetric curves of the unmodified and poly(AA–SA–AM–AMPS)-modified pre-gelatinized starch. There are two degradation stages for unmodified sample. The first stage between 25 and 100 °C is related to water removal. The second stage which can be observed between 280 and 400 °C is related to the degradation of the main chains of polysaccharides where the largest amount of sample is destroyed. The degradation pattern of the modified pre-gelatinized starch is completely different from that of unmodified sample. The thermal degradation process of the modified pre-gelatinized starch has three stages. The first stage is related to the water discharge from the sample. The second stage is for destruction of microgel part (mostly AMPS) and the third stage belongs to the degradation of natural part. In contrast, in an unmodified sample, the TGA thermogram of the modified pre-gelatinized starch has no sharp transition. The TGA test results showed that pre-gelatinized starch is successfully modified and its thermal degradation behavior is certainly changed.

The initial decomposition temperature (IDT) was reduced from about 280 °C in the unmodified sample to 180 °C in the hydrogel of the modified sample. This reduction was due to the instability of sulfonic acid groups in the polymers containing AMPS and desulfonation reaction. The AMPS-containing hydrogel is very sensitive to heat, and it has a low thermal stability. Due to the presence of less stable sulfonic groups in the structure of pre-gelatinized starch modified by poly(AA–SA–AM–AMPS), it is susceptible to degradation and thus the modified sample shows lower IDT than unmodified one [37].

The char yields of unmodified pre-gelatinized starch and pre-gelatinized starch modified by poly(AA–SA–AM–AMPS) were 12.15 and 20.02%, respectively. The lower char yield of unmodified sample compared with that of the modified sample can be attributed to the lower thermal stability of polysaccharides than acrylic polymers. The hydrogel prepared from modified pre-gelatinized starch with 36% acrylic part accounts for its higher char yield compared with pure pre-gelatinized starch [26, 38].

Swelling capacity of hybrid hydrogel after surface crosslinking

Table 5 shows the swelling capacity of surface crosslinked samples of hybrid hydrogel in distilled water and saline solution heated in a conventional oven for 2 h at 120 °C and heated in a microwave for 3, 5, and 7 min. Hybrid hydrogels mostly have low gel strength. To increase their mechanical strength, the hydrogels were subjected to surface crosslinking. After surface crosslinking, the swelling capacity in water and saline solution was decreased due to increasing crosslinking density in the surface of samples, but the AUL was increased.

The absorbency under load (AUL) for surface crosslinked hybrid hydrogels is shown in Table 5. Surface treatment using microwave resulted in achieving hybrid hydrogel with higher AUL. The AUL of surface-treated modified pre-gelatinized starch was increased up to 13 g/g.

During surface crosslinking process, as shown in Fig. 7, the carboxylic acid groups of hybrid hydrogels reacted with epoxy groups, leading to creating new crosslinks on the surface of hybrid hydrogels. The AUL has a direct relationship with crosslink density. Therefore, the increase of crosslink density during surface treatment would lead to AUL enhancement.

The surface crosslinking is a necessary step to have a hybrid hydrogel to increase its potential for industrial applications. Before surface crosslinking, the AUL of a hybrid hydrogel is low, but it can be promoted during surface treatment process. During surface treatment, a chemical reaction is carried out mostly between the carboxylic acid of superabsorbent hydrogel with epoxy groups of surface crosslinking agent. The usual method for surface crosslinking is by the conventional heating which requires high temperature and long time. Microwave-assisted surface crosslinking which has been introduced in this paper for crosslinking of hybrid hydrogels significantly reduces the crosslinking time from hours to less than 10 min.

Rheological measurements

The storage modulus versus angular frequency curves for the pre-gelatinized starch hydrogel modified by poly(AA–SA–AM–AMPS) latex and surface crosslinked hybrid hydrogel are shown in Fig. 8. As shown in both cases, with increasing frequency, the storage modulus of both hydrogels is increased. Surface crosslinking reaction of hybrid hydrogel leads to greater crosslink density which has a direct relationship with storage modulus. Modulus increases with increasing frequency due to the relaxation phenomenon in the polymer chains as a result of the applied tensions. At low frequencies, the polymer chains have enough time to relax and they are deformed in response to imposed shear stress. At high frequencies, the polymer chains do not have sufficient time to relax, so their flexibility decreases and the storage modulus increases [16, 39].

Conclusion

In this study, hybrid hydrogels based on pre-gelatinized starch containing 64% natural component and 36% synthetic component were prepared. Hybrid hydrogels were prepared through a new two-step method. First, glycidyl-crosslinked microgel latex was prepared through inverse emulsion polymerization, and the modification of pre-gelatinized starch with glycidyl-crosslinked microgel was performed to impart water absorbency of the starch. After modification of hybrid hydrogel, the maximum swelling values of 52.4 and 28.8 g/g were obtained, respectively, in distilled water and saline solution. In the preparation of hybrid hydrogels, this new method does not have the limitations of grafting procedure such as homopolymerization, low grafting efficiency, and low contribution of natural component in hybrid hydrogel structure.

Surface crosslinking of the hybrid hydrogel was carried out to overcome low gel strength of the hybrid hydrogels. Hybrid hydrogels were surface crosslinked with EGDGE using two methods including, conventional heating and microwave (MW) heating. The AUL of hybrid hydrogel significantly increased (85%) after surface modification. Surface crosslinking was used as a key process to overcome low AUL of hybrid hydrogels. Microwave heating, as a very efficient technology, was employed for surface crosslinking of hybrid hydrogels to enhance AUL and lower the reaction time. High structural contribution of natural component (64%), low cost of pre-gelatinized starch, and reasonable and acceptable value of AUL make these hybrid hydrogels good candidates for industrial applications.

References

Ulrich H (1993) Introduction to industrial polymers. Hanser Publishers, Munich

Witono JR (2012) New materials by grafting acrylic acid onto cassava starch. Rijksuniversiteit Groningen ISBN 978‐90‐367‐5695‐2

BeMiller J, Whistler R (2009) Starch: chemistry and technology. Elsevier, New York

Noordergraaf IW, Heeres HJ, Janssen LPBM (2008) Initiation methods for the grafting of acrylic acid monomers onto starch. A review (to be published). University of Groningen, Groningen

Zohurian-Mehr MJ, Pourjavadi A, Salimi H, Kurdtabar M (2009) Protein and homo poly(amino acid)-based hydrogels with super-swelling properties. Polym Adv Technol 20:655–671

Buchholz FL, Graham AT (1998) Modern superabsorbent polymer technology. Wiley-VCH, New York

Zohuriaan-Mehr MJ, Omidian H, Doroudiani S, Kabiri K (2010) Advances in non-hygienic applications of superabsorbent hydrogel materials. J Mater Sci 45:5711–5735

Zohuriaan-Mehr MJ (2006) Superabsorbents. Publication of Iran Polymer Society

Parvathy PC, Jyothi AN (2012) Synthesis, characterization and swelling behavior of superabsorbent polymers from cassava starch-graft-poly(acrylamide). Starch/Stärke 64:207–218

Ahmed EM (2015) Hydrogel: preparation, characterization, and applications: a review. J Adv Res 6:105–121

Pourjavadi A, Salimi H (2008) New protein-based hydrogel with superabsorbing properties: effect of monomer ratio on swelling behavior and kinetics. Ind Eng Chem Res 47:9206–9213

Pourjavadi A, Eftekhar Jahromi P, Seidi F, Salimi H (2010) Synthesis and swelling behavior of acrylated starch-g-poly(acrylic acid) and acrylated starch-g-poly (acrylamide) hydrogels. Carbohydr Polym 79:933–940

Salimi H, Pourjavadi A, Seidi F, Eftekhar Jahromi P, Soleyman R (2010) New smart carrageenan-based superabsorbent hydrogel responsiveness. J Appl Polym Sci 117:3228–3238

Pourjavadi A, Afjeh SS, Seidi F, Salimi H (2011) Preparation of acrylated agarose-based hydrogels and investigation of their application as fertilizing systems. J Appl Polym Sci 122:2424–2432

Pourjavadi A, Mazaheri Tehrani Z, Salimi H, Banazadeh A, Abedini N (2015) Hydrogel nanocomposite based on chitosan-g-acrylic acid and modified nanosilica with high adsorption capacity for heavy metal ion removal. Iran Polym J 24:725–734

Hajighasem A, Kabiri K (2015) Novel crosslinking method for preparation of acrylic thickener microgels through inverse emulsion polymerization. Iran Polym J 24:1049–1056

Sabzevari A, Kabiri K, Siahkamari M (2016) Induced superabsorbency in polyester fiber. Iran Polym J 25:635–646

Moini N, Kabiri K, Zohuriaan-Mehr MJ (2015) Practical improvement of SAP hydrogel properties via facile tunable cross-linking of the particles surface. Polym Plast Technol Eng 55:278–290

Moini N, Kabiri K, Zohuriaan-Mehr MJ, Smaeili N (2015) Simple and efficient approach for recycling of fine acrylic-based superabsorbent waste. Polym Bull 73:1119–1133

Moini N, Kabiri K (2015) Effective parameters in surface cross-linking of acrylic-based water absorbent polymer particles using bisphenol A diethylene glycidyl ether and cycloaliphatic diepoxide. Iran Polym J 24:977–987

Yang F, Li G, He YG, Ren FX, Wang G (2009) Synthesis, characterization, and applied properties of carboxymethyl cellulose and polyacrylamide graft copolymer. Carbohydr Polym 78:95–99

Ramazani-Harandi MJ, Zohuriaan-Mehr MJ, Yousefi AA, Ershad-Langroudi A, Kabiri K (2006) Rheological determination of swollen gel strength of superabsorbent polymer hydrogels. Polym Test 25:470–474

Islam MT, Rodriguez-Hornedo N, Ciotti S, Ackermann C (2004) Rheological characterization of topical carbomer gels neutralized to different pH. Pharm Res 21:1192–1199

Agarwal YK, Kaushik SD, Kumar PC (2007) Synthesis and rheological studies of methacrylic acid-ethyl acrylate-allyl methacrylate terpolymers. J Macromol Sci A Pure Appl Chem 44:877–880

Kabiri K, Faraji Dana S, Zohuriaan Mehr MJ (2005) Novel sulfobetaine-sulfonic acid-contained superswelling hydrogels. Polym Adv Technol 16:659–666

Bao Y, Ma J, Li N (2011) Synthesis and swelling behaviors of sodium carboxymethyl cellulose-g-poly(AA–co–AM–co–AMPS)/MMT superabsorbent hydrogel. Carbohydr Polym 84:76–82

Kabiri K, Hesarian S, Jamshidi A, Zohuriaan-Mehr MJ, Boohendi H, Poorheravi MR, Hashemi SA, Ahmad-Khanbeigi F (2011) Minimization of residual monomer content of superabsorbent hydrogels via alteration of initiating system. J Appl Polym Sci 120:2716–2723

Zhou Y, Fu SH, Zhang L, Zhan H (2013) Superabsorbent nanocomposite hydrogels made of carboxylated cellulose nanofibrils and CMC-g-p(AA-co-AM). Carbohydr Polym 97:429–435

Zhang J, Wang Q, Wang A (2007) Synthesis and characterization of chitosan-g-poly(acrylic acid)/attapulgite superabsorbent composites. Carbohydr Polym 68:367–374

Shi J, Fan L, Song J, Bai W (2012) Swelling properties and kinetics of starch-g-poly(acrylic acid) hydrogels. Adv Mater Res 550:1316–1320

Abd Alla SG, Sen M, El-Naggar AWM (2012) Swelling and mechanical properties of superabsorbent hydrogels based on Tara gum/acrylic acid synthesized by gamma radiation. Carbohydr Polym 89:478–485

Riham RM, Mahmoud HA, Magdy WS (2015) Synthesis, characterization and applications of N-quaternized chitosan/poly (vinyl alcohol) hydrogels. Int J Biol Macromol 80:149–161

Samanta HS, Ray SK (2013) Synthesis, characterization, swelling and drug release behavior of semi interpenetrating network hydrogels of sodium alginate and polyacrylamide. Carbohydr Polym 99:666–678

Mandal B, Ray SK (2014) Swelling, diffusion, network parameters and adsorption properties of IPN hydrogel of chitosan and acrylic copolymer. Mater Sci Eng C 44:132–143

Pimpa W, Pimpa C (2014) Characterization of durian seed starch/PVOH composite hydrogel as a potential adsorbent for removal of hazardous dyes. Adv Mater Res 931–932:286–290

Witono JR, Noordergraaf IW, Heeres HJ, Janssen LPBM (2014) Water absorption, retention and the swelling characteristics of cassava starch grafted with polyacrylic acid. Carbohydr Polym 103:325–332

Kabiri K, Mirzadeh H, Zohuriaan-Mehr MJ (2008) Undesirable effects of heating on hydrogels. J Appl Polym Sci 110:3420–3430

Kabiri K, Azizi A, Zohuriaan-Mehr MJ, Marandi GB, Bouhendi H (2011) Poly(acrylic acid-sodium styrene sulfonate) organogels: preparation, characterization, and alcohol superabsorbency. J Appl Polym Sci 119:2759–2769

Kohestanian M, Bouhendi H (2015) Novel cross-linking mechanism for producing PAA microgels synthesized by precipitation polymerization method. Colloid Polym Sci 293:1983–1995

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ashkani, M., Kabiri, K., Salimi, A. et al. Hybrid hydrogel based on pre-gelatinized starch modified with glycidyl-crosslinked microgel. Iran Polym J 27, 183–192 (2018). https://doi.org/10.1007/s13726-018-0599-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-018-0599-4