Abstract

With the aim to exhibit the advantages of catalytic accelerator in enhancing the selective hydrolysis of cellulose to sugar, cellulose is hydrolyzed in low acid aqueous system with catalytic accelerator. And then sugar products are extracted and fermented by yeast. By the assistance of catalytic accelerator, cellulose conversion rate and total reducing sugar yield are 95.7% and 90.9%. And the glucose yield is as high as 73.6%. The sugar products with high glucose content can be easily extracted from cellulose hydrolysate. Low toxicity of the sugar products to yeast is found during yeast fermentation. The glucose in cellulose hydrolysate can be fully consumed after 12 h. A highly actual ethanol yield is exhibited, which is equal to the actual yield level of standard glucose solution. The important role of catalytic accelerator in aqueous hydrolytic system to produce fermentable sugar is clearly reflected. Furthermore, a simple but effective way is established to efficient utilization of cellulose as an applicable carbon source for the conversion of more value-added chemicals and materials.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

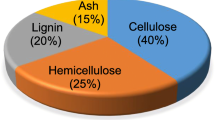

With the rapid economic development, the demand of fossil resources as carbon source to be used for energy and materials is gradually increasing [1,2,3]. Due to the continuous exploitation of fossil resources such as oil, coal, and natural gas, more and more carbon emissions are caused on the land surface, which results in serious environmental problems. Under this situation, it is becoming very important to find a renewable carbon source to supply and even to replace fossil resources. As a non-grain renewable biomass derived from bio-carbon, cellulose has the potential to be converted into sugar platform compounds to support the application of energy and materials [4]. Accordingly, a renewable carbon source will be developed to promote the above-ground carbon neutral cycle.

The hydrolysis of cellulose to sugar is mainly concerning with the dissociation of glycosidic bonds. The hydrolytic rate and efficiency of glycosidic bond determine the hydrolytic ability of cellulose. However, due to the great deal of hydroxyl groups on the molecular chain of cellulose, a large number of hydrogen bonds form between and within the cellulose chains. It induces a recalcitrant structure greatly to hinder the contact between glycosidic bonds and catalysts [5]. This leads to a severely decline of the efficiency of glycosidic bond during and cellulose hydrolysis [6,7,8]. Research showed that there are two main processes in the formation of the recalcitrant structure. The one is produced naturally in the plant growth [9], and the other is from the rapid reorganization of free cellulose molecular chains during processing [10] and even in hydrolysis [11, 12]. Both the two processes are caused by the rapid self-aggregation of the molecular chains of cellulose produced by the interaction of hydrogen bonding, which is even recognized as the particular nature of cellulose [13]. Ionic liquids [14], alkaline solutions [15], and concentrated phosphoric acid [16] were reported to break the recalcitrant structure of cellulose in processing and hydrolysis effectively. However, it causes the difficulty to collect and to separate the sugar products from the hydrolysate by use of these systems.

In order to improve the collection of sugar products with high quality, chemical catalysis in aqueous system is mainly considered. Various concentrated acids were firstly used to speed up the hydrolysis of cellulose. Although high acid strength and large dosage are helpful to enhance the hydrolytic response of cellulose, it easily causes strong side reaction of the sugar product formed in hydrolysis. Another way was regarding the utilization of inorganic salt [17], organic solvent [18], and ion liquid [19, 20]. There still exists the difficulty in the separation and collection of sugar product. Besides, many solid catalysts including of carbonaceous solid acids [16], inorganic oxides [17], zeolites [20, 21], cation exchange resins [22], modified clays [23], and heteropoly acids [24] were utilized in aqueous hydrolytic system. By limiting acid catalytic sites around the surface of solid support, the sugar products can be easily separated from the hydrolysate. The only problem of solid acids is the weak ability to break recalcitrant structure of cellulose. Halogen group with hydroxyl affinity was introduced on the surface of solid acid to increase the contact ability between catalytic active sites and glycosidic bonds of cellulose [25]. However, it still failed fundamentally to change a lot on the hydrolytic response of cellulose. The ability and efficiency of cellulose hydrolysis to sugar are still insufficient. Inspired by the enhancement of hydrolytic efficiency of the cellulose to platform compound by cellulase through particular non-hydrolytic physical affinity to resist the self-aggregation of cellulose molecular chain, catalytic accelerators which owned strong affinity with cellulose including ZrO2 and hydroxyl-enriched carbon sphere were designed to be used in aqueous hydrolytic system [11, 26]. Accordingly, the inhibition of recalcitrant structure of cellulose is effectively eliminated. The hydrolysis of cellulose can be carried out under relatively mild condition. As a result, the side reaction of sugar product will be possibly reduced.

In this study, the ability and effect of catalytic accelerators to hydrolyze cellulose in low acid aqueous system are discussed. Sugar products with high quality to fit for fermentation are tried to be separated and extracted from the hydrolysate of cellulose. Yeast fermentation is utilized to show the quality and fermentability of the sugar product. The advantage of catalytic accelerator in enhancing the selective hydrolysis of cellulose to produce fermentable sugar is revealed.

2 Materials and methods

2.1 Materials

Microcrystalline cellulose (MCC) (purity 97%, DP 179) was purchased from Longbao New Material Company (Jiangsu) and dried in a vacuum oven at 100 °C for 24 h before use. D-( +)-Glucose (standard glucose, AR grade) was supplied from Aladdin Co., Ltd., and dried under vacuum at 80 °C for 6 h before use. CaCO3 (AR grade, 99%) was also provided by Aladdin Co., Ltd. ZrO2 (AR grade, 99%, particle size 144.6 ± 27.6 nm (see Figure S1)) and acetone were from Sinopharm Chemical Reagent Co., Ltd. Activated carbon was provided by Suzhou Carbon Cyclone Activated Carbon Co., Ltd. Potato dextrose agar (PDA) and yeast extract peptone dextrose medium (YPD) liquid medium were from Haibo Biotechnology Co., Ltd. Highly active yeast is from Angel Yeast Co., Ltd. All the reactants were in chemical grade and used without further purification.

2.2 Pretreatment of cellulose

MCC was pretreated to remove the small amount of impurities according to the method reported in the previous work of our team [11]. MCC was dissolved in 85% H3PO4, heated at 50 °C, and continuously stirred for 3 h. A uniform solution was formed and placed in a refrigerator at 7 °C for 12 h, then poured into deionized water for cleaning, and then repeated cleaning for many times until neutrality was measured with a pH tester. Finally, the treated cellulose was vacuum dried at 80 °C for 12 h and ground into powder for further use. The degree of polymerization (DP) and crystallinity of the treated cellulose was 38 and 47.3%.

2.3 Preparation of hydroxyl-enriched carbon sphere (HECS) as catalytic accelerator

Sixty mL of 1 mol/L glucose solution was poured into the polytetrafluoroethylene liner of the hydrothermal synthesis reactor, and then the reactor was heated by a high-temperature reaction chamber at 180 °C for 12 h. The constant temperature oven (Ex-YZJX-8) and hydrothermal synthesis reactor (YH-100 mL) is from Shanghai Exceed Equipment Co., Ltd. After reaction, the cooling product was, respectively, washed by deionized water and ethanol for three times. Finally, HECS was obtained after dried in a blast drying oven at 80 °C for 24 h [23], which will be used as a catalytic accelerator in the following steps. The structure of HECS was characterized by SEM and FT-IR and shown in Figure S2.

2.4 Hydrolysis of cellulose to sugar

Hydrolysis of the treated cellulose to sugar was carried out in the autoclave vessel (35 mL, 300psi) of the high energy density microwave reactor (CEM SP). The frequency of microwave was 2450 ± 0.050 GHz, and the output power was 0 to 300 W. The hydrolytic temperature was controlled by the combined use of microwave radiation and a synchronous cooling, which was achieved through air cooling by using special equipment from CEM Company. During hydrolysis, 0.1 g of catalytic accelerator (including HECS and milled ZrO2), 0.2 g of treated cellulose, and 0.02 mol/L H2SO4 were put into the autoclave vessel and mixed with magnetic stirring. Then, the autoclave vessel was heated to 150 °C under 300 W microwave radiation and kept at 150 °C for 15 min.

2.5 Extraction of sugar from cellulose hydrolysate

Above hydrolytic process of cellulose was repeated for 50 times to obtain ~ 1L of hydrolysate. An ~ 4 g CaCO3 was added into the cellulose hydrolysate to neutralize H2SO4. After stirring and filtration, 10 g activated carbon was added into the filtrate and stirred for 30 min. And then, the activated carbon was filtrated to obtain a colorless and transparent cellulose hydrolysate. The obtained decolorized cellulose hydrolysate was concentrated by use of a rotary evaporator (RE-2000A) with a low-temperature circulating pump (coolant is ethylene glycol/water equals to 4:1) at 50 °C to obtain an ~ 7.5 mL concentrated cellulose hydrolysate, which is known as a saturated sugar solution. Ten mL acetone was added into the saturated sugar solution and then treated with an ultrasonic cell pulverizer at the power of 50 W for 1 h. At the last, the formed floc was placed in a vacuum drying oven at 30 °C for 2 h to obtain the solid sugar product.

2.6 Detection of toxicity of sugar products to yeast

The hydrolysis of cellulose to sugar usually requires extreme hydrolysis condition. By-products such as formic acid and levulinic acid can form from the degradation of sugar products, which were reported to be toxic to yeast. So the toxicity detection of sugar products to yeast was necessary before fermentation. The specific step of detection was operated as follows. Yeast was added into 100 mL basic medium of DPA (20 g potato, 20 g glucose, and 2 g agar) to inoculate and purify. YPD liquid medium was also prepared to obtain a certain concentration of bacterial suspension for further inoculation. Fifty mL YPD basal medium was divided into 10 groups on average. Eighty mg, 120 mg, and 160 mg sugar product obtained from the hydrolysis of cellulose with catalytic accelerator (namely, HECS and ZrO2) were used as the substrate in groups 1–6. Eighty mg, 120 mg, and 160 mg standard glucose were used in groups 7–9. Group 10 was blank control group (no additional sugar). All the above groups are mixed thoroughly again. Two mL solution of each above group was taken out and then, respectively, dropped into 10 wells of a 24-well plate. After fermentation with the yeast for 24 h, it was inoculated into a fixed medium and cultivated for another 24 h and then count the colonies. Two mL of each of the above liquids was taken out to add dropwise into a 24-well plate and then to add a certain amount of methylene blue solution. After incubating for 4 h, take 200μL to a 96-well plate. A microplate reader was used to detect the absorbance to obtain the survival rate of yeast.

2.7 Quantitative yeast fermentation of sugar products

Saccharomyces cerevisiae powder is dissolved in 2% glucose solution. After cultured in a shaking table at 35 °C at 150 rpm for 1–2 h, centrifuged, and mixed with sterile water, seed liquid of Saccharomyces cerevisiae was obtained. Cellulose hydrolysates with the glucose concentration at ~ 40, ~ 60, and ~ 80 g/L were obtained by from the hydrolysis of treated cellulose by using of HECS as a catalytic accelerator in low acid aqueous system. These hydrolysates were directly used for yeast fermentation. Changes of glucose concentration and ethanol production obtained in yeast fermentation within 48 h were then detected. Treated MCC was also used as the blank control group for comparison.

2.8 Characterization

The conversion of cellulose and yield of total reducing sugar (TRS) was calculated according to Eqs. (1) and (2), respectively. The TRS yield in the cellulose hydrolysate was analyzed by DNS (3,5-dinitrosalicylic acid) method according to literature [13]:

where mRC is the mass of the initial loaded cellulose, mrRC is the mass of the residual cellulose after the reaction, and mTRS is the mass of TRS. Also, the content of glucose in the product of TRS was measured by an Agilent 1200 high-performance liquid chromatography (HPLC) apparatus (Agilent Technologies, Santa Clara, California) and equipped with a Zorbax-NH2 column (250 × 4.6mm2, 5 μm particle size) from Agilent (Palo Alto, CA). The mobile phase was consisted of acetonitrile/water (70:30, v/v) in the isocratic elution with a flow rate of 1.4 mL/min. The column temperature was kept at 30 °C. The glucose yield was calculated according to Eq. 3:

where Cglucose is the glucose concentration in the product of TRS and V is the volume of the cellulose hydrolysate.

Fourier transform infrared spectroscopy (FT-IR, Nicolet 6700, Thermo) was used to determine the structure of cellulose sugar. The spectral range of each sample was 400–4000 cm−1, the resolution was 0.09 cm−1, and the number of scans was 32.

The microscopic morphology of the sugar product extracted from the cellulose hydrolysate was observed by scanning electron microscope. Anion sputter coater (E-1045, Hitachi) was used to sputter-coat all samples with ~ 10 nm gold sputter to improve the conductivity of the samples and the quality of the SEM image.

1H-NMR and 13C-NMR spectra were recorded on a Bruker Avance II spectrometer at 400 MHz and 100 MHz, respectively, using D2O as the solvent. Gas chromatography mass spectrometry (GC–MS, 7890B-5977A, Agilent) was used to detect ethanol formed in the culture medium after sugar product after yeast fermentation for 24 h. The whole test was performed by using a DB-WAX capillary column (30 m × 0.25 mm × 0.25 μm, Agilent 7890 BGC instrument, connected in series with 5977A MS system). The temperature was firstly controlled at 35 °C for 3 min and then increased to 100 °C at a rate of 25 °C/min for 4 min. The total running time was 9.6 min. The inlet temperature was 100 °C, the split ratio was 10:1, the constant pressure was 6.77psi, and the constant flow rate was 1 mL/min.

3 Results and discussion

3.1 Sugar product from the hydrolysis of cellulose

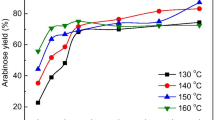

Hydrolysis of the treated cellulose is carried out in low acid aqueous system with catalytic accelerator as schematized in supporting information (Figure S3). HECS and ZrO2 are, respectively, used as the catalytic accelerator. Figure 1 gives cellulose conversion rate, TRS yield, and glucose yield. Without catalytic accelerator, the conversion rate of cellulose is 64.2%. TRS and glucose yields are 60.5% and 47.4%, respectively. After adding ZrO2 into the hydrolytic system, the conversion rate of cellulose and the TRS yield improves to 99.7% and 95.3%. And the glucose yield also increases to 62.5%. As to the hydrolytic system with HECS, the conversion rate of cellulose and the TRS yield are 95.7% and 90.9%, respectively. The glucose yield reaches 73.6% (improved over a quarter). Figure S4 gives the effect of cellulose hydrolysis to sugar with HECS at different amount. With the increase of HECS, the efficiency of catalytic conversion of cellulose is improving.

These results indicate that both of the two catalytic accelerators can efficiently enhance the hydrolytic efficiency of the treated cellulose to sugar. Generally, the molecular chains of cellulose have the intrinsic self-aggregation to form dense and recalcitrant structure in aqueous system because of relative strong interaction between molecular chains [10, 11, 27,28,29] and even in the hydrolytic process [13, 27]. After using catalytic accelerator in hydrolytic system, it produces the non-hydrolytic strong affinity with cellulose. During the hydrolysis, the self-aggregation of the molecular chain of cellulose is partially inhabited. The hydrolytic ability and efficiency are enhanced. Figure S5 shows the role of catalytic accelerator (namely HECS and ZrO2) on enhancing the hydrolytic reactivity of cellulose in aqueous hydrolytic system. This phenomenon is similar with the effect of cellulase. The detailed process was exhibited in our previous researches [11, 26].

The process of the preparation and extraction of the sugar product from cellulose hydrolysate is summarized in Figure S6. After the hydrolysis of the treated cellulose in aqueous system with catalytic accelerator, cellulose hydrolysate is firstly separated from the reaction system by filtration. The obtained cellulose hydrolysates are shown in Fig. 2a and e. A small amount of CaCO3 is added into the cellulose hydrolysate to remove SO42−, and then activated carbon is also used to decolorize the cellulose hydrolysate for 30 min. Colorless and transparent solutions of sugar product are obtained (Fig. 2b, f). The decolorized cellulose hydrolysate is concentrated at 50 °C to obtain a saturated sugar solution. After that, acetone is dropped into the saturated sugar solution under 100 W ultrasonic treatment for 1 h. Finally, the saturated sugar solution is put in a vacuum oven at 30 °C for 12 h to obtain solid sugar product (Fig. 2c, g). The micro-morphology of the sugar products shows as similar as a polycrystalline structure (Fig. 2d, h).

Two types of sugar obtained from the aqueous systems with the catalytic accelerators of HECS and ZrO2. Hydrolysate obtained by the system with HECS (a) and ZrO2 (e); the decolorized cellulose hydrolysate with HECS (b) and ZrO2 (f); sugar products extracted from the aqueous systems with HECS (c, d) and ZrO2 (g, h)

Figure 3a shows the FT-IR spectra of two kinds of extracted sugar from different cellulose hydrolysates. It appears many similar adsorption bands at 3380 cm−1, 2923 cm−1, an 1640 cm−1 on the FT-IR curve, which reflects the stretching vibrations of –OH, –CH, –CHO, and so on [30]. These main absorption bands are all related to the characteristic structure of glucose. Furthermore, 1H-NMR and 13C-NMR analyses are, respectively, carried out further to determine the structure of the extracted sugar products (see Fig. 3b, c, and d and Fig. 3e and f). The sugar products obtained from the hydrolytic system with HECS and ZrO2 mainly contain glucose only with a very small amount of impurity. The improvement in the quality of sugar product will be helpful to promote subsequent transformation and application.

FT-IR, 1H-NMR, and 13C-NMR spectrum of standard glucose and sugar product extracted from the cellulose hydrolysate. FT-IR spectra a of the sugar product extracted from the hydrolytic system with HECS and ZrO2; 1H-NMR spectra of b standard glucose, c the sugar product extracted from hydrolytic system with HECS, d the sugar extracted from hydrolytic system with ZrO2; and 13C-NMR spectra of e the sugar product extracted from hydrolytic system with HECS; f the sugar product extracted from hydrolytic system with ZrO2. 1H-NMR (400 MHz, D2O): δ 5.12 (α-H1), 4.55 (β-H1), 3.81 (α-H6), 3.80 (β-H4), 3.75 (α-H5), 3.72 (α-H3), 3.64 (α-H4), 3.60 (β-H6), 3.44 (β-H3), 3.38 (α-H6’), 3.36 (β-H6’), 3.30 (α-H2), 3.29 (β-H5), 3.11 (β-H2). 13C-NMR (400 MHz, D2O): δ 92.0 (α-C1), 95.9 (β-C1), 71.5 (α-C2), 74.1 (β-C2), 72.7 (α-C3),75.9 (β-C3), 71.4 (α-C4,β-C4), 69.5 (α-C5), 69.6 (β-C5), 60.7 (α-C6), 60.6 (β-C6)

3.2 Toxicity detection and yeast fermentation of sugar product

The content of glucose in cellulose hydrolysate is detected by HPLC. In Fig. 4, without catalytic accelerator, a clear peak related to the content of glucose and a tiny dispersion peak concerning with impurity can be found on the HPLC curve of cellulose hydrolysate. After using HECS and ZrO2 in hydrolytic system, the content of glucose in cellulose hydrolysates is both increased (see Fig. 4a and b), which is consistent with the results shown in Fig. 1. After decolorization, no matter the hydrolysate produced in the hydrolytic system with HECS or ZrO2, there does not appear large difference on the HPLC curve. It shows that the main components of cellulose hydrolysate have not changed before and after decolorization. With the proceeding of concentration, both the content of glucose and impurity in cellulose hydrolysate increase. The glucose content in the concentrated cellulose hydrolysate obtained by the hydrolytic system with HECS is much higher than the system with ZrO2. By detecting the content of extracted sugar product (see Fig. 4a and b), it can be further noticed that the amount of impurities in the sugar product obtained by the hydrolytic system with HECS is less than that with ZrO2 under the same glucose content. These results are also consistent with the trend of influence of the two catalytic accelerators on the hydrolysis of cellulose to sugar.

Toxicity detection of the sugar products to yeast was performed with standard glucose solutions of 80 mg/L, 120 mg/L, and 160 mg/L and extracted sugar products, respectively. Figure 5a shows the growth of yeast after 48 h. The number of yeast in blank control group (without added sugar product) was 429 ± 12. For the sugar product of hydrolysis with ZrO2, although the amount of sugar produced by yeast increased, the number of yeast decreased. With the solution of 160 mg/L, the number of yeast was 297 ± 10, and the survival rate of yeast is 69.7%. The number of yeast was a little lower than the standard glucose group. However, the number of yeast was significantly increased by using HECS hydrolysis of sugar products for yeast culture. The maximum number of yeast was 1288 ± 37, the survival rate of yeast is 2.9 times higher than the blank control group. Tables S1–S3 give the results of statistical analysis. It reflects yeast numbers of different groups of sugar products after 48 h fermentation are significant at the 5% significance level. These results can be attributed to the best quality and low toxicity of sugar products to yeast obtained by HECS hydrolysis system. The lower the amount of impurities in the sugar product (as shown in Fig. 3), the better the yeast grows during fermentation. Ethanol production from the yeast culture with the sugar product of cellulose hydrolysis is examined by GC–MS. As shown in Fig. 5b, the sugar products obtained from the hydrolytic system with HECS or ZrO2 are fit for the yeast culture to produce ethanol as similar as the group with standard glucose. And the effect of ethanol production formed in yeast culture is all higher than blank control group. These results reflect the low toxicity of the obtained sugar product to yeast.

With the understanding of low toxicity of the sugar product to yeast, the cellulose hydrolysate directly obtained from the hydrolysis of cellulose is used for yeast fermentation. Six sugar solutions were, respectively, prepared. Among them, cellulose hydrolysate-1 (32.88 g/L), cellulose hydrolysate-2 (42.45 g/L), and cellulose hydrolysate-3 (70.31 g/L) are obtained by after simple concentration and decolorization with activated carbon of primary hydrolysate. Cellulose hydrolysate-4 (32.28 g/L), cellulose hydrolysate-5 (53.09 g/L), and cellulose hydrolysate-6 (76.80 g/L) are prepared by only simple concentration of primary hydrolysate. Standard glucose solution marked with glucose solution-1 (27.16 g/L), glucose solution-2 (44.23 g/L), and glucose solution-3 (61.28 g/L) and treated cellulose are also prepared for comparison. Impurities (including formic acid, levulinic acid, and 5-hydroxymethylfurfural produced by side reaction) produced during the hydrolysis of cellulose to sugar are also characterized. From Figure S7, only small amount of impurities can be detected in all the 6 groups of cellulose hydrolysate. It will not produce large toxicity to yeast as narrated above. Figure 6 shows the changes of glucose concentration and ethanol production of yeast fermentation. From Fig. 6a, it can be found almost all the glucoses in the 9 samples including cellulose hydrolysates and standard glucose solutions have been fermented and transformed within 12 h during yeast fermentation. These results reflect the 6 groups of cellulose hydrolysate have low content of toxic substances and are suitable for yeast fermentation culture to prepare ethanol. As we know, on basis of the metabolic process of Saccharomyces cerevisiae, the highest yield of ethanol in theory is 51%. Through the measurement and calculation of the actual ethanol yield obtained by fermentation of cellulose hydrolysates in Fig. 6b, the actual ethanol yield of decolorized hydrolysate can reach 97.8% of the theoretical yield. And the actual ethanol yield of non-decolorized hydrolysate is 83.1% of the theoretical yield. Both the ethanol yield is equal to the actual yield level of standard glucose solution (~ 92.6%).

By the toxicity detection and yeast fermentability, it clearly demonstrates the ability and function of catalytic accelerator in promoting the highly selective catalytic conversion of cellulose to glucose in low acid aqueous system. By use of the low acid system with catalytic accelerator, it easily achieves the hydrolysis of cellulose to and yeast fermentation to glucose. In comparison with the preparation of ethanol from cellulose catalyzed by enzyme [31, 32], the route of preparing ethanol from cellulose shown in this paper avoids the relatively complex culture, screening, and preserving process of enzymes and bacteria to a certain extent; it shows the characteristics of being simpler, easier to operate, and even better potential economy.

4 Conclusion

By use of hydroxyl-enriched carbon sphere as a catalytic accelerator, cellulose was hydrolyzed in low acid aqueous solution. Cellulose conversion and TRS yield reached 95.7% and 90.9%, respectively. And the yield of glucose is up to 73.6%, which was significantly higher than that of the hydrolysis in pure acid solution. On the basis of that, sugar products with high glucose content can be easily extracted from cellulose hydrolysates. Toxicity test to yeast shows the quality of the sugar products was good and suitable for yeast fermentation to produce ethanol. After 12-h fermentation, the glucose in both the decolorized and non-decolorized cellulose hydrolysates achieves fully conversion. It exhibits a high actual ethanol yield of the theoretical yield, which is equal to the actual yield level of standard glucose solution.

References

Tian H, He J (2016) Cellulose as a scaffold for self-assembly: from basic research to real applications. Langmuir 32:12269–12282. https://doi.org/10.1021/acs.langmuir.6b02033

Zhu H, Luo W, Ciesielski PN, Fang Z, Zhu JY, Henriksson G, Himmel ME, Hu L (2016) Wood-derived materials for green electronics, biological devices, and energy applications. Chem Rev 116:9305–9374. https://doi.org/10.1021/acs.chemrev.6b00225

Nishio Y (2006) Material functionalization of cellulose and related polysaccharides via diverse microcompositions. Adv Polym Sci 205:97–151. https://doi.org/10.1007/12_095

Huber GW, Iborra S, Corma A (2006) Synthesis of transportation fuels from biomass: chemistry, catalysts, and engineering. Chem Rev 106:4044–4098. https://doi.org/10.1021/cr068360d

Jarvis M (2003) Chemistry: cellulose stacks up. Nature 426:611–612. https://doi.org/10.1038/426611a

Majumdar S, Naha A, Bhattacharyya DK, Bhowal J (2019) Effective delignification and decrystallization of cauliflower wastes by using dilute phosphoric acid for efficient enzymatic digestibility to produce fermentable sugars. Biomass Bioenerg 125:169–179. https://doi.org/10.1016/j.biombioe.2019.04.017

Turner S, Kumar M (2018) Cellulose synthase complex organization and cellulose microfibril structure. Philos Trans A Math Phys Eng Sci 376:1471–1485. https://doi.org/10.1098/rsta.2017.0048

Fernandes AN, Thomas LH, Altaner CM, Callow P, Forsyth VT, Apperley DC, Kennedy CJ, Jarvis MC (2011) Nanostructure of cellulose microfibrils in spruce wood. Proc Natl Acad Sci USA 108:1195–1203. https://doi.org/10.1073/pnas.1108942108

Thomas LH, Forsyth VT, Sturcova A, Kennedy CJ, May RP, Altaner CM, Apperley DC, Wess TJ, Jarvis MC (2013) Structure of cellulose microfibrils in primary cell walls from collenchyma. Plant Physiol 161:465–476. https://doi.org/10.1104/pp.112.206359

Jeoh T, Ishizawa CI, Davis MF, Himmel ME, Adney WS, Johnson DK (2007) Cellulase digestibility of pretreated biomass is limited by cellulose accessibility. Biotechnol Bioeng 98:112–122. https://doi.org/10.1002/bit.21408

Zhu K, Qiu C, Lu A, Luo L, Guo J, Cong H, Chen F, Liu X, Zhang X, Wang H, Cai J, Fu Q, Zhang L (2018) Mechanically strong multifilament fibers spun from cellulose solution via inducing formation of nanofibers. ACS Sustain Chem Eng 6:5314–5321. https://doi.org/10.1021/acssuschemeng.8b00039

Qiao Y, Zhai CK, Liu F, Chen L, Na HN, Chen J, Zhu J (2020) Highly efficient microwave driven assisted hydrolysis of cellulose to sugar with the utilization of ZrO2 to inhibit recrystallization of cellulose. Carbohydr Polym 228:115358. https://doi.org/10.1016/j.carbpol.2019.115358

Ni JP, Wang HL, Chen YY, She Z, Na HN, Zhu J (2013) A novel facile two-step method for producing glucose from cellulose. Bioresour Technol 137:106–110. https://doi.org/10.1016/j.biortech.2013.03.104

Samikannu R, Shukla SK, Samikannu A, Mikkola JP (2019) Lutidinium-based ionic liquids for efficient dissolution of cellulose. New J Chem 43:2299–2306. https://doi.org/10.1039/C8NJ04698K

Martin-Bertelsen B, Andersson E, Kohnke T, Hedlund A, Stigsson L, Olsson U (2020) Revisiting the dissolution of cellulose in NaOH as “seen” by X-rays. Polymer 12:342. https://doi.org/10.3390/polym12020342

Boerstoel H, Maatman H, Westerink JB, Koenders BM (2001) Liquid crystalline solutions of cellulose in phosphoric acid. Polymer 42:7371–7379. https://doi.org/10.1016/S0032-3861(01)00210-5

Bao Y, Xu D, Qian L, Zhao L, Lu ZY, Cui S (2017) Hydrophilicities of amylose and natural cellulose are regulated by the linkage between sugar rings. Nanoscale 9:3382–3385. https://doi.org/10.1039/C7NR00198C

Song J, Fan H, Ma J, Han B (2013) Conversion of glucose and cellulose into value-added products in water and ionic liquids. Green Chem 15:2619–2635. https://doi.org/10.1039/C3GC41141A

Vom Stein T, Grande P, Sibilla F, Commandeur U, Fischer R, de Leitner W, María PD (2010) Salt-assisted organic-acid-catalyzed depolymerization of cellulose. Green Chem 12:1844–1849. https://doi.org/10.1039/C0GC00262C

Li C, Wang Q, Zhao ZK (2008) Acid in ionic liquid: an efficient system for hydrolysis of lignocellulose. Green Chem 10:177–182. https://doi.org/10.1039/B711512A

Kontturi E, Vuorinen T (2008) Indirect evidence of supramolecular changes within cellulose microfibrils of chemical pulp fibers upon drying. Cellulose 16:65–74. https://doi.org/10.1007/s10570-008-9235-3

Kobayashi H, Fukuoka A (2013) Synthesis and utilisation of sugar compounds derived from lignocellulosic biomass. Green Chem 15:1740–1763. https://doi.org/10.1039/C3GC00060E

Zhang YH, Lynd LR (2004) Toward an aggregated understanding of enzymatic hydrolysis of cellulose: noncomplexed cellulase systems. Biotechnol Bioeng 88:797–824. https://doi.org/10.1002/bit.20282

Gusmao MSS, Gopal P, Siloi I, Curtarolo S, Fornari M, Nardelli MB (2019) Mechanical properties of chemically modified clay. Sci Rep 9:13698–13705. https://doi.org/10.1038/s41598-019-49972-7

Zhang X, Xiao B, Chen J, Guo M, Yang Q (2016) Adjusting the acid strength of hybrid solid acids in confined nanospace. Top Catal 59:1748–1756. https://doi.org/10.1007/s11244-016-0696-6

Zhang ZY, Qiao Y, Liu F, Chen J, Na HN, Zhu J (2020) Utilization of hydroxyl-enriched glucose-based carbonaceous sphere (HEGCS) as a catalytic accelerator to enhance the hydrolysis of cellulose to sugar. ACS Appl Mater Inter 12:25693–25699. https://doi.org/10.1021/acsami.9b23540

Zhai CK, Teng N, Pan BH, Chen J, Liu F, Zhu J, Na HN (2018) Revealing the importance of non-thermal effect to strengthen hydrolysis of cellulose by synchronous cooling assisted microwave driving. Carbohydr Polym 197:414–421. https://doi.org/10.1016/j.carbpol.2018.06.031

Cheng B, Cui S (2015) Supramolecular chemistry and mechanochemistry of macromolecules: recent advances by single-molecule force spectroscopy. Top Curr Chem 369:97–134. https://doi.org/10.1007/128_2015_628

Luo Z, Zhang A, Chen Y, Shen Z, Cui S (2016) How big is big enough? Effect of length and shape of side chains on the single-chain enthalpic elasticity of a macromolecule. Macromolecules 49:3559–3565. https://doi.org/10.1021/acs.macromol.6b00247

Ibrahim M, Alaam M, El-Hans H, Jalbout AF, de Leon A (2006) Analysis of the structure and vibrational spectra of glucose and fructose. Ecl. Quím. São Paulo 31:15–21. https://doi.org/10.1590/S0100-46702006000300002

Gao L, Wang F, Gao F, Wang L, Zhao J, Qu Y (2011) Purification and characterization of a novel cellobiohydrolase (PdCel6A) from Penicillium decumbens JU-A10 for bioethanol production. Bioresour Technol 102:8339–8342. https://doi.org/10.1016/j.biortech.2011.06.033

Liu Y, Yu P, Song X, Qu Y (2008) Hydrogen production from cellulose by co-culture of Clostridium thermocellum JN4 and Thermoanaerobacterium thermosaccharolyticum GD17. Hydrogen production from cellulose by co-culture of Int. J Hydrogen Energ 33:2927–2933. https://doi.org/10.1016/j.ijhydene.2008.04.004

Rinaldi R, Palkovits R, Schuth F (2008) Depolymerization of cellulose using solid catalysts in ionic liquids. Angew Chem Int Ed Engl 47:8047–8050. https://doi.org/10.1002/ange.200802879

Deguchi S, Tsujii K, Horikoshi K (2008) Effect of acid catalyst on structural transformation and hydrolysis of cellulose in hydrothermal conditions. Green Chem 10:623–626. https://doi.org/10.1039/B803384F

Drissen RET, Maas RHW, Tramper J, Beeftink HH (2009) Modelling ethanol production from cellulose: separate hydrolysis and fermentation versus simultaneous saccharification and fermentation. Biocatal Biotransfor 27:27–35. https://doi.org/10.1080/10242420802564358

Zhang B, Shi R, Duan W, Luo Z, Lu Z-Y, Cui S (2017) Direct comparison between chemisorption and physisorption: a study of poly(ethylene glycol) by means of single-molecule force spectroscopy. RSC Adv 7:33883–33889. https://doi.org/10.1039/C7RA05779B

Acknowledgements

We are also grateful for the use of HPLC equipment provided by Dr. Yingying Han in Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences.

Funding

This study is funded by the National Natural Science Foundation of China (21978310), the Science and Technology Service Network Plan (KFJ-STS-QYZD-2021–16-002), the “One belt, one road” Projects of China Academy of Sciences (174433KYSB20190082), the Key Projects of Ningbo Public Welfare Science and Technology Plan (2021S020), the Leading Innovative and Entrepreneur Team Introduction Program of Zhejiang (2018R01014), the Natural Science Foundation of Education Department of Liaoning province (LJ2020038), and the Natural Science Foundation of Science and Technology Department of Liaoning Province (2019-ZD-0084).

Author information

Authors and Affiliations

Contributions

Wei Liu, conceptualization, formal analysis, methodology, writing — original draft, and writing — review and editing. Haining Na, conceptualization, formal analysis, methodology, and writing — review and editing. Changhui Hu, formal analysis and validation. Fang Zhou, investigation and writing — review and editing. Zhenyu Zhang, investigation. Zhuo Guo, resources. Jin Zhu, resources. Mian Li: resources.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Liu, W., Na, H., Hu, C. et al. Extraction and yeast fermentation of sugar product from cellulose hydrolysis in low acid aqueous system with catalytic accelerator. Biomass Conv. Bioref. 13, 4343–4351 (2023). https://doi.org/10.1007/s13399-022-03000-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-03000-3