Abstract

This study aims to investigate the effect of the ultrasonic, microwave, and combined ultrasonic-microwave pretreatment of palm oil mill effluent (POME) sludge before fermentation to analyze hydrogen (H2) production and chemical oxygen demand (COD) removal efficiency in batch fermentation. Experimental results showed that the pretreatment of sludge (ultrasonication, microwave, and ultrasonication-microwave pretreatment) had positively influence the H2 production and COD removal efficiency during fermentation as compared to control one (without any pretreatment). Combined ultrasonication-microwave pretreatment of POME sludge was shown to be more effective for increasing both H2 production and COD removal from POME with the highest cumulative H2 and COD removal efficiency of 4080 mL H2/L-POME and 75.56%, respectively. The improvement observed for cumulative H2 production and COD removal was 12.14% and 21.42%, respectively, compared to the control one. These observations concluded that the POME sludge pretreatment with ultrasonication-microwave irradiation could be an effective strategy for improved treatment of POME with simultaneous production of H2.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The biological transformation of carbohydrate-rich agro-industrial waste to the low carbon energy biofuel has been considered a promising approach to produce a potential value-added product with the simultaneous treatment of waste [13, 21, 49]. Hydrogen (H2) (the cleanest energy carrier with intrinsic high combustion calorific value of 143 MJ·Kg−1 than any other hydrocarbons) production by dark fermentative processes using palm oil mill effluent (POME) wastewater as a source of carbon has been studied by various researchers in recent years [20, 32, 48]. The maximum theoretical stoichiometric yield for fermentative H2 production from glucose is 12 mol· H2·mol−1glucose [33]. However, this maximum H2 yield is still limited by the selective conditions of the fermentative process which includes the pretreatment of biomass, types of inoculum (pure or mixed culture), type of reactors, operating parameters (pH, temperature, substrate type) [35, 50], etc.

Malaysia is the second largest contributor of crude palm oil in the world by exporting 1,687,558 t of palm oil in the period of Jan–Dec 2018 [4, 54]. Nevertheless, the production of 1 t of crude palm oil requires 6–8 t of water, and over 50% of the water ends up as toxic and higher organic containing wastewater [9, 31]. The presence of high organic matter content in POME marks it as the most polluting wastewater in the world but in parallel an ideal substrate for fermentative hydrogen production. A typical POME is physio-chemically characterized as chemical oxygen demand (COD): 45,000–65,000 mg/L; biological oxygen demand (BOD): 18,000–50,000 mg/L; pH: 3.53–4.52; and oil and grease: 0.72–1.03% [36, 38]. Although the raw POME is used as a source for biogas production, the complex composition of POME increases the processing time and limited the maximum H2 productivity. In this scenario, the implementation of pretreated sludge before anaerobic digestion is considered as sustainable and efficient method to increase H2 productivity [3]. Different pretreatment strategies (biological and physicochemical) have been employed for high-strength agro-industrial wastewater and sludges to increase fermentative H2 production [27, 30]. Currently, biological and physio-chemical pretreatment processes employed for POME include deoiling [42], sedimentation [61], pre-hydrolysis [11], acid pretreatment [28], alkali pretreatment [37], ozonation pretreatment [8], peroxidation pretreatment [25], microwave irradiation [45], coagulation [41], etc., and these are evidenced for successful increment in biogas productivities.

The development of sonochemistry prevails a promising pretreatment of industrial and domestic wastewater to increase biodegradability and reduces toxicity with ultrasonic energy [5, 44]. The accelerative effect of ultrasonication on increased digestibility by sludge disintegration, COD solubilization in anaerobic digestion, and process stabilization have been reported in various literatures [10, 56]. Besides, the electromagnetic radiations (oscillation frequency of 0.3 to 300 GHz) of the microwave have also been applied for the pretreatment processes [40]. Although the quantum of energy applied to microwave irradiation is not capable of breaking down chemical bonds, H2 bonds can be broken [53]. These pretreatment processes disintegrate the particle sizes and help accelerate the hydrolysis of sludge solids which subsequently improves the H2 production from complex cellulosic organic wastewaters. Nonetheless, studies have focused on pretreatment of POME before dark fermentative H2 production, with some of them reporting enhanced H2 production by following physio-chemical pretreatment methods [2, 24, 28, 37, 47]. As compared to untreated sludge, the pretreatment of sludges before fermentation has significantly increase the organic matter biodegradability. However, the pretreatment efficiency is highly influenced by the nature of pretreatment methods as well as the composition of sludge. Therefore, it is necessary to test the impact of various pretreatment strategies of sludge on H2 production through anaerobic digestion. There is little information that exists on the best pretreatment method to produce H2 by enriching H2-producing microbes from POME sludge. Therefore, in the present study, the POME sludge was pretreated before fermentation by ultrasonication, microwave, and combined ultrasonic-microwave to assess its effect on hydrogen production and COD removal using POME as a substrate.

2 Material and methods

2.1 Substrate and inoculum

The POME sludge and wastewater were taken from an anaerobic pond (1 m below from the sludge-pond surface) and fresh outlet, respectively, from the Felda palm oil industry, Lepar Hill, Gambang, Pahang, Malaysia. The collected POME was initially filtered by passing through a laboratory sieve (aperture 0.15/R20 cm 100 mesh) to remove major solid and coarse aggregates. The collected material was preserved in a laboratory fridge at 4 °C before experimentation to decrease microbial acidification and degradation [51]. Before fermentation the POME was sterilized by autoclaving at 121 °C for 20 min to ensure the removal of indigenous microorganisms. The POME was analyzed for COD, biochemical oxygen demand (BOD), pH, volatile solid (VS), acetate and butyrate concentration, and ethanol concentrations prior and after treatment, as depicted in Tables 1 and 2.

2.2 Sludge pretreatment

Three pretreatment processes were applied to POME sludge which include ultrasonication, microwave, and ultrasonication-microwave pretreatment. These pretreated sludges were further used as seed inoculum for fermentative H2 production from sterilized POME.

-

(a).

Ultrasonication: Sonication of sludge was performed using a probe-type ultrasonic sonicator (Qsonica, USA). Ultrasonic irradiation was performed at 500 W at 20 kHz. The tip of the probe was placed in the center of the sludge medium. The applied amplitude and ultrasonication time were 75% and 25 min, respectively [1, 17].

-

(b).

Microwave pretreatment: Seed sludge was irradiated with microwave using a laboratory microwave (Transform MW680, Thailand). Microwave irradiation was applied to the sludge for 40 min at 160 °C as suggested in the literature [39].

2.3 Experimental setup

The experimentations were carried out in a series of 1 L scott bottles which served as batch reactors in the present study. Seed inoculum of 30% v/v (210 mL) was added to each rector obtaining the final working volume of 700 mL. The pretreated sludge samples in different scott bottles were subjected to the aforementioned pretreatments. Before inoculation of seed sludge to the POME, 0.50% glucose along with 0.20% NH4HCO3 was added to sterilized POME for initial bacterial acclimatization [34]. The run was conducted at 35 ± 2 °C and initial pH of 5.50 (adjusted by adding 1 N NaOH), which is reported to be favorable for H2 production [37]. The headspace of reactors was flushed with nitrogen gas (99.60% purity) to reach anaerobic conditions and sealed properly. The entire experiment lasted for 225 h and was performed on duplicates to get reproducibility of the results.

2.4 Analytical

The biogas production rate was measured every 24 h of interval using water displacement through a graduated cylinder filled with acidic water to reduce the dissolution of gas components [51]. The composition of produced gas was analyzed using a gas chromatograph (GCMS-QP, 2010; Shimadzu, Japan), equipped with the thermal conductive detector (GC-TCD) and a 0.2 m × 3 mm diameter Porapak Q stainless steel column. The operational parameters of GC were set according to our previous literature [33]. Nitrogen gas at a flow rate of 3.50 mL/min was used as a carrier gas. The soluble metabolites including volatile fatty acids (VFAs) were analyzed using high-performance liquid chromatography (Agilent 1200) equipped with a C-18 column and refractive index detector (RID). KH2PO4 with 0.05 M was used for the mobile phase with a flow rate of 0.50 mL/min [23]. The sample volume of 15 μL was injected into the column at a constant temperature of 55 °C. Besides, COD, BOD, and VS analysis was carried out by following methods recommended by APHA standard methods [43]. The H2 yield was calculated by using the total volume of hydrogen produced in each batch of experiments over the amount of COD consumed from the POME.

3 Results and discussion

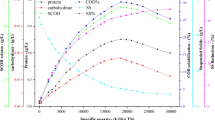

The H2 production test was carried out using ultrasonic, microwave, and ultrasonic-microwave pretreated sludge and POME as substrate. The H2 production rate is an index to evaluate the H2 production performance by biological means [58]. Upon the comparison of effects of ultrasonication irradiation and microwave pretreatment POME with control (without pretreatment), it can be observed from Fig. 1 that differences in H2 production rate for both pretreatment are apparent. It can be observed that pretreatment of sludge brings a positive effect on biodegradability which is confirmed by improved H2 production rate compared with the control one. The marked increase of 29 mLH2/h (control: 26 mLH2/h) was observed when sludge was subsequently pretreated with ultrasonication-microwave, and the highest COD reduction of 75.56% is apparent for the highest H2 rate at this scenario. On contrary, the ultrasonicated sludge had the lowest H2 production rate of 24 mLH2/h. The microwave pretreated sludge showed the maximum H2 production rate of 26 mLH2/h. These variations in production rate can be explained by the fact that the physical pretreatment of sludge before anaerobic digestion increases the sludge solubility as well as activates acidogenic bacteria more efficiently [44]. These observations are consistent with the earlier reports, where the combined approach of microwave-ultrasonic has increase the performance of anaerobic digestion significantly [46].

The biological H2 production is accompanied with the formation of VFAs (acetate, butyrate, propionate) in the fermentation period [7]. The fermentative microbes hydrolyze and ferment carbohydrates, proteins, and lipids to VFAs, which are further converted into acetate/butyrate and H2 by acetogenic bacteria. In this study, the effect of sludge pretreatments on the pattern of VFA production can be seen in Fig. 2. Initially, the observed concentrations of acetate (at 24 h) in control, ultrasonicated, microwave, and ultrasonic-microwave pretreated were 0.32, 0.41, 0.41, and 0.31 g/L POME, respectively. The observed concentrations after 216 h of fermentation for the same were 14.36, 15.42, 17.59, and 17.77 g/L. Similar trend is observed for the butyrate concentrations, during the fermentation period at 24 h, were 1.42, 0.79, 1.24, and 1.43 g/L which increases after 216 h of the fermentation as 28.91, 39.84, 31.5, and 39.78 g/L for control, ultrasonicated, microwave and ultrasonic-microwave pretreated, respectively. These results suggest that pretreatment of sludge influences VFA production, which results in an improvement in H2 production. Throughout the fermentation period, butyrate concentrations were dominated over the acetate in all sets of experiments. This suggests that the microbial consortium in sludge has followed the butyrate type of fermentative H2 production as illustrated in Eq. (1). Ismail et al. demonstrated a similar pattern of VFA production profile in the study of H2 production with anaerobic sludge from POME [18]. In another study, Sompong et al. reported similar results where the butyrate production dominated over the other metabolites during H2 production from POME seeded with thermophilic microflora [52]. Besides being less significant than acetate and butyrate, ethanol in each fermentative reactor was observed, e.g., in control it ranged between 1.10 and 1.28 g/L, while using pretreated sludge in POME showed in the range 0.49 to 1.97 g/L which is also considerable.

The differences in pretreated sludge effects on a physical-chemical characteristic of POME after treatment, especially in terms of COD, BOD, pH, VS, acetate, butyrate, and ethanol dissolved in POME, indicate the microbial activities during the fermentation [12]. COD removal concentrations observed for control, ultrasonic pretreated, ultrasonic pretreated, and ultrasonic-microwave pretreated were 32,150 ± 70, 28,130 ± 110, 21,150 ± 130, and 17,980 ± 80 mg/L, respectively. BOD observation followed similar trends where it observed 29,150 ± 40, 19,500 ± 65, 17,250 ± 110, and 13,250 ± 70 mg/L for control, ultrasonic pretreated, and ultrasonic-microwave pretreated, respectively.

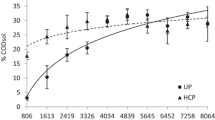

The higher BOD consumption and soluble metabolite production by ultrasonic-microwave pretreated sludge could be attributed to the selective microorganism selection by sludge pretreatment that properly adapted to the substrate and fermentative operational conditions. Metabolites such as ethanol production during fermentation were observed as 1.28 ± 0.20, 1.97 ± 0.25, 1.41 ± 0.22, and 1.78 ± 0.20 g/L for control, ultrasonic pretreated, ultrasonic-microwave pretreated, respectively. Despite this, the changes in pH of the fermentative medium reflect the efficiency of fermentative microbes. The final pH observed for ultrasonic pretreated, ultrasonic-microwave pretreated were 4.01 ± 0.30, 4.17 ± 0.25, and 3.97 ± 0.40, respectively, where the control account for final pH was 4.37 ± 0.35. This drop of pH in the medium after fermentation could be attributed to the accumulation of the metabolite which was produced during operations. In order to provide more explanation about sludge pretreatment effect on H2 production and organic matter consumption, COD removal percentage was observed for each set of experimentation as illustrated in Fig. 3. It showed that the percentage of COD removal is influenced by the pretreatment strategies employed on sludges for H2 production. Ultrasonic pretreatment has recorded 61% of COD reduction, compared to control one which was accounted for 55.65%. The microwave pretreated sludge has removed 70% of COD from POME, whereas the subsequent ultrasonic-microwave treated sludge resulted maximum COD removal percentage of 75.56. Results showed that the pretreatment of sludge can increase the COD consumption up to 15%. Grady et al. [16] has suggested that COD can be used as a parameter for organic waste conversion measurement in an anaerobic process related to biogas production [16]. To analyze the H2 production during experimentations, the calculations of COD mass balance in the form of measurable parameters was undertaken for the organic matter fluxes (before the experiment and after experiments). Acetate and butyrate were predominated in the fermentative medium, while ethanol was also observed in the 1.20 to 1.70 g/L. The maximum H2 yield of 0.18 mol.H2 was observed when ultrasonic-microwave pretreated sludge was used as fermentative inoculum. The calculations of COD mass balance were based on experimental data which includes the presence of soluble metabolites, VS and H2 (as 1 mol of H2 at STP represents COD mass of 16 g COD/mol H2) ([55]; G. [22]). As shown in Table 2, it was found that the COD mass balance was lower than 100% (w/w), i.e., in the range of 82 to 84%. This closure mass balance emphasizes data reliability.

The combined ultrasonic-microwave pretreatment was shown to be the most effective pretreatment enhancing H2 production from POME which appeared to coincide with enhanced cumulative H2 production. The cumulative H2 production of each batch fermentation was 3360, 3684, 3504 and 4080 mL for control, ultrasonicated, microwave and combined ultrasonic-microwave pretreated sludge, respectively (Fig. 3). The combined ultrasonic-microwave pretreated improved the cumulative H2 by 13% compared to control. These results suggest that pretreatment of sludge could be an important strategy to accelerate anaerobic biodegradability and disintegration of lignocellulosic biomasses, which is considered as one rate-limiting step and augments the fermentative H2 production (Fig. 4) [26, 29]. The observed results are quite consistent with those in H2 production from industrial wastewater, in which the substrate was pretreated ultrasonically followed by microwave and reported the improved H2 productivity [6]. Elbeshbishy et al. demonstrated a similar pattern in a the study where they concluded that the ultrasonication pretreatment promotes the release of carbohydrate and protein into the liquid phase of the substrate, which causes increases in H2 productivity [14]. In another study, a synergistic effect of ultrasonication pretreatment on biodegradability on dairy wastewater has been reported and observed a twofold increase in H2 production in comparison with a controlled one [15]. Similarly, microwave irradiation pretreatment of wastewater is advisable as it was established that the microwave pretreatment causes polarized macromolecules alignment with the poles of the electromagnetic field, which results in the disruption of existing H2 bonds and simultaneously increases the substrate availability [57]. Microwave pretreatment comprises the thermal and the non-thermal effect, which has been used for microbial disruption of waste activated sludge and reported the improved solubilization of waste and enhanced H2 production [60]. Similar to observed results in the present study, the subsequent mechanical and ultrasonic pretreatments have reported enhanced hydrolysis, biodegradability, and biogas production when household organic waste was subject as a substrate for the anaerobic digestion [19, 59]. The subsequent ultrasonication and microwave pretreatment of POME sludge before fermentation increases the solubilization of organic waste which helps to improve the H2 productivity. Even though fermentative H2 production can be achieved without any pretreatment of sludge or wastewater, the application of ultrasonication and microwave treatment (thermal treatment) resulted in a considerable enhancement in H2 productivity and COD reduction. Besides, the coupling of ultrasonication pretreatment followed with microwave could be a more effective approach to restrain H2 production. Overall, results entail the application of pretreatment coupled with anaerobic digestion before the wastewater gets discharged to the water bodies to reduce its negative impact on the environment.

4 Conclusion

The pretreatment of POME before anaerobic digestion is advantageous for the maximum conversion of complex organic waste into H2. Sonication, microwave, and coupling of sonication-microwave pretreatment employed for seed sludge have shown a considerable impact on cumulative H2 production and COD reduction from POME wastewater. The improvement observed for cumulative H2 production and COD removal was 12.14% and 21.42%, respectively, compared to the control one. The highest cumulative H2 production and COD removal were observed when the ultrasonication and microwave pretreatment were applied together which suggested that the combined pretreatment approach gave better treatment performance of POME compared to ultrasonic and microwave pretreatment applied alone to sludge. Overall, sonication coupled with microwave pretreatment of sludge inoculum was more effective than the control one to neutralize the organic content of POME wastewater.

References

Alagöz BA, Yenigün O, Erdinçler A (2015) Enhancement of anaerobic digestion efficiency of wastewater sludge and olive waste: synergistic effect of co-digestion and ultrasonic/microwave sludge pre-treatment. Waste Management 46:182–188

Aziz MMA, Kassim KA, ElSergany M, Anuar S, Jorat ME, Yaacob H et al (2020) Recent advances on palm oil mill effluent (POME) pretreatment and anaerobic reactor for sustainable biogas production. Renewable and Sustainable Energy Reviews 119:109603

Beaudry G, Macklin C, Roknich E, Sears L, Wiener M, Gheewala SH (2018) Greenhouse gas assessment of palm oil mill biorefinery in Thailand from a life cycle perspective. Biomass Conversion and Biorefinery 8:43–58

Bhuyar P, Sundararaju S, Rahim MHA, Ramaraj R, Maniam GP, Govindan N (2019) Microalgae cultivation using palm oil mill effluent as growth medium for lipid production with the effect of CO 2 supply and light intensity. Biomass Conversion and Biorefinery:1–9

Braguglia C, Gianico A, Mininni G (2012) Comparison between ozone and ultrasound disintegration on sludge anaerobic digestion. Journal of environmental management 95:S139–S143

Bundhoo ZM (2017) Effects of microwave and ultrasound irradiations on dark fermentative bio-hydrogen production from food and yard wastes. International Journal of Hydrogen Energy 42:4040–4050

Cai M, Liu J, Wei Y (2004) Enhanced biohydrogen production from sewage sludge with alkaline pretreatment. Environmental science & technology 38:3195–3202

Chaiprapat S, Laklam T (2011) Enhancing digestion efficiency of POME in anaerobic sequencing batch reactor with ozonation pretreatment and cycle time reduction. Bioresource technology 102:4061–4068

Chin MJ, Poh PE, Tey BT, Chan ES, Chin KL (2013) Biogas from palm oil mill effluent (POME): opportunities and challenges from Malaysia’s perspective. Renewable and Sustainable Energy Reviews 26:717–726

Chiu Y-C, Chang C-N, Lin J-G, Huang S-J (1997) Alkaline and ultrasonic pretreatment of sludge before anaerobic digestion. Water science and technology 36:155–162

Climent M, Ferrer I, del Mar Baeza M, Artola A, Vázquez F, Font X (2007) Effects of thermal and mechanical pretreatments of secondary sludge on biogas production under thermophilic conditions. Chemical Engineering Journal 133:335–342

Deepanraj B, Sivasubramanian V, Jayaraj S (2017) Effect of substrate pretreatment on biogas production through anaerobic digestion of food waste. International Journal of Hydrogen Energy 42:26522–26528

Dhanya B, Mishra A, Chandel AK, Verma ML (2020) Development of sustainable approaches for converting the organic waste to bioenergy. Science of The Total Environment 723:138109

Elbeshbishy E, Hafez H, Nakhla G (2012) Viability of ultrasonication of food waste for hydrogen production. International journal of hydrogen energy 37:2960–2964

Gadhe A, Sonawane SS, Varma MN (2015) Influence of nickel and hematite nanoparticle powder on the production of biohydrogen from complex distillery wastewater in batch fermentation. International Journal of Hydrogen Energy 40:10734–10743

Grady C, Daigger G, Lim H (1999) Biological wastewater treatment. Marcel Dekker, Inc, New York

Hay JXW, Wu TY, Juan JC, Jahim JM (2015) Improved biohydrogen production and treatment of pulp and paper mill effluent through ultrasonication pretreatment of wastewater. Energy conversion and management 106:576–583

Ismail I, Hassan MA, Rahman NAA, Soon CS (2010) Thermophilic biohydrogen production from palm oil mill effluent (POME) using suspended mixed culture. Biomass and Bioenergy 34:42–47

Karouach F, Bakraoui M, El Gnaoui Y, Lahboubi N, El Bari H (2020) Effect of combined mechanical–ultrasonic pretreatment on mesophilic anaerobic digestion of household organic waste fraction in Morocco. Energy Reports 6:310–314

Krishnan S, Singh L, Mishra P, Nasrullah M, Sakinah M, Thakur S et al (2017) Comparison of process stability in methane generation from palm oil mill effluent using dairy manure as inoculum. Environmental Technology & Innovation 8:360–365

Kumar R, Kumar P (2017) Future microbial applications for bioenergy production: a perspective. Frontiers in microbiology 8:450

Kumar G, Bakonyi P, Sivagurunathan P, Kim S-H, Nemestóthy N, Bélafi-Bakó K et al (2015) Enhanced biohydrogen production from beverage industrial wastewater using external nitrogen sources and bioaugmentation with facultative anaerobic strains. Journal of bioscience and bioengineering 120:155–160

Kyazze G (2007) Hydrogen production via dark fermentation of carbohydrate-rich substrates. University of South Wales, United Kingdom

Leano EP, Anceno AJ, Babel S (2012) Ultrasonic pretreatment of palm oil mill effluent: impact on biohydrogen production, bioelectricity generation, and underlying microbial communities. International journal of hydrogen energy 37:12241–12249

Lim CH, Ang JJ, Lau S, Tay MG (2017) Optimization of hydroxyl radical production using electro-Fenton method for chemical oxygen demand reduction in diluted palm oil mill effluent. Water and Environment Journal 31:578–583

Liu C-Z, Wang F, Stiles AR, Guo C (2012) Ionic liquids for biofuel production: opportunities and challenges. Applied Energy 92:406–414

Loh L-M, YAN Y, Yap P-W, Nadarajan R, Ong AS-H (2019) Palm oil mill effluent as alternate carbon source for ammonia removal in wastewater treatment. Sains Malaysiana 48:871–876

Mahmod SS, Jahim JM, Abdul PM (2017) Pretreatment conditions of palm oil mill effluent (POME) for thermophilic biohydrogen production by mixed culture. International Journal of Hydrogen Energy 42:27512–27522

Mari AG, Andreani CL, Tonello TU, Leite LC, Fernandes JR, Lopes DD et al (2020) Biohydrogen and biomethane production from cassava wastewater in a two-stage anaerobic sequencing batch biofilm reactor. International Journal of Hydrogen Energy 45:5165–5174

Mishra, P. (2018) Biohydrogen production from palm oil mill effluent via sequential dark-photo fermentation

Mishra P, Thakur S, Singh L, Ab Wahid Z, Sakinah M (2016) Enhanced hydrogen production from palm oil mill effluent using two stage sequential dark and photo fermentation. International Journal of Hydrogen Energy 41:18431–18440

Mishra P, Thakur S, Singh L, Krishnan S, Sakinah M, Ab Wahid Z (2017) Fermentative hydrogen production from indigenous mesophilic strain Bacillus anthracis PUNAJAN 1 newly isolated from palm oil mill effluent. International Journal of Hydrogen Energy 42:16054–16063

Mishra P, Singh L, Ab Wahid Z, Krishnan S, Rana S, Islam MA et al (2018) Photohydrogen production from dark-fermented palm oil mill effluent (DPOME) and statistical optimization: renewable substrate for hydrogen. Journal of Cleaner Production 199:11–17

Mishra P, Ameen F, Zaid RM, Singh L, Ab Wahid Z, Islam MA et al (2019a) Relative effectiveness of substrate-inoculum ratio and initial pH on hydrogen production from palm oil mill effluent: kinetics and statistical optimization. Journal of Cleaner Production 228:276–283

Mishra P, Krishnan S, Rana S, Singh L, Sakinah M, Ab Wahid Z (2019b) Outlook of fermentative hydrogen production techniques: an overview of dark, photo and integrated dark-photo fermentative approach to biomass. Energy Strategy Reviews 24:27–37

Mishra, P., Ab Wahid, Z., Zaid, R. M., Rana, S., Tabassum, S., Karim, A., et al. (2020) Kinetics and statistical optimization study of bio-hydrogen production using the immobilized photo-bacterium. Biomass Conversion and Biorefinery, 1–12

Mohammadi P, Ibrahim S, Annuar MSM, Law S (2011) Effects of different pretreatment methods on anaerobic mixed microflora for hydrogen production and COD reduction from palm oil mill effluent. Journal of Cleaner Production 19:1654–1658

Osman NA, Ujang FA, Roslan AM, Ibrahim MF, Hassan MA (2020) The effect of palm oil mill effluent final discharge on the characteristics of Pennisetum purpureum. Scientific Reports 10:1–10

Özön E, Erdinçler A (2019) Effects of microwave, H 2 O 2/MW and H 2 O 2/heat pre-treatments on the methane production from wastewater sludges: experimental and modeling approach. Environmental Science and Pollution Research 26:35411–35421

Park B, Ahn J-H, Kim J, Hwang S (2004) Use of microwave pretreatment for enhanced anaerobiosis of secondary sludge. Water Science and Technology 50:17–23

Parthasarathy S, Gomes RL, Manickam S (2016) Process intensification of anaerobically digested palm oil mill effluent (AAD-POME) treatment using combined chitosan coagulation, hydrogen peroxide (H 2 O 2) and Fenton’s oxidation. Clean Technologies and Environmental Policy 18:219–230

Rasit N, Idris A, Harun R, Ghani WAWAK (2015) Effects of lipid inhibition on biogas production of anaerobic digestion from oily effluents and sludges: an overview. Renewable and Sustainable Energy Reviews 45:351–358

Rice A, Baird E, Eaton R (2017) APHA 2017 Standard methods for examination of water and wastewater. American Public Health Association, American Water Works Association, and Water Env. Federation ISBN, Washington

Saha M, Eskicioglu C, Marin J (2011) Microwave, ultrasonic and chemo-mechanical pretreatments for enhancing methane potential of pulp mill wastewater treatment sludge. Bioresource technology 102:7815–7826

Saifuddin, N. & Fazlili, S. (2009) Effect of microwave and ultrasonic pretreatments on biogas production from anaerobic digestion of palm oil mill effluent. American Journal of Engineering and Applied Sciences, 2

Salihu A, Alam MZ (2016) Pretreatment methods of organic wastes for biogas production. J. Appl. Sci 16:124–137

Seengenyoung, J., Prasertsan, P. & Sompong, O. (2013) Biohydrogen production from palm oil mill effluent pretreated by chemical methods using Thermoanaerobacterium-rich sludge. In Proceedings of the Iranica Journal of Energy & Environment. Citeseer

Seengenyoung J, Mamimin C, Prasertsan P, Sompong O (2019) Pilot-scale of biohythane production from palm oil mill effluent by two-stage thermophilic anaerobic fermentation. International Journal of Hydrogen Energy 44:3347–3355

Shanmugam S, Hari A, Pandey A, Mathimani T, Felix L, Pugazhendhi A (2020) Comprehensive review on the application of inorganic and organic nanoparticles for enhancing biohydrogen production. Fuel 270:117453

Sharma K (2019) Carbohydrate-to-hydrogen production technologies: a mini-review. Renewable and Sustainable Energy Reviews 105:138–143

Singh L, Siddiqui MF, Ahmad A, Rahim MHA, Sakinah M, Wahid ZA (2013) Application of polyethylene glycol immobilized Clostridium sp. LS2 for continuous hydrogen production from palm oil mill effluent in upflow anaerobic sludge blanket reactor. Biochemical engineering journal 70:158–165

Sompong O, Prasertsan P, Intrasungkha N, Dhamwichukorn S, Birkeland N-K (2007) Improvement of biohydrogen production and treatment efficiency on palm oil mill effluent with nutrient supplementation at thermophilic condition using an anaerobic sequencing batch reactor. Enzyme and microbial technology 41:583–590

Sun, B., Hu, Y. & Cheng, H. (2019) Microwave-induced degradation as a novel treatment for destruction of decabromodiphenyl ether sorbed on porous minerals. Chemical Engineering Journal, 123550

Tan YD, Lim JS (2019) Feasibility of palm oil mill effluent elimination towards sustainable Malaysian palm oil industry. Renewable and Sustainable Energy Reviews 111:507–522

Tchobanoglus G, Burton F, Stensel HD (2003) Wastewater engineering: treatment and reuse. American Water Works Association. Journal 95:201

Tiehm A, Nickel K, Zellhorn M, Neis U (2001) Ultrasonic waste activated sludge disintegration for improving anaerobic stabilization. Water research 35:2003–2009

Tyagi VK, Lo S-L (2013) Microwave irradiation: a sustainable way for sludge treatment and resource recovery. Renewable and Sustainable Energy Reviews 18:288–305

Xiao B, Liu J (2006) pH dependency of hydrogen fermentation from alkali-pretreated sludge. Chinese Science Bulletin 51:399–404

Yang S-S, Guo W-Q, Meng Z-H, Zhou X-J, Feng X-C, Zheng H-S et al (2013) Characterizing the fluorescent products of waste activated sludge in dissolved organic matter following ultrasound assisted ozone pretreatments. Bioresource technology 131:560–563

Yin Y, Wang J (2018) Pretreatment of macroalgal Laminaria japonica by combined microwave-acid method for biohydrogen production. Bioresource technology 268:52–59

Zinatizadeh, A., Mohamed, A., Mashitah, M., Abdullah, A. & NAJAFPOUR, G. D. (2006) Pretreated palm oil mill effluent (POME) digestion in an up-flow anaerobic sludge fixed film bioreactor: a comparative study

Acknowledgments

The authors acknowledge the support of the Ministry of Higher Education Malaysia (Ref. code FRGS/1/2018/STG05/UMP/01/1; UMP Ref.: RDU190121). Puranjan Mishra would like to acknowledge the Postdoctoral Research Fellowship awarded by the Research and Innovation Department, Universiti Malaysia Pahang.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mishra, P., Wahid, Z.a., Singh, L. et al. Synergistic effect of ultrasonic and microwave pretreatment on improved biohydrogen generation from palm oil mill effluent. Biomass Conv. Bioref. 12, 3655–3662 (2022). https://doi.org/10.1007/s13399-021-01285-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01285-4