Abstract

The wastewater sludge stabilization by anaerobic digestion is sufficient to reduce the organic content of the sludge, so that it can be safely disposed of without causing odor problems and pathogen contamination, while producing energy in form of biogas. Efficiency of anaerobic digestion in terms of biogas/methane production and organic removal can be enhanced by pretreating the sludge prior to anaerobic digestion. This study compares the effects of microwave (MW), combined hydrogen peroxide/microwave (H2O2/MW), and combined hydrogen peroxide/heat (H2O2/heat) pre-treatments on the digestion efficiency and methane production potential of wastewater sludges. The methane productions were also estimated by using modified Gompertz equation through the calculation of the kinetic parameters. The pre-treatments applied to sludge samples speeded up the hydrolysis step and improved the biodegradability of the organics by increasing their solubility. Application of MW, combined H2O2/MW, and combined H2O2/heat pre-treatments increased the methane yields by 64%, 38%, and 19%. The modified Gompertz model fitted well to the experimental results (R2 of 0.999, 0.983, 0.997, and 0.998 for control, MW, H2O2/MW, and H2O2/heat, respectively).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The increasing amount of sewage sludge production in wastewater treatment plants (WWTPs) has become a serious problem. To overcome the rising problem, the wastewater sludge disposal amount should be diminished by the application of varied sludge treatment and pre-treatment methods. The sludge stabilization must be applied to wastewater sludges for the safe disposal.

The wastewater sludge production is increasing worldwide with gradual growth of population and industrialization. The energy need is also increasing with the developing world and there is a necessity of alternative energy source. The anaerobic digestion (AD) is a promising technology for generating energy from waste sludge by producing biogas. Biogas, which comprises of biomethane and carbon dioxide, is a renewable source of energy obtained from biodegradable organic wastes like biomass, agricultural and animal wastes, and industrial waste (W. Li et al. 2018; Kuglarz et al. 2013; Abudi et al. 2016).

AD is the most widely used beneficial approach for wastewater sludge stabilization reducing odors and pathogens in sludge, while providing recovery of renewable energy through the biogas production (Ahn et al. 2009; Priadi et al. 2014; Weiland 2010). Anaerobic digestion is a complicated conversion process of biodegradable organic material in microorganisms converting into biogas in the absence of oxygen, and it comprises mainly methane (CH4) and inorganic end-products like carbon dioxide (CO2). Anaerobic digestion of organic material occurs in four stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis (Climent et al. 2007; Lastella et al. 2002; Wu-Haan 2008).

The performance of anaerobic digestion of sludges can be enhanced with the application of various physical (thermal, mechanical, ultrasonic, microwave), chemical (alkaline, hydrogen peroxide, ozone oxidation), and biological (enzymatic) pre-treatment methods or their combinations. These pre-treatments disintegrate the sludge solids and improve the biodegradability of sludge solids, biogas/methane production, and removal of the micropollutants (Angelidaki et al. 2009; Ariunbaatar et al. 2014; Climent et al. 2007; Weiland 2010; Tyagi and Lo 2011).

Advanced oxidation pre-treatment techniques have gained importance in recent years. Many disinfectant oxidants like ozone, hydrogen peroxide, chlorine, and chlorine dioxide have been used in the disintegration of the sludge. Hydrogen peroxide (H2O2) and ozone (O3) applications in sludge have been investigated by many researchers. Although ozone is a very strong oxidant, ozonation is an expensive process that limits large-scale application. For this reason, applications of other chemicals such as hydrogen peroxide (H2O2) and Fenton (hydrogen peroxide/iron catalyst) have come to the forefront. Hydrogen peroxide is the simplest peroxide and acts as a strong oxidant, enhancing the sludge disintegration. H2O2 pre-treatment can be improved by the heat application, direct heat or microwave irradiation, to the sludge samples as a combined pre-treatment method (Bougrier et al. 2006; Eswari et al. 2016; Feki et al. 2015; Hannmann et al. 2012; Liu et al. 2016; Neyens and Baeyens 2003; Shahriari et al. 2012; SONG et al. 2013).

Microwave irradiation is an alternative thermal sludge pre-treatment method. It is more advantageous than the conventional thermal processes due to several reasons like rapid heating, high reaction rate, easy control, compactness, and creation of greater damage on microbial cells at similar applied temperatures compared with conventional heating (Alagöz et al. 2015; 2017; Eskicioglu et al. 2007; Mudhoo et al. 2011). Microwave irradiation disintegrates the sludge flocs and disrupts the sludge cells by the effect of rapid heating. It causes the release of extracellular and intracellular substances leading to an increase in the organic components such as soluble COD, soluble proteins, and soluble carbohydrates in the liquid phase of the wastewater sludges (Eskicioglu et al. 2007; Tyagi and Lo 2013).

Combined pre-treatment methods give more effective results than the single pre-treatment methods. Therefore, it is expected to reach higher biogas production efficiencies with the application of combined pre-treatment methods to sludge samples prior to anaerobic digestion. However, there are some contradicting studies in literature reporting that the H2O2/MW and H2O2/heat pre-treatments resulted with lower biogas yields compared with MW pre-treatment (Shahriari et al. 2012; Valo et al. 2004; Eskicioglu et al. 2008b; Liu et al. 2017).

This study investigates the effects of microwave (MW), combined hydrogen peroxide/microwave (H2O2/MW), and combined hydrogen peroxide/heat (H2O2/heat) pre-treatments on the anaerobic digestion efficiency of wastewater sludges in terms of methane production and organic removal. Biochemical methane potential (BMP) test was used to determine the anaerobic digestibility of sludge samples by measuring biogas productions. The kinetic parameters of methane production were also modeled by using modified Gompertz equation.

Materials and methods

Sludge samples

The wastewater sludge samples were obtained from recirculation unit of a biological wastewater treatment plant located in Istanbul. The inoculum sludge was supplied from the anaerobic digester of the same plant.

The inoculum and sludge samples were characterized by analyzing their total solids (TS), volatile solids (VS), chemical oxygen demand (COD), soluble chemical oxygen demand (sCOD), total suspended solids (TSS), volatile suspended solids (VSS), total organic carbon (TOC), total Kjeldahl nitrogen (TKN), phosphorus (P), volatile fatty acids (VFA), alkalinity concentrations, and the pH values. All of the characterization analyses were conducted in triplicates as described in the Standard Methods of the Examination of Water and Wastewaters (APHA 2012). The characteristics of wastewater sludge and inoculum are given in the Table 1.

Table 2 summarizes the analytical methods and instruments used in this study.

Application of sludge pre-treatments

The wastewater sludge samples were pre-treated with MW, combined H2O2/MW, and H2O2/heat pre-treatment methods to show their effects on methane production comparatively.

Microwave pre-treatment

The microwave pre-treatment was applied to sludge samples by irradiating them for 15 min at 160 °C and 2000 kPa in a microwave (MW) digestion (Berghoff MWS+3) by using a 5-staged temperature program. In the 1st and 2nd stages, the temperature is risen to 120 ° C in 2 min and then 140 °C in the following minute. In the 3rd stage, the temperature reached to 160 °C and remained constant for 10 min. In the next 2 min, the temperature drops to 140 °C and then 100 °C in the 4th and 5th stages, respectively. The application conditions of MW pre-treatment were selected based on the results of a preliminary MW optimization study (TUBITAK-KAMAG 2013).

Combined hydrogen peroxide and MW pre-treatments (H2O2/MW)

Combined H2O2/MW treatment consisted of a preheating step, H2O2 (30% w/w) addition, and microwave irradiation. First, the sludge samples were heated at 120 °C for 15 min in the MW system to destruct the biological enzymes in the sludge to avoid the excessive consumption of hydrogen peroxide (Wang et al. 2009). After the preheating step, 1 g H2O2/g TS was added into the sludge samples, and the samples were irradiated in a microwave digester at 160 °C for 15 min. The applied peroxide concentration of 1 g H2O2/g TS was selected based on the results of the studies in literature using the wastewater sludges as substrate (Bilgin Oncu and Akmehmet Balcioglu 2013; Jung et al. 2014; Kim et al. 2009; Wong et al. 2006; Yin et al. 2007). Especially, the optimization study by Bilgin Oncu and Akmehmet Balcioglu (2013) used a wastewater sludge having quite similar characteristics to the sludge used in this study.

Combined hydrogen peroxide and heat pre-treatments (H2O2/heat)

In combined H2O2/heat pre-treatment, the sludge samples placed in polytetrafluoroethylene (PTFE) beakers were preheated to 75 °C for 2 min prior to the addition of 1 g H2O2/g TS (30% w/w) in order to initiate the chemical reaction. Then, the sludge samples were subjected to heat treatment at 75 °C for 90 min in a temperature-controlled water bath (Julabo, SW22). The heat pre-treatment conditions were selected based on a previous study conducted in the Institute of Environmental Sciences, Boğaziçi University (Mercan 2015).

Biochemical methane production potential experiments

The biochemical methane potential (BMP) test was used to investigate the effects of MW, combined H2O2/MW, and combined H2O2/heat pre-treatments on the anaerobic digestion efficiency of wastewater sludges in terms of methane production. Biochemical methane potential test helps to determine the anaerobic digestibility of sludge samples by measuring biogas productions. The BMP assay process was first established by Owen et al. (1979) as a simple and inexpensive procedure to monitor relative anaerobic biodegradability of substrates.

In this study, the BMP tests were performed in six parallel sets of four different reactor groups (total of 24 reactors) according to the procedure described by Owen et al. (1979). The four main reactor groups were control reactors, MW reactors, H2O2/MW reactors, and H2O2/heat reactors. Table 3 shows the contents of the reactor groups.

The pre-treatments were applied to the wastewater sludge (substrate) samples only. The pretreated wastewater sludge samples were mixed with the inoculum in reactors having 80 mL active volume. In the reactors, the inoculum-to-substrate ratio (ISR) was adjusted to 1:1 (w/w on VS basis) by feeding the reactors with 23 mL of inoculum and 57 mL of wastewater sludge. The control reactors included inoculum and un-pretreated sludge.

The initial pH of the reactor contents was adjusted to 7–7.2 to be in the favorable range for anaerobic digestion (Appels et al. 2008; Feki et al. 2015). In the same way, the initial alkalinity concentrations in the reactors were adjusted to be in the range of 3000–4500 mg/L as CaCO3 to keep the alkalinity in the safe range for anaerobic digestion (Raposo et al. 2012; Turovskiy and Mathai 2006). The reactors were sealed and flushed with nitrogen gas for 2 min to create an anaerobic environment. The reactors were anaerobically digested at 37 °C for 40 days under mixing conditions in the temperature-controlled shaking water baths.

The effects of applied pre-treatments on the removal of organic matters were investigated by measuring TS, VS, COD, and sCOD concentrations of the reactor contents weekly by opening one of the parallels for each reactor groups.

Total biogas productions in reactors was measured daily with the pressure method by using a manometer (Lutron PM-9107). The biogas compositions were analyzed weekly by using a gas chromatograph (GC) (Agilent HP 6850). The gas samples were taken from each reactor with a GC autosampler syringe and injected into the GC to analyze the gas compositions in the reactors.

Kinetic modeling of methane production

In this study, kinetic modeling of methane production was performed by using modified Gompertz equation. Gompertz equation was found to be the most suitable model for the biogas/methane productions (Zwietering et al. 1990). The modified Gompertz equation was originally developed for the prediction of bacterial growth. Later, the Gompertz equation was implemented for the modeling of specific growth rate of methanogenic bacteria. The kinetics of methane yields directly link with the specific growth rate of methanogenic bacteria.

In many studies, the nonlinear regression of Gompertz equation was used for modeling of biogas and methane production potentials of several systems (L. Li et al. 2015; Y. Li et al. 2013; Syaichurrozi and Sumardiono 2013; Tsapekos et al. 2017; Yusuf et al. 2011; Budiyono et al. 2014).

The modified Gompertz equation is as follows:

where M is the cumulative methane production (mL CH4/g VS) at time t (day), λ is the lag time (day), P is the methane production potential (mL CH4/g VS), Rm is the maximum methane production rate (mL CH4/g VS/day), and e is the mathematical constant (2.7182) (Córdoba et al. 2018).

Kinetic constant of P, λ, and Rm was evaluated by using nonlinear regression approach with the help of solver function of the MS Excel (Matheri et al. 2016; Yusuf et al. 2011; Ghatak and Mahanta 2017; Ghatak and Mahanta 2014).

Results and discussions

Effects of pre-treatments on sludge solubility and organic removal

The pre-treatments considerably improved the solubility of organics in sludge samples. The microwave pre-treatment disrupts the sludge flocs and cells, breaks the hydrogen bonds, and releases the soluble organic components into the liquid phase of the sludge. In the H2O2 pre-treatment, the hydroxyl radicals (OH•) and hydroperoxyl radicals (HO2•), generated from the decomposition of hydrogen peroxide, attack on sludge particles and cause the destruction of cell walls of the microorganisms and solubilize the particulate component of sludge into the soluble form.

TS and VS reductions

The application of pre-treatments to the sludge samples increased the total solid (TS) and volatile solid (VS) removal rates in the anaerobic digestion process. The control reactor, containing un-pretreated sludge and inoculum, has an initial TS concentration of 25 g/L and a VS concentration of 13 g/L. The TS and VS concentrations in the reactors were measured weekly by opening one of the parallel reactors. At the end of the digestion period, the overall TS and VS removal rates in the control reactor were 15% and 24%, respectively. In the combined H2O2/MW, H2O2/heat, and MW pretreated sludge–containing reactors, the TS removal efficiencies were determined to be 53%, 29%, and 28%, respectively. The VS removal efficiencies in these reactors were about 59%, 40%, and 42% in the same order. Figure 1 shows the VS concentration changes in the reactors during anaerobic digestion period.

COD and sCOD removals

The initial COD concentrations in the reactors were measured to be in the range of 20000 to 22200 mg/L. At the end of the anaerobic digestion period, the COD removal rate in the control reactor was 18%. The applied sludge pre-treatments increased the COD removal efficiencies in the reactors two- to threefolds by increasing the solubility of the sludge organics. The COD removal efficiencies were found to be 58%, 55%, and 43% in the MW, H2O2/MW, and H2O2/heat pretreated sludge–containing reactors, respectively.

Accordingly, Wang et al. (2015) applied a lower H2O2 dose of 0.2 g H2O2/g TSS to a wastewater sludge sample at 100 °C and reported that H2O2/MW pre-treatment resulted to a COD removal of 19.35% for 15 min. to a wastewater sludge, having similar characteristics with the sludge used in this study, and achieved a COD removal of 23% and 41%, respectively (Bilgin Oncu and Akmehmet Balcioglu 2013).

The pre-treatments considerably improved the solubility of sludge samples by disintegrating the sludge structure and releasing organic matter into the soluble phase. The initial sCOD of inoculum and un-pretreated sludge mixture in the control reactor was measured to be 470 mg/L. After the application of pre-treatments, the initial sCOD concentrations in the reactors were increased by 751%, 517%, and 158% for H2O2/heat, H2O2/MW, and MW pre-treatments, respectively.

This increase in the solubility of the sludge solids led to an improvement in the sCOD removal rates. The sCOD removal rates increased from 14% (in control reactor) to 74%, 68%, and 59% in the MW, H2O2/MW, and H2O2/heat pretreated sludge–containing reactors, respectively. In the MW pre-treatment–applied reactor, the conversion of sCOD to biogas started immediately after sealing the reactor in day 0. The change in sCOD concentrations during anaerobic digestion is shown in Fig. 2.

In accordance with this study, Wong et al. (2006) investigated the effect of combined H2O2 and MW pre-treatment at different temperatures on sewage sludge treatment and achieved COD solubilization of 72% and 77% with 1 mL H2O2 addition and MW application at 120 °C and 100 °C, respectively. When they increased the H2O2 dose to 2 mL H2O2, the COD solubilizations increased to 97% and 104% at 120 °C and 100 °C, respectively. Their study showed that the increased temperature of MW in combined H2O2 and MW pre-treatment may lead to lower COD solubilization (Wong et al. 2006). Similarly, combined MW and hydrogen peroxide pre-treatment (110 °C and 0.3 H2O2 mg/g SS) of waste activated sludge obtained COD solubilization of up to 50.3% (Eswari et al. 2016).

Effects of pre-treatments on methane production

The biochemical methane potential (BMP) test was used to investigate the effects of MW, combined H2O2/MW, and combined H2O2/heat pre-treatments on the methane production potential of the wastewater sludges. The VFA and ammonia concentrations in the reactors were measured weekly to control the formation of ammonia and/or VFA inhibition during the anaerobic digestion period. The ammonia concentrations in the reactors were ranged between 275 and 930 mg/L throughout the digestion process, being much lower than the critical inhibition concentration of 1700 mg/L for anaerobic digestion (Franke-Whittle et al. 2014; Koster and Lettinga 1984). The highest VFA concentration measured in the reactors was 1340 mg/L. Based on the literature, this concentration was in safe limits for a successful anaerobic digestion. There are many studies reporting that the VFA concentrations should be under 4000 mg/L to control any possible inhibition in an anaerobic digestion process (Lee et al. 2015; Chen et al. 2008; Fricke et al. 2007). Siegert and Banks (2005) stated that total VFA concentrations higher than 4000 mg/L cause to a slight inhibition and concentrations higher than 8000 mg/L to a serious inhibition in the anaerobic digestion process.

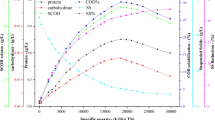

The pre-treatments applied to sludge samples improved the methane productions. The cumulative methane productions were increased by 64%, 38%, and 19% in the reactors containing sludges pretreated with MW, H2O2/MW, and H2O2/heat, respectively. The cumulative methane productions in the reactors are given in Fig. 3. In the MW pre-treatment–applied reactor, the biogas/methane production started right after the start of anaerobic digestion process.

The methane contents of the biogas produced in the reactors stayed in the range of 55–65%, indicating successful methane production. The contribution of the inoculum sludge was subtracted from the total gas productions in each reactor when calculating the yields. The highest methane yield of 618 mL CH4/g VS was obtained from MW pretreated sludge. Application of MW, combined H2O2/MW, and combined H2O2/heat pre-treatments to the sludge samples improved the methane yields by 64%, 38%, and 19%, respectively. The methane yields were in accordance with the sCOD removal rates in the reactors.

Supportively, Kuglarz et al. (2013) achieved 41% and 52% improvement in the methane productions from wastewater sludge samples by the application of microwave pre-treatment at temperatures of 60 °C and 70 °C, respectively. In the same way, Alagöz et al. (2015) reported that microwave pre-treatment applied to the sludge samples at 175 °C improved the methane yield by 52%. Eskicioglu et al. (2008a) obtained 10.8%, 10.9%, 16%, and 31% increase in the overall biogas production from the application of microwave pre-treatment to the sludge samples prior to mesophilic digestion at 65 °C, 75 °C, 85 °C, and 175 °C, respectively.

The combined H2O2/MW pre-treatment (1.0 g H2O2/g TS) resulted with lower biogas/methane production than the MW pre-treatment alone. Based on the literature, this can be explained with the negative effect of H2O2 residual or byproducts on the methanogens. In the anaerobic digestion process, methanogenesis is generally the rate limiting step due to the sensitivity of methanogens to the environmental conditions. In accordance with the results of this study, there are several studies in literature stating that the residual H2O2 or byproducts sourced from the application of H2O2 to the sludge samples may cause to a limiting effect on the activity of methanogens, and decrease the biogas production. Liu et al. (2015) investigated inhibitory effect of the residual H2O2 after the application of H2O2/MW pre-treatment to the waste activated sludge samples at three different concentrations (0.2 g H2O2/g TS, 0.6 g H2O2/g TS, and 1.0 g H2O2/g TS). They reported that application of combined H2O2/MW pre-treatment to the sludge samples with high H2O2 concentrations (0.6 and 1.0 g H2O2/g TS) created an inhibitory impact on the metabolic activity of methanogens and decreased the methane yield due to the generation of H2O2 refractory compounds and rise in a long lag phase in the initial days of methane productions throughout the anaerobic digestion process. They stated that the low H2O2 concentration in pre-treatment increased the sludge biodegradability and anaerobic digestion performance (Liu et al. 2015). In the same way, Valo et al. (2004) obtained higher methane production with the application of MW pre-treatment than combined H2O2/MW and combined H2O2/FeSO4 MW pre-treatments in their study. They reported that the addition of chemicals (H2O2 and H2O2/FeSO4) limits the positive effect of high-temperature thermal pre-treatments applied to the waste activated sludge samples. Similarly, Eskicioglu et al. (2008b) applied MW and H2O2/MW (1.0 g H2O2/g TS) pre-treatments to the thickened waste activated sludge samples at temperatures of 60 °C, 80 °C, 100 °C, and 120 °C and obtained 20–54% higher methane yields with MW pre-treatment than combined H2O2/MW pre-treatment at all temperatures. They stated that soluble organics generated by the application of combined H2O2/MW pre-treatment were slower to biodegrade or more refractory than those generated by the application of MW pre-treatment (Eskicioglu et al. 2008b). Additionally, Shahriari et al. (2012) applied the combined H2O2/MW pre-treatment (0.66 g H2O2/g TS at 85 °C) to a different substrate of organic fraction of municipal solid waste. They also obtained lower methane production by combined H2O2/MW pre-treatment than the MW pre-treatment and reported that the residual H2O2 or refractory compounds from advanced oxidation can inhibit methanogenesis and decrease biogas production (Shahriari et al. 2012).

Kinetic modeling of methane production by using modified Gompertz equation

The results obtained from the modified Gompertz equation model by using nonlinear regression showed good fit to the experimental data for cumulative methane yield. Figure 4 shows the comparison of cumulative methane yields obtained from experimental data and modified Gompertz model. The kinetic parameters estimated with the model are presented in Table 4. The pre-treatments considerably improved the methane yields and the methane production rates as compared with the control. The model resulted slightly lower methane production potential values (P) than the experimental methane yields (EMY) for all of the pre-treatments. The difference between experimental and predicted methane yields is under 4.4% for all of the pre-treatments. The lag phase time (λ) shows the start-up time of anaerobic digestion process. In the MW pre-treatment–applied reactor, the conversion of sCOD to biogas started immediately after sealing the reactor in day 0. Then, no lag phase was observed in this reactor during the anaerobic digestion period. The solver function of the MS Excel created the best fit by trials and resulted a lag phase time of − 1.367 for MW pre-treatment. It should be noticed that the methane production data fitted with the popular Gompertz model can render a negative lag time, which has no physical meaning. This is one of the results of the Gompertz model’s mathematical structure, which implies that methane production potential in day 0 is not equal to initial methane production potential (P(0) ≠ P0) but has little influence on its fit (Normand and Peleg 2014). In literature, there are many studies which used Gompertz model and resulted with a negative lag time (H. Zhang et al. 2018; L. Li et al. 2015; Budiyono et al. 2014).

The combined H2O2/MW and H2O2/heat pre-treatments had long lag phase time of about 12 days related to the limiting effects of residual H2O2 or byproducts on the activity of methanogens, leading to deceleration of the start-up time. The correlation coefficients (R2) ranged from 0.983 to 0.999 that showed the results of modified Gompertz equation were well fitted to the cumulative methane yield in this study. The kinetic study proved that the pre-treatments significantly increased the anaerobic digestion performance.

Conclusion

This study investigated the effects of microwave (MW), combined hydrogen peroxide/microwave (H2O2/MW), and combined hydrogen peroxide/heat (H2O2/heat) pre-treatments on the digestion efficiency and methane production potential of wastewater sludges. Pre-treatments improved the methane yields considerably by increasing the solubility and the biodegradability of the organics in sludges. Application of MW, combined H2O2/MW, and combined H2O2/heat pre-treatments increased the methane yields by 64%, 38%, and 19%, respectively. The predicted results by nonlinear modified Gompertz equation model were compatible with the experimental methane yields, and kinetic parameters showed a good fit to the experimental data.

References

Abudi ZN, Hu Z, Xiao B, Abood AR, Rajaa N, Laghari M (2016) Effects of pretreatments on thickened waste activated sludge and rice straw co-digestion: experimental and modeling study. J Environ Manag 177:213–222. https://doi.org/10.1016/J.JENVMAN.2016.04.028

Ahn J-H, Shin SG, Hwang S (2009) Effect of microwave irradiation on the disintegration and acidogenesis of municipal secondary sludge. Chem Eng J 153(1):145–150. https://doi.org/10.1016/j.cej.2009.06.032

Alagöz AB, Yenigün O, Erdinçler A (2015) Enhancement of anaerobic digestion efficiency of wastewater sludge and olive waste: synergistic effect of co-digestion and ultrasonic/microwave sludge pre-treatment. Waste Manag 46:182–188. https://doi.org/10.1016/J.WASMAN.2015.08.020

Angelidaki I, Alves M, Bolzonella D, Borzacconi L, Campos JL, Guwy AJ, van Lier JB (2009) Defining the biomethane potential (BMP) of solid organic wastes and energy crops: a proposed protocol for batch assays. Water Sci Technol 59(5):927. https://doi.org/10.2166/wst.2009.040

APHA (2012) SMWW: standard methods for the examination of water and wastewater (22nd Edition). American Public Health Association, American Water Works Association, Water Environment Federation. Retrieved from https://www.standardmethods.org/. Accessed 4 Feb 2019

Appels L, Baeyens J, Degrève J, Dewil R (2008) Principles and potential of the anaerobic digestion of waste-activated sludge. Prog Energy Combust Sci 34(6):755–781. https://doi.org/10.1016/j.pecs.2008.06.002

Ariunbaatar J, Panico A, Esposito G, Pirozzi F, Lens PNL (2014) Pretreatment methods to enhance anaerobic digestion of organic solid waste. Appl Energy 123:143–156. https://doi.org/10.1016/j.apenergy.2014.02.035

Bilgin Oncu N, Akmehmet Balcioglu I (2013) Microwave-assisted chemical oxidation of biological waste sludge: simultaneous micropollutant degradation and sludge solubilization. Bioresour Technol 146:126–134. https://doi.org/10.1016/j.biortech.2013.07.043

Bougrier C, Albasi C, Delgenès JP, Carrère H (2006) Effect of ultrasonic, thermal and ozone pre-treatments on waste activated sludge solubilisation and anaerobic biodegradability. Chem Eng Process Process Intensif 45(8):711–718. https://doi.org/10.1016/J.CEP.2006.02.005

Budiyono, Syaichurrozi I, Sumardiono S (2014) Kinetic model of biogas yield production from vinasse at various initial pH: comparison between modified Gompertz model and first order kinetic model. Res J Appl Sci Eng Technol 7(13):2798–2805. https://doi.org/10.19026/rjaset.7.602

Chen Y, Cheng JJ, Creamer KS (2008) Inhibition of anaerobic digestion process: a review. Bioresour Technol 99(10):4044–4064. https://doi.org/10.1016/j.biortech.2007.01.057

Climent M, Ferrer I, Baeza M d M, Artola A, Vázquez F, Font X (2007) Effects of thermal and mechanical pretreatments of secondary sludge on biogas production under thermophilic conditions. Chem Eng J 133(1):335–342. https://doi.org/10.1016/j.cej.2007.02.020

Córdoba V, Fernández M, Santalla E (2018) The effect of substrate/inoculum ratio on the kinetics of methane production in swine wastewater anaerobic digestion. Environ Sci Pollut Res 25(22):21308–21317. https://doi.org/10.1007/s11356-017-0039-6

Eskicioglu C, Terzian N, Kennedy KJ, Droste RL, Hamoda M (2007) Athermal microwave effects for enhancing digestibility of waste activated sludge. Water Res 41(11):2457–2466. https://doi.org/10.1016/j.watres.2007.03.008

Eskicioglu C, Kennedy KJ, Droste RL (2008a) Initial examination of microwave pretreatment on primary, secondary and mixed sludges before and after anaerobic digestion. Water Sci Technol 57(3):311. https://doi.org/10.2166/wst.2008.010

Eskicioglu C, Prorot A, Marin J, Droste RL, Kennedy KJ (2008b) Synergetic pretreatment of sewage sludge by microwave irradiation in presence of H2O2 for enhanced anaerobic digestion. Water Res 42(18):4674–4682. https://doi.org/10.1016/J.WATRES.2008.08.010

Eswari P, Kavitha S, Kaliappan S, Yeom I-T, Banu JR (2016) Enhancement of sludge anaerobic biodegradability by combined microwave-H2O2 pretreatment in acidic conditions. Environ Sci Pollut Res 23(13):13467–13479. https://doi.org/10.1007/s11356-016-6543-2

Feki E, Khoufi S, Loukil S, Sayadi S (2015) Improvement of anaerobic digestion of waste-activated sludge by using H2O2 oxidation, electrolysis, electro-oxidation and thermo-alkaline pretreatments. Environ Sci Pollut Res 22(19):14717–14726. https://doi.org/10.1007/s11356-015-4677-2

Franke-Whittle IH, Walter A, Ebner C, Insam H (2014) Investigation into the effect of high concentrations of volatile fatty acids in anaerobic digestion on methanogenic communities. Waste Manag 34(11):2080–2089. https://doi.org/10.1016/j.wasman.2014.07.020

Fricke K, Santen H, Wallmann R, Hüttner A, Dichtl N (2007) Operating problems in anaerobic digestion plants resulting from nitrogen in MSW. Waste Manag 27(1):30–43. https://doi.org/10.1016/j.wasman.2006.03.003

Ghatak MD, Mahanta P (2014) Comparıson of kinetic models for biogas production rate from saw dust. IJRET: International Journal of Research in Engineering and Technology. Retrieved from http://www.ijret.org

Ghatak M, Mahanta P (2017) Kinetic model development for biogas production from lignocellulosic biomass. IJTech 8(4):673. https://doi.org/10.14716/ijtech.v8i4.9491

Hannmann L, Powers K, Shepherd O, Taylor H (2012) Removal of ciprofloxacin from water with chemical oxidation. Worcester Polytechnic Institute (WPI), Worcester, MA

Jung H, Kim J, Lee S, Lee C (2014) Effect of mild-temperature H 2 O 2 oxidation on solubilization and anaerobic digestion of waste activated sludge. Environ Technol 35(13):1702–1709. https://doi.org/10.1080/09593330.2014.880517

Kim T-H, Lee S-R, Nam Y-K, Yang J, Park C, Lee M (2009) Disintegration of excess activated sludge by hydrogen peroxide oxidation. Desalination 246(1):275–284. https://doi.org/10.1016/j.desal.2008.06.023

Koster IW, Lettinga G (1984) The influence of ammonium-nitrogen on the specific activity of pelletized methanogenic sludge. Agricultural Wastes 9(3):205–216. https://doi.org/10.1016/0141-4607(84)90080-5

Kuglarz M, Karakashev D, Angelidaki I (2013) Microwave and thermal pretreatment as methods for increasing the biogas potential of secondary sludge from municipal wastewater treatment plants. Bioresour Technol 134:290–297. https://doi.org/10.1016/J.BIORTECH.2013.02.001

Lastella G, Testa C, Cornacchia G, Notornicola M, Voltasio F, Sharma VK (2002) Anaerobic digestion of semi-solid organic waste: biogas production and its purification. Energy Convers Manag 43(1):63–75. https://doi.org/10.1016/S0196-8904(01)00011-5

Lee D-J, Lee S-Y, Bae J-S, Kang J-G, Kim K-H, Rhee S-S, Seo D-C (2015) Effect of volatile fatty acid concentration on anaerobic degradation rate from field anaerobic digestion facilities treating food waste leachate in South Korea. Journal of Chemistry 2015:1–9. https://doi.org/10.1155/2015/640717

Li Y, Zhang R, Liu X, Chen C, Xiao X, Feng L, Liu G (2013) Evaluating methane production from anaerobic mono- and co-digestion of kitchen waste, corn stover, and chicken manure. Energy Fuel 27(4):2085–2091. https://doi.org/10.1021/ef400117f

Li L, Chen C, Zhang R, He Y, Wang W, Liu G (2015) Pretreatment of corn stover for methane production with the combination of potassium hydroxide and calcium hydroxide. Energy Fuel 29:5841–5846. https://doi.org/10.1021/acs.energyfuels.5b01170

Li W, Siddhu MAH, Amin FR, He Y, Zhang R, Liu G, Chen C (2018) Methane production through anaerobic co-digestion of sheep dung and waste paper. Energy Convers Manag 156:279–287. https://doi.org/10.1016/J.ENCONMAN.2017.08.002

Liu J, Jia R, Wang Y, Wei Y, Zhang J, Wang R, Cai X (2015) Does residual H 2 O 2 result in inhibitory effect on enhanced anaerobic digestion of sludge pretreated by microwave-H 2 O 2 pretreatment process? Environ Sci Pollut Res. https://doi.org/10.1007/s11356-015-5704-z

Liu J, Yu D, Zhang J, Yang M, Wang Y, Wei Y, Tong J (2016) Rheological properties of sewage sludge during enhanced anaerobic digestion with microwave-H2O2 pretreatment. Water Res 98:98–108. https://doi.org/10.1016/J.WATRES.2016.03.073

Matheri AN, Belaid M, Seodigeng T, Ngila CJ (2016) Modelling the kinetic of biogas production from co-digestion of pig waste and grass clippings. In Proceedings of the World Congress on Engineering 2016 Vol II (WCE 2016). Retrieved from http://www.iaeng.org/publication/WCE2016/WCE2016_pp813-820.pdf. Accessed 8 Nov 2018

Mercan N (2015) Fate of micropollutants during the advanced treatment of sewage sludge: degradation of triclosan, ciprofloxacin, and oxytetracycline. M.Sc. Thesis, Bogazici University

Mudhoo A, Sanjay, Sharma K, Sharma SK (2011) Microwave irradiation technology in waste sludge and wastewater treatment research. Crit Rev Environ Sci Technol 41(11):999–1066. https://doi.org/10.1080/10643380903392767

Neyens E, Baeyens J (2003) A review of thermal sludge pre-treatment processes to improve dewaterability. J Hazard Mater 98(1):51–67. https://doi.org/10.1016/S0304-3894(02)00320-5

Normand MD, Peleg M (2014) Lag time in microbial growth - Wolfram Demonstrations Project. Retrieved from http://demonstrations.wolfram.com/LagTimeInMicrobialGrowth/. Accessed 6 Mar 2019

Owen WF, Stuckey DC, Healy JB, Young LY, McCarty PL (1979) Bioassay for monitoring biochemical methane potential and anaerobic toxicity. Water Res 13(6):485–492. https://doi.org/10.1016/0043-1354(79)90043-5

Priadi C, Wulandari D, Rahmatika I, Moersidik SS (2014) Biogas production in the anaerobic digestion of paper sludge. APCBEE Procedia 9(Icbee 2013):65–69. https://doi.org/10.1016/j.apcbee.2014.01.012

Raposo F, De la Rubia MA, Fernández-Cegrí V, Borja R (2012) Anaerobic digestion of solid organic substrates in batch mode: an overview relating to methane yields and experimental procedures. Renew Sust Energ Rev 16(1):861–877. https://doi.org/10.1016/j.rser.2011.09.008

Shahriari H, Warith M, Hamoda M, Kennedy KJ (2012) Anaerobic digestion of organic fraction of municipal solid waste combining two pretreatment modalities, high temperature microwave and hydrogen peroxide. Waste Manag 32(1):41–52. https://doi.org/10.1016/J.WASMAN.2011.08.012

Siegert I, Banks C (2005) The effect of volatile fatty acid additions on the anaerobic digestion of cellulose and glucose in batch reactors. Process Biochem 40(11):3412–3418. https://doi.org/10.1016/J.PROCBIO.2005.01.025

Song Z, Yag G, Feng Y, Ren G, Han X (2013) Pretreatment of rice straw by hydrogen peroxide for enhanced methane yield. J Integr Agric 12(7):1258–1266. https://doi.org/10.1016/S2095-3119(13)60355-X

Syaichurrozi I, Sumardiono S (2013) Predicting kinetic model of biogas production and biodegradability organic materials: biogas production from vinasse at variation of COD/N ratio. Bioresour Technol 149:390–397. https://doi.org/10.1016/j.biortech.2013.09.088

Tsapekos P, Kougias PG, Vasileiou SA, Treu L, Campanaro S, Lyberatos G, Angelidaki I (2017) Bioaugmentation with hydrolytic microbes to improve the anaerobic biodegradability of lignocellulosic agricultural residues. Bioresour Technol 234:350–359. https://doi.org/10.1016/j.biortech.2017.03.043

TUBITAK-KAMAG (2013) Project report of management of domestic/urban wastewater sludges in Turkey (108G167). Turkey, Istanbul

Turovskiy IS, Mathai PK (2006) Wastewater sludge processing. John Wiley & Sons, Inc. Publication, Wiley-Interscience, Hoboken. Retrieved from http://www.wiley.com/go/permission. Accessed 18 Nov 2017

Tyagi VK, Lo S-L (2011) Application of physico-chemical pretreatment methods to enhance the sludge disintegration and subsequent anaerobic digestion: an up to date review. Rev Environ Sci Biotechnol 10(3):215–242. https://doi.org/10.1007/s11157-011-9244-9

Tyagi VK, Lo S-L (2013) Microwave irradiation: a sustainable way for sludge treatment and resource recovery. Renew Sust Energ Rev 18:288–305. https://doi.org/10.1016/J.RSER.2012.10.032

Valo A, Carrère H, Delgenès JP (2004) Thermal, chemical and thermo-chemical pre-treatment of waste activated sludge for anaerobic digestion. J Chem Technol Biotechnol 79(11):1197–1203. https://doi.org/10.1002/jctb.1106

Wang Y, Wei Y, Liu J (2009) Effect of H2O2 dosing strategy on sludge pretreatment by microwave-H 2 O 2 advanced oxidation process. J Hazard Mater 169:680–684. https://doi.org/10.1016/j.jhazmat.2009.04.001

Weiland P (2010) Biogas production: current state and perspectives. Appl Microbiol Biotechnol 85(4):849–860. https://doi.org/10.1007/s00253-009-2246-7

Wong WT, Chan WI, Liao PH, Lo KV (2006) A hydrogen peroxide/ microwave advanced oxidation process for sewage sludge treatment. J Environ Sci Health A Tox Hazard Subst Environ Eng 41(11):2623–2633. https://doi.org/10.1080/10934520600928086

Wu-Haan, W. (2008) Evaluation of ultrasonic pretreatment on anaerobic digestion of biomass for methane production.M.Sc. Thesis, Iowa State University. Retrieved from http://lib.dr.iastate.edu/etd. Accessed 18 Dec 2016

Yin G, Liao PH, Lo KV (2007) An ozone/hydrogen peroxide/microwave-enhanced advanced oxidation process for sewage sludge treatment. Journal of Environmental Science and Health Part A 42:1177–1181. https://doi.org/10.1080/10934520701418706

Yusuf MOL, Debora A, Ogheneruona DE (2011) Ambient temperature kinetic assessment of biogas production from co-digestion of horse and cow dung. Res Agr Eng 57(3):97–104. Retrieved from https://www.agriculturejournals.cz/publicFiles/47422.pdf. Accessed 19 Oct 2018

Zhang H, Ning Z, Khalid H, Zhang R, Liu G, Chen C (2018) Enhancement of methane production from cotton stalk using different pretreatment techniques. Sci Rep 8(1):3463. https://doi.org/10.1038/s41598-018-21413-x

Zwietering MH, Jongenburger I, Rombouts FM, Riet K (1990) Modeling of the bacterial growth curve. Appl Environ Microbiol 56(6):1875–1881. Retrieved from https://www.ncbi.nlm.nih.gov/pmc/articles/PMC184525/pdf/aem00087-0379.pdf. Accessed 19 Oct 2018

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Vítor Pais Vilar

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Özön, E., Erdinçler, A. Effects of microwave, H2O2/MW and H2O2/heat pre-treatments on the methane production from wastewater sludges: experimental and modeling approach. Environ Sci Pollut Res 26, 35411–35421 (2019). https://doi.org/10.1007/s11356-019-05190-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-019-05190-2