Abstract

This study describes the effect of microwave and low-frequency ultrasonic pretreatment power intensity, time and density on thickened excess activated sludge (TEAS) characteristics and anaerobic digester performance. Key parameters affecting the efficiency of ultrasonic and microwave pretreatment were identified and optimised. The effect of change in ultrasonication and microwave pretreatment conditions on sludge degradation and other characteristics were analysed. Ultrasonication power, density and time were important factors in the sludge solubilisation process. Microwave density and pretreatment time also influenced solubilisation of TEAS, and the effects were investigated for treatment densities of 3.2, 4.6 and 6.4 W/ml and treatment duration of 1–7 min. Higher sludge degradability, higher volatile solid removal and better digester performance were achieved for anaerobic digestion with lower ultrasonication power of 80 W, ultrasonication time of 6 min, and ultrasonic density of 0.32 W/ml. The volume of biogas produced and kinetics, dewaterability of digested sludge, COD reduction and other sludge properties were optimised for the aforementioned ultrasonication and microwave pretreatment conditions for TEAS. It was observed that sludge dewaterability deteriorated with increasing sonication power density and sludge solubilisation. Hence, the balance between sludge dewaterability and solubilisation should be maintained for optimum performance. Thus, the selection of ultrasonic pretreatment time and power is a trade-off between sludge solubilisation and dewaterability.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Anaerobic digestion performance enhancement can be achieved by improving slow rate-limiting hydrolysis step. Biogas production, solid reduction, dewaterability, pathogen removal and process kinetics can be enhanced using different pretreatment technologies. These technologies can be applied to increase digester performance individually or in combination; such technologies include ultrasonic treatment (Apul and Sanin 2010; Farooq et al. 2009; Saifuddin and Fazlili 2009; Tiehm et al. 2001), chemical treatment (Haug et al. 1978; Penaud et al. 2000; Tanaka and Kamiyama 2002), microwave treatment (Eskicioglu et al. 2007; Park 2011), ozone oxidation (Yeom et al. 2002; Lin and Lee 2002), mechanical disintegration, supercritical and subcritical water oxidation and high-temperature hydrolysis (Carrère et al. 2010). All sludge reduction technologies are working with the principle of disintegration of cell walls and large organic molecules.

Microwave pretreatment has a significant enhancement effect on anaerobic digestion performance and the quality of digested sludge produced from the process (Park and Jang 2011). Increase in methane gas production capacity, improved solid removal, higher organic reduction and enhanced pathogen destruction rate are among the major benefits of the pretreatment or prehydrolysis step recommended by many researchers (Eskicioglu et al. 2008; Park et al. 2004; Park 2011; Toreci et al. 2011; Zheng et al. 2009). Rapid heating and heat penetration effects, energy efficiency, non-contact heating, athermal effects, selectivity, space saving, flexibility and many more other benefits make microwave pretreatment a very efficient pretreatment technique (Yeneneh 2014).

Ultrasonic pretreatment has been extensively tested in industry, particularly as pretreatment for anaerobic digestion. It has been shown that macromolecules with a molar mass above 40,000 are disrupted by the hydro-mechanical shear forces produced by ultrasonic cavitation. The mechanical forces are most effective at frequencies below 100 kHz (Portenlanger 1999). Due to the ultrasonic disruption of putrescible biomass in the sludge, subsequent microbial degradation occurs up to four times faster than in the conventional treatment. The violent collapse of cavitation bubbles in water produces shear forces that can disrupt cell membranes and kill bacteria. At lower acoustic intensities, these forces weaken the membranes rendering the bacteria more susceptible to the effect of biocides. The hydroxyl radical produced during cavitation can also assist disinfection (Oh 2006; Portenlanger 1999). The mechanisms of ultrasonic treatment are influenced by the energy supplied, ultrasonic frequency, duration of pretreatment and the nature of the sludge. Cell disintegration is proportional to energy supplied (Bougrier et al. 2005). High frequencies promote oxidation by radicals, whereas low frequencies promote mechanical and physical phenomena like pressure waves (Portenlanger 1999).

Ultrasonic and microwave pretreatment efficiency is affected by pretreatment power, time, density and pH during the pretreatment process. The pretreatment conditions directly affect the degree of sludge disintegration and solubilisation which in turn influence the gas production, solid removal, dewaterability and flow characteristics of the sludge and overall operational cost of the wastewater treatment plant (Fernández-Cegrí et al. 2012; Saha et al. 2011). Microwave irradiation and ultrasonication are energy-intensive processes where the cost-effectiveness of these techniques is an important aspect to be addressed. This particular study provides valuable results for the optimisation of ultrasonic, microwave and combined-ultrasonic microwave pretreatment methods for enhanced process performance. The effect of change in ultrasonic and microwave pretreatment power, time, density and intensity on biodegradability of sludge is discussed and optimised. The optimum combined microwave and ultrasonic pretreatment power and time for maximum gas generation, improved dewaterability and solid removal is also presented. Optimisation of pretreatment duration, intensity and density contributes significantly to the reduction of operational cost, duration of pretreatment and results in improved digester performance, better digested sludge quality and dewaterability (Wang et al. 2005).

2 Materials and Methods

The effects of microwave and ultrasonic power, time and density on sludge solubilisation and degree of disintegration of organics were investigated when the pretreatment methods are applied individually and in combination. Thickened excess activated sludge sample used in the study was obtained from Beenyup waste water treatment plant, Perth, Western Australia. The characteristics of thickened excess activated sludge samples used for this optimisation study are shown in Table 1.

The sludge samples were subjected to microwave, ultrasonic and combined microwave-ultrasonic pretreatment after characterisation was conducted. Table 2 shows detailed experimental conditions for pretreatment including time, power and density. Sludge solubilisation, dewaterability, pH and other parameters were measured after each pretreatment, and the effect of each pretreatment factor on each of these parameters was investigated. The change in soluble chemical oxygen demand (SCOD) was measured after microwave, ultrasonic and combined microwave-ultrasonic pretreatment for the different pretreatment conditions to investigate the effect of these pretreatment methods on solubilisation of the sludge samples. Pretreatment density and duration of pretreatment were varied. The SCOD/TCOD ratio was measured by using standard COD measurement colorimetric technique for each of untreated and pretreated sludge samples (Park et al. 2004). Each sample was first diluted 50 times and filtered on Whatman filter paper type 1PS-110mm and then SCOD was measured. Three continuously stirred batch digesters each with working volume of 250 ml and five other digesters which were operating in parallel were inoculated separately with digested sludge (DS) as seed from BWWTP. The three digesters were operated to investigate the effect of change ultrasonic pretreatment power for a fixed microwave pretreatment condition. Microwave treatment was conducted in a conventional microwave generator with a microwave frequency of 2450 MHz and a maximum microwave power of 800 W. The ultrasonication unit utilised was SONICs digital ultrasonication unit with titanium tip. This equipment can deliver a maximum power of 500 W at a frequency of 20 kHz. The stack equipment of ultrasonic processor used had a 3–16 μmp-p converter, a 3:1 gain booster and a 2:1 gain probe of 2.54 cm (1 in.) diameter. The amplitude could thus be modulated from 6 to 90%. The ultrasonication chamber used for batch operation was a common borosilicate 250 and 500 ml glass beaker. The lowest 3 cm of the probe was immersed in the solution. The pulse during all ultrasonication tests was 55/5. This depth was enough to avoid air introduction and scum formation in the media (according to sounds produced and visual observations) which would reduce the acoustic transmission and enhances ultrasonication efficiency. Besides, this depth was shallow enough to allow the entire sample to be mixed by acoustic streaming and cavitation. The diameter of the beakers (approximately 7 cm for 250 ml beaker and 13 cm for 500 ml beaker) allowed the half wave length (around 12.7 cm at 20 kHz) to be fully created in this containers. The diameter of the beaker was selected to avoid the introduction of unwanted wall effects. The effects of change in microwave and ultrasonic density, ultrasonic intensity and ultrasonic duration (pretreatment time) were investigated. The digesters were charged with thickened excess activated sludge samples pretreated according to the conditions shown in Table 2 to undergo mesophilic (36.5 °C) digestion for a sludge retention time of 28 days. Biochemical methane potential (BMP), dewaterability, solid and COD removal tests were performed on sludge samples from each of the digesters. The biochemical methane potential test involved regular and continuous measurement of the methane production capacity and methane quality of each digester having specific volume and composition.

2.1 Analytical Methods

All the analyses required for the experimental work in this study include the determination of TS, VS, SCOD, TCOD, pH and dewaterability (CST). pH was measured with WP-90 and WP-81 conductivity/TDS-pH/temperature meter equipped with a glass electrode according to Standard Methods APHA 2000 (Federation 2000). pH was measured before and after pretreatment and during the anaerobic digestion process on a regular basis. Total and soluble chemical oxygen demand was determined by using oxidation method with HACH COD reagent and colorimetric analysis on ORION UV/Vis spectrometer. The total and volatile solids content were determined according to Standard Methods for the Examination of Water and Wastewater, APHA 2000 (Federation 2000).

The biogas composition was measured using ThermoFisher SCIENTIFIC GA 2000 plus. The gas meter is designed to measure volume percentage of methane, carbon dioxide, oxygen and other gases. The concentration of ammonia and hydrogen sulphide was monitored by the meter in addition to the other components of the biogas. Gas chromatographic technique was used to confirm the accuracy and consistency of the biogas composition measured using GA2000 plus biogas analyser. Temperature measurement was conducted using WP-90 and WP-81 conductivity/TDS-pH/temperature meter during all analytical techniques to ensure consistency of the results. Temperature during the digestion process was maintained constant using the water bath heater which pumps the water flowing in the jacket of the digesters. The dewaterability of the different sludge samples was measured using capillary suction timer (Type 304 CST equipment).

3 Result and Discussion

3.1 Effect of Microwave Pretreatment Temperature, Density and Time on Sludge Solubilisation

The degree of sludge solubilisation after microwave heating is shown Fig. 1a and b. The microwave energy is transformed into heat derived from the internal resistance to rotation. Temperature rise during sludge heating is related to heat generated as a result of the absorption of the microwave energy by water or by organic components which undergo constant or induced polarisation (Jang and Ahn 2013). Thus, the thermal activation and sludge solubilisation in the sludge samples is due to the absorption of microwave energy by water and organic complexes available in the sludge sample. Microwave heating is due to the absorption of microwaves radiation by water (Zhao Xiang et al. 2009). The factors influencing microwave irradiation of the dielectric materials include temperature, radiation time and penetration. Optimum pretreatment conditions obtained in this study confirm the benefits. A maximum temperature of 80°C was chosen to avoid vaporisation of liquid (Coelho 2012). Increased solubilisation in SCOD occurred due to the microwave pretreatment as shown in Fig. 1a and b. Sludge solubilisation increased with increasing temperature for the microwave pretreatment at different power intensities. This is because of the fact that the heat generated in the process is the main physical factor causing the solubilisation of sludge flocs. Flocs in activated sludge are composed of a polymeric matrix made up of variable quantities of extracellular polymeric substances (EPS) such as proteins, carbohydrates, humic substances, glycoproteins, lipids and nucleic acids with the bacterial cells embedded in the mesh (Urbain et al. 1993). However, the most prevalent substances are proteins and carbohydrates. The increase in SCOD is due to the release of such components (Miron et al. 2000). The effects of microwave pretreatment temperature, output power and solid concentration in the sludge were investigated (Park 2011). Each of these factors affected the pretreatment process significantly. Correspondingly, the highest sludge solubilisation occurred at microwave pretreatment power of 640 W as shown in Fig. 1a and b. Soluble chemical oxygen demand was the highest for microwave pretreatment duration of 5 min as shown in Fig. 2. The increase in SCOD (mg/l) with increasing microwave pretreatment power density (power/volume), intensity (power/area) and pretreatment time indicates the increase in the degree of sludge disintegration and solubilisation. This is because of the hydrolysis of large organic molecules, cell wall lysis and disintegration of sludge which is enhanced by the microwave pretreatment (Park et al. 2004).

Specific energy of sludge solubilisation calculated according to Eq. 1 (Kuglarz et al. 2013) shows that for the combined microwave-ultrasonic pretreatment, microwave pretreatment duration of 5 min resulted in the highest degree of sludge solubilisation with the least energy consumed. Hence, the optimum microwave pretreatment duration is 5 min for TEAS during the combined pretreatment as shown in Fig. 3.

where

- E SCOD :

-

Specific energy consumption (kJ/g soluble COD released)

- t :

-

exposure time (s)

- P :

-

power of the microwave heater (KW)

- V :

-

volume of sludge treated (l) and

- SCOD:

-

soluble organic matter released into the liquid phase (mg/l).

3.2 Effect of Ultrasonic Power (Intensity), Density and Pretreatment Time on Sludge Solubilisation

Ultrasonic pretreatment significantly increased the degree of sludge solubilisation and anaerobic digestion performance. Ultrasonication pretreatment for a short duration of time resulted in breakdown of macro-flocs and micro-biodegradable organics to a reasonable degree (Oh 2006). Shorter sonication duration is preferred in this study as the sonication is coupled with microwave pretreatment to take advantage of the synergy that combined pretreatment provides over individual pretreatment. Besides, the economic benefit in terms of reducing pretreatment cost by reducing ultrasonication time is significant. Sludge solubilisation for combined pretreatment was far better than individual treatment techniques where the SCOD was almost doubled after the combined treatment which potentially produces higher amount of methane (Figs. 4 and 5).

Sonication density plays a significant role in cavitation bubble formation (Urbain et al. 1993). Particle disruption can be optimised by sonication of sludge sample at high sonication density and shorter sonication time. The particle disruption study against duration of sonication revealed that macro-flocs are more affected than micro-flocs. Larger surface area of exposure favours higher particle disruption. Combined pretreatment with ultrasonication density of 0.52 W/ml resulted in higher degree of sludge solubilisation of 41% for sonication time of 8 min (Figs. 4 and 5). This pretreatment condition was observed to have less specific energy consumption compared to other pretreatment densities with similar sonication time. Generally, the degree of sludge solubilisation is the highest at this condition with the least amount of specific energy consumed as shown in Fig. 6.

The specific energy input is proportional to sonication time. Longer sonication time requires higher specific energy input, thus resulting in higher SCOD release (Fig. 6). Wang et al. (2005) investigated the release in SCOD concentration at three different sonication times of 5, 15 and 20 min at TS content of 3%, frequency of 20 kHz and ultrasonic density of 0.768 W/ml (Wang et al. 2005). This particular study shows the release of SCOD as a function of the specific energy input for ultrasonic densities of 1 W/ml, 0.66 W/ml, 0.5 W/ml and total solid concentration of 45 g/l.

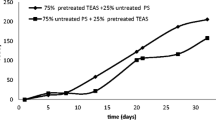

3.3 Effect of Microwave and Ultrasonic Pretreatment Conditions on Anaerobic Digester Performance

The methane production potential for combined microwave-ultrasonic pretreated TEAS was higher for higher ultrasonication density of 1 W/ml and longer pretreatment duration of 8 min as compared to ultrasonic density of 0.66 and 0.5 W/ml for the same sonication time after 28 days of digestion as shown in Fig. 7. The SCOD/TCOD ratio for the set of TEAS digesters confirms that higher sonication density and duration of pretreatment (1 W/ml, 8 min and 0.66 W/ml, 12 min) is associated to higher methane production as shown in Fig. 8. The volatile solid removal for these pretreatment conditions was significantly higher (60.77 for 1 W/ml, 8 min; 69.28 for 0.66 W/ml, 12 min) than the other pretreatment conditions. Total solid reduction of combined microwave-ultrasonic pretreated sludge at the sonication condition of 0.66 W/ml, 12 min was the highest as shown in Fig. 9. Ultrasonication at intermediate power density, intensity and relatively longer duration favours enhanced methane production and solid removal (Liu et al. 2009). The total solid and volatile solid reductions for most of the ultrasonication densities and treatment durations were similar to each other with the volatile solid reduction being slightly greater than the total solid reduction.

3.4 Impact of Microwave and Ultrasonic Pretreatment Energy Density and Duration of Pretreatment on Sludge Dewaterability

Dewatering is an essential cost factor that greatly affects the performance of anaerobic digestion unit in a wastewater treatment plant; it was shown that microwave pretreatment with larger intensities and shorter period of time is more effective than pretreatment for a longer duration (Yu et al. 2009). Longer pretreatment duration increases the percentage of fine particles which are not required during sludge conditioning. Besides, increased release of hydrophilic EPS that bound water contributes to the deterioration of the dewatering process (Hong et al. 2015). Greater level of microwave density of 6.4 W/ml and shorter duration of treatment of 3 min resulted in better dewaterability as shown in Figs. 10 and 11. Microwave pretreated sludge shows relatively better dewaterability than untreated or ultrasonic pretreated sludge. Yu et al. (2009) have reported that shorter duration and higher pretreatment density enhance dewaterability. Microwave pretreated TEAS for shorter duration of 1 min (60s) resulted in dewaterability of 18.6 s (measured in capillary suction time) which was comparatively better than the result for longer duration as shown in Fig. 11. Microwave pretreatment under such a condition enhances sludge dewaterability and settleability by breaking the flocs into small fragments which will be reflocculated easily for improved dewaterability (Tyagi et al. 2013).

Ultrasonication has both negative and positive effects on sludge dewaterability. Lower ultrasonic power level enhances dewaterability (Pilli et al. 2011). However, the extent of solubilisation for lower ultrasonic power is limited. Better dewaterability of 198 s was observed for ultrasonication time of 12 min with ultrasonication power of 1 W/ml as shown in Fig. 12. This shows that the selection of ultrasonic pretreatment time and power is a trade-off between sludge solubilisation and dewaterability. Dewaterability decreases with increasing ultrasonic intensity, but anaerobic digestion improves dewaterability (Quarmby et al. 1999). Greater ultrasonic power increases bound water content and reduces particle size, thereby enhancing the surface area for the adsorption of more bound water (Chu et al. 2001). Higher ultrasonic density and intensity resulted in the deterioration of dewaterability of sludge as shown in Fig. 12.

The increase in SCOD/TCOD ratio is associated with the increased release of EPS. The increase in the concentration of EPS and soluble organics increases the viscosity of the sludge (Oliveira et al. 2016). Increased viscosity along with the thin film that EPS builds on the filter media deteriorates the dewaterability (Oh 2006). The relationship between SCOD/TCOD ratio and dewaterability can be represented by an exponential function as shown in Fig. 13. Dewaterability requires optimisation of sludge disintegration for enhanced methane production and solid removal as optimal sludge degradation contributes positively to the dewaterability. Besides, EPS content of the sludge significantly affects the bound water content and the floc network strength. Hence, the flocculation behaviour and floc strength of the digested sludge, viscosity and its dewaterability are a function of the EPS and organic content of the sludge (Yeneneh et al. 2016; Oliveira et al. 2016; (Liu et al. 2016).

In evaluating the effects of sonication conditions on sludge, disintegration factors such as pH is also very important. Figure 14 shows how pH drops down with increasing pretreatment duration. The release of soluble organics and EPS (mainly protein, carbohydrates and VFA) is the cause of the drop in pH. The observed change in pH is small and limited to a narrow range. However, this result was shown to initiate further research work in this direction. During anaerobic digestion, lower pH will result in the growth of filamentous bacteria and a high pH results in build-up of unionised ammonia (Grady Jr et al. 1999).

4 Conclusion

The optimisation study on microwave, ultrasonic and combined microwave-ultrasonic pretreatment has revealed that ultrasonication and microwave pretreatment power density and intensity, duration of pretreatment and sludge concentration have a significant impact on the performance on anaerobic digestion in terms of solid removal, reduction of chemical oxygen demand and biogas production. Besides, these pretreatment techniques also have a significant impact on the dewaterability of the sludge. Microwave pretreatment density of 3.2 W/ml for a duration of 5 min and ultrasonic pretreatment condition of 0.66 W/ml and duration of 8 min resulted in a better anaerobic digester performance in terms of biogas production, dewaterability, solid removal and lower energy consumption. Ultrasonic pretreatment with higher pretreatment power resulted in a higher degree of disintegration of flocs and greater percentage of fine particles and thus deterioration in sludge dewaterability. Hence, the selection of ultrasonic pretreatment time and power is a trade-off between sludge solubilisation and dewaterability.

References

APHA. (2000). American Water Works Association, Water Pollution Control Federation, and Water Environment Federation standard methods for the examination of water and waste water. Washington DC, USA: American Public Health Association.

Apul, O. G., & Sanin, F. D. (2010). Ultrasonic pretreatment and subsequent anaerobic digestion under different operational conditions. Bioresource Technology, 101(23), 8984–8992.

Bougrier, C., Carrère, H., & Delgenès, J. P. (2005). Solubilisation of waste-activated sludge by ultrasonic treatment. Chemical Engineering Journal, 106(2), 163–169.

Carrère, H., Dumas, C., Battimelli, A., Batstone, D. J., Delgenès, J. P., Steyer, J. P., & Ferrer, I. (2010). Pretreatment methods to improve sludge anaerobic degradability: a review. Journal of Hazardous Materials, 183(1–3), 1–15.

Chu, C. P., Chang, B.-V., Liao, G. S., Jean, D. S., & Lee, D. J. (2001). Observations on changes in ultrasonically treated waste-activated sludge. Water Research, 35(4), 1038–1046.

Coelho, N. M. G. (2012). Application of microwaves and thermophilic anaerobic digestion to wastewater sludge treatment, PhD thesis, The Ottawa-Carleton Institute for Environmental Engineering Department of Civil Engineering, University of Ottawa, Ottawa, ON, Canada.

Eskicioglu, C., Terzian, N., Kennedy, K. J., Droste, R. L., & Hamoda, M. (2007). Athermal microwave effects for enhancing digestibility of waste activated sludge. Water Research, 41(11), 2457–2466.

Eskicioglu, C., Kennedy, K., & Droste, R. (2008). Initial examination of microwave pretreatment on primary, secondary and mixed sludges before and after anaerobic digestion. Water Science and Technology, 57(3), 311–318.

Farooq, R., Rehman, F., Baig, S., Sadique, M., Khan, S., & Farooq, U. (2009). The effect of ultrasonic irradiation on the anaerobic digestion of activated sludge. World Applied Sciences Journal, 6(2), 234–237.

Federation, A. A. P. H. A. W. E. (2000). Standard methods for the examination of water and waste water. Washington DC, USA.

Fernández-Cegrí, V., de la Rubia, M. A., Raposo, F., & Borja, R. (2012). Impact of ultrasonic pretreatment under different operational conditions on the mesophilic anaerobic digestion of sunflower oil cake in batch mode. Ultrasonics Sonochemistry, 19(5), 1003–1010.

Grady Jr, C., Daigger, G., & Lim, H. (1999). Biological wastewater treatment: revised and expanded. New York: Marcel Dekker. Inc 72, l.

Haug, R., Stuckey, D., Gossett, J., & McCarty, P. (1978). Effect of thermal pretreatment on digestibility and dewaterability of organic sludges. Journal Water Pollution Control Federation, 50(1), 73–85.

Hong, C., Si, Y., Xing, Y., Wang, Z., Qiao, Q., & Liu, M. (2015). Effect of surfactant on bound water content and extracellular polymers substances distribution in sludge. RSC Advances, 5(30), 23383–23390.

Jang, J.-H., & Ahn, J.-H. (2013). Evaluation of a microwave-heating anaerobic digester treating municipal secondary sludge. Environmental Technology, 34(7), 885–889.

Kuglarz, M., Karakashev, D., & Angelidaki, I. (2013). Microwave and thermal pretreatment as methods for increasing the biogas potential of secondary sludge from municipal wastewater treatment plants. Bioresource Technology, 134, 290–297.

Lin, C.-Y., & Lee, Y.-S. (2002). Effect of thermal and chemical pretreatments on anaerobic ammonium removal in treating septage using the UASB system. Bioresource Technology, 83(3), 259–261.

Liu, C., Xiao, B., Dauta, A., Peng, G., Liu, S., & Hu, Z. (2009). Effect of low power ultrasonic radiation on anaerobic biodegradability of sewage sludge. Bioresource Technology, 100(24), 6217–6222.

Liu, J., Yu, D., Zhang, J., Yang, M., Wang, Y., Wei, Y., & Tong, J. (2016). Rheological properties of sewage sludge during enhanced anaerobic digestion with microwave-H2O2 pretreatment. Water Research, 98, 98–108.

Miron, Y., Zeeman, G., Van Lier, J. B., & Lettinga, G. (2000). The role of sludge retention time in the hydrolysis and acidification of lipids, carbohydrates and proteins during digestion of primary sludge in CSTR systems. Water Research, 34(5), 1705–1713.

Oh, S. E. (2006). Improvement of anaerobic digestion rate of biosolids in waste activated sludge (WAS) by ultrasonic pretreatment. Environmental Engineering Research Seoul, 11(3), 143.

Oliveira, I., Reed, J. P., Abu-Orf, M., Wilson, V., Jones, D., & Esteves, S. R. (2016). The potential use of shear viscosity to monitor polymer conditioning of sewage sludge digestates. Water Research, 105, 320–330.

Park, W. J. (2011). Effects of microwave pretreatment on mesophilic anaerobic digestion for mixture of primary and secondary sludges compared with thermal pretreatment. Environmental Engineering Research, 16(2), 103–109.

Park, S.-W., & Jang, C.-H. (2011). Effects of carbonization and solvent-extraction on change in fuel characteristics of sewage sludge. Bioresource Technology, 102(17), 8205–8210.

Park, B., Ahn, J., Kim, J., & Hwang, S. (2004). Use of microwave pretreatment for enhanced anaerobiosis of secondary sludge. Resources from Sludge: Forging New Frontiers, 50(9), 17–23.

Penaud, V., Delgenes, J., & Moletta, R. (2000). Influence of thermo-chemical pre-treatment conditions on solubilization and anaerobic biodegradability of a microbial biomass. Environmental Technology, 21, 87–96.

Pilli, S., Bhunia, P., Yan, S., LeBlanc, R. J., Tyagi, R. D., & Surampalli, R. Y. (2011). Ultrasonic pretreatment of sludge: a review. Ultrasonics Sonochemistry, 18(1), 1–18.

Portenlanger, G. (1999). Mechanical and radical effects of ultrasound. Ultrasound in Environmental Engineering. TU Hamburg-Harburg Reports on Sanitary Engineering 25, 139–151.

Quarmby, J., Scott, J., Mason, A., Davies, G., & Parsons, S. (1999). The application of ultrasound as a pre-treatment for anaerobic digestion. Environmental Technology, 20(11), 1155–1161.

Saha, M., Eskicioglu, C., & Marin, J. (2011). Microwave, ultrasonic and chemo-mechanical pretreatments for enhancing methane potential of pulp mill wastewater treatment sludge. Bioresource Technology, 102(17), 7815–7826.

Saifuddin, N., & Fazlili, S. (2009). Effect of microwave and ultrasonic pretreatments on biogas production from anaerobic digestion of palm oil mill effluent. American Journal of Engineering and Applied Sciences, 2, 139–146.

Tanaka, S., & Kamiyama, K. (2002). Thermo-chemical pre-treatment in the anaerobic digestion of waste activated sludge. Water Science and Technology, 46, 173–179.

Tiehm, A., Nickel, K., Zellhorn, M., & Neis, U. (2001). Ultrasonic waste activated sludge disintegration for improving anaerobic stabilization. Water Research, 35(8), 2003–2009.

Toreci, I., Droste, R. L., & Kennedy, K. J. (2011). Mesophilic anaerobic digestion with high-temperature microwave pretreatment and importance of inoculum acclimation. Water Environment Research, 83(6), 549–559.

Tyagi, V. K., Lo, S.-L., Appels, L., & Dewil, R. (2013). Ultrasonic treatment of waste sludge: a review on mechanisms and applications. Critical Reviews in Environmental Science and Technology, null-null.

Urbain, V. B., Block, J. C., & Manem, J. (1993). Bioflocculation in activated sludge: an analytic approach. Water Research, 27, 829–838.

Wang, F., Wang, Y., & Ji, M. (2005). Mechanisms and kinetics models for ultrasonic waste activated sludge disintegration. Journal of Hazardous Materials, 123(1–3), 145–150.

Yeneneh, A. M. (2014) Study on performance enhancement of anaerobic digestion of municipal sewage sludge. PhD thesis, Chemical Engineering Department, Curtin University.

Yeneneh, A. M., Hong, E., Sen, T. K., Kayaalp, A., & Ang, H. M. (2016). Effects of temperature, polymer dose, and solid concentration on the rheological characteristics and dewaterability of digested sludge of wastewater treatment plant (WWTP). Water, Air, & Soil Pollution, 227(4), 1–14.

Yeom, I. T., Lee, K. R., Lee, Y. H., Ahn, K. H., & Lee, S. H. (2002). Effects of ozone treatment on the biodegradability of sludge from municipal wastewater treatment plants. Water Science and Technology, 46(4–5), 421–425.

Yu, Q., Lei, H., Yu, G., Feng, X., Li, Z., & Wu, Z. (2009). Influence of microwave irradiation on sludge dewaterability. Chemical Engineering Journal, 155(1–2), 88–93.

Zhao Xiang, H. K., Yan, L., & Yao, Y. (2009). A preliminary study on numerical simulation of microwave heating process for chemical reaction and discussion of hotspot and thermal runaway phenomenon. Science China—Physics, Mechanics & Astronomy, 52(4), 551–562.

Zheng, J., Kennedy, K. J., & Eskicioglu, C. (2009). Effect of low temperature microwave pretreatment on characteristics and mesophilic digestion of primary sludge. Environmental Technology, 30(4), 319–327.

Acknowledgements

The authors would like to acknowledge Water Corporation of Western Australia and Curtin University for providing financial support and the required laboratory facility for this research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yeneneh, A.M., Sen, T.K., Ang, H.M. et al. Optimisation of Microwave, Ultrasonic and Combined Microwave-Ultrasonic Pretreatment Conditions for Enhanced Anaerobic Digestion. Water Air Soil Pollut 228, 11 (2017). https://doi.org/10.1007/s11270-016-3197-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-016-3197-0