Abstract

The aim of this study is to investigate the properties of biodegradable plantable pots made from biomaterials. Specifically, rapeseed straw and cow manure biomaterials were studied here because these biomaterials add nutrients to the soil during their biodegradation and are readily available agricultural by-products. Furthermore, the use of biomaterials helps in replacing the plastic materials which are currently used to make pots and decreases the environmental impact by producing a cleaner product. The physical and mechanical properties of biocomposites pots were investigated and optimized in the present work. The effect of mixing ratio (straw: cow manure) in the composite, straw particle size, and chemical pre-treatments of straw by 1% HCl or 2% NaOH on the physical and mechanical properties of biodegradable pots was investigated. Additionally, the Taguchi method and ANOVA statistical analyses were employed for parameters optimization. The results indicated the straw to cow manure ratio exhibited a significant effect on the compression strength (CS), penetration strength (PS), and water absorption (WA) of pots. While the CS and PS of pots decreased with increasing the ratio of straw from 2 to 10% and increasing the particle size of straw from 1.5 to 3.0 mm, these changes increased the water absorption of pots (126.52–141.21% for 1.5-mm untreated straw). Chemical pre-treatments of straw investigated here resulted in decreased CS and PS of pots. The straw ratio in the straw/manure mixture is the most significant factor affecting the characteristics of biodegradable pots.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

China is a traditional agricultural country with considerable amounts of crops. After harvesting, there are many quantities of agricultural residues in the fields, which are the source of many environmental impacts [1]. Moreover, with the development of agricultural field in China, productions of straw increase rapidly, where China produces more than 700 million tons of crop straws every year, which considered one of the most abundant crop residues in the world [2]. Therefore, scientific issues are focusing on using of agricultural residues as renewable raw materials for fiber composites and biogas production through anaerobic digestion process [3,4,5]. There are a wide applications of fiber composites available in the world. One of these applications is the production of biodegradable pots through molding process of agricultural residues. Consequently, using biodegradable pots instead of traditional plastic pots reduces plastic trash that produced in plant nurseries [6], where, recently, agricultural products are one of the world’s biggest sources of plastic trash [7]. Furthermore, their use can contribute to reduce the world’s dependency on petroleum products which are continuously decreasing.

Biodegradable pots are divided into two categories based on the raw material including plantable and compostable [8]. Compostable pots should be removed before planting, where it prevents plant root to grow through their walls [9]. On the other hand, plantable pots are buried in the soil with plant roots because they allow for these roots to grow through their walls; hence, it can be biodegraded directly in the field within short time after transplanting [6]. After degradation, the pots release elements such as nitrogen and phosphorus [10]. These elements are very necessary for plant growing; they improve plant nutrition process [11]. Therefore, the use of agricultural wastes for production of biodegradable pots allows the conversion of agricultural wastes into biofertilizers through an indirect and safe process, as well as manufacturing another product that has many pros compared to the traditional product. These pros are saving of transplanting time and labor, preventing container disposal [12], reducing transplanting shock and root deformation which lead to root plant development and plant growing [6], improvement of seedling growth as a result of its high porosity which produces a cooling effect on the warmest days [13], and saving of production costs such as pine apple wastes [10] and sugarcane bagasse wastes [11]. Recently, several studies have been used the agricultural wastes as raw materials for production of biodegradable pots such as sugarcane bagasse [11], tomatoes seeds and peels, hemp fibers [6], different straw types and cow manure [14], pineapple wastes from the cannery industry [10], residual substrate from Ganoderma lucidum mushroom cultivation [13], wood fiber [15], cow manure [16], chicken feather [17]. All these types of biodegradable pots differ in their properties, where there are many variables that influence on the properties of produced pots, including raw materials properties such as type, particle size, adhesive type and chemical pre-treatments, and manufacturing methods (value and time of press, temperature, and drying methods) as well as thickness and geometric shape of pot.

In the present study, promising alternative materials for production of biodegradable pots are investigated. These materials are rapeseed straw and cow manure, which are a source of greenhouse gas emissions, accounting for approximately 12% of global agricultural emissions [18]. On the other hand, in China, the largest oilseed crop is rapeseed and it represented about 20% of world production [19], where, in 2015, the world’s second most important rapeseed producer was China after Canada [20]. According to China statistical yearbook 2021, the cultivated area of rapeseed was about 6.76 million ha producing 14.05 million tons of seeds and approximately 20.28 million tons of straw (1 ha produces 3 ton of straw) [21]. The rapeseed straw and cow manure are employed to produce biodegradable pots, where the last contains natural binding material. The properties of these pots are evaluated. In addition, the effect of raw material parameters including ratio of straw to manure, straw particle size, and straw chemical pre-treatment on the compression strength (CS), penetration strength (PS), and water absorption (WA) of pots is examined; moreover, Taguchi’s signal-to-noise ratio is employed to investigate the optimal parameters and their levels. Furthermore, ANOVA statistical analysis is used to identify the factors significance.

2 Material and Methods

2.1 Preparation of Raw Materials

Rapeseed straw (Brassica napus) and cow manure were collected from the farm of Huazhong Agricultural University (HZAU), Wuhan, China (latitude 30.6°N, longitude 114.1°E, and altitude 23.1 m). Cow manure and straw were gathered and stored in plastic bags till used. The characteristics of rapeseed straw and cow manure are listed in Table T1 (Supplementary material T1).

2.1.1 Straw Preparation and Chemical Pre-Treatments

The rapeseed straw was milled using a milling machine with particle size ≤ 3 mm. For chemical pre-treatment of rapeseed straw, two solutions of 1% HCl and 2% NaOH were prepared using distilled water. The straw was soaked in each solution at a ratio of 1:10 for 4 h at room temperature. Then the treated straw was washed by distilled water for many times until the washing water became clear and was dried in the oven at 105 °C for 24 h or constant weight. The treated and untreated straw was screened into certain particle sizes (1.5 and 3 mm) to evaluate the effect of straw different particle sizes on properties of biodegradable pots.

2.2 Preparation of Biodegradable Pots

Firstly, to prepare the samples of pots, a manual machine pot was self-designed as shown in Fig. S1a (Supplementary material S1). This machine consisted of the main body (frame), holder of power screw, power screw, wheel, slider column, slider, inner part of mold, outer part of mold, lifter of mold base, and holder of mold base. Dimensions of mold are shown in Fig. S1b (Supplementary material S1). This mold was designed to produce a pot with 6, 7, and 5.5 cm height, top diameter, and bottom diameter, respectively (0.5 cm thickness). To prepare the mixture of pots, the different ratios of cow manure and pre-treated and untreated rape straw were mixed manually. It should be mentioned that no glue or any other adhesive materials were added to the mixture.

For production of pots using the designed machine (Fig. S1a, Supplementary material S1), firstly the mixture was placed inside the outer part of the mold. Secondly, the wheel was winded to lower the inner part of the mold until the two parts of the mold match. Thirdly, the wheel was winded once again to raise the internal part of the mold and to take out the formed pot from the internal part of the mold. Finally, the produced pot was removed from the machine. After molding, drying process was accomplished in an oven at 50 °C till constant weight or for 36 h. The dried pots were stored in sealed bags to prevent moisture absorption from the air until use.

2.3 Mechanical Properties

The most important mechanical properties of pots are CS and PS. Hence, 24 samples (4 samples for each test) were selected randomly from each treatment to perform two tests using a universal material test machine (REGER RGM-3005, China) at a crosshead speed of 120 mm/min. The penetration test was carried out with a 5-mm rounded end probe for pot walls and bottoms as shown in Fig. S2(a and b) (Supplementary material S1). The compression test was carried out in one position (vertical position) as shown in Fig. S2c (Supplementary material S1). The penetration and compression tests were carried out on dry and wet samples; new pots were used for measuring dry PS and dry CS, while wet pots were used for measuring wet PS and wet CS. To prepare the wet pots’ samples, samples were soaked in water for 10 min, then removed, and dried by dry cloths to remove the excided water. Each of the dry and wet pots was subjected to a vertical CS test, where the force direction was from top to bottom with pot set upright.

2.4 Water Absorption Test

WA test is performed to define the water permeation rate through the pot wall, and this is useful for determining the mechanical resistance of biodegradable pots in wet soil. Four samples from each treatment were weighted and soaked in water for 60 min at room temperature. Every 10 min during the 60 min, the samples were removed and exceeded water were dried by dry piece of cloth and then weighted, and the data were recorded. The water up-take percentage or WA percentage (WA) was calculated from the following equation:

where \(W_{t}\) and \(W_{d}\) are the weight of samples after and before immersion in the water (g), respectively, at various times.

2.5 Fourier Transform Infrared Spectroscopy (FTIR)

The differences in chemical components of untreated and treated rape straw were determined by Fourier transform infrared spectroscopy (FTIR) using a Thermo Nicolet IS50 FTIR spectrometer, SMART iTX, UK. The data were recorded in a range of 4000–400 cm−1 at a resolution of 4 cm−1 with 200 cumulative scans.

3 Design of Experiment

In this study the control factors were particle size of straw (Ps), ratio of mixture (straw: manure) (Rs), and pre-treatment of straw (Ts). The experiments were accomplished at two different straw particle sizes (1.5 and 3 mm) (representing fine and coarse particle), three different mixture ratios (2% (w.b), 6% (w.b), and 10% (w.b)), and untreated rape straw and treated rape straw with different pre-treatments (2% NaOH or 1% HCl). Table 1 illustrates parameters and their levels. Using Taguchi method, L18 (21 × 32) orthogonal array was selected to identify the optimal parameters and analyze the parameter effects [22]. The L18 mixed orthogonal array was employed for conducting the experiments (see Table T2, Supplementary material T1).

3.1 Taguchi Method

The Taguchi method is a widely used method for engineering analysis and optimization. The number of experiments can be decreased using orthogonal arrays, and the effects of out of control factors can be minimized [23]. Moreover, Taguchi method design is accuracy, simple, and is used to decrease the number of trails, which decreases the time of experiment and production cost. In addition, Taguchi method is used to define the significant factors in less time [24]. The Taguchi method is based on loss function that determines the experimental and desired values deviation. Then this function is converted into a signal/noise (S/N) ratio. The following equation can be used to calculate the S/N ratio [25].

where \({\text{M}}{\text{.S}}{\text{.D}}\) is the mean square deviation for the output characteristic. Generally, there are three types of characteristics quality in the S/N ratio, which are (i) the lower is the better, (ii) the higher is the better, and (iii) the nominal is the better [26].

According to the obtained experimental results, values of CS and PS were too high which led to difficult breakthrough of plant roots into the pot wall and bottom. Accordingly, these strengths should be decreased for improving the performance of biodegradable pots. In addition, the value of WA should be high to reduce the mechanical resistance of biodegradable pots in wet soil. Therefore, the biodegradation process of pot can occur easily.

Taguchi method is used to minimize the CS and PS and maximize the WA. Therefore, the lower is the better and the higher is the highest quality characteristics which can be illustrated from the following equations:

Lower is the better (minimize):

Higher is the better (maximize):

where n is the observation number, and y is the observed data of each characteristic.

4 Results and Discussion

4.1 Evaluation of Experimental Results

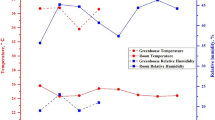

4.1.1 Effect of Control Factors on Water Absorption

Figure 1 shows the influence of ratio of rape straw to cow manure, straw particle size, and pre-treatment of straw on WA of biodegradable pots. Increasing of ratio of straw affects positively on the WA, where increasing ratio of straw exhibited an increase in the WA. For example, the WA increased from 126.52 to 141.21% when the ratio of straw increased from 2 to 10% at 1.5-mm untreated straw particles. This is due to that in the mixture of cow manure and rape straw, the cow manure acted as a binder material and the straw acted as a filler; therefore, the high straw ratio decreases the quantity of cow manure in the mix. Accordingly, the adhesion within the pot decreased, which leads to higher WA. This was consistent with the results of Jirapornvaree et al. [10], who attributed these results to the fact that the quantity of binder material is inversely proportional to WA. In addition, Wei et al. [27] demonstrated that the adhesion between the materials decreases with fiber content increasing and, thus, the WA increased. Moreover, when the ratio of straw increased, the pot’s surface will be rougher than before as well as the density of pot will be decreased. Consequently, the surface pores will increase, which leads to higher WA. Furthermore, WA curves increased rapidly during the initial stage and then slightly increased at the last period during the addition of straw. This is due to the difference in the internal structure of pot before and after addition of straw, which was more compacted before the addition.

The results showed that the pots prepared from large straw particle size had higher WA than pots prepared from small straw particle size, where the WA value increased from 139.48 to 149.34% at 10% NaOH-treated straw ratio. This is attributed to the decreased surface area of coarse straw particle compared with small straw particle size resulted in low adhesion of pot material and increasing in the surface pores of pot leading to the increasing of WA. These results are consistent with the results of Jirapornvaree et al. [10], who reported that the WA depended on the pore surface of biodegradable pots, where pots made from coarse waste texture had higher WA rate than those made from fine texture.

Additionally, results indicated that the effect of straw pre-treatment on WA differed according to the straw particle size. Where the pots made from treated large particles straw had higher WA than those made from the untreated large particles straw. In contrast, pots made from untreated small particles straw had higher WA than those made from treated small particles straw. These results are different from the expectation that increasing WA of treated straw in both large and small straw particles sizes. This is because the straw becomes hydrated after chemical pre-treatments which make straw have more ability to absorb more water. However, these results can be attributed to the factor of straw particle size which has a significant impact on the WA property of pots than the straw chemical pre-treatment factor. The contributions percentage of straw particle size and straw treatment factors were 13.54 and 4.31%, respectively. In both cases, it was found that the pots made from NaOH-treated straw had higher WA than pots made from HCl-treated straw, suggesting that the alkaline treatment (NaOH) increases the damage of straw fibers more than acid treatment (HCl), in which leads to higher WA.

4.1.2 Effect of Control Factors on Strength of Pots

The influence of straw ratio, straw particle size, and straw pre-treatment on dry and wet compression strengthens (CSs) is illustrated in Fig. 2a, b. The increase of straw ratio in the mixture affected negatively on CS, where the dry and wet CSs decreased with increasing of straw ratio, e.g., the dry and wet CSs decreased from 8267.67 to 4516 N and from 1245.33 to 792 N, respectively, when the ratio of straw increased from 2 to 10% with small NaOH-treated straw particles. These results indicated the lower rigidity of pots. In the mixture, when ratio of straw is increased, the quantity of cow manure (functioned as a binder material) decreases. Accordingly, the adhesion within the pots decreases which leads to a reduction in CS. This is consistent with the results obtained by Evans et al. [28] who found that the dry CS is primarily a function of pot wall rigidity. In addition, Wei et al. [27] demonstrated that the adhesion between materials decreases with increasing fiber content and thus the mechanical properties decrease.

Among the produced pots, the pots prepared by small straw particle size had higher dry and wet CSs than pots prepared by large straw particles, where dry and wet CSs values increased from 6105.33 to 6524.67 N and from 875.33 to 1094.67 N, respectively, at 6% untreated straw ratio, while the wet CS at 2% ratio of untreated straw decreased from 1255.67 to 1098 N. This attributed to the increased surface area of small straw particle size compared with large straw particle size. In this case, the adhesive material can cover more surface area of straw. Accordingly, the adhesion within pots is high leading to higher CS and PS.

Based on the results, the pots made from the untreated straw yielded higher dry and wet CSs than those made from the treated straw, as pots prepared from 2% small straw particles ratio yielded a decrease in dry and wet CSs. This result is referring to the damage of straw fibers after chemical pre-treatments, where straw fibers act as a reinforcement inside the pot structure resulted in a decrease in CS and PS. On the other hand, pots made from the NaOH-treated straw exhibited higher dry CS than pots made from treated straw by HCl for both small and large particle sizes. In contrast, for wet CS, the pots made from the treated straw by HCl yielded higher values than others, except for the wet CS of pots made from 2% ratio of small straw particles. These results can be attributed to that the pots made from HCl-treated straw had lower WA than pots made from NaOH-treated straw. Thus, the pots made from HCl-treated straw had higher strength.

The influence of straw ratio, straw particle size, and straw pre-treatment on dry and wet penetration strengths (PSs) for pot walls and bottoms is shown in Fig. 3a–d. Increasing of straw ratio affected negatively on the PSs, where the increase of straw ratio caused a decrease in dry and wet PSs for pot walls and bottoms. For example, the dry and wet PSs for pot wall decreased from 641.33 to 375.33 N (Fig. 3a) and from 84.33 to 43.0 N (Fig. 3b), respectively, at small NaOH-treated straw particles, while the dry and wet PSs for pot bottom decreased from 600.67 to 355.0 N (Fig. 3c) and from 96.67 to 50.33 N (Fig. 3d), respectively, with increasing the ratio of straw from 2 to 10% at the same conditions. These results are due to the increase of surface pores. When ratio of straw increased from 2 to 10%, the density of pots decreased. Accordingly, pot surface pores increased which led to a reduction in PS. This agreed with the results of Evans et al. [28] who found that the openings in pot walls affect negatively on the dry PS.

a Effect of ratio of straw and pre-treatments of straw at different straw particle sizes on dry PS of pot walls, b effect of ratio of straw and pre-treatments of straw at different straw particle sizes on wet PS of pots walls, c effect of ratio of straw and pre-treatments of straw at different straw particle sizes on dry PS of pot bottoms, and d effect of ratio of straw and pre-treatments of straw at different straw particle sizes on wet PS of pot bottoms

It can be seen that the small straw particles-based pots yielded higher dry and wet PSs applied in both walls and bottoms of pot than pots prepared from large straw particles, where the dry and wet PSs values increased from 487 to 569 N and from 57.33 to 68.67 N for pot wall as shown in Fig. 3a, b, respectively, at 2% untreated straw ratio. Moreover, it increased from 462.33 to 521.0 N and from 75.33 to 84.67 N for pot bottom (Fig. 3c, d), respectively, at the same conditions.

Furthermore, it was observed that the pots made from untreated straw exhibited higher dry and wet PSs of pot walls and bottoms than those made from treated straw, except the dry and wet PSs of 2% ratio of small straw particles. Otherwise, the pots made from NaOH-treated straw yielded higher dry PS pot walls and bottoms than pots made from HCl-treated straw. In contrast, the pot made from HCl-treated straw yielded higher wet PS of pot walls and bottoms than pots made from NaOH-treated straw, except the wet PS of 2% ratio of small straw particles. Overall, wet strengths reduced significantly compared to dry strengths for all produced pots due to pot superior water absorption ability [28]. For all strength values, the obtained results here lie in the recommended values which should be more than 20 N as mentioned by Evans et al. [8] for wet PS and CS of pots.

4.1.3 FTIR Analysis

The FTIR absorption spectrum of untreated rape straw and pre-treated straw by NaOH or HCl is shown in Fig. S3 (Supplementary material S1), and assignments are listed in Table T3 (Supplementary material T1). The examination of absorption bands illustrated that there were differences between pre-treated and untreated rape straw in peak width and shapes. For pre-treatments of straw, the peaks intensity at 2917 and 2849 cm−1 decreased and their shapes were clearly changed, suggesting that the chemical pre-treatments increased the damage of straw fibers. Consequently, the pots made from the untreated straw had higher strength than those made from the pre-treated straw. The spectra at 1734 cm−1 showed a decrease in absorption after pre-treatments, especially HCl pre-treatment. Additionally, the band at 1604 cm−1 showed a decrease after pre-treatments with both HCl and NaOH pre-treatments. The changes in both peaks intensity were associated with absorbed water to the highly hydrophilic component that easily became hydrated after chemical pre-treatments [29]. For this reason, the pots made from pre-treated straw had higher WA than those made from untreated straw. The peaks intensity at 1420, 1370, and 1318 cm−1 only decreased at HCl pre-treatment, while they did not exhibit any changes after NaOH pre-treatment compared with untreated straw. Moreover, the peaks intensity at 1231 cm−1 decreased after NaOH pre-treatment and increased after HCl pre-treatment. On the other hand, peaks intensity at 1031 cm−1 obviously decreased after NaOH and HCl pre-treatments. All peaks attributed to the amount of cellulose, hemicellulose, and lignin in rapeseed straw. This means that there is a remarkable change in the amount of these compounds as a result of chemical pre-treatments.

4.2 Analysis of the Signal-to-Noise (S/N) ratio

Effects of each factor on the CS, PS, and WA analysis were performed using Taguchi method, where the measured factors optimization was investigated by S/N ratios. Response of S/N for CS and PS is shown in Table 2. Optimal parameters of the control factors for maximizing the WA and minimizing the CS and PS can be easily shown in Fig. 4a–c. The optimal level for each control factor was determined based on the highest S/N ratio in that control factor levels.

The S/N response for CS, PS, and WA is shown in Table T4 (Supplementary material T1) and Fig. 4a–c. For the S/N response of CS (Fig. 4a), the levels and S/N ratios for the factors that yielded the best CS value were selected as factor A (Level 2, S/N = − 74.66), factor B (Level 3, S/N = − 72.93), and factor C (Level 2, S/N = − 74.49). Therefore, the optimum value of CS was obtained by particle size 3 mm (A2), ratio of mixture (straw: manure) 10% (B3), and pre-treated straw by 1% HCl (C2). Similarly, the levels and S/N ratios for the factors yielding the best PS (Fig. 4b) were selected as factor A (Level 2, S/N = − 52.31), factor B (Level 3, S/N = − 51.38), and factor C (Level 2, S/N = − 52.45). Hence, the optimum PS value was obtained by particle size 3 mm (A2), ratio of straw 10% (B3), and 1% HCl pre-treated straw (C2). In addition, the levels and S/N ratios for the factors yielding the best WA (Fig. 4c) were selected as factor A (Level 2, S/N = 42.90), factor B (Level 3, S/N = 43.06), and factor C (Level 3, S/N = 42.86). Therefore, the optimum WA value was obtained by particle size 3 mm (A2), ratio of straw 10% (B3), and 2% NaOH pre-treated straw (C3).

4.3 Analysis of variance (ANOVA)

ANOVA is a statistical method which can be used to explain the experimental data and determine the influence of all control factors in the experiment design. In this work, ANOVA was employed to analyze the effects of straw particle sizes, straw ratios, and straw pre-treatments on CS, PS, and WA of biodegradable pots. The ANOVA results for the CS, PS, and WA are listed in Table T5 (Supplementary material T1). This analysis was performed at confidence level 95%. The control factors significance in ANOVA was identified using the F values of each control factor. The contribution rate in Table T5 (Supplementary material T1) represents each parameter contribution percentage value, which indicates the degree of influence on the performance of process.

The percentage contributions of A, B, and C factors on the CS were 5.96, 79.77, and 4.04%, respectively, indicating to the most important factor affecting the CS which is ratio of straw (factor B, 79.77%). Moreover, ANOVA results showed that the percentage contributions of A, B, and C factors on PS were 19.66, 62.59, and 5.36%, respectively, which illustrated that the most effective factor on PS is also ratio of straw (factor B, 62.59%). For WA, the most effective factor is ratio of straw (factor B) with 74.27% contribution percentage, and the contributions percentage of A and C factors were 13.54 and 4.31%, respectively. The percentages of error were low (10.23, 12.39, and 7.88% for CS, PS, and WA, respectively).

From the ANOVA results, the ratio of rape straw to cow manure in the mixture of biodegradable pots is the most influence factors on the CS and PS, and WA.

4.4 Optimum CS, PS, and WA Estimation

The CS, PS, and WA values of the S/N ratio means response are illustrated in Table 3. The optimum values for CS, PS, and WA were calculated as A2B3C2, A2B3C2, and A2B3C3, respectively, and Eqs. (5), (6), and (7), respectively, can be used.

where CSopt, PSopt, WAopt are the optimum values of CS, PS, and WA, respectively, (A2, B3, C2), (A2, B3, C2), and (A2, B3, C3) indicate the optimum-level average values of CS, PS, and WA, respectively, TCS, TPS, and TWA state the average of all of the CS, PS, and WA values obtained from the experiment (Table 2). The calculated values of CSopt, PSopt, and WAopt were 3805.34 N, 308.08 N, and 147.66%, respectively.

In Taguchi method, the confirmation test is employed to verify the optimization after the determination of the variable levels that give the optimal results. Accordingly, the results of confirmation experiment were estimated regards the confidence interval (CI). The following equations were used in the CI calculation for estimated CS, PS, and WA [30]:

where \({\text{CI}}_{{\text{CS,PS,WA}}}\) is the confidence interval of CS, PS, and WA, \(F_{ \propto ,1,fe}\) is the F ratio at 95% confidence level, the subscripts ∝, \(fe\), \(V_{e}\) are the significance level (= 0.05), the degrees of freedom of error (= 12), and the variance of error, respectively, \(n_{{{\text{eff}}}}\) is the replications effective number, R is the replications number for confirmation experiments (= 3), N is the total number of trails in the experiment (= 18), and \(T_{{{\text{dof}}}}\) is the freedom total main factor degrees (= 5). Therefore, F0.05, 1, 12 = 4.747 (from F test table), \(V_{e}\) CS = 228539, \(V_{e}\) PS = 1391 and \(V_{e}\) WA = 7.882 (Table 3), and \(n_{{{\text{eff}}}}\) = 3.

Using Eq. (8), confidence intervals were calculated as CICS = ± 850.44, CIPS = ± 66.35, and CIWA = ± 4.99. With the confidence interval at 95% confidence, the estimated optimal values of CS, PS, and WA are:

Consequently, the values of CS, PS, and WA obtained from the experiment remained inside the limits of CI. Hence, CS, PS, and WA optimizations were attained using the Taguchi method at 0.05 significance level.

4.5 Confirmation Test

The obtained confirmation test results and the predicted values by the Taguchi method are listed in Table 4. The experimental values and the predicted values are very close to each other, where the maximum percentage of error defined for CS, PS, and WA are 5.06, 9.41, and 1.28%, respectively. These results indicated that there are inside the appropriate ranges because the error values are less than 20% which means reliable statistical analysis [31]. Consequently, the obtained results from the confirmation tests exhibited a successful optimization.

5 Conclusion

In this study, the optimal parameters to produce biodegradable pots from cow manure and rape straw were investigated using Taguchi method. According to the S/N ratio and ANOVA statistical analysis, the following conclusion can be written:

-

The control factors optimum levels for both CS and PS were found at A2B3C2 (i.e., particle size = 3 mm, ratio of straw = 10%, and pre-treatment straw by 1% HCl), and for WA were found at A2B3C3 (i.e., particle size = 3 mm, ratio of straw = 10%, and pre-treatment of straw by 2% NaOH).

-

The ratio of straw is the most significant factor that affects on properties of pots. The ratio of straw affected on CS, PS, and WA by approximately 79.77, 62.59, and 74.27%, respectively.

This work opens the door for expected future works such as drying methods and conditions of the biodegradable pots and its effect on properties, life cycle assessment of pots, and its environmental impact, in addition the economic study compared to other pots. Finally, the effect of compacting methods during manufacturing process on properties of pots should be investigated.

References

Wang, B.; Dong, F.; Chen, M.; Zhu, J.; Tan, J.; Fu, X., et al.: Advances in recycling and utilization of agricultural wastes in China: based on environmental risk, crucial pathways, influencing factors, policy mechanism. Proc. Environ. Sci. 31, 12–17 (2016)

Zhou, J.; Yan, B.H.; Wang, Y.; Yong, X.Y.; Yang, Z.H.; Jia, H.H., et al.: Effect of steam explosion pretreatment on the anaerobic digestion of rice straw. RSC Adv. 6(91), 88417–88425 (2016)

Li, P.; He, C.; Li, G.; Ding, P.; Lan, M.; Gao, Z., et al.: Biological pretreatment of corn straw for enhancing degradation efficiency and biogas production. Bioengineered 11(1), 251–260 (2020)

Mazurkiewicz, J.; Marczuk, A.; Pochwatka, P.; Kujawa, S.: Maize straw as a valuable energetic material for biogas plant feeding. Materials 12(23) (2019)

Tripathi, N.; Hills, C.D.; Singh, R.S.; Atkinson, C.J.; Biomass waste utilisation in low-carbon products: harnessing a major potential resource. npj Clim. Atmos. Sci. 2(1) (2019)

Schettini, E.; Santagata, G.; Malinconico, M.; Immirzi, B.; Scarascia Mugnozza, G.; Vox, G.: Recycled wastes of tomato and hemp fibres for biodegradable pots: physico-chemical characterization and field performance. Resour. Conserv. Recycl. 70, 9–19 (2013)

Grossman, E.: The biggest source of plastic trash you’ve never heard of: https://ensia.com/features/the-biggest-source-of-plastic-trash-youve-never-heard-of/; 2015 [Available from: https://ensia.com/features/the-biggest-source-of-plastic-trash-youve-never-heard-of/

Evans, M.; Taylor, M.; Kuehny, J.: Physical properties of biocontainers for greenhouse crops production. HortTechnology 20, 549–555 (2010)

Castronuovo, D.; Picuno, P.; Manera, C.; Scopa, A.; Sofo, A.; Candido, V.: Biodegradable pots for Poinsettia cultivation: agronomic and technical traits. Sci. Hortic. 197, 150–156 (2015)

Jirapornvaree, I.; Suppadit, T.; Popan, A.: Use of pineapple waste for production of decomposable pots. Int. J. Recycl. Org. Waste Agric. 6(4), 345–350 (2017)

Jamshidi, A.R.; Tayari, E.; Neisy, A.; Boneobeydi, M.S.; NeisyMorad, H.: Production of biological pots: a strategy for useful utilization of sugar cane Bagasse in Khuzestan Province. Bull. Environ. Pharmacol. Life Sci. 3(5), 96–99 (2014)

Nambuthiri, S.; Ingram, D.L.: Evaluation of plantable containers for groundcover plant production and their establishment in a landscape. Hort-Technology (2014).

Postemsky, P.D.; Marinangeli, P.A.; Curvetto, N.R.: Recycling of residual substrate from Ganoderma lucidum mushroom cultivation as biodegradable containers for horticultural seedlings. Sci. Hortic. 201, 329–337 (2016)

Hussein, Z.; Yuan, Q.; Xu, C.; Zhang, X.; Gouda, S.G.: Effect of drying methods and conditions and straw type and ratio in the mixture on physical and mechanical properties of biodegradable pots-based sustainable biomaterials. Cellulose (2023)

Costa, E.; Benites, N.; Guerra, J.; Melville, P.: Antimicrobial susceptibility of Staphylococcus spp. isolated from mammary parenchymas of slaughtered dairy cows. J. Vet. Med. Ser. B 47(2), 99–103 (2000)

Cucarella, C.; Tormo, M.Á.; Úbeda, C.; Trotonda, M.P.; Monzón, M.; Peris, C., et al.: Role of biofilm-associated protein bap in the pathogenesis of bovine Staphylococcus aureus. J. Infect. Immun. 72(4), 2177–2185 (2004)

Cardozo, V.F.; Lancheros, C.A.; Narciso, A.M.; Valereto, E.C.; Kobayashi, R.K.; Seabra, A.B., et al.: Evaluation of antibacterial activity of nitric oxide-releasing polymeric particles against Staphylococcus aureus and Escherichia coli from bovine mastitis. Int. J. Pharm. 473(1–2), 20–29 (2014)

Kavanagh, I.; Burchill, W.; Healy, M.G.; Fenton, O.; Krol, D.J.; Lanigan, G.J.: Mitigation of ammonia and greenhouse gas emissions from stored cattle slurry using acidifiers and chemical amendments. J. Clean. Prod. 237, 117822 (2019)

Hu, Q.; Hua, W.; Yin, Y.; Zhang, X.; Liu, L.; Shi, J., et al.: Rapeseed research and production in China. Crop J. 5(2), 127–135 (2017)

Bonjean, A.P.; Dequidt, C.; Sang, T.: Rapeseed in China. Ocl 23(6), D605 (2016)

NBSC: China Statistical Yearbook 2021. China statistics press; (National Bureau of Statistics of China), Beijing (2021)

Günay, M.; Yücel, E.: Application of Taguchi method for determining optimum surface roughness in turning of high-alloy white cast iron. Measurement 46(2), 913–919 (2013)

Asiltürk, İ.; Akkuş, H.: Determining the effect of cutting parameters on surface roughness in hard turning using the Taguchi method. Measurement (2011)

Manivel, D.; Gandhinathan, R.: Optimization of surface roughness and tool wear in hard turning of austempered ductile iron (grade 3) using Taguchi method. Measurement 93, 108–116 (2016)

Philip Selvaraj, D.; Chandramohan, P.; Mohanraj, M.: Optimization of surface roughness, cutting force and tool wear of nitrogen alloyed duplex stainless steel in a dry turning process using Taguchi method. Measurement 49, 205–215 (2014)

Gupta, A.; Singh, H.; Aggarwal, A.: Taguchi-fuzzy multi output optimization (MOO) in high speed CNC turning of AISI P-20 tool steel. Expert Syst. Appl. 38(6), 6822–6828 (2011)

Wei, L.; Liang, S.; McDonald, A.G.: Thermophysical properties and biodegradation behavior of green composites made from polyhydroxybutyrate and potato peel waste fermentation residue. Ind. Crops Prod. 69, 91–103 (2015)

Evans, M.; Taylor, M.; Kuehny, J.: Physical properties of biocontainers for greenhouse crops production. HortTechnology 549–55

Bledzki, A.K.; Mamun, A.A.; Volk, J.: Barley husk and coconut shell reinforced polypropylene composites: the effect of fibre physical, chemical and surface properties. Compos. Sci. Technol. 70(5), 840–846 (2010)

Mandal, N.; Doloi, B.; Mondal, B.; Das, R.: Optimization of flank wear using Zirconia Toughened Alumina (ZTA) cutting tool: Taguchi method and Regression analysis. Measurement 44(10), 2149–2155 (2011)

Cetin, M.H.; Ozcelik, B.; Kuram, E.; Demirbas, E.: Evaluation of vegetable based cutting fluids with extreme pressure and cutting parameters in turning of AISI 304L by Taguchi method. J. Clean. Prod. 19(17–18), 2049–2056 (2011)

Acknowledgements

The Major Science and Technology Innovation Plan of Hubei Province, China, financially supports this work (No. 2019ACA153) and the Chinese Scholarships Council Foundation (No. 2017SLJ023756).

Funding

The Major Science and Technology Innovation Plan of Hubei Province, China, supported this work (No. 2019ACA153).

Author information

Authors and Affiliations

Contributions

ZH helped in conceptualization, investigation, methodology, formal analysis, data curation, writing—original draft preparation; QY was involved in supervision, funding, writing—review and editing; SG contributed to investigation, conceptualization, writing—review and editing; SL and CX helped in material preparation, methodology.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest. Also, the authors declare that they have no known financial interests or personal relationships with other people or organizations that could have appeared to influence the work reported in this paper.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hussein, Z., Yuan, Q., Luo, S. et al. Plantable Biodegradable Pots as a Cleaner Product from Biomaterials: Characterization and Optimization of Physical and Mechanical Properties. Arab J Sci Eng 49, 9099–9109 (2024). https://doi.org/10.1007/s13369-023-08550-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-023-08550-w