Abstract

Redundancy allocation problem (RAP) is a non-linear programming problem which is very difficult to solve through existing heuristic and non-heuristic methods. In this research paper, three algorithms namely heuristic algorithm (HA), constraint optimization genetic algorithm (COGA) and hybrid genetic algorithm combined with particle swarm optimization (HGAPSO) are applied to solve RAP. Results obtained from individual use of genetic algorithm (GA) and particle swarm optimization (PSO) encompass some shortcomings. To overcome the shortcomings with their individual use, HGAPSO is introduced which combines fascinating properties of GA and PSO. Iterative process of GA is used by this hybrid approach after fixing initial best population from PSO. The results obtained from HA, COGA and HGAPSO with respect to increase in reliability are 50.76, 47.30 and 62.31 respectively and results with respect to CPU time obtained are 0.15, 0.209 and 3.07 respectively as shown in Table 3 of this paper. COGA and HGAPSO are programmed by Matlab.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Due to innovation of new technology and complex systems there arise a need of more reliable components or machines which are used in manufacturing and mechanical framework for the good quality of products. The increased need of reliability optimization is due to market pressure, safety issues, development risks and management emphasis etc. RAP is a well-known reliability optimization problem. In RAP the resolution of components among discrete choices with suitable stages of redundancy to maximize the reliability of the device under some predefined restrictions. RAP is a non-linear mixed integer programming problem. Because of discrete search space it is quite difficult to solve these problems by direct or indirect methods. Billionnet (2008) applied integer linear programming for solving RAP and consider the number of units of each subsystem and choice of units as decision variables. Garg and kumar (2009) tries to analyses the reliability of a pharmaceutical plant using matlab tool. Devi et al. (2017) also analyses the reliability of the system by heuristic algorithms.

Several researchers have already used GA with so many creative approaches to this problem. Holland (1975a, b) introduced GA on the basis of Darwinian evolution theory “survival of the fittest”. It works with coding variables and converts the design space into genetic space. GA is the heuristic search algorithm for finding RAP resolution. David and Alice (1996) have utilized a consolidated neural system and GA to solve RAP. Busacca et al. (2001) applied informative GA for solving optimization problem where each goal have given a separate importance to be optimized. Gupta and Agarwal (2006) applied GA for solving RAP. Penalty strategy has been used dealing with infeasible solution and a graphical representation has been presented for effective results of using penalty function. Puzzi and Carpinteri (2008) also applied GA with penalty strategy for handling the constraint optimization in a easy and efficient way. Garg and Kumar (2010) also applied GA for finding optimal solution of the availability of the screw plant. After that Zhao et al. (2012) introduced a hybrid GA with a flexible allowance technique to tackle restricted design optimization problems. Ghodrati and Lofti (2012) and Kanagaraj et al. (2013) and introduced a half and half cuckoo seek (CS)/GA calculation to take care of RAP and global enhancement issues, separately. Ghorabaeea et al. (2015) has contemplated a bi-target RAP, which is expounded to independent K-out-n subsystem in series.

Habib et al. (2016) proposed GA and present a comparison between GA and LINGO software tool. They showed how GA is superior to LINGO in respect of speed of getting results. Further, Saleem et al. (2018) developed a hybrid GA to solve RAP and compared the results with previous approaches. A combination of GA with other heuristic algorithm was also a great notion for enhancing the efficiency of GA. While comparing between GA and PSO, it is going to be found that both are executed on the basis of operation of population.

Mechanism of PSO is motivated by social behavior of birds and ants in a swarm. The population and the individuals are considered as swarm and particles respectively in PSO. Each particles in the swarm have a velocity and these particles moves in the search space trying to find the best velocity or solution. To solve optimization problem, Kennedy and Eberhart (1998) presented an effective approach named as PSO algorithm. It is a kind of search algorithm which is grounded on artificial intelligence of school of fish, a group of birds or swarm of bees. PSO is to get a solution of unconstrained optimization problem. Then PSO become a very interesting topic for researchers and been carried out in a diffusion of fields. Coello et al. (2004), Zhang et al. (2008), Chang (2009) and Zielinski et al. (2009) have applied PSO because of its smooth implementation, simplicity and efficiency. For enhancing the efficiency of PSO, Banks et al. (2008) developed a variety of PSO algorithms. Zou et al. (2010) proposed a modified and improved particle swarm optimization technique in which they modifies the velocity updating and introduced a new interia weight into the velocity updating. Kong et al. (2014) focused on specific redundancy allocation problem with multiple strategy choices (RAP-MSE) and applied a simplified particle swarm optimization (SPSO) with new position updating system with stochastic perturbation. A comparative analysis have been done with well-known PSO modifications in literature. Arif et al. (2016) presented the research and advancement calculation of PSO particularly for Distributed Generation (DG) position and estimating. A discussion has been made regarding combination of PSO with other algorithms and attained better results. Ouyang et al. (2019) applied PSO with stochastic disturbance type for solving reliability redundancy allocation problem (RRAP) and considered mixed redundancy strategy. Heterogeneous components are introduced in RRAP that is the strong base of this contribution. Robinson et al. (2002) used two methods hybrid PSO and GA for finding the best solutions of complicated electromagnetic appliance designs. After that Krink and Lvbjerg (2002) applied hybridized PSO with GA and Hill climbing approach for finding the solution of optimization problems without any constraint. Grimaldi et al. (2004) projected a hybrid technique named as Genetically Swarm Optimization (GSO) which is a combination of GA and PSO for solving electromagnetic optimization problems. Gandelli et al. (2006) and Grimaccia et al. (2007) created the application of few other hybridization procedures of GSO technique and verified with a few multimodal standard problems. Garg and Sharma (2013) have applied an efficient penalty based PSO algorithm to solve reliability redundancy allocation problem. They used the algorithm to determine and resolve the problem under cost, weight and volume constraints. After this technique Garg (2014) introduced another hybrid algorithm to solve nonlinear optimization problems with mixed variables under some constraints. Some studies have been conducted to analyze the reliability of the system and results are compared with previous results. Devi et al. (2017) applied a technique named as hybridization of constraint optimization genetic algorithm with particle swarm optimization (H-COGAPSO) and compare results with other heuristic algorithms.

The other contents of this paper are classified as per following: Introduction is followed by methodology which contains description of the system, entire notation used in the paper and formulation of the CRAP and methods. Next section highlights the proposed algorithm HGAPSO and its procedure by flowchart. Next section attends to the results of three techniques and comparison of the results. Last section caters to the drawn conclusion.

2 Methodology

2.1 System description

Seven units named as crane, rolling, blanking, stacking, pressing, molding and packaging of a manufacturing plant is connected in series Devi and Garg (2017). They work in a sequence in which they are connected.

2.2 Notations

- kj:

-

jth component

- Rj(kj):

-

Reliability

- Qj(kj):

-

Unreliability of component-tj

- Rs(k):

-

Overall system reliability

- Nj:

-

Subunit level

- hi(kj):

-

ith resource exhausted by jth component

- n = 7:

-

Total units

- L:

-

Maximum cost

- U (.):

-

A function which calculate value of reliability of whole system

- COGAnum:

-

Number of individuals in running iteration of COGA

- COGAPS:

-

Population size of the particles in COGA

- COGAmaxlter:

-

Maximum limit of iteration in PSO

- PSOj:

-

Running PSO iteration

2.3 Problem description

As any Unit management want to minimize cost L and maximize reliability/productivity in a manufacturing plant. So the given problem which defined by a function U and demonstrated in Table 1.

Problem is to maximize:

Devi et al. (2017) solved RAP by using HA and COGA. Alike algorithms are adopted in this paper and results are shown in Tables 2 and 3.

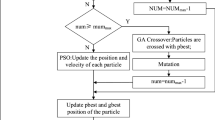

The main attention of the paper revolves around the proposed algorithm HGAPSO. The procedure of HGAPSO is shown by flowchart in Fig. 1.

3 Results

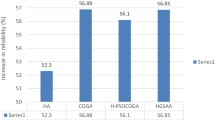

The result of RAP obtained by HA, COGA and HGAPSO is demonstrated by Tables 2, 3 and 4 respectively. Table 5 specifies the comparison of results of three algorithms w.r.t. increase in reliability and CPU time. Result demonstrate that percentage increase in reliability in HGAPSO comparatively much higher than HA and COGA results (Figs. 2, 3, 4).

4 Conclusion

This paper comprised three algorithms HA, COGA and HGAPSO to solve optimization problem with cost constraint. The intent of this paper is to increase the reliability is fulfilled by HGAPSO which is depicted in Table 5. The performance of three algorithms are compared and observed that the performance of proposed HGAPSO is better than other two algorithms with respect to reliability but the CPU time 3.07 s which is more than other two algorithms. It depends on different techniques; if combination of two algorithms is applied then it takes more CPU time than a single algorithm applied. But reliability is improved by 62.31% when combination of algorithms applied together like HGAPSO as shown in Table 5.

References

Arif SM, Hussain A, Shin DR (2016) A survey on particle swarm optimization for use in distributed generation placement and sizing. In: MATEC web conferences 70

Banks A, Vincent J, Anyakoha C (2008) A review of particle swarm optimization, part II: hybridisation, combinatorial, multicriteria and constrained optimization, and indicative applications. Nat Comput 7:109–124

Billionnet A (2008) Redundancy allocation for series-parallel systems using integer linear programming. IEEE Trans Reliab 57(3):507–516

Busacca PG, Marseguerra M, Zio E (2001) Multiobjective optimization by genetic algorithms: application to safety systems. Reliab Eng Saf Syst 72:59–74

Chang WD (2009) PID control for chaotic synchronization using particle swarm optimization chaos. Solitons Fractals 39(2):910–917

Coello CAC, Pulido GT, Lechuga MS (2004) Handling multiple objectives with particle swarm optimization. IEEE Trans Evolut Comput 8(3):256–279

David WC, Alice ES (1996) Solving the redundancy allocation problem using a combined neural network/genetic algorithm approach

Devi S, Garg D (2017) Redundancy-allocation in neel metal products limited. Indian J Sci Technol 10(30):1–5

Devi S, Sahu A, Garg D (2017) Redundancy optimization problem via comparative analysis of H-PSOCOGA. In: IEEE Xplore, pp 18–23

Gandelli Grimaccia F, Mussetta M, Pirinoli P, Zich RE (2006) Genetical swarm optimization: an evolutionary algorithm for antenna design. J Autom 47(3–4):105–112

Garg H (2014) Solving structural engineering design optimization problems using an artificial bee colony algorithm. J Ind Manag Optim 10(3):777–794

Garg D, Kumar K (2009) Reliability analysis of pharmaceutical plant using Matlab-tool. Int J Electron Eng Res 1(2):127–133

Garg D, Kumar K (2010) Meenu, availability optimization for screw plant based on genetic algorithm. Int J Eng Sci Technol 2(4):658–668

Garg H, Sharma SP (2013) Reliability-redundancy allocation problem of pharmaceutical plant. J Eng Sci Technol 8(2):190–198

Ghodrati A, Lotfi S (2012) A hybrid CS/GA algorithm for global optimization. In: Proceedings of the international conference on soft computing for problem solving, Roorkee, pp 397–404

Ghorabaeea MK, Amiria M, Azimib P (2015) Genetic algorithm for solving bi-objective redundancy allocation problem with k-out-of-n subsystems. Appl Math Model 39(20):6396–6409

Grimaccia Mussetta M, Pirinoli P, Zich RE (2007) Genetical swarm optimization: self-adaptive hybrid evolutionary algorithm for electromagnetic. IEEE Trans Antennas Propag 55(3):781–785

Grimaldi EA, Grimacia F, Mussetta M, Pirinoli P, Zich RE (2004) A new hybrid genetical swarm algorithm for electromagnetic optimization. In: Proceedings of international conference on computational electromagnetics and its applications, Beijing, China, pp 157–160

Gupta R, Agarwal M (2006) Penalty guided genetic search for redundancy optimization in multi-state series-parallel power system. J Comb Optim 12:257–277

Habib M, Chehade H, Yalaoui F, Chebbo N, Jarkass I (2016) Availability optimization of a redundant dependent system using genetic algorithm. IFAC-Papers Online 49(12):733–738

Holland JH (1975a) Adoption in neural and artificial systems. The University of Michigan Press, Ann Arbor

Holland JH (1975b) Adaptation in natural and artificial systems. The University of Michigan Press, Ann Arbor

Kanagaraj G, Ponnambalam SG, Jawahar N (2013) A hybrid cuckoo search and genetic algorithm for reliability-redundancy allocation problems. Comput Ind Eng 66:1115–1124

Kennedy J, Eberhart R (1998) Particle swarm optimization. In: Proceedings of the IEEE conference on neural networks, Piscataway, NJ, USA

Kong X, Gao L, Ouyang H, Li S (2014) Solving the redundancy allocation problem with multiple strategy choices using a new simplified particle swarm optimization. Reliab Eng Syst Saf 144:147–158

Krink T, Lvbjerg M (2002) The lifecycle model: combining particle swarm optimization, genetic algorithms and hill climbers. In: Proceedings of the parallel problem solving from nature, pp 621–630

Ouyang Z, Liu Y, Ruan SJ, Jiang T (2019) An improved particle swarm optimization algorithm for reliability-redundancy allocation problem with mixed redundancy strategy and heterogeneous components. Reliab Eng Syst Saf 181:62–74

Puzzi S, Carpinteri A (2008) A double-multiplicative dynamic penalty approach for constrained evolutionary optimization. Struct Multidisc Optim 35:431–445

Robinson J, Sinton S, Samii YR (2002) Particle swarm, genetic algorithm, and their hybrids: optimization of a profiled corrugated horn antenna. In: Proceedings of the IEEE international symposium in antennas and propagation society, pp 314–317

Saleem EAA, Dao TM, Liu ZH (2018) Multiple-objective optimization and design of series-parallel systems using novel hybrid genetic algorithm meta-heuristic approach. World J Eng Technol 6:532–555

Zhang JD, Jia DL, Li K (2008) FIR digital filters design based on chaotic mutation particle swarm optimization. In: Proceedings of the IEEE international conference on audio, language and image processing, pp 418–422

Zhao JQ, Wang L, Zeng P, Fan WH (2012) An effective hybrid genetic algorithm with flexible allowance technique for constrained engineering design optimization. Expert Syst Appl 39:6041–6051

Zielinski K, Weitkemper P, Laur R (2009) Optimization of power allocation for interference cancellation with particle swarm optimization. IEEE Trans Evol Comput 13(1):128–150

Zou D, Wu L, Gao L, Wang X (2010) A modi¯ed particle swarm optimization algorithm for reliability problems. In: IEEE fifth int. conf.: bio-inspired computing: theories and applications (BIC-TA), pp 1098–1105

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Devi, S., Garg, D. Hybrid genetic and particle swarm algorithm: redundancy allocation problem. Int J Syst Assur Eng Manag 11, 313–319 (2020). https://doi.org/10.1007/s13198-019-00858-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13198-019-00858-x