Abstract

The aim of present study was to develop and characterize the biodegradable sweet potato starch-based nanocomposite films reinforced with barley starch nanoparticles (SNP). Sweet potato starch-based films with varying concentrations of barley SNP (5–25% w/w) were manufactured by adopting solution casting method using glycerol as a plasticizer. The morphology, thickness, transparency, water solubility, water vapor transmission rate (WVTR), tensile strength, elongation at break and thermal stability properties of nanocomposite films were evaluated. The results showed that the incorporation of barley SNP led to a significant increase in tensile strength from 2.63 (control film) to 8.98 MPa (nanocomposite with 15% (w/w) SNP). Compared with the native starch film, the surface of the nanocomposite films became more rough and uneven with the increasing concentration of nanofillers. High concentration of SNP (upto 25%, w/w) significantly decreased the transparency and WVTR, and water solubility (upto 20%, w/w) of nanocomposite films. The WVTR decreased from 3294.53 to 349.06 g/m2/24 h. In addition, the thermal stability of nanocomposites got improved after incorporation of SNP into starch-film matrix.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The grueling environmental pollution provoked by excessive use of plastic packaging materials, has evoked a substantial curiosity in production of edible and biodegradable bioplastics using various biopolymers. The manufacturing of polythene bags emits carbon and many other harmful gases aggravating the environmental concerns (Jain et al. 2015), alternatively, the production of bioplastics as biodegradable packaging materials may reduce the use of fossil fuel, non-degradable plastic waste, and emission of carbon dioxide gas (Siakeng et al. 2019). The primary reason to consider the biopolymers as alternative packaging material is their readily available nature, low cost, renewability, biodegradability, biocompatibility, and eco-friendliness (Herniou-Julien et al. 2019). However, the restricted performance and high cost of other biopolymeric materials like proteins (e.g. soy, gelatin, wheat gluten, corn zein, whey and casein) and polysaccharides (e.g. cellulose, chitosan, pectins) are the limiting factors in contrast to conventional thermoplastics and starch.

Polysaccharides are the most abundant macromolecules in nature, which may be the most suitable raw materials for the production of bioplastics (Emre and Pukánszky 2015). Starch could be a popular biopolymer as an alternative material due to its abundance in nature, cost-effectiveness, and biodegradability. Starch-based bioplastics are widely used for packaging applications as about 50% of commercially used bioplastics are manufactured using starch (Gadhave et al. 2018).

The turn of the industries towards eco-friendly nanocomposites, one of the promising areas of starch nanoparticles, is to improve the physicochemical, mechanical, and thermal properties of the biodegradable nanocomposites. Nowadays, starch-based nanocomposites are finding diverse applications in food packaging, pharmaceutical, medical, and agri-based industry. Nanometric dimension of nanoparticles may improve the distribution and compactness of polymeric structure (Da Silva et al. 2018). The starch can be transformed into varied forms such as molded, extruded, blown articles, or thermoformed. Casting and extrusion are the frequently used methods for material processing (Madhumita et al. 2018). Out of these, the casting method is more appropriate for laboratory use to prepare starch nanocomposites. The properties like tensile strength, elongation at break, and water vapour permeability of starch-based nanocomposites are dependent to a great extent on the amylose content of starch. The high amylose content of starches has been a better choice for biopolymer films (Muscat et al. 2012). The starch nanoparticles (SNP) have been used as nanofillers in starch-based nanocomposites greatly affecting the morphological, barrier, mechanical strength, and thermal stability of starch-based nanocomposites (Piyada et al. 2013; Li et al. 2015; Dai et al. 2015). Waxy maize starch nanocrystals (SNC) have been produced by adopting acid hydrolysis and used as a reinforcing agent in rice starch-based nanocomposites resulting into improved mechanical strength of films (Piyada et al. 2013). Since the conventional starches such as corn, potato, rice, waxy maize etc. are being over exploited for various food and non-food applications, a wide scope could be there for the production of SNP using underutilized cereal and tuber starches. Crops like sweet potato and barley could be excellent alternative sources of starch for the fabrication of SNP and their applications in nanocomposites.

Sweet potato (Ipomoea batatas) is a tuber crop and is largely grown in the world's tropical and sub-tropical areas. Every year up to 15% of sweet potato tubers are discarded due to difficulties in storage and inefficient processing, and therefore, extraction of starch from tubers is considered as the finest way to diminish this wastage (Flores et al. 2007). Starch is the major component of sweet potato tuber with 19–36% amylose content (Saman et al. 2019). The good amylose content of sweet potato starch makes it suitable for films production. Barley (Hordeum Vulgare L.) is one of the first crop to get domesticated and cultivated commercially all over the world. Barley grains are mainly used in malting for beer and whiskey production and for animal feed, the major reason for less exploitation of barley starch (Satnca et al. 2016). The barley endosperm occupies about 60–70% starch as the main component (Kong et al. 2016) with amylose content varying from 15 to 29% (Fan et al. 2019; Kumari et al. 2022). To the best of our knowledge there are no publications reporting the use of barley SNP in nanocomposites. Hence, the objective of this work was to manufacture the sweet potato starch-based bionanocomposite films reinforced with barley SNP and to investigate the morphological and thermomechanical properties of nanocomposites.

Materials and methods

The sweet potato tubers were purchased from the local market of Rohtak, Haryana (India) and the barley seeds (H. Vulgare L.) of non-waxy variety BH-393 were procured from Chaudhary Charan Singh, Haryana Agricultural University, Hisar (India). All the chemicals/reagents used in the present investigation were of analytical grade and were purchased from Spectrum Technologies, Hisar, Haryana (India).

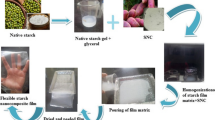

Preparation of starch-based nanocomposite films

The sweet potato starch (polygonal shaped granules with diameter ranging from 6 to 24 µm, with amylose content of 23.94%, and gelatinization temperature of 62.37 °C) was used for nanocomposite films formation (Kumari et al. 2021). Barley SNP were used as nano fillers in sweet potato starch-based nanocomposites. The barley SNP produced by sulfuric acid (3.16 M) hydrolysis were round or irregular shaped with average hydrodynamic diameter of 140 nm, crystallinity value of 48.08% and gelatinization temperature of 135.87 °C (Kumari et al. 2022).

Starch-based nanocomposite films were prepared by using casting method as used by Piyada et al. (2013) with some modification. Dry sweet potato starch (3 g) in water (100 ml) was gelatinized at 95 °C on a hot plate with constant stirring for 30 min. The mixture was then cooled to 50 °C. Plasticizer i.e., glycerol, was added at a level of 40% (w/w) of native starch, subsequently the dispersions of SNP (5, 10, 15, 20, and 25%, w/w of native starch) were prepared in 20 ml distilled water and sonicated for 10 min before pouring into the native starch gel and stirring for 30 min at 50 °C in an incubator shaker at 100 rpm. The starch matrix was casted on rectangular plastic trays, dried overnight at 45 °C and then cooled to room temperature before peeling off the films. The translucent films free from cracks and holes were stored in plastic bags for further testing. All nanocomposites blends were made in triplicate.

Characterization of starch-based nanocomposites

Morphology of starch-based nanocomposites

The morphological characteristics of the developed films were studied by using SEM (Zeiss EVO 50) by examining the surface of the films. Films pieces (6 mm) were dried in a vacuum drier, coated with a layer of gold, and photographed at a magnification of 1000X and acceleration voltage of 15 kV.

Moisture content of starch nanocomposites

The moisture content of starch nanocomposites was determined by following Müller et al. (2011) method with minor modification. The weight of the film samples taken in triplicate (3 cm × 3 cm) was recorded before and after drying at 100 °C overnight. The moisture content of nanocomposites film was expressed in percent (%).

Water vapor transmission rate (WVTR) of starch nanocomposite films

The water vapor transmission rate of the starch-based nanocomposite films was carried out using water vapor permeability tester (PermeH2O model, extra solution s.r.l) (ASTM F1249 standard). The film samples were conditioned at 23 ± 2 °C temperature and 50 ± 5% relative humidity prior to testing. Circular films of 10 cm diameter were cut and sealed between wet and dry chambers with a relative humidity of 90% at 38 °C temperature. In this system, a pressure modulated sensor measures water vapor transmitted through the sample tested. The WVTR was measured in g/m2/day.

Solubility of starch nanocomposites in water

The solubility of native starch film and nanocomposite films was determined by following Nafchi et al. (2012), method with minor modification. Three samples of 3 cm × 3 cm were cut from each film and placed in a desiccator containing silica gel for 48 h. The film’s samples were weighed and dipped into beakers with 100 ml distilled water. The samples were agitated constantly on the shaker for 1 h at room temperature. The samples were filtered through a filter paper Whatman No.1. The wet film samples were dried in oven at 55 °C until they reached a constant weight. The following formula calculates the water solubility:

Thickness of starch nanocomposites

The thickness of nanocomposites films were recorded by using an electronic digital caliper (0.001 accuracy, china) at 10 random locations. The average thickness values was recorded and used to determine the mechanical properties (tensile properties and elongation at break) and water vapor transmission rate of films.

Transparency/opacity properties of starch nanocomposites

The transparency of films was determined using Shi et al. (2013) method. The film samples were cut into rectangular (0.5 × 4 cm) shapes and placed inside the spectrophotometer cell. The air was used as a reference, and the absorbance spectrum was measured at 600 nm wavelength. The opacity of films was obtained by calculating the area under absorbance at a given wavelength, and three replicate samples were analyzed.

Tensile properties and elongation at break of starch nanocomposites

Tensile strength and elongation at break of nanocomposites films were determined using a universal testing machine according to the ASTM 882 standard method. For measurement thin films strips (1 × 10 cm) were used. In this test the film strip was mounted between two grips that were 50 mm apart at the beginning of the test distance and which were pulled apart by applying a tensile load. Tensile strength and elongation at break was calculated from crosshead displacement.

Thermogravimetric analysis (TGA)

To study the thermal stability of nanocomposites, thermogravimetric analysis was performed using a thermogravimetric apparatus (Hitachi, STA7300). Each sample (10 mg) was loaded into an aluminum pan and ramped from 30 to 500 °C at a heating rate of 10 °C/min, and performed under a nitrogen environment at a flow rate of 30 ml/min and the mass loss of the sample was analyzed as a function of temperature.

Statistical analysis

Data were subjected to one way analysis of variance (ANOVA), followed by Tukeys HSD test (p < 0.05) using SPSS version 19.0. The results were interpreted as the mean of three independently samples and reported as mean ± standard deviation.

Results and discussion

Morphological characteristics

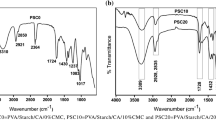

The Fig. 1 displays the photographic images of the nanocomposite films reinforced with barley SNP and showed that the obtained films were translucent, flexible and free from cracks. The SEM micrographs of flexible and translucent films as shown in Fig. 2 revealed a smooth and clean surface of the control film but the films became rougher with the increasing concentrations of nano fillers. The Fig. 2B, C shows that nanoparticles were dispersed evenly throughout the film matrix when loaded at a level of 5–10% (w/w). However, Fig. 2D, F showed rougher and uneven surfaced nanocomposite films ascribed to the aggregations of nanoparticles. No obvious clusters of nanoparticles and microphase separation were observed up to 10% (w/w) filler content. Rough or uneven surface has been reported for rice starch nanocomposite films reinforced with rice SNC at 25 and 30% (w/w) levels (Piyada et al. 2013) and for corn starch nanocomposite films reinforced with freeze-dried and spray-dried nanoparticles (Shi et al. 2013).

Generally, the low filler content get dispersed homogeneously in the matrix than high filler content resulting in stronger interaction and adhesion on the interfaces of matrix and filler. At lower concentrations, the SNP have more tendency to touch the starch matrix and establish stronger interactions (Chen et al. 2008) and this fact is in agreement with the results of this study for mechanical properties (tensile strength); the tensile strength of nanocomposites film increased with increasing filler content loaded upto 15% (w/w) and start decreasing beyond a level of 15% (w/w). In addition, uniform distribution of nanoparticles is essential for obtaining optimum properties of nanocomposite films.

Moisture content, solubility and water vapor transmission rate (WVTR)

The moisture content of nanocomposite films was affected inconsistently when compared to native starch films. At 5% concentration of nanofiller, the moisture content increased significantly but it showed an insignificant decrease at 10 and 15% concentration followed by a significant increase at 25% concentration of nanofiller content. However, a significant (p < 0.05) decrease in the water solubility of nanocomposite films was recorded with the incorporation of SNP up to 20% (w/w). The water solubility was found to be highest for control film (22.86%) and lowest (18.41%) for nanocomposite film reinforced with 20% (w/w) SNP content. The reduction in solubility of nanocomposite films could also be attributed to the inclusion of more crystalline SNP (Li et al. 2015). Consequently, the inter/interamolecular combination is improved by the interaction between SNP and films matrix, indicating that nanoparticles can increase films stability in water. The increase in water solubility of nanocomposite films above 20% (w/w) nano filler content could be attributed to the uneven distribution of SNP on account of aggregation of nano filler at higher concentration. However, low filler content in the matrix facilitates uniform distribution of nanoparticles and establishes a regular structure with relative impermeability lowering the solubility of films. Further, the incorporation of nano fillers suppressed the diffusion of water through the film’s structure (Voon et al. 2012).

The most important function of packaging material is to prevent the moisture transfer between food and the environment. The lower WVTR of films is preferable for packaging purposes. The results as given in Table 1 illustrated that the WVTR decreased significantly (p < 0.05) as the SNP content was increased up to 25% (w/w).The WVTR of nanocomposite films decreased from 3294.53 to 349.06 g/m2/24 h with the increasing concentrations of nano filler. It was recorded to be maximum for control film (3294.53 g/m2/24 h) and minimum (349.06 g/m2/24 h) for nanocomposite film filled with 25% (w/w) nano filler. This decrease in WVTR could be ascribed to the nanometric size of SNP which boosts the compactness of films and interferes with polymer chain mobility (Shi et al. 2013) or alternatively also be due to the uniform distribution of SNP throughout the film matrix. The decrease in water vapor resistance of nanocomposite films with the incorporation of SNP has been attributed to nano fillers that can create a tortuous path for water molecules to pass through composite minimizing the diffusion through nanocomposite films by creating a longer diffusive path which further reduces WVTR (Liu et al. 2016; Charoenthai et al. 2018). Incorporation of SNP also restricts the formation of intermolecular hydrogen bonding in between starch molecules (Gujral et al. 2021).

However, increased WVTR at high loading levels has been ascribed to the aggregation of SNP which disturbs the uniformity of films, creates an easy pathway, and allows diffusion of water molecules through films at a high rate (Müller et al. 2011). The reduction in WVTR of starch nanocomposites suggested that these nanocomposites may be used for the wrapping of fruits, vegetables and bakery products (Castillo et al. 2017) by using some additives for preservation and production of edible films which could be eaten with food materials. Edibles films enhance the quality of food products and protect the food from physical, chemical and biological deteriorations, which is directly related to the self-life extension. Edible films might be located between the heterogeneous food components to prevent the migrations of moisture and preserve the quality, for example pizza crust absorbs the moisture from the filling/toppings and lost the crispness.

Thickness and transparency

The results of thickness and transparency of starch-based nanocomposites are elaborated in Table 2. The film's thickness increased significantly (p < 0.05) as the nanoparticles concentration increased in the film matrix up to 25% (w/w). The thickness was observed to be lowest for control film (0.106 mm) and the highest for nanocomposite film loaded 25% (w/w) SNP (0.186 mm). The increased thickness may possibly be due to an increase in the total dry mass content of films, which may further influence the mechanical and barrier properties of films. Similar observations have been reported for corn starch films filled with waxy corn SNP (1–25%, w/w); taro SNP (0.5–15%, w/w) (Dai et al. 2015; Liu et al. 2016).

The transparency of films decreased significantly (p < 0.05) with increasing SNP concentrations up to 25% (w/w) as given in Table 2. Transparency was recorded to be maximum for control film (99.72%) and minimum (97.64%) for nanocomposite film loaded with 25% (w/w) SNP. The increase in opacity can be related to the thickness of films with the increasing dry mass in the film matrix may increases the number of established bonds and thickness of nanocomposite films resulting in reduced light penetration, and hence increased film opacity. This increase in opacity of nanocomposite films could also be ascribed to the aggregations of nanoparticles at higher filler levels. Previously, a similar tendency was also reported for corn starch-based films reinforced with taro SNP at different levels (Dai et al. 2015).

Mechanical properties

Packaging materials must be undeformable to provide structural integrity to the food materials and this tendency of deformation is evaluated by measuring the tensile strength and elongation of break with the later being inversely proportional to the tensile strength. The results of tensile strength and elongation at break measurements are given in Table 3. The results revealed that after an initial significant increase in tensile strength of nanocomposite films loaded with upto 15% (w/w) SNP, it started decreasing at a higher concentrations of SNP (above 15% (w/w). The increase in tensile strength has been related to the much smaller size, larger surface area, and higher surface energy of nanoparticles. The larger surface area of SNP plays an important role in improving the mechanical strength of nanocomposite films through better interfacial interaction between filler-filler and filler-polymeric matrix due to hydrogen bonding. Additionally, the improvement in mechanical strength of nanocomposite films reinforced with nano-fillers has also been attributed to the fact that nano-sized particles due to much smaller size dispersed more homogenously and formed stronger interaction with polymeric matrix than micron-sized granules (Chen et al. 2008). However, the decrease in tensile strength beyond 15% (w/w) nano filler content might be due to the ability of nanoparticles to form aggregates, which reduces SNP effective surface area for interacting with film′s matrix (Zheng et al. 2009). A reduction in tensile strength above 15% (w/w) nano filler content has also been reported for the nanocomposite films (Lin et al. 2020).

On the other hand, the elongation at break values of films decreased significantly (p < 0.05) with increasing nano filler content and it was recorded as maximum (26.25%) for the control film and minimum (17.47%) for nanocomposite films reinforced with 25% (w/w) barley SNP (Table 3). The decrease in elongation at break with increasing filler content is ascribed to the differences between the polymeric matrix and fillers' rigidity. Due to the rigid nature of fillers, the polymers deform at high strain and therefore, the deformation of nanocomposite films reduces (Piyada et al. 2013). Besides, higher rigidity of nanocomposite films and decreased elongation at break has also been ascribed to increment in hydrogen bonds with hydroxyl group of starch (Selene et al., 2013). Similarly, a decrease in elongation at break has also been reported in earlier studies for corn starch nanocomposite films loaded with waxy corn SNP (Liu et al. 2016). The increased mechanical strength of starch nanocomposites may be helpful in protecting the food products more effectively from the physical damage caused by transportation, vibrations, pressure, and mechanical factors. The improved tensile strength of starch nanocomposites may also enhance the holding capacity of packaging materials.

Thermogravimetric analysis (TGA)

The thermograms of control film and nanocomposites are shown in Fig. 3. The thermal decomposition process of nanocomposite films occurred in three stages. The initial stage was observed in between 40 and 150 °C, second stage in between 275 and 350 °C and third stage at a temperature beyond 350 °C. The maximum degradation temperature was found to be around 350 °C for nanocomposite film incorporated with 15% (w/w) SNP (Fig. 3D). The higher degradation temperature corresponds to the higher thermal stability.

The decomposition temperature at 50% mass loss was recorded to be lowest (340 °C) for control film and highest (348 °C) for nanocomposite film loaded with 15% (w/w) SNP. The thermal stability started decreasing at a concentration of SNP beyond 15% (w/w).This may be attributed to the aggregations of nanoparticles or non-uniform distribution of nanoparticles at higher loading level as revealed by SEM micrographs of films. The residual amount of nanocomposite films (7.84–10.37%) was higher than that of the control film (7.29%) due to the higher crystallinity and higher thermal stability of SNP.

For sweet potato starch-based films loaded with barley SNP, the increased decomposition temperature with increasing filler content could be due to the more crystalline and compact structure attributed to the presence of starch nanoparticles requiring more time to melt and hence more thermal stability (Liu et al. 2016). It could also be justified with the help of results of DSC study for barley SNP as the results revealed a higher melting temperature for barley SNP than their native counterpart and the compact crystalline structures of nanoparticles required higher thermal energy to disrupt amylopectin double helices (Kim et al. 2013). The finding of the present study suggested that the addition of barley SNP enhanced the thermal stability of nanocomposites. Similar observation has been reported earlier for rice starch matrix loaded with rice SNC (Piyada et al. 2013). Higher melting temperature also reported for corn starch film loaded with taro SNP than control starch film (Dai et al. 2015). Thus, the incorporation of starch nano fillers improved the thermal stability of nanocomposites and the results of TGA study suggested that these nanocomposites could better tolerate thermal stress during food processing, shipping and storage.

Conclusion

The nanocomposite films were obtained using acid hydrolyzed round or irregular shaped barley SNP as reinforcing phase and sweet potato starch as film matrix. The results of study revealed that the addition of barley SNP had a significant impact on the performance of sweet potato starch-based films. Compared to the native starch film, the water solubility of nanocomposites decreased by 19.46% up to a filler content of 20% (w/w).The WVTR of nanocomposites film decreased by 89% at 25% (w/w) nano filler content. Nanocomposite film containing 15% (w/w) SNP exhibited the highest (8.98 MPa) tensile strength. Additionally, incorporation of SNP improved the thermal stability of nanocomposite films. The findings of current study suggested that the barrier, mechanical and thermal stability of sweet potato starch films were enhanced by the reinforcement of barley SNP. Therefore, the starch nanocomposites impregnated with SNP obtained from different starch sources could have great potential for developing environment friendly packaging materials for food and non food applications.

Data availability

The datasets used or analyzed during the current research study are available from the corresponding author on the reasonable request.

Code availability

Not Applicable.

Abbreviations

- SNP:

-

Starch nanoparticles

- SNC:

-

Starch nanocrystals

- TGA:

-

Thermogravimetric analysis

- WVTR:

-

Water vapor transmission rate

References

Castillo LA, Farenzena S, Pintos E, Rodríguez MS, Villar MA, García MA, López OV (2017) Active films based on thermoplastic corn starch and chitosan oligomer for food packaging applications. Food Packag Shelf Life 14:128–136

Charoenthai N, Wickramanayaka A, Sungthongjeen S, Puttipipatkhachorn S (2018) Use of cassava starch nanocrystals to make a robust rupturable pulsatile release pellet. J Drug Deliv Sci Technol 47:283–290

Chen Y, Cao X, Chang PR, Huneault MA (2008) Comparative study on the films of poly (vinyl alcohol)/pea starch nanocrystals and poly (vinyl alcohol)/native pea starch. Carbohydr Polym 73(1):8–17

Dai L, Qiu C, Xiong L, Sun Q (2015) Characterisation of corn starch based films reinforced with taro starch nanoparticles. Food Chem 174:82–88

Fan X, Zhu J, Dong W, Sun Y, Lv C, Guo B, Xu R (2019) Comparison of pasting properties measured from the whole grain flour and extracted starch in barley (Hordeum vulgare L). PLoS ONE 14(5):e0216978

Flores S, Haedo AS, Campos C, Gerschenson L (2007) Antimicrobial performance of potassium sorbate supported in tapioca starch edible films. Eur Food Res Technol 225(3–4):375–384

Gadhave RV, Das A, Mahanwar PA, Gadekar PT (2018) Starch based bio-plastics: the future of sustainable packaging open. J Polym Chem 8:21–33

Gujral H, Sinhmar A, Nehra M, Nain V, Thory R, Pathera AK, Chavan P (2021) Synthesis, characterization, and utilization of potato starch nanoparticles as a filler in nanocomposite films. Int J Biol Macromol 186:155–162

Herniou-Julien C, Mendieta JR, Gutiérrez TJ (2019) Characterization of biodegradable/non-compostable films made from cellulose acetate/corn starch blends processed under reactive extrusion conditions. Food Hydrocoll 89:67–79

Imre B, Pukánszky B (2015) Compatibilization in bio-based and biodegradable polymer blends. Eur Polym J 49(6):1215–1233

Jain R, Tiwari A (2015) Biosynthesis of planet friendly bioplastics using renewable carbon source. J Environ Health Sci Eng 13:11

Kim HY, Park DJ, Kim JY, Lim ST (2013) Preparation of crystalline starch nanoparticles using cold acid hydrolysis and ultrasonication. Carbohydr Polym 98:295–301

Kong X, Kasapis S, Zhu P, Sui Z, Bao J, Corke H (2016) Physicochemical and structural characteristics of starches from Chinese hull-less barley cultivars. Int J Food Sci Tech 51:509–518

Kumari S, Yadav BS, Yadav RB (2021) Acid hydrolysis-induced nanoconversion of sweet potato (Ipomoea Batatas) starch: effect on morphological rheological and thermal properties. Starch/Stärke 73(3–4):e2000173

Kumari S, Yadav BS, Yadav RB (2022) Effect of nano-conversion on morphological, rheological and thermal properties of barley starch. J Food Sci Tecnol 59(2):467–477

Li X, Qiu C, Ji N, Sun C, Xiong L, Sun Q (2015) Mechanical barrier and morphological properties of starch nanocrystals-reinforced pea starch films. Carbohydr Polym 121:155–162

Lin Q, Ji N, Li M, Dai L, Xu X, Xiong L, Sun Q (2020) Food Hydrocoll fabrication of debranched starch nanoparticles via reverse emulsification for improvement of functional properties of corn starch films. Food Hydrocoll 104:105760

Liu C, Jiang S, Zhang S, Xi T, Sun Q, Xiong L (2016) Characterization of edible corn starch nanocomposite films: the effect of self-assembled starch nanoparticles. Starch/stärke 68:239–248

Madhumitha G, Fowsiya J, Roopan SM, Thakur VK (2018) Recent advances in starch–clay nanocomposites. Int J Polym Anal Charact 5:1–15

Müller CM, Laurindo JB, Yamashita F (2011) Effect of nanoclay incorporation method on mechanical and water vapor barrier properties of starch-based films. Ind Crops Prod 33(3):605–610

Muscat D, Adhikari B, Adhikari R, Chaudhary DS (2012) Comparative study of film forming behaviour of low and high amylose starches using glycerol and xylitol as plasticizers. J Food Eng 109(2):189–201

Nafchi AM, Karim AA, Mahmud S, Robal M (2012) Antimicrobial rheological and physicochemical properties of sago starch films filled with nanorod-rich zinc oxide. J Food Eng 113(4):511–519

Piyada K, Waranyou S, Thawien W (2013) Mechanical thermal and structural properties of rice starch films reinforced with rice starch nanocrystals. Int Food Res J 20:439–449

Saman WR, Yuliasih I, Sugiarto Mr (2019) Physicochemical characteristics and functional properties of white sweet potato starch. Int J Eng Manag Res 9(3):53–57

Selene AS, Heidi M, Palma R, Adriana IRH (2013) Characterization of films made with chayote tuber and potato starches blending with cellulose nanoparticles. Carbohydr Polym 98:102–107

Shi AM, Wang LJ, Dong L, Adhikari B (2013) Characterization of starch films containing SNP’s part 1: physical and mechanical properties. Carbohydr Polym 96(2):593–601

Siakeng R, Jawaid M, Arin H, Sapuan S, Asim M, Saba N (2019) Natural fiber reinforced polylactic acid composites: a review. Polym Compos 40:446–463

Da Silva FF, Lima RL, Fialho EC, Albuquerque JI, Velasco FM (2018) Fakhouri in applications of modified starches. In: Huicochea EF, Rendon R (eds), Chapter 4 IntecOpen, London

Stanca AM, Gianinetti A, Rizza F, Terzi V (2016) Barley: an overview of a versatile cereal grain with many food and feed uses. Encyclopedia of food grains, pp 147–152

Voon HC, Bhat R, Easa AM, Liong MT, Karim AA (2012) Effect of addition of halloysite nanoclay and SiO2 nanoparticles on barrier and mechanical properties of bovine gelatin films. Food Bioproc Tech 5(5):1766–1774

Zheng H, Ai F, Chang PR, Huang J, Dufresne A (2009) Structure and properties of starch nanocrystals reinforced soy protein plastics. Polym Compos 30:474–480

Acknowledgements

The authors are thankful to the CIPET, Murthal, Haryana; CIPET, Jaipur, Rajasthan; and CIPET, Bengaluru, Karnataka for providing the tensile strength, TGA and WVTR, respectively facilities required for the research study.

Funding

This research work was supported by the Rajiv Gandhi National Fellowship (F1-17.1/201516RGNF-2015–17-SC-HAR-3446/(SA-III/Website) under the aegis of University grant Commission, New Delhi.

Author information

Authors and Affiliations

Contributions

SK contributed to experimental work and writing original draft of paper, BSY contributed to the experimental design, interpretation of results and finalization of the manuscript. RBY contributed to the final editing and revision of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The author declares no conflict of interest.

Ethical approval

Not Applicable.

Consent to participate

Not Applicable.

Consent for publication

Not Applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumari, S., Yadav, B.S. & Yadav, R. Morphological and thermo-mechanical characterization of sweet potato starch based nanocomposites reinforced with barley starch nanoparticles. J Food Sci Technol 59, 4924–4934 (2022). https://doi.org/10.1007/s13197-022-05581-3

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-022-05581-3