Abstract

The octenyl succinyl anhydride (OSA) esterified pearl millet (Pennisetum typhoides) starch was evaluated as fat replacer in soft serve ice cream in comparison to other fat replacers viz. inulin, whey protein concentrate-70 and commercial starch. During temperature sweep test, the yield stress and flow behaviour index of un-pasteurized ice cream mixes increased as the temperature increased from 40 to 80 °C, while the consistency index decreased. Consistency index of aged ice cream mixes containing 2% fat replacer was higher as compared to mixes with 1% level. The aged ice cream mixes exhibited non-Newtonian behaviour as flow behaviour index values were less than one. Apparent viscosity (at 50 s−1 shear rate) of control as well as ice cream mix containing 1% OSA-esterified pearl millet starch samples was 417 and 415 mPas, respectively and did not differ significantly. The overrun of the ice cream (with 5 and 7.5% fat) containing 1 and 2% of above fat replacers ranged between 29.7 and 34.3% and was significantly lower than control (40.3%). The percent melted ice cream was also low for the ice creams containing 2% of above fat replacers at 5% fat content as compared to control. However, sensory acceptability and rheological characteristics of reduced fat ice creams containing 1.0 and 2.0% OSA-esterified pearl millet starch were at par with other fat replacers under the study. Thus, OSA-esterified pearl millet starch has potential to be used as fat replacer in reduced fat ice cream.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Low-fat foods are becoming an ideal option for consumers concerned about health-related issues or in maintaining sound physical health status. Furthermore, consumers look for healthy foods with satisfactory sensory characteristics and always look for traits normally associated with conventional products (Verbeke 2006). Removal of fat from dairy products is a major challenge as it modifies composition and structure as well as the expected interactions among components, giving rise to, in most cases, noticeable changes in colour, flavour and texture (Guinard et al. 1997; Gonzalez-Tomas et al. 2007). Hence, ingredients used as fat replacers in such products should be able to ideally imitate the texture, mouthfeel, and functional properties of fat and should convey the desired flavour profile.

Frozen desserts manufacturers have adopted the substitution of milk fat with approved fat replacers to create products that meet the demands of health-conscious consumers. A variety of low-fat and fat-free ice cream products have been developed by various researchers (Goyal and Srinivasan 1973; Specter and Setser 1994; Roland et al. 1999; Adapa et al. 2000; Prindiville et al. 2000; Aime et al. 2001). Adapa et al. (2000) reported the influence of protein and carbohydrate-based fat replacers on the linear visco-elasticity of ice cream. He found that fat replacers increased the viscous properties with little effect on the elastic properties. Goyal and Srinivasan (1973) showed that the viscosity of soft-serve mixes increased slightly when glycerol monostearate, corn syrup or dextrose was added. Ohmes et al. (1998) and Prindiville et al. (2000) studied the effect of protein based fat replacers on the sensory and physical characteristics of ice cream.

In this regard, starches with unique functionality, nutritional and other attributes have attracted the attention of food formulations. Modified starches, cellulose derivatives, pectin, inulin, xanthan gum or carrageenan are suitable for imparting the desirable functionality in low/reduced/no-fat formulations because of their excellent physicochemical properties (Warrand 2006). Modified starches encourage development of viscosity in the aqueous phase of ice cream (Jimenez-Flores et al. 1993) and inhibit ice crystal growth (Stanley et al. 1996), which in turn helps in improving the texture of reduced fat ice creams. Maltodextrin from potato and tapioca have been used as fat replacers in reduced fat ice cream by various researchers (Specter and Setser 1994; Roland et al. 1999). Modified pea starch has been used as a fat replacer in vanilla ice creams by Aime et al. (2001).

Octenyl succinic anhydride (OSA) esterified starch are one of the commonly used modified starches in the processed food products owing to the introduction of amphiphilic character in the starch, which can thus be suitably used as an effective emulsifier (Trubiano 1995). Moreover, OSA at a level of 3.0% (degree of substitution, DS < 0.02) is approved by legal regulations in the U.S. for food use (Ai et al. 2013). Further, OSA modified corn starch has been used as fat replacer in mayonnaise (Cho et al. 1999) and muffins (Chung et al. 2010).

Pearl millet (Pennisetum typhoides) being an underutilized food crop, low cost and easily available can be a cheap alternative source of starch and could be used as a substitute for corn starch (Abdalla et al. 2009). Limited studies have been carried out on pearl millet starch as compared to other cereal and tuber crops, although some efforts have been made in the recent past to modify pearl millet starch using heat moisture treatment and OSA esterification (Sharma et al. 2015a, b; Sharma et al. 2016). It is significant to mention that, in one of our (Sharma et al. 2016) previous study we found that esterification of pearl millet starch with OSA induces the balance of elastic and viscous proportions (an important property of fat replacer) in pearl millet starch–water gels as well as lowers the pasting temperature and improves the stability ratio. OSA-starch gels also exhibits homogeneous mixing and self leveling characteristics, thereby making it potential fat replacers. However, as per the literature available, so far, no studies have been reported on utilization of octenyl succinic anhydride (OSA) esterified pearl millet (Pennisetum typhoides) starch as a fat replacer in dairy or food products.

The present investigation was carried out to explore the potential of OSA esterified pearl millet starch as a fat replacer in the ice cream and compared with three commonly used fat replacers in ice cream i.e. inulin, whey protein concentrate-70 (WPC-70) and commercially available modified starch. The rheological properties of ice cream mix and changes in melting rate, overrun as well as sensory acceptability were studied.

Materials and methods

Materials

Cow milk, cream, whey protein concentrate-70 (WPC-70) containing 69.8% protein and sugar used for ice cream preparation were provided by experimental dairy, National Dairy Research Institute, Karnal. Commercial modified starch used in the study was supplied by National Starch Ltd., Mumbai. All the reagents used in the investigation were of analytical grade. 2-Octen-1-ylsuccinic anhydride (OSA) was purchased from Sigma–Aldrich Corporation (Bangalore, India).

Preparation of octenyl succinic anhydride (OSA) esterified pearl millet starch

Isolation of starch from pearl millet was carried out following the process described by Sharma et al. (2015a). The isolated starch contained 0.18 ± 0.014, 0.16 ± 0.012 and 0.14 ± 0.008 g/100 g protein, fat and ash, respectively (Sharma et al. 2015a, b). The method optimized by Sharma et al. (2016) was used for the preparation of octenyl succinic anhydride (OSA) esterified pearl millet starch with 3 h reaction time at 35 °C and pH 8.0. The starch slurry concentration was 35 g/100 mL. The pH was adjusted by adding 3 g/100 mL NaOH solution. Constant stirring of samples was done and pH was monitored during the reaction process. The constant amount of OSA i.e. 3 g/100 g (dry starch basis) was used in all the samples for esterification. The pH was brought down to 6.5 after the reaction time using HCl solution. The degree of substitution (DS) was 0.0208 as determined by the method described by Zhang et al. (2011).

Preparation of soft serve ice cream

The OSA-esterified pearl millet starch was used as fat replacer in ice cream mix containing 7.5 and 5% fat and compared with control (10% fat) and three commonly available fat replacers i.e. inulin, whey protein concentrate-70 (WPC-70) and commercially available modified starch. The amount of fat and level of fat replacers used in the 9 ice cream formulations prepared in this study using four types of fat replacers were: standard control ice cream with 10% fat content (Control); ice cream with 1% inulin and 7.5% fat content (Inulin-1); ice cream with 2% inulin and 5% fat content (Inulin-2); ice cream with 1% whey protein concentrate-70 and 7.5% fat content (WPC-1); ice cream with 2% whey protein concentrate-70 and 5% fat content (WPC-2); ice cream with 1% commercially modified starch and 7.5% fat content (CMS-1); ice cream with 2% commercially modified starch and 5% fat content (CMS-2); ice cream with 1% octenyl succinylated pearl millet starch and 7.5% fat content (OS-PMS-1); ice cream with 2% octenyl succinylated pearl millet starch and 5% fat content (OS-PMS-2).

First of all, the different ingredients required for making soft serve ice cream were calculated. Weighed quantity of cream and cow milk was taken in a steel container and heated to 40–45 °C, skimmed milk powder and sugar were added to it to adjust the SNF content in the mix. Stabilizer and emulsifier mixture was mixed with a portion of weighed sugar and added to above mix. The selected fat replacers i.e. inulin, WPC-70, OSA-pearl millet starch, commercial modified starch were added to the mix upon heating to 40 °C and the mix was blended using a hand blender for 15 s. The mix was filtered through double layered muslin cloth to remove impurities and then heated from 40 to 82 °C, where the mix was hold for 30 s in order to pasteurize. The mix was cooled in water bath containing chilled water and the temperature was brought to 15–20 °C. The cooled mix was kept in refrigerator overnight for ageing at 4 °C. Later, flavour was added to the aged mix and it was frozen into a batch freezer. Five kg mix was prepared for each batch. The initial temperature of the mix was maintained at 4 °C and the final drawing temperature of ice cream was −4 to −5 °C.

Analytical methods for milk and cream

Fat in milk and cream was determined by Gerber method as described in IS: 1479, Part I (1960). The SNF was calculated using lactometer reading. The solid not fat (SNF) was calculated using following equation:

where CLR = corrected lactometer reading; F = fat percentage in mix.

Rheological measurements for ice cream mix

The rheological measurements were performed on dynamic rheometer (Physica MCR 101, Anton Paar, GmbH, Ostifildern, Germany), using cone and plate configuration (PP50) of 50 mm diameter. The samples were loaded on rheometer base plate and allowed to rest for 10 min to prevent the influence of structural modification during sample handling and loading. The flow curves of the ice cream mix were determined at 40, 50, 60, 70 and 80 °C for the samples collected before pasteurization and at 4 °C for samples taken after ageing of the mix at variable shear rate ranging from 0 to 300 s−1. The rheological data were fitted to rheological models i.e. Power law, Herschel-Bulkley and Casson models.

Analysis of ice cream

Percent overrun

The overrun of ice cream samples was determined using the formula of Marshall and Arbuckle (1996). The formula for calculating the percentage overrun was:

where W1 = weight of ice cream mix per unit volume; W2 = weight of soft serve ice cream per unit volume.

Melting resistance

The melting resistance of ice cream samples was determined by the Innocente et al. (2002) method with some modifications Verma (2005). The ice cream of known weight was placed on a wire mesh which was placed on a pre-weighed glass funnel and conical flask. The whole assembly was placed in an incubator at 20 °C for 45 min. The weight of the melted ice cream was expressed as percentage weight melted.

Sensory evaluation

The sensory evaluation of ice cream samples was performed using 9 point Hedonic scale by a panel of nine semi-trained judges. The ice cream cups were served immediately after withdrawing the cups from freezer chest after 24 h of storage and promptly offered to the panelists. The samples were coded with three digit random numbers in odourless HIPS (high impact polystyrene) cups with all the orders of servings completely randomized.

Statistical analysis

The data were analyzed using analysis of variance for three replicates with the help of SAS version 9.2. Differences between the sample means were analyzed by Duncan’s multiple range test (DMRT) and least square difference (LSD) at α level of 0.05.

Results and discussion

Rheological properties

The flow behaviour of the mix is an important parameter as the mix undergoes temperature dependent changes during pasteurization and it has to pass/flow through process equipments/pipes in continuous systems. Hence, it becomes vital to examine its behaviour during these changes through rheological studies. The flow behaviour data obtained for the un-pasteurized ice cream mixes containing 7.5 or 5% fat and 1 or 2% fat replacers were fitted into Herschel Bulkley model. The rheological parameters are summarized in Tables 1 and 2. The yield stress and flow behaviour index of the mix increased with increase in temperature from 40 to 80 °C, while consistency index increased up to 50 °C and thereafter decreased. In general fat replacers have high water binding capacity and hence contribute to increased viscosity. The increase in consistency index up to 50 °C might be due to initial absorption of water by starch or protein based fat replacers leading increase in viscosity. The consistency index of all the ice cream mix decreased after 50 °C, which might be due to disruption of swollen molecules with higher shear rate. The ice cream mix containing OSA esterified pearl millet starch also exhibited similar kind of behaviour as observed for other fat replacers. The OSA esterified starch had hydrophobic groups attached to starch chains, which act as hydrogen bonding disrupters and thus facilitates the entry of water in starch chains thereby resulting in more viscous solutions. Sharma et al. (2016) also reported increase in flow behaviour index and yield stress of OSA esterified starch gels when temperature was increased from 5 to 85 °C. The consistency index values were lower for ice cream mix containing OSA esterified pearl millet starch (DS: 0.0208) and commercial starch in comparison to other mixes. The flow behaviour index values are more than unity at higher temperatures due to the swelling of molecules of added fat replacers leading to Non-Newtonian behaviour, while the mix behaved like a pseudoplastic material at lower temperatures. These factors must be considered while designing the processing equipment. Tavakolipour et al. (2014) also reported that the flow behaviour of gelatin and modified starch incorporated frozen dessert exhibited pseudoplastic behaviour and can be predicted by Herschel Bulkley model.

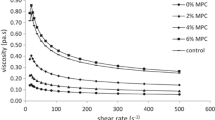

The aged ice cream mixes were also evaluated for flow behaviour characteristics. Out of the three models fitted, Herschel Bulkley had highest R2 values (Table 3). The consistency index was higher for the ice cream mix having 2% fat replacer as compared to those having 1% level. Among all the mixes, the consistency index values as observed for Herschel-Bulkley model were highest for OSA pearl millet starch containing mixes (Table 3). Consistency index is an important parameter for estimating the viscous nature of the products. Higher consistency index of the aged ice cream mix containing OSA-starch was due to the fact that it contains a hydrophobic group which alters the ordered structure and disrupt the hydrogen bond of the starch chains allowing more water penetration between the starch granules at lower temperature and resulting in a more viscous paste than that of their native counterparts. The flow behaviour index values were less than one confirming the non-Newtonian and pseudoplastic behaviour of aged ice cream mix. An increase in shear stress was observed in all the ice cream mixes with respect to increase in shear rate.

All the ice cream mixes exhibited shear thinning behaviour as the viscosity values deceased with increase in shear rate. Originally, the molecules are arranged in random manner, which leads to higher viscosity even at lower shear rates. However, as shear rate increases, the molecules get aligned in more systematic way (uni-directional) as a result intermolecular friction and viscosity decreases. The apparent viscosity of control ice cream mix having 10% fat was 417 mPas at shear rate of 50 s−1, which was very close (415 mPas) to the ice cream mix having 7.5% fat containing 1% OSA-esterified pearl millet starch. Further, the apparent viscosity values for the ice cream mix containing 5% fat and WPC, pearl millet starch and commercial starch at a level of 2% had higher viscosity than the control ice cream mix. Soukoulis et al. (2009) also demonstrated that the addition of dietary fibres in ice cream mix formulations significantly increases viscosity, consistency index and shear thinning behaviour owing to water retention and molecular restriction caused by the presence of extended network of cellulosic material. Further, OSA pearl millet starch containing ice cream mix exhibited highest apparent viscosity and yield stress value as compared to other mixes except the ice cream mix containing 2% commercial starch (Table 3). This is due to the fact that introduction of bulky OSA group into the pearl millet starch matrix weakens the intermolecular hydrogen bonds and thus leads to higher swelling power and secondly, the cool paste viscosity increases upon substation with OSA in pearl millet starch (Sharma et al. 2016) which might be responsible for the enhancement of viscosity of the aged ice cream mix. Sharma et al. (2016) also observed higher strain value for causing structural deformation in OSA-esterified pearl millet starch gels showing greater structural strength. The yield stress of reduced fat ice cream mixes was higher than the control. The apparent viscosity and consistency index were higher in ice cream mixes containing WPC as compared to inulin. Akalin et al. (2008) also observed similar results in reduced-fat and low-fat ice cream containing whey protein isolate and inulin.

Overrun

Overrun in ice cream is mainly the functionality of milk proteins, emulsifiers and to certain extent milk fat. The emulsion formed during mixing is aerated to induce air bubbles in mix in absence of adequate fat emulsion formation might have adversely affected. The overrun of the control was 40.3%, while it was less for other reduced fat ice creams. The overrun of reduced fat ice creams containing 5% fat ranged from 29.7 to 32.2%, while for ice creams with 7.5% fat, it varied from 32.9 to 34.3%. Lowest value was observed for ice cream mix containing 5% fat and 2% WPC. Among the reduced fat ice creams, highest overrun was observed for ice cream with 7.5% fat and 1% inulin. Lower overrun was correlated with increased viscosity. Mahdian and Karazhian (2013) also observed lower overrun for ice cream containing inulin and milk protein concentrate.

Melting resistance

Melting characteristic is an important property of ice cream as it is instrumental in predicting the organization of frozen structure. According to Silva et al. (2010), the melting of ice and collapse of the stabilized foamy structure takes place during the melting of ice cream, where the exterior ice melts first and diffuses into the viscous unfrozen serum phase. The melted ice later flows downwards through the structural constituents of ice cream viz. destabilized fat globules, air cells and ice crystals. However, according to Muse and Hartel (2004), the melting rate of ice cream is dependent on fat destabilization which in turn is related to the viscosity of ice cream mix and its ingredients. The percent ice cream melted varied from 80.76 to 86.56% for all the ice creams. The percent melted ice cream was lesser for ice creams containing 2% fat replacer and 5% fat. This could be due to better structural strength and gel network formed in the ice creams due to higher amount of fat replacers. Further, the values for per cent ice melted were quite similar for ice cream containing 1% OSA- pearl millet starch and control ice cream (10% fat), indicating that even with lesser fat content in the ice cream, it is able to simulate the melting behaviour similar to control. This is again contributed by the higher structural strength of OSA-esterified starch gels. The lowest values were observed for ice creams containing commercially modified starch followed by inulin containing samples. This may be due to the higher water binding capacity of the starch. According to Mahdian and Karazhian (2013) the melting resistance was higher for the ice cream containing inulin than milk protein concentrate.

Sensory acceptability

The scores obtained for sensory evaluation of reduced fat ice creams are mentioned in Table 4. All the samples were accepted by the sensory panelists, however maximum acceptance was observed for control (7.9) soft serve ice cream containing 10% fat. It is clear from the sensory scores that reduction of fat along with addition of fat replacer doesn’t affect the sensory quality of the ice cream adversely. Further, OSA-esterified pearl millet starch is quite comparable to other fat replacers i.e. WPC-70, inulin and commercial starch. Thus, OSA-esterified pearl millet starch could be suitably used as fat replacer owing to its characteristics of homogenous mixing and self leveling phenomenon.

Conclusion

Soft serve ice cream mix (7.5 and 5% fat) containing 1.0 and 2.0% OSA esterified pearl millet starch resulted in a product which was at par with other fat replacers i.e. inulin, WPC-70 and commercial starch with respect to sensory acceptability, overrun and melting characteristics. The hydrophobic bulky group in OSA- esterified pearl millet starch gels contributes to the fat like behaviour of its starch–water gels. The higher viscosity and structural strength of OSA-starch–water gels makes it suitable to be used as fat replacers in ice cream mix. Further, it offers additional health benefit due to its resistant starch content. Thus, along with processing functionality as a fat replacer, addition of OSA esterified pearl millet starch would enhance the nutritional and physiological aspects of the developed products.

References

Abdalla AA, Ahmed UM, Ahmed AR, El Tinay AH, Ibrahim KA (2009) Physicochemical characterization of traditionally extracted pearl millet starch (Jir). J Appl Sci Res 5:2016–2027

Adapa S, Dingeldein H, Schmidt KA, Herald TJ (2000) Rheological properties of ice cream mixes and frozen ice creams containing fat and fat replacers. J Dairy Sci 83(10):2224–2229

Ai Y, Nelson B, Birt DF, Jane J-L (2013) In vitro and in vivo digestion of octenyl succinic starch. Carbohyd Polym 98(2):1266–1271

Aime DB, Arntfield SD, Malcolmson LJ, Ryland D (2001) Textural analysis of a reduced vanilla ice cream products. Food Res Int 34:237–246

Akalin AS, Karagozlu C, Unal G (2008) Rheological properties of reduced-fat and low-fat ice cream containing whey protein isolate and inulin. Eur Food Res Technol 227:889–895

Cho SJ, Lim HS, Park HJ, Hwang HJ, Lim ST (1999) Physical properties of octenyl succinylated corn amylodextrins as fat replacers in mayonnaise. Food Sci Biotechnol 8:322–328

Chung HJ, Lee SE, Han JA, Lim ST (2010) Physical properties of dry-heated octenyl succinylated waxy corn starches and its application in fat-reduced muffin. J Cereal Sci 52:496–501

Gonzalez-Tomas L, Bayarri S, Taylor AJ, Costell E (2007) Flavour release and perception from model dairy custards. Food Res Int 40:520–528

Goyal GK, Srinivasan MR (1973) The quality of soft-serve ice cream as influenced by the levels of fat, emulsifier, sucrose substitutes, and processing conditions. J Food Sci Technol 10:122–124

Guinard JX, Zoumas-Morse C, Mori B, Uatoni B, Panyam D, Kilara A (1997) Sugar and fat effects on sensory properties of ice cream. J Food Sci 62:1087–1094

Innocente N, Comparin D, Corradini C (2002) Proteose-peptone whey fraction as emulsifier in ice-cream preparation. Int Dairy J 12(1):69–74

IS: 1479, Part I (1960) Methods of test for dairy industry: rapid examination of milk. Indian Standards Institution, New Delhi

Jimenez-Flores R, Klipfel NJ, Tobias J (1993) Ice cream and frozen desserts. In: Hui YH (ed) Dairy science and technology handbook, vol 2: product manufacturing. VCH Publishers, New York, pp 15–57

Mahdian E, Karazhian R (2013) Effects of fat replacers and stabilizers on rheological, physicochemical and sensory properties of reduced-fat ice cream. J Agric Sci Technol 15(6):1163–1174

Marshall RT, Arbuckle WS (1996) Ice cream, 5th edn. Chapman & Hall, New York

Muse MR, Hartel RW (2004) Ice cream structural elements that affect melting rate and hardness. J Dairy Sci 87:1–10

Ohmes RL, Marshall RT, Heymann H (1998) Sensory and physical properties of ice creams containing milk fat or fat replacers. J Dairy Sci 81:1222–1228

Prindiville EA, Marshall RT, Heymann H (2000) Effect of milk fat, cocoa butter, and whey protein fat replacers on the sensory properties of low fat and nonfat chocolate ice cream. J Dairy Sci 83:2216–2223

Roland AM, Phillips LG, Boor KJ (1999) Effects of fat replacers on the sensory properties, color, melting, and hardness of ice cream. J Dairy Sci 82:2094–2100

Sharma M, Yadav DN, Singh AK, Tomar SK (2015a) Rheological and functional properties of heat moisture treated pearl millet starch. J Food Sci Technol 52(10):6502–6510

Sharma M, Yadav DN, Singh AK, Tomar SK (2015b) Effect of heat moisture treatment on resistant starch content as well as heat and shear stability of pearl millet starch. Agric Res 4(4):411–419

Sharma M, Singh AK, Yadav DN, Arora S, Vishwakarma RK (2016) Impact of octenyl succinylation on rheological, pasting, thermal and physicochemical properties of pearl millet starch. LWT Food Sci Technol 73:52–59

Silva ED, Silva ERTD, Muramatsu M, Lannes SCDS (2010) Transient process in ice creams evaluated by laser speckles. Food Res Int 43(5):1470–1475

Soukoulis C, Lebesi D, Tzia C (2009) Enrichment of ice cream with dietary fibre: effects on rheological properties, ice crystallisation and glass transition phenomena. Food Chem 115:665–671

Specter SE, Setser CS (1994) Sensory and physical properties of a reduced calorie frozen dessert system made with milk fat and sucrose substitutes. J Dairy Sci 77:708–717

Stanley DW, Goff HD, Smith AK (1996) Texture-structure relationships in foamed dairy emulsions. Food Res Int 29:1–13

Tavakolipour H, Vahid-moghadam F, Jamdar F (2014) Textural and sensory properties of low fat concentrated flavored yogurt by using modified waxy corn starch and gelatine as a fat replacer. Int J Biosci 5(6):61–67

Trubiano PC (1995) The role of specialty food starches in flavor encapsulation. ACS Symp Ser 610:244–253

Verbeke W (2006) Functional foods: Consumer willingness to compromise on taste for health? Food Qual Pref 17:126–131

Verma (2005) Technological studies on the manufacture of frozen desserts using artificial sweeteners. Ph.D. Thesis, National Dairy Research Institute, Karnal

Warrand J (2006) Healthy polysaccharides. The next chapter in food products. Food Technol Biotechnol 44:355–370

Zhang B, Huang Q, Luo FX, Fu X, Jiang H, Jl Jane (2011) Effects of octenylsuccinylation on the structure and properties of high-amylose maize starch. Carbohyd Polym 84:1276–1281

Acknowledgement

The authors would like to gratefully acknowledge Director, ICAR-NDRI, Karnal, India for extending Ice cream freezer facilities. The authors also thank Director, ICAR-CIPHET for providing financial assistance for conducting the study.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sharma, M., Singh, A.K. & Yadav, D.N. Rheological properties of reduced fat ice cream mix containing octenyl succinylated pearl millet starch. J Food Sci Technol 54, 1638–1645 (2017). https://doi.org/10.1007/s13197-017-2595-7

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-017-2595-7