Abstract

Pearl millet (Pennisetum typhoides) starch was subjected to heat moisture treatment (HMT) at different moisture levels i.e., 20 % (HMT-20), 25 % (HMT-25) & 30 % (HMT-30) for 8 h at 110 °C and evaluated for changes in rheological, thermal, functional and morphological properties. Peak, breakdown, cool paste and setback viscosity decreased, while pasting temperature increased after HMT. Shear stability of HMT-30 sample was maximum (stability ratio 0.54). Highest (33.5 Pa) G′ value was observed for native and lowest (14.8 Pa) for HMT-25 sample. Yield and flow point of starch gels also decreased after HMT, indicating softer gels and higher spreadability. HMT increased gelatinization temperature from 62.59 °C for native to 84.05 °C for HMT-30. Resistant starch content increased about three times in HMT-30 sample (7.07 %) as compared to native. Swelling power and solubility decreased after HMT. HMT also induced cavity and some dents on starch granules surface.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The requirement of starch properties depends on the desired final product quality. Starch granules are composed of alternating amorphous and semi–crystalline rings. Native starches are limited in their food applications, due to cohesive texture, heat and shear sensitivity, lack of clarity, opacity, low viscosity and retrogradation or precipitation upon storage (Junistia et al. 2008). These limitations can be addressed through starch modification, by application of various physical, chemical, enzymatic and combined methods. The modified starch derivatives offer significant value addition, enhances starch versatility and provide scope to develop a variety of fabricated food products e.g., low dextrose equivalent starch hydrolysates having good water binding properties, resistant starch rich foods etc. Heat moisture treatment is an environmental friendly physical method of improving poor functional properties of native starch and particularly favourable for food applications (Maache-Rezzoug et al. 2008). Heat-moisture treatment of starch also leads to modification of its rheological properties. Rheological characterization of food becomes increasingly important for evaluating the quality of both raw materials and end products and predicting its behavior during processing. Chakraborty et al. (2014) studied rheological properties of millet based dough under thermo-mechanical stress and successfully optimized the level of ingredients for wheat flour-millet based bread. Rheological/pasting behaviour of starch is governed by amylose content and degree of amylose leaching (Ziegler et al. 1993), granule size distribution, volume fraction, shape, rigidity and extent of granule swelling (Lineback and Rasper 1988), inter-granular interactions and continuous phase viscosity. Stute (1992) observed higher peak viscosity and onset temperature for HMT (20 % moisture, 110 °C/ 120 °C) samples. Hoover and Vasanthan (1994) also observed significant effect of HMT on the flow properties of gelatinized starch suspensions (6 %). Most studies on heat-moisture treatment have involved starches from different sources, such as rice, potato, cassava, wheat, maize, canna and sorghum. However, relatively little work (Balasubramanian et al. 2014) has been done on pearl millet (Pennisetum typhoides) starch. Pearl millet contains starch in the range of 59 to 80 % and can be a cheap alternative source. Abdalla et al. (2009) also reported that, pearl millet starch may be used as a substitute for corn starch. Although, pearl millet is perceived as a crop with poor economic value, while, exploitation of its starch for various food applications can significantly improve its economic importance. Therefore, the present study is planned to investigate the changes in rheological and functional properties of pearl millet starch following heat-moisture treatment.

Materials and methods

Materials

Pearl millet (Pennisetum typhoides) grains (var. HC-10), grown in the year of 2013 were procured from Haryana Agricultural University, Hisar, India. The grains were cleaned using cleaner cum grader (Indosow, Ambala, India) and stored in air tight plastic containers at 10 ± 2 °C till further use. The moisture content of the grains was 9.1 ± 0.12 %. The average size and thousand grain weight was 2.45 ± 0.05 mm and 11.20 ± 0.45 g. The protein, fat, ash and starch content of the grains were 13.7 ± 0.24, 5.5 ± 0.15, 1.8 ± 0.08, and 59.4 ± 0.36 % (db), respectively.

Starch isolation

Isolation of starch from pearl millet was carried out following the process described by Balasubramanian et al. (2014) with slight modification. Pearl millet flour (0.251 mm particle size) was steeped in 0.3 % NaOH in the ratio of 1:6 (w/v) and incubated in water bath at 45 ± 2 °C for 90 min with continuous stirring, followed by centrifugation at 4000 rpm for 15 min. The supernatant was discarded and brownish yellow layer containing protein over the whitish portion of starch was removed with spatula. Whitish sediment obtained was suspended in distilled water and above process was repeated until completely white sediment was obtained. The pH of starch dispersions was adjusted to 6.5 to 7.0 using 0.1 N HCl, dried at 50 °C in hot air oven and kept in airtight containers at ambient conditions (15–35 °C) for further study. The isolated starch contained 0.18 ± 0.014, 0.16 ± 0.012 and 0.14 ± 0.008 %, protein, fat and ash, respectively.

Heat moisture treatment

The method of Sun et al. (2014) was employed for the heat moisture treatment with slight modification. Starch samples were weighed into different glass containers: the starch moisture content was equilibrated to 20, 25 and 30 %. The sealed samples (in glass jars) were heated in a hot air oven at 110 ± 2 °C for 8 h followed by drying at 40 ± 5 °C to uniform moisture level (~10 %).

Chemical composition

The moisture (method 44–19), protein (method 46–12), fat (method 30–25) and ash (method 8–01) contents of samples were determined using AACC (2000) standard methods. Starch content was determined using the method described by Osborne and Voogt (1978). Dextrose equivalent was determined using the method of Uthumporn et al. (2010). Resistant starch content was determined using the resistant starch assay kit (Megazyme International, Wicklow, Ireland) following the approved AACC method 32–40 (AACC 2009). All chemicals used in the investigation were of AR grade and procured from SD fine-chemicals limited, Mumbai, India.

Pasting properties

Pasting properties were determined using rapid viscosity analyser (Model 3D, Newport Scientific Pvt. Ltd, Warriewood, NSW, Australia) equipped with thermocline software version 3.0 (AACC 2000). The pasting profile of each sample (2.5 g, db) with distilled water was determined at final weight of 25 ± 0.01 g. RVA plot of viscosity (cP) versus time (s) and temperature (°C) was used to determine peak viscosity (PV), hot paste viscosity (HPV), cool paste viscosity (CPV), breakdown (BD = PV-HPV), setback (SB = CPV-HPV), stability ratio (HPV/PV), set back ratio (CPV/HPV) and pasting temperature.

Dynamic rheological measurement

The rheological measurements were performed on dynamic rheometer (Physica MCR 101, Anton Paar, GmbH, Ostifildern, Germany), using parallel plate configuration (PP50) of 50 mm diameter at 20 °C keeping 0.5 mm gap between the plates. Five percent (w/v) starch dispersions were stirred at 200 rpm for 30 min at 20 °C, heated in an oil bath to 95 °C for 10 min and then hold at 95 °C for another 30 min followed by cooling at 20 °C for 2 h. For dynamic visco-elastic determinations, two steps of rheological measurements were performed: (1) amplitude sweep at constant frequency (10 rad/s) to determine the maximum deformation (% strain) attainable by a sample in the linear visco-elastic range (LVE range), yield point, flow point and (2) frequency sweep at constant deformation within the linear visco-elastic range. The mechanical spectra were obtained recording storage shear modulus (G′) and the loss shear modulus (G″), and damping factor/loss tangent (tan δ = G″/G′) as a function of strain (0.01 to 100 %) for amplitude sweep test and frequency in the range of 0.1–100 s−1 for frequency sweep.

Thermal properties

Differential scanning calorimetry (DSC) studies were performed using a DSC (DSC-6000, PerkinElmer Instruments LCC., USA) equipped with a digital DEC-425 thermal analysis data station (Pyris software). The instrument was calibrated using indium and purified de-ionized distilled water as standards. Starch sample (2.0 mg, db) was weighed directly into aluminium pans, followed by addition of 8 μl of purified de-ionized distilled water. A sealed aluminium pan containing 8 μl of purified de-ionized distilled water was used as reference. Samples were held at −20 °C for one min followed by heating from −20 to 200 °C at the rate of 10 °C/min. Gelatinization onset (To), peak (Tp), conclusion (Tc) temperatures and gelatinization enthalpy (ΔH) were computed from thermogram. The gelatinization temperature range (R) and peak height index (PHI) were calculated as (Tc–To) and ΔH/(Tp–To) respectively, as described by Krueger et al. (1987).

Swelling power and solubility

Swelling power and solubility were determined as per the method described by Qing-Bo et al. (2005). Each sample (3.0 g) was dispersed in 30 ml of distilled water and stirred gently. The dispersion was allowed to stand for 30 min in a water bath at 30 ± 2 °C. Subsequently, the dispersion was centrifuged at 3000 rpm for 15 min. The supernatants were decanted into an evaporating dish of known weight, dried at 110 °C and weighed. The swelling power and solubility were calculated using following equations:

Oil absorption capacity

Oil absorption capacity (OAC) was determined according to AACC (2000). Starch sample (0.5 g) was weighed in a tube and oil was added until it was completely wet. The tubes were then centrifuged at 6400 rpm for 10 min, the supernatant discarded and swollen sample weighed. The OAC was calculated as:

where; Ssw: swollen sample weight, Sw: sample weight

Morphology

The observations were made using Zeiss EVO 18 Special edition Electron Microscope at 3000× magnification at a working distance of 8 mm with an accelerating potential of 15 kV. The images of selected area were recorded with the help of Smart SEM software.

Statistical analysis

The data were analyzed using analysis of variance technique as per Snedecor and Cochran (1994) with the help of statistica software version-7 (State Soft Corporation, Tulsa, OK, USA).

Results and discussion

Pasting behaviour

Pasting properties of heat moisture treated (HMTd) and native pearl millet starch are presented in Table 1. Pasting temperature increased with increase in moisture content during HMT. The pasting temperature of native starch was 77.3 °C and it increased by 5.3 and 6.5 °C for HMT-25 and HMT-30, respectively. The increase in pasting temperature may be attributed to rearrangement of amorphous region into more compact crystalline region as well as formation of cross-linkages. Therefore, more heat is required for structural disintegration and paste formation. Olayinka et al. (2008) also observed increased pasting temperature of white sorghum starch after HMT. Other pasting parameters i.e., PV, BD, CPV and SB decreased significantly (p < 0.05) as the moisture level of the samples increased after HMT. The PV of HMT-30 sample was 1699.5 cP, which was 1126.2 cP lower as compared to native starch (2825.7 cP). The reduction in PV might be attributed to strengthening of cross linkages among starch chains, which might have not allowed amylose molecules to be leached out in the aqueous medium. The BD and SB of HMTd samples also decreased significantly (p < 0.05). The BD of HMT-25 (454.2 cP) and HMT-30 (329.3 cP) decreased by 858.5 and 983.4 cP, respectively when compared to native starch (1312.7 cP). The reduction in BD indicated a higher stability of these samples during continuous heating and shearing (Yadav et al. 2012). Starches with lower BD are more suitable for use in different heat processed food products based upon the requirement.

Setback (SB), measure of recrystallization/retrogradation of gelatinized starch during cooling, also decreased significantly (p < 0.05) for HMTd samples. However, the differences in setback values among HMTd samples were not significant. Amylose molecules re-associate more easily due to their linear structure, and are primarily responsible for the occurrence of retrogradation. Since, pearl millet contains lower level of amylose, hence it is believed that there may not be much differences in the amount of leached amylose after HMT. Starches with lower setback value may have potential applications in canned and frozen food products, for their respective advantages. Cool paste viscosity (CPV) or final viscosity indicates the ability of the starch to form a viscous paste. It also significantly (p < 0.05) decreased after HMT, however moisture did not show significant effect.

Stability ratio explains the resistance of a starch paste to viscosity breakdown as shear is applied. The starch paste of HMT-30 was most stable to shear (stability ratio 0.81), whereas, native starch paste was least stable (stability ratio 0.54). The moisture content had significant (p < 0.05) effect on stability ratio and it increased as the moisture content increased. Starch with higher stability ratio has potential applications in heat processed food products i.e., gravies, soups etc. Setback ratio (SBR), an indicator of starch retrogradation was highest (2.61) for native starch and decreased significantly (p < 0.05) after HMT. The reduction in SBR might be attributed to reduced amylose leaching as well as amylose-amylose and amylopectin- amylopectin chain interactions formed during HMT. Changes in pasting viscosities are attributed to the association amongst the chains in the amorphous region of the granules and the changes in crystallinity during hydrothermal treatment (Watcharatewinkul et al. 2009).

Dynamic rheological properties

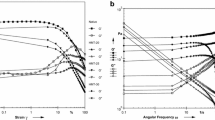

Changes in G′ (storage modulus) and G″ (loss modulus) as a function of variable strain and stress for native and HMT pearl millet starches are represented in Figs. 1 and 2, respectively. The corresponding values of G′, G″, loss factor, linear visco-elastic (LVE) range, yield and flow point are presented in Table 2. Within the LVE range, starch gels having G′ > G″, indicated gel character (solid behaviour). Moisture content of the samples during HMT significantly (p < 0.05) affected the structural strength (G′) of the gels. The highest G′ (33.5 Pa) was observed for native starch followed by HMT-20 (30.6 Pa), HMT-30 (27.1 Pa) and HMT-25 (14.8 Pa). The lower G′ values may be due to deformability of starch granules or lower elasticity of the continuous phase. The loss factor (G″/G′) of native, HMT-20 and HMT-25 did not differ significantly. Maximum (0.17) loss factor was observed for HMT-30 sample. The G′ and G″ curves for native and HMT-20 samples fall sharply after LVE range and hence, had low spreadability. The sharp decline of G′ curve indicates that these two samples had brittle behaviour thus, exhibited poor proportioning or mixing. The G″ curve of native and HMT-20 samples showed a sharp rise before decline, indicating micro-cracks before breaking. However, increase in G″ curve before decline for HMT-25 and HMT-30 samples were hardly noticeable. The HMT-25 and HMT-30 samples had lower G′ values, hence the gels of these two samples were softer and had higher self leveling phenomenon as compared to native and HMT-20 samples. Yield point (shear stress value at the limit of LVE-range) of HMTd samples were significantly (p < 0.05) lower than native starch and it further decreased significantly (p < 0.05) as the moisture content of the samples increased (Fig. 2). The lowest yield point (0.03 Pa) was observed for HMT-30 sample. The flow point (shear stress value at the crossover point G′ = G″) also showed similar trend as yield point. The curve of G′ and G″ for HMT-25 and HMT-30 samples fall constantly, representing a homogeneous deformation and spreadability as compared to native and HMT-20 starch gels (Fig. 2). Harder gels have limited applications in food processing as they require more force for fluidity and also lead to non-homogeneous mixing. The gel structure of HMT-25 and HMT-30 changed to liquid phase without sharp fracture edge, indicating more balanced ratio of elastic and viscous portion. Figure 3 represents the relationship between shear stress and strain for native and HMTd samples. It is clear that the starch gels showed pseudoplastic (shear thinning) behaviour. Further, the rigidity of the gels decreased as the moisture content increased during HMT.

Figure 4 illustrates the visco-elastic behaviour of native and HMTd dispersions with variations of storage modulus and loss modulus as a function of frequency. The native and HMT-20 samples exhibited the weak gel behavior as G′ >> G″ for these samples. Complex viscosity of all the samples decreased as frequency increased, showing a shear thinning behaviour. Yadav et al. (2014) also observed shear thinning behavior of pearl millet porridge due to breakage of swollen starch granules at higher shear rate. The continuous phase, volume fraction of dispersed phase and deformability of swollen starch granules mainly decide the rheological behaviour of starch dispersions. Hence, the decrease in complex viscosity and storage modulus after HMT may be related to degree of deformability.

Thermal properties

The thermal properties of native and HMTd pearl millet starch are summarized in Table 3. HMT induced a shift of gelatinization temperatures, viz. onset (To), peak (Tp) and conclusion (Tc) towards higher side with increasing moisture content. Gelatinization peak was observed at 62.59 °C for native starch whereas, 69.02, 76.78 and 84.05 °C for HMT-20, HMT-25 and HMT-30, respectively. Onset (To) temperature also increased significantly (p < 0.05) after HMT and it was 4.73, 9.9 and 18.13 °C higher for HMT-20, HMT-25 and HMT-30 samples, respectively as compared to native starch. Similarly, Tc was also higher (89.04 °C) for HMT-30 than native starch (73.55 °C). The gelatinization range (R) was significantly (p < 0.05) lower for HMTd starches than native starch. It was 13.57 °C for native starch, while 12.68, 11.56 and 10.92 °C for HMT-20, HMT-25 and HMT-30, respectively. Similar trend was observed for thermal enthalpy (∆H) of gelatinization. PHI, a measure of uniformity in gelatinization, varies as the height of the peak changes in relation to its width. PHI of native starch was 4.59, which decreased significantly (p < 0.05) after heat moisture treatment. These results are in agreement with the findings of Adebowale et al. (2005) for finger millet. The disruption of amorphous region during HMT might be the reason for decrease in ∆H and R. Gunaratne and Hoover (2002) reported that disruption of double helices present in the crystalline and non-crystalline regions of the granules results in decrease in ∆H during HMT.

Resistant Starch (RS) and Dextrose Equivalent (DE)

RS content and DE value of native and HMTd samples are given in Table 4. RS content of native starch was 2.41 ± 0.016 % and, the DE value was zero. HMT significantly (p < 0.05) increased the RS content and the increase was more as moisture content of the samples increased during HMT. The highest (7.07 %) RS was observed in HMT-30, which was about three times higher than native. Kurakake et al. (1997) suggested that water facilitates creation of hydrogen bonds between molecular chains within starch granules and form a more compact region, which is resistant to enzymatic hydrolysis thus increases RS content. Chung et al. (2009) also found increased RS in corn, pea and lentil starches by 7.7, 2.3 and 5.6 %, respectively after HMT. Crystalline polymerization (B type to A+B type) may be another reason for RS formation during HMT (O’Brien and Wang 2008; Chung et al. 2009). Limited hydrolysis of starch also occurred during HMT as evident by increased DE value from 0 (native) to 8.37 % (HMT-30). Thus, the increase in DE during HMT supports the theory of re-orientation of starch chains to increase crystalline region, along with simultaneous hydrolysis. Hence, it can be stated that starch modification by HMT is a polymorphic transformation.

Swelling power, solubility and oil absorption capacity

Swelling power, solubility and oil absorption capacity of native and HMTd starches are presented in Table 4. The swelling power of starch samples decreased after heat moisture treatment. The decrease was significantly (p < 0.05) affected by moisture content of the samples. Solubility of HMTd starches also exhibited similar trend. It decreased significantly (p < 0.05) from 5.96 % (native) to 1.51 % (HMT-30). The solubility of HMT-25 and HMT-30 samples did not differ significantly (p < 0.05). Starch solubility is affected by the amount of leached amylose during hydration and swelling. The formation of cross linkages in amorphous region and thus increase in crystallinity during heat moisture treatment might be possible reason for decrease in swelling power and solubility. The oil absorption capacity of heat moisture treated samples was significantly (p < 0.05) higher than native. On an average, it was twice than that of native starch. This indicates that lipophilic tendency of pearl millet starch increased after heat moisture treatment. Similar observations have been reported for potato and wheat starch by Kulp and Lorenz (1981) and for autoclaved corn starch by Dundar and Gocmen (2013).

Granular morphology

Figure 5a–d represents the scanning electron micrographs (3000× magnification) of native and HMTd pearl millet starch samples. The pearl millet starch granules are of various shapes mainly round/oval with 3–12 μm size. Some granules are also irregular and polygonal. HMT induced some dents/holes on the surface of starch granules (Fig. 5b–d), possibly due to rearrangement of molecular structure as well as disintegration. The severity increased with increase in moisture content during HMT. Loss of physical integrity with degradation of the granular surface (characteristic of partial gelatinization) was also observed in HMTd samples. Lee et al. (2012) suggested that this may be due to partial swelling and disruption of starch granules in the presence of abundant water.

Conclusions

Heat moisture treatment improved heat and shear stability, reduced retrogradation and increased resistant starch of pearl millet starch. The stability ratio was highest (0.81) for HMT-30 while, lowest (0.54) for native starch. Heat moisture treated starch gels exhibited the phenomenon of homogeneous deformation, spreadability and gel softness, owing to balanced ratio of elastic and viscous portion. At higher moisture level, HMT also caused surface degradation along with some dents/holes on the surface. HMTd pearl millet starch may find applications in heat processed food as well as in frozen food products. It is hoped that the data generated from the study will provide an efficient utilization route for pearl millet starch. This will further reduce the over-dependence on other cereal starches especially maize and rice as well as increase the diversified uses of underutilized millets.

References

AACC (2000) Approved methods of analysis (10th ed.). AACC International, St. Paul

AACC (2009) Approved methods of analysis (11th ed.). AACC International, St. Paul

Abdalla AA, Ahmed UM, Ahmed AR, Tinay AH, Ibrahim KA (2009) Physicochemical characterization of traditionally extracted pearl millet starch. J Appl Sci Res 5:2016–2027

Adebowale KO, Afolabi TA, Olu-Owolabi BI (2005) Hydrothermal treatments of Finger millet (Eleusine coracana) starch. Food Hydrocoll 19:974–983

Balasubramanian S, Sharma R, Kaur J, Bhardwaj N (2014) Characterization of modified pearl millet (Pennisetum typhoides) starch. J Food Sci Technol 51(2):294–300. doi:10.1007/s13197-011-0490-1

Chakraborty SK, Tiwari A, Mishra A, Singh A (2014) Rheological properties of refined wheat - millet flour based dough under thermo-mechanical stress. J Food Sci Technol. doi:10.1007/s13197-014-1339-1

Chung HJ, Liu Q, Hoover R (2009) Impact of annealing and heat-moisture treatment on rapidly digestible, slowly digestible and resistant starch levels in native and gelatinized corn, pea and lentil starches. Carbohydr Polym 75:436–447

Dundar AN, Gocmen D (2013) Effects of autoclaving temperature and storing time on resistant starch formation and its functional and physicochemical properties. Carbohydr Polym 97:764–771

Gunaratne A, Hoover R (2002) Effect of heat-moisture treatment on the structure and physicochemical properties of tuber and root starches. Carbohydr Polym 49:425–437

Hoover R, Vasanthan T (1994) The effect of annealing on the physicochemical properties of wheat, oat, potato and lentil starches. J Food Biochem 17:303–325

Junistia L, Sugih AK, Manurung R, Picchioni F, Janssen L, Heeres HJ (2008) Synthesis of higher fatty acid starch esters using vinyl laurate and stearate as reactants. Starch-Starke 60:667–675

Krueger BR, Walker CE, Knutson CA, Inglett GE (1987) Differential scanning calorimetry study on the effect of annealing on gelatinization behaviour of corn starch. J Food Sci 52:715–718

Kulp K, Lorenz K (1981) Heat-moisture treatment of starches. I. Physicochemical properties. Cereal Chem 58:46–48

Kurakake M, Noguchi M, Fujioka K, Komaki T (1997) Effect on maize starch properties of heat-treatment with water ethanol mixtures. J Cereal Sci 25:253–260

Lee CJ, Kim Y, Choi SJ, Moon TW (2012) Slowly digestible starch from heat moisture treated waxy potato starch: preparation, structural characteristics, and glucose response in mice. Food Chem 133:1222–1229

Lineback DR, Rasper VF (1988) In: Pomeranz Y (ed) Wheat: chemistry and technology, Vol. 1. AACC, St Paul, pp 277–372

Maache-Rezzoug Z, Zarguili I, Loisel C, Queveau D, Bule’on A (2008) Structural modifications and thermal transitions of standard maize starch after D.I.C. hydrothermal treatment. Carbohydr Polym 74:802–812

O’Brien S, Wang YJ (2008) Susceptibility of annealed starches to hydrolysis by α-amylase and glucoamylase. Carbohydr Polym 72:597–607

Olayinka OO, Adebowale KO, Olu-Owolabi BI (2008) Effect of heat moisture treatment on physicochemical properties of white sorghum starch. Food Hydrocoll 22:225–230

Osborne DR, Voogt D (1978) The analysis of nutrients in foods. Academic, London

Qing-Bo D, Ainsworth P, Tucker G, Marson H (2005) The effect of extrusion conditions on the physicochemical properties and sensory characteristics of rice-based expanded snacks. J Food Eng 66:283–289

Snedecor GW, Cochran WG (1994) Statistical methods, 8th edn. Iowa State University Press, Iowa

Stute R (1992) Hydrothermal modification of starches. The differences between annealing and heat-moisture treatment. Starch-Starke 44:205–214

Sun Q, Han Z, Wang L, Xiong L (2014) Physicochemical differences between sorghum starch and sorghum flour modified by heat-moisture treatment. Food Chem 145:756–764

Uthumporn U, Zaidul ISM, Karim AA (2010) Hydrolysis of granular starch at sub-gelatinization temperature using a mixture of amylolytic enzymes. Food Bioprod Process 88:47–54

Watcharatewinkul Y, Puttanlek C, Rungsardthong V, Uttapap D (2009) Pasting properties of a heat-moisture treated canna starch in relation to its structural characteristics. Carbohydr Polym 75:505–511

Yadav DN, Kaur J, Anand T, Singh AK (2012) Storage stability and pasting properties of hydrothermally treated pearl millet flour. Int J Food Sci Technol 47:2532–2537

Yadav DN, Chhikara N, Anand T, Sharma M, Singh AK (2014) Rheological quality of pearl millet porridge as affected by grits size. J Food Sci Technol. doi:10.1007/s13197-013-1252-z

Ziegler GR, Thompson DB, Casasnovas J (1993) Dynamic measurement of starch granule swelling during gelatinization. Cereal Chem 70:247–251

Acknowledgment

The authors would like to gratefully acknowledge Director, NDRI, Karnal, India for extending Scanning Electron Microscope facilities and Haryana Agricultural University, Hisar, India for providing pearl millet variety. The authors also thank Director, CIPHET for financial assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharma, M., Yadav, D.N., Singh, A.K. et al. Rheological and functional properties of heat moisture treated pearl millet starch. J Food Sci Technol 52, 6502–6510 (2015). https://doi.org/10.1007/s13197-015-1735-1

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-015-1735-1