Abstract

Reducing the water absorption of wood is important as less permeability to water implies enhanced resistance against wood-decaying organisms and is mechanically stable. Many preservatives are in current practice, configuring which type of preservative is more effective on which species of wood requires an effort. Hence, this can be evaluated by water absorption of differently treated wood. Thus, this review aims to focus on the phenomenon of water absorption on treated wood and build an argument on the impact of chemical modification on water absorption. This study describes the practical applications of wood treatment techniques and how they could be integrated to solve the problematic areas in wood–moisture relations. The initial phase of the study overview the current level of knowledge on essential features of moisture in wood and attempts to identify the existing knowledge gaps in the field of the wood industry. This review is conducted by referring to 85.5% journals, 8.4% conference papers, 3.05% electronic books, and 3.05% others. The review identifies more research ought to be conducted about chemicals that would reduce hygroscopicity and provide durability with minimum toxicity to nature. Such knowledge might be applied to a variety of sectors of research, including how to improve decomposition resistance, how to improve the performance of moisture-induced wooden actuators, and combining various revelations of moisture in wood with the introduction of specific chemical alterations. Regulating the spatial distribution should provide a unique overview of the wood–water reactions. Therefore, the resultant innovative ideas would be useful in related disciplines such as polymer science and the construction industry.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Wood has served humans from the distant past for various purposes such as fuel, means of shelter, manufacturing of equipment, furniture, and construction of ships, boats, and bridges (Falk 2009; Mendis et al. 2020a; Mendis and Umesh Halwatura 2019). Yet, to date, it remains a highly favored engineering material due to its lightweight, and environmental friendliness (Ramage et al. 2017). It also has a greater structural capacity as the bearing load per unit of wood weight, when assessed relative to reinforced concrete and steel (Mendis et al. 2019a). This wood or lumber is a sustainable construction material with economic feasibility (Sudeshika et al. 2020a; Asif 2009; Mendis et al. 2020b). It is naturally a hydrophilic or hygroscopic material (Kartal et al. 2007; Thybring and Fredriksson 2021). Wood is subjected to water absorption and desorption throughout its lifecycle (Adedeji et al. 2017). When structural elements are in contact with liquid water or atmospheric moisture regularly, their mechanical properties such as compressive strength and hardness wear off (Khazaei 2007).

As a result, forecasting how moisture affects the functionality of wood is vital for determining the serviceability and safety of structural elements. Moreover, the harvesting of wood should be limited, as reckless tree-cutting leads to deforestation and global warming (Sandberg et al. 2017).

Due to the anisotropic nature of wood in longitudinal, radial, and tangential directions, with the absorption of water molecules, it tends to swell differently through those directions (Devi and Maji 2012). Besides, reducing the water absorption of wood is extremely important as less permeability to water implies enhanced resistance against wood-decaying organisms(Kutnik 2013; Fukasawa et al. 2011; Schmidt 2007; Mubarok et al. 2017; Marcot 2017; Shiny et al. 2019; Korkmaz and Büyüksarı 2019; Can et al. 2010; Perçin et al. 2015).

Numerous wood modification techniques have been documented (Dong et al. 2020). Four basic procedures can be used to modify wood: chemical treatments, thermo-hydro (TH) and thermo-hydro-mechanical (THM) treatments, biological process-based treatments, and electromagnetic irradiation-based physical treatments. Wood can be altered through active modifications, which modify the material's chemical composition, or passive alterations, which change the qualities of the material without changing its chemical composition (Tomak et al. 2010; Kartal et al. 2015; Rowell et al. 2010; González-Laredo et al. 2015).

The interplay between wood and moisture is one of the unique characteristics of wood. Moreover, the ultimate goal, the mechanical properties rely on dimensional stability, which is affected by water absorption. The majority of active modification techniques examined to date involved a chemical reaction between a reagent and the hydroxyl groups in cell-wall polymers. These hydroxyl groups are the most reactive locations and also play a significant role in the interaction between wood and water (Mendis et al. 2018 ; Dissanayake et al. 2019; Dissanayake et al. 2020; Mendis 2018 ; Dissanayake et al. 2018, Mendis et al. 2020, Mendis et al. 2020; Mendis et al. 2021; Mendis et al. 2022).

This review presents the knowledge gaps of how water absorption is influenced after wood modifications, as well as how modifications have already been used up to date and the ability to utilize them to cover existing research gaps. Finally, the review is targeted at the selection of literature to inspire future study in the essential topic of wood moisture, water absorption, and modifications research and promote state-of-the-art in wood moisture research. The developments would pave paths to create new or optimize commonly practiced modification procedures and chemicals to maximize wood capability with a thorough understanding of moisture in wood and the impacts of wood chemistry.

Materials and methodology

Scientific publications including journal articles, conference papers, and electronic books, since 1996 were studied with the aid of electronic databases such as Google Scholar, ResearchGate, and Google.

Literature review planning protocol

The related articles were recognized through the keywords: “Wood and chemical modification”, “wood and water interaction” and “chemically modified wood and water absorption”. All the corresponding abstracts were perused to fathom the relativeness of the studies. Next, the complete documents of the required references were procured and saved. A total of 150 articles were assessed, of which 131 were finally used in this review.

Methodology

The following flow chart represents the area focused on in the review; Fig. 1.

The below chart represents the sources used for the review; Fig. 2.

Background on wood modification

A brief overview of wood

With the increasing demand for wood in the application, wood has been studied with attention on its scientific advances. Among them, yet, knowledge gaps remain in the fundamental understanding of how water absorption causes and how this sensitive material behaves with respect to this phenomenon.

Wood is harvested from trees, and by sawing them it is used as a construction material (Falk 2009; Mendis et al. 2019b). Different timber species display diverse properties and have distinct uses. The longitudinal arrangement of fibers is important since grain orientation affects its properties (Sudeshika et al. 2020a; Mascia et al. 2010; Miksic et al. 2013). An engineering aspect of timber is that it has a high strength-to-weight ratio implying that it is useful as a structural member which carries a great extent of its self-weight (Akpan et al. 2021) (Fig. 3).

A Cell Structure, Cell Lumen, Wood cell wall, Micro Fibrils, Elementary Fibrils; B Cellulose, Hemicellulose, Lignin; C Cellulose’s many hydroxyls (–OH) groups attract water molecules, making the substance hydrophilic, D Reaction of hydrogen bonds; E Bound and free water distribution (Zhou et al. 2009)

Macro-structure and microstructure

The wood structure can be observed from different levels, namely macro-structure, sub-macro structure, microstructure, sub-microstructure, and molecular structure (Nilsson and Rowell 2012). The macro-structure is divided into two categories; softwood and hardwood (Sudeshika et al. 2020a).

It is elaborated that the sub-macro structure identifies wood in the manner of a solid board (Nilsson and Rowell 2012). The level next in line is the microstructure. The cell wall alone is present in the microstructure. In a general micro-level section, the pith exists in the middle followed by the heartwood (a collection of non-living xylem cells) surrounding it (Mendis et al. 2020b). Then, the sapwood is present to transport water, minerals, and glucose which are extracted by the roots. The layer separating phloem and sapwood, where cell division of sapwood and phloem cells occurs, is known as the cambium (Asif 2009; Mendis et al. 2019b). The sub-micro structure comprises cell components such as vessels, pits, ray cells, and lumens. Cell wall polymers are the main structures at the molecular level (Nilsson and Rowell 2012). The wood cell wall is a significant structure where cellulose fibers are fixed in a network of cellulose, hemicellulose, and lignin in an orderly matrix (Ringman et al. 2019). The emergence of capillary water occurs through nanopores.

A transport system is required in plants to transport the nutrients gained from the roots by diffusion, mass flow, or interception in a fluid medium (Dissanayake et al. 2019). The availability of the pores or the vessels in hardwoods acts as the main feature differentiating hardwoods and softwoods (Asif 2009).

The cell structure of hardwoods is more complex than that of softwoods and considering their evolution, hardwoods are known to be younger than softwoods (Ansell 2015).

It is documented that wood owns a cylindrical orthotropy with the longitudinal direction (main growth direction), the radial direction (secondary growth direction), and the tangential direction (perpendicular to the two former directions) (Khalid et al. 2010; Bajpai 2018; Thibaut et al. 2001). Furthermore, the orientation of wood fibers assures a variation of wood properties with the three axes with broadening of the trunk during growth leading to its anisotropy (Bajpai 2018; Borůvka et al. 2020; Backman and Lindberg 2001; Hanhijärvi 2000).

Hence, when the mechanical wood properties are defined, the values that are given for radial and tangential direction are the same. Thus, the mechanical characteristics of wood are referred to as parallel to the grain direction and perpendicular to the grain direction (Mendis et al. 2019b) (Fig. 4).

Chemical composition

The primary chemical components of wood are carbon, hydrogen, and oxygen. By the combination of these three elements, a network of organic compounds, cellulose, hemicellulose, lignin, and extractives are formed (Teischinger 2016). These compounds existing in different species of trees determine the properties such as wood density, elasticity, and stiffness which are specific to each tree type (Asif 2009).

Moreover, cellulose is a chain polymer built up of glucose units produced during the photosynthesis process. Cellulose sums up approximately 50% of the dry wood and is the primary constituent of timber. Hemicellulose is made up of glucose and other water-soluble sugars and owns 20–35% of its dry weight. Lignin is the bonding material that keeps cellulose and hemicellulose fixed together. Lignin provides rigidity to the tree and the dry wood weight comprises 15–35% of it (Asif 2009; Ansell 2015). It is suggested that softwood contains a higher percentage of lignin relative to hardwood, whereas, lignin is of two types; guaiacyl and syringyl. Better resistance to microbial degradation is offered by guaiacyl lignin.

It was found that approximately the entire lignin content in softwoods was guaiacyl lignin and their decay rate was less than that of hardwoods (Nilsson and Rowell 2012).

Extractives are about 1–10% of the dry weight of wood and are the reason for wood color, density, resistance to deterioration, and hygroscopicity. It is mentioned that extractives in heartwoods improve wood durability, while the moist nature of sapwood promotes wood decay (Asif 2009; Nilsson and Rowell 2012) (Fig. 5).

Water absorption phenomenon

Fiber saturation point

Wood is known to be hygroscopic, defining that wood keeps absorbing and exchanging moisture with the environment (Ringman et al. 2019). It is reviewed that wood cellulose contains hydroxyls which have a high affinity toward water molecules (Mendis et al. 2019b). A monomolecular water layer is constructed by these hydroxyls forming strong H bonds during contact with moisture (Shen et al. 2021; Zhang et al. 2021). Thus, water absorption is directly proportional to relative humidity (Humar et al. 2020). The limit “Fiber Saturation Point (FSP)” is where wood moisture content is taken as the bound water in the cell walls of untreated wood (Ringman et al. 2019; Brischke and Alfredsen 2020; Ishimaru et al. 2001).

When wood has absorbed water beyond the FSP, water molecules are collected in macro voids and cell lumen via capillary condensation. This FSP is achieved in wood at the range of 97–98% relative humidity (RH) under natural conditions. Moisture content (MC) below the range of 23–25% at 22 °C, corresponding to 95% RH, has been identified to have prevented the decaying of wood (Ringman et al. 2019). The two zones below and above the 97–98% relative humidity (RH) range are identified as the hygroscopic region and over-hygroscopic region, respectively. The hygroscopic range is governed by moisture absorption through cell walls and the over-hygroscopic region is governed by capillary condensation (Brischke and Alfredsen 2020; Meel et al. 2011).

Water content remaining in the cell lumen or voids, beyond the FSP is known as free water. The permeability of wood controls free water existence (Meel et al. 2011). Decaying of wood does not occur unless free water is present in the wood cells (Sandberg and Salin 2012).

The NMR (nuclear magnetic resonance) signal amplitudes were used to calculate FSP values (Zhou et al. 2020).

Equilibrium moisture content

Fiber saturation point (FSP) is also elaborated as the increase of equilibrium moisture content (EMC) with relative humidity (RH) till the saturation of cell walls, with relative humidity reaching 100% (Brischke and Alfredsen 2020; Meel et al. 2011; Zhou et al. 2020). This approach reduces the problems arising when wood specimens with changes in moisture gradients are compared by properties such as grain orientation, wood density, and geometry. It creates a common platform to analyze wood species.

Here, the problem in experimental procedures is how to identify whether a certain wood sample has reached equilibrium. Numerous studies have adapted from ISO 12571 (ISO 2013) and ASTM C1498 (ASTM 2016) standards to determine moisture consistency. In those specifications, the minimum mass variation is assumed to occur at equilibrium. They require mass variations below 0.1% in one of the following scenarios (Thybring et al. 2018).

-

1.

Taking daily mass readings for 5 consecutive days

-

2.

Two successive mass readings in readings taken over 7 days

Hernández and Pontin (2006) followed a procedure of identifying the equilibrium moisture content when the daily loss of moisture content was below 0.007% for 0–90% RH at 25 °C by taking weekly readings of samples. Their experiments were carried out on three tropical hardwoods namely tornillo (Cedrelinga cateniformis), pumaquiro (Aspidosperma macrocarpon), and huayruro (Ormosia coccinea). At 60% relative humidity (RH) and 20 °C the EMCs were 13%, 11%, and 11%, respectively.

In the end, there is still a lot to learn about the mechanisms that determine the EMC across the entire relative humidity range, in addition to the interactions of water in cell walls and the cell lumen. The employment of complementary experimental methodologies is necessary to identify moisture levels and to discover the optimum conditioning which guarantees a consistent transference of moisture in the wood matrix. This will be critical to gaining new knowledge.

Hygroscopic hysteresis

The processes of water absorption and desorption are reversible. The hygroscopic hysteresis can be elaborated as a higher EMC in initial desorption than subsequent absorption (Meel et al. 2011). It is a commonly considered aspect regarding the water absorption phenomenon of wood (Ishimaru et al. 2001; Shi et al. 2021). It is evaluated by a coefficient which is the ratio between the EMC values of adsorption and desorption by prevailing equal relative humidifies at both processes (Esteban et al. 2005; Olek et al. 2013). The mechanism can be explained as the formation of additional bonds between the water sorption sites at the cell wall polymers when the wood is subjected to shrinkage during desorption. This lowers the active sorption sites for the next adsorption process. However, when successive adsorption occurs, the wood swells, and again hygroscopicity is increased (Olek et al. 2013).

The degree of change in the physical properties of wood between the adsorption and desorption of water is reduced with the decreasing of the flexibility of the cell wall constituent polymers. Otherwise expressed, lower hysteresis causes lesser stiffness in the wood matrix (Zhou et al. 2020).

Shrinkage and swelling

During water absorption, initially, the cell wall is filled with water, and only after that water accumulates in the cell lumen. Swelling in wood is observed when both the cell wall and lumina are impregnated with water. It is hypothesized that free water is not responsible for swelling as it is only held by weak capillary forces. Thus, during a desorption process where the bound water is also dried out, wood displays radial and tangential shrinkage (Meel et al. 2011). It is also mentioned that shrinkage and swelling are considered wood movements, and wood movements in radial and tangential grain directions predominate that of the longitudinal direction (Mendis et al. 2019b). In other words, shrinkage in the longitudinal direction is negligible (Rafsanjani et al. 2014; Usta and Guray 2000; Christoforo et al. 2016; Almeida and Hernández 2006).

It is observed by plotting the shrinkage of wood with moisture content. On the contrary, in some wood types (example-beechwood) shrinkage occurs above the FSP. The FSP values of tornillo, pumaquiro, and huayruro hardwoods were approximately 28%, 22.5%, and 21.5% in order. However, changes in radial, tangential, and volumetric shrinkage occurred at 52%, 36%, and 77% EMCs for the three wood types, respectively (Hernández and Pontin 2006). Therefore, it is not always correct to consider that limit as FSP. Yet, considering the fiber saturation point as an approximate margin value, keeping wood moisture near the fiber saturation point in desorption processes is important to prevent the structural failure of wood (Ishimaru et al. 2001).

The layer of hydrogen bonds formed during moisture sorption pushes the cellulose polymers into the amorphous sections and the microfibrils, causing the swelling of the wood (Mendis et al. 2019b). This phenomenon is linked to the structure of cell wall pores.

Natural weathering of wood causes the leaching of cell wall constituents such as lignin, which leads to an increase in pore diameter (Cai et al. 2020). Cell walls of hardwoods are not lignified as much as tracheids of softwoods, thus, indicating a higher porosity to allow water movement. The main pore type which allows the conducting of water in the xylem are macropores represented by cell lumens. The other pore types are mesopores and micropores. The micropores in xylem walls are significant in heartwood formation as the water molecules are replaced with gums and extractives, reducing permeability. These micropores also allow a way for water to be removed during timber drying and absorb chemicals during preservation techniques (Donaldson et al. 2018).

Wood modification

Reasons for wood modification

The macrostructure of timber outlooks its texture, color, smell, cracking, swelling, shrinkage, and moisture. These factors affect the mechanical properties listed as stiffness, compression resistance, flexural capacity, hardness, resilience, and shear resistance (Sudeshika et al. 2020b). Therefore, the prime objective of wood modification is enhancing durability while retaining these characteristics or improving them. Using newly sawn wood for long-term uses is not practical as it is susceptible to harm by natural and artificial causes (Meel et al. 2011; Devi et al. 2003). Wood modification, apart from drying, was scarce in historical practices (Sandberg et al. 2017). However, converting wood into an improved state was important, as the number of trees cut for human purposes needed to be limited (Karlsson et al. 2011).

Types of wood modification

Chemical modification and wood coating are emphasized as wood preservation methods to decrease the decaying rate and drying rate (Devi et al. 2003; Sivertsen and Flæte 2012). Apart from that heat treatment is also commonly practiced.

Based on data gathered on wood modification worldwide as per the findings of Jones and Sandberg (2020).

Thermal modification

Countless articles examine the thermal modifications that expose the wood to temperatures over 160 °C with inhibited oxygen supply. Different procedures such as kiln drying by nitrogen or steam and immersing in heated oil are utilized for this (Sandberg et al. 2017; Karlsson et al. 2011). The thermal treatments presently existing in the world are Plato process (uses liquid water followed by conditioning), Thermo wood process (uses steam), Les Bois Perdure, Rectification (uses nitrogen gas), and OHT (Oil Heat Treatment) process (Mendis et al. 2019a; Robert Welzbacher and Otto Rapp 2007). Thermal modifications differ according to their oxygen-removing and heat-conducting mechanisms and are recognized for the enhancement of hygroscopicity, durability, and dimensional stability. It is an active modification as it alters the chemical composition of timber (Robert Welzbacher and Otto Rapp 2007).

It is established that the wood species, temperature, rate of heat transfer, treatment duration, and dimensions of raw timber correspond to the effectiveness of the technique. Much higher temperatures (above 200 °C) are not favored due to the loss of bending strength (lowered Modulus of Rupture) in lumber (Herrera-Builes et al. 2021; Lekounougou et al. 2011). Applying heat to wood always darkens the wood surface due to the deterioration of lignin and hemicellulose (Herrera-Builes et al. 2021; Homan et al. 2000). Heat-treated wood is unproductive for structural applications due to the degeneration of mechanical characteristics. Formerly, only softwoods were thermally treated, however, presently certain hardwoods are also heat-treated to enhance durability (Sandberg et al. 2017).

Impact of thermal modification on water absorption

Plato’s process has been recognized to have increased the water-repellency of wood. The mechanism of thermal treatment is explained as the change of cell wall polymers, which causes the reduction of OH− groups, cross-linking, and/or (unwanted) cleavage of chains. (Homan et al. 2000). Here, the lowering of the amount of OH− ions restricts access to water, preventing an undesirable increase in wood moisture content (Wang et al. 2018). The hygroscopicity improvement by 40% and an average Anti Shrinking Efficiency (ASE) of 40% were observed in thermally modified wood. The resistance for brown rot, soft rot, and white-rot fungi was also strikingly improved (Homan et al. 2000; Tsapko et al. 2021). A maximum of 20% weight loss is reported through thermal modification. The reduction of hydrophilic hemicellulose polymers lowers the EMC to an approximate value of half the EMC of the untreated wood (Sandberg et al. 2017; Awoyemi et al. 2009).

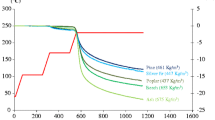

Heat treatment causes the water absorption to decline with higher temperature and time of applying heat (Kartal et al. 2007). This phenomenon was observed in heat-treated Mahogany wood, where the rate of water absorption incremented with greater immersion intervals till 25 h, and, after 150 h it declined. The EMC at 65% relative humidity and 20 °C of Mahogany wood with 150 °C heat treatment was 8.8%. It dropped to 6.1% with heat treatment of 210 °C (Zhou et al. 2020). The impact on bound water by heat modification was higher than that on free water as the cell wall entry of water molecules was blocked (Pelit et al. 2016).

Impregnation

Impregnating the cell wall with chemicals and locking it inside the cell wall does not alter the wood matrix, despite the wood properties being changed. Hence, it is a passive modification method. Normally, the cell wall or cell lumen is saturated with a monomer which is polymerized afterward (Li et al. 2013). This is normally done by applying pressure. Here, cell lumen bulking does not affect the dimensional stability or lifecycle of wood. In addition, the chemical molecules must be 2–4 nm in diameter for cell wall penetration during impregnation (Sandberg et al. 2017). Some impregnating chemicals are Furfuryl Alcohol (FA), styrene, 1,3-dimethylol-4,5 dihydroxy ethylene urea (DMDHEU), phenol–formaldehyde, and methyl methacrylate(MMA) (Han et al. 2015).

Furfurylation is explained as the impregnation of wood by furfuryl alcohol. The earliest methodology was to treat wood with FA with a catalyst present at 100 °C temperature. Furfurylated timber at high concentrations appears as a black shade, while lower concentrations present a dark tropical hardwood hue when softwood is considered (Esteves et al. 2011; Ormondroyd et al. 2015; Li et al. 2011).

Impact of impregnation on water absorption

Impregnating with acrylic or vinyl-type monomers alone shows dimensional instability with high humidity as the chemicals are locked in the cell lumina, not the cell wall (Devi et al. 2003). Vacuum pressure impregnation of 1,3-dimethylol-4,5-dihydroxyethyleneurea (DMDHEU) in the presence of catalysts at temperatures over 100 °C is a practiced impregnation technique. Resin-filled lumens hinder the access of cell walls for water molecules. The deactivation of hydroxyl groups in cell wall polymers and bulking of cell walls both contribute to improving dimensional stability (Xie et al. 2013). DMDHEU impregnation reduces water absorption through cell-wall pores, although it has a negligible impact on capillary water uptake (Emmerich et al. 2019). GMA also has depicted a lower water uptake and lesser swelling in a 168 h water immersion test, due to its low molecular weight and reaction with a larger amount of 0H− groups (Ghorbani et al. 2019). The water absorption of controlled, styrene-treated, and styrene + GMA-treated rubberwood samples were 142.86%, 98.64%, and 72.5% from a water-submerging test carried out for 6 days (Devi et al. 2003). Furfurylation of pine with 70% solution has achieved 38% of WPG and accomplished an ASE increase of 45% and a 40% decrease in EMC (Esteves et al. 2011).

Chemical modification

Chemical modification is elaborated as the forming of covalent bonds between reagents and cell wall polymers. It is an active modification method. The mechanism of chemical wood modification includes one or a combination of; a reduction of EMC, physical blocking of entering of wood-rotting fungi, and hindering the actions of certain enzymes (Sandberg et al. 2017; Mantanis 2017). Since wood is heterogenous and exhibits a non-uniform moisture distribution, a majority of wood treatments contain both absorption and diffusion penetration. Diffusion happens through liquid pathways in untreated wood such as free water in the cell lumen (Williams 1996). The basic concept of chemical modification is to change hydrophilic OH− groups into larger hydrophobic groups (Hom et al. 2020). Chemical modifications display favorable impacts on water repellency and dimensional stability, as it mainly reduces the number of hydroxyl groups (Dong et al. 2020).

It is suggested that more hydrophobic chemical groups replace the OH− groups through chemical reactions such as etherification, esterification, urethanes, oxidation, and sialylation (Homan et al. 2000). Acetylation is an esterifying wood modification that replaces hydroxyl groups with acetyl groups and produces acetic acid as a by-product. Though it is a feeble acid, its irremovable nature, lingering odor, and metal corroding nature adversely affect acetylated wood usage (Jebrane et al. 2011). It is described that there are improvements in wood quality corresponding to its WPG. The weight percentage gain (WPG) regarding acetylation is given by the following equation (Stefke et al. 2008).

This is the general method used to calculate weight gain after chemical modifications.

Types of chemicals used for modifications

There are mainly two chemical modifications; natural (chemicals derived from plant-based matter such as essential oils, tannins, and extractives) and artificial (Broda 2020). This study is based on the most abundantly used artificial chemicals in the world.

Inorganic chemicals

CCA (Copper Chrome Arsenic) is a heavily toxic but stable-after-fixed preservative utilized due to its cost-effectiveness. Traditional kiln drying and CCA application take about 7–16 days. CCA-treated wood was used for structural purposes rather than for furniture manufacturing due to its resultant unnatural color (Teoh et al. 2011). CCA was banned in many countries after realizing that the continuous use of heavy metals is substantially hazardous (Pan et al. 2015). Eventually, to replace arsenic in this chemical combination, boron was used (Lloyd et al. 2020).

Boron compounds are considered productive to inhibit fungi, insects, and termite attacks against the wood and are well known for their fire and heat resistance and possess low mammalian toxicity (Tomak et al. 2011). Boron salts are used as water-borne chemicals, and due to their hygroscopicity, the dimensional stability of treated wood would be negatively affected at high relative humidity. Mechanical strength would also have deteriorated at high temperatures and greater retention (Lloyd et al. 2020; Baysal et al. 2006). According to Kartal et al. (2007), based on the research of combined boron and heat treatment, the hydrophobic wood obtained through heat treatment is affected by the hygroscopic structure of boron compounds with high atmospheric moisture content.

Additionally, it is less volatile and odorless, thereby desirable as a wood preservative (Williams 1996). Borax–boric acid (BB) and copper chrome boron (CCB) are accepted as water-borne chemicals. Soaking of rubberwood keeping its MC close to FSP in BB and CCB solutions was effective against deterioration. Apart from soaking or dip-diffusion, fuel cell processes are also used for rubberwood preservation (Teoh et al. 2011).

An advantage of water-based preservatives is the ability to safely use them in indoor applications. Disadvantages are leachability due to their natural solubility, being subjected to warping unless properly dried, and not enabling protection against excessive weathering. In the USA, borate standards are declared by the American Wood-Preservers’ Association (AWPA) for aboveground and protected uses only due to its leachability issues (Jorge et al. 2004). Boron treatments are conducted through dipping or impregnation (Mendis et al. 2019a). Dipping of Rubber, Alastonia, and Mango timber for 24 h in boric acid and borax, followed by kiln drying for 7 days at 60 °C was conducted to determine the mechanical strength variations obtained through chemical modification. The specimen sizes complied with BS 373:1957 standard. It confirmed an improvement in elasticity, modulus of rupture (MOR), and compressive strength along grain direction (Sudeshika et al. 2020b). Tomak et al. (2011) have explained a procedure for the impregnation of boron. Initially, the sawn wood samples were subjected to vacuum impregnation of boron at 760 mmHg pressure for 60 min at 20 °C temperature. Then, the samples were kept submerged in the solution for another 60 min at barometric pressure. Next, the retaining boron content (R) in kg/m3 was determined by the equation below.

G = (sample weight after impregnation (g)—sample weight prior to impregnation (g)), V = sample volume in cm3, C = concentration (%).

Impacts of chemical modifications

Chemical modifications of wood lead to durability, extending woods’ lifespan, dimensional stability, and water absorption. Each Section was further reviewed through literature as follows.

Durability

The wood used for construction has a significantly higher lifespan, and most construction lumber can be recycled (Ramage et al. 2017; Rowell et al. 2010; Blom and Bergström 2005). Generally, a moisture content of 20–25% is sufficient to evade decaying (Sivertsen and Flæte 2012). When evaluating the lifespan of wood; durability tests, the effect of contact with the soil is explored (Acker et al. 2003). Termites and fungi are the organisms responsible for wood decay and resulting in weight loss (Priadi et al. 2020). The durability classes of wood are given in BS EN 350-1:1994 according to tests conducted by exposure to various wood-deteriorating fungi.

Field tests should comply with EN 252, where reference species are Fagus sylvatica and Pinus sylvestris sapwood. Here, the parameter, average lifespan of test specimens is also accounted to determine the durability class. Additionally, laboratory tests are based on EN 113. The validity of the test depends on the corrected values of average mass loss of the test samples for respective fungi, and the maximum average mass loss is taken for evaluation. Then, its relativeness to reference specimens is considered in configuring the durability class. Furthermore, the natural durability of termites corresponds with EN 118 (British Standards Institution 1999).

A laboratory decay test (terrestrial microcosm-TMC) using three soils; mixed soil from a coniferous forest, garden compost in Sweden, and soil from a Simlangsdalen test site was investigated in the research done by Alfredsen and Westin (2021). Here, CCA modification was compared with an impregnation technique: Furfurylation regarding pine wood. The results implied that there was no conclusive increase in durability with FA (Furfuryl Alcohol) concentration, however, significant variations were visible in copper-organic preservative-treated wood. Yet an approximate value of 25% WPG, the weight loss percentage of FA treated wood during the decay tests was inversely proportional to WPG. This implies that the higher the gross chemical uptake, the lesser the wood was susceptible to degradation until a gross chemical uptake percentage of 25% was attained.

It has been found that a 15% of WPG is adequate to evade white rot and brown rot fungi, while a WPG of 10% prevents weathering by soft rot fungi by acetylation. It is pointed out that soft rot decay is more critical in wood that is exposed to soil (Homan et al. 2000). Biological tests conducted for pine throughout 12 weeks on control samples yielded 61.3% and 7.8% weight losses through brown-rot fungi and white-rot fungi, respectively. 17.8% WPG in acetic anhydride showed 1.7% and 1.1% weight losses in the above fungi species, conveying an improvement in decay resistance (Rowell 2006).

Red Jabon (hardwood) impregnated with Boric-borax (5% concentration solution) and methyl methacrylate (MMA) for 4 h at 5 atm pressure was tested for durability. Boron and MMA impregnation showed lower weight loss relative to untreated wood. The variance test and the Duncan test at 95% confidence level interpreted the reduction of mass in Red Jabon modified using borax or BA was lesser than untreated wood (Priadi et al. 2020).

Boron preservatives are problematic due to their leachability. To resolve this issue boron fixation mechanisms are introduced. In such a model, a reaction between boric acid and flavonoid tannins was performed. This modified preservative displayed durability between 3 and 6 times the original durability when an accelerated termite field test was performed, revealing that boron fixation was higher (Jorge et al. 2004). It is also documented that MMA possesses the ability to contain boron compounds from leaching and withstand termite attacks, indicating that it is also a fixative (Priadi et al. 2020).

Dimensional stability

Repetition of shrinkage and swelling leads to variations in the wood matrix or dimensional instability. It could be prevented by reducing the absorption of water molecules, bulking the cell walls to restrict the capacity of water retained by wood, or cross-linking the cellulose chains of timber (Deka and Saikia 2000). The anti-swelling efficiency (ASE) is the most important parameter considering dimensional stability. It is usually calculated by determining volumetric swelling coefficients by performing water-soaking tests before and after chemical treatments (Sargent 2019). They comply with ASTM-1037 standards (Islam et al. 2012).

It is maintained that the reduction of EMC occurs with a rise in the ASE (Ormondroyd et al. 2015). Rowell (2006) explicates via his study that, the EMCs of control samples of pine at 35% RH, 60% RH, and 85% RH at 27 °C were 5%, 8.5%, and 16.4%, whereas, with WPG of 20.4% acetic anhydride yielded 2.4%, 4.3%, and 8.4% EMCs. The weight percentage gain (WPG) is proportional to the ASE of white pine, and when more acetic anhydride is retained by the timber, the swelling reduces. Some observations were that the volumetric swelling of cross-sections was reduced by up to 75% through acetylation (Ormondroyd et al. 2015).

It is confirmed by another study that claims 22.5% WPG of acetic anhydride resulted in an ASE of 70.3% compared to control samples (Rowell 2006). This points out a rise in dimensional stability through anhydride modification. The commonly acknowledged process for increasing dimensional stability through the bulking of cell walls has become controversial, with the proposal of an alternative mechanism of cross-linking. It was provided that OH− group substitution was proved to be irrelevant. However, with the inability to justify why similar dimensional stabilization values were achieved by identical WPGs with different linear chain anhydride reagents, cross-linking was ruled out to a great extent (Hill 2006).

An anisotropy ratio (tangential dimension change divided by radial dimension change) is considered in evaluating dimensional stability as the wood movement in the longitudinal direction is trivial (Borůvka et al. 2020; Brémaud et al. 2011; Malaga-Toboła et al. 2019). The anisotropy ratio of modified wood varies with the type of modification (Sargent 2019; Stanzl-Tschegg et al. 2009). The cell wall bulking with chemicals tends to decrease the anisotropy and cell lumen filling increases it.

The impact of boron impregnation in 2, 24, and 48 h on Red Jabon was analyzed as boric acid and borax separately. It was overviewed by the influence on the T/R ratio. Tests revealed that the T/R ratio of Red Jabon treated with borax was greater in comparison to boric acid treatment, thus, the dimensional stability of borax-treated wood was worse than boric acid-treated wood (Priadi et al. 2020). This suggests that in a boric acid and borax mix solution, it is preferable to increase the relative boric acid percentage.

Water absorption

The hygroscopic nature of wood is affected in numerous ways by chemical modification, in turn, altering its water absorption characteristics (Zhang et al. 2021). With chemicals bulking the cell wall or lumen, the moisture sorption can be decelerated, not withstanding the mechanism remains the same.

Water absorption testing

The term “absorption” indicates the uptake of material, irrespective of the mechanism that was utilized (Papanicolaou et al. 2006). Meanwhile, “adsorption” refers to a material uptake on surfaces/interphases by attaching water molecules within the wood structure (IUPAC guidelines). The common phrase “absorption” is utilized to include both cell wall-water uptake and capillary condensation into lumber (Thybring et al. 2018). Water uptake by both adsorption (bound water) and absorption (free water) is measured through the water absorption tests, and they cannot be accounted for individually (Penvern 2020). However, 25% of this uptake can be allocated for bound water at cell wall saturation if the cell wall material was not previously changed via hot pressing (Xu et al. 1996).

The testing standards of water absorption are interpreted similarly in most research. The water uptake is calculated by the given equation (Kartal et al. 2007; Devi and Maji 2012).

Wt = Weight of the sample after immersion in distilled water after a certain time interval, Wd = Weight of the oven-dry sample.

A water absorption test procedure conducted on chemically modified Simul wood (Salmalia malabarica) (hardwood) can be described as follows. The specimens were dried in an oven for 24 h at 105 °C. Next, the treated and untreated (control) specimens were submerged in water maintaining room temperature (30 °C). Subsequently, the specimens were weighted for certain intervals between 0.5 and 168 h (Devi and Maji 2012). A similar test was carried out on boron-treated and heat-modified Sugi (Cryptomeria japonica D. Don) sapwood, a softwood. The authors have documented that oven-drying previous to the test was for 24 h at 103 °C. The specimens were weighed 6, 24, 48, 72, 96, and 148 h after the immersion. They have specified that the water was changed daily (Kartal et al. 2007). The oven-drying of wood samples to 103–105 °C is done to determine the moisture content before water saturation as well as to obtain an irreversible loss of hygroscopicity ensuring a constant weight (Sargent 2019).

Impacts of chemical modification on water absorption

Studies declare changes in equilibrium moisture content (EMC) in acetylated pine under different relative humidities (Ormondroyd et al. 2015). When the amount of acetic anhydride substitution is increased, the hygroscopicity of wood reduces. As the WPG increases at a specific RH, the EMC decreases. Furthermore, when the increasing RH is scrutinized at a certain WPG, it can be observed that the EMC goes up. Numerous anhydrides such as acetic, hexanoic, propionic, and butyric are used and all of them acted similarly in experiments. Yet, anhydrides with smaller molecule sizes were more efficacious than larger sizes.

The water absorption of anhydride-modified Pinus radiata yielded the findings stated below. The untreated specimens absorbed more water than the treated samples and both treated and untreated samples displayed an increased water absorption in successive water soaking cycles. Yet, in certain cycles the water uptake was constant. The water-retaining volume of the cell wall was reduced as the weight percentage gain increased (acetyl groups invaded the cell walls). It is argued that water absorption can be delayed for a longer time by acetylation, and at high retention levels, a water uptake reduction of 35% is achievable (Hom et al. 2020).

It is maintained that cell wall damage would be caused through anhydride substitution of 32% of white spruce. A 76% reduction of water absorption attributed to cell wall bulking was obtained at FSP. The FSP values of raw earlywood and raw latewood obtained by H–H data were 29% and 30%. After acetylation, it was reduced to 14% and 18% for earlywood and latewood, respectively. Many types of research claim reduction of FSP through acetylation (Rowell and Bongers 2015; Hill 2009).

The water absorption after standard 24 h testing of untreated rubberwood was 38.8%, while that of resin-modified rubberwood was 40% (Menon 2002). However, the water absorption of Mango wood before and after treatment of the same process was 52% and 49%, respectively. The resin syrup consisted of different proportions of cardanol, caustic soda, formalin, linseed oil, cobalt naphtholate, and manganese naphtholate. When a different mixture of linseed oil, cobalt naphtholate, and manganese naphtholate was used rubberwood showed a water absorption of 45.28% before treatment and 18.48% after treatment. The second method of resin modification significantly lessened water absorption.

A water uptake test was performed on Sugi sapwood modified with BA and DOT (Disodium Octoborate Tetrahydrate) solutions combined with thermal-treatment. The water absorption incremental values were smaller in samples treated at 180 °C for 2 h and 4 h, and 220 °C for 2 h relative to samples treated at 220 °C for 4 h. The analysis unravels that the untreated samples (180 °C for 2 h) displayed a water absorption of approximately 90%, while 5% BA treated samples (180 °C for 2 h) displayed 140% after a 24 h soaking period. Meanwhile, the untreated unheated samples showed a water absorption slightly above 90% (Kartal et al. 2007). A rise in the water uptake was visible in water saturation tests as the temperature and time increased (Gezici-Koç et al. 2017; Kuciel et al. 2014).

An investigation was implemented to analyze the viability of chemical modification of sugi (Cryptomeria japonica D. Don) wood with disodium octoborate tetrahydrate (DOT) with a combination of allyl glycidyl ether (AGE) and methyl methacrylate (MMA) to hinder the leaching of boron. When the standard water absorption test was conducted, it was apparent that the water absorption was reduced by separate mixtures of MMA + AGE and DOT + monomer mixtures. The water absorption of untreated samples was 11.23%, while the 1% DOT-treated samples showed a water absorption of 19.22% (Kartal et al. 2004). Hence, it is evident that boron compounds increased water uptake.

Red Jabon preserved with boron (borax + BA) treatment, MMA impregnation, and subsequent thermal modification were subjected to the water absorption test (Priadi et al. 2020). The variance and Duncan test analysis indicated that the WA of Red Jabon was lowered by a considerable amount through boron preservation and MMA impregnation. Moreover, the minimum WA of the research was observed in MMA impregnation combined with 90 °C heat treatment. The 24 h WA of boric-impregnated, borax-impregnated, and control samples with 90 °C heat treatment were 120%, 150%, and 170%, respectively. With 180 °C heat treatment the above values were 140%, 140%, and 100%, respectively. Incorporating MMA noticeably limited the WA more than applying borates alone.

Baysal et al. (2006) have researched the water absorption levels and leachability of borates impregnated on Douglas fir (Pseudotuga menziesii var. viridis) sapwood. A boric-borax solution of 7% concentration was prepared with boric acid: borax, 7:3 (weight/weight) ratio. During a 120 h water immersion leaching test, the water absorption amounts were greater initially, mostly between 6 and 24 h, and later were reduced. It was assumed to be due to the water sorption into empty pores at the start, and the decrease of pores with continuous soaking. The average WA of borax–boric treated samples was higher than untreated samples. The correlation between the water absorption of borate-treated samples and leached chemical contents was linear (P < 0.01) up to 72 h in the leaching test. Moreover, the greater the water absorption, the higher amount of leachate produced.

Conclusion

This review demonstrates that wood alteration can be applied in a variety of creative ways. A timely and accurate understanding of wood–moisture interactions will also create novel insights into wood degradation. Thus, crucial information can be retrieved to design modifications that would uplift wood functionality in outdoor applications while retaining its eco-friendly, structurally feasible, and cost-effective aspects. The following data can be presented to understand the water uptake reduction through different treatments. Heat treatment-Plato process (160–190 °C) (Homan et al. 2000), Styrene and GMA treatment (Devi et al. 2003), Anhydride modification (Hill 2006), 7% Boric-borax treatment (after 120 h water immersion) (Baysal et al. 2006), 5% Boric acid impregnation (24 h water immersion) (Kartal et al. 2007) have resulted in 40%, 70.36%, 76%, (− 54.07%) and (− 50%) average water absorption reduction. Considering an in-depth study of the above-mentioned treatments it can be concluded that;

-

Wood–water interactions substantially affect the mechanical aspects of wood; thus, the water absorption phenomenon should be explored through FSP, EMC, sorption hysteresis, and wood shrinkage and swelling.

-

A comprehensive study of wood–water relationships generates new ideas to upgrade the performance of moisture-affected wood by challenging the wood anisotropy.

-

The ASE was improved with higher WPG of acetylation by lowering the EMC. It was also evident that acetylation hindered water absorption of wood to a significant extent relative to borates.

-

Additionally, the water uptake of wood was reduced with immersion time (due to loss of sorption sites) and high temperature.

-

Combining different modification methods successfully lessened hygroscopicity.

The timber industry would benefit if moisture processes occurring in wood could be managed properly and forecasted. Currently disregarded wood types could be identified as potential materials (Tables 1, 2).

References

Adedeji A, Jimoh A, Aina S (2017) Timber as a sustainable construction material; its impact on climate change and innovative development of the African continent

Akpan EI, Wetzel B, Friedrich K (2021) Eco-friendly and sustainable processing of wood-based materials. Green Chem 23(6):2198–2232. https://doi.org/10.1039/D0GC04430J

Alfredsen G, Westin M (2021) Durability of modified wood—laboratory vs field performance

Almeida G, Hernández RE (2006) Changes in physical properties of tropical and temperate hardwoods below and above the fiber saturation point. Wood Sci Technol 40(7):599–613. https://doi.org/10.1007/s00226-006-0083-8

Ansell MP (2015) 1. Wood microstructure: a cellular composite. In: Ansell MP (ed) Wood composites. Woodhead Publishing, Cambridge, pp 3–26. https://doi.org/10.1016/B978-1-78242-454-3.00001-9

Asif M (2009) 2-Sustainability of timber, wood and bamboo in construction. In: Khatib JM (ed) Sustainability of construction materials. Woodhead Publishing, Cambridge, pp 31–54. https://doi.org/10.1533/9781845695842.31

Awoyemi L, Cooper PA, Ung TY (2009) In-treatment cooling during thermal modification of wood in soy oil medium: soy oil uptake, wettability, water uptake and swelling properties. Eur J Wood Prod 67(4):465. https://doi.org/10.1007/s00107-009-0346-9

Aydemir D, Gunduz G, Hakk M (2011) Investigating changes in the chemical constituents and dimensional stability of heat-treated hornbeam and Uludag fir wood, p 14

Backman AC, Lindberg KAH (2001) Differences in wood material responses for radial and tangential direction as measured by dynamic mechanical thermal analysis. J Mater Sci 36(15):3777–3783. https://doi.org/10.1023/A:1017986119559

Bajpai P (2018) Chapter 7. Properties of wood. In: Bajpai P (ed) Biermann’s handbook of pulp and paper, 3rd edn. Elsevier, New York, pp 215–232. https://doi.org/10.1016/B978-0-12-814240-0.00007-0

Baysal E, Ozaki SK, Yalinkilic M (2004) Dimensional stabilization of wood treated with furfuryl alcohol catalysed by borates. Wood Sci Technol. https://doi.org/10.1007/s00226-004-0248-2

Baysal E, Sonmez A, Colak M, Toker H (2006) Amount of leachant and water absorption levels of wood treated with borates and water repellents. Biores Technol 97(18):2271–2279. https://doi.org/10.1016/j.biortech.2005.10.044

Bekhta P, Niemz P (2003) Effect of high temperature on the change in color, dimensional stability and mechanical properties of spruce wood. Holzforschung 57(5):539–546. https://doi.org/10.1515/HF.2003.080

Blom Å, Bergström M (2005) Mycologg: a new accelerated test method for wood durability above ground. Wood Sci Technol 39(8):663–673. https://doi.org/10.1007/s00226-005-0003-3

Borůvka V, Novák D, Šedivka P (2020) Comparison and analysis of radial and tangential bending of softwood and hardwood at static and dynamic loading. Forests. https://doi.org/10.3390/f11080896

Brémaud I, Gril J, Thibaut B (2011) Anisotropy of wood vibrational properties: dependence on grain angle and review of literature data. Wood Sci Technol 45(4):735–754. https://doi.org/10.1007/s00226-010-0393-8

Brischke C, Alfredsen G (2020) Wood–water relationships and their role for wood susceptibility to fungal decay. Appl Microbiol Biotechnol 104(9):3781–3795. https://doi.org/10.1007/s00253-020-10479-1

British Standards Institution (1999) Durability of wood and wood-based products: natural durability of solid wood. Part 1. Guide to the principles of testing and classification of the natural durability of wood. BSI, London

Broda M (2020) Natural compounds for wood protection against fungi—a review. Molecules 25(15):3538. https://doi.org/10.3390/molecules25153538

Cahyono TD, Darmawan W, Priadi T, Iswanto AH (2020) Flexural properties of heat-treatment samama (Anthocephalus macrophyllus) wood impregnated by boron and methyl metacrylate. J Korean Wood Sci Technol 48(1):76–85. https://doi.org/10.5658/WOOD.2020.48.1.76

Cai C, Javed MA, Komulainen S, Telkki V-V, Haapala A, Heräjärvi H (2020) Effect of natural weathering on water absorption and pore size distribution in thermally modified wood determined by nuclear magnetic resonance. Cellulose 27(8):4235–4247. https://doi.org/10.1007/s10570-020-03093-x

Can A, Yildiz S, Umit C, Dizman Tomak E (2010) Effects of boron impregnation and heat treatment on some physical and mechanical properties of spruce and pine wood. https://doi.org/10.13140/RG.2.1.5135.8807

Čermák P, Rautkari L, Horáček P, Saake B, Rademacher P, Sablík P (2015) Analysis of dimensional stability of thermally modified wood affected by re-wetting cycles. BioResources 10(2):3242–3253. https://doi.org/10.15376/biores.10.2.3242-3253

Chang Y-S, Han Y, Eom C-D, Jeon S, Yeo H (2019) Hygroscopic property of heat treated yellow poplar (Liriodendron tulipifera) wood. J Korean Wood Sci Technol 47(6):761–769. https://doi.org/10.5658/WOOD.2019.47.6.761

Christoforo A, Almeida T, Almeida D, Santos J, Panzera T, Rocco Lahr F (2016) Shrinkage for some wood species estimated by density. Int J Mater Eng 6:23–27. https://doi.org/10.5923/j.ijme.20160602.01

Dissanayake, DMNA, Mendis M, Halwatura R (2019) Investigation on chemical insertion and physical property changes of sunken timber; Terminalia arjuna along with River water in Sri Lanka

Dissanayake DMNA, Mendis MS, Jayasinghe GY, Halwatura RU (2018) Possible Cellular Structural and Chemical Changes of Timber Under Water

Dissanayake DMNA, Mendis MS, Jayasinghe GY, Halwatura RU (2019) Utilization of Sustainable Timber Materials for Innovative Green Building Solutions.

Dissanayake DMNA, Mendis MS, Jayasinghe GY, Halwatura RU (2020) A study on chemical insertion and physical property changes of sunken timber; Terminalia arjuna along with river water in Sri Lanka. IOSR J Environ Sci Toxicol Food Technol (IOSR-JESTFT) 14(1): 54–69

Deka M, Saikia CN (2000) Chemical modification of wood with thermosetting resin: effect on dimensional stability and strength property. Biores Technol 73(2):179–181. https://doi.org/10.1016/S0960-8524(99)00167-4

Devi RR, Maji TK (2012) Chemical modification of simul wood with styrene–acrylonitrile copolymer and organically modified nanoclay. Wood Sci Technol 46(1):299–315. https://doi.org/10.1007/s00226-011-0406-2

Devi RR, Ali I, Maji TK (2003) Chemical modification of rubber wood with styrene in combination with a crosslinker: effect on dimensional stability and strength property. Biores Technol 88(3):185–188. https://doi.org/10.1016/S0960-8524(03)00003-8

Ding W-D, Koubaa A, Chaala A (2012) Dimensional stability of methyl methacrylate hardened hybrid poplar wood. BioResources 7(1), Art. no. 1

Donaldson LA, Cairns M, Hill SJ (2018) Comparison of micropore distribution in cell walls of softwood and hardwood xylem. Plant Physiol 178(3):1142–1153. https://doi.org/10.1104/pp.18.00883

Dong Y, Wang K, Li J, Zhang S, Shi SQ (2020) Environmentally benign wood modifications: a review. ACS Sustain Chem Eng 8(9):3532–3540. https://doi.org/10.1021/acssuschemeng.0c00342

Emmerich L, Bollmus S, Militz H (2019) Wood modification with DMDHEU (1.3-dimethylol-4.5-dihydroxyethyleneurea)—state of the art, recent research activities and future perspectives. Wood Mater Sci Eng 14(1):3–18. https://doi.org/10.1080/17480272.2017.1417907

Esteban L, Gril J, Palacios P, Casasús A (2005) Reduction of wood hygroscopicity and associated dimensional response by repeated humidity cycles. Ann for Sci. https://doi.org/10.1051/forest:2005020

Esteves B, Nunes L, Pereira H (2011) Properties of furfurylated wood (Pinus pinaster). Eur J Wood Prod 69(4):521–525. https://doi.org/10.1007/s00107-010-0480-4

Falk RH (2009) Wood as a sustainable building material. For Prod J 59(9):6–12

Fukasawa Y, Osono T, Takeda H (2011) Wood decomposing abilities of diverse lignicolous fungi on nondecayed and decayed beech wood. Mycologia 103(3):474–482. https://doi.org/10.3852/10-246

Gaff M et al (2019) Plasticity properties of thermally modified timber in bending: the effect of chemical changes during modification of European oak and Norway spruce. Compos Part B Eng 165:613–625. https://doi.org/10.1016/j.compositesb.2019.02.019

Gezici-Koç Ö, Erich SJ, Huinink HP, Van der Ven LG, Adan OC (2017) Bound and free water distribution in wood during water uptake and drying as measured by 1D magnetic resonance imaging. Cellulose 24(2):535–553

Ghorbani M, Aghmashadi ZA, Amininasab SM, Abedini R (2019) Effect of different coupling agents on chemical structure and physical properties of vinyl acetate/wood polymer composites. J Appl Polym Sci 136(19):47467. https://doi.org/10.1002/app.47467

Giridhar N, Pandey KK, Prasad BE, Bisht SS, Vagdevi HM (2017) Dimensional stabilization of wood by chemical modification using isopropenyl acetate. Maderas Cienc Tecnol. https://doi.org/10.4067/S0718-221X2017005000002

González-Laredo RF, Rosales-Castro M, Rocha-Guzmán NE, Gallegos-Infante JA, Moreno-Jiménez MR, Karchesy JJ (2015) Preservación de la madera usando productos naturales. MYB. https://doi.org/10.21829/myb.2015.210427

Hadi YS, Massijaya MY, Zaini LH, Pari R (2019) Physical and mechanical properties of methyl methacrylate-impregnated wood from three fast-growing tropical tree species. J Korean Wood Sci Technol 47(3):324–335. https://doi.org/10.5658/WOOD.2019.47.3.324

Han X, Miao X, Zheng X, Xing L, Pu J (2015) Chemical modification by impregnation of poplar wood with functional composite modifier. BioResources 10(3):5203–5214. https://doi.org/10.15376/biores.10.3.5203-5214

Hanhijärvi A (2000) Deformation properties of Finnish spruce and pine wood in tangential and radial directions in association to high temperature drying. Part IV. Modelling. Holz Als Roh- Und Werkstoff 58(4):211–216. https://doi.org/10.1007/s001070050415

Hernández RE, Pontin M (2006) Shrinkage of three tropical hardwoods below and above the fiber saturation point. Wood Fiber Sci 474–483

Herrera-Builes JF, Sepúlveda-Villarroel V, Osorio JA, Salvo-Sepúlveda L, Ananías RA (2021) Effect of thermal modification treatment on some physical and mechanical properties of Pinus oocarpa wood. Forests 12(2):249. https://doi.org/10.3390/f12020249

Hill C (2006) Chemical modification of wood (I): acetic anhydride modification. In: Wood modification: chemical, thermal and other processes, pp 45–76. https://doi.org/10.1002/0470021748.ch3

Hill CAS (2009) Why does acetylation protect wood from microbiological attack? Wood Mater Sci Eng 4(1–2):37–45. https://doi.org/10.1080/17480270903249409

Hom SK, Ganguly S, Bhoru YU, Samani A (2020) Effect of chemical modification on dimensional stability of Pinus radiata D. Don using acetic anhydride. J for Sci 66(5):208–217. https://doi.org/10.17221/13/2020-JFS

Homan W, Tjeerdsma B, Beckers E, Jorissen A (2000) Structural and other properties of modified wood. In: World conference on timber engineering

Humar M, Lesar B, Kržišnik D (2020) Moisture performance of façade elements made of thermally modified norway spruce wood. Forests. https://doi.org/10.3390/f11030348

Ishimaru Y, Arai K, Mizutani M, Oshima K, Iida I (2001) Physical and mechanical properties of wood after moisture conditioning. J Wood Sci 47(3):185–191. https://doi.org/10.1007/BF01171220

Islam MS, Hamdan S, Rusop M, Rahman MR, Ahmed AS, Idrus MAMM (2012) Dimensional stability and water repellent efficiency measurement of chemically modified tropical light hardwood. BioResources 7(1), Art. no. 1

Jebrane M, Pichavant F, Sèbe G (2011) A comparative study on the acetylation of wood by reaction with vinyl acetate and acetic anhydride. Carbohydr Polym 83(2):339–345. https://doi.org/10.1016/j.carbpol.2010.07.035

Jones D, Sandberg D (2020) A review of wood modification globally: updated findings from COST FP1407. Interdiscip Perspect Built Environ. https://doi.org/10.37947/ipbe.2020.vol1.1

Jorge FC, Nunes L, Botelho C (2004) Boron in wood preservation: problems, challenges and proposed solutions. An overview on recent research. J Fac Sci Technol 1:3–15

Karlsson O, Sidorova E, Morén T (2011) Influence of heat transferring media on durability of thermally modified wood. BioResources. https://doi.org/10.15376/biores.6.1.356-372

Kartal SN, Yoshimura T, Imamura Y (2004) Decay and termite resistance of boron-treated and chemically modified wood by in situ co-polymerization of allyl glycidyl ether (AGE) with methyl methacrylate (MMA). Int Biodeterior Biodegrad 53(2):111–117. https://doi.org/10.1016/j.ibiod.2003.09.004

Kartal SN, Hwang W-J, Imamura Y (2007) Water absorption of boron-treated and heat-modified wood. J Wood Sci 53(5):454–457

Kartal SN, Terzi E, Yılmaz H, Goodell B (2015) Bioremediation and decay of wood treated with ACQ, micronized ACQ, nano-CuO and CCA wood preservatives. Int Biodeterior Biodegrad 99:95–101. https://doi.org/10.1016/j.ibiod.2015.01.004

Khalid M, Yusof R, Meriaudeau F (2010) A comparative study of feature extraction methods for wood texture classification. In: 2010 Sixth international conference on signal-image technology and internet based systems, pp 23–29

Khazaei J (2007) Water absorption characteristics of three wood varieties, p 12

Korkmaz O, Büyüksarı Ü (2019) Effects of moisture content on mechanical properties of micro-size oak wood, p 9

Kuciel S, Jakubowska P, Kuźniar P (2014) A study on the mechanical properties and the influence of water uptake and temperature on biocomposites based on polyethylene from renewable sources. Compos B Eng 64:72–77. https://doi.org/10.1016/j.compositesb.2014.03.026

Kutnik M (2013) Focus on the European standardization—towards a revision of the EN 350 natural durability standard: a different approach to the inherent resistance and performance of wood and wood-based materials

Lekounougou S, Kocaefe D, Oumarou N, Kocaefe Y, Poncsak S (2011) Effect of thermal modification on mechanical properties of Canadian white birch (Betula papyrifera). Int Wood Prod J 2(2):101–107. https://doi.org/10.1179/2042645311Y.0000000016

Li Y-F, Liu Y-X, Wang X-M, Wu Q-L, Yu H-P, Li J (2011) Wood–polymer composites prepared by the in situ polymerization of monomers within wood. J Appl Polym Sci 119(6):3207–3216. https://doi.org/10.1002/app.32837

Li Y, Liu Z, Dong X, Fu Y, Liu Y (2013) Comparison of decay resistance of wood and wood–polymer composite prepared by in-situ polymerization of monomers. Int Biodeterior Biodegrad 84:401–406. https://doi.org/10.1016/j.ibiod.2012.03.013

Lloyd JD, Taylor AM, Brischke C, Irby N (2020) Protecting the heartwood of wood infrastructure—improving performance with borate dual treatments. Wood Mater Sci Eng 15(6):361–367. https://doi.org/10.1080/17480272.2020.1749881

Malaga-Toboła U, Łapka M, Tabor S, Niesłony A, Findura P (2019) Influence of wood anisotropy on its mechanical properties in relation to the scale effect. Int Agrophys 33(3):337–345. https://doi.org/10.31545/intagr/110808

Mantanis GI (2017) Chemical modification of wood by acetylation or furfurylation: a review of the present scaled-up technologies. BioResources 12(2):4478–4489. https://doi.org/10.15376/biores.12.2.Mantanis

Marcot BG (2017) A review of the role of fungi in wood decay of forest ecosystems, p 32

Mascia NT, Vanalli L, Paccola RR, Scoaris MR (2010) Mechanical behaviour of wood beams with grain orientation. Mecánica Computacional 29(29), Art. no. 29. Accessed 04 Oct 2021. http://venus.ceride.gov.ar/ojs/index.php/mc/article/view/3201

Mendis MS (2018) Non-verbal communicative aspects of verandah in “walauwa” under uva province: a case study

Mendis MS, Halwatura RU, Somadeva DRK, Jayasinghe RA (2020) Spectroscopic determination of chemical elements on abundantly available five leaf types in tropics. In 9TH YSF Symposium (p. 31).

Mendis MS, Halwatura RU, Amarasekera H, Randika A (2021) Jayasinghec, Investigating the Potentials of Mango Timber as a Sustainable Construction Material, International Conference on Innovation and Emerging Technologies (ICIET), (2021, November), Faculty of Technology, University of Sri Jayewardenepura, Sri Lanka(pg 76).

Mendis MS, Halwathura R, Amarasekera H, Jayasinghe R, Somadewa R (2020) Investigating Hydroscopic Property of Historical Timber against Load Bearing: A Case Study on Ambalam (s) Sri Lanka. In Proceedings of International Forestry and Environment Symposium (Vol. 25).

Mendis MS, Abeyrathna W, Halwatura R, Amarasekara H, Somadewa R, Jayasinghe R (2022) Accumulate and Consolidate the Traditional Vernacular Timber Preservation Technologies Through a Field Survey. Available at SSRN 4033448.

Mendis MS, Halwatura RU, Somadeva DRK, Jayasinghe RA, Gunawardana M (2019b) Influence of timber grain distribution on orientation of saw cuts during application: reference to heritage structures in Sri Lanka. Case Stud Constr Mater 11:e00237. https://doi.org/10.1016/j.cscm.2019.e00237

Mendis MS, Rajapaksha M, Halwatura RU (2020a) Unleashing the potentials of traditional construction technique in bio-climatic building designs: a case of Ambalam, Sri Lanka. IJESD 11(6):298–304. https://doi.org/10.18178/ijesd.2020.11.6.1266

Mendis MS, Umesh Halwatura R (2019) Decoding the societal transitions on environmental innovation under vernacular timber construction practice in Sri Lanka. In: 2019 From innovation to impact (FITI), Colombo, Sri Lanka, 2019, pp 1–6. https://doi.org/10.1109/FITI49428.2019.9037628

Mendis M, Halwatura R (2019a) A study on most abundantly utilized timber for structural application in Sri Lanka

Mendis MS, Halwatura RU, Somadeva DRK (2018) Investigation on the significance of design elements of timber with respect to architectural and structural Engineering Aspects: Review on Ambalam in Sri Lanka. Asian Stud Int J 1:28

Mendis M, Perera H, Amarasekera H, Dharmaratne D, Jayasinghe R, Halwatura R (2020b) Preliminary investigation on ancient timber structures through microscopic analysis. In: 2020b From innovation to impact (FITI), 2020, vol 1, pp 1–5. https://doi.org/10.1109/FITI52050.2020.9424882

Menon CC (2002) Chemical modification of wood. JSIR 61(06). Accessed 26 Aug 2021. http://nopr.niscair.res.in/handle/123456789/26360

Miksic A, Myntti M, Koivisto J, Salminen L, Alava M (2013) Effect of fatigue and annual rings’ orientation on mechanical properties of wood under cross-grain uniaxial compression. Wood Sci Technol 47(6):1117–1133. https://doi.org/10.1007/s00226-013-0561-8

Mubarok M et al (2017) Feasibility study of utilization of commercially available polyurethane resins to develop non-biocidal wood preservation treatments. Eur J Wood Prod 75(6):877–884. https://doi.org/10.1007/s00107-016-1128-9

Nilsson T, Rowell R (2012) Historical wood–structure and properties. J Cult Herit 13(3):S5–S9. https://doi.org/10.1016/j.culher.2012.03.016

Olek W, Majka J, Czajkowski Ł (2013) Sorption isotherms of thermally modified wood. Holzforschung 67(2):183–191. https://doi.org/10.1515/hf-2011-0260

Ormondroyd G, Spear M, Curling S (2015) Modified wood: review of efficacy and service life testing. Proc Inst Civ Eng Constr Mater 168(4):187–203. https://doi.org/10.1680/coma.14.00072

Pan C, Ruan G, Chen H, Zhang D (2015) Toxicity of sodium fluoride to subterranean termites and leachability as a wood preservative. Eur J Wood Prod 73(1):97–102. https://doi.org/10.1007/s00107-014-0849-x

Papanicolaou GC, Kosmidou ThV, Vatalis AS, Delides CG (2006) Water absorption mechanism and some anomalous effects on the mechanical and viscoelastic behavior of an epoxy system. J Appl Polym Sci 99(4):1328–1339. https://doi.org/10.1002/app.22095

Pelit H, Budakçı M, Sönmez A (2016) Effects of heat post-treatment on dimensional stability and water absorption behaviours of mechanically densified Uludağ fir and black poplar woods. BioResources 11(2), Art. no. 2

Penvern H et al (2020) How bound water regulates wood drying. Phys Rev Appl 14(5):054051. https://doi.org/10.1103/PhysRevApplied.14.054051

Perçin O, Sofuoglu SD, Uzun O (2015) Effects of boron impregnation and heat treatment on some mechanical properties of oak (Quercus petraea Liebl.) wood. BioResources 10(3):3963–3978. https://doi.org/10.15376/biores.10.3.3963-3978

Priadi T, Orfian G, Cahyono TD, Iswanto AH (2020) Dimensional stability, color change, and durability of boron-MMA treated red Jabon (Antochephalus macrophyllus) wood. J Korean Wood Sci Technol 48(3):315–325. https://doi.org/10.5658/WOOD.2020.48.3.315

Rafsanjani A, Stiefel M, Jefimovs K, Mokso R, Derome D, Carmeliet J (2014) Hygroscopic swelling and shrinkage of latewood cell wall micropillars reveal ultrastructural anisotropy. J R Soc Interface 11(95):20140126. https://doi.org/10.1098/rsif.2014.0126

Ramage MH et al (2017) The wood from the trees: the use of timber in construction. Renew Sustain Energy Rev 68:333–359. https://doi.org/10.1016/j.rser.2016.09.107

Ringman R, Beck G, Pilgård A (2019) The importance of moisture for brown rot degradation of modified wood: a critical discussion. Forests. https://doi.org/10.3390/f10060522

Robert Welzbacher C, OttoRapp A (2007) Durability of thermally modified timber from industrial-scale processes in different use classes: results from laboratory and field tests. Wood Mater Sci Eng 2(1):4–14. https://doi.org/10.1080/17480270701267504

Rowell RM (2006) Chemical modification of wood: a short review. Wood Mater Sci Eng 1(1):29–33. https://doi.org/10.1080/17480270600670923

Rowell R, Bongers F (2015) Coating acetylated wood. Coatings. https://doi.org/10.3390/coatings5040792

Rowell RM, Ibach RE, Nilsson T (2010) Wood durability and stability without toxicity. Sustainable development in the forest products industry: Chapter 8. Porto, [Portugal]: Universidade Fernando Pessoa, pp 181–208

Sandberg K, Salin J-G (2012) Liquid water absorption in dried Norway spruce timber measured with CT scanning and viewed as a percolation process. Wood Sci Technol 46(1):207–219. https://doi.org/10.1007/s00226-010-0371-1

Sandberg D, Kutnar A, Mantanis G (2017) Wood modification technologies: a review. iForest Biogeosci for 10:895–908. https://doi.org/10.3832/ifor2380-010

Sargent R (2019) Evaluating dimensional stability in solid wood: a review of current practice. J Wood Sci 65(1):36. https://doi.org/10.1186/s10086-019-1817-1

Schmidt O (2007) Indoor wood-decay basidiomycetes: damage, causal fungi, physiology, identification and characterization, prevention and control. Mycol Prog 6:261–279. https://doi.org/10.1007/s11557-007-0534-0

Shen X, Guo D, Jiang P, Yang S, Li G, Chu F (2021) Water vapor sorption mechanism of furfurylated wood. J Mater Sci 56(19):11324–11334. https://doi.org/10.1007/s10853-021-06041-7

Shi J, Kawai Y, Avramidis S, Cai J, Dong H (2021) Water sorption hysteresis in wood near 100 °C. Holzforschung 75(1):13–21. https://doi.org/10.1515/hf-2019-0228

Shiny KS et al (2019) A new approach to wood protection: preliminary study of biologically synthesized copper oxide nanoparticle formulation as an environmental friendly wood protectant against decay fungi and termites. Maderas Ciencia y Tecnología 21(3):347–356. https://doi.org/10.4067/S0718-221X2019005000307

Sivertsen MS, Flæte PO (2012) Water absorption in coated Norway spruce (Picea abies) cladding boards. Eur J Wood Prod 70(1):307–317. https://doi.org/10.1007/s00107-011-0557-8

Stanzl-Tschegg S, Beikircher W, Loidl D (2009) Comparison of mechanical properties of thermally modified wood at growth ring and cell wall level by means of instrumented indentation tests. Holzforschung 63:443–448. https://doi.org/10.1515/HF.2009.085

Stefke B, Windeisen E, Schwanninger M, Hinterstoisser B (2008) Determination of the weight percentage gain and of the acetyl group content of acetylated wood by means of different infrared spectroscopic methods. Anal Chem 80(4):1272–1279. https://doi.org/10.1021/ac7020823

Sudeshika DMP, Mendis MS, Halwatura RU (2020a) Investigation on the mechanical property variation on timber caused due to the thermal and chemical modification. In: 2020a Moratuwa engineering research conference (MERCon), pp 78–83. https://doi.org/10.1109/MERCon50084.2020.9185330

Sudeshika DMP, Mendis MS, Halwatura RU (2020b) Investigation on the mechanical property variation on timber caused due to the thermal and chemical modification. In: 2020b Moratuwa engineering research conference (MERCon), Moratuwa, Sri Lanka, pp 78–83. https://doi.org/10.1109/MERCon50084.2020.9185330

Teischinger A (2016) Opportunities and limits of timber in construction

Teoh YP, Don MM, Ujang S (2011) Assessment of the properties, utilization, and preservation of rubberwood (Hevea brasiliensis): a case study in Malaysia. J Wood Sci 57(4):255–266. https://doi.org/10.1007/s10086-011-1173-2

Thibaut B, Gril J, Fournier M (2001) Mechanics of wood and trees: some new highlights for an old story. Comptes Rendus De L’académie Des Sciences Series IIB Mechanics 329(9):701–716. https://doi.org/10.1016/S1620-7742(01)01380-0

Thybring EE, Fredriksson M (2021) Wood modification as a tool to understand moisture in wood. Forests 12(3):372. https://doi.org/10.3390/f12030372

Thybring EE, Kymäläinen M, Rautkari L (2018) Experimental techniques for characterising water in wood covering the range from dry to fully water-saturated. Wood Sci Technol 52(2):297–329. https://doi.org/10.1007/s00226-017-0977-7

Tomak ED, Hughes M, Yildiz UC, Viitanen H (2011) The combined effects of boron and oil heat treatment on beech and Scots pine wood properties. Part 1: Boron leaching, thermogravimetric analysis, and chemical composition. J Mater Sci 46(3):598–607. https://doi.org/10.1007/s10853-010-4859-8

Tomak DE, Yildiz CÜ, Can A (2010) Treatment of scots pine wood with oil in water and water in oil emulsion systems: effects on boron leaching and water absorption. Working paper. Accessed 09 Sep 2021. https://acikerisim.bartin.edu.tr/handle/11772/168

Tsapko Y, Bondarenko O, Horbachova O, Mazurchuk S (2021) Research of the process of water absorption by thermally modified wood. IOP Conf Ser Mater Sci Eng 1164(1):012030. https://doi.org/10.1088/1757-899X/1164/1/012030

Usta İ, Guray A (2000) Comparison of the swelling and shrinkage characteristics of corcisan pine (Pinus nigra var. mantima), p 4

Van Acker J et al (2003) Biological durability of wood in relation to end-use. Holz Roh Werkst 61(1):35–45. https://doi.org/10.1007/s00107-002-0351-8

van Meel PA, Erich SJF, Huinink HP, Kopinga K, de Jong J, Adan OCG (2011) Moisture transport in coated wood. Prog Org Coat 72(4):686–694. https://doi.org/10.1016/j.porgcoat.2011.07.011

Wang X et al (2018) Effects of thermal modification on the physical, chemical and micromechanical properties of Masson pine wood (Pinus massoniana Lamb.). Holzforschung 72(12):1063–1070. https://doi.org/10.1515/hf-2017-0205

Williams LH (1996) Borate wood-protection compounds: a review of research and commercial use. APT Bull J Preserv Technol 27(4):46–51. https://doi.org/10.2307/1504564

Xie Y, Fu Q, Wang Q, Xiao Z, Militz H (2013) Effects of chemical modification on the mechanical properties of wood. Eur J Wood Prod 71(4):401–416. https://doi.org/10.1007/s00107-013-0693-4

Xu W, Winistorfer PM, Moschler WW (1996) A procedure to determine water absorption distribution in wood composite panels. Wood Fiber Sci 28(3), Art. no. 3

Zhang J et al (2021) Fire retardancy, water absorption, and viscoelasticity of borated wood—polycarbonate biocomposites. Polymers. https://doi.org/10.3390/polym13142234

Zhou J et al (2009) Structure and magnetic properties of regenerated cellulose/Fe3O4 nanocomposite films. J Appl Polym Sci 111(5):2477–2484. https://doi.org/10.1002/app.29236

Zhou F, Fu Z, Gao X, Zhou Y (2020) Changes in the wood–water interactions of mahogany wood due to heat treatment. Holzforschung 74(9):853–863. https://doi.org/10.1515/hf-2019-0192

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mendis, M.S., Ishani, P.A.U. & Halwatura, R.U. Impacts of chemical modification of wood on water absorption: a review. J Indian Acad Wood Sci 20, 73–88 (2023). https://doi.org/10.1007/s13196-023-00309-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13196-023-00309-y