Abstract

Furfuryl alcohol has a sufficiently small molecular size, which allows impregnation into wood and can be polymerized in the cell walls. Polymerization can be accomplished using a catalyst, heat or penetrating radiation. This research illustrates a natural wood polymer composite (NWPC) that was obtained under the catalytic effect of borates. Furfuryl alcohol (FA) and borates were mixed at different ratios before treatment. When borates alone are used, they were totally leached from wood after cyclic leaching periods. However, this was not encountered with the mixture of furfuryl alcohol and borates. Furfuryl alcohol considerably improved antiswelling efficiency by about 85% for both Japanese cedar ( Cryptomeria japonica) and Scots pine ( Pinus sylvestris L.) wood specimens. Results of the leaching tests of borate indicated that boric acid readily lost its boron content in the early cycles of the leaching periods and the highest leaching rate of boron was observed at the first leaching cycle (512 ppm). When furfuryl alcohol mixed with borates, boron was released to the leaching water at slower amounts, suggesting the possibility of longer protection of treated wood in service.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In recent years, there has been a rapid increase in the application of chemicals to wooden materials in order to improve their physical and mechanical properties such as acetylation of wood hydroxyl groups, cross-linking of cellulose molecules with formaldehyde and adding bulk vinyl monomers to the cell lumen (Yalinkilic et al. 1999a; Schneider 1995; Rowell and Konkol 1987; Mathias et al. 1991; Meyers 1981).

Biodegradability of wood material is another criterion of wood treatment for longer serviceability; however, many of the effective poisonous chemicals were also questionable. Increased public concern on the environmental effect of many wood preservatives has rendered a special importance to borates as an environmentally friendly agent. Borates have several advantages as wood preservative in addition to imparting flame retardancy, providing sufficient protection against wood destroying organisms, having a low mammalian toxicity and low volatility. Moreover, they are colorless and odorless (Hafizoğlu et al. 1994; Murphy 1990; Yalinkilic et al. 1999b; Drysdale 1994; Chen et al. 1997). However, they are generally leachable from treated wood in ground contact under rainfall (FAO 1986; Yalinkilic et al. 1995a; Yalinkilic et al. 1995b). Therefore, the utilization of boron compounds is restricted for indoor conditions. Many attempts have already been made to reduce leaching of borates from treated wood through chemical fixation of boron. To achieve a long-lasting boron effect in wood, one practical approach is the chemical complexion of boron with a fixing agent capable of forming water-insoluble complexes upon dehydration in wood (Nicholas et al. 1980). Lloyd et al. (1990) reported that addition of polyols to borate solutions greatly increased the boron stability through borate/polyol chelate complexion. However, it reduced the efficacy against wood-decay fungi. The latest research has, therefore, been directed to partial fixation systems of boron in wood while conserving sufficient mobility to maintain preservative action (Pizzi and Baecker 1996; Thevenon et al. 1997; Yalinkilic et al. 1998a). Another practical approach is to physically restrict water access in wood by impregnating by hydrophobic agents to limit boron mobility without interfering with its bioactive structure. Accordingly, a number of hydrophobic agents were tested; waxes and resins only provided short-term surface protection against leaching (Peylo and Welleitner 1995; Peylo and Welleitner 1997; Su et al. 1997; Yalinkilic et al. 1997a). Murphy et al. (1995) found no significant difference in soil depletion of boron from wood treated with combined formulations of a boric acid and borax mixture dissolved in an aqueous solution of acrylic polymer containing aluminum chlorohydrate as a water repellent and wood treated only with boron. They suggested a dual treatment in which boron impregnation is followed by polymer treatment as a means of overcoming incompatibility problems. Blocking of the OH- groups of cell walls of boron-treated wood by cross-linking with formaldehyde is an attempt to reduce the water attractiveness of wood and resulted in a very limited slow-down of boron leachability. However, boron caused a remarkable decrease in the cross-linking efficacy of formaldehyde (Liu et al. 1997; Manning et al. 1997; Yalinkilic et al. 1998b; Yalinkilic et al. 1997b) and special care should be paid to this process due to the formaldehyde toxicity to human beings (Yusuf et al. 1995). Therefore, formaldehyde is a dangerous material to work with and has to be received as the same rating as phenol (Knob and Scheib 1979). It has been reported that wood can be alternatively treated with non-or low-formaldehyde agents, which have a similar cross-linking ability with the OH- groups of the cell wall (Frick et al. 1960; Hurwitz and Conlon 1958; Mehta and Mody 1960). Yusuf et al. (1995) proved the dimensionally stabilizing effects of boron addition to the reagent dimethylene dihidroxy ethylene urea, glutaraldehyde and glyoxal on wood. More recently, new wood preservatives based on protein borates have been described which greatly retard the leaching rate of boron from treated timber (Thevenon et al. 1998).

Together with improvement of the synthetic polymer industry in general, vinyl monomers in particular are widely used for wood modification, filling the capillaries, vessels and other void spaces and being polymerized in the wood structure; utilization of polymeric materials to improve wood properties has gained much attention worldwide. But, there are some restrictions of using petroleum based chemicals including vinyl monomers in terms of their high mammalian toxicity and carcinogenic effects during polymerization (Nagao et al. 2000; Renwick and Walton 2001).

Concerning environmental safety, many researches subjected vegetable based chemicals for wood protection. Pentosans, obtained as agricultural byproducts, produce furfural by acid reaction. Furfural, in turn, can be transformed into furfuryl alcohol by hydrogenation. Furfuryl alcohol is a polymerizing chemical that causes wood to swell, and most of the swelling becomes permanent by the homopolymerization (Goldstein 1969). Its molecules are sufficiently small and polar so that they enter wood cell walls. Thus, they can be cured there to form a cell wall wood polymer composite with good dimensional stability and resistance to acids and bases (Goldstein 1955; Yun 1991). Earlier works used strong acids as catalysts but they reduced mechanical properties of wood and showed significant effect on fire-resistance. It is expected that furfuryl alcohol-boron complexes can provide wood with biological resistance. According to Ozaki et al. (2001), furfuryl alcohol mixed with boron compounds showed great resistance against termites and wood decay fungi. Ryu et al. (1992) observed that the increase of weight percent gain ( WPG) in FA treated samples caused increased resistance to termite attacks. Accordingly, in the present study furfuryl alcohol as a natural plant based polymerizing agent was used with the aim of obtaining a dimensionally stable natural wood polymer composite (NWPC). Borates were also incorporated into the impregnation trial due to their catalytic effect on the polymerization of furfuryl alcohol as well as their known additional protective properties and inherited low toxic effect on mammals; in addition, they are colorless and odorless. Moreover, they have no negative effect on the mechanical properties of wood. The initial treatment with borates followed by furfuryl alcohol further increased the termite resistance and demonstrated that resistance was not influenced by WPG of furfuryl alcohol, suggesting that the termiticidal action was due to residual boron. Results were similar to those obtained from wood treated with phenolformaldehyde resin but better than those obtained from acetylated wood.

2 Materials and methods

2.1 Sample preparation

Wood specimens measuring 20 mm (tangential)×20 mm (radial)×10 mm (longitudinal) were prepared from air dried sapwood of Crytomeria japonica D. and Pinus sylvestris L. Before impregnation, all specimens were oven dried for 48 hours at 102±1°C. Then, initial and final oven-dried weights and sizes of the specimens were measured.

2.2 Chemicals and treatment conditions

Furfuryl alcohol was pure laboratory type chemical. Boric acid (BA), ammonium borate (BO) and ammonium biborate (BI) were used as catalysts. All the reagents were purchased from Nacalai Tesque, Japan. Vacuum was applied for 30 min at 760 mmHg before supplying the solution into the treatment chamber followed by another 30 min at 760 mmHg diffusion period under vacuum. Impregnated wood specimens were then wrapped with aluminum foil before curing at 120°C for 12 hours.

Weight and dimensions of the wood specimens were measured before and after treatments. Fifty replicates were used for each treatment. The experimental procedure is given in Table 1. Weight percent gain ( WPG) due to chemical load was calculated from the following equation:

where W oi is the initial oven-dried weight (g) of a wood specimen before impregnation and W of is the final oven-dried weight of the treated block.

2.3 Dimensional stability

Test blocks were soaked in water and evacuated until they submerged to the bottom. They were then oven dried at 60°C for 3 days. Volumetric swelling values of both the water swollen and oven-dried states were determined using a digital micrometer (±0.01 mm). From the swelling difference between testing and control specimens, the anti-swelling efficiency ( ASE) was calculated according to the following formula:

where S u is volumetric swelling of untreated wood and S is that of treated wood.

Water absorption ( WA) of the specimens was calculated from the following equations as an index of water repellency efficiency from the initial and final wet weights after water saturation:

where W wf is the wet weight of a wood specimen after saturation with water and W oi is the initial dry weight.

Water repellency efficiency ( WRE) efficiency was calculated according to the following formula:

where W at is the water uptake levels of treated wood samples, and W ac is the water absorption of control.

2.4 Leachability test procedure

Leachability tests were conducted according to Japanese Industrial Standard JIS A 9201 (Japanese Standards Association 1991). Water leaching and evaporation were conducted for 10 cycles under ion chromatography principles (Small 1989). Wood specimens were exposed to leaching cycles in deionized water, stirred by a magnetic stirrer (400–500 rpm) at 25°C for 8 hours, and evaporation cycles in an oven at 60°C for 16 hours. After each leaching period, leachate was sampled to boron analyze with ion chromotography (IC) 500 P (Yokogawa-Hokushin Electric, Japan) equipped with an ion exclusion column. Analytical conditions included a 100 μl sample injection, 5cs5–052 t 5cs5–252 column, 40°C temperature, a 1 ml H2SO4 effluent, a flow rate of 1 ml/min, and a refractive index detector.

3 Results and discussions

3.1 Weight gains of specimens

The weight gains of specimens treated with furfuryl alcohol and furfuryl alcohol with other borates are given in Table 2.

Weight gain of Japanese cedar specimens after impregnation with furfuryl alcohol was higher than those of Scots pine specimens. Weight gain of the furfuryl alcohol (FA) treated specimens catalyzed with boric acid were lower than those catalyzed with the other boron compounds. In other words, all detectable boron was removed from the wood by water (Yalinkilic 2000). In the present study, however, small amounts of leaching was still occurring until the last leaching period with treated Scots pine specimens, according to findings in Table 2.

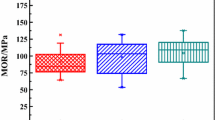

3.2 Antiswelling efficiency ( ASE), water repellent efficiency ( WRE) and water absorbtion ( WA) of wood specimens treated with FA-boron combinations

Antiswelling efficiency ( ASE), water repellent efficiency ( WRE) and water absorption ( WA) of treated wood are given in Table 3. Additions to the furfuryl alcohol changed the ASE values depending on the type of borates. However, it was not found to significantly affect ASE values. ASE values of the catalyst had yielded about 70% to 87%. ASE levels of FA provided approximately 85% ASE values. Furfuryl alcohol fixes boron but it is also possible that boron interacts with hydroxyl groups of wood, and is bonded or imprisoned by cross-linking between FA chains and wood polymers. Borate complexes can be formed with hydroxyl groups of holocellulose and lignin. Boric acid reacts with polyalcohols, particularly those that have hydroxyl groups neighboring carbon atoms forming complexes. These interactions between OH- groups and furfuryl alcohol are considered to effectively improve dimensional stability. An increase in biological resistance is also expected due to the effect of blocking enzymatic reactive cellulose sites, resulting in fungi and insects not recognizing these sites, as well as the non- availability of OH groups to form hydrogen bonds with water molecules (Ozaki 1999). Toussaint-Douvergne et al. (2000) found a new low cost boron preservation system for hazard class III, involving glycerol/glyoxal and H3BO3 mixtures, capable of improving not only the durability but also the anti-swelling efficiency of treated timber to around 37–47 % levels. Water absorption of Scots pine specimens had increased when treated with boric acid. But, the same behavior was not observed with the specimens of Japanese cedar. Water absorption of the furfuryl alcohol and borates treated wood could be reduced ten times as much as untreated wood. Yalinkilic (2000) found that water absorption levels of boron-vinyl monomer treated wood could be reduced 13 times as much as untreated wood. Styren was the most effective monomer followed by methylmetacrylate and a mixture of both treatments in reducing water absorption levels of wood. Except for ammonium biborate addition to the furfuryl alcohol, other boron-FA combinations resulted in an ASE lower than that of the solely furfuryl alcohol treatment. Since chemical bonding between the cross-linking reagents and the wood cell wall is desired (Rowell 1984), the reduction in ASE accounts for a probable decrease of the cross-linking efficacy in wood after a boron addition. On the contrary, the increase of ASE caused by a BO addition into FA may reflect the catalyzing effect of boron on establishing strong bonds between FA and wood cell walls (Knob and Scheib 1979).

3.3 Leachability test

Ion chromatography results from boron leaching tests showed that the ionic boron which appeared on chromatograms drastically decreased (Table 4). After three cyclic leaching periods, much of the boron was removed by water from specimens treated only with boric acid. In other words, all detectable boron was removed from wood. These results are in good agreement with data from earlier studies (Peylo and Welleitner 1995). The highest boron leaching value was obtained with BA treated wood in the first leaching period (512 ppm; 29.36%) and the lowest boron leaching was seen with FA mixed with BO treated wood specimens (3.42%). While wood specimens treated solely with BA readily lost its boron content at early leaching cycles, FA treatment resulted in less boron release into water. Slowed boron release may suggest the possibility of a longer term protection in service since controlled migration of free, bioactive boron molecules to the wet wood sites could remain effective and extend the service life of timber (Hafizoglu et al. 1994). Leaching rates showed that FA mixed with BA was the most effective treatment in terms of slowing the boron leaching rate after 10 leaching cycles (2.74%). When wood is treated by furfuryl alcohol, FA probably occupies the active cell wall sites promoting cross-linkings. The addition of boron in the form of boric acid and ammonium borates was used to discover an improved way of fixing boron in complex form with a cross-linked polymer. The use of furfuryl alcohol increases the dimensional stability of wood and also promotes its bulking. It is expected that furfuryl alcohol-boron complexes increase boron fixation in wood, but do not entirely halt is mobility, since boron is an effective fungicide and insecticide only when it is free and uncomplexed (Peylo and Willeitner 1995). Liang et al. (2001) found that after ten cyclic leaching periods, the boron retention of C. japonica wood specimens treated with 0.5% tetraphenylborate salt was reduced by 60%, and in specimens treated with 1% tetraphenylborate salt, the boron retention was reduced by 47%. Yalinkilic et al. (1998c) reported that vinyl monomers such as styren and methylmetacrylate mixed with boric acid treated wood specimens had a five times lesser boron release into water compared to those treated with solely boric acid. But, since the total amount of boron was lower for boron-monomer treated wood in comparison with that of solely boric acid treated wood, boron leaching was likely to continue below the detection limit in the later cycles of leaching. In another study conducted by Yalinkilic et al. (1999a), it is noteworthy that high concentrations of boron in the first cycle leachate of the compressed wood polymer composites (CWPCs) are likely due to the boron deposited at the wood surface or located in the lumens and, after leaching cycles, the highly controlled nature of the boron release from the CWPCs was shown. Our results are in good agreement with these results.

Therefore, marked decline in the boron concentration, gradual leaching levels and presence of equilibrated amounts in the successive leachates showed the highly controlled nature of the boron release from NWPCs. Controlled mobility of boron in the NWPCs is favored for inhibition of any biological attack that may take place in the wet zones of wood in ground contact; whereas, boron was no longer detectable in the BA-only treated wood after three leaching periods. Because boron is known to establish oxygen bonds with OH- groups of cell walls. Boron oxygen bonds (with hydroxyl groups of lignin guaiacyl units, and in a similar manner with the wood carbohydrates) are water soluble, and hence easily leachable from treated wood (Kubel and Pizzi 1982). Although no evidence was reported of such a linkage between boron and FA after cured in wood, boron was supposed to interact with reactive sites of FA, referring to the leachability. So, boron released into the leaching water was at very low levels from wood treated with a boron-FA combination at early leaching cycles. But, since FA-boron combinations were not capable of fixing boron in wood permanently, they could retard boron mobility in wood.

4 Conclusions

Boron was added to FA with the aim of reducing boron leachability while improving biological resistance and dimensional stability of wood. Also, boron addition to FA provided high ASE levels of 70–86%. Boron in the BA-treated wood became undetectable by IC after earlier leaching periods. Nearly all of the boron was removed by BA-treated wood after three cyclic leaching periods; whereas, boron release from the obtained FA with boron combinations in a cyclic weathering process was significantly controlled compared to that for only BA treated wood. This situation may suggest a possibility of FA-boron combinations in promoting longer term protection to wood in service. However, the protective effectiveness of FA-boron combinations may be entirely eliminated with the use of boron treated timber in an extremely wet environment, even if sole FA treatments provided rather high ASE. It is necessary to determine fire properties and resistance to insect and fungi of FA-boron treatments for practical applications. As a result, the addition of compatible chemical substances to FA as catalysts seemed to be necessary to afford a satisfactory resistance to exterior conditions and decay.

References

Chen PYS, Puttmann ME, Williams LH, Stokke DD (1997) Treatment of hardwood lumber with borate preservation. Forest Prod J 47(6):63–68

Drysdale JA (1994) Boron treatments for the preservation of wood—a review of efficacy data for fungi and termites. The Intern Res Group on Wood Preservation, document IRG/WP, p 8

FAO (1986) Wood preservation manual. Mechanical Wood Products Branch, Forest Industries Division, Forestry Department, p 152

Frick JG, Andrews BAK, Reid J (1960) Effects of cross-linkage in wrinkle-resistant cotton fabrics. Textile Res J 30:495–504

Goldstein IS (1955) The impregnation of wood to impart resistance to alkali and acid. Forest Prod J 5(4):265–267

Goldstein IS (1960) Stable furfuryl alcohol impregnating solutions. Ind Eng Chem 52(1):57–58

Hafizoğlu H, Yalinkilic MK, Yildiz UC, Baysal E, Demirci Z, Peker H (1994) Utilizations of Turkey’s boron reserves in wood preservation industry. Project of the Scientific and Technical Research Council of Turkey, No TOAG-875, p 377

Hurwitz MD, Conlon LE (1958) Dialdehydes as cotton cellulose cross-linkers. Textile Res J 28:257–262

Japanese Standards Association (1991) Japanese industrial standard (JIS) A 9201. Qualitative standards and testing methods of wood preservatives. Japanese Standards Association, Tokyo

Knob A, Scheib W (1979) Chemistry and application of phenolic resins. Polymers/properties and applications. Springer, Berlin Heidelberg New York, p 269

Kubel H, Pizzi A (1982) The chemistry and kinetic behaviour of Cu-Cr-As/b wood preservatives. Part 6. Fixation of CCB in wood and physical and chemical comparison of CCB and CCA. Holzforsch Holzverw 34(5):80–86

Liang L, Takeshi F, Sadanobu K (2001) Leachability and decay resistance of tetraphenylborate salt-treated wood. Holzforschung 55:355–357

Liu X, Laks PE, Pruner MS (1997) A preliminary report on the wood preservative properties of phenylboronic acid. Forest Prod J 44(6):46–48

Lloyd JD, Dickinson DJ, Murphy RJ (1990) The probable mechanism of action of boric acid and borates as wood preservatives. International Research Group on Wood Preservation, No IRG/WP 97–40077, p 21

Manning MJ, Lloyd JD, Schoeman M (1997) The future of preservative and pesticide systems. In: Proceedings of the second international conference on wood protection with diffusible preservatives and pesticides, Proceeding No 7284, Forest Prod Society, USA, pp 157–168

Mathias L, Lee S, John R, Warren C (1991) Improvement of wood properties by impregnation with multifunctional monomers. J Appl Polym Sci 42:55–67

Mehta PC, Mody JR (1960) Reaction of dimethylol ethylene urea with cotton. Textile Res J 30:532–539

Meyers J (1981) Wood polymer materials: state of the art. Wood Sci 14(2):49–54

Murphy RJ (1990) Historical perspective in Europa. In: Hamel M (ed) Proceedings of the first international conference on wood protection with diffusible preservatives, Nashville, Tennessee, 28–30 Nov, pp 9–13

Murphy RJ, Barnes HM, Gray M (1995) Decay and soil depletion studies with polymer/boron preservatives system. Forest Prod J 45(9):77–81

Nagao T, Wada K, Kuwagata M, Ono H (2000) Effects of prenatal and postnatal exposure to styrene dimers and trimers on reproductive toxicology. Toxicol Lett 158(5):403–415

Nicholas D, Jin L, Preston AF (1980) Immediate research needs for diffusible boron preservatives. In: Proceedings of the first international conference on wood protection with diffusible preservatives. Nashville, Tennessee, 28–30 Nov, pp 121–123

Ozaki SK (1999) Effects of furfuryl alcohol combined with boron compounds treated wood. MS Thesis, Physical Institute of Sao Carlos, University of Sao Paulo

Ozaki SK, Yalinkilic MK, Imamura Y, Souza MF (2001) Effect of combined boron compounds and furfuryl alcohol treatment on termite and decay resistance in wood. In: Imamura Y (ed) High-performance utilization of wood for outdoor uses. Report on research project. Grant-in-aid for scientific research, Kyoto, pp 97–103

Peylo A, Welleitner H (1995) The problem of reducing the leachability of boron by water repellents. Holzforschung 49(3):211–216

Peylo A, Welleitner H (1997) Leaching of boron more than 3 years of field exposure. International Research Group on Wood Preservation, No IRG/WP 97–30143, Stockholm, Sweden, p 7

Pizzi A, Baecker A (1996) A new boron fixation mechanism for environmentally friendly wood preservatives. Holzforschung 50(6):507–510

Renwick AG, Walton K (2001) The use of surrogate endpoints to assess potential toxicity in humans. Toxicol Lett 120(1–3):97–110

Rowell RM (1984) Penetration and reactivity of cell wall components. In: Rowel RM (ed) The chemistry of solid wood. Advances in the chemistry series 207. American Chemical Society, pp 175–210

Rowell RM, Konkol P (1987) Treatments that enhance physical properties of wood. Gen Tech Rep, FPL-GTR-55, US Department of Agriculture, Forest Service, Forest Products Laboratory, Madison, WI, p 12

Ryu JY, Imamura Y, Takahashi, M (1992) Biological resistance of phenolic resin treated wood incorpaorating boric acid impregnation. In: Chemical modification of Lignicellulosics. Rotarua, New Zealand

Schneider MH (1995) New cell wall and cell lumen wood polymer composites. Wood Sci Technol 29:121–127

Small H (1989) Ion chromography. In: Hercules D (ed) Modern analytical chemistry series. Plenum, New York, pp 276

Su WY, Yalinkilic MK, Hata T, Imamura Y, Ishihara S (1997) Enhancement of leach and termite resistances of plywood treated with boric acid compounds. Mokuzai Gakkaishi 43(7):595–601

Thevenon M, Pizzi FA, Haluk JP (1997) Non toxic albumin and soja protein borates as ground-contact wood preservatives. Holz Roh Werkst 55(2):293–296

Thevenon MF, Pizzi A, Haluk JP (1998) Protein borates as non toxic, long-term, wide spectrum ground contact wood preservatives. Holzforschung 52(3):241–248

Toussaint-Dauvergne E, Soulounganga P, Gerardin P, Loubinoux B (2000) Glycerol/glyoxal: a new boron fixation system for wood preservation and dimensional stabilization. Holzforschung 54:123–126

Yalinkilic MK, Baysal E, Demirci Z (1995a) Effect of boron preservatives on hygroscopicty of brutia pine wood. Pamukkale University Denizli, Turkey, Engineering Science J 1(2–3):161–168

Yalinkilic MK, Baysal E, Demirci Z (1995b) Effect of boron preservatives of hygroscopicity properties of douglas fir wood. In: Proceedings of the first black sea forestry II, pp 47–60

Yalinkilic MK, Baysal E, Demirci Z (1997a) Water uptake and water-repellency of douglas fir treated with boron compounds. In: Proceedings of the XI world forestry congress, 13–22 Oct, Antalya, vol 4, p 45

Yalinkilic MK, Yoshimura T, Takahashi M, Sudiyani Y (1997b) Phenylboronic acid treatment of wood. Abstracts of 47th annual meeting of Japan wood research society, Kochi, Japan, p 420

Yalinkilic MK, Tsunoda K, Dwianto W, Inoue M, Tanaka F, Takahashi M (1998a) Effect of hot-compression of boron treated wood at radial direction on boron leachability. Proceedings of the second international wood science seminar, 6–7 Nov, Serpong, Indonesia, p 69–79

Yalinkilic MK, Yoshimura T, Takahashi M (1998b) Enhancement of the biological resistance of wood by phenylboronic acid treatment. Wood Sci 44(2):152–157

Yalinkilic MK, Tsunoda K, Takahashi M, Gezer ED, Dwianto W, Nemato H (1998c) Enhancement of biological and physical properties of wood by boric acid-vinyl monomer combination treatment. Holzforschung 52(6):667–672

Yalinkilic MK, Imamura Y, Takahashi M, Yalinkilic AC (1999a) In situ polymerization of vinyl monomers during compressive deformation of wood treated with boric acid to delay boron leaching. Forest Prod J 49(2):43–51

Yalinkilic MK, Takahashi M, Imamura Y, Gezer ED, Demirci Z, İlhan R (1999b) Boron addition to non or low formaldehyde cross-linking reagents to enhance biological resistance and dimensional stability for wood. Holz Roh Werkst 57(1):351–357

Yalinkilic MK (2000) Improvement of boron immobility in the borate treated wood and composite materials. PhD Thesis, Kyoto University, p 151

Yun RJ (1991) Improvement of biological resistance and some physical properties of wood by resin-based treatments and its application to particle board production. PhD Thesis, Kyoto University, p 110

Yusuf S, Imamura Y, Takahashi M, Minota K (1995). Biological resistance of wood chemically modified with non-formaldehyde cross-linking agents. Mokuzai Gakkaishi 41(2):163–166

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Baysal, E., Ozaki, S.K. & Yalinkilic, M.K. Dimensional stabilization of wood treated with furfuryl alcohol catalysed by borates. Wood Sci Technol 38, 405–415 (2004). https://doi.org/10.1007/s00226-004-0248-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-004-0248-2