Abstract

Poor fragmentation is one of the most side effects induced by blasting operations. Therefore, risk assessment and prediction of rock fragmentation are essential to reduce the mentioned effects. In the present study, an attempt has been made to evaluate the risk associated with rock fragmentation as well as its prediction at Sarcheshmeh copper mine, Iran, proposing the rock engineering system (RES) technique. A total number of 52 blasting events were collected and considered and the values of 10 key effective parameters in rock fragmentation were carefully measured in the mine. These 10 key parameters were only related to blasting design and rock mass properties were not considered in the analysis of this study due to some limitations regarding their measurements in the mine. The RES result showed that the level of overall risk, based on the considered blast events, is in the range of medium–high. Furthermore, it was found that the burden is the most interaction factor in the rock fragmentation. In case of rock fragmentation prediction, all of datasets were divided randomly to training and testing datasets for proposing RES model. For comparison purpose, non-linear multiple regression (NLMR) was also employed for estimating rock fragmentation. The performances of the proposed predictive models were examined according to three performance indices, i.e. coefficient of determination (R 2), root mean square error (RMSE) and variance account for (VAF). The obtained results of this study indicated that the RES is a reliable method to predict rock fragmentation with a higher degree of accuracy in comparison to NLMR model. For instance, RMSE values of 1.95 and 4.002 for testing datasets of RES and NLMR models, respectively, suggest the superiority of the RES model in predicting rock fragmentation compared to other developed model.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The ultimate objective of conducting blasting operation is to create proper rock fragmentation. However, these works have some undesirable environmental impacts such as ground vibration, airblast, flyrock and back-break (Tonnizam Mohamad et al. 2012; Monjezi et al. 2013; Marto et al. 2014; Jahed Armaghani et al. 2015a, c; Hasanipanah et al. 2015; Tonnizam Mohamad et al. 2016). Properly fragmented rocks will maintain successfulness of the subsequent operations of loading, hauling and crushing (Morin and Ficarazzo 2006). Quality of the fragmented rock shows the efficiency level of a blasting work. Hence, blasting design factors play a vital role in generating the desired rock fragmentation (Monjezi et al. 2009). According to several scholars such as Thornton et al. (2002), Monjezi et al. (2009) and Shams et al. (2015), all effective parameters on rock fragmentation can be categorized into three groups; (1) rock mass properties, (2) blast geometry and (3) explosive properties. Normally, detonation and the dynamic response of the rock are affected by rock fracture and fragmentation around a borehole (Zheming et al. 2007, 2008). Collecting all effective parameters is not possible in some occasions especially when some of them are not available or they are very difficult to measure (Monjezi et al. 2009). Therefore, sometimes, proper production of the fragmented rock seems to be difficult due to above discussion (Monjezi et al. 2009).

Several empirical models have been developed for estimating blast-induced rock fragmentation (e.g., Kuznetsov 1973; Cunningham 1983). Hjelmberg (1983) proposed as fragmentation prediction model with name of SveDeFo. He used type of rock mass and drilling pattern to predict the mean fragment size. In another study, Stagg et al. (1992) developed a model to assess distribution of fragment size using two parameters namely fracture strength and rock density. Furthermore, Roy and Dhar (1996) incorporated the effect of joint orientation in their fragmentation model. As a fact, in developing the empirical models, only one or two effective parameters on rock fragmentation such as explosive characteristics, blast-hole diameter and compressive strength were used (Bahrami et al. 2011). This fact makes these models inaccurate and unreliable.

To overcome drawbacks of empirical model, application of soft computing techniques, e.g., artificial neural network (ANN) and fuzzy system (FS) in predicting rock fragmentation has been highlighted by several researchers. A FS model was proposed to estimate rock fragmentation resulting from blasting operation of Gol-E-Gohar iron mine in the study conducted by Monjezi et al. (2009). Moreover, Bahrami et al. (2011); Sayadi et al. (2013) and Ebrahimi et al. (2015) utilized ANN technique for purpose of fragmentation prediction. Karami and Afiuni-Zadeh (2013) developed an adaptive neuro-fuzzy inference system (ANFIS) for estimating size of fragmented rock resulting from blasting. Table 1 presents results of several fragmentation studies and their utilized soft computing models.

The rock engineering systems (RES) proposed by Hudson (1992), is a multi-objective and powerful system for solving complex engineering problems. Many researchers have been applied RES model in various engineering problems especially in the field of rock mechanics. Castaldini et al. (1998) used a RES-based model to evaluate the earthquake-induced surface effects on the stability of natural slopes. In their research, neotectonics, hydrogeology, tectonics, geology, seismology, geomorphology, and soil/rock mechanics were selected and utilized. They concluded that the RES is a robust tool for evaluation of the surface effects induced by earthquake. Latham and Lu (1999) utilized RES and Bond’s comminution theory at predicting blasting results for cases where intrinsic rock properties are relatively constant. An application of RES methodology in hazard assessment of rockfalls was used in the study conducted by Zhang et al. (2004). They indicated that RES is a useful method in hazard assessment of rockfalls. A comprehensive study for failure susceptibility zoning by RES and interaction matrices (IM) methodology was presented by Ceryan and Ceryan (2008). Frough and Torabi (2013) employed RES approach and conventional statistical methods for predicting tunnel boring machine (TBM) downtimes. The results of their study revealed that the TBM downtimes values predicted by RES are much closer to the actual values compared to conventional statistical methods. An attempt has been made to propose a rock groutability index (RGI) based on the RES in the study carried out by Saeidi et al. (2013). Saffari et al. (2013) utilized the RES to categorize coal spontaneous combustion in coal regions. Based on their results, the RES is an applicable tool to categorize coal spontaneous combustion. Bahri Najafi et al. (2014) presented a RES to predict the level of risk due to out-of-seam dilution (OSD) in longwall faces. The RES model was applied by Rafiee et al. (2015) to study rock mass cavability in block caving mines. In their research, a fuzzy system was also used to optimize the RES.

In the field of blasting environmental issues, Faramarzi et al. (2013a) developed a RES model for risk assessment and prediction of back-break resulting from blasting. Furthermore, Faramarzi et al. (2014) used RES for flyrock risk analysis and also prediction of flyrock distance. Based on these studies, it was found that RES is a reliable method for risk assessment and prediction of back-break and flyrock.

In the present study, RES is selected to develop a risk assessment and predictive model for rock fragmentation produced by blasting works in Sarcheshmeh copper mine, Iran. In fact, proposing a model for risk evaluation and also prediction, is advantage of RES compared to soft computing techniques like ANN. In terms of rock fragmentation prediction, non-linear multiple regression (NLMR) was also developed for comparison purposes.

Theory and method

Rock engineering system

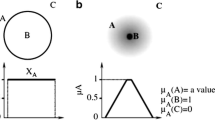

The rock engineering systems (RES) is a powerful tool for characterizing the effective parameters in the rock engineering problems (Hudson 1992). The interaction matrix device is the key element in RES approach. This matrix is used for characterizing the principal parameters and the interaction mechanisms in RES. To construct the interaction matrix, the principal parameters influencing the system (e.g., the effective parameters on rock fragmentation) are located along the main diagonal of the matrix, while the intensity of the influence of one parameter on the other parameter, which assigned with coded values, are located in the off-diagonal positions. Figures 1 and 2 illustrate a 2 × 2 interaction matrix and a general concept of the coding of the interaction matrix, respectively.

A general view of interaction matrix with two parameters (Hudson 1992)

One of the most powerful and useful procedures for the coding interaction matrix is expert semi-quantitative (ESQ), which was highlighted by Hudson (1992). According to this procedure, the interaction between each two factors is quantified using numbers zero (no interaction), one (weak interaction), two (medium interaction), three (strong interaction) and four (critical interaction) as they can be seen in Table 2 (Hudson 1992; Bahri Najafi et al. 2014).

The sum of each row in the interaction matrix is called cause (C) while the sum of each column is called effect (E). In other words, the influence of each parameter on the system and the influence of the system on each parameter are called C and E, respectively.

Also, the sum and subtraction of the C and E values, (C + E, C − E) are called interactive intensity and dominance, respectively. The parameter weighting factor (α i ) is formulated as follows (Benardos and Kaliampakos 2004):

where C i is the cause of the ith parameter, E i is the effect of the ith parameter.

Non-linear multiple regression

The regression analysis is a statistical tool that can be utilized to recognize the relationships between variables. The purpose of multiple regressions is to learn more about the relationships between several independent variables and dependent variable(s) (Ceryan et al. 2013). Non-linear multiple regression (NLMR) is a method to achieve a non-linear relationship between independent and dependent variables (Yagiz et al. 2009). In the NLMR technique, both non-linear and linear relationships, e.g., exponential, logarithmic and power can be employed. The NLMR approach has been used for the establishment of mathematical formulas to solve many geotechnical applications. Yagiz et al. (2009) used this technique for prediction of TBM performance. In the other study, a NLMR equation was suggested in the study carried out by Yagiz and Gokceoglu (2010) to estimate rock brittleness. Shirani Faradonbeh et al. (2015) utilized and developed NLMR model for prediction of back-break induced by blasting. Jahed Armaghani et al. (2015b) introduced this method for estimation of uniaxial compressive strength (UCS) of granite rock type.

Site investigation and data source

To achieve the aim of this study, Sarcheshmeh copper mine, Iran was selected. This mine is located in Kerman province, the south of Iran, at latitude of 32°6′0″ and longitude of 56°6′0″ (see Fig. 3). Considering the proved reserve of the deposit (approximately 826 Mt), Sarcheshmeh is the largest copper mine in Iran and one of the largest copper mines in the world. Sarcheshmeh’ deposit is mainly composed of folded and faulted Tertiary volcano sedimentary rocks. The geology of Sarcheshmeh deposit, first has been described by Bazin and Hubner (1969). Based on their study, Eocene andesite is the oldest host rock and the main minerals of the deposit are chalcopyrite, pyrite and malachite. Also, the average grade of copper, molybdenum, gold, silver, nickel and cobalt are 0.78, 0.03 %, 0.27, 1.14, 1.2 and 0.9 ppm, respectively. The mine is extracted by open pit mining with height and slope of the working benches of 12.5 m and 63.4°, respectively. A range of 30° to 35° was observed for angle of the overall slope. In addition, width and slope of the ramp are 30 m and 5°, respectively. In this mine, drilling and blasting method is used for excavating the rock mass. In these blasting operations, ammonium nitrate fuel oil (ANFO) and dynamite cartridges were used as main explosive and priming, respectively. Also, the diameter and depth of blast-holes are in the ranges of 152–225 mm and 12–15 m, respectively.

A general view of coding values in the row and column through each parameter to establish the C and E (Hudson 1992)

Poor fragmentation is one of the adverse effects of blasting operation. Therefore, evaluation of the level of the risk induced by poor fragmentation as well as prediction of fragmentation are important to avoid impact effects. For risk assessment and prediction of fragmentation in this case study, 52 blast events were considered, and in each blasting, based on previous researches (e.g., Faramarzi et al. 2013b) for determining the effective parameters in the intensity of fragmentation, the values of 10 key parameters including burden (m), maximum instantaneous charge (kg), specific charge (g/ton), spacing to burden ratio, stemming to burden ratio (ST/B), stiffness factor, number of rows, blast-hole inclination (°), blast-hole diameter (mm) and burden to blast-hole diameter ratio were carefully measured. Also, in all of 52 blast events, the values of D 80 of fragmentation in terms of centimeter, as representative of muck pile fragmentation size, were measured. Note that, Stiffness is the ratio of bench height and burden and also influences the resultant fragmentation (Singh and Sinha 2013). Also, rock mass stiffness controls distortion of blast-hole wall and hence the pressure developed inside the blast hole (Ghose and Joshi 2013).

The range of mentioned parameters for all of 52 blast events, carried out in Sarcheshmeh copper mine, are given in Table 3. To determine the D 80 values, image processing technique, due to its low-cost and quickly utilized, was considered. In this regard, digital images with the help of Split desktop software were used to analyze the size distributions of the fragmented rocks.

As suggested in the literature, all 52 datasets were selected randomly for training and testing to develop predictive models. The idea of utilizing some data for testing is to evaluate capability of the developed models. Swingler (1996) suggested 20 % of whole datasets for testing purpose, while this value was recommended as 25 % in the study conducted by Looney (1996). Therefore, in the present study, 80 % (42 datasets) of whole datasets (52 datasets) was chosen randomly for models development, whereas the remaining 20 % (10 datasets) of data was assigned to testing the models.

RES-based model for risk assessment and predicting rock fragmentation

Benardos and Kaliampakos (2004) presented the vulnerability index (VI) methodology for assessing geotechnical hazards for TBM tunneling operation. In their research, the VI was utilized for assessment of the risk level. In this study, a similar procedure was used for assessment of the risk level due to poor fragmentation as well as for predicting rock fragment size. To achieve the mentioned aims, as the first step, the parameters that are effective on the risk level were identified and evaluated, based on recommendations in the literature and the RES principles.

In the second step, the level of risk corresponding to poor fragmentation can be determined based on VI Benardos and Kaliampakos (2004):

where, α i and Q i are the weighting and rating value of the ith parameter, respectively, and Q max is the maximum value assigned to the ith parameter.

Considering Eq. 4, the level of overall risk corresponding to fragmentation can be determined. According to Benardos and Kaliampakos (2004), three main categories are used for the classification of the VI (see Table 4). In the third step, a relation between rock fragmentation size and VI can be proposed. The higher values of VI reveal poorer fragmentation and vice versa.

Parameters influencing rock fragmentation

Many parameters affect rock fragmentation as suggested by previous investigators. In this study, based on literature’s recommendations (e.g., Faramarzi et al. 2013b; Esmaeili et al. 2014; Shams et al. 2015) 10 key parameters were applied to define the RES. These parameters together with the parameter number are given in Table 5.

Interaction matrix

The ten main parameters (see Table 5) influencing on the rock fragment size are arranged along the main diagonal of the interaction matrix, while the intensity of the influence of one parameter on the other parameter are arranged on the off-diagonal positions. In the present study, to quantify the off-diagonal cells, the ESQ coding method, according to Hudson (1992), has been utilized. Based upon the several previous researches and the authors’ experience, the interaction matrix was constructed as given in Table 6. Considering this matrix, the values of C, E, C + E, C − E and weight of each parameter (α i ) for fragmentation aim, are given in Table 7.

Aside from that, E–C plot for the effective parameters of rock fragmentation is shown in Fig. 4. In this figure, the parameters located in the bottom and top portions of the C = E line are named dominant and subordinate parameters. In other words, dominant and subordinate parameters are dominant in the system and highly dominated by the system, respectively. As it can be seen in Fig. 4, burden, stiffness factor, blast-hole inclination, blast-hole diameter and B/D ratio are dominant parameters, while max instantaneous charge, specific charge, S/B ratio, ST/B ratio and number of rows are subordinate parameters. In addition, the values of interactive intensity (C + E) for each parameter are displayed in Fig. 5. As shown in this figure, burden has the most interaction in the system.

Rating of parameters

To determine the VI (based on Eq. 4), knowing the ranting values of the effective parameters is necessary. In this regard, a rating range of 0–5 was considered for the worst and best cases, respectively. In the other words, zero indicates the poor fragmentation, while five represents the proper fragmentation. Table 8 tabulates the ranting of the effective parameters, based on obtained results from the other researchers and experts’ view.

The values of VI obtained from all 52 blasting events, collected from Sarcheshmeh copper mine, are shown in Fig. 6. As displayed in this figure, blast No. 39 shows the maximum VI (or the maximum level of risk), while blast No. 16 has the minimum VI (or the minimum level of risk). Moreover, the overall level of risk of poor fragmentation was obtained as 54.04, which according to Table 4 is in the second category (medium to high level of vulnerability).

To predict rock fragmentation, firstly, based on 42 blasting events (training datasets), a linear regression analysis was developed (see Fig. 7) for estimating rock fragmentation using VI values as presented in Eq. 5:

where, F is D 80 of fragmentation (cm) and VI is the vulnerability index or risk level. Considering the Eq. 5 and also using the remained 10 blasting events (testing datasets), the performance of the developed RES model can be evaluated. Figure 8 illustrates the predicted rock fragmentation by RES model and the measured one for training and testing datasets. Coefficient of determination (R 2) of 0.866 and 0.859 for training and testing datasets, respectively, indicate applicability level of the RES model in predicting rock fragmentation. More details regarding the performance prediction of the RES model are given later.

Rock fragmentation estimation using NLMR

In this study, NLMR model was used and developed to introduce a predictive model for rock fragmentation prediction. In this regard, using simple regression between independent and dependent variables and also considering the same training and testing datasets, a NLMR equation was proposed and presented as in Eq. 6. In constructing the NLMR model, results of burden, max instantaneous charge, specific charge, spacing to burden ratio, stemming to burden ratio (ST/B), stiffness factor, number of rows, blast-hole inclination, blast-hole diameter and burden to blast-hole diameter ratio were used as model predictors. NLMR model was built using statistical software package of SPSS version 16 (SPSS Inc 2007).

Fragmentation value obtained from the Eq. 6 is expressed as cm. Predicted rock fragmentation by NLMR technique and measured rock fragmentation for training and testing datasets is illustrated in Fig. 9. Results of R 2 values presented in Fig. 9 express suitable performance prediction of the proposed NLMR model. More discussion regarding the evaluation of NLMR model is given in the next section.

Results and discussion

In this paper, firstly, RES was developed for the risk associated with poor fragmentation in the Sarcheshmeh copper mine. In this regard, 52 blasting events in the studies case were monitored and the values of the ten influential parameters on the fragmentation were measured. The results indicated that the burden was the most influential parameter on the fragmentation (see Table 7). Also, it was found the maximum and minimum of the risk were for blast. No 39 and 20 (risk39 = 67.72, risk20 = 38.86), respectively. As a result, the level of overall risk (riskoverall = 54.04) was in the range of medium to high level.

Secondly, RES model was utilized to predict rock fragmentation produced by blasting. For comparison purposes, NLMR technique was also used and proposed by using the same datasets. These models were constructed using ten parameters as predictors. In this study, R 2, variance account for (VAF) and root mean square error (RMSE) were calculated to check the performance prediction of the developed models. Theoretically, a predictive model is excellent when R 2 = 1, VAF = 100 % and RMSE = 0. Table 9 shows the performance prediction of the developed RES and NLMR models for training and testing datasets based on the mentioned performance indices. As shown in this table, RES model can provide higher performance prediction for estimating rock fragmentation compared to NLMR. Considering testing datasets, values of 0.859, 85.243 and 1.950 were obtained for R 2, VAF and RMSE, respectively, indicate higher degree of accuracy provided by RES model, while these values were achieved as 0.556, 55.456 and 4.002 for NLMR technique. To have a better comparison, the measured and predicted fragmentation values using RES and NLMR models are plotted for all datasets as shown in Fig. 10. This figure demonstrates that obtained results by RES model are closer to the measured rock fragmentation compared to obtained results by NLMR predictive model. It should be mentioned that the proposed predictive models in this study are designed based on the blasting parameters operated in the mentioned mine, hence, the direct use of these models for rock fragmentation prediction of other condition is not recommended.

Conclusions

The prediction of rock fragmentation and also analysis the risk associated with poor fragmentation are crucial in mining projects. In this paper, a RES was developed for risk assessment and predicting the rock fragmentation. To do this, Sarcheshmeh copper mine, Iran was selected and 52 blasting operations were investigated in the mentioned mine. The values of burden, maximum instantaneous charge, specific charge, spacing to burden ratio, stemming to burden ratio (ST/B), stiffness factor, number of rows, blast-hole inclination, blast-hole diameter and burden to blast-hole diameter ratio were considered to propose RES model. It is worth noting that all utilized parameters were related to blasting design (controllable parameters) and because of some limitations of data collection, rock mass properties were not measured and used in the analysis of this study.

In the analysis of risk assessment, based on the RES results, the ranges of VI values were obtained between 38.86 and 67.72. In the other word, the overall risk level was achieved as 54.04, which is in the second category (medium–high risk). In addition, it was found that the burden is the most interaction factor in the rock fragmentation. Note that, the use of a controlled blasting pattern such as pre-splitting, cushion blasting can be very useful to minimize the risk associated with poor fragmentation. It is also important to mention that the obtained results of this study should be used only in the Sarcheshmeh copper mine, and the direct use of it is not recommended.

In the case of rock fragmentation prediction, both RES and NLMR models proposed. It was found that RES model with a RMSE of 2.603 and 1.950, for training and testing datasets, respectively, can predict rock fragmentation values with higher level of accuracy in comparison to NLMR with a RMSE of 3.376 and 4.002, for training and testing datasets, respectively.

References

Bahrami A, Monjezi M, Goshtasbi K, Ghazvinian A (2011) Prediction of rock fragmentation due to blasting using artificial neural network. Eng Comput 27:177–181

Bahri Najafi A, Saeedi GR, Ebrahimi Farsangi MA (2014) Risk analysis and prediction of out-of-seam dilution in longwall mining. Int J Rock Mech Min Sci 70:115–122

Bazin D, Hubner H (1969) La region cuprifere a gisements porphyry de Kerman (Iran). Miner Deposita 74:200–212

Benardos AG, Kaliampakos DC (2004) A methodology for assessing geotechnical hazards for TBM tunnelling—illustrated by the Athens Metro, Greece. Int J Rock Mech Min Sci 41:987–999

Castaldini D, Genevois R, Panizza M, Puccinelli A, Berti M, Simoni A (1998) An integrated approach for analyzing earthquake induced surface effects: a case study from the Northern Apennins. Italy. J Geodyn 26(2–4):413–441

Ceryan N, Ceryan S (2008) An application of the interaction matrices method for slope failure susceptibility zoning: dogankent settlement area (Giresun, NE Turkey). Bull Eng Geol Environ 67(3):375–385

Ceryan N, Okkan U, Kesimal A (2013) Prediction of unconfined compressive strength of carbonate rocks using artificial neural networks. Environ Earth Sci 68:807–819

Cunningham CVB (1983) The Kuz-Ram model for prediction of fragmentation from blasting. 1st International Symposium on Rock Fragmentation by Blasting, pp 439–453

Ebrahimi E, Monjezi M, Khalesi MR, Jahed Armaghani D (2015) Prediction and optimization of back-break and rock fragmentation using an artificial neural network and a bee colony algorithm. Bull Eng Geol Environ. doi:10.1007/s10064-015-0720-2

Esmaeili M, Salimi A, Drebenstedt C, Abbaszadeh M, Aghajani Bazzazi A (2014) Application of PCA, SVR, and ANFIS for modeling of rock fragmentation. Arab J Geosci. doi:10.1007/s12517-014-1677-3

Faramarzi F, Mansouri H, Ebrahimi Farsangi MA (2013a) A rock engineering systems based model to predict rock fragmentation by blasting. Int J Rock Mech Min Sci 60:82–94

Faramarzi F, Ebrahimi Farsangi MA, Mansouri H (2013b) An RES based model for risk assessment and prediction of backbreak in bench blasting. Rock Mech Rock Eng 46:877–887

Faramarzi F, Mansouri H, Ebrahimi Farsangi MA (2014) Development of rock engineering systems-based models for flyrock risk analysis and prediction of flyrock distance in surface blasting. Rock Mech Rock Eng 47:1291–1306

Frough O, Torabi SR (2013) An application of rock engineering systems for estimating TBM downtimes. Eng Geol 157:112–123

Ghose AK, Joshi A (2013) Blasting in mines—New trends. Taylor & Francis Group, London, p 104

Hasanipanah M, Monjezi M, Shahnazar A, Jahed Armaghani D, Farazmand A (2015) Feasibility of indirect determination of blast induced ground vibration based on support vector machine. Measurement 75:289–297

Hjelmberg H (1983) Some ideas on how to improve calculations of the fragment size distribution in bench blasting. 1st International Symposium on Rock Fragmentation by Blasting, pp 469–494

Hudson JA (1992) Rock engineering systems: theory and practice. Ellis Horwood, Chichester

Jahed Armaghani D, Hasanipanah M, Tonnizam Mohamad E (2015a) A combination of the ICA-ANN model to predict air-overpressure resulting from blasting. Eng Comput. doi:10.1007/s00366-015-0408-z

Jahed Armaghani D, Tonnizam Mohamad E, Hajihassani M, Yagiz S, Motaghedi H (2015b) Application of several non-linear prediction tools for estimating uniaxial compressive strength of granitic rocks and comparison of their performances. Eng Comput. doi:10.1007/s00366-015-0410-

Jahed Armaghani D, Hajihassani M, Monjezi M, Mohamad ET, Marto A, Moghaddam MR (2015c) Application of two intelligent systems in predicting environmental impacts of quarry blasting. Arab J Geosci. doi:10.1007/s12517-015-1908-2

Karami A, Afiuni-Zadeh S (2013) Sizing of rock fragmentation modeling due to bench blasting using adaptive neuro-fuzzy inference system (ANFIS). Int J Min Sci Technol 23(6):809–813

Kuznetsov VM (1973) The mean diameter of the fragments formed by blasting rock. Sov Min Sci 9(2):144–148

Latham JP, Lu P (1999) Development of an assessment system for the blastability of rock masses. Int J Rock Mech Min Sci 36:41–55

Looney CG (1996) Advances in feed-forward neural networks: demystifying knowledge acquiring black boxes. IEEE Trans Knowl Data Eng 8(2):211–226

Marto A, Hajihassani M, Jahed Armaghani D, Tonnizam Mohamad E, Makhtar AM (2014) A novel approach for blast-induced flyrock prediction based on imperialist competitive algorithm and artificial neural network. Scic World J 2014(5):643715. doi:10.1155/2014/643715

Monjezi M, Rezaei M, Yazdian Varjani A (2009) Prediction of rock fragmentation due to blasting in Gol-E-Gohar iron mine using fuzzy logic. Int J Rock Mech Min Sci 46:1273–1280

Monjezi M, Rezaei M, Yazdian A (2010) Prediction of backbreak in open-pit blasting using fuzzy set theory. Expert Syst Appl 37:2637–2643

Monjezi M, Hasanipanah M, Khandelwal M (2013) Evaluation and prediction of blast-induced ground vibration at Shur River Dam, Iran, by artificial neural network. Neural Comput Appl 22:1637–1643

Morin AM, Ficarazzo F (2006) Monte Carlo simulation as a tool to predict blasting fragmentation based on the Kuz-Ram model. Comput Geosci 32:352–359

Rafiee R, Ataei M, Khalokakaie R, Jalali SME, Sereshki F (2015) Determination and assessment of parameters influencing rock mass cavability in block caving mines using the probabilistic rock engineering system. Rock Mech Rock Eng 48(3):1207–1220

Roy PP, Dhar BB (1996) Fragmentation analyzing scale-A new tool for breakage assessment. Proceedings 5th International Symposium on Rock Fragmentation by blasting-FRAGBLAST 5, Balkema, Rotterdam

Saeidi O, Azadmehr A, Torabi SR (2013) Development of a rock groutability index based on the Rock Engineering Systems (res): a case study. Indian Geotech J. doi:10.1007/s40098-013-0068-0

Saffari A, Sereshki F, Ataei M, Ghanbari K (2013) Applying Rock Engineering Systems (RES) approach to evaluate and classify the coal spontaneous combustion potential in Eastern Alborz coal mines. Int J Min Geo Eng 47:115–127

Sayadi A, Monjezi M, Talebi N, Khandelwal M (2013) A comparative study on the application of various artificial neural networks to simultaneous prediction of rock fragmentation and backbreak. J Rock Mech Geotech Eng 5(4):318–324

Shams S, Monjezi M, Johari Majd V, Jahed Armaghani D (2015) Application of fuzzy inference system for prediction of rock fragmentation induced by blasting, Arab J Geosci. doi:10.1007/s12517-015-1952-y

Shirani Faradonbeh R, Monjezi M, Jahed Armaghani D (2015) Genetic programing and non-linear multiple regression techniques to predict backbreak in blasting operation. Eng Comput. doi:10.1007/s00366-015-0404-3

Singh PK, Sinha A (2013) Rock fragmentation by blasting, fragblast 10. Taylor & Francis Group, London, p 184

SPSS Inc (2007) SPSS for Windows (Version 160). SPSS Inc, Chicago

Stagg MS, Otterness RE, Siskind DE (1992) Effects of blasting practices on fragmentation. In: Proceedings of the 33rd US. Symposium on Rock Mechanics, pp 313–322

Swingler K (1996) Applying neural networks: a practical guide. Academic Press, New York

Thornton D, Kanchibotla SS, Brunton I (2002) Modelling the impact of rock mass and blast design variation on blast fragmentation. Int J Blast Fragment 6(2):169–1168

Tonnizam Mohamad E, Hajihassani M, Jahed Armaghani D, Marto A (2012) Simulation of blasting-induced air overpressure by means of artificial neural networks. Int Rev Model Simul 5(6):2501–2506

Tonnizam Mohamad E, Jahed Armaghani D, Hasanipanah M, Murlidhar BR, Asmawisham Alel MN (2016) Estimation of air-overpressure produced by blasting operation through a neuro-genetic technique. Environ Earth Sci 75:174

Yagiz S, Gokceoglu C (2010) Application of fuzzy inference system and nonlinear regression models for predicting rock brittleness. Expert Sys Appl 37(3):2265–2272

Yagiz S, Gokceoglu C, Sezer E, Iplikci S (2009) Application of two non-linear prediction tools to the estimation of tunnel boring machine performance. Eng Appl Artif Intell 22(4):808–814

Zhang LQ, Yang ZF, Liao QL, Chen J (2004) An application of the rock engineering systems (RES) methodology in rockfall hazard assessment on the Chengdu-Lhasa highway, China. Int J Rock Mech Min Sci 41(3):833–838

Zheming X, Mohanty B, Heping Z (2007) Numerical investigation of blasting-induced crack initiation and propagation in rocks. Int J Rock Mech Min Sci 44:412–424

Zheming Z, Heping X, Mohanty B (2008) Numerical investigation of blasting-induced damage in cylindrical rocks. Int J Rock Mech Min Sci 45:111–121

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hasanipanah, M., Jahed Armaghani, D., Monjezi, M. et al. Risk assessment and prediction of rock fragmentation produced by blasting operation: a rock engineering system. Environ Earth Sci 75, 808 (2016). https://doi.org/10.1007/s12665-016-5503-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-016-5503-y