Abstract

Appropriate prediction of rock fragmentation is a vital task in the blasting operations of open pit mines. Rock fragmentation is affected by various parameters including blast pattern and rock characteristics, causing understanding the process difficult. As such, application of the robust techniques such as artificial intelligence can be utilized in this regard. In this paper, a predictive model was developed to predict rock fragmentation using fuzzy inference system (FIS) in Sarcheshmeh copper mine, Iran. For this purpose, blasting parameters including burden, spacing, hole diameter, Schmidt hammer rebound number, density of joint, powder factor, and stemming length were considered as model inputs to predict rock fragmentation (D80). In addition, by using the same data, a multiple equation was proposed with the help of multiple regression analysis (MRA). Results of coefficient of determination (R 2) between predicted and measured rock fragmentation were computed as 0.922 and 0.738 for FIS and MRA models, respectively. Moreover, root mean square error (RMSE) and variance account for (VAF) FIS model were obtained as 2.423 and 92.195 %, respectively, while these values were achieved for MRA technique as 4.393 and 73.835 %, respectively. Comparison of the performance indices of the predictive models showed the superiority of the FIS model over the regression technique. Results of sensitivity analysis indicated that burden, spacing, and powder factor are the most influential parameters on rock fragmentation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The main goal of blasting operations is to create the desired fragment size distribution leading to optimize the overall mine/plant economics (Michaux and Djordjevic 2005). Rock fragmentation is the ultimate objective of the blasting operation in open pit mines. Properly fragmented rock will maintain successfulness of the subsequent operations of loading, hauling, and crushing (Morin and Ficarazzo, 2006). Efficiency of a blast can be evaluated by the quality of rock fragmentation. Therefore, parameters related to blast design can play an important role in order to produce the desired rock fragmentation (Monjezi et al. 2009). However, it should be mentioned that the fragmentation, too, encounters with problems because many factors are out of reach of the blast engineer hence; solution seems to be difficult (Monjezi et al. 2009). According to Thornton et al. (2002), influential parameters on rock fragmentation are divided into three categories, namely explosive properties, blast geometry, and rock mass properties. Normally, detonation and the dynamic response of the rock are affected rock fracture and fragmentation around a borehole (Zheming et al. 2007, 2008).

Many attempts have been made to develop empirical models for prediction of blast-induced rock fragmentation. However, involvement of the several effective parameters has made the available models inefficient. Cunningham (1983) model is the most renowned fragmentation prediction model. To cope with weakness of the model developed by Kuznetsov (1973), he used blastability index. In the SveDeFo model (Hjelmberg, 1983), rock mass type and drilling pattern are incorporated for prediction of the mean fragment size. Roy and Dhar (1996) utilized joint orientation in their predictive model. Stagg et al. (1992) established a model to assess fragment size distribution by considering rock density and fracture strength. These empirical models, which are based on obtained data from various blasting works, cannot be implemented for different conditions (Monjezi et al. 2009). Moreover, collecting all relevant parameters is not possible in some occasions especially when some of them are not clearly understood or the effect of others is difficult to quantify. Therefore, considering these limitations, new innovative and more powerful approaches such as artificial intelligence techniques are required in order to predict rock fragmentation (Bahrami et al. 2011).

Fuzzy sets with ability of modeling logic reasoning can be implemented in capturing experiential knowledge especially when the system is semi-continuous or degree of heterogeneity is high, the case applicable while involving to rock structures. In comparison with conventional statistical method, fuzzy models can efficiently be used to solve multivariable problems (Grima and Babuska, 1999). Furthermore, these models are applicable in the systems with vague (qualitative) parameters that cannot be represented by crisp sets. In the recent years, applicability of artificial intelligence methods in the field of geotechnical engineering (Alvarez Grima et al. 2000; Sakellariou and Ferentinou 2005; Choobbasti et al. 2009; Torabi et al. 2013; Jahed Armaghani et al. 2014a; Momeni et al. 2014) and specially in mining engineering and rock mechanics has been highlighted in literature (Monjezi et al. 2011; Jahed Armaghani et al. 2014b; Marto et al. 2014; Hajihassani et al. 2014; Tonnizam Mohamad et al. 2012, 2014; Jahed Armaghani et al. 2014c, Momeni et al. 2015; Ebrahimi et al. 2015).

Among these techniques, fuzzy inference system (FIS) of Mamdani and Tagaki-Sugeno algorithms has been widely utilized. Nguyen and Ashworth (1985), Gokay (1998), Sonmez et al. (2003), and Aydin (2004) applied FIS model to develop an expert knowledge-based rock mass classification system. Chuang (1995) proposed a FIS model to predict shear strengths of soils. Bascetin (1999) and Iphar and Goktan (2006)) used fuzzy sets in selecting surface mine equipments. Jiang et al. (1997) and Deb (2003) employed fuzzy reasoning technique for the analyzing roof condition in underground mining. Grima and Babuska (1999), Gokceoglu (2002), and Topcu and Sarıdemir (2008) used FIS model to predict uniaxial compressive strength (UCS) of the rock. Klose (2002) introduced a fuzzy logic model for geological description using seismic information. Gokceoglu and Zorlu (2004) employed the fuzzy approach to predict UCS and elasticity modulus of the rock. Kayabasi et al. (2003) introduced a FIS model for indirect estimation of the deformation modulus. Nefeslioglu et al. (2006) predicted joint density for evaluating rock mass block size using fuzzy logic. Acaroglu et al. (2008) established a FIS model to simulate rock cutting process in tunnel boring machine (TBM) tunneling. Azimi et al. (2010) applied fuzzy set theory to develop a classification system for rock blastability. Yagiz and Gokceoglu (2010) applied FIS to estimate rock brittleness. Gligoric et al. (2010) used a hybrid FIS model to evaluate shaft location. Galetakis and Vasiliou (2010) implemented FIS model in selective mining. Li et al. (2010) introduced a fuzzy probability measure for predicting ground subsidence due to underground mining. Especially, in the field of blasting, Mishnaevsky and Schmauder (1996) successfully utilized fuzzy set theory to describe blast-induced damage extent in the heterogeneous rocks. Moreover, Wu et al. (1999) constructed a fuzzy probability model to simulate rock mass condition under explosive impact. Furthermore, Monjezi et al. (2009) used FIS to predict rock fragmentation induced by blasting. In addition, Monjezi et al. (2010a, b) employed the same approach for predicting blast-induced back-break. A FIS model was developed by Rezaei et al. (2011) to predict flyrock. They compared the FIS results with conventional statistical models and showed the higher efficiency of the developed FIS model compared to statistical models.

In this paper, a FIS model was developed to predict rock fragmentation resulting from blasting operations in the Sarcheshmeh copper mine, Iran. For comparison purpose, multiple regression analysis was also employed to demonstrate capability of the FIS model in predicting rock fragmentation.

FIS

The fuzzy set theory was originally introduced by Zadeh (1965). In fact, this theory provides a mathematical (satisfactorily approximation) solution for complex decision problems with subjective, incomplete and imprecise information which cannot be easily described with classical methods (Zimmermann 1992). In this method, any type of information ranging from interval-valued numerical data to linguistic expressions can be processed (Dubois and Prade 2000). In the recent years, there is an increasing interest in obtaining fuzzy models from experimental or measured data. As compared to the classic sets, fuzzy sets are more applicable to reflect the real world and even the fuzziness of human decision can be taken into account (Monjezi et al. 2010a, b; Rezaei et al. 2011).

In the classic or ordinary sets, membership of an element is crisp; hence, an element belongs to or does not belong to a set. In these sets, a unique membership function is sufficient to describe all of the members. But, in the fuzzy sets which are generalization of the ordinary sets, there are no sharp boundaries and an element can be a member of a set with a specific degree ranging the interval [0, 1] (Iphar and Goktan 2006) (see Fig. 1).

The process of determining membership functions for fuzzy variables is defined as fuzzification. In this process, individual inputs are converted to degrees of membership by selecting an appropriate membership function. Membership function selection is performed according to relevant expert’s experiences (Yagiz and Gokceoglu 2010). There exist various types of membership functions such as triangular, trapezoidal, piecewise-linear, Gaussian, bell-shaped, etc. In the fuzzy sets, linguistic expressions of the uncertainties such as “very low,” “low,” “medium,” “high,” and “very high” are represented mathematically with the help of membership functions.

FIS is a robust computing system with capabilities such as classification and decision analyses (Galetakis and Vasiliou 2010). The system basically consisted of three main components, namely database, rule base, and reasoning mechanism. In the rule base construction, in order to solve the problem, a number of rules have to be selected. On the other hand, database is implemented for defining membership functions, and finally, reasoning mechanism is employed to generate logic outputs. A FIS model can be constructed by fuzzy rules (relationships of inputs and outputs parameters) in order to describe complex and uncertain vague systems. In a rule-based model, fuzzy propositions are replaced by implication functions or fuzzy if-then rules (Grima 2000). A rule-based model with the ability of combining experts’ knowledge and numerical data can be considered as the key component of a FIS model (Grima 2000; Iphar and Goktan 2006). The process of combining the individual consequents into a single fuzzy set or final consequent is called aggregation of rules. This process can be performed using maximum operator. The most widely employed FIS models in the aggregation process are as follows:

-

Mamdani fuzzy model

-

Takagi–Sugeno–Kang fuzzy (TSK) model

-

Tsukamoto fuzzy model

-

Singleton fuzzy model

Among these models, Mamdani is considered as one of the most commonly applied algorithms in the fuzzy logic (Sonmez et al. 2003; Aydin 2004; Iphar and Goktan 2006). Mamdani and Assilian (1975) indicated that fuzzy sets and fuzzy logic can provide a totally unstructured set of linguistic heuristics into a structured algorithm. General form of the Mamdani “if-then” rule structure is given below:

where k represents the rule number, and x i and y are the input and output variables, respectively (Sonmez et al. 2003).

There exist various composition methods of fuzzy relations but max–min composition is the most frequently utilized method. A diagram of a Mamdani model with two-rule is shown in Fig. 2. Base on this figure, overall system output “z” which is subjected to two crisp inputs “x” and “y” can be seen. For each rule, using the minimum operator, consequent fuzzy set is truncated considering the minimum of the antecedent fuzzy sets.

A diagram of Mamdani FIS (Jang et al. 1997)

The final step of a FIS model procedure is defuzzification in which a representative crisp value is obtained from a fuzzy set. Among many methods of defuzzification such as centroid of area (COA), smallest of maximum, and mean of maximum, COA is the most extensively used method (Grima 2000). In the COA technique, crisp value is obtained as follows:

where Z *COA represents the crisp value of output (“z”), and μ A(z) is the aggregated output membership function (Iphar and Goktan 2006).

Data collection and site investigation

In this study, Sarcheshmeh copper mine which is located in Kerman Province, Iran was investigated to predict rock fragmentation induced by blasting. Sarcheshmeh porphyry deposit is located in an elongated NNW–SSE range extending from Turkey to the southeast of Iran in Baluchestan Province. It is mainly composed of folded and faulted Tertiary volcano-sedimentary rocks. Figure 3 indicates location of the Sarcheshmeh copper mine in Iran.

The deposit has an elliptical shape with diameters of 2,300 and 1,200 m. The host rocks are Eocene andesite and mineralized grandiorite. Waste is mainly composed of hornblende, feldspar, and biotite porphyritic rocks. The mine production is 40,000 t/day, and average grade of primary crusher feed is 1.1 %. In the Sarcheshmeh blasting operations, mostly blast holes of 228 and 251 mm with length of 15 m were vertically drilled with the help of three-cone bits. Detonating cord is used for initiation, and ammonium nitrate and fuel oil (ANFO) with specific gravity of 0.85–0.95 g/cm3 is utilized as the main explosive material. Delay time between the first and second row is 80 ms, whereas it is 50 ms between the other rows.

Evaluation of the fragmentation by image processing is a low-cost and quick technique. In this study, size distributions of the fragmented rocks were analyzed using digital images with the help of Split Desktop software. In this regard, a number of photographs were taken after each blast and during loading of the muck pile. A scaling device of known dimensions has to be placed in each view to reference the sizing. Figure 4 shows a sample photo prepared for the process. In addition, Fig. 5 displays output of the employed software, i.e., size distribution curve.

A number of 185 datasets were prepared from the Sarcheshmeh mine blasting operations. The data was collected from benches with various rock strength and jointing properties. Table 1 lists input parameters of several studies of rock fragmentation prediction. According to this table, a wide range of input parameters (e.g., spacing, burden, powder factor, stemming, hole diameter, and hole depth) was utilized to solve the problem of rock fragmentation. In addition, for prediction of rock fragmentation empirically, many input parameters such as explosive charge, powder factor, blastability constant, hole depth, and specific charge should be used. Based on above discussion, performing several input parameters may solve rock fragmentation problem. Hence, burden, spacing, hole diameter, Schmidt hammer rebound number, density of joint, powder factor, and stemming length were measured and used in the modeling. The input–output variables along with their respective limit values are presented in Table 2. According to this table, overall range of powder factors in these operations was between 150 and 180 g/t, whereas the exact range was between 136.40 and 240.14 g/t. The maximum measured stemming length (fine gravel) was 8 m. Generally, design of holes was like rhomb with distance (B × S) of 6 m × 8 m in the rock deposit. Maximum and minimum number of holes in these operations was 81 and 16, respectively. In this study, L-type Schmidt’s hammer was used for estimation of rock surface strength. The procedure suggested by ISRM (2007) was used to conduct Schmidt hammer test. The values of 10 and 49.2 were measured as the minimum and maximum values of Schmidt hammer rebound number, respectively.

Empirical predictors for fragmentation prediction

In order to demonstrate the capability of the empirical predictors, the most popular empirical predictors were utilized to predict rock fragmentation (D50), as shown in Table 3. In Kuznetsov model, A presents the rock factor (very soft rocks (A = 3); soft rocks (A = 5); medium rocks (A = 7); hard rocks (A = 13)), q depicts the powder factor (kg/m3), Q presents the explosive charge in a blast hole (kg), and S ANFO depicts the relative weight of explosive that determine D50 (cm). In the SveDeFo model, B is the burden (m), S is the spacing (m), L is the blast hole depth (m), T is the stemming length (m), CE is the specific charge (kg/m3), S′ is the blastability constant (very jointed and fissured rock (S′ = 0.6); jointed rock (S′ = 0.55); relatively homogeneous rock (S′ = 0.45); normal rock with hair cracks (S′ = 0.4)), and C is the rock constant (normally in the range of 0.3–0.5) that determine D50 (cm).

The correlations between the predicted and actual values of D50 were determined using the mentioned equations, and relevant results are displayed in Figs. 6 and 7. As shown in these figures, coefficient of determination (R 2) values of 0.262 and 0.459 for Kuznetsov and SveDeFo models, respectively, reveals poor prediction capabilities of these models. Additionally, root mean square error (RMSE) values were obtained as 8.820 and 12.541 for Kuznetsov and SveDeFo, respectively. Results of empirical equations show that there is a need to develop new models with higher accuracy for prediction of rock fragmentation. Therefore, a FIS model is developed to estimate rock fragmentation as described in the following section.

Fuzzy model for fragmentation prediction

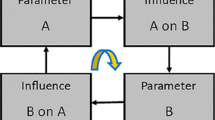

A Mamdani algorithm-based fuzzy model was developed for prediction of rock fragmentation in the Sarcheshmeh copper mine. Burden, spacing, hole diameter, Schmidt rebound number, density of joints, powder factor, and stemming length were considered as model inputs (dependent variables) to predict rock fragmentation as model output (independent variable). The input and output parameters in the developed FIS model are depicted in Fig. 8. As mentioned earlier, fuzzification of the input/output variables is performed using an appropriate membership function. As the most applicable membership functions, triangular and trapezoidal were utilized for fuzzification in this study (Monjezi et al. 2009; Monjezi et al. 2010a, b; Rezaei et al. 2011). Here, the linguistic variables for some parameters were set as low (L), medium (M), and high (H) and for other parameters were assigned as very low (VL), low (L), medium (M), high (H), and very high (VH). It should be noted that the selection of membership degrees for inputs is according to field observations and engineering experience. The assessment of membership function number was usually obtained based on the experience of fuzzy expert in addition to trial-and-error method. It can be said that insufficient rules can cause “underfitting,” whereas excessive rules can result in “overfitting.” In the underfitting, the requisite accuracy of the modeling is not achieved, whereas in the overfitting, the fuzzy model performance would not be real because instead of realizing relationship between the patterns, fuzzy inference system just remembers the patterns. Accordingly, fuzzy experts can realize the optimum number of rules based on their experiences. Figures 9, 10, 11, 12, 13, 14, and 15 show membership functions of model inputs. Moreover, Fig. 16 displays membership function of model output. In this study, a total of 150 rules were employed to develop the rule base of the Mamdani fuzzy model. Based on the variety parameter interval in the available database for constructing of the fuzzy models and the expert experiences, the number of membership functions can be variable. Considering the number of membership functions, all of the possible rules are not required in the model construction due to overlap of some rules and overfitting considerations. However, the optimum number of membership functions and relevant rules can be obtained based on the experience of fuzzy expert. Based on the complexity of the problem, the aggregation method is selected. In this research, the Mamdani aggregation algorithm which is one of the most used FIS to apply in complex engineering geological problems was utilized. Several samples of fuzzy rules implemented in the modeling can be seen in Table 4. As the last step of model development (defuzzification), converting of the obtained fuzzy values into crisp (numeric) values was performed using COA method. The rule viewer and fuzzy reasoning mechanism of the MATLAB environment is shown in Fig. 17. The trial-and-error method is used for selecting the better type of fuzzification and defuzzification methods in this research. Precise estimation of rock fragmentation is possible when input parameters are given to the proposed fuzzy model. Based on Fig. 17, when input parameters are B = 5 m, S = 6 m, D = 152 mm, E = 45, J = 102 cm, PF = 188 g/t, and ST = 59 m, model output or D80 of the rock fragmentation would be 34.6 cm, which is very identical to the real fragmentation obtained in the mine that performed blasting operation.

Multiple regression analysis

Multiple regression analysis (MRA) is utilized to establish relationship between independent and dependent variables. By this, parameters of a function which is best fitted to a set of data observations are determined. In the statistics, there exist two main regression analyses, i.e., simple and multiple. MRA can be implemented to achieve the best-fit equation when there is more than one independent or input parameter.

Here, rock fragmentation (D80) is set to be the product of the seven parameters (i.e., burden, spacing, hole diameter, Schmidt rebound number, density of joint, powder factor, and stemming length). The statistical software package SPSS 11.5 was used to propose a predictive model for estimation of rock fragmentation (see Eq. 2). Additionally, Table 5 presents statistical information regarding the developed predictive model.

where F is D80 of fragmentation, B is burden (m), S is spacing (m), D is hole diameter (mm), E is Schmidt rebound number, J is density of joint (cm), PF is powder factor (g/t), and ST is stemming length (m).

Results and discussion

In this study, 185 results of rock fragmentation (D80) obtained from Sarcheshmeh mine were predicted through FIS and MRA techniques. In order to have a comprehensive comparison between the performance of the FIS and MRA models, variance account for (VAF), RMSE, and R 2 were selected as they can be seen in Eqs. 3–5, respectively.

where var = variance, y i = the measured value, y i ^ = the predicted value, N = the number of samples, and y a^ and y a are the averages of prediction and measured sets, respectively. The model will be excellent if the VAF is 100, RMSE is 0, and R 2 is 1.

The graphs of the estimated rock fragmentation (D80) using the MRA and FIS approaches against the measured rock fragmentation (D80) for testing datasets are displayed in Figs. 18 and 19, respectively. As indicated in these figures, FIS model can provide higher performance capacity for prediction of D80 compared to the MRA technique. The R 2 of the FIS model equal to 0.901 suggests the superiority of the FIS model in predicting D80, while this value is 0.727 for MRA technique.

Performance indices obtained by predictive models for all 185 datasets are shown in Table 6. As shown in this table, considering results of RMSE, VAF, and R 2, it was found that performance capacities of the FIS predictive model are higher than the MRA model. It can be concluded that the FIS model outperforms the MRA technique in predicting rock fragmentation.

Sensitivity analysis

Sensitivity analysis is a technique to evaluate the most effective input parameters on output(s). To apply this, the cosine amplitude method can be utilized (Yang and Zang 1997). This method is given in the following equation:

where x i and x j represent input and output parameters, respectively, and n is the number of all datasets. The strengths of the relations between input and output parameters are shown in Table 7. According to this table, burden, spacing, and powder factor are the most influential parameters on D80.

Conclusion

In this paper, a FIS model was efficiently developed for prediction of rock fragmentation in the blasting operations of a copper mine by encountering probable uncertainties. In this regard, blasting parameters as well as rock fragmentation of 185 blasting works were measured in Sarcheshmeh copper mine, Iran. To compare performance of the fuzzy model, MRA technique was also applied. Developing of both the predictive models was fulfilled using the same datasets. The mentioned predictive models were constructed using seven input parameters (i.e., burden, spacing, hole diameter, Schmidt rebound number, density of joint, powder factor, and stemming length) to predict rock fragmentation (D80). It was observed that the fuzzy model efficiency is considerably better than the statistical model. R 2, RMSE, and VAF for the FIS model were calculated as 0.922, 2.423, and 92.195 %, respectively, while these values for MRA technique were computed as 0.738, 4.393, and 73.835 %, respectively. Although all proposed methods in this study are applicable in predicting rock fragmentation, FIS model can provide higher performance capacity compared to MRA technique. Results of sensitivity analysis indicated that burden, spacing, and powder factor are the most influential parameters on rock fragmentation.

References

Acaroglu O, Ozdemir L, Asbury B (2008) A fuzzy logic model to predict specific energy requirement for TBM performance prediction. Tunnel Undergr Sp Technol 23:600–608

Alvarez Grima M, Bruines PA, Verhoef PNW (2000) Modeling tunnel boring machine performance by neuro-fuzzy methods. Tunnel Undergr Sp Technol 15(3):259–269

Aydin A (2004) Fuzzy set approaches to classification of rock masses. Eng Geol 74:227–245

Azimi Y, Osanloo M, Aakbarpour-Shirazi M, AghajaniBazzazi A (2010) Prediction of the blastability designation of rock masses using fuzzy sets. Int J Rock Mech Min Sci 47:1126–1140

Bahrami A, Monjezi M, Goshtasbi K, Ghazvinian A (2011) Prediction of rock fragmentation due to blasting using artificial neural network. Eng Comput 27:177–181

Bascetin A (1999) Optimal equipment selection in open-pit mines. Ph.D. thesis, Istanbul Technical University, Istanbul, [In Turkish]

Choobbasti AJ, Farrokhzad F, Barari A (2009) Prediction of slope stability using artificial neural network (case study: Noabad, Mazandaran, Iran). Arab J Geosci 2(4):311–319

Chuang PH (1995) Use of fuzzy sets for evaluating shear strength of soils. Comput Geotech 17(4):425–446

Cunningham CVB (1983) The Kuz-Ram model for prediction of fragmentation from blasting. 1st International Symposium on Rock Fragmentation by Blasting, pp 439–453

Deb D (2003) Analysis of coal mine roof fall rate using fuzzy reasoning techniques. Int J Rock Mech Min Sci 40:251–257

Dubois D, Prade H (2000) Fundamentals of fuzzy sets. Kluwer, Norwell, MA, p 647

Ebrahimi E, Monjezi M, Khalesi MR, Jahed Armaghani D (2015) Prediction and optimization of back-break and rock fragmentation using an artificial neural network and a bee colony algorithm. Bull Eng Geol Environ DOI. doi:10.1007/s10064-015-0720-2

Galetakis M, Vasiliou A (2010) Selective mining of multiple-layer lignite deposits. A fuzzy approach. Expert Syst Appl 37:4266–4275

Gligoric Z, Beljic C, Simeunovic V (2010) Shaft location selection at deep multiple orebody deposit by using fuzzy TOPSIS method and network optimization. Expert Syst Appl 37:1408–1418

Gokay MK (1998) Fuzzy logic usage in rock mass classifications. J Chamber Min Eng Turkey 37(4):3–11

Gokceoglu C (2002) A fuzzy triangular chart to predict the uniaxial compressive strength of the Ankara agglomerates from their petrographic composition. Eng Geol 66:39–51

Gokceoglu C, Zorlu K (2004) A fuzzy model to predict the uniaxial compressive strength and the modulus of elasticity of a problematic rock. Eng Appl Artif Intel 17:61–72

Grima MA (2000) Neuro-fuzzy modeling in engineering geology. A.A. Balkema, Rotterdam

Yang Y, Zang O (1997) A hierarchical analysis for rock engineering using artificial neural networks. Rock Mech Rock Eng 30:207–222

Grima MA, Babuska R (1999) Fuzzy model for the prediction of unconined compressive strength of rock samples. Int J Rock Mech Min Sci 36:339–349

Hajihassani M, Jahed Armaghani D, Marto A, Tonnizam Mohamad E (2014) Ground vibration prediction in quarry blasting through an artificial neural network optimized by imperialist competitive algorithm. Bull Eng Geol Environ. doi:10.1007/s10064-014-0657-x

Hjelmberg H (1983) Some ideas on how to improve calculations of the fragment size distribution in bench blasting. 1st International Symposium on Rock Fragmentation by Blasting, pp 469–494

Iphar M, Goktan RM (2006) An application of fuzzy sets to the diggability index rating method for surface mine equipment selection. Int J Rock Mech Min Sci 43:253–266

ISRM (2007) The complete ISRM suggested methods for rock characterization, testing and monitoring. In: Ulusay R, Hudson JA, Ulusay R, Hudson JA (eds) Suggested methods prepared by the Commission on Testing Methods, International Society for Rock Mechanics. ISRM Turkish National Group, Ankara, Turkey, pp 1974–2006

Jahed Armaghani D, Tonnizam Mohamad E, Momeni E, Narayanasamy MS, Mohd Amin MF (2014a) An adaptive neuro-fuzzy inference system for predicting unconfined compressive strength and Young’s modulus: a study on Main Range granite. Bull Eng Geol Environ. doi:10.1007/s10064-014-0687-4

Jahed Armaghani D, Hajihassani M, Tonnizam Mohamad E, Marto A, Noorani SA (2014b) Blasting-induced flyrock and ground vibration prediction through an expert artificial neural network based on particle swarm optimization. Arab J Geosci 7:5383–5396

Jahed Armaghani D, Hajihassani M, Yazdani Bejarbaneh B, Marto A, Tonnizam Mohamad E (2014c) Indirect measure of shale shear strength parameters by means of rock index tests through an optimized artificial neural network. Measurement 55:487–498

Jang RJS, Sun CT, Mizutani E (1997) Neuro-fuzzy and soft computing. Prentice-Hall, Upper Saddle River

Jiang YM, Park DW, Deb D, Sanford R (1997) Application of fuzzy set theory in the evaluation of roof categories in longwall mining. Min Eng 49(3):53–57

Kayabasi A, Gokceoglu C, Ercanoglu M (2003) Estimating the deformation modulus of rock masses: a comparative study. Int J Rock Mech Min Sci 40:55–63

Klose D (2002) Fuzzy rule-based expert system for short-range seismic prediction. Comput Geosci 28:377–386

Kuznetsov VM (1973) The mean diameter of the fragments formed by blasting rock. Sov Min Sci 9(2):144–148

Li WX, Liu L, Dai LF (2010) Fuzzy probability measures (FPM) based non-symmetric membership function: engineering examples of ground subsidence due to underground mining. Eng Appl Artif Intel 23:420–431

Mamdani EH, Assilian S (1975) An experiment in linguistic synthesis of fuzzy controllers. Int J Man Mach Stud 7:1–13

Marto A, Hajihassani M, Jahed Armaghani D, Tonnizam Mohamad E, Makhtar AM (2014) A novel approach for blast-induced flyrock prediction based on imperialist competitive algorithm and artificial neural network. Scic World J Article ID 643715

Michaux S, Djordjevic N (2005) Influence of explosive energy on the strength of the rock fragments and SAG mill throughput. Miner Eng 18:439–448

Mishnaevsky JR, Schmauder S (1996) Analysis of rock fragmentation with the use of the theory of fuzzy sets. In: Barla, editor. Proceedings of the Eurock 96:735–40

Momeni E, Nazir R, Jahed Armaghani D, Maizir H (2014) Prediction of pile bearing capacity using a hybrid genetic algorithm-based ANN. Measurement 57:122–131

Momeni E, Jahed Armaghani D, Hajihassani M, Mohd Amin MF (2015) Prediction of uniaxial compressive strength of rock samples using hybrid particle swarm optimization-based artificial neural networks. Measurement 60:50–63

Monjezi M, Rezaei M, Yazdian Varjani A (2009) Prediction of rock fragmentation due to blasting in Gol-E-Gohar iron mine using fuzzy logic. Int J Rock Mech Min Sci 46:1273–1280

Monjezi M, Rezaei M, Yazdian A (2010a) Prediction of backbreak in open-pit blasting using fuzzy set theory. Expert Syst Appl 37:2637–264

Monjezi M, Bahrami A, Yazdian Varjani A (2010b) Simultaneous prediction of fragmentation and flyrock in blasting operation using artificial neural networks. Int J Rock Mech Min Sci 47(3):476–480

Monjezi M, Ghafurikalajahi M, Bahrami A (2011) Prediction of blast-induced ground vibration using artificial neural networks. Tunnel Undergr Sp Technol 26(1):46–50

Morin AM, Ficarazzo F (2006) Monte Carlo simulation as a tool to predict blasting fragmentation based on the Kuz–Ram model. Comput Geosci 32:352–359

Nefeslioglu HA, Gokceoglu C, Sonmez H (2006) Indirect determination of weighted joint density (wJd) by empirical and fuzzy models: Supren (Eskisehir, Turkey) marbles. Eng Geol 85:251–269

Nguyen VU, Ashworth E (1985) Rock mass classification by fuzzy sets. In: Proceedings of the 26th US symposium on rock mechanics, Rapid City, 937–45

Rezaei M, Monjezi M, Yazdian Varjani A (2011) Development of a fuzzy model to predict flyrock in surface mining. Safety Sci 49(2):298–305

Roy PP, Dhar BB (1996) Fragmentation analyzing scale—a new tool for breakage assessment. Proceedings 5th International Symposium on Rock Fragmentation by blasting-FRAGBLAST 5, Balkema, Rotterdam

Sakellariou MG, Ferentinou MD (2005) A study of slope stability prediction using neural networks. Geotech Geol Eng 23(4):419–445

Sayadi A, Monjezi M, Talebi N, Khandelwal M (2013) A comparative study on the application of various artificial neural networks to simultaneous prediction of rock fragmentation and backbreak. J Rock Mech Geotech Eng 5(4):318–324

Sonmez H, Gokceoglu C, Ulusay R (2003) An application of fuzzy sets to the Geological Strength Index (GSI) system used in rock engineering. Eng Appl Artif Intel 16:251–269

Stagg MS, Otterness RE, Siskind DE (1992) Effects of blasting practices on fragmentation. Proceedings of the 33rd US. Symposium on Rock Mechanics, pp 313–322

Thornton D, Kanchibotla SS, Brunton I (2002) Modelling the impact of rock mass and blast design variation on blast fragmentation. Int J Blast Fragment 6(2):169–1168

Tonnizam Mohamad E, Jahed Armaghani D, Noorani SA, Saad R, Alvi Abad NK (2012) Prediction of flyrock in boulder blasting using artificial neural network. Electr J Geotech Eng 17:2585–2595

Tonnizam Mohamad E, Jahed Armaghani D, Momeni E, Alavi Nezhad Khalil Abad SV (2014) Prediction of the unconfined compressive strength of soft rocks: a PSO-based ANN approach. Bull Eng Geol Environ. doi:10.1007/s10064-014-0638-0

Topcu IB, Sarıdemir M (2008) Prediction of compressive strength of concrete containing fly ash using artificial neural networks and fuzzy logic. Comput Mat Sci 41:305–311

Torabi SR, Shirazi H, Hajali H, Monjezi M (2013) Study of the influence of geotechnical parameters on the TBM performance in Tehran–Shomal highway project using ANN and SPSS. Arab J Geosci 6(4):1215–1227

Wu C, Hao H, Zhou Y (1999) Fuzzy-random probabilistic analysis of rock mass responses to explosive loads. Comput Geotech 25:205–225

Yagiz S, Gokceoglu C (2010) Application of fuzzy inference system and nonlinear regression models for predicting rock brittleness. Expert Syst Appl 37:2265–2272

Zadeh LA (1965) Fuzzy sets. Inf Control 8:338–353

Zheming X, Mohanty B, Heping Z (2007) Numerical investigation of blasting-induced crack initiation and propagation in rocks. Int J Rock Mech Min Sci 44:412–24

Zheming Z, Heping X, Mohanty B (2008) Numerical investigation of blasting-induced damage in cylindrical rocks. Int J Rock Mech Min Sci 45:111–21

Zimmermann HJ (1992) Fuzzy set theory and its applications. Kluwer, Boston

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shams, S., Monjezi, M., Majd, V.J. et al. Application of fuzzy inference system for prediction of rock fragmentation induced by blasting. Arab J Geosci 8, 10819–10832 (2015). https://doi.org/10.1007/s12517-015-1952-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12517-015-1952-y