Abstract

The present study is focused on the extraction and characterization of pectin from different parts of Aegle marmelos (bael) fruit such as pulp, shells, and seeds on the dry and wet basis. Moreover, the comparative analysis of the extracted pectin from different fruit parts was also performed by using various parameters. Physicochemical properties, antioxidant activity, functional group, and structural analysis were carried out on the extracted pectin. In the present study, the yield percentage of bael seed pectin was found to be higher as compared to bael pulp pectin and bael shell pectin. The equivalent weight, methoxyl content, total anhydrouronic acid content (AUA), and degree of esterification (on a dry basis) of bael pulp, shell, and seed pectin were found to be 1119.53 ± 14.58 g/mol, 1095.01 ± 13.94 g/mol, and 1071.54 ± 13.35 g/mol; 7.25 ± 0.10%, 6.77 ± 0.03% and 7.39 ± 0.07%; 56.9 ± 0.81%, 54.56 ± 0.35% and 58.43 ± 0.60%; 72.37 ± 0.03%, 70.53 ± 0.22% and 71.88 ± 0.05%, respectively. On the other hand, the moisture content and ash content of bael pulp, shell, and seed pectin were found to be 10.23 ± 0.57%, 8.33 ± 2.08% and 9.9 ± 0.99%, and 6.77 ± 0.5%, 6.99 ± 0.66%, and 6.55 ± 0.50%, respectively which were in the acceptance range of purity. The functional group of extracted pectin was determined by Fourier transform infrared (FTIR) spectral analysis and peaks within the fingerprint region suggested that the extracted polysaccharide was pectin. Extracted bael pulp pectin demonstrated higher antioxidant activity with IC50 21.16 ± 0.99 µg/mL as compared to bael seed pectin (34.67 ± 1.34 µg/mL) and bael shell pectin (52.38 ± 0.62 µg/mL). The total phenolic content of bael pulp pectin was also found to be the highest (46.83 ± 2.8 mgGAE/g) in comparison with bael seed pectin (35.16 ± 2.8 mg GAE/g) and bael shell pectin (23.5 ± 5 mg yield percentageGAE/g). According to these findings, the bael seed has the maximum pectin output and AUA concentration, followed by the bael pulp and shell. However, the antioxidant activity and phenolic content were found to be highest in bael pulp. As a result, it was established that bael pulp and seed were a more significant source of pectin than bael shell. Although, pectin yielded from all parts of underutilized bael fruit can be utilized as a functional ingredient in biomedical and nutraceutical compounds and categorized as high-methoxyl pectin.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Most indigenous fruits are not commonly grown on a large scale due to a lack of awareness and limited knowledge of their nutritional and medicinal properties. However, these underutilized fruits can have a high content of vitamin C, antioxidants, and carotenoids (Vino and Sinija 2016). Mostly these fruits are limited to the local markets and rarely exported to other areas. The industrial uses of these “less known fruits” are limited which also largely affects their cultivation.

The stone apple (Aegle marmelos), besides having many nutritional and medicinal properties, is classified as an underutilized fruit due to lack of knowledge of its nutritive and medicinal values. The stone apple, also known as bael, is found in abundance in summer and is native to India, as well as Southeast Asia. Bael is a good source of protein, fat, minerals, carbohydrates, and dietary fibers, not only in the fruit but in each part of the tree and fruit, far exceeding their limitations of benefits in controlling many health problems like diabetes, cardiovascular diseases, inflammatory diseases, and gastro-intestinal problems (Singh et al. 2012). Bael has surprising characteristics for being used as a functional food. The adequate amount of dietary fibre present in bael pulp, hard shells, and seeds makes it a potential source of prebiotics. Health-conscious consumers are increasingly interested in food supplements that have a good impact on the host, which will play a significant part in driving the market expansion of functional foods. Therefore, in recent years, pectin has also been used as a prebiotic in functional foods. (Surolia et al. 2022). Pectin is a polysaccharide present in the cell walls of all plant species and is a major component of the plant. Citrus and apple fruits are common sources of commercial pectin. Although many other fruits also contain high amounts of pectin, the major issue with pectin is that the composition and gelling properties of the pectin in each source vary, which does not allow other sources to be used for commercial production (Venkatanagaraju et al. 2019). These variations in pectin structures make it a versatile biopolymer that can be used in a wide variety of applications (Surolia and Singh 2022a, b), not just for use as a gelling agent. Pectin is also used as a stabilizer, emulsifier, and ingredient in low-calorie food products in place of sugar. In recent past years, pectin is also been used as a prebiotic and as edible thin films and coatings (Venkatanagaraju et al. 2019).

According to the Future Market Insight 2023 report (https://www.futuremarketinsights.com/reports/pectin-market), the market value of pectin in 2023 will roughly US$ 890.9 million, and the expected projected value by 2033 will be US$ 1.5 billion with a global growth rate of 5.1%. Demand for functional foods has increased due to increased health consciousness among people over the past few years, which has driven the expansion of the pectin market. The pectin market in India is expected to rise due to factors such as an expanding population and middle-class income. Nevertheless, because of the small-scale apple and citrus processing businesses, India cannot generate enough pectin to satisfy domestic demand despite its abundant resources. So, proper utilization of unexplored fruits such as bael may become a potential source of pectin.

Hot acid extraction is the most practical and broadly applied technology for industrial pectin production (Oliveira et al. 2016). According to the International Pectin Producer Association pectin is produced using mineral acids as a processing aid in water (IPPA 2014). Commercially, pectin extraction typically involves boiling up strong acid solutions such as nitric, sulfuric, phosphoric, and hydrochloric acids (Freitas et al. 2020).

The industrial value of bael is also abandoned and limited to local markets only. But individually not only can each part of the bael fruit be used as a good source of pectin for commercial production but also for the development of processed and functional foods. Therefore, the present study aims to extract pectin from bael fruit pulp, hard shell, and seeds individually on a wet and dry basis and compare the different physiochemical properties of each part of the fruit. Only bael fruit pulp is used in making food products by local and small-scale industries but the content of pectin fibres present in the hard shells and seeds of bael fruit can equally contribute to making nutraceutical functional food products and may be used in other food and non-food products. Hence, this research may contribute to the proper and complete utilization of each part of the bael fruit for the production of pectin to be used in different applications and thus increase the demand for this neglected fruit.

Materials and methods

Sample collection and processing

The semi-ripe bael samples were collected from the local market in Noida, Uttar Pradesh, India during the summer months of 2021. The collected samples were brought to the laboratory for further processing. In brief, different samples of bael (bael pulp, bael shell, and bael seed) were prepared for pectin extraction on a wet and dry basis. The bael pulp was extracted from the shell and seeds were removed from the pulp. The dried powder of all three samples was prepared by keeping the bael pulp at 60 °C for 24 h and the bael shell and seeds overnight in a hot air oven. All the samples were sealed, packed, and stored at 4–6 °C for further experiments.

Pectin extraction

Pectin was extracted by the method used by Maskey et al. (2018) and Mendez et al. (2021), with some modifications. Three replications for each sample were performed. Pectin was extracted by using mineral acids as a processing aid in water. Each sample was mixed thoroughly with hot water maintained at 90 °C in the ratio of 1:6 (solute/solvent) in a heating mantle round flask and acidified with 1 M HCl at pH 1.5 with continuous stirring at constant temperature for 60 min. The mixture was then instantly brought to 50 °C by using an ice water bath and filtered through a three-layered muslin cloth. Alcohol treatment was given to filtrate for complete precipitation of pectin by adding double the volume of 96% ethanol and kept overnight. The coagulated pectin was extracted from the filtrate by using cheesecloth followed by washing with 70% ethanol and absolute alcohol to remove alcohol-soluble impurities. The extracted pectin was dried at 50 °C in a hot air oven and ground to obtain pectin powder. The pectin samples were stored in small pouches for further use.

The pectin yield was calculated as follows:

Characterization of extracted pectin

The dried pectin extracted from three different parts of bael fruit (bael pulp, bael shell, and seed) were subjected to the following quantitative test for their characterization.

Equivalent weight (Eq. wt.)

Equivalent weight was determined by the titration method given by Ranganna (1986). 5.0 g of pectin sample moisture in 5 mL of ethanol and mixed with 1.0 g of NaCl, 100 mL of distilled water was further added to the mixture followed by six drops of phenol red indicator and titrated against 0.1 N NaOH until the colour of the solution changed to pink and persisted for 30 s. The equivalent weight of the sample was determined by using the formula (1)

Methoxyl content (MeO)

Methoxyl content was determined by the method given by Ranganna (1986) with a slight modification. 25 mL of 0.1 NaOH was added to the neutral solution used in the equivalent weight determination, shaken vigorously, and allowed to stand for 30 min. After incubation, 25 mL of 1 N HCl was added to the solution and titrated against 0.1 N NaOH to the same endpoint as before. The methoxyl content of the sample was determined by using the formula (2)

Total anhydrouronic acid content (AUA)

The value of the equivalent weight and the methoxyl content was used to determine the total anhydrouronic acid content. It is calculated by the formula given below (Ania et al. 2012).

where molecular unit of AUA (1 unit) = 176 g, z = mL (titer) of NaOH from equivalent weight determination, y = mL (titer) of NaOH from methoxyl content determination, W = weight of the sample.

Degree of esterification (DE)

The degree of esterification of extracted pectin was calculated by using values of methoxyl and anhydrouronic acid content using the expression given below (Ania et al. 2012).

Moisture content and ash content

Association of Official Analytical Chemists (1995) method was used to determine the moisture and ash content of pectin from the samples.

Fourier transform infrared (FTIR) spectral analysis

FTIR spectra of pectin samples were obtained in the frequency ranges between 4000 and 600 cm−1 using attenuated total reflectance (ATR) mode with the help of a Bruker Alpha FTIR spectrophotometer (Bruker, Germany).

Scanning electron microscopy (SEM)

High-resolution field emission scanning electron microscope (HR- FESEM) (Sigma VP, Zeiss, Germany) was used to analyze the nanostructure of bael pulp, shell and seed pectin. An accelerating voltage of 20 kV was used to capture a SEM image of all the samples.

X-ray diffraction analysis (XRD)

X-ray diffractometer (Rigaku Smart Lab Guidance, Rigaku, Japan) was used to obtain X-ray diffraction (XRD) patterns of bael pulp,shell and seed pectin. The scanning level was 2°/min at a 2θ diffraction angle which ranged from 20 to 80.

Antioxidant activity by 2,2-diphenyl-1-picrylhydrazyl (DPPH) assay

Antioxidant activity was determined by the method used by Hendel et al. (2016) with a slight modification. Briefly, 2 mL of pectin solution (1 mg/mL) was mixed with 2 mL of 0.1 mM DPPH solution and incubated for 30 min at room temperature. The absorbance was recorded at 517 nm by a UV–visible spectrophotometer (Shimadzu, Kyoto, Japan) against methanol. Ascorbic acid was used as a reference. The inhibition percentage (I %) was calculated by using the following formula.

where A1 was the absorbance of the pectin samples and A0 was the absorbance of the control. The IC50 level was calculated from the linear regression curve and Eq. (5).

Total phenolic content

The total phenolic content of pectin was determined by employing a method previously proposed by McDonald et al. (2001) using the Folin Ciocalteu reagent. Briefly, 0.5 mL of pectin solution was mixed with 0.1 mL Folin-Ciocalteu reagent (0.5 M), and after 15 min of incubation, 2.5 mL of saturated sodium carbonate was added and incubated for 30 min at room temperature. Finally, the absorbance was measured at 760 nm by using a UV–visible spectrophotometer (Shimadzu, Kyoto, Japan). Gallic acid was used as a positive control. Total phenolic content is expressed in terms of gallic acid equivalent mg/g of the sample on a dry basis.

Statistical analysis

The Statistical significance of the variables was evaluated through one-way analysis of variance (ANOVA) at the P < 0.05 level by using IBM® SPSS® Version 25 (IBM, Armonk, New York, USA). The data were expressed as the mean ± standard deviation (SD) of the triplicates. Post- Hoc Duncan test was applied for mean comparison. Graph Pad Prism version 5.01 was used for the graph.

Result and discussion

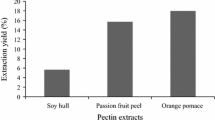

The yield % of extracted pectin from bael pulp, bael shell, and bael seed is presented in Table 1. Bael pulp yielded 14.43 ± 1.5 of pectin on a dry basis, slightly lower than the bael pulp pectin (16.7%) reported by Maskey et al. (2018). However, there are no reports available in the literature on pectin extracted from bael shell and bael seeds. Our group explored bael pulp residue, as an underutilized source for pectin extraction and yielded 24.02 ± 0.63% pectin by hot acid extraction (Surolia and Singh 2022a, b). Bael seeds showed a surprisingly highest yield (17.05 ± 0.74%) which was more than that obtained in banana peel and similar to mango peel ranging between 5 and 12% and 12–19%, respectively (Grima and Worku 2016). The yield of pectin extracted from bael shell (7.07 ± 0.83%) was less than the yield reported above but more than the study conducted on the lemon peel (1.5%) (Salam et al. 2012). The pectin extracted from dried orange peel yielded 2.2% (Langrish et al. 2006) and the grapefruit peel was 6.35% (Rouse and Crandal 1976) which was also lower than that of bael shell. Many other researchers reported 16.24–21.28% of pectin from grapefruit peel (Cui et al. 2020), 6.4% from apple peel (Cho et al. 2019), and 4.2% from cocoa pod husks (Priyangini et al. 2018) by using the acid extraction methods. Therefore bael seed pectin showed a significantly higher pectin yield compared to bael pulp and shell.

Characterization of bael pectin

Characterizations of the extracted pectin were carried out for various parameters to evaluate its suitability for different applications.The physicochemical characterizations of pectin depend mainly on the raw material source and conditions selected for the isolation and purification of pectin.

Pectin with a high value of the equivalent weight has a high gel-forming ability (Vaclavik and Christian 2008). The equivalent weight of bael pulp was 1293.29 ± 19.47 g/mol (on a wet basis) and 1119.52 ± 14.57 g/mol (on a dry basis) and the equivalent weight of wet and dry bael shell and bael seed was 1172 ± 15.98, 1095 ± 13.94 and 1071 ± 133.35 g/mol respectively, which was similar to citrus pectin that ranges between 635.63 and 2219.39 mg/mol based on different extraction methods (Rodsamran and Sothornvit 2019) and apple pomace pectin that ranges between 833.33–1666.30 g/mol (Kumar and Chauhan 2010). The methoxyl content indicates the pectin settling time and their characeristics in gel formation and film preparation (Ranajit et al. 2013). The methoxyl content of pectin extracted from bael pulp, shell and seed were within the range of 6.4 ± 0.06–7.39 ± 0.07%, this is similar to the methoxyl content of pectin extracted from the pomace of different cultivars of apple (6.93%) (Mariana et al. 2011) and less than that found in banana- papaya mixed peel pectin (8.37%) (Mada et al. 2022) but within the range notified by the International Pectin Producers Association (IPPA, 2014) standard i.e., 2.2–7.8%. The AUA content of pectin is suggested to be not less than 65% by the Food Chemical Codex (1996) and according to the IPPA (2014) standard it should be a minimum of 35%. The total AUA% of extracted pectin was found to vary between 50.21 ± 0.53 and 58.43 ± 0.40% which is quite low according to the Food Chemical Codex but within an acceptable range based on IPPA standards. The AUA% of pectin from Citrus sinensis (sweet orange) peel was between 38.47 and 41.30% as reported by Kamal et al. (2021). The AUA value of different varieties of apple pomace was also reported in the range of 48–53% (Mariana et al. 2011) and the total AUA % of banana peel pectin was recorded around 53.60 (Girma and Worku 2016). The low value of AUA indicates the presence of proteins, starch and sugar in the extracted pectin (Ismail et al. 2012). Degree of esterification of more than 50% is considered high methoxyl pectin and less than 50% is considered low methoxyl pectin (Mesbahi et al. 2005). The degree of esterification in extracted pectin from different parts of bael fruit ranged between 71.88 ± 0.05–72.89 ± 0.16%, indicating that extracted pectin from all samples was categorized as high methoxyl pectin similar to C. sinensis peel pectin (73.26–77.56%) (Kamal et al. 2021) and less than the value reported in banana peel pectin (76.7%) (Arias et al. 2021).

The moisture and ash content indicate the purity of pectin. The moisture content should be less than 12% for the longer shelf life of pectin (Rokeya et al. 2014). In the present study, the moisture content of all extracted pectin was within the acceptable range of 8.33 ± 2.08 and 10.23 ± 0.52% which was similar to the moisture content of mangosteen (Garcinia mangostana L.) rind (9.85%) (Wathoni et al. 2019). The moisture content of a different variety of prickly pear peel pectin was quite low as compared to the present study which ranges between 7.57 and 8.87% and commercial pectin ranges around 7.0% (Lekhuleni 2021). Low moisture content indicates the increased shelf life of pectin and is also necessary to inhibit the growth of pathogens. The ash content is an indicator of inorganic impurities present in pectin. The ash content of good-quality pectin is always less than 10% which is favourable for the gel forming property of pectin (Bhat and Singh 2014). The ash content in extracted pectin ranges between 6.55 ± 0.83 and 8.77 ± 1.95%, indicating that extracted pectin is of better quality. Similarly, 6.88% ash content in dragon fruit pectin was also reported by Ismail et al. (2012). Comparative characterization studies of various parts of bael pectin are shown in Fig. 1.

Comparative characterization of different parts of bael pectin a Equivalent weight b Methoxyl content c Total AUA d Degree of esterification e Moisture content % f Ash content %. Values are represented as means of triplicate measurements: Means with different alphabets are significantly different at p < 0.05

All these parameters results are within an acceptable range so the data obtained suggest that all the parts of bael can be used as a protentional source of pectin for commercial applications.

FTIR analysis of extracted sample:

The primary structural analysis and functional group determination of pectin were done by FTIR analysis, as shown in Fig. 2. The spectrum showed peaks at 3334.77, 3310.78, and 3276. 89 cm−1 of bael pulp pectin, bael shell pectin, and bael seed pectin, respectively, due to stretching of –OH groups; similarly the pomegranate peel pectin showed the major peak at about 3309 cm−1 (Abid et al. 2017). The aliphatic C-H groups were centered at 2923.98 and 2926.09 cm−1 for bael seed and bael shell respectively. The major peak of mangosteen rind extracted pectin appeared at 2927.94 cm−1 (Wathoni et al. 2019). C-H groups include CH, CH2, and CH3 of D-galacturonic acid whereas jackfruit slimy sheath pectin also showed the vibration of C-H groups at 2920 cm−1 (Kumar et al. 2021). The absorbance peak between 1750 and 1500 cm−1 indicates the presence of carboxylic acid and carboxylic ester groups of the pectin molecules (Mota et al. 2020). The bael pulp pectin, bael shell pectin, and bael seed pectin showed the absorbance of C = O at 1732.73, 1740.01, and 1738.70 cm−1, respectively. The mangosteen rind extract pectin showed the C = O carbonyl group at 1747.51 cm−1 (Wathoni et al. 2019). The quince pectin spectrum centered at 1617 cm−1 indicates the asymmetrical stretching vibration due to the COO− group of poly galacturonic acid (Caglayan 2010). The present study showed the COO− stretching at 1604.79, 1602.93, and 1626.70 cm−1 for bael pulp pectin, bael shell pectin, and bael seed pectin, respectively. The peaks within 800–1200 cm−1 are denoted as ‘fingerprint’ regions, therefore, the absorbance peak at 1104 and 1000 cm−1 indicates the presence of galacturonic acid (Caglayan 2010). Similarly, bael pulp pectin, bael shell pectin, and bael seed pectin showed FTIR bands around 1006.98, 1008.02, and 1158.62 cm−1 respectively, suggesting that the extracted polysaccharide from all the samples was pectin.

Scanning electron microscopy (SEM)

The surface morphology of extracted pectin was investigated by scanning electron microscopy at 500X magnification as shown in Fig. 3. It can be seen that the extracted pectin demonstrated roughness on the surface. The particle size of all the samples is almost the same and comparable to each other. The result was similar with the surface morphology of the pectin extracted from Jerusalem artichoke residue (Zhou et al. 2022).

X-ray diffraction analysis (XRD)

X-ray diffraction analysis was used to investigate the amorphous or crystalline nature of the pectin. The XRD pattern of the bael pulp, shell and seed pectin was presented in Fig. 4. It can be seen that all the samples had a wide range of background patterns indicating that the pectin extracted from bael pulp, shell and seed pectin was an amorphous pectin, which is consistent with the amorphous nature of Jerusalem artichoke reported by Zhou et al. (2022) and commercial pectin investigated by Hosseini et al. (2020). The bael pulp, shell, and seed pectin are found to have an almost similar structure.

Antioxidant activity of the extracted pectin (DPPH assay)

DPPH assay is considered to be a valid, accurate and easy method that can be used to evaluate and estimate the free radical scavenging activity of different antioxidants. The compound DPPH is a purple coloured solution, a free radical molecule that gets reduced when reacting with any antioxidant compounds and changes to yellow colour due to the formation of DPPH-H. DPPH is a hydrogen donor for antioxidant compounds (Catteau et al. 2006). The % inhibition of sample and standard was expressed as a percentage of the disappearance of DPPH. The result of antioxidant activity is shown in Fig. 5, which indicates that bael pulp pectin has the highest amount of % inhibition as compared to bael shell pectin and bael seed pectin in all concentrations. However, it was less than standard ascorbic acid. The IC50 value of bael pulp pectin was found to be 21.16 ± 0.99 µg/mL and has potential as an antioxidant for biomedical applications followed by bael seed pectin (34.67 ± 1.34 µg/mL) and bael shell pectin (52.38 ± 0.62 µg/mL) which has a moderate level of antioxidant activity.

Total phenolic content (TPC) of extracted pectin

TPC of extracted pectin was estimated by the Folin-Ciocalteu reagent method using gallic acid as a positive control (Fig. 6). The TPC of bael pulp pectin was found to be maximum (46.83 ± 2.8 mgGAE/g) as compared with bael seed pectin (35.16 ± 2.8 mg GAE/g) and bael shell pectin (23.5 ± 5 mg GAE/g). The high phenolic content of bael pulp pectin may be due to the co-extraction of phenols with pectin as a result of hot-acid extraction process (Khubber et al. 2020). The jackfruit slimy sheath pectin showed a little higher amount of phenolic content (65.7 mg GAE/g) (Kumar et al. 2021) as compared to the entire sample, but the observed result of the present study was almost consistent with commercial citrus pectin (30.7 mg GAE/g) and apple pectin (51.3 mg GAE/g) (Kumar et al. 2021).

Conclusion

In the present study, different parts of the bael fruit i.e. pulp, shell, and seed were explored as a potential alternative source of pectin. This study showed that the bael shell is not commercially competitive because of its hard and thick texture and has a significantly lower pectin yield compared to the bael pulp and seed. Nevertheless, based on pectin characterization bael shell pectin has the potential to be used for distinct applications.

Surprisingly, the bael seed showed a significantly higher yield compared to the bael pulp. However, the antioxidant activity and TPC were significantly higher in bael pulp pectin. The pectin yielded from the bael pulp, shell, and seed was categorized as high methoxyl pectin based on its degree of esterification The pectin structure was confirmed by FTIR analysis and the fingerprint region confirmed that the extracted polysaccharide was pectin in all the samples. Therefore, it was concluded that bael pulp, shell, and seed could be used as a pectin source although, comparatively bael pulp and seed are more promising alternative sources than shell and suitable for industrial production of pectin. Therefore, each part of the underutilized bael fruit i.e., bael pulp, seed, and shell pectin could be used as a functional ingredient in biomedical, pharmaceutical, food, and cosmetic products.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Abid M, Cheikhrouhou S, Renard CMGC, Bureau S, Cuvelier G et al (2017) Characterization of pectins extracted from pomegranate peel and their gelling properties. Food Chem 215:318–325. https://doi.org/10.1016/j.foodchem.2016.07.181.hal-01561183

Ania AO, Mustapha M, Barau OA, Mamman AZ, Hauwa H, Hauwa MSU, Yagana BA (2012) Extraction and characterization of pectin from peels of lemon (Citrus limon), grape fruit (Citrus paradise) and sweet orange (Citrus sinensis). Br J Pharmacol Toxicol 3(6):259–262

Arias D, Rodriguez J, Lopez B, Mendez P (2021) Evaluation of the physicochemical properties of pectin extracted from Musa paradisiaca banana peels at different pH conditions in the formation of nanoparticles. Heliyon 7(1):e06059. https://doi.org/10.1016/j.heliyon.2021.e06059

Association of Official Analytical Chemists (AOAC) (1995) Official methods of analysis 16th edn. Association of Official Analytical Chemists, Inc. USA

Bhat SA, Singh R (2014) Extraction and characterization of pectin from guava fruit peel. IJREAT 2(3):2320–8791

Caglayan A (2010) Extraction and characterization of pectin obtained from quince fruits (Cydonia vulgaris pers) grown in Turkey. Asian J Chem 23:149–152

Catteau JP, Vergoten G, BernierJL ZV, BaillyF VH (2006) 4- Mercaptoimidazoles derived from the naturally occurring antioxidant ovothiols 2. Computational and experimental approach of the radical scavenging mechanis. Free Radic Res 32:525–533

Cho EH, Jung HT, LeeBH KHS, Rhee JK, Yoo SH et al (2019) Green process development for apple-peel pectin production by organic acid extraction. Carbohydr Polym 204:97–103. https://doi.org/10.1016/j.carbpol.2018.09.086

Cui J, Ren W, Zhao C, Gao W, Tian G, Bao Y, Zheng J et al (2020) The structure–property relationships of acid- and alkali-extracted grapefruit peel pectins. Carbohydr Polym 229:115524. https://doi.org/10.1016/j.carbpol.2019.115524

Food Chemical Codex (1996) IV monographs. National Academy Press, Washington, DC, p 283

Freitas C, Sousa R, Dias M, Coimbra J (2020) Extraction of pectin from passion fruit peel. Food Eng Rev 12:460–472

Girma E, Worku T (2016) Extraction and characterization of pectin from selected fruit peel waste. Int J Sci Res 6(2):2250–3153

Hendel N, LarousL BL (2016) Antioxidant activity of rosemary (Rosmarinus officinalis L.) and its in vitro inhibitory effect on Penicillium digitatum. Int Food Res J 23(4):1725–1732

Hosseini S, Parastouei K, Khodaiyan F (2020) Simultaneous extraction optimization and characterization of pectin and phenolics from sour cherry pomace. Int J Biol Macromol. 158:911–921. https://www.futuremarketinsights.com/reports/pectin-market

International Pectin Producers Association (IPPA) (2014) Pectin commercial production and pectin in organic food products. Neuenbuerg, Germany

Ismail NSM, Ramli N, Hani NM, Meon Z (2012) Extraction and characterization of pectin from dragon fruit (Hylocereus polyrhizus) using various extraction conditions. Sains Malays 41:41–45

Kamal MM, Kumar J, Mamun MAH et al (2021) Extraction and characterization of pectin from Citrus sinensis Peel. J Biosyst Eng 46:16–25. https://doi.org/10.1007/s42853-021-00084-z

Khubber S, Misra NN, Yadav S (2020) Extraction of pectin from black carrot pomace using intermittent microwave, ultrasound and conventional heating: kinetics, characterization and process economics. Food Hydrocoll 102:105592. https://doi.org/10.1016/j.foodhyd.2019.105592

Kumar A, Chauhan GS (2010) Extraction and characterization of pectin from apple pomace and its evaluation as lipase (steapsin) inhibitor. Carbohydr Polym 82:454–459

Kumar M, Potkule J, Tomar M, Punia S, Singh S, Patil S et al (2021) Jackfruit seed slimy sheath, a novel source of pectin: studies on antioxidant activity, functional group, and structural morphology. Carbohydr Poly Technologies Appl 2:100054

Langrish TAG, Shi J, Liu Y (2006) Water-based extraction of pectin from flavedo and albedo of orange peels. Chem Eng J 120:203–209

Lekhuleni I, Kgatla T, Mashau M, Jideani A (2021) Physicochemical properties of South African prickly pear fruit and peel: extraction and characterisation of pectin from the peel. Open Agric J 6(1):178–191. https://doi.org/10.1515/opag-2021-0216

Mada T, Duraisamy R, Guesh F (2022) Optimization and characterization of pectin extracted from banana and papaya mixed peels using response surface methodology. Food Sci Nutr 00:1–17. https://doi.org/10.1002/fsn3.2754

Mariana S, Dayana R, Maria C, Carmen P, Alessandro N, Gilvan W (2011) Chemical and instrumental characterization of pectin from dried pomace of eleven apple cultivars. Acta Sci Agron 33(3):383–389. https://doi.org/10.4025/actasciagron.v33i3.7125

Maskey B, Dhakal D, Pradhananga M, Shrestha NK (2018) Extraction and process optimization of bael fruit pectin. Food Sci Nutr 6:1927–1932. https://doi.org/10.1002/fsn3.761

McDonald S, Prenzler PD, Antolovich M, Robards K (2001) Phenolic content and antioxidant activity of olive extracts. Food Chem 73(1):73–84. https://doi.org/10.1016/S0308-8146(00)00288-0

Mendez DA, Fabra MJ, Gomez-Mascaraque L, Lopez-Rubio A, Martinez-Abad A (2021) Modelling the extraction of pectin towards the valorisation of watermelon rind waste. Foods 10(4):738

Mesbahi G, Jamaliana J, Farahnaky A (2005) A comparative study on functional properties of beet and citrus pectins in food systems. Food Hydrocoll 19:731–738. https://doi.org/10.1016/j.foodhyd.2004.08.002

Mota J, MuroC IJ, Hernandez OA, Tecante A, Rivera E (2020) Extraction and characterization of pectin from the fruit peel of Opuntia robusta. ChemistrySelect 5:11446

Oliveira TIS, Rosa MF, Cavalcante FL, Pereira PHF, Moates GK, Wellner N (2016) Optimization of pectin extraction from banana peels with citric acid by using response surface methodology. Food Chem 198:113–118

Priyangini F, Walde SG, Ramalingam C (2018) Extraction optimization of pectin from cocoa pod husks (Theobroma cacao L.) with ascorbic acid using response surface methodology. Carbohydr Polym 202:497–503. https://doi.org/10.1016/j.carbpol.2018.08.103

Ranajit KS, Yoga NAPP, Asrul A (2013) Opimized extraction condition and characterization of pectin from kaffir lime (Citrus hystrix). Res J Agric for Sci 1:1–11

Ranganna S (1986) Handbook of analysis and quality control of fruit and vegetable products. Tata McGraw Hill Publishing Co., Ltd, New Delhi, India

Rodsamran P, Sothornvit R (2019) Microwave heating extraction of pectin from lime peel: Characterization and properties compared with the conventional heating method. Food Chem 278:364–372

Rokeya B, Mohammad A, Uddin MB, Yusof YA (2014) Characterization of jackfruit (Artocarpus heterophyllus) waste pectin as influenced by various extraction conditions. Agric Agric Sci Procedia 2:244–251. https://doi.org/10.1016/j.aaspro.2014.11.035

Rouse AH, Crandal PG (1976) Nitric Acid extraction of pectin from citrus peel. Proc Fla State Hort Soc 89:166–168

Salam MA, Jahan N, Islam MA, Hoque MM (2012) Extraction of pectin from lemon peel: technology development. J Chem Eng 27(2):25–30

Singh U, Kochhar A, Boora R (2012) Proximate composition, available carbohydrates, dietary fibres and anti-nutritional factors in Bael (Aegle maemelos L.) leaf, pulp and seed powder. Int J Sci Res 2(4):2250–3153

Surolia R, Singh A (2022a) Study on physicochemical properties, structural morphology, and prebiotic potential of extracted pectin from a novel source: Bael pulp (Aegle marmelos) residue. J Biotech Resn 13:247–259

Surolia R, Singh A (2022b) Underutilized sources of pectin as edible coating. Lett Appl NanoBioScience 12(3):83

Surolia R, Ali S, Singh A (2022) Synbiotics: a promising approach for improving human health. J Pharm Negat 13(7):766–777

Vaclavik VA, Christian EW (2008) Essentials in food science, 3rd edn. Springer Science and Business, New York, NY, USA

Venkatanagaraju E, Bharathi N, Sindhuja RH, Chowdhury RR, Sreelekha Y (2019) Extraction and purification of pectin from agro-industrial wastes. In: Martin M [ed] Pectins-extraction, purification, characterization and applications. IntechOpen. https://doi.org/10.5772/intechopen.85585

Vino SA, Sinija VR (2016) Underutilized fruits in India. Indian Food Ind Mag 35(2):45–46

Wathoni N, Shan CY, Shan WY, Rostinawati T et al (2019) Characterization and antioxidant activity of pectin from Indonesian mangosteen (Garcinia mangostana L.) rind. Heliyon 5(8):e02299. https://doi.org/10.1016/j.heliyon.2019.e02299

Zhou X, Liu L, Li J, Wang L, Song X (2022) Extraction and characterization of pectin from Jerusalem ArtiChoke residue and its application in blueberry preservation. Coatings 12(3):385

Funding

No funding was provided.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Surolia, R., Dubey, M.K., Bhatnagar, T. et al. Comparative study on the physicochemical properties, structural, and functional group analysis of pectin extracted from underutilized bael (Aegle marmelos) pulp, shell, and seed. Vegetos 37, 828–837 (2024). https://doi.org/10.1007/s42535-023-00614-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42535-023-00614-4