Abstract

Purpose

Moringa oleifera seeds have been studied as a natural coagulant to treat different kinds of wastewater. However, from this seed, ben oil can be extracted, which has other commercial applications, generating a residue. In this study, the purpose is to use Moringa oleifera seeds and the residue from the ben oil extraction to treat a fish processing plant wastewater. Therefore, the research aims at biomass valorization because a residue would be given a nobler goal. Besides, a comparison between aqueous and saline biocoagulants intends to verify the influence of salt in the coagulant extraction.

Methods

The aqueous extract, as well as, saline extracts were compared for the Moringa oleifera seeds in natura, and the defatted seeds regarding characterizations such as protein content and Fourier-transform infrared spectroscopy, and applied in the wastewater treatment.

Results

The characterizations showed that the bioactive compounds responsible for coagulation are probably still in the seeds, and the results from the treatment showed that the defatted seeds extract prepared with salts have potential as a natural coagulant for fish processing industry effluent, being similar, and sometimes even better, than in natura seeds. Using a saline solution and defatted seeds, removals up to 90.85% of turbidity, 79.50% apparent color, and 71.48% of chemical oxygen demand were obtained.

Conclusion

Therefore, a satisfactory primary treatment was achieved, enabling good results for the treatment. In addition, the good results were possible using a residue as the coagulant, promoting biomass valorization, and thus contributing to a circular bioeconomy.

Graphic Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of novelty

This research uses a residue, the Moringa oleifera seeds after ben oil extraction, to successfully treat a fish processing plant wastewater. The Moringa oleifera seeds were also used for comparison purposes. Several characterizations were made, and conditions were tested for the coagulation treatment. The fish processing plant wastewater was satisfactory primarily treated using this residue, showing the potential to avoid waste, and to remedy the wastewater problem.

Introduction

According to the Food and Agriculture organization of the United Nations [1], the global aquiculture production reached 122.6 million tons with an annual growth rate of 6.7%, being the Nile tilapia (Oreochromis niloticus) the species that is most produced in the world, representing 9% of global aquiculture. In 2021, Brazil produced 551.9 thousand tons according to the Brazilian Institute of Geography and Statistics, being that more than 50% of national Nile tilapia concentrated on the South and Southeast region of the country. Paraná, South of Brazil and where this study was conducted, was highlighted with a production of 140 thousand tons in 2020 [2].

This higher fish consumption has led to an increase in the number of fish processing plants, plants that abundantly use water almost in all production stages [3]. Besides, residues are generated during fish processing vary, but considering seafood, for example, 47% is not adequate for human consumption, and can include, depending on the fish, heads, entrails, skin, and viscera [4]. In Brazil, there is not a standardized volume of water required for a safe processing per kg of fish. Ferraciolli et al.[5] evaluated the minimization in the use of water in the fish processing and reduction of liquid effluents generated in this industrial process. The authors verified the water used in the area to clean the fish before, after, and during evisceration, and also water used for personal hygiene and cleaning of equipment and installations. The volume of water used to clean the industry, such as washing boxed, internal floor, and equipment was 0.54 m3 T−1. For the employees higyene, including sanitary barrier and boots washing, 0.056 m3 T−1. Also, the water volume used in the ice plant, in the washing drum, and in the evisceration process was 7.73 m3 T−1, besides other volumes of water that were not contabilized with water wastage of 2.15 m3 T−1, totaling 10.47 m3 T−1. The increase in the fish demand viabilizes the increase in the processing plant, promoting a higher water consumption, ranging from 8.4 to 33.4 m3 T− 1. Thus, this results in a significant volume of residual water, which presents high polluting potential and with physicochemical characteristics ranging according to the processed species, size and weight of the fish, and industrialization level of the processing plant [5]. Therefore, water consumption in the fish processing industry and wastewater production are of great concern all over the world [6].

To perform the wastewater treatment, essential stages used for the removal of suspense and colloidal responsible for turbidity, primary industrial wastewater treatment, are the processes of sedimentation/flotation and coagulation/flocculation [7]. The simplicity, high efficiency, and low cost are the main characteristics that involve the coagulation/flocculation process [8]. In addition, coagulation and flocculation decreases chemical oxygen demand (COD) and color from wastewater [9].

Lately, an effort of the scientific community has aroused to develop studies that would include sustainable and ecological natural coagulants, as an alternative to inorganic coagulants [10], because of the cost and also environmental and health concerns associated with chemical products commonly used as coagulants [11].

Natural coagulants such as chitosan [12], fava bean [13], tannin [14], and Moringa oleifera (MO) [15] had their efficiency proved in “lab scale”. However, studies that present alternatives with industrial or commercial applicability are scarce. Among the vegetables, MO seeds have demonstrated promising qualities as a natural coagulant, verified as efficient in several studies and largely studies [15,16,17,18,19,20,21,22].

MO is a tree from India that grows in the tropics and subtropics of Africa, Asia, and America. It is known as a “miracle tree”, with great economical and environmental importance in industrial and medical areas [10, 23, 24]. Regarding effluent treatment, the seeds may be used as coagulants in superficial and residual water treatment due to the presence of cationic proteins soluble in water [, 25, 26]. Generating lower sludge volume, being degradable, and maintaining the treated water pH, are some of the competitive advantages of this natural coagulant [16].

MO seeds also contain a high nonvolatile oil content (27–40%), which may be used for human consumption and in the cosmetic industry, as well as a raw material in biodiesel production [27, 28]. The extraction process generates a residue that presents a richness in bioactive compounds, turning it into a potential source of components that can be extracted, fractionated, and used for biotechnological purposes [28]. For example, this residue, obtained during the oil, known as “ben oil”, extraction process of the Moringa seeds, retains positively charged proteins, which favors the apprehension process of suspense particles in the water, through processes like coagulation/flocculation [29]. The exploration of these residues is important for the oils and biodiesel market because it adds value to a residue of the extraction process [28].

Saline extract of MO “in natura” had its efficiency proved as a coagulant in many studies [15, 30, 31]. However, studies that use the residue of the “ben oil” extraction from the seeds to prepare saline solutions of the Moringa coagulant are scarce. Another factor that needs to be considered as advantageous is the utilization of the defatted seeds, according to Dezfooli et al. [32], its use may help in the decrease of the necessary dosage. Besides, organic matter may increase when using the Moringa seeds due to their oil and carbohydrate content [33].

Considering the great volume of fish processing wastewater generated and expected to increase, and the necessity for efficient treatments, the present study investigated several bioactive coagulant extracts from the MO seeds. Moreover, since ben oil has commercial value, the MO seeds residue obtained from its extraction was also used, contrarily of common research which use the MO seeds in natura, aiming to valorize this biomass and contribute to a more sustainable industrial chain.

Materials and Methods

Residual fish Processing Wastewater Characterization

The residual water studied was collected in a fish processing plant from the species Oreochromis niloticus (Nile tilapia), located in western Paraná state, Brazil (24o43’09.5”S 53o42’06.9”W).

The raw residual wastewater was characterized regarding the parameters: apparent color, turbidity, pH, conductivity, COD, total phosphor, total nitrogen, total solids, and total coliforms, according to procedures described in Standard Methods for the Examination of Water and Wastewater [34]. When the coagulation/flocculation study was finished, resulting in the best conditions among the studied ones, this same characterization was performed for the treated effluent for comparison purposes.

Ben oil Extraction from MO Seeds

The MO seeds were provided by Sergipe Federal University, located in Aracaju, Sergipe, Brazil (Coordinates: 10º55’17.96 “S/37006’07.71”O).

The ben oil chemical extraction from the MO seeds was performed in a continuous Soxhlet extractor. 10 g of crushed MO seeds were transferred to an extraction cartridge and taken to the extractor with hexane [35] with solvent evaporation occurring in a 3-hour cycle [36]. The MO seed residue after the ben oil extraction was washed with distilled water at 60ºC and dried at 40 ºC in an oven. After the ben oil extraction, the MO seed oil percentage obtained was determined according to Santos et al. [37].

MO Seeds Characterization

The MO seeds were characterized before and after the ben oil extraction by Fourier-transform infrared spectroscopy (FTIR) and by X-ray diffractometry (XRD). For the FTIR analysis, tablets composed of KBr (99%) and sample (1%) were made. The spectra were obtained in the range of 4000 to 400 cm− 1 in absorbance way using a spectrometer PerkinElmer 1600. For the XRD analysis, the samples were exposed to X-ray with an angle of 2θ ranging between 5º and 80º in the interval of 0.02º. A copper tube lamp was used with Kα of 1.5406 Â. 40 kV of voltage and 30 mA of current were applied.

In natura and defatted MO seeds were evaluated regarding pH variation behavior (4, 6, 8, 10, and 12) versus Zeta potential. For the zeta potential analysis, a Nano Zeta Beckman Coulter Delsa (TM) Nano Zeta Potential Analyzer was employed coupled to the DelsaMTNano UI version 3.73 software and usage according to the fabricant orientation.

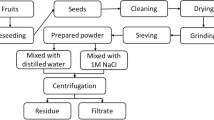

Biocoagulant Preparation of the MO seed (Mob)

For the preparation of the biocoagulant (Mob) solutions, 5 g of dried MO seeds, in natura or from the dried residue, were crushed with 100 mL of 1 M NaCl solution (MobNa), 1 M KCl solution (MobK), or distilled water (MobW) in a blender for 3 min. The obtained mixture was kept under stirring for 30 min in a magnetic stirrer for the extraction of the active compounds from MO. Then, the biocoagulant was vacuum filtered and used in the coagulation/flocculation/sedimentation experiments, according to adapted methodology from Cardoso and Beltrán-Heredia and Sánchez-Martín [38, 39].

For all biocoagulant solutions (MobNa, MobK, and MobW) protein concentration and zeta potential were determined. Protein was determined by the Lowry method [40], and zeta potential as previously described. All analyses were performed in triplicate.

Operating Coagulation/Flocculation Conditions Evaluation

A Jar Test (Milan brand), with a capacity of six simultaneous assays and a volume of 300 mL of residual water was used for each experiment. The temperature during the experiments was 25 oC ± 3 oC. The biocoagulants MobNa, MobK, and MobW prepared with MO “in natura” seeds (without oil extraction) were used in the dosage of 1500 mg L− 1 for this study [41, 42].

A complete factorial experimental design 32 was performed, in which two parameters were evaluated: rapid mixing speed (RMS), and slow mixing speed (SMS), according to the levels in Table 1. Rapid mixing time of 2 min and slow mixing time of 10 min and sedimentation time of 60 min were constant. The parameters optimization used in the coagulation/flocculation step helps in the parameter’s removal efficiency or/and in electric energy economy [43].

The experiments were performed with 3 repetitions for each combination between the levels of the variables RMS and SMS, totalizing 27 experiments, according to methodology adapted from Bhuptawat et al. [44], Table 1.

The response variables used were apparent color and turbidity removal. An aliquot of approximately 20 mL of treated residual water was taken to determine these parameters.

Coagulation/flocculation/sedimentation Process

After the optimum conditions of RMS (90 rpm/2minutes) and SMS (15 rpm/10minutes) (Sect. 2.5) were determined, coagulation/flocculation/sedimentation experiments were performed, using dosages of 750 to 2250 mg L−1 in order to have a broader range of concentration for the biocoagulants MobNa, MobK, and MobW prepared with in natura and defatted seeds. The aim was to evaluate the influence of the presence or absence of the “ben oil” in this process and the coagulant dosage. The sedimentation time and the response variables used were the same as previously used.

Coagulation/flocculation/sedimentation Characterization post Treatment

After establishing the best preparation way and the respective dosage of Mob for the fish processing residual water treatment, a coagulation/flocculation/sedimentation experiment was performed with 1000 mL of sample, in triplicate, based on the results of Sect. 2.5 and 2.6. The parameters apparent color, turbidity, COD, dissolved organic carbon, total phosphor, total nitrogen, pH, total solids, and total coliforms were evaluated according to procedures described in Standard Methods for the Examination of Water and Wastewater [34].

Data Analysis

For the statistical analysis of the experiments, the Analysis of Variance (ANOVA), and the F test were performed considering two factors (coagulant type and dosages), to observe their influence on the treatment efficiency. The mean comparison test, the Tukey test, was applied to evaluate the dosages in the treatment efficiency. A confidence level of 95% was applied and the tests were implements by the SISVAR statistical software.

Results and Discussion

Ben oil Extraction from MO seed

After the conventional extraction using n-hexane as the solvent, the oil content of the peeled MO seeds was 38.2%, near the yield obtained by Dezfooli et al. [32] and Garcia-Fayos et al. [45]. MO seeds contain 35 to 45% of oil content and a high concentration of oleic acid (> 73%), making possible its economical exploration [46] in the cosmetics, food, and biodiesel industry [27]. The difference in the oil content of the MO seed is justified by the kind of soil and fertilizer used in the MO cultivation, and also the technique used in the ben oil extraction.

MO seed Characterization

The FTIR spectra in the range of 400–4000 cm−1 of the seeds and defatted seeds are shown in Fig. 1.

A lower intensity of the bands was achieved in the defatted MO seed sample (Fig. 1). According to Vongsvivut et al. [47], in the band of the lipidic fraction in the region of ~ 1743 cm−1, there is the functional group ester of lipid triglycerides, which represent the total lipid in the cells. Thus, when observing Fig. 1, after the seed oil extraction, the band of the fatty acids was not found, similar behavior obtained by Magalhães et al. [48]. The band 1534 cm− 1 is the C–N, and other bands below this group are residual bands of the N-H group, present in the MO seed residue [49].

According to Rajeswari et al. [50], the peak near 1600 cm−1 is related to the presence of amide I and amide II of MO, which indicates the presence of soluble protein in the MO residue [49]. Characteristics bands of functional groups from the protein structure were kept after the ben oil extraction from the MO seed (Fig. 1), demonstrating that extraction residue has added value especially by the presence of coagulant proteins, such as globulin and albumin.

The XRD patterns are shown in Fig. 2 for the in natura MO seeds and the defatted MO seeds. Through those XRD patterns, it is possible to verify the predominance of amorphous nature, since the peaks are poorly resolved, and this is due to protein and lipids, mainly, matrix of the seeds [51, 52]. Even so, it is possible to identify a broad peak at approximately 20º in both patterns, in accordance with patterns for MO seeds found in the literature [51, 53]. Those peaks are of different intensities and are from the oil source material [54], thus justifying the lower intensity of the defatted sample, also confirmed by the FTIR behavior. When extracting the oil, the crystallinity index of the MO seed decreases turning it into a more fibrous material, consequently, increasing the superficial surface [48].

Figure 3 shows the influence of pH in the zeta potential for the in natura and the defatted MO seeds.

According to Fig. 3, different isoelectric points in MO seeds were obtained; the pH values in which the zeta potential was 0 mV were 5.10 for in natura MO seeds, and 8.72 for defatted MO seeds, occurring a displacement of the isoelectric point of the protein after the ben oil extraction. This trend is related to the H+ ions decrease, with leads to the alkaline region, progressively diminishing the zeta potential [55].

From the isoelectric points obtained for MO seeds (in natura and defatted), the ideal ranges for the coagulation process can be concluded as being under pH 5.10 and 8.72, respectively, for the primary treatment of the residual wastewater from fish processing, in which the highest zeta potentials are observed. Therefore, the ben oil extraction, enabled the enlargement of the pH range which it can be used, an important characteristic for the industrial process regarding economic and operating factors.

Biocoagulants Characterization

The aqueous (MobW) and the saline (MobNa and MobK) biocoagulants were characterized regarding protein concentration and zeta potential (Table 2).

MobW presents a protein concentration of 547.87 mg L− 1 (Table 3), similar to the value obtained by Baptista et al. [20], 630.45 mg L− 1. There is an increase in the MO protein concentration when using defatted MO, and according to Ali et al. [35], and Amante et al. [29], the advantages of extracting the oil from MO seed is clear, because there is an increase in the availability of the positively charged protein, organic load reduction of the seeds, besides producing edible oil. The oil extraction of the seed before the coagulant extract preparation is believed to be a primary purification of the protein [32, 33].

The association of the oil extraction with saline solutions enabled better results regarding protein quantity. For the MobNa and MobK biocoagulants, the protein quantity was seven times higher than the one obtained in the aqueous medium. The two main protein fractions in MO seeds are albumin and globulin, which present a solubility difference; albumin is soluble in aqueous medium, while globulins are soluble only in saline solutions [56].

All evaluated coagulants presented positive zeta potential values, confirming that the protein fraction of the MO seed is cationic. In Table 3, the higher value obtained was for MobK coagulant. The protein concentration and the zeta potential of the MobW coagulant were similar to the ones obtained by Baptista et al. [57].

Optimum Conditions for the Coagulation Process

Table 3 presents the mean and the standard deviation values for the removals of the parameters apparent color and turbidity for the coagulants in natura MobNa, MobK, and MobW and the Tukey test result. Therefore, in each column, equal letters mean that there is no statistical difference between the values (p-value > 0.05), and as the letter increases alphabetically, the higher the apparent color or turbidity removal.

The best apparent color and turbidity removals occurred at runs 2, and 8, 2 and 7, 2 and 3 for MobNa, MobK, and MobW, respectively. RMS was not significant for MobNa (p-value = 0.09) and for MobK (p-value = 0.64), however, it was significant for MobW (p-value = 0.00). For all coagulants, SMS and the interaction RMS x SMS were significant (p-value = 0.00), showing that these variables influenced the apparent color and turbidity removals in the confidence level of 95%.

Through Table 3, the behavior is advantageous regarding operating; in the condition in which there are the lower electric consumption and mechanic strength of the equipment, the best turbidity removals percentages were achieved. For the saline biocoagulant MobNa, the best results were obtained in the RMS of 90 rpm and SMS of 15 rpm. For apparent color removal, still considering MobNa, the best results were RMS 90 and 120 and for SMS 15 and 15 rpm, respectively, however, with a difference of 1.26% of removal between both best-obtained conditions. Therefore, the best condition would be attributed to the condition which enabled a lower energy consumption.

The biocoagulants MobK and MobW also presented relevant results in lower mixing speeds. Among the evaluated coagulants, MobK enabled the best apparent color (70.66 and 71.59%), and turbidity (83.07 and 80.57%) removals.

Based on the results obtained in the experimental planning, the experimental conditions of the coagulation/flocculation process were standardized as 90 rpm of RMS, 15 rpm of SMS, with mixing times of 2 and 10 min, respectively.

Efficiency of the MO Biocoagulants

Figure 4a–c present the efficiencies of apparent color and turbidity removals according to different dosages, for the biocoagulants MobNa, MobK, and MobW prepared using in natura and defatted MO seeds.

Apparent color (left column) and turbidity (right column) removal efficiencies obtained with in natura and defatted MO seeds for the biocoagulants: a MobNa, b MobK, c MobW. Capital different letters represent statistical difference between in natura and defatted seeds, and lower case different letters represent statistical difference between the dosages

The results of apparent color and turbidity removals of the evaluated biocoagulants indicate a significant statistical influence (p = 0.00) between the biocoagulants and the dosages evaluated.

For the biocoagulant MobNa (Fig. 4a) prepared with in natura MO seeds, the best apparent color (76.44%) and turbidity (86.17%) removals were achieved in the dosage of 2250 mg L-1. While when prepared with defatted seeds, at a lower dosage (2000 mg L-1), higher apparent color (82.59%) and turbidity (91.40%) removals were possible. However, using MobK (Fig. 4b), similar results were possible with lower dosage; for in natura MO seeds, in the dosage of 1250 mg L-1, 79.34% and 89.42% of apparent color and turbidity removals, respectively, were achieved. In this same dosage, but using defatted MO seeds, the removals were 81.98% for apparent color and 89.15% for turbidity. The best turbidity removal using MobK prepared with defatted MO seeds was 91.01% in the dosage of 1500 mg L-1. Statistically, according to Tukey test, there is no significant difference between the dosages 1250 and 1500 mg L-1. Using a lower biocoagulant dosage in the coagulation/flocculation process is favorable regarding operating cost reduction, and efficiency improvement, besides minimizing the sludge generation and decreasing the organic matter in the aqueous medium [32, 33].

The highest removal efficiencies were obtained with the saline defatted biocoagulants when compared to the in natura coagulants. The biocoagulants extracted in the aqueous medium presented unsatisfactory removals, a behavior observed in the studies of Baptista et al., Madrona et al., and Muthuraman and Sasikala [20, 58, 59], in which they verified that the results from aqueous extraction were not representative regarding apparent color and turbidity removal efficiency. This behavior was observed in this study, in which the best color and turbidity removals obtained by the biocoagulant extracted in the aqueous medium occurred when the defatted seeds were used (91% of turbidity removal and 78% of color removal at 1500 mg L-1). Formentini-Schmitt et al.[15] reported significant results using saline extractions in the treatment of a real effluent from dairy wastewater; Triques et al.[41] comparing saline and aqueous extract also observed better results with saline extracts to treat dairy wastewater.

The difference between the efficiencies of the coagulants extracted with aqueous or saline solution, according to Okuda et al., [30], Madrona et al., [58], and Kansal and Kumari [10], is due to the ionic force of the solution and higher soluble protein solubility. The higher charge density in the salt dissociation causes an improvement in the extraction efficiency of the active component of the MO seeds, consequently, the coagulant activity may increase compared with the aqueous coagulant (7.4 fold higher). This value is similar to the one of the present study (Table 2) in which the concentration of the extracted protein in saline solution was 7.5 and 7.7 fold higher than the aqueous extract (MobW), for MobNa and MobK, respectively.

In the saline extractions, the biocoagulants extracted with KCl were observed to present higher efficiency in apparent color and turbidity removal efficiency, compared to the ones extracted with NaCl. Prasad [60], Madrona et al. [31], and Formentini-Schmitt [22] obtained similar results using the salts KCl and NaCl to extract protein from MO seed.

It is verified that there is no significant difference in the use of MO in natura and defatted in the dosage of 2250 mg L-1 for apparent color removal, and 1250 e 2250 mg L−1 for turbidity removal, using MO seeds extracted with NaCl.

This result has a higher effect in the biocoagulants extracted with KCl, in which the utilization of Mob in natura or defatted did not present a significant difference in the dosages of 750, 1000, 1250, 1750, and 2000 mg L−1 for apparent color removal and in the dosages of 750, 1000, 1250, 1750, 2000, 2250 mg L-1 for turbidity removal.

However, the presence of the “ben oil” in the biocoagulants extracted from “in natura” seed, did not significantly affect the coagulation activity [48, 61], that is, there were no positive nor negative alterations in the color and turbidity removal results. This behavior confirms that when the ben oil is extracted from the MO seeds, the bioactive compound responsible for the coagulant activity of MO seeds remain in the structure (Fig. 1). This is proved by the FTIR spectra of in natura and defatted Moringa seed, in which it is verified that the peaks between 1643 cm−1 and 1532 cm−1, characteristics of the protein structure in the MO seeds that were kept.

The combination of the ben oil extraction and the use of saline solutions for the extraction of coagulant proteins from MO seed can result in economical and sustainable advantages. Muyib et al. [62] and Magalhães et al. [48] observed an increase in the flocculation activity of MO residue generated after ben oil extraction.

Ben oil from MO seed has characteristics that are of industrial interest especially because of the significant quantity of behenic acid, high concentration of oleic acid (higher than 73%), natural emollient with almost no color and odor [46], and low levels of polyunsaturated fatty acids. This low content of polyunsaturated fatty acids provides the oil good stability, important to the cosmetic industry. It also has application in biofuels [27, 63]. Thus, the utilization of the MO seed can be an environment, sustainable, and viable alternative, expanding its use in different industrial sectors.

Coagulation/Flocculation/Characterization After the Primary Treatment

After obtaining the optimum Jar test conditions, the best MOB solution, and its optimum concentration, the optimized experiment was performed and the physical-chemical parameters were analyzed for the characterization of the raw residual water and the treated one.

Table 4 presents the values of the physical-chemical parameters analyzed in the characterization of the raw residual water and treated residual water by the process of coagulation/flocculation/sedimentation in the conditions RMS 90 rpm for 2 min, SMS 15 rpm for 10 min, and sedimentation time of 60 min, using MobK defatted as coagulant solution in the dosage of 1250 mg L−1.

In Brazil, the release of effluents is conditioned to the requirements established by the Federal Resolution 430/2011 from CONAMA which establishes conditions, standards, and applicable requirements [64]. Regionally, the Paraná state follows determinations from the Resolution 070/2009 from the State Board of Environment [65] regarding environmental licensing and conditions of industrial enterprises. The maximum standard for the release of animals slaughterhouse wastewater into hydric resources is 125 mg L−1 for COD and the pH range is between 5 and 9 for both resolutions [64, 65]. The pH is already in concordance with legislation, while the COD would require a secondary or polishment treatment (Table 4).

Through Table 4, a significant reduction of most analyzed parameters can be observed, highlighting turbidity (90.85%), apparent color (79.50%), COD (71.48%), and Total Solids (62.72%). The high turbidity removal confirms the influence of initial turbidity in the coagulation process efficiency using MO coagulant, better removal percentages are obtained at higher initial turbidity in waters to be treated [66].

It is verified that the pH variation of raw residual water (7.68), and treated residual water (7.20) by the coagulation/flocculation process did not present significant difference, similar behavior observed by Prasad [60] and Formentini-Schmitt et al. [67], both used MO seeds as coagulants. Besides, the natural pH of the residual water was at the bigger range of stability, lower than 8.72, isoelectric point of defatted MO (Fig. 3). In operational and economic terms in an industrial process, the unchanged effluent pH before and after the treatment can be considered an advantage to the use of MO seed coagulant.

In Table 4, removal of 84.77% of Total coliforms in the treated residual water, however, it was not completely removed, but shows that MO residue has an antimicrobial function. Kwabena Ntibrey et al. [68] obtained similar removal of 91% of Total Coliforms for residual water treatment. Literature reports that MO soluble proteins besides bioactive compounds with excellent coagulant property also presents antimicrobial action, reducing the bacteria load presented in residual waters [69, 70].

The COD removal efficiency reveals that the coagulation/flocculation process using defatted MO as a coagulant for a primary treatment exceeds expectations. It is highlighted that experimental studies that used MO seed as a coagulant, usually, do not reach satisfactory COD removals. Formentini-Schimitt et al.[22] obtained 39% of COD removal from dairy effluent after the coagulation/flocculation step using protein coagulant of MO extracted with KCl; Triques et al.[41] did not obtain COD removal using MO coagulant extracted with CaCl2 in the treatment process of a dairy cleaning-in-place effluent; Thus, there is an indication that the extraction residue utilization may be a sustainable and viable coagulation technique that helps in the reduction of organic matter from residual waters. It is believed that the presence of oil in the MO seed creates an emulsion or a coating film promoting inhibition of the contact between the coagulant and the particulate material surface, reducing the formation of bigger flocs [33].

An effluent with high COD indicates contamination through organic matter and in general, it turns the primary treatment not enough to remove it to acceptable levels of post-treated effluent discharge into receiving bodies or reuse for different purposes. Residual organic matter in treated waters can be disadvantageous if the water is going to be reused because microorganisms easily develop themselves in such conditions [71]. Thus, the COD removal result obtained in the present study point to a promising way in the application of biocoagulant of defatted MO seed in the primary treatment of residual waters with high organic matter concentration.

Table 5 presents a comparative between the COD removals from studies from the literature to treat fish processing wastewaters. From the Table, coagulation/flocculation using MobK is a very promising primary treatment since the result obtained for this important parameter was very competitive compared to other techniques. Even so it is not the highest removal achieved, it was better when compared to other coagulants from the literature [72]. Also, compared to other techniques, coagulation/flocculation with MobK is advantageous for being simpler and faster [7].

In general, the use of MO seeds as a natural coagulant for the treatment of residual waters from fish processing presented good results of removal of the parameters studied, with great possibilities of application in a primary treatment step, for being a simple, of easy operation, and low-cost process in the treatment of those effluents. According to Cristóvão [7], the primary treatment coagulation/flocculation/sedimentation is of extreme importance for the efficiency of the subsequent polishing treatments. The authors claimed that MO seeds are a great alternative to use in the primary treatment of residual waters from fish processing industries.

Another relevant aspect in the use of MO seeds is to reduce the processing cost and enable a favorable approach to the environment, for being a natural coagulant [73]. However, it is evident in the present study that the residue obtained in the ben oil extraction can be used without decreasing the MO protein coagulant efficiency.

Conclusion

The treatment of residual water from fish processing using Mob in the coagulation/flocculation/sedimentation process was efficient and showed itself as an alternative to the primary treatment step. The ideal concentration considered was 1250 mg L− 1 of MobK (defatted). With this saline biocoagulant and concentration, 90.85% of turbidity, 79.50% of apparent color, and 71.48% of chemical oxygen demand removals were achieved. Even with this high removals, the wastewater is still not adequate to be released into hydric resources, but compared to other treatments, is efficient and an excellent option considering that coagulation/flocculation is a primary treatment.

The presence of “ben oil” in the biocoagulant extracts did not affect the performance of them in the treatment of residual waters from fish processing. There were no significant increases in the removal of apparent color and turbidity, which could be attributed to the oil presence. The extraction residue, a residue from “ben oil” extraction from MO seeds, can be used in the obtention of MobK (defatted), which represents an environmentally friendly alternative, because the ben oil can be destined a commercial product while the residue can be used in the wastewater treatment. Thus, this research contributes to both the wastewater treatment and to biomass valorization.

Data Availability

Not applicable.

Abbreviations

- ANOVA:

-

Analysis of Variance

- COD:

-

Chemical oxygen demand

- FTIR:

-

Fourier-transform infrared spectroscopy

- MO:

-

Moringa oleifera

- Mob:

-

Moringa oleifera biocoagulant

- MobK:

-

Moringa oleifera biocoagulant prepared with KCl

- MobNa:

-

Moringa oleifera biocoagulant prepared with NaCl

- MobW:

-

Moringa oleifera biocoagulant prepared with water

- RMS:

-

Rapid mixing speed

- SMS:

-

Slow mixing speed

- XRD:

-

X-ray diffractometry

References

FAO, UNICEF, F.I.D.A., PAM, OMS: : O Estado da Segurança Alimentar e Nutricional no Mundo 2022. Redefinir políticas alimentares e agrícolas para tornar as dietas saudáveis mais acessíveis. (2020). https://doi.org/10.4060/cc0639en

Instituto Brasileiro de Geografia e Estatística - IBGE:. Produção da Pecuária Municipal. (2021). https://www.ibge.gov.br/estatisticas

de Ribeiro, M., Naval, F.H.: Reuse alternatives for effluents from the fish processing industry through multi-criteria analysis. J. Clean. Prod. 227, 336–345 (2019). https://doi.org/10.1016/j.jclepro.2019.04.110

Sasidharan, A., Venugopal, V.: Proteins and Co-products from Seafood Processing Discards: Their Recovery, Functional Properties and Applications. Waste Biomass Valorization (2020). https://doi.org/10.1007/s12649-019-00812-9

Ferraciolli, L.M.R.V.D., de Bem Luiz, D., dos Santos, V.R.V., Naval, L.P.: Reduction in water consumption and liquid effluent generation at a fish processing plant. J. Clean. Prod. 197, 948–956 (2018). https://doi.org/10.1016/j.jclepro.2018.06.088

Chowdhury, P., Viraraghavan, T., Srinivasan, A.: Biological treatment processes for fish processing wastewater - A review. Bioresour Technol. 101, 439–449 (2010). https://doi.org/10.1016/j.biortech.2009.08.065

Cristóvaõ, R.O., Botelho, C.M., Martins, R.J.E., Loureiro, J.M., Boaventura, R.A.R.: Fish canning industry wastewater treatment for water reuse - a case study. J. Clean. Prod. 87, 603–612 (2015). https://doi.org/10.1016/j.jclepro.2014.10.076

Carvalho, F., Prazeres, A.R., Rivas, J.: Cheese whey wastewater: Characterization and treatment. Sci. Total Environ. 445–446, 385–396 (2013). https://doi.org/10.1016/j.scitotenv.2012.12.038

Domínguez-Robles, J., Palenzuela, M.V., Sánchez, R., Loaiza, J.M., Espinosa, E., Rosal, A., Rodríguez, A.: Coagulation–flocculation as an alternative way to reduce the toxicity of the Black Liquor from the Paper Industry: Thermal valorization of the solid Biomass recovered. Waste Biomass Valorization. 11, 4731–4742 (2020). https://doi.org/10.1007/s12649-019-00795-7

Kansal, S.K., Kumari, A.: Potential of M. oleifera for the treatment of water and wastewater. Chem. Rev. 114, 4993–5010 (2014). https://doi.org/10.1021/cr400093w

Ghebremichael, K.A., Hultman, B.: Alum sludge dewatering using Moringa oleifera as a conditioner. Water Air Soil Pollut. 158, 153–167 (2004). https://doi.org/10.1023/B:WATE.0000044852.23764.9c

Ang, W.L., Mohammad, A.W., Benamor, A., Hilal, N.: Hybrid coagulation – NF membrane processes for brackish water treatment: Effect of pH and salt / calcium concentration. DES. 390, 25–32 (2016). https://doi.org/10.1016/j.desal.2016.03.018

Kukić, D.V., Šćiban, M.B., Prodanović, J.M., Tepić, A.N., Vasić, M.A.: Extracts of fava bean (Vicia faba L.) seeds as natural coagulants. Ecol. Eng. 84, 229–232 (2015). https://doi.org/10.1016/j.ecoleng.2015.09.008

Hameed, Y.T., Idris, A., Hussain, S.A., Abdullah, N.: A tannin-based agent for coagulation and flocculation of municipal wastewater: Chemical composition, performance assessment compared to Polyaluminum chloride, and application in a pilot plant. J. Environ. Manage. 184, 494–503 (2016). https://doi.org/10.1016/j.jenvman.2016.10.033

Formentini-Schmitt, D.M., Fagundes-Klen, M.R., Veit, M.T., Palácio, S.M., Trigueros, D.E.G., Bergamasco, R., Mateus, G.A.P.: Potential of the Moringa oleifera saline extract for the treatment of dairy wastewater: Application of the response surface methodology. Environ. Technol. (United Kingdom). 40, 2290–2299 (2019). https://doi.org/10.1080/09593330.2018.1440012

Ndabigengesere, A., Narasiah, K.S.: Quality of Water treated by coagulation using Moringa oleifera seeds. Water Res. 32, 781–791 (1998)

Katayon, S., Noor, M.J.M.M., Asma, M., Ghani, L.A.A., Thamer, A.M., Azni, I., Ahmad, J., Khor, B.C., Suleyman, A.M.: Effects of storage conditions of Moringa oleifera seeds on its performance in coagulation. Bioresour. Technol. 97, 1455–1460 (2006). https://doi.org/10.1016/j.biortech.2005.07.031

Yin, C.: Emerging usage of plant-based coagulants for water and wastewater treatment. Process Biochem. 45, 1437–1444 (2010). https://doi.org/10.1016/j.procbio.2010.05.030

Nishi, L., Vieira, A.M.S., Vieira, M.F., Silva, G.F.: Application of hybrid process of coagulation / flocculation and membrane filtration for the removal of protozoan parasites from water. Procedia Eng. 42, 148–160 (2012). https://doi.org/10.1016/j.proeng.2012.07.405

Baptista, A.T.A., Coldebella, P.F., Cardines, P.H.F., Gomes, R.G., Vieira, M.F., Bergamasco, R., Vieira, A.M.S.: Coagulation-flocculation process with ultrafiltered saline extract of moringa oleifera for the treatment of surface water. Chem. Eng. J. 276, 166–173 (2015). https://doi.org/10.1016/j.cej.2015.04.045

Camacho, F.P., Sousa, V.S., Bergamasco, R., Ribau Teixeira, M.: The use of Moringa oleifera as a natural coagulant in surface water treatment. Chem. Eng. J. 313, 226–237 (2017). https://doi.org/10.1016/j.cej.2016.12.031

Formentini-Schmitt, D.M., Fagundes-Klen, M.R., Veit, M.T., Bergamasco, R., Ferrandin, A.T.: Estudo da Eficiência do Composto Ativo de Moringa Oleifera Extraída com Soluções Salinas na Tratabilidade de Águas Residuárias da Indústria de Laticínios. Engevista. 16, 221 (2013). https://doi.org/10.22409/engevista.v16i2.435

Razis, A.F.A., Ibrahim, M.D., Kntayya, S.B.: Health benefits of Moringa oleifera. Asian Pac. J. Cancer Prev. 15, 8571–8576 (2014). https://doi.org/10.7314/APJCP.2014.15.20.8571

Santos, A.F.S., Luz, L.A., Pontual, E.V., Napoleão, T.H., Paiva, P.M.G., Coelho, L.C.B.B.: Moringa oleifera: resource management and multiuse life tree. Adv. Res. 4, 388–402 (2015). https://doi.org/10.9734/air/2015/18177

Ndabigengesere, A., Narasiah, K.S., Talbot, B.G.: Active agents and mechanism of coagulation of turbid waters using Moringa oleifera. Water Res. 29, 703–710 (1995). https://doi.org/10.1016/0043-1354(94)00161-Y

Ghebremichael, K.A., Gunaratna, K.R., Henriksson, H., Brumer, H., Dalhammar, G.: A simple purification and activity assay of the coagulant protein from Moringa oleifera seed. Water Res. 39, 2338–2344 (2005). https://doi.org/10.1016/j.watres.2005.04.012

Mofijur, M., Masjuki, H.H., Kalam, M.A., Atabani, A.E., Arbab, M.I., Cheng, S.F., Gouk, S.W.: Properties and use of Moringa oleifera biodiesel and diesel fuel blends in a multi-cylinder diesel engine. Energy Convers. Manag. 82, 169–176 (2014). https://doi.org/10.1016/j.enconman.2014.02.073

de Oliveira, A.P.S., de Santana Silva, L.L., de Albuquerque Lima, T., Pontual, E.V., de Lima Santos, N.D., Coelho, L.C.B.B., Navarro, D.M.D.A.F., Zingali, R.B., Napoleão, T.H., Paiva, P.M.G.: Biotechnological value of Moringa oleifera seed cake as source of insecticidal lectin against Aedes aegypti. Process Biochem. 51, 1683–1690 (2016). https://doi.org/10.1016/j.procbio.2016.06.026

Amante, B., López-Grimau, V., Smith, T.: Valuation of oil extraction residue from Moringa oleifera seeds for water purification in Burkina Faso. Desalin. Water Treat. 57, 2743–2749 (2016). https://doi.org/10.1080/19443994.2015.1047408

Okuda, T., Baes, A.U., Nishijima, W., Okada, M.: Research note improvement of extraction method of coagulation active components from Moringa oleifera seed. Water Res. 33, 3373–3378 (1999)

Madrona, G.S., Bergamasco, R., Seolin, V.J., Fagundes Klen, M.R.: The potential of different saline solution on the extraction of the Moringa oleifera seed’s active component for water treatment. Int. J. Chem. Reactor Eng. (2011). https://doi.org/10.1515/1542-6580.2511

Dezfooli, S.M., Uversky, V.N., Saleem, M., Baharudin, F.S., Hitam, S.M.S., Bachmann, R.T.: A simplified method for the purification of an intrinsically disordered coagulant protein from defatted Moringa oleifera seeds. Process Biochem. 51, 1085–1091 (2016). https://doi.org/10.1016/j.procbio.2016.04.021

Gidde, M.R., Bhalerao, A.R., Malusare, C.N.: Comparative study of different forms of Moringa Oleifera extracts for turbidity removal. Int. J. Eng. Res. Dev. 2, 14–21 (2012)

APHA: Standard Methods for the Examination of Water and Wastewater. 21st Edition. Washingtong, DC:. (2005)

Ali, E.N., Muyibi, S.A., Salleh, H.M., Alam, M.Z., Salleh, M.R.M.: Production of natural coagulant from Moringa Oleifera seed for application in treatment of low Turbidity Water. J. Water Resour. Prot. 02, 259–266 (2010). https://doi.org/10.4236/jwarp.2010.23030

Nwaiwu, N.E., Zalkiful, M.A., Raufu, I.A.: Seeking an alternative antibacterial and coagulation agent for household water treatment. J. Appl. Phytotechnology Environ. Sanitation. 1, 1–9 (2012)

Santos, K.A., Frohlich, P.C., Hoscheid, J., Tiuman, T.S., Gonçalves, J.E., Cardozo-Filho, L., da Silva, E.A.: Candeia (Eremanthus erythroppapus) oil extraction using supercritical CO2 with ethanol and ethyl acetate cosolvents. J. Supercrit. Fluids. 128, 323–330 (2017). https://doi.org/10.1016/j.supflu.2017.03.029

Cardoso, K.C.: Estudo do processo de coagulação/floculação por meio da Moringa oleifera Lam para obtenção de água potável, Maringá PR. Universidade Estadual de Maringá, 123p. Dissertação (Mestrado). (2007). (2007)

Beltrán-Heredia, J., Sánchez-Martín, J.: Removal of sodium lauryl sulphate by coagulation/flocculation with Moringa oleifera seed extract. J. Hazard. Mater. 164, 713–719 (2009). https://doi.org/10.1016/j.jhazmat.2008.08.053

Lowry, O.H., Rosebrough, N.J., Farr, A.L., Randall, R.J.: Protein measurement with the Folin phenol reagent. J. Biol. Chem. 193, 265–275 (1951). https://doi.org/10.1016/s0021-9258(19)52451-6

Triques, C.C., Fagundes-Klen, M.R., Suzaki, P.Y.R., Mateus, G.A.P., Wernke, G., Bergamasco, R., Rodrigues, M.L.F.: Influence evaluation of the functionalization of magnetic nanoparticles with a natural extract coagulant in the primary treatment of a dairy cleaning-in-place wastewater. J. Clean. Prod. (2020). https://doi.org/10.1016/j.jclepro.2019.118634

Antunes, A., dos Triques, S., Buzanello-Martins, C.C., Mateus, C.V., Bergamasco, G.A.P., Fagundes-Klen, R.: Influence of bionanoparticles to treat a slaughterhouse wastewater. Environ. Technol. (United Kingdom). 43, 4528–4544 (2022). https://doi.org/10.1080/09593330.2021.1955016

dos Santos, T.R.T., Silva, M.F., de Andrade, M.B., Vieira, M.F., Bergamasco, R.: Magnetic coagulant based on moringa oleifera seeds extract and super paramagnetic nanoparticles: optimization of operational conditions and reuse evaluation. Desalin. Water Treat. 106, 226–237 (2018). https://doi.org/10.5004/dwt.2018.22065

Bhuptawat, H., Folkard, G.K., Chaudhari, S.: Innovative physico-chemical treatment of wastewater incorporating Moringa oleifera seed coagulant. J. Hazard. Mater. 142, 477–482 (2007). https://doi.org/10.1016/j.jhazmat.2006.08.044

Garcia-Fayos, B., Arnal, J.M., Sancho, M., Rodrigo, I.: Moringa oleifera for drinking water treatment: Influence of the solvent and method used in oil-extraction on the coagulant efficiency of the seed extract. Desalin. Water Treat. 57, 23397–23404 (2016). https://doi.org/10.1080/19443994.2015.1137144

Ayerza, R.: Seed yield components, oil content, and fatty acid composition of two cultivars of moringa (Moringa oleifera Lam.) Growing in the Arid Chaco of Argentina. Ind. Crops Prod. 33, 389–394 (2011). https://doi.org/10.1016/j.indcrop.2010.11.003

Vongsvivut, J., Heraud, P., Gupta, A., Puri, M., McNaughton, D., Barrow, C.J.: FTIR microspectroscopy for rapid screening and monitoring of polyunsaturated fatty acid production in commercially valuable marine yeasts and protists. Analyst. 138, 6016–6031 (2013). https://doi.org/10.1039/c3an00485f

Magalhães, E.R.B., de Menezes, N.N.F., Silva, F.L., Garrido, J.W.A., Sousa, M.A.D.S.B., dos Santos, E.S.: Effect of oil extraction on the composition, structure, and coagulant effect of Moringa oleifera seeds. J. Clean Prod. (2021). https://doi.org/10.1016/j.jclepro.2020.123902

Zaid, A.Q., Ghazali, S.B.: Dataset on physicochemical properties of particle-sized Moringa oleifera seed cake and its application as bio-coagulants in water treatment application. Chem. Data Collections (2019). https://doi.org/10.1016/j.cdc.2019.100284

Rajeswari, M., Agrawal, P., Roopa, G., Jain, A.A., Kumar Gupta, P.: Green Synthesis and Characterization of Multifunctional Zinc Oxide Nanomaterials using Extract of Moringa Oleifera Seed. (2018)

Araújo, C.S.T., Alves, V.N., Rezende, H.C., Almeida, I.L.S., De Assunção, R.M.N., Tarley, C.R.T., Segatelli, M.G., Coelho, N.M.M.: Characterization and use of Moringa oleifera seeds as biosorbent for removing metal ions from aqueous effluents. Water Sci. Technol. 62, 2198–2203 (2010). https://doi.org/10.2166/wst.2010.419

Kebede, T.G., Mengistie, A.A., Dube, S., Nkambule, T.T.I., Nindi, M.M.: Study on adsorption of some common metal ions present in industrial effluents by Moringa stenopetala seed powder. J. Environ. Chem. Eng. 6, 1378–1389 (2018). https://doi.org/10.1016/j.jece.2018.01.012

Reck, I.M., Paixão, R.M., Bergamasco, R., Vieira, M.F., Vieira, A.M.S.: Removal of tartrazine from aqueous solutions using adsorbents based on activated carbon and Moringa oleifera seeds. J. Clean. Prod. 171, 85–97 (2018). https://doi.org/10.1016/j.jclepro.2017.09.237

Vaziri, A.S., Alemzadeh, I., Vossoughi, M., Khorasani, A.C.: Co-microencapsulation of Lactobacillus plantarum and DHA fatty acid in alginate-pectin-gelatin biocomposites. Carbohydr. Polym. 199, 266–275 (2018). https://doi.org/10.1016/j.carbpol.2018.07.002

Barick, P., Prasad Saha, B., Mitra, R., Joshi, S.V.: Effect of concentration and molecular weight of polyethylenimine on zeta potential, isoelectric point of nanocrystalline silicon carbide in aqueous and ethanol medium. Ceram. Int. 41, 4289–4293 (2015). https://doi.org/10.1016/j.ceramint.2014.11.115

Aderinola, T.A., Alashi, A.M., Nwachukwu, I.D., Fagbemi, T.N., Enujiugha, V.N., Aluko, R.E.: In vitro digestibility, structural and functional properties of Moringa oleifera seed proteins. Food Hydrocoll. 101, 105574 (2020). https://doi.org/10.1016/j.foodhyd.2019.105574

Baptista, A.T.A., Silva, M.O., Gomes, R.G., Bergamasco, R., Vieira, M.F., Vieira Salcedo, A.M.: Protein fractionation of seeds of Moringa oleifera lam and its application in superficial water treatment. Sep. Purif. Technol. 180, 114–124 (2017). https://doi.org/10.1016/j.seppur.2017.02.040

Madrona, G.S., Serpelloni, G.B., Salcedo Vieira, A.M., Nishi, L., Cardoso, K.C., Bergamasco, R.: Study of the effect of saline solution on the extraction of the Moringa oleifera seed’s active component for water treatment. Water Air Soil Pollut. 211, 409–415 (2010). https://doi.org/10.1007/s11270-009-0309-0

Muthuraman, G., Sasikala, S.: Removal of turbidity from drinking water using natural coagulants. J. Ind. Eng. Chem. 20, 1727–1731 (2014). https://doi.org/10.1016/j.jiec.2013.08.023

Prasad, R.K.: Color removal from distillery spent wash through coagulation using Moringa oleifera seeds: Use of optimum response surface methodology. J. Hazard. Mater. 165, 804–811 (2009). https://doi.org/10.1016/j.jhazmat.2008.10.068

Nordmark, B.A., Przybycien, T.M., Tilton, R.D.: Comparative coagulation performance study of Moringa oleifera cationic protein fractions with varying water hardness. J. Environ. Chem. Eng. 4, 4690–4698 (2016). https://doi.org/10.1016/j.jece.2016.10.029

Muyibi, S.A., Noor, M.J.M., Loon, L.H.: Effects of oil extraction from Moringa oleifera seeds on coagulation of turbid water. Int. J. Environ. Stud. 59, 243–254 (2002). https://doi.org/10.1080/00207230210924

Rashid, U., Anwar, F., Ashraf, M., Saleem, M., Yusup, S.: Application of response surface methodology for optimizing transesterification of Moringa oleifera oil: Biodiesel production. Energy Convers. Manag. 52, 3034–3042 (2011). https://doi.org/10.1016/j.enconman.2011.04.018

Brasil:. : Ministério do Meio ambiente. CONAMA. Resolução no 357 de 17 de março de 2005. https://www.icmbio.gov.br/cepsul/images/stories/legislacao/Resolucao/2005/res_conama_357_2005_classificacao_corpos_agua_rtfcda_altrd_res_393_2007_397_2008_410_2009_430_2011.pdf

CEMA: : Resolução CEMA no 70 de 01/10/2009. https://www.legisweb.com.br/legislacao/?id=144192

Salazar Gámez, L.L., Luna-delisco, M., Cano, R.E.S.: Comparative study between M oleifera and aluminum sulfate for water treatment: case study Colombia. Environ. Monit. Assess. (2015). https://doi.org/10.1007/s10661-015-4793-y

Formentini-Schmitt, D.M., Alves, Ã.C.D., Veit, M.T., Bergamasco, R., Vieira, A.M.S., Fagundes-Klen, M.R.: Ultrafiltration combined with coagulation/flocculation/sedimentation using moringa oleifera as coagulant to treat dairy industry wastewater. Water Air Soil Pollut. (2013). https://doi.org/10.1007/s11270-013-1682-2

Kwabena Ntibrey, R.A., Kuranchie, F.A., Gyasi, S.F.: Antimicrobial and coagulation potential of Moringa oleifera seed powder coupled with sand filtration for treatment of bath wastewater from public senior high schools in Ghana. Heliyon. 6, e04627 (2020). https://doi.org/10.1016/j.heliyon.2020.e04627

Bancessi, A., Pinto, M.M.F., Duarte, E., Catarino, L., Nazareth, T.: The antimicrobial properties of Moringa oleifera Lam. For water treatment: A systematic review. SN Appl. Sci. 2, 1–9 (2020). https://doi.org/10.1007/s42452-020-2142-4

Ueda Yamaguchi, N., Cusioli, L.F., Quesada, H.B., Camargo Ferreira, M.E., Fagundes-Klen, M.R., Salcedo Vieira, A.M., Gomes, R.G., Vieira, M.F., Bergamasco, R.: A review of Moringa oleifera seeds in water treatment: trends and future challenges. Process Saf. Environ. Prot. 147, 405–420 (2021). https://doi.org/10.1016/j.psep.2020.09.044

Boulaadjoul, S., Zemmouri, H., Bendjama, Z., Drouiche, N.: A novel use of Moringa oleifera seed powder in enhancing the primary treatment of paper mill effluent. Chemosphere. 206, 142–149 (2018). https://doi.org/10.1016/j.chemosphere.2018.04.123

Cristóvão, R.O., Botelho, C.M., Martins, R.J.E., Loureiro, J.M., Boaventura, R.A.R.: Primary treatment optimization of a fish canning wastewater from a portuguese plant. Water Resour. Ind. 6, 51–63 (2014). https://doi.org/10.1016/j.wri.2014.07.002

Abdul Hamid, S.H., Lananan, F., Khatoon, H., Jusoh, A., Endut, A.: A study of coagulating protein of Moringa oleifera in microalgae bio-flocculation. Int. Biodeterior. Biodegradation. 113, 310–317 (2016). https://doi.org/10.1016/j.ibiod.2016.03.027

Sanjaya, E.H., Chen, Y., Guo, Y., Wu, J., Chen, H., Din, M.F.M., Li, Y.Y.: The performance of simultaneous partial nitritation, anammox, denitrification, and COD oxidation (SNADCO) method in the treatment of digested effluent of fish processing wastewater. Bioresour. Technol. (2022). https://doi.org/10.1016/j.biortech.2021.126622

Anh, H.T.H., Shahsavari, E., Bott, N.J., Ball, A.S.: The application of Marinobacter hydrocarbonoclasticus as a bioaugmentation agent for the enhanced treatment of non-sterile fish wastewater. J. Environ. Manage. (2021). https://doi.org/10.1016/j.jenvman.2021.112658

Dhanke, P., Wagh, S., Kanse, N.: Degradation of Fish Processing Industry Wastewater in Hydro-cavitation Reactor. (2018)

Acknowledgements

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior - Brasil (CAPES).

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fagundes-Klen, M.R., Gullich, C.T.B., Triques, C.C. et al. Valorization of the Coagulant Bioactive Compound of the Moringa seed Residue: Treatability of Fish Processing Residuary Waters. Waste Biomass Valor 14, 4113–4126 (2023). https://doi.org/10.1007/s12649-023-02110-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-023-02110-x