Abstract

Vegetable oil has shown a promising behaviour in replacing mineral insulating oil for transformer insulation due to the environmental unfriendliness of mineral oil. However, attention was placed mostly on edible oil which may eventually lead to food competition. In this work ester from Thevetia Peruviana oil, non-edible vegetable oil was considered as alternative oil for transformer insulation. The functional groups and the fingerprints of the synthesized methyl ester from the yellow oleander oil were confirmed using Fourier Transform Infrared (FTIR) Spectrometry and the fatty acid composition was determined with Gas chromatography mass spectrometry (GC/MS). The viscosity of methyl ester and mineral oil were obtained to be 4.8 mPas and 9.8 mPas at 30 °C. The pour point of methyl ester was obtained to be 1.4 °C which could be enhanced by a pour point depressant when considering it for use in a low temperate region. The adequacy of this synthesized oil as an insulating oil was further explored by measuring the dielectric properties. The result revealed that methyl ester has a higher dielectric constant relative to mineral oil and a dielectric loss of 0.0045 at 30 °C. The dielectric strength of the oil was analysed using two-parameter Weibull plots. The characteristic breakdown strength of mineral oil and yellow oleander methyl ester was obtained to be 21.9 kV and 23.3 kV respectively. The result obtained from this work is an indication that methyl ester from the non-edible vegetable oil is a promising alternative insulating oil for oil-filled transformer insulation.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of Novelty

In this work, a non-edible oil extracted from Yellow Oleander seed is used. These plants are abundantly found in Nigeria and are mostly used as fences and ornamental plants in houses and schools respectively. Also, the seeds from this plant are un-useful and have no economic value in Nigeria. This oil is highly unsaturated, and the report shows that oil with a high level of unsaturation possesses a good melting point and pour point which makes them a suitable candidate for use in a sub-zero temperature region [1]. In addition, putting attention to this vegetable oil product is a great potential for enhancing rural economic development as this will bring fortune to society at large [1, 2].

Introduction

The importance of a transformer in an electric power network (generation, transmission, and distribution) cannot be overemphasized [3]. This device which plays a key role in an electrical network depends on proper insulation and cooling for a good lifecycle and operational consistency [4]. A composite insulation system is used for a transformer that comprises the oil and the paper insulation [5]. Oil in transformer serves the purpose of cooling, insulation and as a medium of testing the condition of the transformer [4]. Mineral oil over the years has served the electrical industries for cooling and insulation in oil-filled high voltage equipment. This oil is obtained from the fractional distillation of petroleum crude stocks [6]. They possess excellent cooling behaviour and good dielectric properties. Their resistance to quick ageing rate is a major distinguishing property that is associated with these oils. However, for over two centuries, the entire world depends on non-renewable crude oil derived from fossil fuels for energy supply. Estimated records have shown that 90% of this non-renewable crude oil is being used for energy production and transportation [2]. This presently has now tackled the universe with the catastrophe of fossil fuel depletion and environmental degradation [7, 8]. In addition, there is a tendency for a scarcity of these oils in the nearest future [4, 9]. A good dielectric oil must give a reasonable balance between the environmental impact and operational performance. It must also be renewable whenever sustainability is put into consideration [4]. Therefore, the prospective alternative oils must align with the environmental regulations and be renewable. Over the years, the environmental and fire-related performances of ester-based dielectric fluid have been studied and it was revealed that ester dielectric oil provides several advantages in comparison with mineral oil [10]. Among these advantages are high flash point, high thermal conductivity, and high affinity for water which protect against cellulose degradation [11]. Despite the aforementioned qualities of these vegetable oils, they still face some challenges such as high viscosity and high pour point which affect their cooling behaviour and limit their usage in high voltage equipment. These hitches hindered the full acceptance of these oils by the transformers manufacturers [12]. In 2011, Shah et al. worked on the dielectric properties of edible vegetable oil, and it was reported that cottonseed oil and corn oil can serve as a replacement for mineral insulating oil [13]. Abdelmalik, worked on the chemical modification of palm kernel oil, a saturated fatty acid and it was reported that after the chemical modification, the viscosity of the oil reduces which makes it a good cooling oil [14]. But most efforts on alternative insulating oil are on edible seed oil. The two popular commercially available natural ester insulating fluids (FR3 and Midel EN) are from edible seed oil. In 2018, Abdelmalik et al. also worked on the assessment of Jatropha Oil, a non-edible seed oil, as an insulating fluid for power transformers. They reported that Jatropha oil is a good high-temperature liquid due to its high flash point. They also concluded that Jatropha oil has a good dielectric property but with high viscosity [2]. In 2018, a work titled synthesis and characterization of a potential bio-based dielectric fluid from Neem oilseed, another non-edible oil was reported. The report revealed that Neem oil is a potential replacement for mineral insulating oil due to the low value of dielectric loss and AC conductivity [15]. The literature reveals that research in the application of vegetable oil as an insulating oil has gained attention, however, more studies need to be done on this oil especially, the non-edible one to prevent competition with consumption [16]. The oil used in this work is gotten from yellow oleander plant, a plant that is considered economically useless and poisonous [17]. This plant can be found virtually everywhere in the world and can survive in both dry and wetlands. This evergreen plant has its origin in America and is popularly grown in continents like Africa, Asia, and America. The seed from this plant has been reported to have an abundant yield of oil [18].

Materials and Methods

Materials

The seeds of yellow oleander were collected through handpicking at Ahmadu Bello University Zaria. NaOH, citric acid, silica gel, Methanol, and filter paper (Whatman No. 1 and 5) were locally purchased within Nigeria. The bleaching clay was obtained from Parco Enterprises Nig. Ltd.

Sample Preparation

The extraction of Yellow Oleander seed oil was done at the National Research Institute for Chemicals Technology (NARICT), Zaria, Nigeria. The chart in Fig. 1 shows the systematic flow of the sample preparation.

The mechanical press method of extraction was used to extract the oil of yellow oleander instead of chemical method which might introduce some traces of ionic impurities that can be ionized when subjected to a high electric field and eventually leads to an increase in conduction rate. The amount of the seed collected was weighed before and after grinding and it weighed 2.8 kg. The grinding of the seed to smaller particles was done to increase the surface area which aids in the steaming process. This allows virtually every particle to receive a reasonable amount of heat. The steaming process was done to melt the oil present in the seed. The crushed seed was wrapped in a sieve cloth, put in a mesh, and placed at the top of boiling water for 1 h for proper steaming. The steamed particles were then transferred into a mechanical pressing machine, and it was pressed until the oil was completely extracted. The collected oil sample was weighed to see the percentage yield of the seed using Eq. (1).

The mass of the oil obtained after the extraction was 1 kg which amounts to a 35.7% yield. Figure 2a and b show Yellow Oleander seed before extraction and the extracted oil respectively.

The purification method by Oparanti et al., was adopted [7]. A freshly prepared citric acid solution was used for degumming. The degumming was done through the addition of 1.5 ml citric acid solution to a pre-heated 200 ml of oil sample. The solution was stirred using a Faithful SH-2 magnetic stirrer for 25 min at a steady temperature of 60 °C. An aqueous solution of NaOH, 8% w/w concentration was added to the solution to reduce the acidity. The solution was stirred at the same temperature for 20 min for homogeneity and a complete acid–base reaction. The solution was transferred into a vacuum oven and was heated for 1 h at 80 °C, 60 cmHg to remove the moisture content in the solution. To remove any traces of moisture in the sample after the heating, 2 g of Silica gel was added and stirred for 15 min. The solution was bleached by adding 5 g of fuller earth to the solution and stirred for 20 min. The bleaching clay also helps in the cationic exchange of magnesium from the centre of the chlorophyll complex of the oil, attaching directly to the clay. This also helps in the removal of some metal pro-oxidants such as nickel, iron, and copper [19]. The solution was then filtered using Whatman number 1 and number 5. After the purification process of the oil, the viscosity of the oil was reduced through transesterification. The transesterification process was done using methanol, and NaOH pellet was used as the catalyst. The NaOH pellet was dissolved in methanol to form sodium methoxide and the solution was poured into the preheated oil sample. The mixture was stirred and heated at a steady temperature of 60 °C for 1 h. The resulting solution was poured into the separating funnel and the solution was allowed to separate. Figure 3 shows the separation of glycerol from the methyl ester.

Structural Identification

The structural identification of the sample was performed at the Multiuser Science Research Laboratory, Ahmadu Bello University Zaria, Nigeria. The fatty acid components of the oil were analysed with Gas Chromatography–Mass Spectrometry (GC–MS). The alkyl ester composition was analyzed with GC–MS. Agilent 7977 GC/MSD was used to analyze the Chromatograph-Mass spectrometer instrument. The instrument comprises of Agilent 7890B gas chromatograph and Agilent 5977A Mass selective detector. It detects the components as well as determines the molecular mass of each component in a sample. The functional groups of the synthesized methyl ester were determined using Fourier Transform Infrared (FT-IR) Spectrometry. This was carried out using a Carry 630 FTIR Spectrometer. The cap and the sample holder were sterilized using methanol and acetone thoroughly. Immediately after fixing the cap, the background scan was carried out. A drop of the sample was placed on the spectrometer measurement cell and the sample was scanned with infrared radiation through a frequency of 4000–650 cm−1 to obtain the spectrum. The functional groups of the samples were identified from the spectra.

Viscosity Measurement

Viscosity is an important parameter to be considered when selecting an insulating liquid. The dynamic viscosity of the purified Yellow Oleander oil and methyl ester oil were measured according to ASTM D445 standard at temperatures (30, 50, and 70 °C) using an RVDV-1 digital viscometer [21,22,23].

Pour Point

The pour point of the oils was measured according to ASTM standard D5949 [21]. The oil samples were heated up to 48 °C in a test jar and the test jar was immediately transferred into an ice bath. The flow characteristic of the specimen was examined by sight. The test jar was tilted, and the temperature at which the oil becomes semi-solid was recorded as the pour point of the sample.

Flash Point

The flash point of the oil samples was measured according to the ASTM standard D 93 to know the flammability of the synthesized oil and compare it to that of mineral oil. The oil sample in the sample holder was heated until the flame set at the top of the container ignite. The temperature at which ignition is experienced was recorded as the flash point.

Dielectric Loss and Dielectric Permittivity

The dielectric permittivity and dielectric loss of mineral oil and methyl ester were measured according to IEC 60247 [24], using Rohde and Schwarz HM8118 Programmable LCR BRIDGE. The two parallel plates with a diameter of 30 mm and a gap of 2.5 mm were used and the electrodes were fully immersed in the oil samples. The dielectric permittivity and dielectric loss were measured at various frequencies ranging from 20 Hz to 200 kHz at temperatures 30 °C, 50 °C, 70 °C. The capacitance of the sample taken from the machine was used to calculate the dielectric permittivity using Eq. (2) [15].

where Cx is the capacitance of the material in farad and Co is the capacitance of the free space.

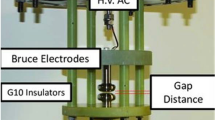

Dielectric Strength Measurement

The dielectric strength of the oil was measured using a bench-top test setup with high voltage DC source. The source was connected to a limiting resistor, and then to a test cell having a sphere-sphere electrode as seen in Fig. 4. The electrode gap was set to 2.5 mm according to ASTM standard [25] and the voltage supply was controlled steadily until the breakdown occur. The leakage current was measured through a measuring resistor of 50 kΩ by a digital multi-meter and the voltage before the breakdown occurred was recorded as the breakdown voltage. Five breakdown test was done for each sample and Weibull statistical analysis was used to obtain the characteristic breakdown strength using two parameters Weibull distribution given by Eq. (3).

The cumulative probability of breakdown is F(x), the AC breakdown voltage is x, \(\alpha\) is the scale parameter corresponding to a probability of 63.2% and \(\beta\) is the shape parameter that corresponds to the scattering of the data failure rate [26].

Results and Discussion

Structural Identification

FTIR

The infrared spectrum of the methyl ester was taken, and the result is shown in Fig. 5. The peaks at 2922 cm−1and 2855 cm−1 indicate the presence of carboxylate [3]. These peaks are asymmetric and symmetric stretching vibrations of CH2 respectively. A long fingerprint around 1740 cm−1 is a C=O stretching vibration corresponding with the one reported by Ref. [19]. The strong evidence that shows the methyl ester fingerprint can be attributed to the characteristic medium peak at 1196 cm−1 and a strong peak around 1166 cm−1 [19, 27].

GC–MS of Yellow Oleander Oil

The gas chromatograms of the methyl ester are shown in Fig. 6. The peaks displayed on the chromatograms represent the chemical components of the ester. The relative percentage of the components can be determined from the area of the peak. The chromatograms were analyzed with mass spectrometry. The first elution which corresponds to methyl palmitate occurred after 30.29 min. This peak was followed by the elution of methyl oleate at 34.91 min, methyl stearate at 35.13 min, methyl arachidate at 37.9 min, and methyl behenate at 41.48 min respectively. The mass spectra of methyl stearate of yellow oleander oil are shown in Fig. 7. The fatty acid compositions as determined from the mass spectra are shown in Table 1. Methyl oleate has the highest percentage composition of 68.14%. Approximately 30.7% of the fatty acids in the methyl ester are saturated, while 68.14 are mono-unsaturated. Due to the high percentage of unsaturated fatty acid in the oil, by implication, the oil will have a good pour point which will make it function well in a low-temperature environment. The high level of unsaturated fatty acid indicates that the oil can only be used in a hermetically sealed transformer.

Viscosity

The heat generated in a transformer is from the loss that comes from the magnetic circuit plus the windings of the transformer [3]. Insulating oil in the transformer performs a vital role as it helps in reducing the temperature of the parts to a bearable level for the smooth operation of the transformer and also, prevention of accelerated thermal aging as a result of overheating [7, 28]. The heat transfer coefficient is inversely related to the dynamic viscosity this is an indication that oil with low viscosity is desired for cooling [21]. The dynamic viscosity of mineral oil and methyl ester was measured. The viscosity of methyl ester sample was observed to be 4.8 mPas and that of mineral oil to be 9.8 mPas at 30 °C. The low viscosity of methyl ester can be attributed to the removal of glycerol from the purified oil. The effect of temperature on the viscosity of the oils was carried out and the result can be seen in Fig. 8. The increase in the temperature of the oil causes an increase in the kinetic energy of each molecule of the oil, this leads to a reduction in the cohesive energy of the molecules of the liquid [3]. Since dynamic viscosity is a measure of internal friction in a liquid, reduction in viscosity reveals that there is a decrease in the resistive force acting between layers of methyl ester. The working temperature of a new transformer is 60–65 °C [29], at this temperature, the viscosity of the synthesized methyl ester is low indicating that, the efficiency of this oil at this temperature as a cooling liquid is higher relative to mineral oil.

Pour Point

The pour point is the measure of temperature at which a liquid loss its fluidity. Insulating oil is expected to have a very low temperature especially when they are considered for use in a low-temperate region. The pour point of yellow oleander methyl ester was observed to be 1.4 °C which is inferior to the pour point of mineral oil, − 41 °C. However, this will perfectly work in some regions of the world with the temperature above the pour point of this methyl ester. The addition of pour point depressant may be able to reduce the pour point.

Flash Point

The flash point of any insulating oil is expected to be high to prevent fire outbreak especially, in conditions when the transformer is overloaded and highly energized. A highly overheated oil gives out traces of spark-like flash, the temperature at which this flash is experienced is called the flash point. If the temperature of the oil is not regulated, the flash continues and there could be an outburst of fire in the system. The flash point of mineral oil and methyl ester was measured 3 times and the average of the results was taken. The flash point of mineral oil was observed to be 147 °C and that of methyl ester was observed to be 171 °C on average. This is an indication that synthesized methyl ester will perform well as a high-temperature insulating liquid relative to mineral oil.

Dielectric Loss

Dielectric loss of insulating materials originated from two different parts, the one from conduction and the one from polarization phenomena [13]. The dielectric loss of the synthesized ester was compared with the loss of conventional mineral oil. Due to the polar nature of ester, the loss of methyl ester is higher than that of conventional mineral oil. The loss from a good mineral insulating oil at power frequencies and operating temperatures result from conduction only [7, 13]. The dielectric loss of mineral insulating oil was obtained to be 0.0022 at 60 Hz and the dielectric loss of methyl ester was obtained to be 0.0045 at the same frequency. This shows an inferior property to mineral-insulating oil. However, the dielectric loss of methyl ester obtained in this work is still within the recommended value according to (IEC 60247) [7]. Figure 9 shows the frequency dependence of dielectric loss, it was observed that the dielectric loss of ester and mineral insulating oil decreases as the frequency increases. The effect of temperature on the dielectric loss was measured at 30, 50 and 70 as seen in Fig. 10. The result revealed that the dielectric loss increases as the temperature increases. As the temperature increases, the viscosity of the oil reduces and this gives free movement to the electron which, consequently, increases the charge transport. Conductivity is proportional to dielectric loss, as the conductivity increases due to low viscosity, the loss increases. However, the dielectric loss of methyl ester at 0.0053 (70 °C, 60 Hz frequency) still falls within the range of recommended value by IEC 60247 [7].

Dielectric Permittivity

The dielectric constant which is related to the energy stored was measured for mineral oil and methyl ester. Figure 11 shows the frequency dependence of dielectric constant έ for mineral oil and yellow oleander methyl ester at room temperature. The vegetable oil has dielectric permittivity which is relatively higher than that of the mineral oil-based transformer oil. The high value of dielectric permittivity in methyl ester relative to mineral oil can be attributed to the presence of triglycerides in vegetable oils which are polar [13]. On the other hand, transformer oil mainly consists of refined petroleum which contains non-polar alkane molecules and thus it has a comparatively lower dielectric constant [30]. It is clear from Fig. 11 that there is a slight decrease in the relative permittivity with frequency and this is similar to some of the earlier reports [3, 13, 30]. A dielectric dispersion occurs as the frequency increases, this causes a decrease in dielectric spectra and consequently, leads to a decrease in relative permittivity values. This change can be related to the Debye equations for the dependence of the relative permittivity on a frequency which show that relative permittivity decreases with frequency [13]. The relative permittivity of mineral oil at operating frequency of 60 Hz was observed to be 2.28 at room temperature and that of methyl ester was obtained to be 3.32. This is an indication that methyl ester has higher energy storing ability compared to mineral oil. The effect of temperature at 60 Hz on the relative permittivity can be seen in Fig. 12. A slight decrease in the relative permittivity as the temperature increases was observed. The decrease in the relative permittivity as the temperature increases can be attributed to a decrease in the density of the sample which is directly related to the density of dipoles in the sample. Also, the kinetic energy of the moving segments increases as the temperature increases, this increases the randomness of the molecule and thus, decreases the dipole orientation which consequently reduces relative permittivity.

DC Breakdown Voltage

The DC breakdown voltage of both mineral oil and yellow oleander methyl ester can be seen in Table 2. From this table, it can be observed that at ambient temperature, yellow oleander oil has a breakdown voltage higher than mineral oil. This result is relatively better than the one obtained by Ref. [3] in which it was reported that the DC breakdown voltage of palm kernel oil methyl ester is 21 kV. Since breakdown analysis is a random event, Weibull analysis was done on the obtained results at ambient temperature. Table 3 shows the characteristic breakdown strength, shape parameter, and the correlation coefficient for two parameters Weibull analysis. Figure 13 shows the Weibull plot for mineral oil and yellow oleander methyl ester. The two samples have nearly the same slope which is an indication of similar statistical distribution. The graph indicates that methyl ester from Yellow oleander oil has higher dielectric strength than mineral oil. The high value of the correlation coefficient, close to one, is an indication of a strong positive correlation between the measured data (Breakdown strength) and the Weibull probability [31]. Also, a low dispersion in the breakdown data is evident from the high value of shape parameter obtained in Table 3. The methyl ester was observed to have the highest shape parameter, and this may be attributed to the molecular arrangement of the oil sample which minimizes the effect of random breakdown characteristics in the oil sample.

Conclusion

Alternative insulating oil from nonedible vegetable oil was successfully synthesized in this work and the oil shows some promising properties. The natural ester consists of long-chain fatty acids and this may have a positive effect on the thermal stability of the liquid. The cooling properties of insulating oil are important parameter that is related to the viscosity of the insulating oil. The viscosity of synthesized yellow oleander methyl ester is considered better than mineral oil since oil with low viscosity is desired for insulation. The pour point of the oil is not up to the recommended value of − 40°, however, it will serve well in a high temperate region. The pour point can be enhanced with a pour depressant when the oil is considered for use in low-temperature regions. The methyl ester shows good dielectric properties, the dielectric loss is within the recommended value according to IEC 60247 and also the relative permittivity of methyl ester is considered better than the mineral oil. It was observed that the characteristic breakdown of the synthesized yellow oleander methyl ester is 6.4% higher than the mineral oil (shell Diala BX). Non-edible seed oil is considered in this work to prevent food competition and to create added value to the agricultural product. The obtained results show that methyl ester from yellow oleander oil is a promising alternative to conventional mineral oil for insulation in oil-filled high voltage equipment especially hermetically sealed transformers.

Data Availability

The data obtained/analyzed in this work will be made available by the corresponding author upon a reasonable request.

Code Availability

Not applicable.

References

Sanjay, B.: Yellow oleander (Thevetia peruviana) seed oil biodiesel as an alternative and renewable fuel for diesel engines: a review. Int. J. ChemTech Res. 7(6), 2823–2840 (2015)

Abdelmalik, A.A., Abolaji, P.A., Sadiq, H.A.: Assessment of Jatropha oil as insulating fluid for power transformers. J. Phys. Sci. 29(1), 1–16 (2018). https://doi.org/10.21315/jps2018.29.1.1

Oparanti, S.O., Khaleed, A.A., Abdelmalik, A.A.: Nanofluid from palm kernel oil for high voltage insulation. Mater. Chem. Phys. 259, 123961 (2021). https://doi.org/10.1016/j.matchemphys.2020.123961

Mohan Rao, U., Fofana, I., Jaya, T., Rodriguez-Celis, E.M., Jalbert, J., Picher, P.: Alternative dielectric fluids for transformer insulation system: progress, challenges, and future prospects. IEEE Access 7, 184552–184571 (2019). https://doi.org/10.1109/ACCESS.2019.2960020

Bartko, P., Rajňák, M., Cimbala, R., Paulovičová, K., Timko, M., Kopčanský, P., Kurimský, J.: Effect of electrical polarity on dielectric breakdown in a soft magnetic fluid. J. Magn. Magn. Mater. 497, 166007 (2020). https://doi.org/10.1016/j.jmmm.2019.166007

Rao, U.M., Sood, Y.R., Jarial, R.K.: Performance analysis of alternate liquid dielectrics for power transformers. IEEE Trans. Dielectr. Electr. Insul. 23(4), 2475–2484 (2016). https://doi.org/10.1109/TDEI.2016.7556527

Oparanti, S.O., Khaleed, A.A., Abdelmalik, A.A.: AC breakdown analysis of synthesized nanofluids for oil-filled transformer insulation. Int. J. Adv. Manuf. Technol. 117, 1395–1403 (2021). https://doi.org/10.1007/s00170-021-07631-0

Aransiola, E.F., Daramola, M.O., Ojumu, T.V., Aremu, M.O., Layokun, S.K., Solomon, B.O.: Nigerian Jatropha Curcas oil seeds: prospect for biodiesel production in Nigeria. Int. J. Renew. Energy Res. 2(2), 317–325 (2012)

Kumar, A., Patil, N., Kumar, R., Mandal, D.: Irrigation scheduling and fertilization improves production potential of jatropha (Jatropha curcas L.): a review. Int. J. Curr. Microbiol. Appl. Sci. 6, 1703–1716 (2017). https://doi.org/10.20546/ijcmas.2017.605.185

Rao, U.M., Pulluri, H., Kumar, N.G.: Performance analysis of transformer oil/paper insulation with ester and mixed dielectric fluids. IEEE Trans. Dielectr. Electr. Insul. 25(5), 1853–1862 (2018). https://doi.org/10.1109/TDEI.2018.007224

Jeong, J., An, J., Huh, C.: Accelerated aging effects of mineral and vegetable transformer oils on medium voltage power transformers. IEEE Trans. Dielectr. Electr. Insul. 19(1), 156–161 (2012). https://doi.org/10.1109/TDEI.2012.6148514

Olmo, C., Fernandez, I., Ortiz, F., Renedo, C.J., Perez, S.: Dielectric properties enhancement of vegetal transformer oil with TiO2, CuO and ZnO nanoparticles. In: Proceedings of International Conference on Renewable Energies and Power Quality (ICREPQ’18), pp. 623–627 (2018). https://doi.org/10.24084/repqj16.412

Shah, Z.H., Tahir, Q.A.: Dielectric properties of vegetable oils. J. Sci. Res. 3(3), 481–492 (2011). https://doi.org/10.3329/jsr.v3i3.7049

Abdelmalik, A.A.: Chemically modified palm kernel oil ester: a possible sustainable alternative insulating fluid. Sustain. Mater. Technol. 1, 42–51 (2014). https://doi.org/10.1016/j.susmat.2014.06.001

Umar, S., Abdelmalik, A.A., Sadiq, U.: Synthesis and characterization of a potential bio-based dielectric fluid from neem oil seed. Ind. Crops Prod. 115(117), 123 (2018). https://doi.org/10.1016/j.indcrop.2018.02.009

Gnanasekaran, D., Chavidi, V.P.: Vegetable Oil Based Bio-lubricants and Transformer Fluids: Applications in Power Plants. Springer, New York (2017)

Bandara, V., Weinstein, S.A., White, J., Eddleston, M.: A review of the natural history, toxinology, diagnosis and clinical management of Nerium oleander (common oleander) and Thevetia peruviana (yellow oleander) poisoning. Toxicon 56(3), 273–281 (2010). https://doi.org/10.1016/j.toxicon.2010.03.026

Bora, M.M., Gogoi, P., Deka, D.C., Kakati, D.K.: Synthesis and characterization of yellow oleander (Thevetia peruviana) seed oil-based alkyd resin. Ind. Crops Prod. 52, 721–728 (2014). https://doi.org/10.1016/j.indcrop.2013.11.012

Abdelmalik, A.A.:. The feasibility of using a vegetable oil-based fluid as electrical insulating oil (Doctoral dissertation, University of Leicester) (2012)

Sanjay, B., Deka, D.C.: Transesterification of yellow oleander (Thevetia peruviana) seed oil to fatty acid methyl esters (biodiesel) using a heterogeneous catalyst derived from rhizome of Musa balbisiana Colla. Int. J. ChemTech Res. 6(4), 2377–2384 (2014)

Oparanti, S.O., Abdelmalik, A.A., Khaleed, A.A., Abifarin, J.K., Suleiman, M.U., Oteikwu, V.E.: Synthesis and characterization of cooling biodegradable nanofluids from non-edible oil for high voltage application. Mater. Chem. Phys. 277, 125485 (2022). https://doi.org/10.1016/j.matchemphys.2021.125485

Sani, L., Ajibola, V.O., Abechi, S.E.: Effect of degumming and catalyst type on physiochemical and biodiesel properties of tropical-almond (Terminalia catappa) seed oil. J. Appl. Sci. Environ. Manag. 22(12), 1909–1916 (2018). https://doi.org/10.4314/jasem.v22i12.7

Abdulsalam, I.G., Abdelmalik, A.A., Maharaz, M.N., Auwal, S.M., Oparanti, S.O.: Physico-chemical characterization of a multiparticle vegetable oil-based nanofluid for high voltage application. ATBU J. Sci. Technol. Educ. 9(4), 298–303 (2022)

Katim, N.I.A., Nasir, M.S.M., Ishak, M.T., Hamid, M.H.A.: An investigation on rapeseed oil as potential insulating liquid. In: AIP Conference Proceedings, vol. 1930, no. 1, p. 020032. AIP Publishing LLC (2018). https://doi.org/10.1063/1.5022926

Du, Y., et al.: Effect of semiconductive nanoparticles on insulating performances of transformer oil. IEEE Trans. Dielectr. Electr. Insul. 19(3), 770–776 (2012). https://doi.org/10.1109/TDEI.2012.6215079

Makmud, M., Illias, H., Chee, C., Sarjadi, M.: Influence of conductive and semi-conductive nanoparticles on the dielectric response of natural ester-based nanofluid insulation. Energies 11(2), 333 (2018). https://doi.org/10.3390/en11020333

Silverstein, R.M., Clayton Bassler, G.: Spectrometric identification of organic compounds. J. Chem. Educ. 39(11), 546 (1962). https://doi.org/10.1021/ed039p546

Tambuwal, F.R., Oparanti, S.O., Abdulkadir, I., et al.: Investigative study on the AC and DC breakdown voltage of nanofluid from Jatropha-Neem oil mixture for use in oil-filled power equipment. Int. J. Adv. Manuf. Technol. 119, 4375–4383 (2022). https://doi.org/10.1007/s00170-021-08447-8

Mohamad, M.S., Zainuddin, H., Ab Ghani, S., Chairul, I.S.: AC breakdown voltage and viscosity of palm fatty acid ester (PFAE) oil-based nanofluids. J. Electr. Eng. Technol. 12(6), 2333–2341 (2017). https://doi.org/10.5370/JEET.2017.12.6.2333

Oparanti, S.O., Khaleed, A.A., Abdelmalik, A.A., Chalashkanov, N.M.: Dielectric characterization of palm kernel oil ester-based insulating nanofluid. In: 2020 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), pp. 211–214 (2020).https://doi.org/10.1109/CEIDP49254.2020.9437477

Oparanti, S.O., Tambuwal, F.R., Khaleed, A.A., Abdelmalik, A.A.: DC and AC breakdown analysis of Neem Ester/SiO2 nanofluid for high voltage insulation. In: 2021 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), pp. 383–386 (2021). https://doi.org/10.1109/CEIDP50766.2021.9705313

Funding

This work was supported by Nigeria’s Tertiary Education Trust Fund (TETFund) National Research Fund (NRF) Research Grant 2019. TETF/DR&D/CE/NRF/UNI/ZARIA/STI/55/VOL.1

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Ethical Approval

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Oparanti, S.O., Salaudeen, I.K., Adekunle, A.A. et al. Physicochemical and Dielectric Study on Nigerian Thevetia Peruviana as a Potential Green Alternative Fluid for Transformer Cooling/Insulation. Waste Biomass Valor 14, 1693–1703 (2023). https://doi.org/10.1007/s12649-022-01949-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-022-01949-w