Abstract

Power transformer insulating oil is essential to the transformer’s usable life. Mineral base transformer insulation oil is the most commonly used type; however, biodegradable alternatives have been developed due to safety and environmental concerns. This paper improves the insulation properties of power system transformers through the utilization of natural liquid-based insulation with additives. This work aims to enhance the functionality and dependability of transformer insulation-based vegetable seed oil for power system analysis. Here, vegetable seed oil-based natural liquid is used, which includes soybean oil, maize oil, mustard oil, and rice bran oil, which are chosen for analysis together with artificial and natural antioxidants like propyl gallate and citric acid. Blending vegetable seed oil with mineral oil of different compositions and adding additional 0.5 g and 1 g of additives allows for the analysis of the property improvement. The different properties, both with and without the influence of additives, are assessed in accordance with IEC/ASTM standards for breakdown voltage, water content, flash point, fire point, acidity, viscosity, and interfacial tension. The results demonstrate that the proposed natural liquid-based insulation with additives exhibits superior electrical and thermal properties compared to conventional insulation systems. It shows enhanced dielectric strength, improved thermal conductivity, and better resistance to ageing effects. These improvements give the reliability and efficiency of power system transformers. The findings indicate that the proposed insulation system offers significant environmental benefits compared to traditional mineral oil-based insulation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Consistent pursuit of sustainable economic growth necessitates the efficient use of energy and resources, including investments in renewable resources and environmentally friendly procedures [1]. Transformer oil is often a highly refined mineral oil (MO) with good electrical insulation qualities and stability at high temperatures. Its purposes include cooling, insulating, and suppressing arcing and corona [2]. Large power transformer cooling can be enhanced by adding exterior radiators to the oil-filled tank so that the oil circulates naturally by convection [3]. Static electrical equipment that uses inductive coupling to transmit energy and change voltages is called a transformer. For insulation and heat transfer, insulating oil is placed within transformers [4]. The most widely used transformer insulating fluid in transformers is petroleum-based, like MO [5]. Power transformers have employed MOs for more than a century to provide cooling and electrical insulation [6]. In the later half of the twentieth century, ester fluids, silicone, and synthetic hydrocarbon fluids were introduced, albeit their use was limited at the time [7]. Additionally, spills from equipment malfunctions and leaks can contaminate land and water, making MOs very flammable, non-biodegradable, and environmentally dangerous.

Numerous research studies previously presented in the literatures depend on the investigation of VSO for power system transformer insulation. Banerje et al. [8] have illustrated that transformer dependability required periodic assessments of the oil-impregnated paper reaction and estimated insulation quality using sensing. The solid insulation-impregnated material’s behaviour was examined under several thermal ageing scenarios, according to Siddique et al. [9]. A thermal analysis of a transformer prototype using computational fluid dynamic (CFD) application while taking into account six different colouring structures has been demonstrated by Santisteban et al. [10]. Additionally, the rendering result makes it possible by visualising the temperature distribution and the effectiveness of each cooling system. MO was mixed with vegetable oils in a variety of combinations, including olive and coconut oil by Madavan et al. [11]. Important factors like acid content, dielectric strength, flash and fire point, and viscosity were computed using the standards. The results of the simulation demonstrate that natural ester outperforms MO, and mixed liquid insulation also performs better with higher mixing ratios.

By considering the acidity and moisture contents, Sangineni et al. [12] have demonstrated the high-frequency signals that might be used to assess transformer liquid insulation deterioration without being obtrusive. The latest methods for non-destructive and non-intrusive testing techniques boost liquid insulation degradation depending on the ageing duration by using an S-band pyramidal horn antenna, through the use of a technique of single charging and many discharges. Zhang et al. [13] have demonstrated transformer oil paper insulation’s dielectric voltage response properties. The changing rule of the first slope features of the dielectric voltage response was found by examining the relationship among the attenuation amplitude of the dielectric polarisation intensity reflected through the equivalent circuit and the dielectric voltage response’s first slope. Melnikova et al. [14] have established an approach for calculating the variation in transformer oil volume in the heavily stressed oil passages of the primary insulation of high voltage power transformers and the statistical features of these passages’ dielectric strength, all the while accounting for the influence of the transformers’ rated capacities and voltages. Hemalatha et al. [15] have suggested that this research deviates from standard evaluations by carefully analysing the impact of antioxidants—in this case, tocopherol—on the properties of individual oils as well as their combinations. The industry recognises the need of antioxidants in addressing issues like oxidative degradation and extending the life of insulating fluids, which is why they have been included. Tocopherol is a naturally occurring antioxidant that is purposefully added to investigate the way it may enhance important attributes. Thangaraj et al. [16] have suggested adding olive oil and more natural esters to the mixture for additional testing in order to create a better insulating medium. For this investigation, butylated hydroxyanisole (BHA) and butylated hydroxytoluene (BHT) were selected as antioxidants. The purpose of this study was to examine the significance of important input variables such as A-speed, B-time, and C-temperature. Karthik and Narmadhai [17] have focused on utilising antioxidants to improve the characteristics of natural ester. Antioxidants including gallic acid, citric acid, propyl gallate, and tertiary butylated hydroxy quinone are selected for study along with natural esters such mustard oil, rice bran oil, punna oil, and castor oil. For the studies, natural esters are combined with 1 g, 2 g, 3 g, and 5 g of antioxidants.

MO is a petroleum-based liquid insulator that has been utilized for over a century. Because of its superior qualities, including its high dielectric strength, medium viscosity, and effective heat transfer capacity, conventional MO is used as an insulating medium. Transformers also use silicone-based oil in a few unique applications. But they are completely distinct from MO in terms of flammability and physical characteristics. Additionally, they are much more expensive than MO. MO pollution makes it difficult to dispose of it, and kraft paper and MO are typically used to insulate transformers. MO suggests that transformer cooling is necessary. In environmentally sensitive areas, the use of MOs is restricted due to their poor performance when the temperature rises. This work is done in order to address the aforementioned shortcomings.

The investigation of VSO for power system transformer insulation is a study that explores the potential of using VSO as insulation in power system transformers. The study evaluates the dielectric properties, thermal stability, and oxidative stability of vegetable seed oils like soybean oil, corn oil, rice bran oil, and mustard oil which are chosen for examination together with natural and artificial antioxidants like propyl gallate and citric acid (CA) and compares them to MO’s commonly used transformer insulation. The IEC/ASTM standards are used to evaluate a number of qualities, both with and without the influence of additives. These parameters include water content, acidity, breakdown voltage, viscosity, flash and fire points, and interfacial tension. Finally, the statistical-based regression analyses are carried out to determine the relation between different parameter variables.

The contribution of this study is the exploration of a sustainable and eco-friendly alternative to traditional transformer insulation materials that could have a significant impact on the power industry. The main contribution of this work is as follows:

-

This work improves the insulation properties of power system transformers by utilizing natural liquid-based insulation with additives. The proposed insulation system shows improved dielectric strength, thermal conductivity, and resistance to ageing effects compared to traditional mineral oil-based insulation. This achievement helps to improved reliability and efficiency of power system transformers.

-

This work points the environmental concerns associated with traditional insulation materials by exploring natural liquid-based insulation. Ester-based fluids are a better biodegradable option and have less of an adverse effect on the environment than mineral oil. This work gives the characterization and evaluation of natural liquid-based insulation materials and additives. Various experimental techniques and analysis methods are employed to assess their dielectric strength, thermal conductivity, and ageing characteristics. This helps in identifying suitable materials and additives for achieving optimal insulation performance.

-

The outcome of this work can give the further enhancement of transformer insulation technology, enabling the industry to adopt more sustainable and efficient insulation systems.

-

The proposed natural liquid-based insulation with additives has the potential to be implemented in power system transformers, leading to improved performance, reliability, and environmental sustainability.

-

The overall improvement of this work is enhancing the insulation performance of power system transformers, addressing environmental concerns, providing a comparative analysis, characterizing and evaluating insulation materials, and offering practical implications for the power industry.

Some of the key achievements of using VSO for power system transformer insulation include improved fire safety, enhanced environmental friendliness, increased transformer lifespan, and reduced maintenance costs. Moreover, VSO has proven to be a highly effective alternative to traditional transformer oils. It improves fire safety, environmental friendliness, and increased lifespan of transformers.

The investigation of VSO for power system transformer insulation is examined by this paper. The transformers are considered to be the predominant equipment in power system, without this a whole universe never functions. For many years, petroleum-related MO is utilized as liquid insulation medium for isolation and cooling purpose. The remainder of the manuscript is as follows: part 2 shows the transformer oil properties, part 3 shows the methodology, part 4 illustrates results and discussion, and part 5 concludes the paper.

2 Transformer oil properties

Based on the standards, many properties of transformer oils are evaluated.

2.1 Dielectric strength

It is denoted as the breakdown of the transformer oil (BDV). The withstand capacity is estimated by the std. IEC 60156.

2.2 Resistivity

The insulation fluid resistivity should be more than 1016 ohm m, for high voltage applications, and it is satisfied. Resistivity measures the DC between two sides of 1 cm3 block of oil [18]. And it decreases rapidly, when the temperature increases. Its unit is expressed as ohm centimetres at specific temperature.

2.3 Dissipation factor

It is called as delta of transformer oil and estimated by the std. IEC 60247. This factor is assessed by placing an insulating material between live and grounded parts of electrical apparatus and so there will be a flow of leakage current.

2.4 Aniline point

The total aromatic content in the oil is assessed by the aniline point, and it is measured by the std. ASTM D3487. It is considered by a qualifying test and related to the impulse strength, gassing nature, and oxidation stability of oil [19]. It is represented as the minimum temperature at which equal quantity of a line and oil samples is completely miscible.

2.5 Flash and fire point

The ability of oil to tolerate temperature is determined by its flash and fire point properties. The temperature at which the small sound and extinguish of flame exist is said to be flash point, and the temperature at which flame colour becomes blue and fire continues is said to be fire point. This test is carried out using the Pensky-Martin closed-cup apparatus, in which 50 ml of oil is placed inside a test cup. The flash and fire point are altered by changing the temperature evaluated by exposing a fire based on the indication of flash and firing nature is identified. Based on the ASTM D 93 standard, the quality of oil should possess high flash and fire point.

2.6 Viscosity

Viscosity is the challenging quality of oil based on the resistance of oil flow which is witnessed that helps to adhere the cooling property [20]. Viscosity is tested using an Ubbelohde viscometer in accordance with ASTM D445 standard. When using the Ubbelohde viscometer, 50 ml oil samples are taken in a measuring jar, and the time it takes for 50 ml fluid to be collected is recorded in a beaker to provide the oil’s viscosity [21].

2.7 Interfacial tension

Interfacial tension decides the surface tension in between two liquid medium in which one medium is oil and other medium is water. This test is used to identify the presence of polar contaminants and other decay products. The measurement hook is connected to balance by placing a platinum ring. The ring is dropped below the interface by varying the platform location in which the liquid container is positioned [22]. The container comprised of oil sample and water. After immersion, the top most position of the platform is decreased, and therefore, the ring wrenches through the interface fetching meniscus of liquid with it. If the container is dropped further, the meniscus will tear from the ring [23]. The control of the surface or interfacial surface tension is based on the measurement of supreme force and the perimeter of the ring. As per the standard ASTM D971, the interfacial tension should be > 30 mN/m.

2.8 Water content

Water content is one of the crucial pollutants of oil recorded as ppm. The estimation of water content kit comprised of electrodes with a moisture sensor. The beaker is filled with a test sample, and when the electrodes are dipped into the fluid, the number of water molecules in the sample is indicated by a digital metre based on the output of the moisture sensor [24].

2.9 Acidity

Acidity test is performed by using titration method. This test is one of the quality indicators of oil, taking oil samples as beaker and potassium hydroxide as burette solution. By titrating the potassium hydroxide neutralizes the hydrogen ions in the oil samples. This assessment determines the amount of potassium hydroxide needed to neutralize acidity, utilizing the concentration of hydrogen ions per gram of oil sample [25]. Based on the recommended standard ASTM D 974, the high-quality oil contains acidity < 0.1 mg KOH/g.

3 Methodology

In this work, the experimental validations are performed to analyse various characteristics of VSO with the traces of additives with a focus of identifying better environmental friendly insulating fluid. The commonly available vegetable seed-based oils are purchased from nearby manufacturers, such as soybean, corn, mustard, and rice bran oils. Natural and synthetic antioxidant additives, such as CA and PG, are chosen, which are included in various proportions, like 0.5 g and 1 g.

3.1 Sample preparations

The 500 ml of oil is considered for sample preparation that undergoes various experimental validations. Since moisture in oil might interfere with its efficiency, the 500 ml of oil samples are heated to a temperature of 100 °C in order to completely eliminate any moisture content. The VSO is mixed with high performance natural antioxidants as citric acid (CA) and synthetic antioxidant as propyl gallate (PG). The samples are made by incorporating various amounts of antioxidants into the basic fluids and mixing them with a magnetic stirrer. The antioxidants utilised as additions had purity grades greater than 99%, and the weights of 2.5 g and 5 g were chosen in a 1:1 ratio for inquiry purposes. Each antioxidant was directly dissolved in MO at ratios of 2.5 and 5 g (1:1). For blending the VSO with the MO and inclusion of additives in numerous compositions, the magnetic stirrer is used. Based according to the composition requirement, both fluids are combined and then added to a magnetic stirrer, which operates at 50 rpm for 30 minutes [26]. Then, for the purpose of testing, the fluids are taken individually. Further, for the blended samples, the additives are added in several proportions by subjecting to an ultra sonicator about 30 min for the complete dispersion of additives with oil.

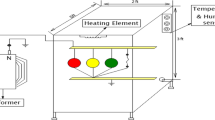

3.2 Test preparation

A breakdown voltage test setup that determines the breakdown voltage is shown in Fig. 1. It is used to estimate the dielectric strength of oil. This setup consists of oil chamber with a set of spherical electrodes of 2.5 mm spacing. The chamber is filled with 500 ml of oil, and the voltage is gradually increased by 2 kV/s. This process will continue until the breakdown takes place. The testing process for particular samples has been repeated for five times, and its average gives the breakdown value. The breakdown value of ideal fluid should be ≥ 60 kV which is represented by IEC 60156 standards.

3.3 Modelling of R 2 coefficient

The determination coefficient, or R-squared, is a statistical measure that shows how well a model predicts an outcome. It is also known as r-squared. The percentage of variance in the dependent variable that is predicted by the statistical model is shown by the R-squared value, which is a number between 0 and 1. It can alternatively be interpreted as an effect size indicating a relationship between the two variables or as the ratio of the independent to dependent variables’ share of variance. The origins of “regression” can be linked to the coefficient’s inception. The percentage of the dependent variable’s variance that can be predicted based on the independent variables is known as the coefficient of determination. Coefficient of determination (R2) is determined by

where the real j value is represented by the yj element, while the anticipated j value is denoted by xj. The xj element is predicted using the regression approach for the associated yj element. The mean of the true values is the total sum of squares, where \(\overline{y}\) is given as

4 Results and discussion

Here, many properties of identified samples with and without the traces of selected natural and synthetic antioxidant additives are discussed. Comparison of base sample with VSO is shown in Fig. 2.

By estimating the properties of base sample and VSO samples, the following inferences are listed.

-

Sample 1 and sample 2 of vegetable seed-based oil consists of high breakdown voltage and high flash and fire point compared with existing base sample and satisfies the standards.

-

Sample 3 and sample 4 of vegetable seed-based oil offers lower breakdown voltage with better flash and fire point, which indicates that there is a suitable chance for property betterment in breakdown voltage with the influence of additives.

-

All VSOs have a higher viscosity compared to the base sample. However, they can still be considered for transformer applications with the justification that viscosity is inversely proportional to temperature. Therefore, as temperature increases, the viscosity of the fluid decreases, which helps in satisfying the cooling requirements of the transformer.

-

All VSO consist of high interfacial tension over base sample; it makes it abundantly evident that when interfacial tension rises, the fluid’s breakdown voltage will likewise rise sufficiently because of the potential for lower impurity content.

-

All VSO consists of low water content and acidity over base sample. As the water content and acidity are lower, there will be a greater breakdown voltage and interfacial tension.

Based on the above inference, it is understood that sample 1 holds high fire point, flash point, breakdown voltage, and interfacial tension with low viscosity, moderate water content, and acidity than other vegetable seed oil.

The natural and synthetic antioxidant additives, like CA and PG, are added in the ratio of 0.5 g and 1 g, respectively.

The comparison of different properties of different composition of MO with VSO with and without the addition of natural and synthetic antioxidants, like CA and PG, is shown in Figs. 3–9.

For samples 5 to 20, the maximum breakdown voltage with CA is 41 V and PG is 42 V, and the blended samples with synthetic additives like propyl gallate of 1 g own high breakdown voltage for sample 12 than other samples. Overall, it is witnessed that samples 5–12 offer elevated breakdown voltage as displayed in Fig. 3.

In samples 5 to 12, flash points are increased and samples 13 to 20 slightly decreased. Sample 13 exhibits minimum flash point with CA and PG and without CA and PG. The maximum flash point of samples with CA is 340 °C, and samples with PG are 350 °C; it gives safer environments where there is a risk of ignition or fire as displayed in Fig. 4.

Blending antioxidant compounds into CA and PG significantly enhances both flash and fire points. The fire point temperature of an oil sample is measured by directing a small test flame onto its surface. With the inclusion of CA, samples 8–12 show flash and firing characteristics beyond 300 °C, and with PG, samples 7–12 own better flash and fire point characteristics than CA. Sample 13 exhibits lower fire point, and the maximum fire point of sample with CA is 350 °C and sample with PG is 351 °C as displayed in Fig. 5.

By adding the antioxidant additives, the decrement in viscosity is identified. By adding the CA, the viscosity is reduced for samples 10–12. Similarly, by adding PG, the decrements in viscosity for samples 8–12 are witnessed. The viscosity of samples with CA is 21 mm2/s and samples with PG is 20 mm2/s indicating better flow characteristics as displayed in Fig. 6.

Figure 7 shows that adding antioxidants to CA and PG resulted in high interfacial tension that meets the criteria. New oils with high interfacial tension are typically considered good. Oil oxidation impurities reduce the interfacial tension. The maximum interfacial tension of sample with CA is 40 mN/m and sample with PG is 37 mN/m. It is found that the interfacial tension in with CA and PG after adding antioxidant compounds is high and also satisfies the standards.

Water can damage transformer oil and insulators. Moisture reduces oil thickness and lowers its boiling point compared to oil. The water content with CA is 39 ppm and samples with PG are 37 ppm. Sample 5 exhibits low water content among all samples. The water content levels in samples with CA and PG after adding antioxidant compounds are also less and satisfy the standard as shown in Fig. 8.

The maximum acidity of the oil sample without CA is 0.08 KOH/g, whereas the sample with CA has an acidity of 0.07 KOH/g. This suggests better stability and less corrosiveness. Overall, it recorded that blending of vegetable seed based oil, MO along with the effect of synthetic additives, like PG a superior quality insulating fluid of high biodegradable and environmental friendly nature can be identified for the replacement of petroleum based MO it is displayed in Fig. 9.

Table 1 delves into the fascinating realm of these powerful antioxidants, exploring both their natural and synthetic forms.

This table provides a succinct overview of two types of antioxidants like natural and synthetic. Representing the natural category is citric acid (CA), with the chemical formula C6H8O7, commonly found in citrus fruits and known for its potent antioxidant properties, crucial for protecting cells from oxidative damage. On the synthetic side, propyl gallate (PG), denoted by the chemical formula C10H12O5, serves as a manufactured alternative with antioxidant capabilities, primarily utilized in various products to preserve freshness and stability.

In Table 2, MO is represented as base sample. Samples 1–4 are considered as a vegetable seed-based oil. Samples 5–20 are considered as a different combination of MO with vegetable seed-based oil.

Numerous samples are assessed for various qualities, including acidity, breakdown voltage, viscosity, water content, flash point, and fire point, in accordance with the criteria. The petroleum-based MO is also examined, and it is represented as base sample. The mathematical model is created by using the non-linear regression tool to determine the appropriate fitness of all samples that are made up of various amounts of additives. Experimental validations of several samples for several properties without any additives are given in Table 3, and its comparison is depicted in Fig. 2. MO is being mixed with various other oils (rice bran oil, corn oil, soybean oil, and mustard oil) in different proportions. Sample 5 comprises 5 ml of MO mixed with 45 ml of rice bran oil. For sample 6, the composition consists of 10 ml of MO mixed with 40 ml of rice bran oil. Sample 7 is 15 ml of MO mixed with 35 ml of rice bran oil. Sample 8 contains a mixture of 25 ml of MO and 25 ml of rice bran oil. Sample 9 comprises 5 ml of MO mixed with 45 ml of soybean oil. For sample 10, there is a mixture of 10 ml of M O and 40ml of soybean oil. Sample 11 consists of 15 ml of MO mixed with 35 ml of soybean oil. Sample 12 contains 25 ml of MO mixed with 25 ml of soybean oil. Sample 13 includes 5 ml of MO mixed with 45 ml of mustard oil. Sample 14 comprises 10 ml of MO mixed with 40 ml of mustard oil. For sample 15, there is a mixture of 15 ml of MO and 35 ml of mustard oil. Sample 16 contains 25 ml of MO mixed with 25 ml of mustard oil. Sample 17 comprises 5ml of MO mixed with 45 ml of corn oil. Sample 18 consists of 10 ml of MO mixed with 40 ml of corn oil. Sample 19 contains 15 ml of MO mixed with 35 ml of corn oil. Sample 20 comprises 25 ml of MO mixed with 25ml of corn oil.

The properties of base sample with other samples without additives are displayed in Table 3.

Each sample, ranging from the base sample 1 to sample 20, offers insights into the performance and quality of different oil formulations. These parameters play crucial roles in determining the suitability of oils for diverse applications. Breakdown voltage reflects insulation strength, while flash point and fire point indicate flammability characteristics. Viscosity measures flow resistance, interfacial tension evaluates interaction capabilities, and water content and acidity serve as indicators of stability and purity as displayed in Table 3.

The properties of MO blended with VSO with CA, focusing on key parameters like breakdown voltage, flash point, fire point, viscosity, interfacial tension, water content, and acidity, are displayed in Table 4.

The oil samples are characterized by their breakdown voltage, flash point, fire point, viscosity, interfacial tension, water content, and acidity. Each sample, ranging from sample 5 to Sample 20, provides crucial insights into the performance and quality of various oil formulations as displayed in Table 4.

The properties of mineral oil blended with VSO and PG are shown in Table 5.

The properties of MO blended with PG are being investigated across various critical parameters to enhance our understanding of their performance and applications. Each sample, numbered from 5 to 20, is evaluated under two conditions denoted as PG 0.5 and 1. Breakdown voltage, flash point, fire point, viscosity, interfacial tension, water content, and acidity are among those characteristics examined. Breakdown voltage measures insulation strength, while flash point and fire point indicate flammability as shown in Table 5.

Table 6 provides a clear comparison of two materials, highlighting their key properties.

Vegetable seed-based oil is clearly the more abundant resource, making it a more sustainable option in the long run. The significant difference in biodegradability is crucial. Vegetable seed-based oil breaks down much faster, minimizing its environmental footprint. The environmental impact score reinforces the advantage of vegetable seed-based oil, causing less harm to the ecosystem. While petroleum-based MO is cheaper upfront, its environmental impact might lead to higher long-term costs. Both materials offer similar insulation and cooling properties. However, vegetable seed-based oil has excellent fire resistance with a higher rating and a much safer flash point as displayed in Table 6.

By analysing the diverse properties of different composition of VSO by MO with the addition of CA and PG additives, the following inference is made.

4.1 Mathematical functions of properties

For obtaining the associations between different variables, the mathematical regression analysis tool is used. This tool is used to find the relationship between variables. In this effort, the non-linear regression is used by which the coefficient of determination (r2) is determined for many compositions of samples and the intermediate range of composition is witnessed.

The coefficient of determination (r2) varies from zero to one. Value 1 represents the best fit and value 0 represents worst fit of data. The regression analysis is carried out for the samples with an influence of PG, as it is superior in the properties of oil. The mathematical functions along with the coefficient of determination for PG blended samples are described as follows:

The interfacial tension (mN/m), viscosity (cSt), and water content (ppm) could be

where, Interfacial Tension mN/m, or Water Content ppm depending on the values of a and b, y Represents Samples Viscosity cSt, x represents a variable (perhaps a chemical or physical property of the Samples),a is the slope of the equation (the pace at which y changes in relation to x), and b is the equation's y-intercept (the value of y at x = 0).

The following is the mathematical function of breakdown voltage of fire and flash point:

Breakdown voltage kV = ax + b, where a and b are constants. Flash point °C = cx + d, where c and d are constants. Fire point °C = ex + f, where e and f are constants.

Therefore, the mathematical function for each variable can be represented in a single equation:

Breakdown Voltage is determined as kV = ax + b, Flash Point is calculated as °C = cx + d, and Fire Point is calculated by °C = ex + f

Where, the values of a, b, c, d, e and fare determined by the specific experimental data.

The following is the mathematical function of acidity:

where y represents acidity, x represents some independent variable related to the mathematical function, b is the y-intercept, and m is the slope of linear relationship.

For all the samples with the traces of PG additives, properties such as breakdown voltage, water content, acidity, viscosity, and interfacial tension are obtained as mathematical functions. Moreover, with this function, the superior concentration of additives to obtain elevated property in oil samples can be evaluated. In this mathematical analysis, the coefficient of determination for various properties are found to be 1, which indicates the best fitting of data.

5 Conclusion

Power system transformer for natural liquid-based insulation with additive-based property betterment is proposed in this manuscript. This work gives the comparative analysis between the proposed natural liquid-based insulation and traditional mineral oil-based insulation and gives the better performance. Further, the work is extended with the addition of antioxidants and found the rise of properties than the blended vegetable seed-based oil along with mineral oil without additives. Lastly, it is mentioned that the constitution of mineral oil combined with soybean and rice bran oils will make them appropriate fluid substitutes. For better oxidation stability, it is identified that synthetic antioxidants of PG of 1 g will be the better choice to have elevated properties than other samples. The maximum breakdown voltage with CA is 41V and PG is 42V; it indicates better insulation properties; the maximum flash point of samples with CA is 340 °C and samples with PG are 350 °C; it gives safer environments where there is a risk of ignition or fire. The viscosity of samples with CA is 21 mm2/s and samples with PG is 20 mm2/s indicating better flow characteristics. The water content with CA is 39 ppm and samples with PG are 37 ppm; water contamination needs to be minimized. The maximum acidity of the oil sample without CA is 0.08 KOH/g, while the sample with CA has an acidity of 0.07 KOH/g, indicating better stability and less corrosiveness. The result of comparison is as follows: the availability is abundant, biodegradability is 95%, environmental impact is 2.3, cost is $1.2 /litre, insulation property is 23 kV/mm, cooling property is 0.10 cal/cm2 °C, fire resistance is 4, and flash point is 310 °C. The proposed is high performance, which is compared to existing system.

Data availability

This paper does not fall under the data sharing policy because no new data were generated or examined for this research.

Code availability

Not applicable

Abbreviations

- CFD:

-

Computational fluid dynamics

- MC:

-

Moisture content

- VSO:

-

Vegetable seed oil

- MO:

-

Mineral oil

- CA:

-

Citric acid

- PG:

-

Propyl gallate

- x :

-

Variable (perhaps a chemical or physical property of the samples)

- a :

-

Slope of the equation (the rate of change of y with respect to x)

- b :

-

y-intercept of the equation

- m :

-

Slope of linear relationship

- r 2 :

-

Coefficient of determination

- y :

-

Sample viscosity

References

Fabian J, Wieser B, Muhr M, Schwarz R, Pukel GJ, Stössl M. (2012) Partial discharge behavior of environmentally friendly and hardly inflammable ester liquids compared to mineral oil for power transformers. In 2012 IEEE International Conference on Condition Monitoring and Diagnosis (pp. 621-624). IEEE

Mohamad NA, Azis N, Jasni J, AbKadir MZ, Yunus R, Yaakub Z (2018) Ageing study of palm oil and coconut oil in the presence of insulation paper for transformers application. Materials 11(4):532

Shajin FH, Rajesh P, Raja MR (2022) An efficient VLSI architecture for fast motion estimation exploiting zero motion prejudgment technique and a new quadrant-based search algorithm in HEVC. Circuits Systems Signal Process 41:1–24

Cai S, Zhou X, Chen J, Yu H, Zhou C. (2012) Transesterification reaction reduce viscosity of vegetable insulating oil. In2012 International Conference on High Voltage Engineering and Application (pp. 648-650). IEEE.

Rajakumar S, Sreedhar PS, Kamatchi S, Tamilmani G (2023) Gray wolf optimization and image enhancement with NLM Algorithm for multimodal medical fusion imaging system. Biomed Signal Process Control 85:104950

Wu W, Wang ZD, Revell A, Iacovides H, Jarman P (2012) Computational fluid dynamics calibration for network modelling of transformer cooling oil flows–part I heat transfer in oil ducts. IET Electr Power Appl 6(1):19–27

Rajesh P, Shajin FH, Kumaran GK (2022) An efficient IWOLRS control technique of brushless DC motor for torque ripple minimization. Appl Sci Eng Prog 15(3):5514

Banerjee CM, Baral A, Chakravorti S (2022) Influence of de-trapped charge polarity in sensing health of power transformer insulation. IEEE Sensors J 22(7):6706–6716

Siddique ZB, Basu S, Basak P (2022) Effect of graphene oxide dispersed natural ester based insulating oil on transformer solid insulation. IEEE Trans Dielectr Electr Insul 29(2):378–385

Santisteban A, Ortiz F, Köseoğlu AK, Altay R, Renedo CJ, Ortiz A. (2022) CFD study of the impact of the deviation on the mass flow inlet on winding hot-spot temperature of a power transformer using mineral and ester oils. In2022 IEEE 21st International Conference on Dielectric Liquids (ICDL) (pp. 1-4). IEEE.

Madavan R, Saroja S, Karthick A, Murugesan S, Mohanavel V, Velmurugan P, Al Obaid S, Alfarraj S, Sivakumar S (2022) Performance analysis of mixed vegetable oil as an alternative for transformer insulation oil. Biomass Convers Biorefin:1–6

Sangineni R, Nayak SK, Becerra M (2022) A non-intrusive and non-destructive technique for condition assessment of transformer liquid insulation. IEEE Trans Dielectr Electr Insul 29(2):693–700

Zhang T, Mandala AT, Zhong T, Jiang S, Zhang N (2022) The dielectric voltage response characteristics of transformer oil–paper insulation and its aging state assessment. MAPAN 37(4):929–935

Melnikova O, Nazarychev A, Suslov K (2022) Enhancement of the technique for calculation and assessment of the condition of major insulation of power transformers. Energies 15(4):1572

Hemalatha N, Kamaraja AS, Bhuvanesh A, Karthik Kumar K (2023) Exploring the insulating characteristics of transesterified used cooking oil and blends with corn oil infused with natural antioxidants. Biomass Convers Biorefin:1–6

Thangaraj H, David PW, Balachandran GB, Sivasekar GK (2024) Performance evaluation of natural Olea europaea (olive oil)-based blended esters with butylated hydroxyanisole and butylated hydroxytoluene: optimization using response surface methodology. Environ Sci Pollut Res 31(3):4985–5000

Karthik M, Narmadhai N (2022) Experimental evaluation on suitability of alternate fluids with the influence of additives for power system transformer applications. J Electr Eng Technol 17(3):1883–1906

Kuljaca O, Gadewadikar J, Selmic RR (2011) Adaptive neural network frequency control for thermopower generators power system. Int J Robot Autom 26(1):86

Tian F, Zhu Z, Pan W (2019) Automatic prediction of leave chemical compositions based on NIR spectroscopy with machine learning. Int J Robot Autom 34(4)

Sankaranarayanan R, Krolczyk GM (2021) A comprehensive review on research developments of vegetable-oil based cutting fluids for sustainable machining challenges. J Manuf Process 67:286–313

Tokunaga J, Koide H, Mogami K, Kawanishi K, Hikosaka T (2017) Lifetime estimation of cellulosic insulation material in palm fatty acid ester for power transformers. IEEE Trans Dielectr Electr Insul 24(2):1010–1017

Madavan R, Balaraman S (2017) Comparison of antioxidant influence on mineral oil and natural ester properties under accelerated aging conditions. IEEE Trans Dielectr Electr Insul 24(5):2800–2808

Maharana M, Baruah N, Nayak SK, Meher N, Iyer PK (2019) Condition assessment of aged ester-based nanofluid through physicochemical and spectroscopic measurement. IEEE Trans Instrum Meas 68(12):4853–4863

Sarfi V, Mohajeryami S, Majzoobi A (2017) Estimation of water content in a power transformer using moisture dynamic measurement of its oil. High Voltage 2(1):11–16

Madavan R, Saroja S (2020) Decision making on the state of transformers based on insulation condition using AHP and TOPSIS methods. IET Sci Meas Technol 14(2):137–145

Chicco D, Warrens MJ, Jurman G (2021) The coefficient of determination R-squared is more informative than SMAPE, MAE, MAPE, MSE and RMSE in regression analysis evaluation. Peerj Comput Sci 7:e623

Author information

Authors and Affiliations

Contributions

Mr. M. Karthik (corresponding author): conceptualization, methodology, original draft preparation

Dr. N. Narmadhai: supervision

Corresponding author

Ethics declarations

Ethical approval

None of the authors’ studies involving human participants are included in this article.

Consent to participate

Not applicable

Consent for publication

Not applicable

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Karthik, M., Narmadhai, N. Transformer insulation-based vegetable seed oil for power system analysis. Biomass Conv. Bioref. 14, 21565–21578 (2024). https://doi.org/10.1007/s13399-024-05635-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-024-05635-w