Abstract

This work presents the effect of nanoparticles (Al2O3 and TiO2) on methyl ester synthesized from palm kernel oil for oil-filled power equipment. It investigates the loss tangent, AC conductivity, and AC breakdown strength of the methyl ester-based nanofluid. The surface of the nanoparticles was functionalized with oleic acid before dispersing it into methyl ester to modify the stability of the mixture. Scanning electron microscopy coupled with electron dispersive X-ray was done on the two nanoparticles to know the morphology and elemental composition of the nanoparticles. The preparation of nanofluids was achieved through the dispersion of 0.2, 0.4, 0.6, 0.8, and 1wt% of nanoparticles into the ester. It was observed that the loading of the two nanoparticles reduces the loss tangent and the AC conductivity of methyl ester but with a pronounced enhancement in Al2O3 nanofluid. The Weibull statistical analysis of the breakdown data shows that the dispersion of the nanoparticles in the base fluid increases the characteristic breakdown strength of the ester with an optimum performance at 0.6 wt%. The characteristic breakdown strength for TiO2 and Al2O3 nanofluid is 60.6 kV and 64.1 kV, respectively. The result revealed that Al2O3 nanofluid possesses the highest dielectric properties with low loss, low conductivity, and high characteristic breakdown strength which makes it a better replacement for mineral insulating oil.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Mineral oil has over the years being the desired insulating and cooling oil in oil-filled power transformers, cable, and capacitors due to its unique properties over other transformer oil types especially when it comes to aging [1]. This oil is inexpensive and commercially available in the market; however, it has been observed that leakage of transformer mineral oil causes environmental pollution. Due to the negative environmental impact and non-renewability of this oil, there was a quest for an environmentally friendly and sustainable insulating oil to prevent issues like global warming, acid rain, and pollution [2]. Methyl ester gained attention as a dielectric liquid in the transformer application due to some outstanding characteristics over petroleum-derived insulating mineral. These characteristics include nontoxicity, biodegradability, high flash point, and high thermal conductivity [3, 4]. It also has a high water retention capacity (hydrophilicity) compared to mineral oil, and this helps in protecting the cellulose paper whenever there is leakage of water in the transformer [5]. Furthermore, natural ester oil is environmentally friendly and has excellent dielectric performance [6]. Also, report shows that ester has higher biological oxygen demand (BOD) which indicates good biodegradability of the fluid. In addition, the emission profile of ester is good compared to that of mineral oil. This is because the content of mineral oil is hydrocarbons, and it is harmful to the environment whenever there is ignition. Conversely, the ignition of ester releases no harmful gases as it contains only acid and alcohol [7]. The most commonly used ester oil is palm fatty acid ester (PFAE) oil developed by Lion Corporation in 2006 for transformer insulation [8]. Researchers have continued to explore the applicability of natural ester as transformer oil to improve its quality as an alternative for mineral insulating oil. In 2014, Abdelmalik modified palm kernel oil ester chemically and he reported high breakdown voltage compared to mineral oil [9]. Murad et al. did an investigation on the effect of moisture absorption on the dielectric behavior of palm fatty acid ester. Their result revealed that PFAE oil has higher AC breakdown strength compared with mineral insulating oil [10]. Research was also extended to nonedible oil where Jatropha curcas was considered, and it was reported to have the requirement of an insulating oil when subjected to refining process [11]. From the studies thus far, vegetable oil esters have demonstrated the enormous potential to be a substitute for mineral oils as insulating oil for transformer oil application. However, vegetable oil ester has two major hitches: high conductivity and low volume resistivity that can lead to thermal breakdown of the transformer [12, 13]. To abate these hitches and improve the dielectric properties of vegetable oil ester, nanofluids from vegetable oil ester have attracted great interest. Two techniques are used for the preparation of nanofluids: the one-step method and the two-step method [14]. The one-step method has been reported to be the best method as it reduces agglomeration during the dispersion of nanoparticles in the base oil simultaneously. However, this method is not commonly adopted in transformer oil-based nanofluid research since it is not economical. In the two-step method, the nanoparticle is chemically synthesized, dispersed into the base oil using a homogenizer or ultrasonicator. A well-blended nanofluid has been reported to have high electrical and thermal properties [15,16,17]. Several works have been done regarding the synthesis of nanofluid for transformer application. Jin et al. investigated the effect of SiO2 on mineral insulating oil, and an enhancement in AC breakdown voltage was reported [18]. In 2014, Olmo et al. [19] worked on dielectric enhancement of vegetable transformer oil using non-ferric oxide. They reported an enhancement in the dielectric properties of the oil. TiO2, CuO, and ZnO nanofluids were reported to have an increase in resistivity and a decrease in the loss factor. Madavan and Balaraman investigated the effects of nanoparticles on characteristics of natural ester-based nanofluids using aluminum, boron nitrate (BN), and ferrous ferric oxide (Fe3O4). Their findings are quite promising due to an improvement in the performance of the nanofluids [17]. Characterization of natural ester-based nanofluid using iron oxide nanoparticle was examined by Peppas et al. [20]. They found a decrease in dielectric loss and an increase in thermal conductivity in their nanofluid.

This work seeks the feasibility of reducing the electrical conductivity and increases the dielectric breakdown strength of palm kernel oil methyl ester using semiconductive and insulating nanoparticles. In this work, TiO2 and Al2O3 nanofluids were developed. The choice of TiO2 and Al2O3 nanoparticles is due to their excellent properties that include stability compared to pure metals, nontoxic nature, low cost, and easy production [5, 21]. Dielectric loss, conductivity, and AC breakdown strength of the as-prepared nanofluids were investigated. Weibull statistical tool was used to analyze the breakdown strength from the obtained AC breakdown voltage data.

2 Materials and methods

2.1 Materials

The palm kernel oil used was locally purchased in Nigeria, and methyl ester was synthesized from it. The Al2O3 and TiO2 nanoparticles were purchased from Sky Spring Nanomaterials, Inc., USA. The Tonsil fuller’s earth was obtained from Parco Enterprises Nig. Ltd. In addition, Filter paper Whatman number 1 and number 5, methanol, propane-2-ol, citric acid, NaOH, oleic acid, mineral oil (Shell Diala BX), and KOH were used in the experiment. The physicochemical properties of the nanoparticles are shown in Table 1 according to Sky Spring datasheet.

2.2 Oil purification

The purification of the oil was done by heating 100ml of oil in a round bottom flask to 70°C followed by the addition of proportional citric acid. The solution was thoroughly stirred for 15min. Prepared NaOH solution was added at the same temperature to neutralize the oil from free fatty acid component. The mixture was then stirred for another 15 min. The solution was oven-dried at 85°C inside a vacuum oven for 30min to reduce the water content. To the solution, an accurate proportion of Silica gel (1g) was added to further remove any traces of water molecule in the oil. The solution was thoroughly stirred to prevent silica agglomeration. Bleaching clay was further added to remove the colored compound, metal, and oxidation product. The mixture was stirred for 30 min and then filtered with Whatman No. 1 and followed by No. 5.

2.3 Palm kernel oil ester preparation

400 ml of oil sample was measured in a flask, and sodium methoxide solution prepared through dissolving 5.7g of NaOH into methanol was added into the oil at 60°C. The solution was stirred for 1h, and the solution was then transferred into a separating funnel. The methyl ester was separated from the glycerol, and the ester was washed with warm water to remove any leftover sodium hydroxide catalyst. The ester was oven-dried for 2–3 h to remove remnant moisture in the sample.

2.4 Nanofluid preparation

The surface of the nanoparticles was coated using oleic acid, and nanofluids were prepared with the nanoparticles in different percentage, ranging from 0.2 to 1 wt% in the step of 0.2. The surface coating was to reduce the attraction between the nanoparticles by creating an intermolecular force that separates molecules from each other, thus prevent agglomeration. The functionalization was done by dispersing 5 g of nanoparticle into 100 ml of ethanol. To the ethanol-nanoparticle solution, 0.25 ml of oleic acid was added and stirred for 2h. The solution was centrifuged, and the nanoparticle was collected and oven-dried at 80°C. The oleic acid-coated nanoparticles were dispersed into the methyl ester and stirred using a magnetic stirrer for 30 min for optimum dispersion. Figure 1A–D shows pictures of the prepared samples. A is the purified oil, B is the methyl ester, C is the Al2O3 nanofluid, and D is the TiO2 nanofluid. Table 2 shows the sample description of the analyzed samples.

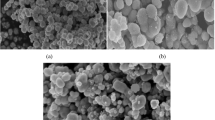

2.4.1 SEM-EDX

The nanoparticles were analyzed using an ultra-high vacuum and high-resolution scanning electron microscope (SEM) integrated with electron dispersive X-ray analysis (EDX). Both the morphology of the nanoparticles and the elemental compositions were determined using ZEISS EVO LS10 operating at 20 kV.

2.4.2 Dielectric measurement

The dielectric loss of MO, ester oil, and NFs were measured according to IEC 60247-2004, using Rohde & Schwarz HM8118 Programmable LCR BRIDGE. The setup consists of two parallel plate electrode test cell of diameter 30 mm and a gap of 2.5 mm. Both electrodes were fully immersed in samples, and the capacitance and dielectric loss were measured at power frequency (60 Hz) at 27°C.

The real permittivity, ε′, which is related to the energy stored within the medium and ε′′, the imaginary permittivity which is related to the dissipation of energy within the medium, are related to the loss tangent with the equation

where δ is the loss angle and is the angle between the effective current and displacement current.

The electrical conductivity of the samples was determined using the equation

where σ is the conductivity in Sm−1, ω =2πf is angular frequency, εo is the permittivity of free space, and ε′′ is the dielectric loss factor.

2.4.3 AC and Weibull plot analyses

The dielectric breakdown voltage of the samples was measured in accordance with the ASTM D1816 standard [2, 22]. An automated test kit “Insulating oil Dielectric strength tester” with model FS2080 was used to determine the dielectric breakdown of each sample. The electrode of the test kit has a spherical mushroom shape with a gap spacing of 2.5 mm. 250 ml of oil sample was used for each breakdown. The test was performed by increasing the supply voltage step wisely at a rate of 1 kV/s until breakdown occurs. The AC breakdown voltage of the samples was analyzed using Weibull statistics. For this analysis, the two-parameter Weibull plot was used and the breakdown probabilities were determined. For any random variable x, the cumulative distribution function of Weibull distribution is defined as follows:

where x is the breakdown voltage, β is the shape parameter that is related to failure rate, and α is the characteristic breakdown strength or scale parameter that is related to the probability of 63.2%.

3 Result and discussion

3.1 SEM-EDX analysis

The elemental composition and the surface morphology of TiO2 and Al2O3 nanoparticles were studied using ultra-high vacuum-high-resolution SEM integrated with EDX. Figures 2 and 3 show the micrograph and elemental composition of TiO2 and Al2O3 nanoparticles, respectively. The micrographs of both nanoparticles displayed uniform dispersion of the nanoparticles with little cluster and little variation in shapes with a high percentage of spherical related shapes. Some noticeable variation in shape may be due to the clustering of some of the particles. Investigation using electron dispersive X-ray further confirmed the purity and the elemental composition of the nanoparticles as illustrated in Figures 2 and 3.

3.2 Dielectric loss and AC conductivity

The dielectric loss of the samples was determined at a power frequency of 60 Hz. Table 3 shows the dielectric loss of MO, ME, TiO2 nanofluids, and Al2O3 nanofluids. It was observed that after the transesterification process, the loss in the methyl oil ester increased which can be attributed to some dissociated chemical used in the process. The dielectric loss of mineral oil was observed to be lower than that of the purified oil and that of the ester. Perfect insulating material is expected to have zero conductivity and no loss but a perfect insulator hardly exists. The dielectric loss of mineral oil can be attributed to polarization phenomena in the liquid and the conduction of ionic impurities in the liquid. Thus, the dielectric loss in mineral oil is a combination of polarization and conduction processes. Table 4 shows the conductivity of all the samples at 60 Hz. The dielectric loss and AC conductivity results of mineral oil obtained in this work are similar to the one reported in the technical datasheet of Shell Diala BX. The oil was reported to have a dielectric loss of 0.002 at 40–60 Hz that agrees to 0.00115 obtained in this work. The conductivity measured in this work is also close to the one in the datasheet at 25°C which is of the order 10−12. The results are also similar to the values reported by Abdelmalik [6]. The dielectric loss and conductivity of natural ester obtained by Umar et al. [23] are of the order 10−2 and 10−10, respectively. This is similar to the result obtained for natural ester in this work. The result comparison with literature was used to affirm the accuracy of the setup before further characterization of the nanofluids. The dispersion of the nanoparticles in the oil was observed to have led to a reduced dielectric loss in the methyl ester. A similar observation was made for the two nanoparticles in the methyl ester. The progressive loading of nanoparticles from 0.2 to 1wt% led to a reduction in conduction rate by trapping and de-trapping of the dissociated electron in the methyl ester by the nanoparticles and consequently reduces the dielectric loss. The aligned layers of the nanoparticle also create a strong intermolecular structure which helps in the trapping of electrons and mobile ions between the interparticle zones; this also reduces the conduction and consequently reduces the dielectric loss [24]. While the dispersion of the two nanoparticles led to reduced dielectric loss, the reduction in the dielectric loss is more pronounced in Al2O3 nanofluid when compared with TiO2 nanofluid. This may be attributed to the dielectric nature of Al2O3 nanoparticle which requires more electrons to get excited before allowing a release of an electron to the next neighboring nanoparticle thereby reducing conductivity that consequently reduces the loss. The AC conductivity of each sample was obtained using equation (2). Since the conductivity is having a direct relationship with dielectric loss, a corresponding decrease in the conductivity of the ester was observed across the loading of nanoparticles. The obtained data revealed that Al2O3 nanofluid would likely serve better as an insulating fluid for oil-filled power equipment when considering the loss and the conductivity.

3.3 AC breakdown test

The breakdown phenomenon in insulating materials is a statistical event. Therefore, the characterization of the breakdown field strength of insulating materials requires several measurements on the sample. Twelve (12) AC breakdowns were performed on each sample of MO, PPKO, ME, ester-based TiO2 nanofluids, and Al2O3 nanofluids. The variation in the values of breakdown voltage for each sample of oil is due to the random distribution of the weakest paths. Weibull statistics is based on extreme-value statistics, and it fails when the weakest link fails. It is the most commonly used statistics in high-voltage materials/system failure, and it is adopted in this analysis. One interesting feature of Weibull statistics is the fact that it can be used to analyze small sample data. Figures 4, 5, 6, 7, and 8 show the Weibull plot of MO, PPKO, ME, and the prepared nanofluids. Figure 4 presents the Weibull plot of PPKO and ME. The two samples have nearly the same slope but PPKO has higher breakdown values as compared with its methyl ester, an indication they have a similar distribution. Figures 5, 6, and 7 also indicate that MO, methyl, and its nanofluid have a similar distribution. Figure 8 presents the Weibull plot of the fluids with optimum breakdown values. The plots for the 0.6wt% Al2O3 and TiO2 nanofluids show that the breakdown data falls within the same range of values.

The scale parameter (α), shape parameter (β), and correlation coefficient (ρ) for MO, PPKO, ME, and ester-based TiO2 and Al2O3 nanofluids based on the two-scale parameter Weibull Plots are summarized in Table 5. It can be observed from the table that the correlation coefficients of the breakdown data when fitted in Weibull function, equation (3), are greater than R2 = 0.918 for 10 breakdowns [25]. Judging from the correlation coefficient values which are close to 1, it is evident that there is a strong positive correlation between the Weibull probability and AC breakdown strength for all samples. The high values of the shape parameter for all the samples show that there is a low dispersion in the breakdown data of every sample. The mean normal distribution breakdown strength of mineral oil (Shell Diala) and palm kernel oil methyl ester was compared with the literature. The mean breakdown strength of mineral oil was obtained to be 24.5kV with a standard deviation of 2.24 kV (9%). This result is similar to the one obtained by [26] for Diala D (26.4kV and 1.9kV (7%)). Also, for palm kernel oil methyl ester, the average breakdown strength was obtained to be 32 kV with a standard deviation of 3.2 kV (10%). This value appeared better when compared with the obtained result by [24] for natural ester (31 kV). It can be observed from Table 5 that mineral oil has the lowest breakdown strength with a value of 26.03 kV/mm. For the vegetable oil insulating fluid (PPKO), the breakdown strength was observed to be 45.91 kV and it is 43.3% greater than the breakdown strength of mineral insulating oil. For effective cooling and proper circulation of the oil in the transformer, transesterification was done and the glycerol which is the backbone of the methyl ester was removed. After the transesterification, the breakdown strength of the PKO methyl ester was obtained to be 35.56 kV which indicates that the removal of glycerol led to the reduction of the AC breakdown strength of the seed oil by 22.5%. However, despite the reduction in breakdown strength after the chemical modification, methyl ester characteristic breakdown strength is still 26.8% greater than that of the mineral oil which indicated that the sustainable alternative oil is a viable alternative to mineral oil. To study the influence of the nanoparticles on the base oil, the loading of the nanoparticles was done in the range of 0.2 to 1wt% in step of two to observe the effect of the nanoparticle on the insulating performance of the green alternative. The addition of nanoparticles (semiconducting and insulating nanoparticles) was observed to have increased the characteristic breakdown strength of the base oil with optimum performance at 0.6wt%. The dispersion of nanoparticles beyond 0.6wt% resulted in a decrease in the breakdown strength of the nanofluid samples. This can be attributed to the decrease in inter-particle distance and a reduction in the potential width of the double layers. This may have led to the overlapping of the nanoparticles which when exposed to a high electric field, may get charged and then bridge the flow of electrons.

The characteristics AC breakdown strength of all the samples for the selected probability of failures can be seen in Table 6.

Since unforeseen failure at low voltage is inevitable, the breakdown voltage at the lowest probability (1%) for each sample was also considered. It was observed that the breakdown strength of the prepared nanofluids at the lowest probability is better than the breakdown voltage of both mineral oil and methyl ester with Al2O3 nanofluids having a remarkable value. At 0.6wt% of Al2O3 nanofluid, an exceptional value of breakdown voltage (42.36 kV/mm) obtained at 1% probability demonstrates high operating reliability of the fluid.

Figure 9 compared the characteristic breakdown strength of the prepared nanofluids from TiO2 and Al2O3 nanoparticles. The dispersion of TiO2 and Al2O3 nanoparticles in the base fluid increases the breakdown strength by 41.3% and 44.5%, respectively. This indicates that the Al2O3 nanoparticle increases the AC breakdown voltage more than TiO2. It has been reported that semiconducting and insulating nanoparticles produce shallow electron traps which captured the fast-moving electrons and convert them to a slower electron through repeated tapping and de-trapping when there is mobility of electron from high electric field to low electric field. The addition of TiO2 nanoparticle to the ester helps to reduce the transport of electron in the nanofluid by repeated trapping and de-trapping mechanism with the aid of the shallow trap created. More shallow traps are created in insulating nanoparticle as compared with a semiconducting nanoparticle. This may be responsible for the higher breakdown strength of the nanofluid sample containing Al2O3 nanoparticle [2]. This trap helps in converting fast electrons created by high electric field to slow electrons through the hopping process. The oil dielectric strength is increased through this hopping process by decreasing the speed of the electrons and also prevents the accumulation of space charges in the oil. The result obtained from this work when considering the effect of the nanoparticles can be compared with the one reported in the literatures. Makmud et al. reported that TiO2 nanofluid from natural ester has breakdown voltage around 53 kV/mm at 1g/L concentration which is less than the optimum breakdown voltage obtained for TiO2 nanofluid in this work (60.6 kV/mm) [24]. Also, Mohamad et al. reported on the characteristic breakdown strength of palm fatty acid ester-Al2O3 nanofluid to be 36.87 kV/mm, whereas the result obtained in this work at optimum performance is 64.1 kV/mm [2]. This indicates that the developed nanofluid is compared well with previously reported results and has higher breakdown strength. It can be deduced from the results that the nanofluids from the two nanoparticles have good dielectric properties. Al2O3 nanofluid will likely serve better as an insulating fluid compared to TiO2 nanofluid.

4 Conclusion

In this work, synthesis of natural ester was done and the influence of semiconducting and insulating nanoparticles on the dielectric loss, conductivity, and AC breakdown voltage of the prepared natural ester was studied. The dielectric loss and the conductivity of samples at every loading of nanoparticle reduce with an increase in loading. This may be attributed to the trapping and de-trapping of the mobile electron and ions in the oil. An increase in AC breakdown strength was observed with the loading of nanoparticles from 0.2wt% with an optimum performance at 0.6wt% for both TiO2 and Al2O3 nanoparticles. The reduction in the value of AC breakdown voltage after 0.6wt% may be attributed to the higher percentage of nanoparticle which causes a reduction in inter-particle distance and consequently led to conduction which eventually reduces dielectric breakdown strength. This work revealed that the dispersion of nanoparticles in palm kernel oil ester resulted in the reduction of the dielectric loss and AC conductivity and improved breakdown strength at 0.6wt% loading. Meanwhile, the nanofluid with Al2O3 nanoparticle appears to perform better as an insulating fluid for oil-filled high-voltage equipment, especially transformer insulation. Further research should be done on the compatibility of cellulose paper with the prepared nanofluid to examine the effect of the dispersed nanoparticles on the mechanical and dielectric properties of the nanofluid-impregnated cellulose paper.

Data availability

Not applicable.

Code availability

Not applicable.

References

Spohner M (2012) A study of the properties of electrical insulation oils and of the components of natural oils. Acta Polytechn 52:5

Mohamad MS, Zainuddin H, AbGhani S, Chairul IS (2017) AC breakdown voltage and viscosity of palm fatty acid ester (PFAE) oil-based nanofluids. J Electric Eng Technol 12(6):2333–2341

Fofana I (2013) 50 years in the development of insulating liquids. IEEE Electr Insul Mag 29(5):13–25

Fernández I, Ortiz A, Delgado F, Renedo C, Perez S (2013) Comparative evaluation of alternative fluids for power transformers. Electr Power Syst Res 98:58–69

Oparanti SO, Khaleed AA, Abdelmalik AA (2020) Nanofluid from palm kernel oil for high voltage insulation. Mater Chem Phys 259:123961

Abdelmalik AA (2012) The feasibility of using a vegetable oil-based fluid as electrical insulating oil. Doctoral dissertation, University of Leicester

Rao UM, Fofana I, Jaya T, Rodriguez-Celis EM, Jalbert J, Picher P (2019) Alternative dielectric fluids for transformer insulation system: progress, challenges, and future prospects. IEEE Access 7:184552–184571

Wakimoto K (2015) Features of eco-friendly transformers using palm fatty acid ester (PFAE), a new vegetable-based insulation oil. Meiden Rev 163:39–45

Abdelmali AA (2014) Chemically modified palm kernel oil ester: a possible sustainable alternative insulating fluid. Sustain Mater Technol 1:42–51

Murad NS, Muhamad NA, Suleiman AA, Jamail NAM (2013) A study on palm oil-based oil moisture absorption level and voltage breakdown. In 2013 Annual Report Conference on Electrical Insulation and Dielectric Phenomena. IEEE, pp 925–928

Beltrán N, Palacios E, Blass G (2017) Potential of Jatropha curcas oil as a dielectric fluid for power transformers. IEEE Electr Insul Mag 33(2):8–15

Hikosaka T (2007) Basic characteristics of environment-conscious transformers impregnated with oil palm fatty acid ester (PFAE). In 15th International Symposium on High Voltage Engineering, 2007

Kato K, Nara T, Okubo H, Endo F, Yamazaki A, Koide H, Hikosaka T (2009) Space charge behavior in palm oil fatty acid ester (PFAE) by electro-optic field measurement. IEEE Trans Dielectr Electr Insul 16(6):1566–1573

Lv YZ, Zhou Y, Li CR, Wang Q, Qi B (2014) Recent progress in nanofluids based on transformer oil: preparation and electrical insulation properties. IEEE Electr Insul Mag 30(5):23–32

Choi SU, Eastman JA (1995) Enhancing thermal conductivity of fluids with nanoparticles, No. ANL/MSD/CP-84938; CONF-951135-29. Argonne National Lab, IL

Karthik R, Raja TSR, Madavan R (2013) Enhancement of critical characteristics of transformer oil using nanomaterials. Arab J Sci Eng 38(10):2725–2733

Madavan R, Balaraman S (2017) Investigation on effects of different types of nanoparticles on critical parameters of nano-liquid insulation systems. J Mol Liq 230:437–444

Jin H, Andritsch T, Morshuis PHF, Smit JJ (2012) AC breakdown voltage and viscosity of mineral oil based SiO 2 nanofluids. In 2012 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, IEEE, pp 902–905

Olmo C, Fernández I, Ortiz F, Renedo CJ, Pérez S (2018) Dielectric properties enhancement of vegetal transformer oil with TiO2, CuO and ZnO nanoparticles. In Proceedings of International Conference on Renewable Energies and Power Quality (ICREPQ’18), pp 623–627

Peppas GD, Bakandritsos A, Charalampakos VP, Pyrgioti EC, Tucek J, Zboril R, Gonos IF (2016) Ultrastable natural ester-based nanofluids for high voltage insulation applications. ACS Appl Mater Interfaces 8(38):25202–25209

Assadian E, Dezhampanah H, Seydi E, Pourahmad J (2019) Toxicity of Fe2O3 nanoparticles on human blood lymphocytes. J Biochem Mol Toxicol 33(6):e22303

Oparanti SO, Khaleed AA, Abdelmalik AA, Chalashkanov NM (2020) Dielectric characterization of palm kernel oil ester-based insulating nanofluid. In 2020 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP). IEEE, pp 211–214

Umar S, Abdelmalik AA, Sadiq U (2018) Synthesis and characterization of a potential bio-based dielectric fluid from neem oil seed. Ind Crop Prod 115:117–123

Makmud MZH, Illias HA, Chee CY, Sarjadi MS (2018) Influence of conductive and semi-conductive nanoparticles on the dielectric response of natural ester-based nanofluid Insulation. Energies 11(2):333

Montanari GC, Fothergill JC, Hampton N, Ross R, Stone G (2005) IEEE Guide for the statistical analysis of electrical insulation breakdown data. IEEE standard 930-2004

Jing Y, Timoshkin IV, Wilson MP, Given MJ, MacGregor SJ, Wang T, Lehr JM (2014) Dielectric properties of natural ester, synthetic ester midel 7131 and mineral oil diala D. IEEE Trans Dielectr Electr Insul 21(2):644–652

Funding

This work was supported by Nigeria’s Tertiary Education Trust Fund (TETFund) National Research Fund (NRF) Research Grant 2019. TETF/DR&D/CE/NRF/UNI/ZARIA/STI/55/VOL.1

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Oparanti, S.O., Khaleed, A.A. & Abdelmalik, A.A. AC breakdown analysis of synthesized nanofluids for oil-filled transformer insulation. Int J Adv Manuf Technol 117, 1395–1403 (2021). https://doi.org/10.1007/s00170-021-07631-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07631-0