Abstract

In this study, the main chemical composition, the total phenolic content (TPC), the total flavonoid content (TFC), the total anthocyanin content (TAC) and antioxidant activity (TAA) of blackthorn (Prunus spinosa L.) fruit growing wild in Edirne province were determined. Furthermore, the phenolic compounds composition was investigated by liquid chromatography–tandem mass spectrometry (LC–MS/MS) and the mineral composition was performed by inductively coupled plasma mass spectrometry (ICP-MS). In addition, the aim of the study was to investigate the effects of temperature (20–40 °C), time (2–6 min) and amplitude (20–60%) on TPC, TFC, TAC, and TAA of blackthorn during ultrasound-assisted extraction. Response surface methodology using central composite design was used to determine the optimum conditions in ultrasound-assisted extraction of bioactive compounds in blackthorn. The optimum extraction conditions were obtained with temperature 40 °C, time 3.592 min, and amplitude of 33.189%. TPC, TFC, TAC, and TAA of blackthorn were found as 3203.31 ± 4.63 mg GAE kg−1 FW, 727.41 ± 4.63 CE kg−1 FW, 135.09 ± 0.33 mg cy-3-glu kg−1 FW, and 19.65 ± 0.06 mmol TE kg−1 FW, respectively, which were consistent with predicted values. The ultrasound-assisted extraction can be considered as an efficient green and practical technique for the recovery of bioactive compounds in blackthorn.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Blackthorn (Prunus spinosa L.), which belongs to the rose family (Rosaceae), is a spiny, deciduous, spontaneous wild shrub plant grown in uncultivated areas. It grows naturally in a wide geography in the world from south-central Europe up to southern Scandinavia, and eastwards to Asia minor [1]. Since it is resistant to cold, drought and calcareous soils and prefers humid climates, it extends mostly in rainy parts of Thrace, Western Black Sea, Aegean Region and Central Anatolia in Turkey [2]. Ripe fruits have a round shape, 5–7 mm in diameter, bluish-black smoky skin, greenish flesh, hard-core and astringent taste [3]. Due to the bitter taste of the fruits, they are not suitable for raw consumption, and they are consumed as homemade products such as jelly, jam, marmalade, fruit juice, syrup and compote [2, 4]. In addition, it is suitable for the production of alcoholic and non-alcoholic beverages such as liquor, brandy and wine due to its intense volatile components [2, 3].

The plant has been known in European tradition for over 7,000 years as a medicinal plant [5]. The fruit, flowers, bark and roots of the plant have been widely used in traditional medicine to treat different diseases [4]. The blackthorn is used in phytotherapy for the treatment of many diseases associated with cough and circulatory system. It is a laxative, vermicide, diuretic, spasmolytic and anti-inflammatory agent. Due to its high tannin content, it is antiseptic and acts against inflammation of the mucosal layer of the digestive tract [4,5,6].

Epidemiological studies have consistently shown that a high daily intake of fruits rich in bioactive components is associated with a reduced risk of various cancer types and cardiovascular diseases [7, 8]. Marchelak, Owczarek [5] and Magiera, Czerwińska [9] reported that the bioactive components of the blackthorn are polyphenols, including flavonoids, A-type proanthocyanins, anthocyanins, coumarins and phenolic acids. Fraternale, Giamperi [3] examined the potential of blackthorn fresh juice to protect human promonocytes (U937 cells) from oxidative damage. Their results showed that necrotic cell death was reduced with increasing fresh juice concentration in the presence of 0.3 mM H2O2. Karakas, Okur [6] also found that methanol extract of blackthorn has significant cytotoxic activities with 50–63% cell viability of glioblastoma brain cancer cells. Recently, Magiera, Czerwińska [9] proved that blackthorn extracts are important for releasing of some vital pro-inflammatory and anti-inflammatory factors in immune cells. As the result of anti-cancer studies, increased attention has been recently paid to the blackthorn fruit, a great potential source of health-promoting bioactive compounds and antioxidants.

In this context, researchers have focused on the development of extraction methods to recover of bioactive compounds and antioxidants from natural products. Although traditional extraction methods are quite easy to use, long processing times, high raw material requirements and toxic effects on the environment restrict the use of these methods [10]. In addition, these techniques result in low-quality products due to extreme extraction conditions such as long extraction times, a large quantity of solvent and higher temperature, which can cause to degradation of thermo instable components. Green novel extraction methods, which are carried out in a short time and do not require organic solvents, provide environmentally friendly, high quality and efficient extracts, have gained considerable importance in recent years. Ultrasound-assisted extraction is coming into prominence among these methods due to shorter extraction time, reduced solvent consumption and enhanced final product quality [11, 12].

This versatile method has been used in food processing such as peeling, emulsification, spraying, degassing, drying, cooking, and crystallization. Ultrasound is a mechanical wave that can cause the collapse of the cavitation bubble, producing micro-jets that facilitate the disruption of plant cell walls and enhance the extraction of components from within the cell by accelerating the mass transfer of extractable compounds [11]. The ultrasound-assisted extraction has been widely used for the extraction of phenolic, flavonoid and anthocyanins components with antioxidant activity from various foods [13,14,15,16,17].

The effectiveness of the application in ultrasound-assisted extraction depends on generator performance, reactor design, extraction process parameters and characteristics of the reaction medium [18]. Therefore, it is necessary to optimize the parameters affecting the process in order to reduce solvent consumption and minimize the workload and time. Response surface methodology (RSM) is a multivariate statistical tool widely used to evaluate the effect of multiple different parameters and their interactions and optimize the process parameters. Central composite design (CCD) is considered as a type of RSM that is more efficient and takes less time to accurately describe the relationships between one or more response variables and several independent variables [10].

It is crucial to reveal the underutilized potential of wild blackthorn fruit to obtain a rich extract of bioactive compounds with green technology that is used for the production of various high value-added products. Therefore, the objectives of this study were: (i) to determine the detailed chemical composition of blackthorn fruits grown locally in Edirne province (Turkey), (ii) to investigate the effects of extraction temperature, extraction time and amplitude on the total phenolic content, total flavonoid content, total anthocyanin content and antioxidant capacity of blackthorn during ultrasound-assisted extraction, (iii) to optimize significant independent variables by RSM using CCD, (iv) to validate model fitting and to compare with the experimental and predicted value.

Material and methods

Chemicals and reagents

Folin-Ciocalteu reagent, anhydrous sodium carbonate, sodium acetate, potassium chloride, 6-hydroxy-2,5,7,8-tetramethylchroman-2-carboxylic acid (Trolox), 2,2′-azinobis-(3-ethylbenzothiazoline-6-sulfonic acid) (ABTS), aluminum chloride hexahydrate, sodium nitrite, sodium hydroxide, hydrogen peroxide, phenolic standards (gallic acid and (+)-catechin) and anthocyanin standard (cyanidin-3-rutinosid) were purchased from Sigma (St. Louis, MO, USA). In addition, suprapur nitric acid was supplied from Merck (Darmstadt, Germany). All solvents were HPLC grade. In all analyses, the ultrapure water (its conductivity less than 0.5 μS cm−1) was obtained from a PURELAB Option-Q (ELGA LabWater, UK) unit.

Plant material and sample preparation

Prunus spinosa L. (Blackthorn) fruit was collected manually from non-cultivated trees in the fields located at 41.6379 latitude 26.6224 longitude coordinates used for agricultural activities within Trakya University (Edirne, Turkey) in October 2020 following the ripening stage. Fresh fruits were washed in cold tap water, dried with filter paper, sealed in plastic bags and stored in a refrigerator at − 20 °C until further use. Following the defrosted process in the refrigerator, the fruit stones were removed by hand, and the remaining fruit flesh (average 200.0 ± 2.0 g) was weighed in Waring blender (Waring 8011 Eb, USA). It was diluted 1:1 with distilled water and homogenized for 2 min at minimum speed. The final extracts were used for all chemical and extraction analyses.

Analytical measurements

Chemical analysis

The total soluble solids (TSS) was measured with a refractometer (Atago, Co., Tokyo, Japan) and expressed as °Brix and. The pH measurements were carried out with a pH meter (Mettler-Toledo SG-2 SevenGo, Switzerland) at 20 °C. Total titratable acidity (expressed as a percentage of malic acid) was analysed by titrating the product with 0.1 N NaOH to pH 8.1. The total solid content was determined by the gravimetric method using a vacuum oven (Nuve EV 018, Turkey) at 70 °C. To determine the ash content, the samples were burnt in an ashing furnace (Protherm PLF 120/7, Labomar, Turkey) at 550 °C. Total nitrogen content (N) was determined according to the Kjeldahl method using an automatic heating system (Kjeldatherm Digestion Systems KB8S, Gerhardt, Germany) and automatic distillation units (Vapodest VAP 20 s, Gerhardt, Germany), and total protein content was calculated from Nx6.25. All measurements were performed in triplicate.

Determination of total phenolic content

Total phenolic content (TPC) was determined spectrophotometrically with Folin-Ciocalteu reagent method according to Shahidi, Chavan [19]. The samples were diluted in appropriate proportions with distilled water and the diluted samples were filtered with filter paper. 1 mL diluted sample, 5 mL Folin-Ciocalteu reagent (previously diluted with distilled water 1:10 v/v) and 4 mL saturated sodium carbonate (75 g/L) were mixed in the tubes. The tubes were vortexed for 10 s, kept in the water bath at 50 °C for 5 min, and cooled immediately. The absorbance at 760 nm was measured with a spectrophotometer (Shimazdu, Japan). Gallic acid was used to calculate the standard curve (10–80 mg/L; y = 0.0116x; R2 = 0.9992), and the results were expressed as mg gallic acid equivalent kg−1 fresh weight (mg GAE kg−1 FW).

Determination of total flavonoid content

Total flavonoid content (TFC) was determined using a colourimetric method described by Dewanto, Wu [20]. 1 mL of the diluted samples was mixed with 5 mL of water. 0.3 mL of 5% NaNO2 was added to the mixture and mixed. After 6 min, 0.6 mL of 10% AlCl3.6H2O was added and vortexed. After 5 min, 2 mL of NaOH solution (1 M) was added to the mixture, and the tube volume was completed to 10 mL with distilled water. The absorbances of the prepared solutions were read at 510 nm in the spectrophotometer, and the total flavonoid amounts were calculated to be equivalent to mg catechin from the calibration curve prepared with ( +)- catechin at different concentrations (0–125 mg catechin/L, y = 0.0064x, R2 = 0.9910). The results were expressed as mg CE kg−1 FW.

Determination of total monomeric anthocyanin content

Total monomeric anthocyanin content (TAC) was determined according to the pH differential method, as Giusti and Wrolstad [21] described. The samples were diluted in appropriate proportions with 0.025 M potassium chloride buffer (pH 1.0) and 0.4 M sodium acetate buffer (pH 4.5). The diluted samples were kept at room temperature (20 ± 2 °C) for 15 min to equilibrate and filtered using 0.45 µm PVDF syringe filters. The absorbance of equilibrated solutions at 514 nm (λmax) for anthocyanin content and 700 nm for haze correction was measured on a UV–VIS spectrophotometer (Shimazdu, Japan) against distilled water as a blank. The difference in absorbance values at pH 1.0 and 4.5 was used to calculate total monomeric anthocyanin content, and the result was given as cyanidin-3-glucoside (molecular weight of 449.2 g mol−1 and extinction coefficient of 26 900) equivalents and expressed as mg cy-3-glu kg−1 FW.

Determination of total antioxidant activity

The total antioxidant activity (TAA) was determined using Trolox Equivalent Antioxidant Capacity (TEAC) method described by Re, Pellegrini [22]. ABTS radical cation (ABTS·+) was generated by the reaction of 7 mM ABTS with 2.45 mM potassium persulfate (K2S2O8), and the mixture was kept in the dark at room temperature for 16 h. The solution was diluted with ethanol to an absorbance reading of 0.70 ± 0.02 at 734 nm. 3 mL of the ABTS·+ solution and 30 μL of the sample were mixed, and the absorbance was measured at 734 nm after 6 min of dark incubation at room temperature. Trolox was used to calculate the standard curve (0.5–2 mM; y = 0.282x; R2 = 0.9995), and the results were expressed as TEAC (mmol TE kg−1 FW).

Determination of elemental composition by ICP-MS

Mineral composition of fruit was measured by inductively coupled plasma mass spectrometry (ICP-MS) Agilent 7800 system (Agilent Technologies, Santa Clara, CA, USA). Samples of approximately 0.5 g fruit samples were placed into a Teflon digestion vessel and 9 ml of HNO3 and 1 ml of H2O2 were added. The mixture was burned in a microwave-assisted digestion system (Ethos, Milestone, Italy). The instrumental parameters involved a ramp of 15 min to reach 200 °C and then the system was maintained at 1000 W for additional 15 min. The digests were filtered through a Whatman No. 1 filter paper and diluted at 50 mL with deionised water, and then analysed by ICP-MS [23]. The results were expressed in mg kg−1 FW.

Determination of individual phenolic compounds by LC–MS/MS

The phenolic composition of the blackthorn fruit was determined by liquid chromatography-tandem mass spectrometry (LC–MS/MS) Agilent 6460 system with a triple quadruple mass spectrometer equipped with an electrospray ionization (ESI) interface (Agilent Technologies, Santa Clara, California, USA). For the extraction of phenolic compounds from the sample before analysis, the hydrolysis and non-hydrolysis extraction method described by Bayram, Canli [23] was used to analyse both sugar-containing and basic phenolic compounds. High-performance liquid chromatography (HPLC) and mass spectrometry (MS) parameters were given detailed in Bayram, Canli [23]. The results were expressed in mg kg−1 FW.

Ultrasound-assisted extraction

Ultrasound-assisted extraction was performed in an ultrasonic homogenizer (BANDELIN, SONOPULS HD 4200, Germany) equipped with GM 4200 generator, ultrasonic converter UW 200, SH 200 G booster horn and titanium probe TS 109 (dia. 9 mm). Blackthorn extract, diluted 1:1 with distilled water and homogenized with a Waring blender, was weighed 12.5 g into a double-walled extraction tube, and 112.5 g of distilled water was added. The ultrasound probe was submerged to half the depth of the sample. The internal extraction temperature was maintained constant with cold water and controlled within ± 1.0 °C with a calibrated thermometer. Ultrasonication was carried out under controlled conditions where the amplitude levels including –α and + α were 6.36, 20, 40, 60, and 73.64%, the temperature were 13.18, 20, 30, 40, and 46.82 °C, and the time was 0.64, 2, 4, 6, and 7.36 min. The final extracts were stored at -20 °C prior to analysis.

Experimental design and data analysis

Response surface methodology (RSM) was used to determine the optimum conditions in ultrasound-assisted extraction of bioactive compounds in blackthorn. The independent variables were determined as temperature (X1), extraction time (X2), and amplitude (X3). These variables were studied at five different levels coded as − α, − 1, 0, + 1, and + α, which the number of α is (23)1/4 = 1.682 (Table 1). The central composite design (CCD) with three independent variables each at five levels was used for the optimization of extraction variables. The CCD included 20 experimental trials, which had six trials as replication of the central points, and the experiments were carried out in a random order without replication. The total phenolic content (Y1, mg GAE kg−1 FW), total flavonoid content (Y2, mg CE kg−1 FW), total monomeric anthocyanin content (Y3, mg cy-3-glu kg−1 FW), and total antioxidant activity (Y4, mmol TE kg−1 FW) were selected as the responses variables.

The second-order polynomial equation for three quantitative factors (Eq. 1) was used in order to correlate the relationship between the responses and independent variables.

where Y was the response value, X1, X2, and X3 represented the level of the factors according to Table 1, and the coefficients of the polynomial were represented by β0 (constant term), β1, β2 and β3 (linear effects), β11, β22, and β33 (quadratic effects), and β12, β13, and β23 (interaction effects); and ε was the residual error.

Statistical software package Design-Expert (Trial Version 6.0.2, State-Ease, Minneapolis, USA) was used for the generation of the regression model and the optimization of the process.

Statistical analysis

Analysis of variance (ANOVA) was used to assess the model’s statistical significance and determine the individual linear, quadratic and interaction regression coefficients. p-values of less than 0.05 were considered to be statistically significant. The optimum condition was established by plotting the response surface plots of each response.

Result and discussion

Chemical composition of the blackthorn fruit

The results of the chemical characterization analyses and antioxidant activity analysis of the blackthorn fruit are presented in Table 2. Total soluble solid content and dry matter of blackthorn were found 23.50 ± 0.20°Brix, and 31.00 ± 1.58 g 100 g−1 FW, respectively. pH and total titratable acidity were detected as 3.45 ± 0.00, and 3.11 ± 0.02 (g malic acid 100 g−1 FW), respectively. pH value and dry matter results were in accordance with values reported in the literature [7, 24, 25]. Ash content (4.20 ± 0.17 g 100 g−1 FW) was higher than reported by Marakogˇlu, Arslan [25] and Ganhao, Estévez [24]. The discrepancies may be due to differences in climatic condition.

The total phenolic content (1716.00 ± 30.48 mg GAE kg−1 FW) was in accordance with Cosmulescu, Trandafir [26], but lower than reported by Ganhao, Estévez [24] and Sikora, Bieniek [27] and higher than stated by [28]. The flavonoid content of blackthorn was found 300.78 ± 1.10 mg CE kg−1 FW. Veličković, Kostić [4] determined the flavonoid content as 0.42 ± 0.013 mg quercetin equivalent/g in water extract of blackthorn, while Cosmulescu, Trandafir [26] measured the flavonoid content as 68.21 mg quercetin equivalent/100 g FW. The anthocyanin content result (97.86 ± 2.02 mg cy-3-glu kg−1 FW) was in accordance with values obtained from water extract reported by Veličković, Kostić [4], and lower than blackthorn fruit harvested at different periods reported by Dragović-Uzelac, Levaj [29]. The antioxidant capacity results given in the literature vary widely (0.26–5.08 mmol TE/100 g FW) [26, 30, 31] and the total antioxidant capacity of blackthorn determined in this study (10.50 ± 0.26 mmol TE kg−1 FW) tends to be in the range from the data reported in the literature. The discrepancies in the qualitative and quantitative chemical characterization results may be due to differences in the growing region, maturation stage and fruit variety.

Mineral composition of blackthorn fruits was shown in Table 3. K, P, Mg, Na and Ca was determined as major mineral compounds of blackthorn fruits. Other mineral compounds were detected at minor levels. The major mineral compounds found in this study were similar to the main mineral compounds distribution reported by Marakogˇlu, Arslan [25]. In this study, K was found as the major component of blackthorn fruits (29,152.19 ± 684.12 mg kg−1 FW), while Cosmulescu, Trandafir [26] reported that the major component of blackthorn fruits was Ca (32.20 mg 100 g−1 FW).

Phenolic compounds of blackthorn fruit were identified using LC–MS/MS technique with respect to retention time and main fragment ion. MRM transitions (m/z), Rt (min), and concentration of phenolic compounds (mg kg−1 FW) were presented in Table 4. Seventeen phenolic components, seven of which were in the flavonoid, were identified in the blackthorn fruit. The main phenolic compound of the blackthorn fruit was hesperidin (27.70 ± 1.13 mg kg−1 FW) at non-hydrolyzed sample, while protocatechuic acid (38.60 ± 1.87 mg kg−1 FW) was detected as the main component in the hydrolyzed sample. Mass spectrum of hesperidin presented a molecular ion [M-H]− at m/z 609 and its MS/MS spectrum showed characteristic fragment ions at m/z 301 and m/z 609. Moreover, mass spectrum of protocatechuic acid presented a molecular ion [M-H]− at m/z 153 and its MS/MS spectrum showed characteristic fragment ions at m/z 53, m/z 91, m/z 109, and m/z 153. As can be seen clearly from Table 4, it was expected that total concentration of phenolic acids obtained by hydrolyzed sample was higher than non-hydrolyzed sample which can be attributed to the breaking of glycosidic bonds and dissolution of bound sugar due to acid hydrolysis [32].

Fitting model

The experimental results for the different combinations of ultrasonic-assisted extraction conditions were performed according to three-factor, five-level CCD. The results of 20 experimental trials are shown in Table 5. The results of TPC, TFC, TAC, and TAA ranged from 2159.48–3431.03 mg GAE kg−1 FW, 557.81–778.91 mg CE kg−1 FW, 96.19–142.27 mg cy-3-glu kg−1 FW, and 14.68–20.40 mmol TE kg−1 FW, respectively. Model selection was made for each response using the Design Expert program, and the “fit summary” report suggested a quadratic polynomial model for each response. ANOVA for quadratic model and fit statistics parameters are listed in Table 6. ANOVA showed that the quadratic model was significant for each response. p-values of the model for TPC, TFC, TAC, and TAA were determined less than 0.01 and F value of the model for TPC, TFC, TAC, and TAA were 24.30, 34.47, 17.20, and 10.27, respectively. A small p-value and a high F-value are associated with independent variables having a significant and large effect on the relevant response variables [33]. The calculated p-value for lack-of-fit of the quadratic model was insignificant for each response at 95% confidence level, revealing that the model adequately represented the experimental results. In addition, the coefficient of determination (R2) showed that the model efficiently estimated the relationship between predicted and experimental values. For the model to fit well, it was recommended that the R2 value be between 0.8 and 1 [34]. The predicted R2 for each response was in reasonable agreement with the adjusted R2 for each response, since the difference between them was less than 0.2. Moreover, the coefficient of variation (CV%) were found to be 3.55% for TPC, 2.76% for TFC, 4.13% for TAC, and 3.96% for TAA. The CV values were within the acceptable limits (below 5%) indicating that the model has high predictive power of the experimental values and good reproducibility of the investigated systems [14, 35]. Besides, the high correlated effect between the predicted and experimental values was detected in the diagnostic plots (Fig. 1). It can be concluded that the developed quadratic model was adequate and can be used for the optimization of ultrasonic-assisted extraction of bioactive components in blackthorn.

Effect of the ultrasound-assisted extraction parameters on TPC

The quadratic model given for TPC had a good regression coefficient (R2 = 0.9563). The second-order polynomial equation for TPC in coded level all terms was generated in Eq. (2). The positive sign in front of the terms indicates a synergistic effect, which means enhancing extraction efficiency, while negative sign indicates an antagonistic effect.

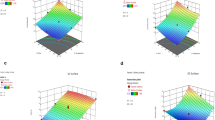

The linear effect, X1 (p < 0.01), X3 (p < 0.05); the interaction effect X1X2 (p < 0.01); the quadratic effect, X12 (p < 0.01), X22 (p < 0.01), and X32 (p < 0.01) were significant. The other effects were not significant due to a higher p-value (p > 0.05) (Table 6). Analysis of the model showed that temperature was the most significant factor among the linear effects. The temperature had a positive effect (β1 = + 266.17), which means that a higher temperature (40 °C) was effective in obtaining higher amounts of phenolic compounds in the blackthorn extract. Similarly, Chen, Zhao [10] reported that the total phenolic content in sugar beet molasses increases reach to 43 °C of extraction temperature during the ultrasonic-assisted extraction. In addition, Ivanovic, Tadic [36] demonstrated that an increase in temperature from 25 to 40 °C led to the rise in the values of phenolic content in the ultrasonic extract obtained from blackberry. It was indicated that moderately high temperature causes the increasing the solubility and diffusion of phenolic compounds in the extract [10]. Also, similar findings were reported for sour cherry juice by Türken and Erge [17] and strawberry juice by Tiwari, O’donnell [16]. On the other hand, in this study, the quadratic effect of temperature exhibited a negative influence (β11 = − 83.89). It has been shown that overheating extraction temperatures (75 °C) have a degradation effect on phenolic compounds such as flavonoids, tannins, and proanthocyanidin and cause a decrease in extraction efficiency [37]. The interaction effects of temperature and time were negative effect on TPC (β12 = − 286.10). Response surface plots for the interactive effect of independent variables on TPC, TFC, TAC, and TAA were given in Fig. 2. Figure 2(A) shows the response surface plots representing the combined effects of temperature and time at the fixed amplitude of 40% on the TPC. The linear effect of temperature on TPC at minimum extraction time is clearly seen in Fig. 2(A). In addition, both the linear effects and the quadratic effect of amplitude exhibited a negative influence (β3 = − 62.89, β33 = − 137.05). Masuzawa, Ohdaira [15] found that weak ultrasonic irradiation promotes an increase in the amount of phenolic compound in red wine. This phenomenon can be attributed to the oxidation reaction initiated by the interaction with the free radicals (·OH) produced during sonication. Also, low sonication frequencies may facilitate the passage of phenolic compounds into the extract by increasing the activity of enzymes such as pectinase, which can break down cell walls and membranes [38]. Furthermore, the quadratic effect of the extraction time had a negative effect on TFC (β22 = − 105.22). Similarly, Lukić, Brnčić [39] revealed that the prolonged extraction time resulted in a lower concentration of phenolic compounds due to the decomposition of active compounds. With respect to all results, a changing trend in the phenolic compounds was obtained against all the extraction condition parameters. This trend can be attributed to isomerization, co-pigmentation, polymerization, depolymerization, and decomposition reactions resulted from cavitation phenomenon during ultrasonic treatment. Particularly the free radicals generated by the reactions may cause the degradation of phenolic compounds.

Effect of the ultrasound-assisted extraction parameters on TFC

As seen from the ANOVA table, the quadratic model was significant for TFC (F = 34.47, p < 0.0001). The coded equation generated for TFC was given in Eq. (3). It also indicated that X1 (p < 0.05), X2 (p < 0.05), X1X2 (p < 0.01), X1X3 (p < 0.01), X2X3 (p < 0.05), X22 (p < 0.01), and X32 (p < 0.01) were significant terms in the model, and that this model explained 96.88% of the variation in TFC, leaving approximately 3.12% to be explained by noise.

Among all the important linear effects, temperature and time were found to have a positive effect, which indicated that the effects would lead to a higher amount of TFC. The quadratic effect of time and amplitude had a negative sign (β22 = – 37.56, β33 = – 62.70). Numerous studies reported that strong correlation between polyphenols and flavonoids in plant and/or plant origin food products [40, 41]. Similarly, the behaviour of total phenolic and flavonoids to be affected by independent variables was consistent with each other in this study. Figure 2 (B-D) illustrates that the effect of both temperature x time had a positive effect on TFC, while temperature x amplitude and time x amplitude had a negative effect on the TFC. The highest TFC was observed at higher temperatures and higher times (Fig. 2(B)). Although the amount of flavonoid substances in the blackthorn extract increased with increasing temperature, the gradual increase in amplitude from 40 to 60% caused adverse effects on TFC (Fig. 2(C)). The 3D plot of time and amplitude showed a greatly concave surface given in Fig. 2(D), representing that the maximum TFC value could be located towards the middle of time and amplitude.

Effect of the ultrasound-assisted extraction parameters on TAC

Table 6 shows a good regression value (R2 = 0.9393) between TAC and temperature, time, and amplitude. The second-order polynomial model to estimate the efficiency of the ultrasound-assisted extraction in terms of coded variables can be explained in Eq. (4). The linear effect, X1; the interaction effect X1X3; the quadratic effect, X12, X22 and X32 were highly significant (p < 0.01).

Interestingly, the linear effect of temperature presented a positive coefficient (β1 = + 5.93), but its quadratic effect was a negative coefficient (β11 = − 4.38). Espada-Bellido et al. (2017) reported the same results in the mulberry pulp during ultrasound-assisted extraction. The literature demonstrated that the stability of the anthocyanin was strongly influenced by high temperature used in unit operations, which can be attributed to oxidation, cleavage of covalent bond or enhanced oxidation reactions [42]. The interactive effect of temperature and amplitude had a negative effect (β13 = − 6.58) on TAC, and also the quadratic effect of amplitude had a negative sign (β33 = − 13.23). Figure 2E represents the effect of temperature and amplitude on TAC. The TAC increased linearly as the amplitude increased up to 40% of the maximum temperature value; gradually decreasing was obtained thereafter. Tiwari, O’donnell [16] also stated that the acoustic energy density had an adverse effect on the amount of anthocyanin compounds. While anthocyanin content decreased at a higher acoustic energy density value (3.2%), a lower acoustic energy density value caused a slight increase (< 1.0%) in anthocyanin content in strawberry juice. There are different explanations in the literature about the effect of ultrasound on anthocyanin components. Slightly increasing behaviour is probably due to the extraction of bound anthocyanin from food matrices [16]. Decreases in the anthocyanin content against increasing ultrasonic amplitude may be attributed to sonolysis of water as a a consequence of cavitation, which initiates the generating of hydroxyl radicals or H2O2 causing to degradation, esterification, ring-opening and formation of chalcones [16, 39]. In addition, the degradation of anthocyanin during sonication may be due to extreme physical conditions localized within the bubble, such as high temperature and pressure, which occur as a result of collapse caused by acoustic cavitation at the microscale [16].

Effect of the ultrasound-assisted extraction parameters on TAA

The regression coefficient was found 0.9023 for TAA, which indicated that the relationship between variables was well correlated. Based on the experimental results of antioxidant activity and regression analysis for CCD, the full quadratic model was given by Eq. (5) in case of antioxidant activity, the p-value of X1 was less than 0.05 and the p-values of X1X2, X2X3 and X32 were less than 0.01.

The model analysis of the result found that the temperature positively affects (β1 = + 0.5540) on the TAA, as observed in the TPC, TFC and TAC results. As far as the interaction effects of the predicted model were concerned, the TAA was negatively affected by temperature x time and time x amplitude (β12 = − 0.9988 and β23 = − 1.18). Figure 2F describes the maximum TAA value was determined at a rise in extraction temperature and a decline in extraction time, and this case was valid in the vice versa. The highest TAA value was obtained between 20 and 40% amplitude values at the 6th minute of the extraction time (Fig. 2G). Although phenolic, flavonoid and anthocyanin compounds contributed to the antioxidant activity of the blackthorn, it was observed that the interaction effects on TPC (X1X2), TFC (X1X2, X1X3, X2X3), and TAC (X1X3) and TAA (X1X2, X2X3) were different from each other following the ultrasound-assisted extraction. The important difference detected in the interaction effect may be attributed to the degradation of some other antioxidant compounds such as ascorbic acid and carotenoids, which are the other contributor to the blackthorn's antioxidant activity during prolonged extraction time higher amplitude value. In the case of TAA, it was determined a negatively significant quadratic effect of amplitude. The result of this study was in agreement with the similar research by Lim, Pang [41], which reported that a higher than 60% of amplitude value led to decreased antioxidant activity expressed as DPPH in Phaleria macrocarpa fruits. This situation can be explained in two ways: (i) sonication-induced bubbles with amplitude decrease extraction yield by preventing the transmission of ultrasonic waves to the extraction medium, (ii) sonication energy treated at high frequencies causes the degradation of polyphenol components with antioxidant properties.

Optimization and model validation

The desirability function method (DF) in RSM for all the responses (TPC, TFC, TAC, and TAA) was used to determine the optimum conditions of independent variables during the ultrasound-assisted extraction of blackthorn. In order to reach the maximum responses content, the level of importance of TPC, TFC, and TAC was chosen as 4 and the level of importance of TAA was set as 5. The 24 optimum solutions were found, and the overall desirability value of the optimal solution was detected as 0.914. The optimum conditions were obtained with an extraction temperature 40 °C, time 3.592 min, and amplitude of 33.189%. Predicted response values obtained by RSM under optimum ultrasound-assisted extraction conditions were checked experimentally. All measurements under the optimized conditions were performed in triplicate (Table 7). The obtained results demonstrated the validation of the RSM model, indicating that the model was adequate for the extraction process.

Conclusions

In this study, the main chemical characteristics of blackthorn were determined. In addition, mineral and phenolic content distribution of blackthorn were identified using ICP-MS and LC–MS/MS, respectively. Total phenolic content, total flavonoid content, total monomeric anthocyanin content, and total antioxidant activity of blackthorn were found as 1716.00 ± 30.48 mg GAE kg−1 FW, 300.78 ± 1.10 mg CE kg−1 FW, 97.86 ± 2.02 mg cy-3-glu kg−1 FW, and 10.50 ± 0.26 mmol TE kg−1 FW, respectively. The effect of independent variables such as temperature, time and amplitude on the extraction efficiency of blackthorn bioactive compounds in the ultrasound-assisted extraction and the optimization of extraction variables were studied with the response surface methodology using the central composite design. The results indicated that the quadratic model was adequate for evaluating the fitting between independent variables and responses. The linear effect of temperature had a significant positive effect on each response, while the quadratic effect of amplitude had a significant negative effect on each response. The optimum extracting conditions of the ultrasound-assisted extraction were described as follows: temperature, 40 °C; time, 3.592 min; and amplitude, 33.189%. The antioxidant activity was detected 19.75 mmol TE kg−1 FW, using optimum extraction conditions. Compared to the bioactive compounds and antioxidant activity obtained before and after the optimum ultrasound-assisted extraction condition, TPC, TFC, TAC, and TAA were increased by 92.09%, 154.51%, 42.75%, and 88.10%, respectively. In addition, the predicted values at optimal extraction conditions were in good agreement with the experimental results. The overall results of the RSM-CCD method highlighted that this developed ultrasound-assisted extraction method provides an appropriate and reliable green technology for the recovery of the important bioactive components from blackthorn. The ultrasonic extract has great potential for further use in developing added value innovative product such as functional foods, food additives, and nutraceuticals.

Data availability

The data was obtained during Research Projects supported by Trakya University (TUBAP, Grant No.: 2020/144). The authors declare that the data supporting the findings of this study are available within the article files and if necessary, the data files can be presented by the corresponding author.

References

I. Popescu, G. Caudullo, Prunus spinosa in Europe: distribution, habitat, usage and threats. U: European Atlas of Forest Tree Species,(San-Miguel-Ayanz, J., de Rigo, D., Caudullo, G., Houston Durrant, T., Mauri, A. ured.), Luxembourg, str, 2016. 145.

T. Özcan, Some vitamin and organic acid contents in the fruits of Prunus spinosa L. subsp. dasyphylla (Schur) Domin from Europe-in-Turkey. Eur. J. Biol. 67(2), 105–114 (2008)

D. Fraternale et al., Prunus spinosa fresh fruit juice: antioxidant activity in cell-free and cellular systems. Nat. Prod. Commun. 4(12), 1934578X0900401211 (2009)

Veličković, J.M., et al., Phenolic composition, antioxidant and antimicrobial activity of the extracts from Prunus spinosa L. fruit. Hemijska industrija, 2014. 68(3): p. 297–303.

Marchelak, A., et al., Bioactivity potential of Prunus spinosa L. flower extracts: Phytochemical profiling, cellular safety, pro-inflammatory enzymes inhibition and protective effects against oxidative stress in vitro. Frontiers in pharmacology, 2017. 8: p. 680.

Karakas, N., et al., Antioxidant activity of blackthorn (Prunus spinosa L) fruit extract and cytotoxic effects on various cancer cell lines. Medeniyet Medical Journal, 2019. 34(3): p. 297.

L. Barros et al., Strawberry-tree, blackthorn and rose fruits: detailed characterisation in nutrients and phytochemicals with antioxidant properties. Food Chem. 120(1), 247–254 (2010)

B.M. Popović et al., Exploring fruits from genus Prunus as a source of potential pharmaceutical agents–In vitro and in silico study. Food Chem. 358, 129812 (2021)

A. Magiera et al., Polyphenol-enriched extracts of Prunus spinosa fruits: anti-inflammatory and antioxidant effects in human immune cells ex vivo in relation to phytochemical profile. Molecules 27(5), 1691 (2022)

M. Chen, Y. Zhao, S. Yu, Optimisation of ultrasonic-assisted extraction of phenolic compounds, antioxidants, and anthocyanins from sugar beet molasses. Food Chem. 172, 543–550 (2015)

F. Chemat, M.K. Khan, Applications of ultrasound in food technology: processing, preservation and extraction. Ultrason. Sonochem. 18(4), 813–835 (2011)

M.G. Leichtweis et al., Ultrasound as a rapid and low-cost extraction procedure to obtain anthocyanin-based colorants from Prunus spinosa L. fruit epicarp: comparative study with conventional heat-based extraction. Molecules 24(3), 573 (2019)

L.G. D’Alessandro et al., Kinetics of ultrasound assisted extraction of anthocyanins from Aronia melanocarpa (black chokeberry) wastes. Chem. Eng. Res. Des. 92(10), 1818–1826 (2014)

E. Espada-Bellido et al., Optimization of the ultrasound-assisted extraction of anthocyanins and total phenolic compounds in mulberry (Morus nigra) pulp. Food Chem. 219, 23–32 (2017)

N. Masuzawa, E. Ohdaira, M. Ide, Effects of ultrasonic irradiation on phenolic compounds in wine. Jpn. J. Appl. Phys. 39(5S), 2978 (2000)

B. Tiwari et al., Stability of anthocyanins and ascorbic acid in sonicated strawberry juice during storage. Eur. Food Res. Technol. 228(5), 717–724 (2009)

T. Türken, H.S. Erge, Effect of ultrasound on some chemical and microbiological properties of sour cherry juice by response surface methodology. Food Sci. Technol. Int. 23(6), 540–549 (2017)

Y. Ma et al., Ultrasound-assisted extraction of hesperidin from Penggan (Citrus reticulata) peel. Ultrason. Sonochem. 15(3), 227–232 (2008)

F. Shahidi et al., Nutrient distribution and phenolic antioxidants in air-classified fractions of beach pea (Lathyrus maritimus L.). J. Agric. Food Chem. 49(2), 926–933 (2001)

V. Dewanto et al., Thermal processing enhances the nutritional value of tomatoes by increasing total antioxidant activity. J. Agric. Food Chem. 50(10), 3010–3014 (2002)

Giusti, M.M. and R.E. Wrolstad, Characterization and measurement of anthocyanins by UV‐visible spectroscopy. Current Protocols Food Analytical Chemistry, 2001(1): p. F1. 2.1-F1. 2.13.

R. Re et al., Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radical Biol. Med. 26(9–10), 1231–1237 (1999)

N.E. Bayram et al., Macronutrient and micronutrient levels and phenolic compound characteristics of monofloral honey samples. J. Food Nutr. Res. 59(4), 211–322 (2020)

R. Ganhao et al., Characterization of selected wild Mediterranean fruits and comparative efficacy as inhibitors of oxidative reactions in emulsified raw pork burger patties. J. Agric. Food Chem. 58(15), 8854–8861 (2010)

T. Marakoğlu et al., Proximate composition and technological properties of fresh blackthorn (Prunus spinosa L. subsp dasyphylla (Schur)) fruits. J. Food Eng. 68(2), 137–142 (2005)

S. Cosmulescu, I. Trandafir, V. Nour, Phenolic acids and flavonoids profiles of extracts from edible wild fruits and their antioxidant properties. Int. J. Food Prop. 20(12), 3124–3134 (2017)

E. Sikora, M.I. Bieniek, B. Borczak, Composition and antioxidant properties of fresh and frozen stored blackthorn fruits (Prunus spinosa L.). Acta Sci. Pol. Technol. Aliment. 12(4), 365–372 (2013)

I. Egea et al., Six edible wild fruits as potential antioxidant additives or nutritional supplements. Plant Foods Hum. Nutr. 65(2), 121–129 (2010)

V. Dragović-Uzelac et al., Total phenolics and antioxidant capacity assays of selected fruits. Agric. Conspec. Sci. 72(4), 279–284 (2007)

F. Celik et al., Determination of phenolic compounds, antioxidant capacity and organic acids contents of Prunus domestica L., Prunus cerasifera Ehrh. and Prunus. spinosa L. fruits by HPLC. Acta Chromatogr. 29(4), 507–510 (2017)

B.M. Ruiz-Rodríguez et al., Wild blackthorn (Prunus spinosa L.) and hawthorn (Crataegus monogyna Jacq.) fruits as valuable sources of antioxidants. Fruits 69(1), 61–73 (2014)

B.A. Acosta-Estrada, J.A. Gutiérrez-Uribe, S.O. Serna-Saldívar, Bound phenolics in foods, a review. Food Chem. 152, 46–55 (2014)

S.F. Tan et al., Ultrasonic emulsification of parenteral valproic acid-loaded nanoemulsion with response surface methodology and evaluation of its stability. Ultrason. Sonochem. 29, 299–308 (2016)

O. Yemiş, G. Mazza, Optimization of furfural and 5-hydroxymethylfurfural production from wheat straw by a microwave-assisted process. Biores. Technol. 109, 215–223 (2012)

Z. Zeković et al., Optimization of microwave-assisted extraction (MAE) of coriander phenolic antioxidants–response surface methodology approach. J. Sci. Food Agric. 96(13), 4613–4622 (2016)

J. Ivanovic et al., Antioxidant properties of the anthocyanin-containing ultrasonic extract from blackberry cultivar “Čačanska Bestrna.” Ind. Crops Prod. 53, 274–281 (2014)

E. Dorta, M.G. Lobo, M. Gonzalez, Reutilization of mango byproducts: study of the effect of extraction solvent and temperature on their antioxidant properties. J. Food Sci. 77(1), C80–C88 (2012)

W. Tchabo et al., Ultrasound-assisted enzymatic extraction (UAEE) of phytochemical compounds from mulberry (Morus nigra) must and optimization study using response surface methodology. Ind. Crops Prod. 63, 214–225 (2015)

K. Lukić et al., Effects of high power ultrasound treatments on the phenolic, chromatic and aroma composition of young and aged red wine. Ultrason. Sonochem. 59, 104725 (2019)

M. Alothman, R. Bhat, A. Karim, Antioxidant capacity and phenolic content of selected tropical fruits from Malaysia, extracted with different solvents. Food Chem. 115(3), 785–788 (2009)

Y.P. Lim et al., Correlation between the extraction yield of mangiferin to the antioxidant activity, total phenolic and total flavonoid content of Phaleria macrocarpa fruits. J. Appl. Res. Med. Arom. Plants 14, 100224 (2019)

A. Patras et al., Effect of thermal processing on anthocyanin stability in foods; mechanisms and kinetics of degradation. Trends Food Sci. Technol. 21(1), 3–11 (2010)

Acknowledgements

This research was supported by Trakya University Office of Scientific Research Projects Coordinations (TUBAP, Grant No.: 2020/144).

Author information

Authors and Affiliations

Contributions

All authors contributed at these stages including formal analysis; investigation; writing-original draft; writing-review & editing.

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Damar, I., Yilmaz, E. Ultrasound-assisted extraction of phenolic compounds in blackthorn (Prunus spinosa L.): characterization, antioxidant activity and optimization by response surface methodology. Food Measure 17, 1467–1479 (2023). https://doi.org/10.1007/s11694-022-01723-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-022-01723-5