Abstract

Contemporary challenges in decreasing Green House Gas emissions and finding alternative carbon and energy sources for fueling our society brought in the forefront processes based on biological conversions of gaseous substrates, such as syngas and carbon dioxide. Generation of synthesis gas or syngas (a gaseous mixture mainly of CO, H2 and CO2 generated during thermal decomposition of carbonaceous material in the presence of limited amount of an oxidizing agent) is known since the beginning of the 17th century and discovery of Fischer–Tropsch synthetic route in the beginning of the 20th century allowed the development of various routes for chemical catalytic synthesis of fuels and chemicals from syngas. Biological processing of syngas came in the forefront much later, following important advances within Microbiology and Biochemistry disciplines. This thermo-biochemical route for production of low-value products like fuels is considered competitive and advantageous compared to the thermochemical route when small-scale installations are concerned. Production of higher value products via the carboxylate platform is also a promising, and certainly worth-investigating route. Biological conversion of syngas and valorization of CO2 via biological means, besides contributing in greening our world, come with similar product portfolio and share the same technological challenges. Therefore, the target of the current study is to provide an overview of the latest scientific advances within syngas and CO2 valorization to fuels and chemicals and industrial applications and propose a way forward taking into account contemporary challenges and needs.

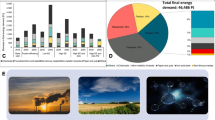

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Statement of Novelty

Biological conversion processes of syngas and carbon dioxide share the same product portfolio and technological challenges and hold the potential to contribute greatly to a sustainable future. The present review is a unique contribution, giving the overview of products and latest technological advances and propose a way forward for both production platforms.

Biological Conversion of Syngas—A Relatively New Development

Discovery of synthesis gas or syngas (a gaseous mixture mainly of CO, H2 and CO2 generated during thermal decomposition of carbonaceous material in the presence of limited amount of oxygen) took place in the beginning of the 17th century when Jan Baptista Van Helmont discovered production of gas by heating wool and coal. However, it was just in 1791 when the first internal combustion engine driven by syngas was entered into practice and towards the beginning of the 19th century that syngas was used in street lighting system in UK and US [1]. After a century, Thomas Hugh Parker invented the first car to run on “wood gas”; due to several challenges though wood gas vehicles were not widespread and were soon replaced with vehicles running on natural gas and petrol [2]. When the interest in biomass gasification resumed after the oil crisis in 1973, chemical catalytic routes, i.e. Fischer–Tropsch synthesis, for transformation of syngas to liquid fuels and chemicals were already well established. On the contrary, biological routes for conversion of gaseous molecules and especially the instrumental, for this type of bioconversions, acetyl-CoA pathway, were not fully elucidated yet. It was just towards the end of the 20th century that the scientific community became fully aware of the metabolic features behind CO2 and CO fixation by acetogenic microorganisms (the interested reader is referred to the excellent book chapter of Drake et al. on acetogenic prokaryotes [3]). To the interpretation of the authors, this is the main reason that gasification coupled with thermochemical conversion has become more like a “mindset” and it is still a rather widespread concept in the academic world.

Based on the abovementioned, it makes sense that biological processing of syngas came in the forefront following important advances within Microbiology and Biochemistry disciplines and much later compared to chemical catalytic processing. It was just in the beginning of the 21st century that the scientific community experienced an exponential growth in research studies dealing with biological conversion of syngas to mainly alcohols and to a lesser extent, methane, while fewer studies are dealing with production of other valuable chemicals and materials, i.e. longer chain fatty acids and alcohols and polyhydroxyalkanoates, PHA. This is depicted clearly in Fig. 1; the great interest in ethanol production was fully in-line with the intense efforts for finding ways to produce sustainable and renewable liquid fuels emerging towards the end of the 20th century. Biochemical methane production on the other hand, was very well established via the anaerobic digestion process and this may justify the relatively fewer research efforts towards this direction although there are several good reasons to advance this very promising field [4]. It is also noticeable that almost 14% of the scientific publications for the last five years are review studies focusing on different aspects of syngas bioconversions. This declares a pronounced interest in the topic and is a fundamental effort towards advancing this exciting field based on diverse and multidisciplinary knowledge accumulated over and across Microbiology, Biochemistry and Chemical Engineering.

Syngas biological conversions processes share the same metabolic features and challenges with processes based on carbon dioxide and hydrogen as production platform. Both microbial systems rely on the existence and activity of the reductive acetyl-CoA pathway for assimilation of CO2 and, in the case of syngas, CO. The low solubility of compounds acting as substrates for the microbial growth (CO and H2) resulting in low mass transfer rates and low microbial growth rates resulting in low microbial mass concentration and consequently to low conversion and production rates, are the main challenges associated with both syngas and carbon dioxide plus hydrogen as production platforms. Therefore, it is very relevant to present an overview of the latest developments and a vision for both platforms and this is exactly the focus of the present study.

Renewable Feedstocks Suitable for Gasification

Gasification is the complete thermal breakdown of solid carbonaceous feedstock into a combustible mixture of gasses (usually known as synthesis gas or syngas and consisting mainly of CO, H2 and CO2). Gasification takes place in an enclosed reactor (gasifier) in the presence of an oxidizing agent (e.g. air, O2, H2O etc.), which is supplied externally at a ratio lower than it is required for the complete oxidation of the feedstock [5]. Syngas can directly be used for generation of heat and power. However, it can also serve as feedstock for production of liquid fuels, chemicals and materials. Because of this flexibility of application, gasification has been proposed as the basis for refineries that would provide a variety of energy and chemical products, including electricity and transportation fuels [6]. Raw materials for gasification may be of fossil origin (e.g. coal) [7], however, the focus should be on sustainable options such as biomass and wastes.

Global production of biomass is estimated to be more than 220 billion dry tonnes/year mainly in the form of natural growth wood and of agricultural and forestry residues [8]. Biomass such as lignocellulosic energy crops are potential candidates for gasification. Nonetheless, the increase in arable land required for farming of these feedstocks has indirect implications on land use and food prices (see “food vs. fuel” debate), bringing about a ripple effect with negative environmental and socio-economic impacts in many regions of the world [9, 9]. As a result, alternative sources of second generation biomasses are preferable. Such sources are lignocellulosic biomass waste like residues from the forestry, agricultural and food sector, which come with very similar characteristics with the abovementioned woody biomasses but also some additional challenging carbonaceous material such as sewage sludge, municipal solid wastes or waste plastics.

The amount of municipal solid waste (MSW) including waste plastics is in a constant increase and is projected to increase even more rapidly in the future due to the growth of the global population [11]. Taking into consideration that landfill of organic wastes, which has detrimental effects on the environment, is still an option in many countries, waste recycling through gasification could be an effective solution. MSW include high fractions of not-recycled but combustible biomass/organic components (paper, cardboard, wood, textiles and plastics) rendering it to a suitable feedstock for gasification systems. In addition, a gate fee is usually paid to the receiving facility by the waste disposer and that fee can favorably alter the economics of an energy production plant [12]. However, MSW is very heterogeneous both physically and chemically which creates operational challenges for energy conversion systems. Therefore, it should be pre-treated to remove non-combustible materials and homogenized to minimize operational variations before it is compatible with mechanical feeding systems [12].

Population growth as well as urbanization and industrialization combined with the global efforts to protect the environment have resulted in an increase of municipal and industrial wastewater treatment plants which only in EU-27, USA, China and Japan generate more than 20ˑmillion dry metric tons of sewage sludge [13] and this is expected to increase significantly in the near future. Conventional methods of sewage sludge management through landfilling and agricultural application are no longer viable owing to the lack of sustainability of such approaches. On the other hand, thermochemical conversion of sewage sludge into energy, fuels and chemicals is being considered as one of the most attractive technologies to tackle its disposal problem [14]. Gasification of sewage sludge comes with the advantages of drastic reduction of sludge volume, total destruction of harmful bacteria and most importantly the possibility of recovering significant amount of energy. Gasification can accept sludge water content up to 30% without significant drawback to overall energy recovery, while at the same time the trapped water content in sludge provides a free source of steam to enhance gasification efficiency. Nevertheless, the relatively high moisture content is the biggest obstacle in the application of gasification as a method to convert sewage sludge to energy, fuels or chemicals [14].

Recent Developments on Syngas and CO2 Bioconversions

As stated above, gas fermentation systems are often restricted by the low gas-to-liquid mass transfer for H2 and CO, due to their low solubility in water, and by the low cell concentration in the bioreactor, both of which ultimately limit the volumetric productivity of these systems. According to Henry's law, the volumetric mass transfer depends on the gas solubility and concentration in the liquid phase (defining the driving force of the mass transfer) and on the volumetric mass transfer coefficient (kLa), which is influenced by several parameters like viscosity, surface tension, diffusivity of the gas and gas–liquid interfacial area. Thus, the volumetric mass transfer may be enhanced by increasing either the mass transfer driving force or the mass transfer coefficient. A few studies have shown improved gas conversion and productivity in gas fermentation systems by increasing the solubility of gases, for instance, by decreasing the incubation temperature [15, 16] or by operating under moderately elevated pressures within a range of 1–15 atm [17,18,19]. The most common approach so far, though, has been to focus on enhancing the kLa through different reactor designs and configurations. Stirred tank reactors (STR) are by far the most common reactor type, in which, depending on the agitation rate and gas inflow, measured kLa values for CO lie between 90 and 104 h−1 when these are equipped with microbubble spargers [20]. Nevertheless, it is known that high gas mass transfer is only attained in STR at the expense of high power input for agitation, which may compromise the economic sustainability of the process. Other reactor configurations used in gas fermentation not relying on mechanical mixing for increasing kLa are bubble columns, gas-lift reactors, STR coupled to hollow fiber membrane modules (HFMBR), trickle bed reactors (TBR) and a few other special reactor designs such as U-loop bioreactor, Bulk-Gas-to-Atomized-Liquid (BGAL) reactor and Multi-Orifice Baffled Bioreactor (MOBB) [21,22,23,24,25,26]. Among these, trickle bed reactors and packed bed reactors come with the additional advantage of allowing for high microbial biomass concentration due to the attached growth of these systems [23, 27]. Other examples of reactor configurations used for addressing the low biomass concentration in gas fermentation include cell retention systems using hollow fiber membranes or membrane encased microorganisms [21, 28]. An alternative approach to the latter, in fact not based on increasing neither the solubility of the gaseous substrates nor the mass transfer coefficient, is the use of co-substrates. A recent study reported synergistic effects on the productivity of a gas fermentation system fed with H2/CO2 and doped with limiting amounts of glucose, where the productivity observed under mixotrophic conditions exceeded the sum of the productivities observed for each individual substrate [29]. Similarly, Maru et al. [30] reported increased carbon recovery in several acetogens growing under mixotrophic conditions. Reactor configurations and elevated pressure systems commonly used in gas fermentation, as well as co-substrate feeding approaches, have been recently reviewed and the reader is referred to those for a more detailed review and discussion [31,32,33].

Regarding the products of gas fermentation systems and as already mentioned, ethanol is undoubtedly the most commonly targeted product, for which a large variety of approaches have been investigated aiming at improving its yield, concentration and production rate. However, over the last years, the research on gas biological conversions has focused more on expanding the product spectrum towards higher alcohols, medium chain fatty acids, CH4 and other more advanced bioproducts. In this section, we provide an overview of the recent developments on the different products generated via biological conversion of syngas and CO2.

Alcohols

Ethanol, typically produced via alcoholic fermentation by yeasts and more recently via gas fermentation, has been one of the major target products over the past decades as it is a suitable alternative for replacing traditional, fossil-based transportation fuels. However, there is a growing interest in the production of higher alcohols, such as butanol and hexanol, as their chemical properties are much more attractive for their integration in the current biofuel market as “drop-in” fuels or blended with gasoline or diesel/biodiesel [34, 35].

The biological production of ethanol and higher alcohols via gas fermentation, carried out by acetogenic microorganisms, has been reported in numerous studies. However, their production is highly dependent on the biocatalyst used and fermentation conditions, as most of the acetogenic species isolated so far (over 60 accounting for mesophilic and thermophilic isolates) produce acetic acid as their only end product [36].

Biocatalysts, Pathways and Gaseous Substrates

Acetogenic bacteria rely on the Wood-Ljungdahl (WLP) or reductive Acetyl-CoA pathway for the production of ethanol, which can take place either through the reduction of acetyl-CoA catalyzed by acetaldehyde dehydrogenase (AldDH) using NADH as electron carrier, or through the reduction of acetate to acetaldehyde catalyzed by aldehyde:ferredoxin oxidoreductase (AOR) using reduced ferredoxin (Fdred) as electron carrier. The biochemistry of the conversion of CO and H2/CO2 via the Acetyl-CoA pathway is analogous for most acetogens (with some variations depending on the species). The main difference lie on the use of carbon monoxide dehydrogenase/acetyl-CoA synthase (CODH/ACS) for oxidizing CO to CO2 and regenerating Fdred when metabolizing CO, and the use of electron-bifurcating hydrogenases for oxidizing H2 and generating equimolar amounts of Fdred and NADH when metabolizing H2/CO2. However, as shown by Bertsch and Müller [37], the latter leads to significant differences in the ATP yield of ethanol synthesis when using CO (2.1 mol ATP/mol ethanol using AOR pathway) and H2/CO2 (0.3 mol ATP/mol ethanol using AOR pathway). In fact, according to the assumptions made by these authors, the production of ethanol via the AldDH pathway would only be possible when CO is used as electron donor (1.7 mol ATP/mol ethanol), as the use of H2 would result in negative ATP balace (− 0.1 mol ATP/mol ethanol). This is consistent with the experimental findings of several studies showing that ethanol is most likely produced exclusively via AOR pathway while the AldDH makes only a residual contribution [38, 39]. Similarly, based on the ATP yields and the thermodynamics of the conversion of CO and H2/CO2, CO would be expected to be a more favorable substrate for ethanol production [39], which has been shown experimentally for Clostridium ljungdahlii [40]. However, H2 has also been shown to drive metabolic rearrangements leading to improved ethanol production when metabolized together with CO by Clostridium autoethanogenum [41].

The production of ethanol through gas fermentation has been reported using many different acetogenic cultures, e.g. Alkalibaculum bacchi, Clostridium aceticum, Clostridium ragsdalei, Clostridium carboxidivorans and several enriched anaerobic mixed cultures [39, 42,43,44,45,46]. However, C. ljungdahlii and C. autoethanogenum are currently the model acetogens for ethanol production as these are by far the best-studied biocatalysts regarding their metabolic aspects affecting the selectivity towards ethanol. Genome-scale metabolic models were recently generated for these two species [47, 48]. Those were used to study the relation between energy conservation, carbon and redox metabolism and the ethanol yield [49], alternative ATP synthesis pathways to boost the growth rate through addition of arginine [50], the effect of process parameters on the production of ethanol [41, 51] and the feasibility of metabolic engineering strategies for overproducing ethanol and other products through either a flux balance analysis or a kinetic ensemble approach [47, 52, 53]. C. autoethanogenum has also been subject to targeted mutagenesis experimentally, where the inactivation of one of the AOR isoforms and a bifunctional aldehyde:alcohol dehydrogenase (adhE1) resulted in 170 and 183% overproduction of ethanol when growing on CO, respectively [54]. The non-model acetogen C. carboxidivorans was also successfully engineered, resulting in a 50% increase in ethanol production when overexpressing adhE2 from Clostridium acetobutylicum ATCC 824 [55].

Among solventogenic acetogens, several species including C. ragsdalei, Clostridium drakei, Eubacterium limosum, C. carboxidivorans and Butyribacterium methylotrophicum present a native ability to synthesize higher carbon chain compounds such as butyrate, butanol and caproate [56,57,58,59]. Nevertheless, up to date, C. carboxidivorans P7 is the only known strain able to produce hexanol when using syngas as the only carbon and energy source. This is why, a rather common approach for higher alcohol production is to use either co-cultures (combining a chain-elongating species like Clostridium kluyveri with one of the model ethanologenic acetogens) or open cultures (mixed cultures or microbial communities) [60, 61]. Recombinant C. ljungdahlii and C. autoethanogenum strains have also been successfully used for the production of butanol through the heterologous expression of butanol synthesis genes from C. acetobutylicum [62, 63]. Independently of the approach used though, the synthesis of higher alcohols typically takes place through re-assimilation, elongation and reduction of the primary metabolites [64] through an AOR pathway analogous to ethanol production. However, due to the latter, their production presents several challenges associated to the low product titer and selectivity achieved with the biocatalysts used so far, as ethanol is usually the dominant end product.

Reactor Configurations and Operating Strategies

A large variety of gas fermentation strategies have been studied for enhancing the productivity and product titer of ethanol and higher alcohols (Table 1), with most of them focusing on batch operating mode in respect to the liquid phase with continuous gas feeding in order to exploit the solventogenic phase typically encountered in acetogens and other Clostridium spp. The pH is one of the most important operational parameters affecting the selectivity towards alcohols. Low pH triggers solventogenesis in many biocatalysts; e.g. using a mixed culture in a HFMBR at pH 4.5 which resulted in a maximum concentration of 16.9 g L−1 of ethanol [65] and in another enrichment study where 1.7 g L−1 of ethanol, 1.1 g L−1 of butanol and 0.6 g L−1 of hexanol were produced when operating at pH 4.8 [60]. Additionally, shifting the pH from 5.8 to 4.8 during fermentation of CO has also been shown to drive a metabolic shift towards solventogenesis in C. autoethanogenum and C. carboxidivorans [66, 67]. The effect of the incubation temperature on the production of higher alcohols from syngas has been also investigated using C. carboxidivorans [15, 68]; low incubation temperature (25 °C) prevented acid crash events in uncontrolled pH systems (most likely due to the lower acid production rates) and promoted the re-assimilation of organic acids, elongation and further reduction to higher alcohols significantly. An alternative approach to boosting the production of alcohols from syngas that was recently proposed is the addition of biochar in the fermentation broth, as it may serve as a source of minerals and metals and the biocatalysts may benefit from its pH buffering and cation exchange capacity [69]. In this study, poultry litter and switch grass biochar enhanced the production of alcohols in C. carboxidivorans, resulting in 90 and 73% higher ethanol production and a fourfold increase in butanol production compared to the control. Overall, continuously gas-fed batch fermentation processes allow for exploiting the solventogenic phase of the biocatalysts and improving the selectivity towards alcohols; the latter may be further enhanced by combining some of the abovementioned fermentation control strategies. However, some of the limitations typically encountered are (a) low product titer derived from nutrient or gas-to-liquid mass transfer limitations, (b) low productivity due to the lower activity rates during solventogenesis and (c) dynamic and incomplete conversion of the gaseous substrates as the gas conversion efficiency drops significantly during solventogenesis.

Continuous operation mode, in respect to the liquid phase, may address some of the limitations of batch fermentations, for instance, allowing for the continuous extraction of the products while keeping a constant high gas conversion efficiency during steady state operation. However, it is common that continuous operation mode experiments suffer from lower product selectivity towards alcohols as organic acids are generally found as the dominant products [70, 71]. In order to overcome this, two-stage gas fermentation processes with separate acidogenic and solventogenic reactors have been applied, resulting in a steady state concentration of ethanol of 6.1 g L−1 in the second reactor and an alcohol-to-acid ratio of 3.9 gethanol gacetate−1 and 4.4 gbutanol gbutyrate−1 [72]. Alternative strategies for improving the ethanol selectivity in one-stage gas fermentation processes have also been investigated. One of the first successful approaches was to increase the age of the cells by using a cell retention system, with which a maximum concentration of ethanol of 48 g L−1 and a molar ethanol-to-acetate ratio of 21 mol mol−1 was achieved [73]. Another approach recently reported consisted in tuning the partial pressure of CO and H2 in a HFMBR using an open culture, where it was found that increasing the partial pressure of the latter resulted in the overproduction of ethanol with a concentration of 4.2 g L−1 while the acetate concentration was 1 g L−1 [65]. Moreover, supplying additional H2 to a CO-fed STR was found to boost considerably the steady state concentration of ethanol from 4 to 12 g L−1 while the concentration of acetate decreased from 6 to 4 g L−1 [41]. Other reactor designs have also improved the selectivity to ethanol using, for example, a pressurized horizontally oriented rotating packed bed reactor, where an ethanol-to-acetate ratio of 1.6 g g−1 and an ethanol titer of around 16 g L−1 was achieved at the minimum dilution rate studied (0.12 day−1). A maximum ethanol productivity of 6.7 g L−1 day−1 and a steady state ethanol titer of 7.0 g L−1 was obtained at a dilution rate of 0.96 day−1 [27].

Based on the abovementioned, it is clear that boosting the selectivity and productivity of ethanol and higher alcohols is a matter of the correct strategy or combination of strategies applied and that this is a very interesting and promising field of research. One of the operating parameters that has been shown to have a significant effect on the initiation of the solventogenic phase and the productivity of solvents in ABE process is the oxidoreduction potential (ORP) [74]. However, work on ORP control strategies in gas fermentation processes has not been studied or published yet. There are a few studies on the effect of the addition of various reducing agents to the growth medium on C. ragsdalei, which resulted in variable success depending on the agents used [75]. On the other hand, higher ethanol production was also reported when C. ljungdahlii was exposed to oxygen under mixotrophic conditions, which was correlated to higher expression levels in the AOR ethanol synthesis pathway [76]. The above imply that ORP control strategies may have high potential for further boosting the productivity of alcohols in gas fermentation and it is worthy of further investigation. Another approach not much investigated is coupling gas fermentation systems with in-situ product recovery (ISPR) systems, which may hold potential for improving the selectivity towards alcohols and their productivity. So far, the only attempt in this direction was carried out by Richter et al. [61], which consisted of coupling a gas stripping and condensation system to a gas fermentation system based on the co-culture of C. ljungdahlii and C. kluyveri, and reported the production of octanol for the first time. Nevertheless, gas stripping and other ISPR technologies such as in-situ liquid–liquid extraction still have to be thoroughly investigated.

Short and Medium Chain Fatty Acids

Medium chain fatty acids (MCFA) are saturated fatty acids with chains of 6–12 carbons including one carboxylic group, which have received much attention recently as potential gas fermentation products. Among these, caproate (C6), heptanoate (C7) and caprylate (C8) are especially interesting due to their many potential applications, e.g. in the pharmaceutical industry as antimicrobial agent, as additive for animal feed and flavor additive in the food industry, as feedstock in the chemical industry and as precursors of biofuels [77, 78]. Short chain fatty acids (SCFA) (chains with < 6 carbons and one carboxylic group) also have a value by themselves as they may be used as feedstock in the chemical industry or as feed and food additives, but they can also be upgraded to MCFA, higher alcohols and a number of other chemicals, e.g. esters, aromatics, amides etc. via subsequent conversion processes [79, 80].

The production of MCFA has been typically studied via the conversion of organic wastes and other biomasses into SCFA as intermediates. Their subsequent upgrading to MCFAs takes place through a chain elongation reaction, where the SCFA are elongated by two carbons at a time by means of an electron donor, e.g. methanol, ethanol, propanol or lactate [78]. However, the possibility of capturing CO2 and CO waste gases and converting them directly into MCFA has attracted considerable attention and several approaches have been explored over the last years.

Biocatalysts and Pathways

There are several acetogenic bacteria with the native ability to produce SCFA other than acetate and some even MCFA directly from gaseous substrates, e.g. C. ragsdalei, C. drakei, E. limosum, C. carboxidivorans and B. methylotrophicum [56, 58, 81]. Two strains of C. ljungdahlii were also genetically engineered for producing butyrate from CO and H2/CO2 [82, 83]. However, monocultures are rarely used in gas fermentation processes targeting MCFA production since researchers tend to focus on exploiting their solventogenic abilities. Instead, the production of SCFA and MCFA via biological conversion of H2/CO2 and CO is typically studied using co-cultures (C. ljungdahlii/C. autoethanogenum and C. kluyveri) [61, 84], and more often open cultures [85,86,87], as the latter present the ability of producing them naturally through cross-feeding microbial interactions. In both cases, MCFA are synthesized by combination of autotrophic acetate and ethanol produced through the Wood-Ljungdahl pathway and the elongation of the latter through the reverse β-oxidation pathway. C. kluyveri is the model organism for ethanol-based chain elongation and it is typically found in gas-converting open cultures when MCFA are produced [60, 85]. Several studies though have also reported the production of MCFA in absence of C. kluyveri in chain-elongating microbial communities [88, 89]. Similarly, a species closely related to C. carboxidivorans was identified when C. kluyveri was absent in enriched cultures and reactivated microbial communities producing SCFA, caproate and alcohols from syngas [39, 71].

Reactor Configurations and Operating Strategies

The production of MCFA through two-stage configurations has been proposed for circumventing the costly distillation of the dilute ethanol of syngas fermentation effluents. This possibility was studied by Vasudevan et al. [86] using an upflow anaerobic filter with real syngas fermentation effluent with acetate and ethanol concentration of 2.3 and 11.4 g L−1, respectively. The caproate concentration achieved in this study corresponded to 1 g L−1 with a volumetric productivity of 1.7 g L−1 day−1, while the maximum butyrate concentration and productivity achieved was around 20 g L−1 and 20 g L−1 day−1. The authors attributed the low caproate concentrations to its toxicity and suggested that ISPR technologies were necessary for the feasibility of the process. However, it is possible that the lower caproate titer compared to that of butyrate was caused by a limitation in ethanol concentration acting as electron donor rather than by its toxicity. A similar approach was also studied by Kucek et al. [88]. In the latter study though, a membrane-based perstraction system using a hydrophobic solvent and an alkaline extraction solution for ISPR was coupled to the upflow anaerobic filter; this allowed for selective production of caprylate at a rate of 7.92 g L−1 day−1and a caprylate-to-caproate ratio of 9.9 g g−1 when using high ethanol-to-acetate ratios in the feed.

On the other hand, single-stage gas fermentation processes are an interesting approach for producing MCFA as this would allow to reduce the number of unit operations and simplify the process. This was investigated using an attached growth reactor filled with a polyester fiber sponge using CO as the sole carbon and energy source [85]. Caproate, heptylate and caprylate production was observed in this study, although the maximum concentrations (0.21, 0.21 and 0.14 g L−1, respectively) and productivities achieved were rather low compared to those of two-stage configurations. The use of HFMBR was also considered for boosting the direct conversion of mixtures of H2/CO2 and H2/CO into MCFA. Conversion of H2/CO2 with concomitant accumulation of several MCFA such as caproate and caprylate at concentrations of 0.98 and 0.42 g L−1, respectively, was observed when using a HFMBR operated in batch mode [87]. The authors of this study did not observe accumulation of ethanol during the whole study, but the elongation of acetate to butyrate and eventually to caproate and caprylate was still attributed to the use of ethanol as intermediate, as it is likely that the continuous ethanol consumption by the biofilm kept it under the detection limit at all times. Other studies investigated the effect of the pore size and temperature on the direct conversion of H2 and CO to MCFA [90, 91]. A pore size between 0.02 and 0.05 µm was found to be more favorable for both obtaining higher gas conversion efficiency and productivity, and favoring the elongation towards MCFA, with a maximum caproate concentration and productivity of 3.5 g L−1 and around 0.14 g L−1 day−1, respectively. Similarly, low temperature (35 °C) favored the accumulation of MCFA, while a higher temperature (55 °C) clearly limited the elongation process and resulted in a selectivity to acetate of over 90%.

Overall, the single-stage production of MCFA from gaseous substrates is an interesting approach and holds potential. However, a more thorough investigation of effect of process parameters and reactor configurations is still necessary, as by now, the productivities reported in recent studies are one order of magnitude below those reported in two-stage configurations (Table 2). A key aspect limiting the productivity and selectivity of the process is either the concentration of ethanol in the feed or its intermediate production rate during gas fermentation. The authors share the view of Baleeiro et al. [92] in that co-feeding gaseous substrates along with other biomass-based feedstock may be an alternative with high potential for boosting the productivity and titer of MCFA of gas fermentation systems. Additionally, coupling gas fermentation systems with ISPR systems, as shown by Kucek et al. [88], may be as well necessary for addressing the low selectivity observed so far.

Methane

With the increase in the consumption of natural gas being the highest among all fossil fuels in an annual basis (4.6% in 2018 year over year [93]), the decarbonization of the gas sector is more urgent than ever. Biomethane is the perfect candidate to achieve that since it can supplant natural gas in the grid, and thus, the research activities and investments for its production have substantially increased over the last decade. Biomethane can also be used as fuel in the transportation and maritime sector [94] and as a platform substrate for the biochemical industry. Recent developments on the biological transformation of CO2 to biomethane are focused on biogas upgrade (also known as biological hydrogen methanation), syngas biomethanation and bioelectrochemical methods.

Biocatalysts and Pathways

The biological conversion of gaseous substrates into CH4 is widespread across the archaeal domain. However, while there is a high diversity of methanogenic species able to convert H2/CO2 into CH4 (hydrogenotrophic methanogens) [95], only a few methanogenic species have been shown to utilize CO as the sole carbon source including Methanothermobacter thermoautotrophicus [96], Methanosarcina barkeri [97], Methanosarcina acetivorans [98] and Methanothermobacter marburgensis [99], among others. Independently of the gaseous substrate used, all methanogens synthesize CH4 through a pathway analogous to the WLP, where the reducing equivalents derived from the oxidation of either H2 or CO are used for the stepwise reduction of CO2 to CH4 through several coenzyme-bound intermediates like methanofuran (MF) and tetrahydromethanopterin (H4MPT). Another relevant methanogenic pathway in some biomethane production systems is aceticlastic methanogenesis, which takes place through the reverse methanogenic WLP, where acetyl-CoA splits into CO and CH3-H4MPT and the reducing equivalents obtained from the oxidation of CO to CO2 are coupled to the reduction of the methyl group into CH4.

The biological production of CH4 has been studied using monoculture, co-culture and open culture systems. A few examples where the use of monocultures or co-cultures is proposed for biomethane production are the process patented by Electrochaea GmbH (Munich, Germany) [100], a co-culture of Carboxydothermus hydrogenoformans and M. thermoautotrophicus [101], and a tri-culture composed by Rhodospirillum rubrum, M. barkeri and Methanobacterium formicicum [102, 103]. However, since CH4 is naturally produced by microbial communities under anaerobic conditions, most of the research studies targeting the production of CH4 focus on the use of open cultures as these may contribute to increasing the robustness of the process and lowering the operational costs due to the possibility of non-sterile operation [4]. Similarly to co-culture systems, methanogenic microbial communities rely largely on cross-feeding interactions to carry out the conversion of CO and H2/CO2 into CH4, involving several microbial groups. Nevertheless, methanogenic microbial communities generally present a higher level of complexity and sustain not only cross-feeding interactions, but also a wide range of other symbiotic and mutual exclusion interactions, which confer them with an overall higher adaptive capacity. The reader is referred to the recent reviews of Grimalt-Alemany et al. [4] for further discussion on this topic, as these aspects are only shortly discussed in the following sections.

Biogas Upgrade

Biogas is the product of anaerobic digestion (AD) and contains approximately 60% CH4 and 40% CO2. Currently it is mainly used for heat and electricity while less than 10% is upgraded to biomethane with a CH4 content above 96% [104]. The applied upgrading processes dominating the market are water scrubbing, chemical scrubbing, pressure swing adsorption and membrane separation, and their purpose is the up-concentration of CH4 through CO2 removal. The abovementioned physicochemical processes have been recently characterized as first-generation biogas upgrade since the excess CO2 is not utilized as a carbon source [105]. Second-generation upgrading involves the simultaneous upgrading of biogas and the exploitation of CO2 for the production of hydrocarbon containing molecules. Among the second generation technologies power-to-gas (also known as P2G or PtG) has attracted the highest scientific attention giving rise to attempts for a common terminological framework to avoid confusion when comparing studies [106].

The concept behind PtG is anchored in the utilization of the excess electricity produced by renewable sources, such as windmills and solar panels, because of the intermittent fluctuations in weather conditions [107]. PtG contributes both to green energy storage and electricity grid stabilization, and its implementation involves two stages: (1) water electrolysis for the production of H2 and (2) the reduction of CO2 to CH4 from hydrogenotrophic methanogens. While the cost of electrolysis can be a hindrance for the process at the moment, scientists and investors project a 74% reduction of this capital expenditure from 2017 to 2050 for proton exchange membrane and alkaline electrolyzers [108]. However, scientific progress in water electrolysis is beyond the scope of this work; interested readers could go through a detailed review that has been recently published on the subject [109].

The biological biogas upgrade can be broken down in two subcategories: (1) in situ and (2) ex situ, with the distinction being whether the conversion of CO2 is performed (1) within the anaerobic digester or (2) in a separate reactor. In situ biogas upgrade can only be performed by mixed microbial consortia since it takes place inside the digester. Its main advantage is that no additional CAPEX (capital expenditures) and space is needed, while the major challenge is the strict control of the H2 supply so that it remains in stoichiometric ratio with the internally produced CO2 from the microbiome [110]. In addition, pH control is fundamental since the conversion of CO2 to CH4 upsets the buffering capacity of the anaerobic sludge resulting in a high increase of the pH to levels where methanogenesis is inhibited (> 8.5) [111]. Attention should also be given to the accumulation of acetate at a high partial pressure of H2 and a low partial pressure of CO2, since it can be fatal to the digester’s performance [112, 113]. To avoid abrupt changes in the environment of a WWTP performing in situ biogas upgrade, Corbellini et al. [114] suggested the injection of increasing dosages of H2 in the digester on a weekly basis starting from 1:1 H2:CO2 ratio to the ideal of 4:1. They tested and validated their idea in fed batch experiments in lab-scale where the results showed a fourfold increase of the specific hydrogenotrophic methanogenic activity of the wastewater sludge. Despite being a time-consuming procedure, the gradual enrichment of the sludge decreases the risks of a system failure and could be applied as a potential strategy in future plants. On a different note, Alfaro et al. [115] addressed the bottleneck of the gas-to-liquid mass transfer of H2 by proposing a submerged polymeric hollow fiber membrane module for the introduction of H2 in the reactor along with gas recirculation. Lab-scale experiments were performed at three different gas recirculation rates (50, 100 and 200 L Lreactor−1 day−1) indicating a positive impact on the mass transfer coefficient as the gas recirculation rate increased. Using a membrane module in the sludge of an anaerobic digester, though, should be cautiously done as it would increase the capital expenditures of the process and potential fouling of the membrane may occur. Further experiments and a technoeconomic assessment would be necessary before upscaling of this technology.

In ex-situ biogas upgrade, biogas flows out of the digester and enters a separate reactor unit where H2 from the electrolyzer is also added. The main advantage over the in-situ upgrade is that potential disruption of the AD process is avoided [116]. The biological reduction of CO2 to CH4 can be performed either from mixed microbial consortia or from pure cultures. While pure cultures significantly decrease the complexity of the microbiological phenomena in the reactor, they come with increased investment costs for the sterilization of the equipment. On the other hand, mixed microbial consortia are more resilient to potential disturbances and more economically beneficial since they come at low or zero cost due to their high abundance and operation at non-sterile conditions [4].

Over the last 5 years the scientific community has intensified its efforts on the study of trickle bed reactors for ex situ biogas upgrade (Table 3). The main reasons are the high surface-to-volume ratio and the cell retention in biofilms, which alleviate the low solubility of H2 in water-based media and increase the productivity of CH4 compared to conventional bioreactors [31]. Operational parameters that vary across studies are the temperature, the direction of the liquid and gas flow (co-current vs. counter-current), the mineral medium (synthetic vs. cheap alternatives), the type of the packing material, the pressure and the liquid recirculation rate. According to a study from Porté et al. [117] the direction of the flow seemed to have little impact on the performance of the bioreactor. Ullrich et al. [118] demonstrated that at an empty bed residence time (EBRT) of 0.85 h the trickling of the digested sludge across the bed could be reduced up to 1 min per day without negative effects on the reactor performance. This is an important observation since it can significantly reduce the pumping energy demand of the unit. The same research group studied the influence of the pressure and showed an improvement of the productivity of CH4 and the conversion rate of H2 and CO2 as the pressure increased from 1.5 to 5 bar [18]. It should be taken into account, though, that operation in higher pressures come with increased investment costs for the needed equipment. Furthermore, comparing the studies in Table 3 it seems that the use of synthetic media is not advantageous to using digestate. The validation of this observation would be important from a financial perspective since synthetic media have a substantially higher market cost. Although the hydrodynamics of trickle bed reactors have been extensively studied for several chemical and biological processes [119, 120], little work has been put in modelling biological methanation in trickle bed reactors. A CFD model was recently presented by Markthaler et al. [121] offering an interesting insight into the hydrodynamics in the reactor and the interaction between multiphase flow and hydrogenotrophic methanogenesis. However, further work is needed in order to strengthen the automation and control of the process.

Bioelectrochemical Methanation

Bioelectrochemical methanation is an emerging technology for the conversion of CO2 to CH4 [122]. The basic principle of the process is the production of protons and electrons through water electrolysis or biological decomposition of organic compounds in an anode and the concomitant conversion of CO2 with the produced protons and electrons in a biotic cathode rich in methanogenic archaea [123]. An ion exchange membrane should separate the anode and the cathode. Similarly to the PtG concept, the electricity should derive from renewable sources so as to guarantee the sustainability of the process. A thorough review was published in early 2019 with extensive details on the microbiological aspect of the process and the main factors affecting it [124]. Since then Zhou et al. [125] performed the first study using intact anaerobic granular sludge as a biocatalyst in the cathode of the electrolytic cell. The methane content of the produced gas exiting the cell reached a maximum value of 97.9 ± 2.3% at an applied voltage of 4 V and the dominant genus in the sludge was the hydrogenotrophic methanogen Methanobacterium. Another important characteristic of the setup was the high stability of the biocathode during the 2 months of operation, since the stability and long-lifetime durability of the electrodes are two main challenges of the process hampering its further upscaling.

An alternative concept is the combination of anaerobic digestion and electromethanogenesis in a single chamber electrolytic cell, a process also known as AD-MEC or anaerobic digestion—microbial electrolysis cell. The decomposition of the organic matter produces electrons that are then transferred to the cathode, where CO2 is subsequently upgraded to biomethane in situ. Recent research work has been focused on the selection of a biocompatible and highly conductive electrode. A promising candidate gaining a lot of attention is graphene with several scientific studies demonstrating a boost of the biomethane yield and productivity rate [126,127,128]. Finally, an innovative idea for the cathode was published in early 2020 with the use of a hydrophilic zeolite cores and conductive magnetite nanoparticles [129]. The researchers reported an increase of the methane productivity by 21% compared to a conventional carbon cathode and attributed it to the increased surface area of the cathode (micro-cannels) and reduced charge transfer resistance. To our knowledge, upscaling of (bio) electrochemical methanation has not been performed yet and this is reasonable since the development of this technology is still at an early stage.

Syngas Biomethanation

The main difference between syngas biomethanation and biogas upgrade with the supply of hydrogen is the presence of CO in the gas substrate. CO is an inhibitory compound that causes important differences in terms of the structure of the symbiotic microbiome that treats the gas. A special group of microorganisms known as carboxydotrophs can use CO as an energy and carbon source converting it to acetate, H2 or even directly to CH4 [4]. Although syngas biomethanation is significantly less studied compared to biogas upgrade, recent scientific efforts focus on the development and deep understanding of acclimated mixed cultures to syngas and selection of an appropriate bioreactor configuration to facilitate and improve the process.

While microbial acclimation in low partial pressures of CO (0.05 bar) can be easily achieved [130], further increase of the CO content (0.17 bar) should be performed in a systematic way to avoid undesirable consequences on the microbial community [131]. Grimalt-Alemany et al. [132] implemented an enrichment procedure involving batch successive transfers of AD microbial consortia in a syngas environment (0.4 bar CO) under mesophilic and thermophilic conditions. The results showed that under mesophilic conditions CO is first converted to acetate by carboxydotrophic acetogens and subsequently to CH4 by aceticlastic methanogens. A less intricate metabolic network was observed in thermophilic condition where CO was converted to H2 by carboxydotrophic hydrogenogens through the biological water–gas shift reaction and concomitantly to CH4 by Methanothermobacter species. Kinetic parameter estimation between the two temperature profiles showed a significantly higher (twofold) maximum specific growth rate of the microbes in thermophilic conditions [133]. An additional finding of this work was that, apart from microbial kinetics, thermodynamic limitations determine the dominant catabolic routes during syngas biomethanation [133]. Another study implementing a successive transfers batch enrichment strategy demonstrated adaptation of a microbial community up to a CO partial pressure of 1.7 bar [134].

Similar to ex-situ biogas upgrade, biofilm based reactors dominate the literature on continuous syngas biomethanation. The use of trickle bed reactors has demonstrated promising results compared to other alternatives achieving the highest CH4 productivities reported so far in the literature [23]. At a lab-scale research study employing enriched anaerobic sludge as inoculum and a syngas composition of 45% H2, 25% CO2, 20% CO and 10% CH4 in a trickle bed reactor the main challenges presented were the pH drop from the accumulation of VFAs (primarily acetate) and the channeling phenomena (non-homogenous wetting of the bed) [135]. Comparison of the reactor performance between 37 and 60 °C showed a significantly better performance in thermophilic conditions with the highest CH4 productivity being 8.5 mmol Lbed−1 h−1 [23]. Another interesting bioreactor setup is the use of sachets with enclosed immobilized microorganisms for the improvement of the cell retention in the reactor [28, 136, 137]. Other effective bioreactor configurations employing the cell immobilization principle include carbon materials such as biochar and activated carbon [138, 139]. These materials have a high porosity, which increases the available surface area for mass transfer and microbial growth. Apart from single-stage reactor systems, the idea of a two-stage setup was recently introduced with the first stage converting syngas to acetate and the second converting acetate to CH4 [140]. The researchers highlighted the inhibitory effects of acetate on syngas bioconversion when its concentration was above 2 g L−1. The inhibition was probably caused due to poor acclimation of their anaerobic microbial consortium on acetate since other studies using as inocula anaerobic consortia have shown satisfactory growth on acetate concentrations up to 13 g L−1 in mesophilic conditions [141] and 42.4 g L−1 in thermophilic conditions [142].

Other Products

Gas fermentation holds a high potential as a production platform due to the inherent benefits of using waste gases, as these contribute to mitigating climate change while their conversion into products provides an economic incentive at the same time. Over the last years, a vast research program has been implemented worldwide for expanding its product portfolio towards more advanced bioproducts.

The most common strategy is to broaden the product spectrum of acetogenic bacteria through metabolic engineering. This proved to be a challenging task due to the initial lack of genetic engineering tools for reconstructing and integrating heterologous metabolic pathways into gas-fermenting Clostridium spp. and the bioenergetic restrictions of energy-deficient substrates like CO2. However, significant progress has been made in recent years [143]. A few examples of successful synthesis of non-native end products through genetic modifications are production of acetone by engineered strains of Acetobacterium woodii [144], 3-hydroxybutyrate by an engineered strain of C. ljungdahlii [145], poly-3-hydroxybutyrate (PHB) by an engineered strain of C. autoethanogenum [146] while synthesis of medium-chain-length polyhydroxyalkanoate was possible by an engineered strain of Rhodospirillum rubrum [147].

Other approaches targeting the expansion of the product portfolio of the gas fermentation platform may involve the direct conversion of waste gases, the combination of production systems following a multi-stage biorefinery approach, as would be the case of MCFAs production discussed above, or the combination of cultures in co-culture systems. One of the advanced products with high potential for direct conversion is single-cell protein (SCP), which can be directly produced from waste gases such as CO and CO2 [148, 149]. An interesting example of co-cultures producing non-native products by interspecies metabolite exchange was reported by Charubin and Papoutsakis [150], who found that co-culturing C. acetobutylicum and C. ljungdahlii under mixotrophic conditions resulted in novel pathways for producing isopropanol and 2,3-butanediol, metabolites that are non-native of these strains. Several examples can be found as well for two-stage processes producing advanced bioproducts from waste gases through intermediate synthesis of SCFAs, such as PHB production through formate [151] and acetate [152], malic acid production through acetate [153], and lipids production through acetate [29].

Industrial Applications

The commercialization of syngas fermentation to ethanol was pursued by three companies (Ineos Bio, Coskata and Lanzatech); however only Lanzatech has reached commercial scale with the rest abandoning their projects after demonstration scale [154]. Lanzatech inaugurated its first commercial scale plant in 2018 at Caofeidian, China, using as a substrate syngas produced at the steel-mill of Shougang Group. The capacity of the plant is 48,000 metric tons per year and has a 3 year estimated return of investment (ROI) [155]. The company uses a proprietary C. autoethanogenum strain as a biocatalyst and a patented microbubble column bioreactor [156]. Apart from the operating plant in China, Lanzatech has announced more partnerships for commercial scale syngas to ethanol plants: (1) with ArcelorMittal in Belgium treating steel mill off gas, (2) with SWAYANA in South Africa treating ferroalloy off gas, (3) with Indian Oil in India treating refinery off gas, (4) with AEMETIS in USA treating syngas from gasified biomass and (5) with SEKISUI in Japan treating gasified municipal solid waste). Lanzatech also aims to expand its commercial product portfolio applying recent breakthroughs in metabolic engineering. Characteristic targeted chemicals are d-2,3-butanediol, acetoin, succinic acid and lactic acid via pyruvate, and heterologous products such as sec-Butanol, methylethylketone (MEK), meso-2,3-Butanediol, n-propanol and propanal [157].

Kiverdi is a California-based company that has commercialized its single cell protein (SCP) production from CO2. The SCP marketed as CO2 AQUAFEED targets the fish farms sector since it is nutritionally comparable to traditional fishmeals [158]. The bioreactor configuration is patented and employs a gas-loop reactor with liquid recirculation [159]. The microorganism used for the fermentation of C1 gases is Cupriavidus necator [160], an oxyhydrogen microorganism that can use hydrogen as an electron donor and oxygen as an electron acceptor. In addition, a Dutch company named KWR reached pilot-scale production for its power-to-protein technology. Reducing power is obtained both from H2 (water electrolysis) and NH3 (recovered at wastewater treatment plants) for the bioconversion of CO2 to SCP used as animal feed [161]. The pilot scale tests in 400 L reactors produced an average of 0.5 kg of SCP per m3 per day, instead of the expected 1.7 with the company indicating that the limiting factor was the gas-to-liquid mass transfer [162]. KWR has now established a new partnership with TKI Water Technology in order to overcome the mass transfer bottleneck and enhance their bioreactor performance.

A recent review [108] assembled 153 past, present and planned projects relevant to the PtG technology. The majority of them (90) delved into water electrolysis, whereas 60 involved a methanogenesis step (raw or artificial biogas upgrade) performed in either catalytic reactors (30) or biological (30). From the biomethanation projects, 14 employed trickle bed reactors, 11 stirred tank reactors, and the rest were performed in situ at anaerobic digester facilities like biogas plants and wastewater treatment plants. Only three projects have reached commercial scale so far located at Avedøre in Denmark, at Solothurn in Switzerland and at Colorado in US. The bioprocess used in all three projects was developed and patented [100] by Electrochaea GmbH (Munich, Germany) during the BioCat research project in Denmark. The bioreactor is inoculated with a proprietary strain of the hydrogenotrophic methanogen Methanothermobacter thermoautotrophicus. The specific patented strain named UC 120910 was the outcome of a focused selection process performed at the Department of Molecular Genetics and Cell Biology at the University of Chicago [163]. The commercial scale reactor in Denmark receives H2 from an electrolyzer supplied with renewable electricity and converts CO2 produced by a wastewater treatment plant on-site at the BIOFOS facility. The biomethanation unit delivers a gas containing > 97% CH4, 0.2–1% CO2 and 1–2% H2 in the injection gas grid station also located in the BIOFOS campus. The annual capacity of the plant is 1 MW and sequesters 740 tons of CO2 from the atmosphere of Denmark [164]. The company aims to expand even further with a 8 MW biomethanation plant at an existing biogas farm in Jutland setting a future goal for a 50 MW plant. It has also established a collaboration with the university Ostbayerische Technische Hochschule Regensburg under the project name ORBIT for the development of a novel trickle bed reactor that would enhance hydrogenotrophic methanogenesis [165].

Despite the highly attractive concept of sustainable biochemicals and biofuels production from waste gases like syngas or CO2, it is currently a big challenge for these emerging technologies to compete with existing ones from the petrochemical industry due to the low price of fossil fuel alternatives in the market. The scientific community is putting significant efforts into encountering the major bottlenecks of CO2 bioconversion and optimizing novel bioreactor configuration for maximum productivities. However, the assistance of governments is also essential in order to achieve global decarbonization and reduce the negative effects of the increasing release of carbon in the environment. Political stakeholders should enhance the incentive for the upscaling of CO2 capturing and utilization bioprocesses through the implementation of additional policy schemes such as subsidies or tariffs. For instance, a carbon footprint fee or a substantial reward for negative CO2 emissions could speed-up the commercialization of bioenergy production units. Such endeavors have proven to be an effective motivation for EU member states [166].

A Way Forward—Opportunities and Challenges

CO2 as Threat and Alternative Resource for Biological Production

Greenhouse gas emissions, especially carbon dioxide and global warming is nowadays receiving a great deal of attention and has been a field of intense debate over the last three decades. More and more studies relate GHG emissions with the rise of temperature and predictions on how the temperature level will evolve with time are being published taking into account diverse scenarios based on different climate policies. Recent analyses show that even if Paris agreement and national pledges are achieved, temperature will still rise above 2 °C, compared to pre-industrial levels, by 2100 [167]. Therefore, besides replacing part of oil, coal and natural gas applications by renewable carbonaceous material like agricultural residues, wastes and algal biomass as feedstock, development of processes targeting re-assimilation of the CO2 generated becomes more and more imperative.

The vast majority of CO2 emissions by 2016 was due to the electricity and heat production, which accounted for the 41% of the emissions worldwide, while the next big emitter is transport with 21% contribution to the global CO2 emissions. Manufacturing and construction comes third, with 17% contribution, while other industrial activities contribute with 4% [167]. It make sense therefore, as an acute action, to prioritizing minimization of emissions from the first three sectors, addressing this way a 79% of the global CO2 sources. There are mainly two ways in limiting carbon dioxide emissions: (1) by replacing part of fossil based resources and by (2) capturing and transforming the generated carbon dioxide on-site, i.e. CO2 coming from combustion plants for electricity and heat generation and other industrial activities.

Harvesting energy from sun, wind and waves for covering electricity needs and substituting thus fossil based production are in the very forefront the last decades; the main challenge associated with the non-carbon based energy resources are the fluctuations in electricity generation, which results in increasing needs for storing electricity and developing relevant technologies. In this respect, the natural gas grid can play a significant and dual role: the surplus electricity can be used for indirect biological reduction of carbon dioxide to an array of products that can be used either directly in the transportation and industrial sector or can be applied as platform molecules for advanced biofuels and materials. Carbon dioxide can be assimilated by autotrophic microbes via five metabolic pathways [168] while energy is reserved either through phototrophy or chemotrophy. As discussed in “Recent Developments on Syngas and CO2 Bioconversions” section, anaerobic bacteria and archaea using the reductive Acetyl-CoA pathway (or Wood–Ljungdahl pathway) are mostly studied for the production of a range of products from carbon dioxide. Methane via indirect (with hydrogen generated via water electrolysis) or direct reduction of carbon dioxide in the bio-cathode of microbial electro synthesis cells is one of the most studied products and indirect reduction of carbon dioxide with H2 has already reached commercial scale. The next step is naturally the development of competitive technologies for the production of a wider array of products where the main challenge lies in the low mass transfer and microbial growth rates, similarly to what has been extensively discussed for syngas.

The Bottleneck of Optimizing Both Yield and Productivity in Gas Bioconversions

It is by now obvious that intensive research for intensification of the bioconversion processes of both syngas and carbon dioxide is a necessity for reaching technological maturity and economic feasibility. Reactors based on attached growth result in enhancing the conversion rates due to high cells concentrations while smart designs, i.e. trickle beds, allow for enhanced mass transfer rates tackling both issues of mass transfer and low cells concentrations at the same time. Thus, operation at increased pressure together with high operating and construction costs, and toxicity problems that come with it may be avoided this way while the productivity of the system can be increased several folds.

However, attached growth systems are generally not applied for biotransformations based on axenic cultures or well-defined co-cultures due to the challenges that the biofilm structure entails for efficient sterilization and decontamination if need be. It is not a coincidence that those reactor types were primarily developed for environmental biotechnological processes, which were mostly based on naturally occurring mixed microbial consortia. On the other hand, applying mixed microbial consortia inevitably compromises the yield that can be optimized only by employing axenic cultures and/or genetically engineered strains tailored to maximize the yield of a specific product. Applying mixed communities for the production process, one may not be able to reach high yields, however, we have the possibility to increase productivities many folds and at a process cost significantly lower, especially with sparingly soluble gases as substrates for the microbial growth. On the other hand, the use of axenic cultures and well-defined co-cultures maybe imperative in case of high-value products that come in relatively low yields anyway and require a tedious separation and purification process and products that can solely be produced by engineered microorganisms. Conclusively, there are several factors to be considered when deciding which approach to follow. Along those lines, the stability and reproducibility of processes based on mixed communities need to be further investigated so they become attractive for industrial applications. There are strong evidences that such processes can indeed be stable and reproducible [71, 169], however, more research on the subject is certainly needed.

When Intracellular Reserves Are on Focus

Certain microbial cells have the possibility to store intracellular polymers of industrial interest under conditions of unbalanced growth with Polyhydroxyalkanoates (PHA) and Single Cell Oil (SCO) being the most representative and thoroughly investigated ones. PHA are microbial polyesters stored in the cytoplasm as carbon and energy storage granules. The most commonly reported polymers are polyhydroxybutyrate (PHB) and polyhydroxyvalerate (PHV), although more than 150 types of monomers have been described in more than 300 different microorganisms. PHA present similar properties to polyethylene and polypropylene, and therefore they have been proposed as a possible renewable and biodegradable bio-based alternative to these petroleum-derived plastics with applications in different fields such as food packaging, medical applications, personal care, agricultural plastics or household appliances. The trends in the sector are mainly focused in reducing the production cost and developing sustainable and economical PHA recovery methods [170]. SCO on the other hand, are microbial lipids that accumulate intracellularly in certain microorganisms serving, similarly to PHA, as carbon and energy reserves for the cells. They consist mainly of long chain fatty acids (C16–C18) and their esters with glycerol with properties being similar to those of plant oils [171]. Therefore SCO have the potential for becoming one of the main raw materials for producing biofuels and thus bringing land and aviation transportation sector closer to a sustainable era by limiting the dependency on fossil fuels or on plant and cooking oils that come with severe availability limitations.

As already mentioned in “Other Products” section, there have already been attempts to produce PHA from syngas; however the PHA content in the cells, yields and productivities achieved are by far lower compared to those obtained with sugars or short chain fatty acids as substrates. To our knowledge, there has not been any study yet addressing production of SCO directly from syngas or carbon dioxide.

Apparently, reactor configurations based on attached growth are not suitable for harvesting intracellular reserves. On the other hand, short chain fatty acids are an excellent feedstock for PHA and in many cases preferable over sugars. Furthermore, several SCO accumulating microorganisms can grow very efficiently on short chain fatty acids. Therefore, an efficient configuration could be an attached growth reactor system where assimilation of gaseous substrates, syngas and CO2 will take place under conditions that favor generation of short chain fatty acids. Short chain fatty acids could be used as feedstock for a subsequent process step of accumulation and harvesting of PHA and SCO. This way optimization of both process steps is possible as gas conversions and accumulation of intracellular reserves have quite different requirements and face different challenges. The approach of producing SCO from syngas via short chain fatty acids has been reported with focus on enhancing the yield in both processes by metabolic engineering with impressive results so far. Approaches focusing on enhancing the productivities and reducing the required volume, improving thus the economics of the overall process would also be desirable to see emerging.

Conclusions

Valorization of residual biomasses via generation and subsequent biological conversion of syngas and valorization of carbon dioxide via biological means has exhibited a tremendous growth the last decade and several industrial applications already exist on ethanol and methane production from industrial off-gases. Given the advantages of full carbon valorization via the syngas platform and the acute necessity for reducing carbon dioxide emissions, gas bioconversions is undoubtedly a very promising and important field on our way to sustainability. Syngas and carbon dioxide can be directed to a number of valuable fuels and chemicals, i.e. methane, alcohols, short- and long chain fatty acids. Here, renewable electricity plays a significant role in providing reducing power for full CO2 recycling either directly in bioelectrochemical cells or indirectly via generation of H2. Besides using them as final products that can be directly generated from gaseous substrates, short chain fatty acids can be further utilized for a number of valuable intracellular reserves for materials production and advanced fuels production. An armature of methods and techniques (from metabolic engineering to reactor design and process intensification), which are already available and are being continuously developed, can contribute towards maturing the respective technologies and production paths. Yield versus productivity is an even more challenging issue for gas bioconversion processes compared to traditional liquid-based processes, which requires careful considerations and analyses before deciding on production microorganisms and reactor systems.

References

Kaupp, A., Goss, J.R.: Summary for policymakers. In: Intergovernmental Panel on Climate Change (ed.) Climate Change 2013: The Physical Science Basis, pp. 1–30. Cambridge University Press, Cambridge (2019)

Ernsting, A.: Biomass gasification and pyrolysis. http://www.biofuelwatch.org.uk/wp-content/uploads/Biomass-gasification-and-pyrolysis-formatted-full-report.pdf. (2015). Accessed 4 Jan 2021

Drake, H.L., Küsel, K., Matthies, C.: Acetogenic prokaryotes. In: Rosenburg, E., Delong, E.F., Lory, S., Stackebrandt, E., Thompson, F. (eds.) Prokaryotes, pp. 354–420. Springer, New York (2006)

Grimalt-Alemany, A., Skiadas, I.V., Gavala, H.N.: Syngas biomethanation: State-of-the-art review and perspectives. Biofuels Bioprod. Biorefining. 12, 139–158 (2018). https://doi.org/10.1002/bbb.1826

Reed, T.B. (1981) Biomass gasification : principles and technology. Noyes Data Corp (1981)

Brown, R.C.: Biomass refineries based on hybrid thermochemical-biological processing: an overview. In: Kamm, B., Gruber, P.R., Kamm, M. (eds.) Biorefineries-Industrial Processes and Products, pp. 227–252. Wiley, Weinheim (2008)

Minchener, A.J.: Coal gasification for advanced power generation. Fuel 84, 2222–2235 (2005). https://doi.org/10.1016/j.fuel.2005.08.035

Hall, D.O., Rosillo-Calle, F., Williams, R.H., Woods, J.: Biomass for energy: supply prospects. In: Johansson, T.B., Burnham, L. (eds.) Renewable Energy: Sources for Fuels and Electricity, pp. 593–651. Earthscan, London (1993)

Ghosh, P., Westhoff, P., Debnath, D.: Biofuels, food security, and sustainability. In: Biofuels, Bioenergy and Food Security, pp. 211–229. Elsevier, New York (2019)

Naylor, R.L., Liska, A., Burke, M.B., Falcon, W.P., Gaskell, J.C., Rozelle, S.D., Cassman, K.G.: The ripple effect: biofuels, food security, and the environment. Environ. Sci. Policy Sustain. Dev. 49, 30–43 (2007). https://doi.org/10.3200/ENVT.49.9.30-43

Kumar, A., Samadder, S.R.: A review on technological options of waste to energy for effective management of municipal solid waste. Waste Manag. 69, 407–422 (2017). https://doi.org/10.1016/j.wasman.2017.08.046

Dieter Stapf, Giovanni Ceceri, Inge Johansson, Whitty, K.: Biomass pre-treatment for bioenergy case study 3: pretreatment of municipal solid waste (MSW) for gasification. https://www.ieabioenergy.com/wp-content/uploads/2019/02/CS3-MSW-pretreatment-for-gasification.pdf (2019). Accessed 4 Jan 2021

Mateo-Sagasta, J., Raschid-Sally, L., Thebo, A.: Global wastewater and sludge production, treatment and use. In: Wastewater: Economic Asset in an Urbanizing World, pp. 15–38. Springer, New York (2015)

Syed-Hassan, S.S.A., Wang, Y., Hu, S., Su, S., Xiang, J.: Thermochemical processing of sewage sludge to energy and fuel: fundamentals, challenges and considerations. Renew. Sustain. Energy Rev. 80, 888–913 (2017). https://doi.org/10.1016/j.rser.2017.05.262

Sangeet, J.: Gas fermentation: a carbon recycling pathway. https://missionenergy.org/gasification2018/presentations/LanzaTech_Sangeet%20Jan.pdf (missionenergy.org) (2018). Accessed 4 Jan 2021

Kundiyana, D.K., Wilkins, M.R., Maddipati, P., Huhnke, R.L.: Effect of temperature, pH and buffer presence on ethanol production from synthesis gas by Clostridium ragsdalei. Bioresour. Technol. 102, 5794–5799 (2011). https://doi.org/10.1016/j.biortech.2011.02.032

Ko, C.W., Vega, J.L., Clausen, E.C., Gaddy, J.L.: Effects of high pressure on a co-culture for the production of methane from coal synthesis gas. Chem. Eng. Comm. 77, 155–169 (1989)

Ullrich, T., Lindner, J., Bär, K., Mörs, F., Graf, F., Lemmer, A.: Influence of operating pressure on the biological hydrogen methanation in trickle-bed reactors. Bioresour. Technol. 247, 7–13 (2018). https://doi.org/10.1016/j.biortech.2017.09.069

Oswald, F., Stoll, I.K., Zwick, M., Herbig, S., Sauer, J., Boukis, N., Neumann, A.: Formic acid formation by Clostridium ljungdahlii at elevated pressures of carbon dioxide and hydrogen. Front. Bioeng. Biotechnol. (2018). https://doi.org/10.3389/fbioe.2018.00006

Bredwell, M.D., Srivastava, P., Worden, R.M.: Reactor design issues for synthesis-gas fermentations. Biotechnol. Prog. 15, 834–844 (1999). https://doi.org/10.1021/bp990108m

Richter, H., Martin, M.E., Angenent, L.T.: A two-stage continuous fermentation system for conversion of syngas into ethanol. Energies 6, 3987–4000 (2013). https://doi.org/10.3390/en6083987

Shen, Y., Brown, R., Wen, Z.: Syngas fermentation of Clostridium carboxidivorans P7 in a hollow fiber membrane biofilm reactor: Evaluating the mass transfer coefficient and ethanol production performance. Biochem. Eng. J. 85, 21–29 (2014). https://doi.org/10.1016/j.bej.2014.01.010

Asimakopoulos, K., Łężyk, M., Grimalt-Alemany, A., Melas, A., Wen, Z., Gavala, H.N., Skiadas, I.V.: Temperature effects on syngas biomethanation performed in a trickle bed reactor. Chem. Eng. J. (2020). https://doi.org/10.1016/j.cej.2020.124739

Petersen, L.A.H., Villadsen, J., Jørgensen, S.B., Gernaey, K.V.: Mixing and mass transfer in a pilot scale U-loop bioreactor. Biotechnol. Bioeng. 114, 344–354 (2017). https://doi.org/10.1002/bit.26084

Sathish, A., Sharma, A., Gable, P., Skiadas, I., Brown, R., Wen, Z.: A novel bulk-gas-to-atomized-liquid reactor for enhanced mass transfer efficiency and its application to syngas fermentation. Chem. Eng. J. 370, 60–70 (2019). https://doi.org/10.1016/j.cej.2019.03.183

Arantes, A.L., Alves, J.I., Alfons, J.M., Alves, M.M., Sousa, D.Z.: Enrichment of syngas-converting communities from a multi-orifice baffled bioreactor. Microb. Biotechnol. (2017). https://doi.org/10.1111/1751-7915.12864

Shen, Y., Brown, R.C., Wen, Z.: Syngas fermentation by Clostridium carboxidivorans P7 in a horizontal rotating packed bed biofilm reactor with enhanced ethanol production. Appl. Energy 187, 585–594 (2017). https://doi.org/10.1016/j.apenergy.2016.11.084

Chandolias, K., Pekgenc, E., Taherzadeh, M.J.: floating membrane bioreactors with high gas hold-up for syngas-to-biomethane conversion. Energies 12, 1–14 (2019). https://doi.org/10.3390/en12061046

Park, J.O., Liu, N., Holinski, K.M., Emerson, D.F., Qiao, K., Woolston, B.M., Xu, J., Lazar, Z., Islam, M.A., Vidoudez, C., Girguis, P.R., Stephanopoulos, G.: Synergistic substrate cofeeding stimulates reductive metabolism. Nat. Metab. 1, 643–651 (2019). https://doi.org/10.1038/s42255-019-0077-0

Maru, B.T., Munasinghe, P.C., Gilary, H., Jones, S.W., Tracy, B.P.: Fixation of CO2 and CO on a diverse range of carbohydrates using anaerobic, non-photosynthetic mixotrophy. FEMS Microbiol. Lett. 365, 1–8 (2018). https://doi.org/10.1093/femsle/fny039

Asimakopoulos, K., Gavala, H.N., Skiadas, I.: V: Reactor systems for syngas fermentation processes: a review. Chem. Eng. J. 348, 732–744 (2018). https://doi.org/10.1016/j.cej.2018.05.003

Van Hecke, W., Bockrath, R., De Wever, H.: Effects of moderately elevated pressure on gas fermentation processes. Bioresour. Technol. 293, 122129 (2019). https://doi.org/10.1016/j.biortech.2019.122129

Emerson, D.F., Stephanopoulos, G.: Limitations in converting waste gases to fuels and chemicals. Curr. Opin. Biotechnol. 59, 39–45 (2019). https://doi.org/10.1016/j.copbio.2019.02.004

Liu, H., Lee, C.F., Huo, M., Yao, M.: Comparison of ethanol and butanol as additives in soybean biodiesel using a constant volume combustion chamber. Energy Fuels 25, 1837–1846 (2011). https://doi.org/10.1021/ef200111g