Abstract

The fermentation of waste gases rich in carbon monoxide using acetogens is an efficient way to obtain valuable biofuels like ethanol and butanol. Different experiments were carried out with the bacterial species Clostridium carboxidivorans as biocatalyst. In batch assays with no pH regulation, after complete substrate exhaustion, acetic acid, butyric acid, and ethanol were detected while only negligible butanol production was observed. On the other side, in bioreactors, with continuous carbon monoxide supply and pH regulation, both C2 and C4 fatty acids were initially formed as well as ethanol and butanol at concentrations never reported before for this type of anaerobic bioconversion of gaseous C1 compounds, showing that the operating conditions significantly affect the metabolic fermentation profile and butanol accumulation. Maximum ethanol and butanol concentrations in the bioreactors were obtained at pH 5.75, reaching values of 5.55 and 2.66 g/L, respectively. The alcohols were produced both from CO fermentation as well as from the bioconversion of previously accumulated acetic and butyric acids, resulting in low residual concentrations of such acids at the end of the bioreactor experiments. CO consumption was often around 50 % and reached up to more than 80 %. Maximum specific rates of ethanol and butanol production were reached at pH 4.75, with values of 0.16 g/h*g of biomass and 0.07 g/h*g of biomass, respectively, demonstrating that a low pH was more favorable to solventogenesis in this process, although it negatively affects biomass growth which does also play a role in the final alcohol titer.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, the low availability of fossil fuels and their environmental impact have forced to look for new alternative fuels obtainable, in a cost-effective way, from renewable sources or from pollutants. In addition to the environmental impact and increasing scarcity of conventional fuels, other aspects, e.g., economic and political, have also led to an ever increasing interest in techniques for the production of such alternative fuels (Gowen and Fong 2011; Abdehagh et al. 2014). Most studies have focused on the production of new energy sources and biofuels (biologically sourced fuels) such as (bio)ethanol, biogas, (bio)hydrogen, and biodiesel (Kennes and Veiga 2013). Additionally, (bio)butanol is also a suitable alternative fuel more similar to gasoline than (bio)ethanol and with interesting characteristics. Butanol exhibits several advantages, e.g., it is less hygroscopic and has a higher caloric content than ethanol (Wallner et al. 2009). It is considered a chemical of great industrial importance and has a high potential to replace gasoline (Dürre 2007; Lee et al. 2008), as there is no need for any adjustment of vehicles and engines using butanol. Besides, blending of butanol and gasoline is possible at any concentrations, and blends have also been reported to be possible in case of diesel (Jin et al. 2011).

Alcohols such as ethanol and butanol can be obtained through fermentation of sugars from sugarcane, corn, or starch feedstocks, among others, which is the conventional and common commercial process nowadays for ethanol, known as a first-generation process. However, this technique for obtaining biofuels leads to food-fuel competition (Kennes et al. 2016). This disadvantage can be avoided by using lignocellulosic feedstocks from agricultural wastes or energy crops, which are inexpensive and renewable starting materials for biofuels production, and do not adversely affect food supplies. After some pretreatments and hydrolytic steps, simple sugars can be obtained from those polymeric feedstocks which can then be fermented into ethanol and/or butanol, in the so-called second-generation process (Kennes et al. 2016). However, there are still numerous scientific and technical challenges involved in the utilization of lignocellulosic materials for biofuel production (Gowen and Fong 2011), and there is a need for further research in order to improve cost-competitiveness of such alternative compared to the more conventional first-generation process.

The conventional second-generation process for the bioconversion of lignocellulosic feedstocks into biofuels is still a complex process (Balat and Balat 2009). As an alternative, gasification of biomass in order to obtain carbon monoxide-rich syngas represents another viable option. Syngas as well as most of its individual dominant components (like CO) can be introduced into a fermentor inoculated with anaerobic bacteria, under specific process conditions to produce biofuels (Abubackar et al. 2011; Bengelsdorf et al. 2013; Mohammadi et al. 2011). Not only syngas but also industrial waste gases rich in carbon monoxide have recently been shown to be suitable substrates for their bioconversion into biofuels in bioreactors (Kennes and Veiga 2013). Both suspended-growth as well as attached-growth bioreactors can efficiently be used for gas-phase biodegradation or bioconversion of such volatile substrates (Kennes and Veiga 2001, 2013). Initially, research on the fermentation of CO-rich gases focused only on ethanol production, which can be either an independent fuel as mentioned above or act as a substitute for gasoline supplemented with MTBE to reduce emissions of CO and NO x (Ahmed and Lewis 2007; Henstra et al. 2007; Shaw et al. 2008). However, its hygroscopic nature and low caloric content limits the use of ethanol with current infrastructures; therefore, very recent research has also focused on butanol production through the fermentation of such gaseous substrates as an alternative alcohol-biofuel.

Fermentation of CO-rich gases, i.e., syngas or waste gases, has been shown to be an attractive and likely cost-effective alternative able to compete with the conventional second-generation process based on the fermentation of carbohydrates (Kennes et al. 2016). This is above all true whenever using waste gases as substrates. Therefore, this process has recently attracted interest from some companies and some demonstration and pre-commercial projects are now being set up for ethanol production (Abubackar et al. 2011; Kennes and Veiga 2013). However, several challenges remain to be addressed in order to further improve the efficiency and cost-effectiveness of this technology. One of those challenges is related to the low water solubility of carbon monoxide and other volatile compounds (e.g., H2, CO2), which limits the mass transfer rate of the substrate to the liquid phase in suspended-growth bioreactors or to the biofilm in attached-growth bioreactors, limiting at the same time the production yields of (bio)fuels or platform chemicals of interest. Some previous and on-going studies are focusing on minimizing such drawback. Among others, the use of membrane systems as well as attached-growth bioreactors seems to allow a more efficient mass transfer of poorly soluble compounds (Jin et al. 2009; Shen et al. 2014) as well as microbubble spargers in suspended-growth bioreactors (Bredwell and Worden 1998). Another drawback to be taken into account and already previously observed in conventional acetone-butanol-ethanol (ABE) fermentation from carbohydrates is solvent toxicity. This is an important factor to take into account in butanol fermentation as acetogenic bacterial cells rarely tolerate more than 2 % butanol (Liu and Qureshi 2009). However, although new strategies can still be developed, experience has already been gained from the conventional ABE fermentation aimed at reducing such inhibitory problems. These strategies may include the use of continuous in situ removal of produced solvents from the fermentation broth, among others (Schugerl 2000). It is also worth mentioning that setting up bioreactors under anaerobic conditions with CO-related gases as substrates may be somewhat more challenging than the conventional fermentation of carbohydrates. However, such harsher conditions will also reduce potential microbial contamination of the bioreactor. Finally, optimizing the fermentation and bioreactor operating conditions is another aspect that will allow improving the yield and selectivity of the biochemical reactions and which is addressed in this paper. Research on such aspects will further improve the efficiency and cost-effectiveness of this process appearing as a promising alternative.

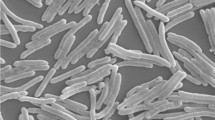

In the present study, the conversion of CO into butanol and ethanol was carried out by the bacterium Clostridium carboxidivorans, which was grown first in batch bottles with no pH regulation and, afterwards, in continuous gas-fed bioreactors using a defined medium under controlled conditions and continuously fed CO gas. The objectives were to develop and optimize culture conditions for a relatively high production of alcohols through anaerobic CO fermentation and to compare the growth and fermentation products between the batch bottle assays and the bioreactors with continuous CO supply. Bioreactor operating conditions were optimized.

Material and methods

Microorganism and culture media

C. carboxidivorans P7 DSM 15243 was obtained from the Deutsche Sammlung von Mikroorganismen und Zellkulturen GmbH (Braunschweig, Germany) and was maintained anaerobically on modified basal medium (Liou et al. 2005; Tanner 2007) at pH 5.75 with CO (100 %) as the sole gaseous substrate. This medium was composed of (per liter distilled water) the following compounds: yeast extract, 1 g; mineral solution (a source of sodium, ammonium, potassium, phosphate, magnesium, sulfate and calcium), 25 mL; trace metal solution, 10 mL; vitamin solution, 10 mL; resazurin, 1 mL; and cysteine-HCl, 0.60 g.

The mineral stock solution contained (per liter distilled water) 80 g sodium chloride, 100 g ammonium chloride, 10 g potassium chloride, 10 g potassium monophosphate, 20 g magnesium sulfate, and 4 g calcium chloride.

The vitamin stock solution contained (per liter distilled water) 10 mg pyridoxine, 5 mg each of thiamine, riboflavin, calcium pantothenate, thioctic acid, paraamino benzoic acid, nicotinic acid, and vitamin B12, and 2 mg each of d-biotin, folic acid, and 2-mercaptoethanesulfonic acid.

The trace metal stock solution contained (per liter distilled water) 2 g nitrilotriacetic acid, 1 g manganese sulfate, 0.80 g ferrous ammonium sulfate, 0.20 g cobalt chloride, 0.20 g zinc sulfate, and 20 mg each of cupric chloride, nickel chloride, sodium molybdate, sodium selenate, and sodium tungstate.

Bottle batch experiments

For batch experiments, 10 % seed culture in the early exponential growth phase, grown with CO as sole carbon source, was aseptically inoculated into 200-mL serum vials containing 100 mL medium at pH = 5.75. In order to remove oxygen, all the media in the bottles were boiled and later flushed with N2 while cooling down the medium. When the temperature of the medium reached 40 °C, 0.06 g cysteine-HCl was added as a reducing agent, and the pH was adjusted to 5.75 with 2 M NaOH while continuing flushing with N2. The bottles were then sealed with Viton stoppers and capped with aluminum crimps and were then autoclaved for 20 min at 121 °C. The bottles were maintained under anaerobic conditions. They were pressurized with 100 % CO to reach a total headspace pressure of 1.2 bar and were agitated at 150 rpm on an orbital shaker, inside an incubation chamber at 33 °C. Every 24 h, a headspace sample of 0.2 mL and 2 mL liquid sample were taken for CO measurements and to measure the optical density (ODλ = 600 nm), which is directly related to the biomass concentration. Besides, 1 mL of those 2 mL was centrifuged at 7000 rpm for 3 min in order to measure the concentration of soluble products in the supernatant, using the same methods as described in “Fermentation products” for the analyses of fermentation products in the continuous bioreactors. All experiments were carried out in triplicate.

Continuous gas-fed bioreactor experiments

Two bioreactor experiments were carried out in 2L BIOFLO 110 bioreactors (New Brunswick Scientific, Edison, NJ, USA) using the same medium as in the batch bottle experiments. Both experiments were done with 1.2 L optimized medium and CO (100 %) as the sole gaseous substrate, fed continuously at a rate of 10 mL/min using a mass flow controller (Aalborg GFC 17, Müllheim, Germany) and a microsparger used for sparging CO. The bioreactor with the medium was autoclaved, and when the temperature was below 40 °C, cysteine-HCl (0.60 g/L) was added, together with nitrogen feeding to ensure anaerobic conditions. The temperature of the bioreactor was maintained at 33 °C by means of a water jacket. Four baffles were symmetrically arranged to avoid vortex formation of the liquid medium and to improve mixing. A constant agitation speed of 250 rpm was maintained throughout the experiments. Ten percent seed culture in the early exponential growth phase, which was grown for 72 h with CO as sole carbon source, was used as the inoculum and was aseptically transferred to the bioreactor. The pH of the medium was automatically maintained at a constant value of either 5.75 or 4.75, through the addition of either a 2-M NaOH solution or a 2-M HCl solution, fed by means of a peristaltic pump. The redox potential was continuously monitored in each experimental run.

When the bioreactor reached its maximum production of acids, the pH in one of the reactors (experiment 1) was maintained at pH 5.75 while it was changed to pH 4.75 in the other reactor (experiment 2). Later, when most of the acids were consumed, part of the medium (around 600 mL) was replaced with the same amount of fresh medium in both bioreactors and the pH was maintained at 5.75 again. During the partial medium replacement procedure, the CO gas flow rate was maintained through the bioreactor and was even slightly increased in order to ensure maintenance of anaerobic conditions inside the bioreactor. Then, when the production of acids reached its maximum value, the pH of the bioreactor in experiment 1 was changed to 4.75.

Growth measurement

One milliliter liquid sample was daily withdrawn from the reactor, in order to measure the optical density (ODλ = 600 nm), using a UV–visible spectrophotometer (Hitachi, Model U-200, Pacisa & Giralt, Madrid, Spain). The measured absorbance allowed to estimate the biomass concentration (mg/L) by comparing it with a previously generated calibration curve.

Gas-phase CO and CO2 concentrations

Gas samples of 1 mL were taken from the outlet sampling ports of the bioreactors to monitor the CO and CO2 concentrations.

Gas-phase CO concentrations were measured using an HP 6890 gas chromatograph (GC, Agilent Technologies, Madrid, Spain) equipped with a thermal conductivity detector (TCD). The GC was fitted with a 15-m HP-PLOT Molecular Sieve 5A column (ID, 0.53 mm; film thickness, 50 μm). The oven temperature was initially kept constant at 50 °C, for 5 min, and then raised by 20 °C/min for 2 min, to reach a final temperature of 90 °C. The temperature of the injection port and the detector was maintained constant at 150 °C. Helium was used as the carrier gas.

Similarly, CO2 was analyzed on an HP 5890 gas chromatograph, equipped with a TCD. The injection, oven, and detection temperatures were maintained at 90, 25, and 100 °C, respectively.

Fermentation products

The water-soluble products, acetic acid, butyric acid, ethanol, and butanol, were analyzed for each of the two bioreactors from liquid subsamples (1 mL) every 24 h using an HPLC (HP1100, Agilent Co., USA) equipped with a 5 μm × 4 mm × 250 mm Hypersil ODS column and a UV detector at a wavelength of 284 nm. The mobile phase was a 0.1 % ortho-phosphoric acid solution fed at a flow rate of 0.5 mL/min. The column temperature was set at 30 °C. The samples were centrifuged (7000g, 3 min) using a centrifuge (ELMI Skyline ltd CM 70M07) before analyzing the concentration of water-soluble products by HPLC.

Redox potential

The redox potential was constantly monitored in each bioreactor using an Ag/AgCl reference electrode connected to a transmitter (M300, Mettler Toledo, Inc., Bedford, MA, USA) and maintained inside the bioreactor.

Results

Bottle batch experiments

In the batch experiments, C. carboxidivorans started growing immediately after inoculation, without any lag phase (Fig. 1a). A maximum biomass concentration of 0.130 g/L was reached after 30 h (Fig. 1a), while a maximum acetic acid concentration of 0.89 g/L was found after 45 h and a maximum concentration of butyric acid of 0.48 g/L had accumulated at the end of the experiment (Fig. 1b).

Batch experiment: a measured growth expressed in grams biomass per liter over time, with data represented as mean values ± standard deviations, and b production of metabolites, acetic acid (diamonds), butyric acid (squares), ethanol (triangles), and butanol (cross marks), expressed in milligrams per liter over time, with data represented as mean values ± standard deviations

On other hand, a maximum ethanol concentration of 0.48 g/L was reached, after 267 h. Its production did not seem to take place at the expense of any acetic acid consumption as that acid was basically not consumed during ethanol accumulation, although clostridia are known to be able to convert acids into alcohols in processes such as the ABE fermentation from carbohydrates (Jones and Woods 1986; Ndaba et al. 2015) as well as in some other fermentation processes such as CO bioconversion to acetic acid followed by the production of ethanol from the accumulated fatty acid (Abubackar et al. 2015). The alcohol was thus formed here directly from the conversion of CO. Although C. carboxidivorans is known to be able to produce butanol, that alcohol was generally not found or produced at low trace levels in these batch bottle assays.

The initial pH of the medium was 5.75 in this experiment. However, when the acetogenic phase started, acids were formed leading to medium acidification, as there was not any pH regulation. Therefore, the pH dropped gradually during the batch assays and reached a minimum value around 4.30 at the end of the experiment. Also, anaerobes are very sensitive to changes in redox potential. The reading oxidoreduction potential (ORP) values are directly linked to the pH of the medium, and a lower pH of the medium will result in less negative values of the redox potential.

Continuous gas-fed bioreactor experiments

Experiment 1

In this continuous CO-fed bioreactor experiment, C. carboxidivorans started growing immediately after inoculation, without any lag phase, similarly as in the batch assays. The growth and fermentation products followed a pattern common to acetogenic clostridia (Fig. 2a, b). After 96 h, the biomass reached its maximum value of 0.52 g/L (Fig. 2a) whereas the maximum concentrations of acetic acid and butyric acid, reached after 144 h, were 5.30 and 1.43 g/L, respectively (Fig. 2b).

Continuous gas-fed bioreactor experiment 1: a measured growth expressed in grams biomass per liter over time; b production of metabolites, acetic acid (diamonds), butyric acid (squares), ethanol (triangles), and butanol (cross marks), expressed in milligrams per liter over time; and c percentage CO consumption over time

The production of alcohols did also start quite soon after inoculation but initially at a quite slower rate than observed for the acids. Alcohols continued accumulating after the fatty acids had reached their highest concentrations. After 240 h, the production of alcohols leveled off, because ethanol and butanol had accumulated up to potentially inhibitory levels. By then, ethanol and butanol had reached quite high maximum concentrations of 5.55 and 2.66 g/L, respectively (Fig. 2b). A different behavior was observed than in the batch experiments, as ethanol production appeared to increase at the expense of acetic acid consumption, and both the decrease in acid concentration and increase in alcohol concentration occurred simultaneously. Similarly, butanol production appeared to take place at the expense of butyric acid conversion. Contrary to what was observed in the batch assay, in the present experiment with pH regulation and continuous CO supply, butyric acid was almost completely consumed (83 %) and 78 % of acetic acid was also converted. Besides, a rather high final concentration of butanol was reached (2.66 g/L), never reported before in the literature for this type of CO fermentation by clostridia.

After 247 h, part of the bioreactor medium (600 mL) was replaced by fresh medium in order to alleviate the potential inhibitory effect of the high concentrations of alcohols and to check if this partial medium renewal might promote a new acids and alcohols production cycle. The biomass was recycled in the bioreactor; thus, its concentration remained constant at 0.51 g/L. The concentrations of alcohols decreased as a result of the dilution effect due to medium replacement, reaching an ethanol concentration of 3.50 g/L and a butanol concentration of 1.70 g/L (Fig. 2b).

While the amount of biomass remained constant until 360 h, the concentrations of acids started to increase again. The maximum concentrations of acetic acid and butyric acid were reached after 336 h with values of 2.40 and 0.617 g/L, respectively (Fig. 2b). Despite maintaining the pH at 5.75, the formation of some alcohols started immediately, although at much lower rates than for the acids. The pH was later changed to 4.75 after 408 h in order to check if this could further improve the production of alcohols, as a lower pH is expected to be favorable to solventogenesis.

However, at that lower pH, the biomass concentration decreased while there was not any production of acids and alcohols nor any consumption of acids. Finally, the experiment was stopped after 504 h. At that moment, the biomass concentration had decreased to 0.32 g/L, and acetic acid and butyric acid concentrations were 1.04 and 0.28 g/L, respectively. The concentrations of alcohols were 4.41 g/L for ethanol and 2.3 g/L for butanol at the end of the experiment, which is significantly higher than in any previously reported study (Fig. 2b). Total net ethanol production in this experiment was 7.52 g corresponding to 6.66 g (in 1.2 L reactor medium) before partial medium replacement and 0.86 g after its replacement, and total net butanol production was 3.91 g corresponding to 3.19 g before partial medium replacement and 0.72 g after its replacement. This type of CO fermentation yields reproducible profiles.

During the experimental production phase, the specific rate of ethanol production was 0.12 g/h*g of biomass between 144 and 192 h, while the specific rate of butanol production was 0.06 g/h*g of biomass during that same period of time (Table 1). Other production and consumption rates are summarized in Table 1 as well.

Carbon monoxide consumption was also monitored during the experiment and is shown in Fig. 2c. A constant carbon monoxide loading rate was maintained throughout the experiment. Most of the time, the average CO consumption was close to 50 %, although higher percentages were observed in the early stages of the experiment, reaching the highest value of 81 % CO removal on the fourth day. It is worth mentioning that, as a general rule, the highest percentage substrate conversions are observed at high pH (5.75) and do then often exceed 50 % (up to 81 %), while conversion decreased when lowering the pH (4.75), which is also concomitant with some biomass decay. CO consumption also dropped within the first few hours after medium replacement.

During the first operation days, and for almost 1 week, the only carbon source for the production of metabolites and biomass is carbon monoxide. As explained above, C2 and C4 acids produced during the first stages become, later on, additional substrates and are then converted to the corresponding alcohols. During the first stage of the experiment, although part of the gaseous substrate is also used for biomass growth, if production of metabolites from CO is only considered during the first experimental stage, then the following reactions would take place:

This would result in CO2 to CO ratios (g/g) of 0.79 for reaction (1) (acetic acid production), 0.94 for reaction (2) (butyric acid production), and 1.04 for reactions (3) and (4) (ethanol and butanol production, respectively). CO2 to CO ratios could be measured experimentally and could be estimated to reach around 0.77, during the first week of operation, with around 10 % fluctuation as this is a dynamic system. This is in agreement with the above equations and theoretical ratios and shows a good fit between the experimental and theoretical substrate to product mass balance calculations.

The redox potential was constantly monitored during each experimental run. Except for the reducing agent added initially to the medium, its value was later on allowed to fluctuate naturally. In experiment 1, before replacing part of the medium, the redox potential (ORP) value was −180 ± 20 mV, while after partial medium replacement, it was −100 ± 10 mV. After the pH change to 4.75, ORP was −62.1 ± 20 mV, and finally at the end of the experiment, it became positive and reached +42.9 mV, which explains the complete inhibition of the anaerobic strain. Inhibition after pH modification could have been due to the fast decrease in pH from 5.75 to 4.75 resulting in an acid shock. As will be explained below, in experiment 2, pH was decreased gradually and no inhibition was observed, allowing to maintain active cells and a negative ORP.

Experiment 2

Similarly as in experiment 1, C. carboxidivorans started to grow immediately after seeding the reactor, without any lag phase. A pattern common for acetogenic clostridia for growth and fermentation products was here also observed (Fig. 3a, b). After 48 h, the biomass reached its maximum value of 0.33 g/L (Fig. 3a) whereas the maximum acetic acid and butyric acid concentrations were found after 3–4 days and were 4.10 and 1.44 g/L, respectively (Fig. 3b). As already observed in experiment 1, and as expected, growth and accumulation of acids were concomitant. It is worth observing that the maximum suspended biomass concentration in the liquid phase was somewhat lower in this experiment compared to experiment 1 because part of the bacteria remained sticked to the glass wall of the bioreactor, slightly above the upper liquid level.

Continuous gas-fed bioreactor experiment 2: a measured growth expressed in grams biomass per liter over time; b production of metabolites, acetic acid (diamonds), butyric acid (squares), ethanol (triangles), and butanol (cross marks), expressed in milligrams per liter over time; and c percentage CO consumption over time

After 72 h, once acetic acid accumulation leveled off, the pH of the medium was gradually and slowly decreased to 4.75 over a period of 48 h, in order to avoid any acid shock and inhibition. The pH value was decreased in order to check if this would stimulate solventogenesis. The rate of accumulation of alcohols increased, and their maximum production was reached after 216 h, with ethanol and butanol concentrations of 2.00 and 1.10 g/L, respectively (Fig. 3b). This increase was at the expense of acid consumption, and acetic acid and butyric acid concentrations had dropped down to 1.56 and 0.53 g/L respectively, after 216 h (Fig. 3b).

When the concentrations of alcohols stabilized, part of the medium of the bioreactor was replaced by fresh medium, similarly as in experiment 1, and the pH was increased to 5.75 again. As a result of the dilution effect, the concentrations of metabolites decreased to 1.03 g/L for acetic acid, 0.32 g/L for butyric acid, 1.4 g/L for ethanol, and 0.76 g/L for butanol. After partial medium replacement, the remaining concentrations of acids were consumed and converted into alcohols. Finally after 360 h, the biomass started decreasing down to 0.15 g/L and the experiment was stopped. By then, the final concentrations of acids and alcohols were 0.06 g/L acetic acid, 0.01 g/L butyric acid, 2.90 g/L ethanol, and 1.60 g/L butanol, showing a basically complete consumption of both acids and their conversion to alcohols (Fig. 3b).

Total net ethanol production in this experiment was 4.21 g corresponding to 2.40 g (in 1.2 L reactor medium) before partial medium replacement and 1.81 g after its replacement, and total net butanol production was 2.29 g corresponding to 1.32 g before partial medium replacement and 0.97 g after its replacement. These concentrations are somewhat lower than in experiment 1, most probably because of the somewhat lower suspended biomass concentration in this assay.

The specific rate of ethanol production was 0.16 g/h*g of biomass between 72 and 120 h, while the specific rate of butanol production was 0.07 g/h*g of biomass during that same period of time, which was thus slightly higher than in experiment 1 (Table 1). Other rates are summarized in Table 1.

Similarly as in experiment 1, a constant inlet carbon monoxide concentration was maintained during the study and CO consumption was monitored throughout experiment 2. Here again, on an average, close to 50 % of the gaseous carbon source was metabolized by the bacteria (Fig. 3c) with higher values during the first part of the study and when using a high pH, as also observed in experiment 1. The highest CO consumption reached 73 %, at pH 5.75, on the second day of operation.

In terms of redox potential, in experiment 2, when the pH was 5.75, the redox potential (ORP) value was −110 ± 10 mV, while after the pH change to 4.75, it was −80 ± 10 mV. Finally after medium replacement and pH increase again to 5.75, the ORP was −90 ± 10 mV. The gradual pH decrease, from 5.75 to 4.75, in this experiment allowed to avoid inhibition of the bacterial activity, and a negative redox potential could be maintained throughout this assay, contrary to what was observed at the end of experiment 1.

Discussion

In the batch bottle experiments, the maximum biomass concentration was reached after 48 h and the biomass concentration (g/L) was about half the value reached in experiment 2. That difference can be explained by the fact that in the batch assays, there was not any continuous feed of CO, resulting in carbon source limitation for the bacteria. Conversely, in experiments 1 and 2 in bioreactors, CO feeding was continuous, resulting in a higher availability of C source for the biomass. Also, in the batch bottle experiments, there was no continuous pH control. Therefore, the production of acetic acid and butyric acid during growth led to a natural and significant decrease of the pH of the medium. This ended up inhibiting bacterial growth and metabolite production. The initial pH of the medium was 5.75, whereas the final pH value was in the range of 3.80–4.00 for all the batch assays in bottles. C. carboxidivorans has an optimum pH value of 4.4–7.6 (Abubackar et al. 2011; Liou et al. 2005). As there was not any pH control in the batch experiments, its value reached a minimum which was below the optimum range. The lower pH value and lower concentration of C source explain the different growth behaviors between the batch experiments and the bioreactors with continuous CO supply.

In the three experiments, two different growth patterns were observed. First a fast exponential growth rate was observed, between 48 and 96 h in the bioreactors and between 0 and 36 h in the batch assays, concomitant with the acidogenic phase. Due to acid production in the Wood-Ljungdahl pathway, more ATP is produced during acidogenesis than during the production of alcohols (White 2007), which explains that growth and acid production from CO take place simultaneously.

In the case of the production of alcohols, in the batch assays, ethanol accumulation was observed but there was basically no butanol accumulation, whereas in the bioreactors (experiment 1 and 2), there was both significant ethanol and butanol production and the fermentation products followed a pattern common to acetogenic clostridia. It can be assumed that the pH had reached a value lower than the optimum range, which could have inhibited the bacterial metabolism before any significant butanol production could take place in the batch assays.

In both bioreactor experiments, acids were produced first, i.e., acetic acid and butyric acid, followed by ethanol and butanol production, with CO consumption around 50 % and reaching up to somewhat more than 80 % during the early acidogenic stage. Thus, the regulation of the pH value throughout the experiments can be considered to represent an important factor largely affecting both biomass growth and the production of metabolites.

In case of other clostridial strains able to produce only ethanol as alcohol (but no butanol), it was also observed that using different pH values is an effective strategy to promote alcohol production in multi-stage syngas fermentation, in which the acidogenesis and solventogenesis phases are separated in two reactors (Klasson et al. 1992). Here, in both bioreactor experiments, we tried to compare the effect of a pH change after the acidogenic phase. That way, in experiment 1, pH was maintained constant, whereas in experiment 2, the pH was changed to 4.75 to promote the solventogenic phase. No clear separate acidogenic and solventogenic phases were observed in C. carboxidivorans during experiment 2, whereas in experiment 1 (without pH change), more pronounced separate acidogenic and solventogenic phases were found. In their study with a different organism and for ethanol production, Klasson et al. (1992) performed a two-stage syngas fermentation experiment, with two reactors in series, using Clostridium ljungdahlii, with the first reactor at pH 5.0 and the second one at pH 4.0∼4.5 to promote ethanol production in that second reactor at the expense of acetate. By using two different pH, 30 times more ethanol production was obtained than in a single continuous gas fed bioreactor.

The rates of alcohol production were lower in experiment 1 than in experiment 2 at a lower pH. In case of ethanol, its production rate was 0.12 g/h*g of biomass in experiment 1, while it was 0.16 g/h*g of biomass in experiment 2. On the other hand, the rate of butanol production was 0.06 g/h*g of biomass in experiment 1 while it was 0.07 g/h*g of biomass in experiment 2. The same relationship was observed between the acid consumption rates, which were lower in experiment 1 than in experiment 2. The acetic acid conversion rates were 0.13 g/h*g of biomass and 0.15 g/h*g of biomass in experiments 1 and 2, respectively. On the other hand, butyric acid conversion rates were 0.03 g/h*g of biomass and 0.04 mg/h*g of biomass in experiments 1 and 2, respectively. So, these results show higher acid to alcohol conversion rates at pH 4.75 than at pH 5.75 (Table 1).

So far, only few studies have focused on butanol production from CO-rich gases in clostridia. In all few previous reports using C. carboxidivorans, butanol concentrations did generally range between a few milligrams per liter and hardly 1 g/L, while butanol concentrations up to 2.66 g/L were reached in the present study together with ethanol concentrations of 5.55 g/L. Bruant et al. (2010), performing a similar batch experiment as ours in our bottles assays, accumulated a minor, near negligible, amount of butanol (below 0.05 mmol) of a few milligrams. Phillips et al. (2015) checked different media in batch experiments and their maximum reported concentrations for ethanol and butanol were 3.25 and 1.09 g/L, respectively. In another study, Ukpong et al. (2012) checked the bioconversion of CO-rich gases by C. carboxidivorans in a gas-fed bioreactor reaching maximum ethanol and butanol accumulation of 2.8 and 0.52 g/L, respectively. In all those studies, the amounts of butanol and ethanol obtained with the same bacterial species were significantly lower than the values obtained in the present work. Overall, comparing the batch assays and the different bioreactor studies, it clearly appears that relatively high butanol-ethanol (B-E) accumulation can be reached when optimizing the experimental conditions. It is worth mentioning that, contrary to the ABE fermentation from carbohydrates in clostridia, here, no acetone is produced at all in CO or syngas fermentation in such acetogenic bacteria, which is interesting as butanol is the main desired end-product as a biofuel and attempts do generally need to be made in order to reduce acetone accumulation in the conventional ABE fermentation (Han et al. 2011).

In a nutshell, it can be concluded that (a) a high pH was favorable to CO conversion to fatty acids; (b) reducing the pH value stimulated the production of alcohols but had a profound negative effect on biomass production; (c) acetic acid and butyric acid are produced first and can then be converted to the alcohols (ethanol, butanol), with complete conversion at higher rates under acidic conditions; (d) contrary to the ABE fermentation, no acetone was formed here from the conversion of C1 gases; and (e) the experimental conditions in this study allowed to produce significantly more butanol and ethanol (B-E) than in any other study reported in the literature on the conversion of CO-rich gases.

References

Abdehagh N, Tezel FH, Thibault J (2014) Separation techniques in butanol production: Challenges and developments. Biomass Bioenerg 60:222–246. doi:10.1016/j.biombioe.2013.10.003

Abubackar HN, Veiga MC, Kennes C (2011) Biological conversion of carbon monoxide: rich syngas or waste gases to bioethanol. Biofuels Bioprod Biorefin 5:93–114. doi:10.1002/bbb.256

Abubackar HN, Veiga MC, Kennes C (2015) Carbon monoxide fermentation to ethanol by Clostridium autoethanogenum in a bioreactor with no accumulation of acetic acid. Bioresource Technol 186:122–127. doi:10.1016/j.biortech.2015.02.113

Ahmed A, Lewis RS (2007) Fermentation of biomass-generated synthesis gas: effects of nitric oxide. Biotechnol Bioeng 97:1080–1086. doi:10.1002/bit.21305

Balat M, Balat H (2009) Recent trends in global production and utilization of bio-ethanol fuel. Appl Energ 86(11):2273–2282. doi:10.1016/j.apenergy.2009.03.015

Bengelsdorf FR, Straub M, Dürre P (2013) Bacterial synthesis gas (syngas) fermentation. Environ Technol 34:1639–1651. doi:10.1080/09593330.2013.827747

Bruant G, Lévesque M-J, Peter C, Guiot SR, Masson L (2010) Genomic analysis of carbon monoxide utilization and butanol production by Clostridium carboxidivorans strain p7T. PLoS ONE 5(9):e13033. doi:10.1371/journal.pone.0013033

Bredwell MD, Worden RM (1998) Mass-transfer properties of microbubbles. 1. Experimental studies. Biotechnol Prog 14(1):31–38. doi:10.1021/bp970133x

Dürre P (2007) Biobutanol: an attractive biofuel. Biotechnol J 2:1525–1534. doi:10.1002/biot.200700168

Gowen CM, Fong SS (2011) Applications of systems biology towards microbial fuel production. Trends Microbiol 10:516–524. doi:10.1016/j.tim.2011.07.005

Han B, Gopalan V, Ezeji TD (2011) Acetone production in solventogenic Clostridium species: new insights from non-enzymatic decarboxylation of acetoacetate. Appl Microbiol Biotechnol 91:565–576. doi:10.1007/s00253-011-3276-5

Henstra AM, Sipma J, Rinzema A, Stams AJM (2007) Microbiology of synthesis gas fermentation for biofuel production. Curr Opin Biotechnol 18:200–206. doi:10.1016/j.copbio.2007.03.008

Jin C, Yao M, Liu H, Lee CFF, Ji J (2011) Progress in the production and application of n-butanol as a biofuel. Renew Sust Energy Rev 15:4080–4016. doi:10.1006/j.rser.2011.06.001

Jin Y, Guo L, Veiga MC, Kennes C (2009) Optimization of the treatment of carbon monoxide-polluted air in biofilters. Chemosphere 74:332–337. doi:10.1016/j.chemosphere.2008.10.001

Jones DT, Woods DR (1986) Acetone–butanol fermentation revisited. Microbiol Rev 50:484–524

Kennes C, Veiga MC (2001) Bioreactors for waste gas treatment. Kluwer Academic Publishers, Dordrecht, The Netherlands, 312 pp

Kennes C, Veiga MC (2013) Air pollution prevention and control: Bioreactors and bioenergy. J. Wiley, Chichester, UK, 549 pp

Kennes D, Abubackar HN, Diaz M, Veiga MC, Kennes C (2016) Bioethanol production from biomass: carbohydrate vs syngas fermentation. J Chem Technol Bioetchnol 91:304–317

Klasson KT, Ackerson CMD, Clausen EC, Gaddy JL (1992) Biological conversion of coal and coal-derived synthesis gas. Fuel 72:1673–1678. doi:10.1016/0016-2361(93)90354-5

Lee SY, Park JH, Jang SH, Nielsen LK, Kim J, Jung KS (2008) Fermentative butanol production by clostridia. Biotechnol Bioeng 101:209–228. doi:10.1002/bit.22003

Liu S, Qureshi N (2009) How microbes tolerate ethanol and butanol. New Biotechnol 26:117–121. doi:10.1016/j.nbt.2009.06.984

Liou JSC, Balkwill DL, Drake GR, Tanner RS (2005) Clostridium carboxidivorans sp. nov., a solvent-producing clostridium isolated from an agricultural settling lagoon, and reclassification of the acetogen Clostridium scatologenes strain SL1 as Clostridium drakei sp. nov. Int J Syst Evol Microbiol 55:2085–2091. doi:10.1099/ijs.0.63482-0

Mohammadi M, Najafpour GD, Younesi H, Lahijani P, Uzir MH, Mohamed AR (2011) Bioconversion of synthesis gas to second generation biofuels: a review. Renew Sust Energy Rev 15:4255–4273. doi:10.1016/j.rser.2011.07.124

Ndaba B, Chiyanzu I, Marx S (2015) n-Butanol derived from biochemical and chemical routes: A review. Biotechnol Reports 8:1–9. doi:10.1016/j.btre.2015.08.001

Phillips JR, Atiyeh HK, Tanner RS, Torres JR, Saxena J, Wilkins MR, Huhnke RL (2015) Butanol and hexanol production in Clostridium carboxidivorans syngas fermentation: Medium development and culture techniques. Bioresour Technol 109:114–121. doi:10.1016/j.biortech.2015.04.043

Tanner RS (2007) Cultivation of bacteria and fungi. In: Hurst CJ, Crawford RL, Garland JL, Lipson DA, Mills AL, Stetzenbach LD (eds) Manual of Environmental Microbiology. ASM Press, Washington, D.C, pp. 69–78

Shaw AJ, Podkaminer KK, Desai SG, Bardsley JS, Rogers SR, Thorne PG, Hogsett DA, Lynd LR (2008) Metabolic engineering of a thermophilic bacterium to produce ethanol at high yield. Proc Natl Acad Sci U S A 105:13769–13774. doi:10.1073/pnas.0801266105

Shen Y, Brown R, Wen Z (2014) Syngas fermentation of Clostridium carboxidivorans P7 in a hollow fiber membrane biofilm reactor: evaluating the mass transfer coefficient and ethanol production performance. Biochem Eng J 85:21–29. doi:10.1016/j.bej.2014.01.010

Schugerl K (2000) Integrated processing of biotechnology products. Biotechnol Adv 18:581–599. doi:10.1016/S0734-9750(00)00051-3

Ukpong MN, Atiyeh HK, De Lorme JM, Liu K, Zhu X, Tanner RS, Wilkins MR, Stevenson BS (2012) Physiological response of Clostridium carboxidivorans during conversion of synthesis gas to solvents in a gas-fed bioreactor. Biotechnol Bioeng 109:2720–2728. doi:10.1002/bit.24549

Wallner T, Miers SA, McConnell S (2009) A comparison of ethanol and butanol as oxygenates using a direct-injection, spark-ignition engine. J Eng Gas Turbines Power 131:032802. doi:10.1115/1.3043810

White D (2007) The physiology and biochemistry of prokaryotes. Oxford University Press, New York, 628 pp

Acknowledgments

This research was financially supported by the Spanish Ministry of Economy and Competitiveness (MINECO) as well as European FEDER funds, through project CTM2013-45581-R.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

This study was financed by the Spanish Ministry of Economy and Competitiveness (MINECO) and through European FEDER funds. All authors declare that they have no conflict of interest. This article does not contain any studies with human participants or animals performed by any of the authors.

Rights and permissions

About this article

Cite this article

Fernández-Naveira, Á., Abubackar, H.N., Veiga, M.C. et al. Efficient butanol-ethanol (B-E) production from carbon monoxide fermentation by Clostridium carboxidivorans . Appl Microbiol Biotechnol 100, 3361–3370 (2016). https://doi.org/10.1007/s00253-015-7238-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-015-7238-1