Abstract

The processing of citrus fruits into juice is one of the world’s largest processing industries. The by-products of this industry are about 50 % of the raw processed fruit. This not only wastes a resource of potential value, but also causes disposal problems. The aim of this work was to study the characteristics of oils extracted from a mixture (MX) of citrus seeds (CS) and citrus peels (CP) using hexane and supercritical carbon dioxide (SC-CO2) so that those by-products can be valorized effectively. The SC-CO2 extraction conditions were 45 and 60 °C, 200 and 250 bar while for hexane was 70 °C. Hexane showed significantly (P < 0.05) higher yield than SC-CO2. The chemical composition was analyzed by GC–MS and phytosterols, monoterpenes, sesquiterpenes and oxygenated monoterpenes were the main compounds of the oils. The fatty acid composition was determined by GC and linoleic acid was the major fatty acid. The oxidative stability (OS) was performed by Rancimat and the hexane extracted oils showed higher OS. The antioxidant activity was tested with DPPH and ABTS assay and SC-CO2 extracted oils showed higher activity with IC50 values of 3.86 and 4.00 mg/ml respectively for MX and CP oils. Antimicrobial activity was tested for both extracted oils against gram positive and gram negative bacteria with SC-CO2 extracted oils exhibiting better inhibition. From this study, we can say that the citrus by-products can be valorized by combining CS and CP which could give the oils with potentiality to be used in many applications.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The citrus fruit of the family Rutaceae is one of the most grown fruit worldwide. It is broadly grown in the tropical and subtropical parts of the world, and many other regions, with a yearly production of about 102 million tons [1]. Besides their huge size consumption as fresh fruits, the Citrus fruits are primarily processed into juice. The by-products of this industry including seeds, peels and pulps are around 50 % of the unprocessed fruits [2]. Consequently, this not only wastes useful resources, but also poses a problem for management, pollution, and environmental issues, due to microbial spoilage [3]. These by-products could be turned into an asset since some studies successively showed their potentiality in many areas such as in food, pharmaceuticals, perfumery and cosmetic industries due to the biomaterials they contain [4, 5].

Citrus peels (CP) contain a high concentration of bioactive compounds. These compounds have been reported to have high antioxidant activity and exert antimicrobial effects against food borne pathogens [6, 7] due to their high contents of terpenoids, coumarins, phenolic acids and flavonoids. One product among a variety of products which can be obtained from CP is essential oils. Citrus essential oils have extensive applications. Principally, they serve as aroma flavor in various food products such as beverages, dairy products, soft drinks, etc. [8]. The pharmaceutical industries use those essential oils as flavoring agents to cover unlikable tastes of drugs. Furthermore, the low volatile essential oil components play a key role in perfumes and cosmetics [8].

Citrus seeds (CS) is another by-product of citrus fruits processing, even though many researchers have drawn much attention to the CP and their essential oils, the importance of CS has been also studied due to the presence of diverse compounds that can be useful for adding value to many products [9]. The chemical composition, the characteristics and structure specifics of CS oils lend to a fascinating features such as a semi-siccative property [10].

Among the different techniques that have been employed to extract the oils from citrus by-products, distillation and solvent extractions are common [11]. However those techniques present some disadvantages including long extraction time, volatile compounds loss, residues of toxic substances and degradation of unsaturated compounds due to high temperature [12, 13]. The supercritical carbon dioxide (SC-CO2) extraction of natural products has recently drawn many researchers. The SC-CO2 extraction is not only the environment friendly extraction, but also the minimum degradation of bioactive compounds (since CO2 has a close-room critical temperature: 31 °C), and the prospect of getting solvent-free products [14, 15]. Also, in SC-CO2 extraction, the solvating power of SC-CO2 fluid can be increased or decreased by manipulating pressure and/or temperature, giving a really high selectivity. More importantly, the separation of dissolved solutes and SC-CO2 could be simply done by depressurization [16]. Therefore the use of SC-CO2 extraction can not only result the extract of high quality but also it can be an arsenal for elimination or notably decrease the necessity for eco- unfriendly organic solvents [17].

Although many studies have been dedicated to the study of CP and CS [18–20], there is still scarcity of information on the possible combination of CP and CS either by using solvent or SC-CO2 extraction. This combination of CP and CS may not only lead to the increase of the bioactivity of resulting oils due to synergistic activity among the compounds they contain but also it may enhance the availability of the active compounds [21].

Therefore, the purpose of the present work was threefold: First, to extract the oils from CS, CP and mixture (MX) of CS and CP by SC-CO2 and hexane. Second, to study the characteristics (chemical and fatty acids composition, physical properties, oxidative stability, antioxidant and antimicrobial activity) of the extracted oils and to assess whether the oil from MX has a potential bioactivity so that it can be used for different applications. Moreover, we compared the characteristics of oils extracted by hexane and those extracted by SC-CO2.

Materials and Methods

Chemicals

Hexane and ethanol were bought from SK CHEMICALS (Busan, South Korea). 1,1 diphenyl-2-picryl-hydrazyl (DPPH), 2,2′-azinobis-(3-ethylbenzothiazoline-6-sulfonic acid) diammonium salt (ABTS), 6-hydroxy-2,5,7,8-tetramethylchroman 2-carboxylic acid (trolox) and Mueller–Hinton agar (MHA) were purchased from Sigma Aldrich (Busan, South Korea). Potassium persulfate (K2S2O8) was purchased from Samchun Company (Busan, South Korea). Carbon dioxide (99.99 % purity) was obtained from KOSEM Company (Busan, South Korea). All the chemicals and reagents used were of HPLC and analytical grade.

Plant Material

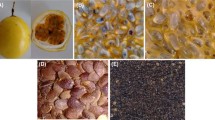

The citrus fruits (Citrus ichangensis × C. reticulata), common name: yuza, provenance: Nam He (Busan, South Korea), season: Nov–Jan (2014) were bought and given kindly by Y.G, Co. All the fruits were of eating quality and without blemishes or damage.

Sample Preparation

Citrus fruits were cleaned using tap water, peeled off and the peels and seeds were collected. The CP were cut and dried in a freeze dryer at −50 °C for 4 days. The CS were cleaned using tap water and oven dried at 103 °C until the weight become constant. Prior to extraction, the dried plant materials (namely CP and CS) were ground with a blender and sieved using a 710 µm metal sieve.

Extraction Procedure

Solvent Extraction

The powders of CP, CS and MX (mixing ratio: 60:40, for CP and CS respectively) were extracted using hexane (10 g of powder sample/200 ml of 95 % hexane) in a Soxhlet apparatus at 70 °C for 20 h. The oil was further recovered by evaporating off the solvent under vacuum at 45 °C using rotary evaporator (Model N-1100, Eyela, Japan) and remaining solvent was removed off by oven drying at 50 °C for 1 h.

The yield of extracted oil was calculated with the following formula:

Supercritical Carbon Dioxide Extraction

The flow diagram of the equipment used for SC-CO2 extraction is shown in Fig. 1. 100 g of powder sample of CP, CS and MX (mixing ratio: 60:40, for CP and CS respectively) was placed in the extractor vessel and cotton piece was placed at bottom and top end of the extraction vessel to avoid any possible carryover of sample materials. The extraction vessel was a stainless steel high pressure cylinder with a water heating jacket and thermostat was used to measure the temperature. The back-pressure regulator (BPR) was used to measure the pressure.

The CO2 was pumped up by a high pressure pump of a maximum capacity of 8.328 l/h with a cooling head at constant flow rate, passed through heat exchanger and directed to the bottom of the extraction vessel in the form of upflow configuration. The CO2 and oil in the SC state left the extractor and reached the valve, where the pressure was decreased. The oil was received in glass tube connected to the valve which was kept in ice packed column whereas CO2 left through the gas meter. SC-CO2 extraction was done at temperatures of 45 and 60 °C, pressure of 200 and 250 bar and CO2 flow rate of 27 g/min and the extraction time of 2 h.

Fatty Acids Composition Determination by Gas Chromatography

The fatty acid methyl esters (FAMEs) were prepared by following the method developed by Metcalf et al. [22]. The FAMEs were then analyzed using a gas chromatograph (Agilent Technologies model 6890, Wilmington, USA) coupled with a flame ionization detector. The column used was a fused silica BPX70 column, 100 m length × 0.25 mm i.d. 0.2 µm of film thickness (Supelco, Bellefonte, USA). The oven temperature was held at 130 °C during separation; both detector and injector were held at 250 °C. The nitrogen was used as carrier gas with a flow rate of 1.0 ml/min. 1.0 µl of methyl esters of free fatty acids were injected by an auto injector. The compounds were identified by comparison of retention time with standard fatty acid methyl esters mixture (Supelco™, USA).

The Chemical Composition of Extracted Oils by GC–MS

GC–MS analyses of extracted oils were performed on a gas chromatograph coupled to a mass spectrometer (GCMS-QP2010 Ultra, Shimadzu, Japan) with electron impact ionization (70 eV). A DB-5MS UI capillary column (30 m × 0.25 mm, 0.25 µm film thickness; Agilent Technologies, Hewlett–Packard, CA, USA) was used. The temperature program used was: 60 °C for 2 min, 60–200 °C at 10 °C/min, 200–325 °C at 5 °C/10.5 min and 325–40 °C at 10 °C/min. The helium was used as carrier gas with a flow rate of 1.0 ml/min; split ratio was 100:1; mass range was 25–600 m/z.

Physical Properties

Color

The Color of the extracted oils was determined by a reflectance tintometer (Lovibond RT Series, model SP60, UK). The values were expressed as L* value as being the lightness of a sample; a* value represents green (−) to red (+); the b* value describes blue (−) to yellow (+).

Viscosity

Viscosity measurements of extracted oils were done by a viscometer (model LV DV-II + P—Brookfield, Middleboro, MA, USA), spindle (25) and only 20 ml of oil was used. It was performed at a temperature of 20 °C with 12 rpm. The viscosity was expressed in cP (centipoise).

Oil Quality and Stability

Peroxide and acid values were determined according to official AOCS methods [23]. Oxidative stability index (OSI) was determined at 120 °C with an air flow of 20 l/h using a 743 Rancimat (Metrohm, Herisau, Switzerland). The sample (3 g) of extracted oils was weighed out in the reaction vessel and then placed in an electric heating block. A flow of air was supplied to the oil samples and volatile organic acids contained in a current of air from the oil sample were gathered in a measuring vessel containing distilled water (60 ml). As oxidation was going on, the conductivity of the water was automatically measured and the results were expressed as induction time (h).

Antioxidant Activity Determination

DPPH Radical Scavenging Assay

The DPPH assay was determined in accordance with a method developed by Brand-Williams et al. [24] with some modifications. 0.1 ml of extracted oil was added to 2.9 ml of a 0.2 mM ethanol DPPH radical solution. After 30 min at ambient temperature (in dark), the absorbance was read at 517 nm using UV–vis spectrophotometer (UVmini-1240, SHIMADZU, JAPAN). The percent of scavenging activity was calculated using the following formula:

where Acontrol and Asample are absorbance of control and sample respectively.

ABTS·+ Radical Scavenging Assay

This was determined by using the ABTS free radical decolorization assay described by Re et al. [25] with some modifications. In brief, the pre-formed radical monocation of ABTS was obtained by reacting ABTS solution (7 mM) with 2.45 mM potassium persulfate. After 14 h in the dark at ambient temperature, the solution was diluted with ethanol to obtain the absorbance of 0.7 ± 0.2 at 734 nm. The extracted oils and trolox were separately dissolved in ethanol at different dilutions. An aliquot of 0.2 ml of undiluted oil and/or of each dilution was added to 1.8 ml of ABTS free radical cation solution. After 1 h the absorbance was measured at 734 nm using UV–vis spectrophotometer.

The percent of scavenging activity was calculated using the previous formula.

A percent inhibition against concentration curve was plotted and the required concentration of oil for 50 % inhibition was determined and expressed as IC50 value.

Antimicrobial Activity

Test Microorganisms

The antimicrobial activity of the extracted oils was tested against pathogenic bacteria. These microorganisms include two Gram-positive bacteria: Staphylococcus aureus KCCM 11335 and Bacillus cereus ATCC 13061; two Gram-negative bacteria: Salmonella typhimurium KCCM 11862 and Escherichia coli ATCC 25922. All bacterial strains were purchased from the Korean Culture Center of Microorganisms (KCCM), South Korea.

Disk Diffusion Assay

The antibacterial activity of extracted oils was performed with the method of disc diffusion. MHA media was prepared and poured into sterilized disposable Petri dishes under aseptic conditions. The plates were inoculated with 100 μl of bacterial suspensions (1 × 107 CFU/ml) and spread using sterile cotton swabs. Next, filter paper discs (6 mm Ø; Whatman #1) were placed on the surface of Petri dishes and impregnated with 15 µl of extracted oils. After staying at 4 °C (2 h), all Petri dishes were incubated at 37 °C overnight and the diameter of zone inhibition (in mm) was recorded.

Statistical Analysis

The results were reported as mean ± SD of three replicates. The analysis of variance (ANOVA) was performed to compare the results using SPSS for Windows (version 20.0.0, SPSS Inc.). Turkey’s multiple-range tests were used to compare the significant differences (P < 0.05) of the mean values.

Results and Discussion

Yield of Extracted Oils

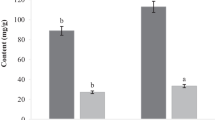

The yield (% w/w) of extracted oils are shown in Fig. 2. The yield of extracted oils from CS, CP and MX using hexane was 24.94, 2.07 and 10.02 %, respectively. Whereas the yield of extracted oils of CS, CP and MX using SC-CO2 extraction at 200 bar and 45 °C was 15.20, 1.61 and 8.85 %, respectively. Again the SC-CO2 extraction at 250 bar and 60 °C showed the yield of 19.6, 1.78 and 11.3 % for CS, CP and MX, respectively. For all samples, the yield was significantly higher (P < 0.05) for hexane than SC-CO2 extraction except for MX where the SC-CO2 extraction at 250 bar and 60 °C showed the highest yield. This is due to the fact that unlike carbon dioxide, hexane is non-selective, extracting more phospholipids, unsaponifiable matters and other substances. Therefore the amount of matter yielded by using hexane was probably increased by those matters. Under SC-CO2 extraction at 200 bar and 45 °C, due to the selectivity of SC-CO2, the solubility of some compounds in SC-CO2 is lower than hexane, furthermore some compounds can be easily soluble in hexane than SC-CO2 under those conditions, for example the solubility of phospholipids was found to be almost impossible in SC-CO2 regardless of conditions that can be used [10, 26]. However, the yield showed an increase when the pressure and temperature were raised up to 250 bar and 60 °C for SC-CO2 extraction. This was also shown well for MX where the yield for SC-CO2 extraction at 250 bar and 60 °C was even higher than hexane. This increase of yield resulting on the increase of pressure and temperature for SC-CO2 extraction might be explained by considering the two mechanisms of temperature on solubility. In fact the vapor pressure of the solute increases always with temperature, whereas the density (or solvent power) of SC-CO2 decreases. In order to elucidate the effect of these mechanisms on the solubility, the crossover pressure can be taken into consideration. This is a pressure around which the convergence of isotherms at different near-critical temperatures occurs. Below the crossover pressure, the density effect dominates, and in this case the solubility diminishes with augmenting the temperature. Contrary at pressures above the crossover pressure, the vapor pressure effect dominates; thus the solubility increases with temperature [27–29]. Therefore matching this with our results it might be worth to say that at that condition (250 bar and 60 °C) the vapor pressure of the solutes might dominate the effect of solvent density decrease hence the solubility of solutes increases which consequently might increase the yield. However since the extraction system was composed of multi-solutes, it is somehow difficult to figure out the exact crossover pressure for individual solute and/or the whole system.

In addition, the non selectivity of hexane extraction also reflects how the refining processes necessary for SC-CO2 extracted oils would be even considerably lesser than those required for hexane extracted oils.

Fatty Acid Composition

Table 1 shows the fatty acids composition of extracted oils both with SC-CO2 and hexane. Generally, hexane extracted oils showed high composition of saturated fatty acids, while the SC-CO2 extracted oils showed high composition of unsaturated fatty acids. Among saturated fatty acids, palmitic acid, stearic acid and undecanoic acid were identified. For all extracted oils palmitic acid was predominant with 21.72 and 26.93 % for CS and MX oil extracted by hexane, respectively. On the other hand, palmitic acid was 17.67 and 18.38 % for CS and MX, respectively for the oils extracted by SC-CO2 at 200 bar and 45 °C. Whereas for SC-CO2 at 250 bar and 60 °C, the palmitic acid was shown to be 20.01 and 19.77 % for CS and MX, respectively. The unsaturated fatty acids viz. oleic acid, linoleic acid, elaidic acid and linolenic were identified and linoleic acid showed highest composition. These differences could be due to the operating temperatures of the two extractions (45 °C for SC-CO2 and 70 °C for hexane extraction), which could result the minimal degradation and higher recovery of unsaturated fatty acids with SC-CO2 than hexane extraction [30]. However even though there was a slight difference between SC-CO2 at 200 bar and 45 °C and SC-CO2 at 250 bar and 60 °C in terms of fatty acid composition, the difference was not pretty remarkable unlike hexane extraction which showed that these conditions (250 bar and 60 °C) did not affect so much the fatty acid composition.

The Chemical Composition of Extracted Oils

The results of chemical composition of extracted oils are given in Table 2. The total number of compounds identified in the oils from CS, CP and MX extracted by hexane were 11, 12 and 14 representing 82.11, 93.16 and 98.66 % of the total peak area respectively. On the other hand, the total number of compounds identified in the oil from CS, CP and MX extracted by SC-CO2 at 200 bar and 45 °C were 8, 13 and 14 representing 82.48, 97.94 and 98.08 % of the total peak area respectively. Moreover, the SC-CO2 extraction at 250 bar and 60 °C showed a total number of 16, 18, 22 compounds for CS, CP and MX respectively. Generally, CS oils were particularly rich in phytosterols, while the oils from CP and MX were rich in monoterpenes hydrocarbons, sesquiterpenes hydrocarbons and oxygenated monoterpenes hydrocarbons. The main phytosterols identified in the oil extracted from CS were β-sitosterol, campesterol and ∆-avenasterol regardless of extraction method.

As far as the composition of the extracted oils of CP is concerned, monoterpene hydrocarbons were the main compounds for both extraction methods and conditions with limonene and β-myrcene as the major components. Sesquiterpene hydrocarbons constituted the second major portion of the oils with γ-terpinene as the major component, while the oxygenated monoterpenes hydrocarbons were only linalool and terpineol. For the oil extracted from MX, it was mainly composed of monoterpene hydrocarbons, sesquiterpenes, oxygenated monoterpene hydrocarbons and some phytosterols as well. As mentioned the total number of compounds was increased for the oils extracted by SC-CO2 extraction at 250 bar and 60 °C compared to SC-CO2 at 200 bar and 45 °C). As discussed above, once again this increase might be a result of the vapor pressure of the solutes which might predominate the effect of solvent density decrease hence the increase of solubility of the solutes which as consequence might allow the larger number of compounds to be extracted. For instance, as can be seen on Table 2, the psoralens (like auraptene) which constitute the non volatile part of citrus essential oils were shown in the oils extracted by SC-CO2 at 250 bar and 60 °C while they were not present in the oils of SC-CO2 extraction at 250 bar and 60 °C. Thus indicates how the SC-CO2 at 250 bar and 60 °C might even allow the extraction of dense molecules [31].

Physical Properties

The results for color and viscosity measurements are presented in Table 3. In general, there was no substantial difference in viscosity of extracted oils. The viscosity of extracted oils ranged between 78 and 80 cP and there was no significance difference among them. Regarding the color, for both extraction methods the oils obtained from CS and MX showed higher L* and b* values compared to CP. In addition the L* value reflecting the lightness was found to be higher in SC-CO2 extracted oils than hexane extracted ones regardless of raw material. For instance, the L* value for CS and MX oil was significantly decreased from 27.74 (200 bar and 45 °C) and 17.80 (250 bar and 60 °C) to 23.66 and 9.05 for hexane, respectively. This low L* value for hexane extracted oils which even appeared to be darker than the SC-CO2 extracted oils might be attributed to the fact that hexane might extracted more pigments than SC-CO2. Even though the color of vegetable oils is often associated with the pigments in raw materials, there could be a possibility that hexane could extract even some other matters (like gums) along with the oil which could make hexane extracted oil darker than that of SC-CO2.

Oil Quality and Stability

Table 4 shows some quality characteristics and the oxidative stability of the extracted oils obtained by hexane and SC-CO2. The average acid and peroxide values ranged between 0.70–1.63 mg KOH/g and 0.52–0.89 meq/kg, respectively. Extracted oils showed significantly higher (P < 0.05) acid and peroxide values in hexane than SC-CO2 extraction. Considering those quality characteristics, these differences could be mainly originated from the operating temperatures of the two extraction processes (for example 45 °C for SC-CO2 vs 70 °C). The high temperature for longtime involved in hexane extraction might contribute to triglycerides break down into fatty acids leading to an increase in the free fatty acids. Therefore the amount of free fatty acids in the hexane extracted oils was increased which could consequently increase the acid value in the hexane extracted oils. Likely the operating conditions for SC-CO2 (at 250 bar and 60 °C) seemed to affect the acid value. Moreover, there was a significance difference (P < 0.05) in terms of peroxide value between those extracted by hexane and SC-CO2. Like for acid value, this might be due to process temperature, since high temperature was used for hexane extraction this could be contribute to the formation of peroxides. These results converge on those reported by other authors for seed oils who found that the oils obtained by hexane extraction presented higher acid and peroxide values than oils obtained by SC-CO2 [32].

The results of OS of the extracted oils are presented in Table 4. Unlike acid and peroxide value, SC-CO2 extracted oils were less stable than hexane extracted oils. The induction time was 2.15 and 3.45 h for hexane, 1.28 and 2.93 h for SC-CO2 (at 200 bar and 45 °C) and 1.13 and 3.27 h for SC-CO2 (at 250 bar and 60 °C) for CS and MX oils, respectively. The OS of oil depends on many factors; the number of unsaturated fatty acids present in the oil is one of those factors [33]. As the double bonds number increases, the rate of oxidation increases. By matching this factor with our results it can be seen in Table 1 that the percentage of unsaturated fatty acids is higher for SC-CO2 extracted oils than hexane extracted oils. Hence this high proportion of unsaturated fatty acids might have contributed to the instability of the SC-CO2 extracted oils. More importantly, this difference in stability might be also related to the phytosterols profile. The phytosterols including sitosterol, stigmasterol, campesterol and ∆-Avenasterol were found to be higher in hexane extracted oils than in SC-CO2 (Table 2). This might have had an impact on the OS since the effect of these phytosterols on stabilizing oils has been pronounced by many authors [34, 35]. They reported that the phytosterols, particularly ∆-Avenasterol may act as antioxidants and antipolymerization agents in oils. Therefore the high OS of hexane extracted oils might be related with their high phytosterols content. In addition, another possible reason for this difference in stability could be the phospholipids content. The role of phospholipids contents in the stability of oils has been explained by many previous authors [26]. They reported that phospholipids may act as an oxygen barrier at the oil/air interface, and thus reduce the rate of oxygen uptake by the sample during the oxidation. Even though, the phospholipids content was not analyzed in this study, it is known that hexane can extract the phospholipids, while phospholipids are insoluble in SC-CO2. Thus this might be among the reason why hexane extracted oils showed higher OS.

However, as shown in Table 4, the induction time increased dramatically from 1.28 and 1.13 h for CS oil to 2.93 and 3.27 h for MX oil for SC-CO2 extraction (200 bar, 45 °C and 250 bar, 60 °C) respectively. Also the induction time was increased up to 3.95 h (data not shown) when the proportion of CP in MX was increased (from 60 to 75 %). This increase in stability might be attributed to the fact that CP contain oxygenated monoterpenes hydrocarbons and other volatile compounds which can either act as antioxidants alone or by their synergistic effect, thus the stability was improved. These results concur with the findings of earlier workers for the role of CP extract on the stabilization of oils and fats [36].

Antioxidant Activity

The results in Fig. 3 show the antioxidant activity (as percentage) of extracted oils. In general, the antioxidant activity changed significantly (P < 0.05) depending on the extraction conditions and the type of sample used for extraction. It is clear from these results that the SC-CO2 extracted oils showed higher antioxidant activity than hexane extracted oils. The antioxidant activity varied between 32.82 and 76.33 % for hexane extracted oils, 36.28–87.12 % for oils extracted by SC-CO2 (at 200 bar and 45 °C) and 36.25–89.51 % for SC-CO2 (at 250 bar and 60 °C) extracted oils, irrespective of type of method used for analysis (ABTS or DPPH). For hexane extracted oils, the antioxidant activity was in the following order: MX oil > CP oil > CS oil. For SC-CO2 extracted oils, the antioxidant values varied in the following order: CP oil > MX oil > CS oil.

The IC50 values are presented in the Table 5. Low IC50 corresponds to a strong antioxidant activity. Generally, the IC50 value was significantly (P < 0.05) lower (high antioxidant activity) for SC-CO2 extracted oils than hexane extracted oils. The lowest IC50 value was recorded for MX oil (SC-CO2 at 250 bar and 60 °C) and CP oil (SC-CO2 at 200 bar and 45 °C) with 3.86 and 4.00 mg/ml respectively whereas for hexane those same oils showed IC50 value of 4.62 and 4.80 mg/ml, respectively. The CS oils showed the highest IC50 values (low antioxidant activity) with 7.72, 7.42 and 7.47 mg/ml for hexane, SC-CO2 (200 bar and 45 °C) and SC-CO2 (250 bar and 60 °C) respectively.

This difference between hexane and SC-CO2 extracted oils might be explained by the fact that the SC-CO2 can extract more oxygenated hydrocarbons monoterpenes than hexane which contribute greatly to the antioxidant activity. For instance the oxygenated monoterpenes (e.g., linalool) is higher in the oils extracted by SC-CO2 (at 200 bar and 45 °C) than in hexane extracted oils. However, the antioxidant activity might not be attributed only to the oxygenated compounds because some furanocoumarins and some phytosterols can contribute also to the scavenging capacity for free radicals. Not only to act alone but also some studies revealed the synergistic effect between those compounds when they act together. On the other hand, the highest IC50 value (low antioxidant activity) of CS oils might be ascribed to their lack of terpenes and terpenoids compounds. Moreover, higher temperature for longtime might also provoke the degradation of some compounds for hexane extraction. Cacace and Mazza [37] reported that an extraction temperature of >50 °C can cause the denaturation and affect the stability of some active compounds, so it can make sense to say that the temperature which was used during hexane extraction could have a negative influence on the antioxidant activity. Nevertheless, the IC50 value of SC-CO2 oil (250 bar and 60 °C) was higher than SC-CO2 oil (200 bar and 45 °C). This might be due to the presence of other minor components in SC-CO2 oil (250 bar and 60 °C) which might intervene to the antioxidant activity.

In addition, the removal of residual solvent by drying after evaporation could affect the composition of the hexane extracted oils since some important minor volatile compounds might be lost, which could adversely affect the antioxidant activity of hexane extracted oils [38].

However, IC50 values of extracted oils are lower than those reported by Lagha-Benamrouche et al. [39] (0.568–0.901 mg/ml) for orange peels and much lower than that of trolox (0.28 mg/ml). This could be likely attributed to the fact that the flavonoids and phenolic acids which are known to contribute a lot to the antioxidant activity of citrus peel and seeds extracts could not fully extracted for the reason that they are polar compounds. Similarly, several factors can have influence on the overall antioxidant activity such as variety, environmental conditions in which they were grown, the degree of fruit ripening and genetic factors [40, 41] as well as many parameters related to the extraction method (temperature, time contact, etc.) [42].

Antimicrobial Activity

The results of the disk diffusion assay of the extracted oils are summarized in Table 6. Generally, the extracted oils showed significantly (P < 0.05) higher inhibition for gram positive bacteria than gram negative bacteria. Also the hexane extracted oils showed significantly (P < 0.05) lower inhibition than SC-CO2 extracted oils. The highest antibacterial activity was obtained with the oil from MX extracted by SC-CO2 (200 bar and 45 °C) against B. cereus and SC-CO2 (250 bar and 60 °C) against S. aureus with inhibition zone diameter of 16 mm. Then followed by the CP oils extracted by SC-CO2 (200 bar and 45 °C) and SC-CO2 (250 bar and 60 °C) which showed good inhibition against B. cereus with inhibition zone diameters of 15 and 14 mm, respectively. As far as gram negative bacteria were concerned, the inhibition zone diameters of oils extracted from MX and CP by SC-CO2 (200 bar and 45 °C) against E. coli were 11 and 10 mm respectively, while they showed 11 mm against S. typhimurium. Again those same oils showed 9 and 10 mm for E. coli whereas 11 and 12 mm for S. typhimurium respectively when extracted by SC-CO2 (250 bar and 60 °C). Unlike for gram positive, all oils extracted by hexane did not demonstrate any inhibition against any of the target gram negative bacteria.

This less susceptibility of gram negative bacteria to the action of extracted oils was perhaps due to the reason that they have an external membrane enclosing the cell wall, which limits the hydrophobic compounds of the oil to diffuse through its lipopolysaccharide covering, therefore reduces the antimicrobial activity. This has also been revealed by other researchers who reported that gram-negative bacteria are less sensitive to the plant extracts than gram-positive bacteria [43]. Regarding the type of extracted oils, it was pretty remarkable that the oils extracted by SC-CO2 exhibited better antimicrobial activity than hexane extracted oils. Volatile compounds especially sesquiterpenes hydrocarbons and oxygenated monoterpenes were also reportedly as important compounds for bacteria inhibition. These compounds play an important role in bacteria inhibition due to their hydrophobic property, which make them able to partition in the lipids of the bacterial cell membrane and mitochondria, distracting the structures and causing them more permeable and leaky which leads to an outflow of proteins and other cell contents and consequently the bacteria dies [44]. So, the high content of those compounds in SC-CO2 extracted oils could have played a role. As far as extraction methods are concerned, it can be understood that there might be a loss of some minor volatile compounds during solvent removal, which could negatively affect the activity since those minor compounds are critical to the activity, therefore the hexane extracted oils showed lower antimicrobial activity than SC-CO2. Interestingly the MX oil showed a little bit high antimicrobial activity compared to CP oil, this might be due to the presence of other compounds (like tocopherol, sterols, etc.) which could contribute to the synergism with the volatile ones and increase the overall antimicrobial activity [44]. However, it is somehow difficult to figure out the individual role of each compound for inhibition of those bacteria since not only major compounds can contribute to the inhibition but also even some minor compounds might involved due to synergism or antagonism effects between those compounds or specificity of some compounds to certain microorganisms [44, 45].

Conclusion

The processing of citrus fruits generates the by-products that are rich sources of bioactive substances. In this study the characteristics of oils extracted from a mixture of citrus by-products have been studied. In general, the SC-CO2 and hexane extracted oils were significantly different (P < 0.05). It appeared that the yield in hexane extraction was higher than SC-CO2 extraction which in turn might be ascribed to the non selectivity of hexane. Since the evaporation and refining process which is necessary in hexane extraction is not needed for SC-CO2, it is clear that this could substantially save energy for SC-CO2 which could make SC-CO2 more economical than hexane extraction. More importantly, shorter extraction time (2 h for SC-CO2 vs 20 h for hexane) and its undisputed environmental friendliness make SC-CO2 a better extraction technique than solvent extraction.

Moreover, the results indicated that the oils extracted by SC-CO2 are rich in unsaturated fatty acids compared to hexane extracted oils; hence their promising alternative to be applied in food industries. One drawback of these SC-CO2 oils is their low oxidative stability compared to hexane extracted oils. However, it was interestingly revealed that this problem can be overcome by combining CS and CP. In addition, the MX oils showed higher potentiality in terms of antioxidant and antimicrobial activity, which reflects how MX oil can be a tailor-made in many applications.

Overall, this study showed that the combination of CS and CP which are considered as wastes yielded the oils with high quality, hence a promising application of these oils in many areas.

References

Mehl, F., Marti, G., Boccard, J., Debrus, B., Merle, P., Delort, E., Baroux, L., Raymo, V., Velazco, M.I., Sommer, H., Wolfender, J.L.: Differentiation of lemon essential oil based on volatile and non-volatile fractions with various analytical techniques: a metabolomic approach. Food Chem. 143, 325–335 (2014)

El-Adawy, T.A., Rahma, E.H., El-Bedawy, A.A., Gafar, A.E.: Properties of some citrus seeds. Part 3. Evaluation as a new source of protein and oil. Nahr. Food 43(6), 385–391 (1999)

Laufenberg, G., Kunz, B., Nystroem, M.: Transformation of vegetable waste into value added products: (A) the upgrading concept; (B) practical implementations. Bioresour. Technol. 87(2), 167–198 (2003)

Matthaus, B., Özcan, M.M.: Chemical evaluation of citrus seeds, an agro-industrial waste, as a new potential source of vegetable oils. Grasas Aceites 63(3), 313–320 (2012)

Fisher, K., Phillips, C.: Potential antimicrobial uses of essential oils in food: Is citrus the answer? Trends Food Sci. Technol. 19(3), 156–164 (2008)

Moo-Huchin, V.M., Moo-Huchin, M.I., Estrada-León, R.J., Cuevas-Glory, L., Estrada-Mota, I.A., Ortiz-Vázquez, E., Betancur-Ancona, D., Sauri-Duch, E.: Antioxidant compounds, antioxidant activity and phenolic content in peel from three tropical fruits from Yucatan, Mexico. Food Chem. 166, 17–22 (2015)

Espina, L., Somolinos, M., Lorán, S., Conchello, P., García, D., Pagán, R.: Chemical composition of commercial citrus fruit essential oils and evaluation of their antimicrobial activity acting alone or in combined processes. Food Control 22(6), 896–902 (2011)

Steuer, B., Schulz, H., Läger, E.: Classification and analysis of citrus oils by NIR spectroscopy. Food Chem. 72(1), 113–117 (2001)

Beveridge, T.H., Girard, B., Kopp, T., Drover, J.C.: Yield and composition of grape seed oils extracted by supercritical carbon dioxide and petroleum ether: varietal effects. J. Agric. Food Chem. 53(5), 1799–1804 (2005)

Sicari, V., Poiana, M.: Recovery of bergamot seed oil by supercritical carbon dioxide extraction and comparison with traditional solvent extraction. J. Food Process Eng (2016). doi:10.1111/jfpe.12341

Guan, W., Li, S., Yan, R., Tang, S., Quan, C.: Comparison of essential oils of clove buds extracted with supercritical carbon dioxide and other three traditional extraction methods. Food Chem. 101(4), 1558–1564 (2007)

Illés, V., Daood, H.G., Perneczki, S., Szokonya, L., Then, M.: Extraction of coriander seed oil by CO2 and propane at super-and subcritical conditions. J. Supercrit. Fluids 17(2), 177–186 (2000)

Yamini, Y., Sefidkon, F., Pourmortazavi, S.M.: Comparison of essential oil composition of Iranian fennel (Foeniculum vulgare) obtained by supercritical carbon dioxide extraction and hydrodistillation methods. Flavour Fragr. J. 17(5), 345–348 (2002)

Pourmortazavi, S.M., Hajimirsadeghi, S.S.: Supercritical fluid extraction in plant essential and volatile oil analysis. J. Chromatogr. A 1163(1), 2–24 (2007)

Biljana, D., Zika, L., Vladimir, Z., Aleksandar, T.: Extraction of fennel (Foeniculum vulgare Mill.) seeds with supercritical CO2: comparison with hydrodistillation. Food Chem. 92, 143–149 (2005)

Salgın, U., Döker, O., Çalımlı, A.: Extraction of sunflower oil with supercritical CO2: experiments and modeling. J. Supercrit. Fluids 38(3), 326–331 (2006)

Shu, X.S., Gao, Z.H., Yang, X.L.: Supercritical fluid extraction of sapogenins from tubers of Smilax china. Fitoterapia 75(7), 656–661 (2004)

Yu, J., Dandekar, D.V., Toledo, R.T., Singh, R.K., Patil, B.S.: Supercritical fluid extraction of limonoids and naringin from grapefruit (Citrus paradisi Macf.) seeds. Food Chem. 105(3), 1026–1031 (2007)

Ueno, H., Tanaka, M., Machmudah, S., Sasaki, M., Goto, M.: Supercritical carbon dioxide extraction of valuable compounds from Citrus junos seed. Food Bioprocess Technol. 1(4), 357–363 (2008)

He, J.Z., Shao, P., Liu, J.H., Ru, Q.M.: Supercritical carbon dioxide extraction of flavonoids from pomelo (Citrus grandis (l.) osbeck) peel and their antioxidant activity. Int. J. Mol. Sci. 13(10), 13065–13078 (2012)

Aparicio, R., Roda, L., Albi, M.A., Gutiérrez, F.: Effect of various compounds on virgin olive oil stability measured by Rancimat. J. Agric. Food Chem. 47(10), 4150–4155 (1999)

Metcalfe, L.D., Schmitz, A.A., Pelka, J.R.: Rapid preparation of fatty acid esters from lipids for gas chromatographic analysis. Anal. Chem. 38(3), 514–515 (1966)

American Oil Chemists, Society, Firestone, D.: Official Methods and Recommended Practices of the American Oil Chemists’ Society, 5th edn. AOCS, Champaign, IL (1989)

Brand-Williams, W., Cuvelier, M.E., Berset, C.L.W.T.: Use of a free radical method to evaluate antioxidant activity. LWT Food Sci. Technol. 28(1), 25–30 (1995)

Re, R., Pellegrini, N., Proteggente, A., Pannala, A., Yang, M., Rice-Evans, C.: Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 26(9), 1231–1237 (1999)

List, G.R., Friedrich, J.P.: Processing characteristics and oxidative stability of soybean oil extracted with supercritical carbon dioxide at 50 °C and 8000 psi. J. Am. Oil Chem. Soc. 62(1), 82–84 (1985)

Chimovitz, E., Kelley, F., Munoz, F.: Analysis of retrograde behavior and the cross-over effect in supercritical fluids. Fluid Phase Equilib. 44, 23–52 (1988)

Chimowitz, E.H.: Introduction to Critical Phenomena in Fluids. Oxford University Press, Oxford (2005)

Gupta, R.B., Shim, J.-J.: Solubility in Supercritical Carbon Dioxide. CRC Press, Boca Raton (2006)

Bozan, B., Temelli, F.: Supercritical CO2 extraction of flaxseed. J. Am. Oil Chem. Soc. 79(3), 231–235 (2002)

Poiana, M., Mincione, A., Gionfriddo, F., Castaldo, D.: Supercritical carbon dioxide separation of bergamot essential oil by a countercurrent process. Flavour Fragr. J. 18(5), 429–435 (2003)

Pradhan, R.C., Meda, V., Rout, P.K., Naik, S., Dalai, A.K.: Supercritical CO2 extraction of fatty oil from flaxseed and comparison with screw press expression and solvent extraction processes. J. Food Eng. 98(4), 393–397 (2010)

Crowe, T.D., White, P.J.: Oxidative stability of walnut oils extracted with supercritical carbon dioxide. J. Am. Oil Chem. Soc. 80(6), 575–578 (2003)

Winkler, J.K., Warner, K.: The effect of phytosterol concentration on oxidative stability and thermal polymerization of heated oils. Eur. J. Lipid Sci. Technol. 110(5), 455–464 (2008)

Yoshida, Y., Niki, E.: Antioxidant effects of phytosterol and its components. J. Nutr. Sci. Vitaminol. 49(4), 277–280 (2003)

Zia-ur-Rehman.: Citrus peel extract—a natural source of antioxidant. Food Chem. 99(3), 450–454 (2006)

Cacace, J.E., Mazza, G.: Mass transfer process during extraction of phenolic compounds from milled berries. J. Food Eng. 59(4), 379–389 (2003)

Almeida, P.P., Mezzomo, N., Ferreira, S.R.: Extraction of Mentha spicata L. volatile compounds: evaluation of process parameters and extract composition. Food Bioprocess Technol. 5(2), 548–559 (2012)

Lagha-Benamrouche, S., Madani, K.: Phenolic contents and antioxidant activity of orange varieties (Citrus sinensis L. and Citrus aurantium L.) cultivated in Algeria: peels and leaves. Ind. Crops Prod. 50, 723–730 (2013)

Rapisarda, P., Tomaino, A., Lo Cascio, R., Bonina, F., De Pasquale, A., Saija, A.: Antioxidant effectiveness as influenced by phenolic content of fresh orange juices. J. Agric. Food Chem. 47(11), 4718–4723 (1999)

Tomás-Barberán, F.A., Espin, J.C.: Phenolic compounds and related enzymes as determinants of quality in fruits and vegetables. J. Sci. Food Agric. 81(9), 853–876 (2001)

Pinelo, M., Rubilar, M., Jerez, M., Sineiro, J., Núñez, M.J.: Effect of solvent, temperature, and solvent-to-solid ratio on the total phenolic content and antiradical activity of extracts from different components of grape pomace. J. Agric. Food Chem. 53(6), 2111–2117 (2005)

Dorman, H.J.D., Deans, S.G.: Antimicrobial agents from plants: antibacterial activity of plant volatile oils. J. Appl. Microbiol. 88(2), 308–316 (2000)

Burt, S.: Essential oils: their antibacterial properties and potential applications in foods—a review. Int. J. Food Microbiol. 94(3), 223–253 (2004)

Bakkali, F., Averbeck, S., Averbeck, D., Idaomar, M.: Biological effects of essential oils—a review. Food Chem. Toxicol. 46, 446–475 (2008)

Acknowledgments

This work was supported by a Research Grant of Pukyong National University (2016).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ndayishimiye, J., Getachew, A. & Chun, B.S. Comparison of Characteristics of Oils Extracted from a Mixture of Citrus Seeds and Peels Using Hexane and Supercritical Carbon Dioxide. Waste Biomass Valor 8, 1205–1217 (2017). https://doi.org/10.1007/s12649-016-9697-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-016-9697-8