Abstract

In this study, the effect of different extraction methods including subcritical fluid extraction (SubFE) with compressed propane at 30 and 60 °C and pressures from 2 to 8 MPa, a solvent extraction using Soxhlet (SE) apparatus with two different solvents (n-hexane and ethanol) and the ultrassound-assisted extraction (UAE) with ethanol as solvent on the extraction yield, physicochemical properties, fatty acids profile and tocopherol content, antioxidant and antibacterial activities of organic yellow passion fruit (Passiflora edulis var. flavicarpa). Higher yields were obtained by SE with n-hexane (26.12%) and compressed propane at 30 °C and 8 MPa (24.68%). The physicochemical parameters were consistent with the requirements of Codex Alimentarius regarding the most popular plant oils. Higher content of unsaturated fatty acids (86.65%) and linoleic acid (68.99%) was obtained by compressed propane at 30 °C and 2 MPa. The oils obtained by Soxhlet with n-hexane and compressed propane at 60 °C and 2 MPa showed higher tocopherol content (8.22 and 5.98 mg/100 goil, respectively). All oil samples presented high antioxidant performance and showed antibacterial activity against Escherichia coli, Salmonella enteritidis, Staphylococcus aureus and Bacillus cereus. This study further confirms that organic yellow passion fruit seed oils represent a good source of essential unsaturated fatty acids and demonstrated that there is an opportunity to add value for this agroindustrial waste with the use of unconventional extraction methods such as compressed propane, a green recovery technology yet still unexplored for seed oil extraction.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The ‘yellow passion fruit’ (Passiflora edulis var. flavicarpa Degener) also known as ‘sour passion fruit’ is the most popular specie of edible passion fruits and is the variety in which the world’s commercial production is based. Brazil is both the largest producer and the largest consumer of fresh and processed passion fruit [1].

The use of organic foods has been increased around the world [2]. Organic foods are derived from raw material produced by organic farming, a method of crop production that involves much more than choosing not to use pesticides, fertilizers, genetically modified organisms, but is a system designed to optimize and preserve the agro-ecosystem, focused on a sustainable and harmonious environment management.

Industries in Brazil have been processing organic yellow passion fruit. The most impacting activity involving this specie is the juice manufacture, which results in a substantial amount of residues, such as seeds, that are usually discarded or underused. In recent years, a considerable interest in the chemical composition of yellow passion fruit seeds have been generated. The results have shown that the seeds are rich in oil with considerable amount of unsaturated fatty acids [3], tocopherols and high antioxidant capacity [4]. The unsaturated fatty acids, mainly linoleic (n-6) and α-linolenic (n-3) acids are important in human nutrition, playing an important role in the regulation of a variety of physiological and biological functions in living organisms and have protective effect against many diseases [5, 6].

Seed oils have been used for centuries as a source of food, energy, medicine and for cosmetic applications [7]. The demand for high quality seed oils associated with the currently development of “bio”, “organic”, “natural” or “ecological” products market resulted in an increase of interest in unusual oil raw materials [8], as well as in the adequate use and extraction of industrial byproducts.

Although several methods can be used for obtaining oil from vegetable sources, the method features define the quality of the final product [9, 10]. The commonly used processes of lipid extraction from oil seeds such as pressing and extraction with organic solvents (cold or hot) show a series of drawbacks including the use of time-consuming procedures, lower selectivity, solvent contamination and degradation of bioactive compounds [11].

Among the unconventional extraction techniques, ultrasound-assisted extraction may be one of the most widely explored in both laboratory and an industrial scales, not only because it involves a simple operation and relatively inexpensive equipment [12], but also for presenting high efficiency derived from the mechanical effects induced in the material to which they are being applied [13]. Ultrasonic enhancement of the solid–liquid extraction is mainly attributed to the phenomenon of acoustic cavitation, consisting of the formation, growth and collapse of microbubbles inside the liquid phase, which generates high localized pressures and micro-streamings, causing plant tissue disruption and improving the release of intracellular substances into the solvent [14, 15]. The application of ultrasound has been widely studied for extracting oil from vegetable raw materials [16, 17]. Nevertheless, this process is complex, and its efficiency depends on many factors, e.g., temperature, time, ultrasound frequency, type of solvent and ratio of solids (raw material) to liquid (solvent) [18].

The use of pressurized solvents at supercritical or subcritical fluids condition is an interesting option for replacing the conventional methods, and is one of the newly emerging clean and environmentally friendly technologies for food and pharmaceutical products [19]. This technology provides several advantages such as one step from the extraction to the separation and a solvent-free oil, shorter extraction time, and lower demand of solvent, raw material and energy while not causing toxic residuals harmful to human/nature. Although carbon dioxide is the most commonly used fluid in this type of extraction process, subcritical propane has been investigated in extraction of oilseeds [20, 21]. Propane has been used without co-solvent due the high solubility of the oil, and also it has been combined with CO2 to avoid the flammability [22,23,24,25,26]. Besides that, the propane is a relatively low-cost solvent and it does not leave toxic residue in the product. The pressures involved in oil extraction using propane are at least an order of magnitude (hundreds of psi compared with thousands psi) lower than those using CO2 for extraction of vegetable oils [22]. Subcritical fluid extraction (SubFE) is rapidly emerging as a promising technique of extraction of solid samples, especially oilseeds and it can be considered a technological breakthrough in the extraction industry [23]. Despite some studies about subcritical propane extraction of various oilseeds [20, 21], studies using subcritical propane and ultrasound-assisted extraction of organic yellow passion fruit seed oil and its antimicrobial activity were not explored and presented in the literature.

Therefore, the aim of this study was to evaluate the effect of different extraction techniques for obtaining organic yellow passion fruit seed oil. The oils obtained by subcritical propane, ultrasound-assisted extraction using ethanol as solvent and Soxhlet extraction using n-hexane and ethanol as solvents were analyzed and compared in terms of their overall extraction yield, physicochemical properties, fatty acids profile, tocopherol content, antioxidant and antimicrobial activities.

Materials and Methods

Sample Collection and Preparation

Yellow passion (Passiflora edulis var. flavicarpa) fruits were collected in February 2016 in a certified farm (Rede Ecovida de Agroecologia, certificate number SC08030/2016) in Gravatal city, state of Santa Catarina, Brazil.

Fruits were washed with water and cut into halves. The pulp containing the seeds was removed and to improve its separation and the aryl withdraw an enzymatic extract with pectinase and hemicellulase (Rapidase® TF, DSM Food Specialties) from Aspergillus sp. and Trichoderma longibrachiatum was used. The pulp added with enzymatic extract (750:1 m/m, respectively) was heated and maintained at 50 °C for 30 min. Subsequently, the seeds were collected, washed in running water until complete removal of the pulp and dried in air circulating oven (Nova Ética) at 50 °C until reaching a constant moisture content of 8.00 ± 0.14 wt%, measured according to AOCS [27]. The dried samples were vacuum packed in polyethylene bag and stored in absence of light at 4 °C, until further use. Figure 1 shows the aspect of the seeds in each step. Immediately prior to extraction the dried seed samples were ground in a household blender and separated using different Tyler series sieves with the help of a mechanical stirrer (Produtest, São Paulo, Brazil). The average particle diameter was 13.61 × 10−4 m, estimated using the method described by Gomide [28] considering the mass fractions of milled material retained in the following sieves: 8 mesh (31 wt%), 12 mesh (27 wt%), 20 mesh (16 wt%), 32 mesh (16 wt%) and 48 mesh (9 wt%).

Aspect of organic yellow passion fruit (P. edulis f. flavicarpa) seeds: a whole fruit and a half cut showing inside view; b after first step to remove the excess of pulp (by gravity); c process to remove the arils with enzymes; c dried seeds and d dried seeds packed under vaccum; e ground seed particles

Oil Extraction Process

Conventional Extraction

The Soxhlet method was selected as conventional extraction technique using n-hexane and ethanol as solvents. Around 10 g of sample was packed in a filter paper and inserted in the extractor (Nova Etica, Curitiba, Brazil). Then, 200 mL of solvent was added and the system was heated until boiling. Reflux was kept for 4 h, and then the solvent was evaporated under vacuum (IKA®, HB 10, Germany) at 60 °C and 450 mmHg. The content was then dried in an oven under circulating air at 65 °C until constant weight. The recovered oil was weighted and stored at − 5 °C ± 2 °C and protected from light prior to analysis. The extraction was performed in triplicate.

Ultrasound-Assisted Extraction (UAE)

The ultrasound-assisted extraction was performed in an ultrasonic bath (Eco-sonics, Q 5.9/37A, Brazil), with 37 kHz frequency and 165 W, using a solid (ground seeds) to solvent ratio (m/v) of 2%, following the optimum solid to solvent ratio obtained in our previous study [29]. Samples and ethanol (Neon, 99.8% purity) were placed in a glass flask and sonicated at 60 °C for 60 min. Then the mixture was filtered through Whatman No. 1 paper and the solvent was removed with a rotary vacuum evaporator (IKA®, HB 10, Germany) at 70 °C and 450 mmHg. The content was then dried in an oven under circulating air at 65 °C until constant weight. The recovered oil was weighted and stored at − 5 ± 2 °C and protected from light prior to analysis. The extraction was performed in triplicate.

Subcritical Propane Extraction (Compressed Propane)

Extraction was performed in a bench scale unit, described in other work of our research group [29,30,31]. Briefly, the experimental apparatus consists of a high-pressure jacketed-vessel (0.08 m3 inner volume, L = 0.16 m and Ø = 2.52 × 10−2 m) coupled to a circulation bath, a micro-metering needle valve to control the flow inside the extractor, a syringe-type pump (ISCO, model 500D, Lincoln, NE 68504, USA), and pressure and temperature sensors and transducers.

Propane was supplied by White Martins SA (99.5% purity in the liquid phase). The extractions were carried out with a constant flow rate of 2.0 ± 0.2 cm3 min−1, where the syringe pump was kept at 10 °C and the pressure set the extraction process value (experimental condition). In order to evaluate the influence of the temperature and pressure on the extraction yields and oil properties, three experiments were performed with the following temperature and pressure combination: 30 °C at 2 MPa, 30 °C at 8 MPa and 60 °C at 2 MPa. For all runs, around 25 g of ground dried seeds (with approximate apparent density of 0.31 g cm−3) were load in filter paper cartridge (0.15 × 0.025 m) forming a fixed bed and inserted in the extractor. Thus, propane was pumped at the required pressure using the syringe-type pump. A confinement period of 90 min was stated after reaching the pressure and temperature set to the extraction. After that, the extraction was performed, and the oil samples were collected inside the trap, at atmospheric temperature (around 25 °C). The extract samples were collected and weighted in amber vials at intervals of 10 min, with a total extraction time of 180 min. The extracts were gravimetrically quantified at the end of each run (after 180 min). The vials containing oil samples were sealed and stored at − 5 ± 2 °C and protected from light prior to analysis.

Analysis by Scanning Electron Microscopy (SEM)

SEM images were obtained in samples of the unextracted dry raw material, of the material which results from the Soxhlet and ultrasound-assisted extraction and of the passion fruit seed particles after subcritical fluid extraction with compressed propane. The SEM equipment was a scanning electron microscope (SEM; Tescan VEGA3 LMU, Czech Republic). Prior to analysis and to improve the conductivity of the material, the samples were coated with gold in a SCD 030 splutter coater (Oerlikon-Balzers, Balzers, Principality of Liechtenstein). The surface analyses were performed under vacuum, using an acceleration tension of 15.0 kV.

Oil Evaluation

Global Yield (X0)

The global yield of conventional (SE), UAE and compressed propane extractions was calculated as the mass ratio between extract (mext) and dry sample (F), as show in the following equation:

Fatty Acid Composition

Fatty acid composition of organic yellow passion fruit seed oil samples was analyzed by using a Varian CP 3900 gas chromatograph system (Santa Clara, CA 95051, USA). Fatty acid methyl esters (FAMEs) were prepared [32] and the samples were injected into the column (CP-SIL 88 CB; 100 m × 0.25 mm × 0.2 µm). The injector and detector (FID) temperatures were 260 and 300 °C, respectively. Temperature program was 140 °C for 40 min ramped to 240 °C at a 2 °C min−1 rate and kept at this temperature for the remaining time of analysis. FAMEs were identified by comparison with retention times of the standard mixture FAMEs (Supelco, MIX FAME 37, St. Louis, MO 63103, USA). Results were expressed as percentage of each individual fatty acid present in the sample.

Physicochemical Properties of Seed Oil

Oil from the seeds was subjected to physical characterization. The colors and state of the oil at room temperature were noted by visual inspection. The density measurements were performed using a digital densitometer DMA 5000 M (Anton Paar, Austria) and was determined at 20 and 40 °C. The refractive index was determined at 40 °C using the Abbé refractometer (Biobrix, model 2WAJ). The procedures for determination of chemical indices, such as the acid value, free fatty acid and iodine value and were carried out following the official method [33]. Each oil sample was analyzed in triplicate.

Tocopherol Composition

Tocopherol composition was determined using the method of Tasioula-Margari and Okogeri [34], with some modifications. Prior to HPLC analysis, 500 mg of oil was added to 10 mL of absolute methanol (Panreac, 99.9%) and the mixture was sonicated in an ultrasonic bath (Eco-sonics, Q 5.9/37A, Brazil) during 5 min. The supernatant phase was separated and the extraction procedure was repeated more two times. The supernatant phases were mixed, and the solvent was removed under vacuum (IKA®, HB 10, Germany) at 40 °C and 450 mmHg. The residue was dissolved in 1 mL of a methanol/isopropanol mixture (80:20, v/v). Tocopherol was analyzed by HPLC system using an Agilent 1200 Series rapid resolution liquid chromatograph (Agilent Technologies, Santa Clara, USA) consisting of a vacuum degasser, an auto-sampler, a quaternary pump, an automatic liquid injection system and diode-array detection (DAD) system. Data analysis was performed with Agilent HPLC EZChrom Elite software. The column used was a Kinetex-C18 (4.6 mm × 150 mm, 5 µm, CA, USA). The wavelength selected for monitoring the signs of the chromatographic peaks was at 292 nm for all analyzed tocopherols. The injection volume was 20 µL, with a flow rate of 1 mL min−1. Methanol and isopropanol (90:10, v/v) were used as mobile phases A and B, respectively, in an isocratic mode. The total running time was 7 min. All identified tocopherols (α, γ, and δ-tocopherol) were quantified with external standards (Sigma-Aldrich), using calibration curves. The standard response curve was a linear regression fitted to values obtained at each concentration within the range of 0.5–50 mg L−1.

Determination of Antioxidant Activity

The antioxidant capacity of the oils obtained from organic passion fruit seeds was determined through the DPPH free radical scavenging capacity method. The samples’ antioxidant activity was evaluated using the DPPH (2.2-diphenyl-1-picrylhydrazyl) radical scavenging activity [35] with minor modifications. 100 mg of oil were diluted in isopropanol (100 mg mL−1) and mixed with 230 µL of 60 µmol L−1 methanolic DPPH solution. The decrease in absorbance (Abs) was detected at 515 nm using a microplate reader (Synergy HT-BioTek, Winooski, VT, USA) after 30 min incubation in darkness at room temperature. A DPPH solution devoid of sample was used as a control. The DPPH radical scavenging activity (%) was determined using the following equation: \({\text{Antioxidant activity }}\left( \% \right)\,=\,({\text{Ab}}{{\text{s}}_{{\text{control}}}}\, - \,{\text{Ab}}{{\text{s}}_{{\text{sample}}}}/{\text{Ab}}{{\text{s}}_{{\text{control}}}})\, \times \,{\text{1}}00\).

Antimicrobial Activity

The antimicrobial activity of oils from Passiflora edulis f. flavicarpa seeds obtained using different extraction techniques was determined for four bacterial strains and quantitatively evaluated by the micro dilution method in culture broth, described as follows.

Bacterial Cultures

The antimicrobial activity of oil samples was evaluated against the bacteria strains Gram-positive Staphylococcus aureus (ATCC 25923), Bacillus cereus (ATCC 11778) and Gram-negative Escherichia coli (ATCC 25922) and Salmonella enteritidis (ATCC 13076). The bacteria strains were obtained from the culture collection of the Microbiology Laboratory at Federal University of Technology of Paraná, Curitiba (E. coli and S. aureus), Department of Biochemistry at Federal University of Paraná (B. cereus) and of the Laboratory of Enterobacteria at Oswaldo Cruz Institute (S. enteritidis). These pathogenic microorganisms were chosen because they commonly occur in various food products. The bacteria were resuscitated in TSB (tryptic soy broth) and incubated for 24 h at 37 °C. The bacterial cultures were maintained on TSA (tryptic soy agar) at 4 °C. Transfers were conducted similarly to the resuscitation method to prepare microorganisms for analysis.

Minimum Inhibitory Concentration (MIC)

Minimum inhibitory concentration (MIC) of oil samples was determined using the microdilution method in culture broth [36]. E. coli, S. enteritidis, S. aureus and B. cereus cultures were incubated for 24 h at 37 °C in agar plate. The bacterial suspension (inoculum) was diluted with sterile saline solution 0.9% (initial concentration of to 108 Colony Forming Unit (CFU)/mL) and subsequently in Mueller–Hinton (MH) broth to a final density of 106 CFU/mL (adjusted by turbidity comparing with McFarland scale 0.5). MIC analyses were carried out in a sterilized microdilution plate with 96 wells. The higher concentration tested was prepared with pure oil (1000 mg/mL—100%). The initial solutions were prepared with 50 µL of Mueller–Hinton (MH) broth and 50 µL of prepared tested sample (500 mg/mL—50%) and serial dilutions were performed to reach a final concentration range between 500 mg/mL (50%) and 1.95 mg/mL (0.195%). The inoculum previously diluted in MH broth (final concentration of 1.0 × 105 CFU/mL) was added to the microplate wells. Positive control (growth control) was prepared containing inoculum and MH broth. Sterility control was also prepared with MH broth to ensure that broth was not contaminated. Once plates were prepared, they were covered with mylar plate sealer and incubated at 37 °C for 18 h. To indicate bacterial growth, 2,3,5-triphenyltetrazolium chloride (TTC) dissolved in methanol was added to the microplate wells and incubated at 37 °C for 30 min. The analyses were carried out in duplicate. MIC is defined as the lowest concentration of the antimicrobial agent that inhibits visible growth of the tested bacteria. The results were expressed as %.

Statistical Analysis

Results were reported as means and standard deviation. Analysis of variance (ANOVA) and Tukey’s honestly significant difference (HSD) tests were conducted to determine the differences among means, using the software Statistica 8.0 (StatSoft TM. Inc.).

Results and Discussion

The overall extraction yield is defined as the amount of solute extractable by the solvent at the established extraction conditions and indicates the process efficiency. The oil extraction yields for organic yellow passion fruit seeds obtained by Soxhlet (SE), ultrasound-assisted extraction (UAE) and compressed propane (or subcritical fluid extraction, SubFE) at different extraction conditions are presented on Table 1. It can be observed that the global yield obtained by SE using n-hexane as solvent was higher than those obtained by all the other extraction methods. Even so, SubFE conditions achieved an overall yield close to those of SE with n-hexane. Assuming that the SE extraction with n-hexane recovered all the oil from the seeds, the best condition of the SubFE process in terms of global yield (24.68%—30 °C and 8 MPa) reached a recovery of 94.49% of the oil from yellow passion fruit seeds. The good performance from the non-polar solvents (compressed propane and n-hexane) is attributed to the high content of lipids in the seeds. Oliveira et al. [37] studied the supercritical fluid extraction with CO2 of a conventional passion fruit seed sample at different conditions (flow rate, temperature and pressure). According to those authors, the highest extraction yield (18.5%) was obtained by them when a flow rate of 3.0 mL min−1, 25 MPa and 50 °C were used. The results of our study with compressed propane provided higher yield (24.68%) at low temperature and pressure (30 °C and 8 MPa) conditions, which indicates the potential of this non-conventional extraction technique for oilseeds recovery.

Similarly, lower yield results were obtained for the polar solvent (ethanol) by SE and UAE process (20.46 ± 1.36% and 21.28 ± 0.33%, respectively). No significant differences (P > 0.05) were observed between UAE extraction yield and the results obtained by SE with ethanol. According to [38], the ultrasound propagation in a solid/liquid media promotes cavitation phenomena that leads to high shear forces in the media. The implosion of cavitation bubbles on a product’s surface results in micro-jetting which generates several effects such as surface peeling, erosion, particle breakdown, macro-turbulences and to a micro mixing that improve the extraction yield. In the present work, the SE yield obtained with n-hexane (26.12 ± 0.74%) and ethanol (20.46 ± 1.36%) were higher than the values obtained by Oliveira et al. [39] (24.3 and 13.5%) at similar extraction time (4 h).

The differences in the extraction yields and consequently for the amount of recovered oil may be attributed to the extraction time, solid-to-solvent ratio, solvent power and to the process temperature and pressure [39]. For compressed propane process, the increase in the pressure at constant temperature resulted in a slightly enhancement of the overall extraction yields due to the increase of compressed propane density (from 487.53 to 504.11 kg/m3) and consequent enhancement of its solvent power, leading to no significantly different (P > 0.05) results. The increase of temperature at constant pressure leads to the reduction of extraction yield, because compressed propane density also decreases following the temperature increase.

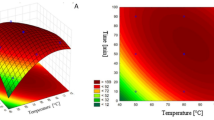

The overall extraction curves with compressed propane are presented in Fig. 2. It can be observed a higher initial (first 20 min) extraction rate for all conditions tested. Despite of the highest extraction yield was achieved at 30 °C and 8 MPa, this curve almost overlaps that at 30 °C and 2 MPa, as in this study the increase in pressure did not affected significantly (P > 0.05) the overall extraction yield. The majority amount of oil was obtained during the first 30 min, which represents the constant extraction rate (CER) period. Due to this, the falling extraction rate (FER) period, from 30 to 70 min, was shorter. After 70 min, the extraction yield increased slowly and remained constant, as in this period the diffusion process was predominant. Comparing the extraction yields, the compressed propane reached higher values than UAE with ethanol. The overall extraction yield was 24.68% with propane, while UAE provided 21.28 ± 0.33% (Table 1; Fig. 2). Furthermore, compressed propane provides a solvent-free oil, which preserve its quality as the step to remove the solvent by evaporation is unnecessary. In Fig. 3, photographs of the oil obtained from the extraction with compressed propane at different conditions are shown.

Scanning Electron Microscopy (SEM) Images

The effects of SE, UAE and compressed propane extractions on the morphological structure of the seeds were evaluated through SEM. Figure 4 shows SEM images of organic yellow passion fruit seeds before extraction (A) and after UAE (B), SE extraction with n-hexane (C) and with ethanol (D), and after extraction with compressed propane at 8 MPa/30 °C (E); 2 MPa/30 °C (F) and 2 MPa/60 °C (G). The oil-bearing cells are evidenced (Fig. 4a). From images (B–G) it is possible to observe the presence of fragmented materials deposed on the seeds surface. It could be attributed to the grind process before extraction and in minor scale, to the removal of material from inside the seed, such as superficial tissue that covers the seed particles because of the mechanical action of the extraction process and its posterior deposition on the particle surface. After the extraction processes, the samples presented smaller sizes compared to the unextracted ones. When higher magnification images are taken (Fig. 5; scale bar 20 µm), it can be observed that the reduction of oil cells size was more prominent when SE with n-hexane and compressed propane at 30 °C and 8 MPa were used. Figure 5a, b indicate the damage in the cell wall and the predominance of ‘exhausted cells’ after these extraction process. The aggressive effect of compressed propane and SE with n-hexane on the cell walls promoted an increase in the oil release that resulted in higher extraction yields (Table 1). The aspect of the seeds after UAE (Fig. 5c) is different from the others, because it presents more amount and higher size of oil-bearing cells than observed in (A) and (B). The UAE provided lowest extraction yield, which justifies the aspect observed in Fig. 5c.

Scanning Electron Microscopy (SEM) images of organic yellow passion fruit seed particles: unextracted (a); after ultrasound-assisted extraction (b); after Soxhlet extraction with n-hexane (c) and with ethanol (d); after compressed propane extraction at 8 MPA/30 °C (e); 2 MPA/30 °C (f) and 2 MPA/60 °C (g). Magnification ×1200

Fatty Acid Composition

Table 2 shows the fatty acid composition, the average of total saturated fatty acid (SFA), monounsaturated fatty acid (MUFA), polyunsaturated fatty acid (PUFA) and the values of polyunsaturated/saturated indexes (P/S) for the oil from organic yellow passion fruit seeds obtained by different extraction methods. A wide variation in the linoleic acid content is observed in the oil obtained with n-hexane and the other extraction methods, leading to differences in the total polyunsaturated fatty acids. All oil samples presented high amounts of total unsaturated fatty acids, which consisted mainly of linoleic followed by oleic and α-linolenic acid, representing 84.07% for the oil obtained with n-hexane, 86.63 and 86.58% for the oil obtained with ethanol (SE and UAE, respectively) and 86.65% (at 30 °C and 2 MPa and at 30 °C and 8 MPa) and 86.19% (at 60 °C and 2 MPa) for the oil obtained with compressed propane. Nyanzi et al. [40] found 85.04% of unsaturated fatty acid, in which the dominant fatty acids were linoleic acid (67.8%), followed by oleic acid (16.9%), palmitic acid (11.0%), stearic (3.1%) and α-linolenic (0.4%) in yellow passion fruit seed oil obtained by Soxhlet extraction with petroleum ether.

The oil obtained with compressed propane at 30 °C and 2 MPa presented the highest content of linoleic acid (68.99%), and the lowest amount of oleic acid (17%) was obtained at 60 °C and 2 MPa. Compared with these results, Silva and Jorge [41] found lower linoleic (66.3%) and higher oleic acid (18.7%) in their study with conventional yellow passion fruit seed oil obtained by cold extraction with chloroform, methanol and water, in the proportion of 2:1:0.8 v/v/v, respectively, according to the method of Bligh and Dyer.

The relation of oleic/linoleic fatty acid was higher (1/4.05) for the oil extracted with compressed propane at 60 °C and 2 MPa. The higher the amount of linoleic acid in relation to oleic, the better is the quality of vegetable oil in avoiding the formation of bad cholesterol. The presence of high amounts of the essential linoleic acid suggests that these oils are highly nutritious [42]. All the oil samples studied in this work are rich in both oleic and linoleic acid. Therefore, organic yellow passion fruit seed oil could be used as promising source of oil with high value for food, pharmaceutical and cosmetic sectors [43]. The total saturated fatty acids content of the oil obtained with n-hexane (15.93%) and compressed propane at 60 °C and 2 MPa (14.26%) was higher than the other oils (around 13.35%). The relationship between polyunsaturated and saturated fatty acids content is expressed as P/S index. This value is an important parameter for determination of nutritional value of certain oils. Oils with higher value of P/S index more than 1 are considered with nutritional value [44]. All oils evaluated in our study presented high P/S index (Table 3), above 4. The highest value for P/S index was found for the oil obtained by compressed propane at 30 °C and 2 MPa (5.20). Studies have indicated that higher value of P/S index means a smaller deposition of lipids in the body [45] and it is regarded as favorable for prevention of heart diseases.

Physicochemical Characteristics

The results of some important physicochemical properties of the oil obtained from organic yellow passion fruit seeds are shown in Table 3. Oils are characterized mainly by their fatty acid composition, however, bulk properties are commonly used in their specifications and/or to monitor the transformation processes [46]. The color of the organic yellow passion fruit seed oil extracted by SE with ethanol was golden-orange; the oils obtained by UAE and compressed propane were golden-yellow (as presented in Fig. 2), whereas the oil obtained by SE with n-hexane was almost without coloration. The state of oils was liquid at room temperature.

Refractive index is an important quality control parameter, often used as a criterion in detection of the purity value and to determine authenticity of oils [47] and is also used in identification of oil oxidation status [48]. From the results obtained in the present study, it is observed that the refractive indexes varied from 1.4660 (SE with n-hexane) to 1.4680 (SE with ethanol, UAE and compressed propane at 30 °C and 2 MPa) and presented significant statistical differences (P < 0.05). This parameter increases with an enhancement in the chain length and the unsaturation fatty acids content (Tables 2, 3). The refractive index are within the range found for other vegetable oils such as corn oil (1.465–1.468) [49]. The results indicate that the extraction process used presented no considerable impacts on the refraction index of the extracted oils from the different process and conditions.

Density is an important property often used in process optimization [50]. The density analysis was carried out at 20 and 40 °C. At 20 °C, the average values were from 0.90836 g/cm3 for the oil extracted with n-hexane to 0.92040 g/cm3 for the oil extracted by SE with ethanol. There were significant differences (P < 0.05) among all the oils evaluated at 20 °C. The density at 40 °C values ranged from 0.89453 to 0.90676 g/cm3. For both temperature conditions, the oil obtained with n-hexane presented the lowest and the oil obtained by SE with ethanol presented the highest density value. Density values decreased with the increase in the temperature (Table 3). The oil samples presented high iodine values, thus reflecting a high degree of unsaturation and indicates that the oil seeds has the good qualities of edible oil [51]. The highest iodine values were obtained for the oil samples extracted with ethanol (135.28 and 135.15 g I2.100 g−1 for SE and UAE, respectively) and compressed propane at 30 °C and 2 MPa (135.31 g I2.100 g−1) and at 30 °C and 8 MPa (135.28 g I2.100 g−1), with no significative differences (p > 0.05) between these oils. The oil obtained with n-hexane showed the lowest iodine value (130.98 g I2.100 g−1). These results are within the range found in literature for other seed oils, such as soybean oil (124 to 139 g I2.100 g−1) [49], probably by the similar unsaturation degree of soybean oil and the oil samples evaluated in this study. Acid value accounts for the free fatty acids amount and is usually considered to be one of the main parameters that reflects the quality of vegetable oils, degree of refining and quality change during the processing and storage. Acid value increases with the deterioration of the oil, forming free fatty acids, a product of hydrolytic degradation of triglycerides [52]. Free fatty acids determination is particularly important for industrial purposes since free fatty acids can modify the organoleptic or physicochemical properties of the oil [53]. The oil samples obtained by compressed propane at 30 °C and 8 MPa showed the lowest acid value (1.44 ± 0.05 mg KOH/g oil) and free fatty acids (0.73 ± 0.02%). The highest values were obtained by SE with ethanol (2.06 ± 0.16 mg KOH/g oil and 1.03 ± 0.08%). The highest polarity of this solvent may have contributed to lixiviate likely organic acids residues from the passion fruit pulp that were adsorbed in the seeds. As the analytical procedure to determine the content of free fatty acid is based in the neutralization reaction (alkali/acid) some results can be overestimated. Comparing the extracts obtained with ethanol, as it can be seen in Table 3, the oil obtained with UAE had lower acidity than the oil obtained by SE with ethanol because in the UAE extraction a lower ratio of ethanol was used. High values of free fatty acids for yellow passion fruit seed oil were reported by [54], with an average of 7.35%. Free fatty acids value below 1% indicate an oil with low hydrolysis level [55]. However, in our work the acid values were in agreement with the international standards of 4.0 mg KOH/g for crude oil [49].

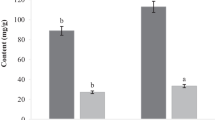

Tocopherol Content

Tocopherols in seed oil are extremely important owing to their role in the protection against oxidative deterioration of polyunsaturated fatty acids. They are natural lipophilic antioxidants mainly found in vegetable oils. Table 4 shows the tocopherol composition of the organic yellow passion fruit seed oils. α-tocopherol, γ-tocopherol and δ-tocopherol were identified in all samples. δ-tocopherol was found at higher concentration, which present significant differences (P < 0.05) for the extraction methods. Low δ-tocopherol content is found in most vegetable oils (0–6% of total tocopherols). In this study, δ-tocopherol was observed within the range from 41.61% (SE with ethanol) to 76.25% (compressed propane at 30 °C and 8 MPa) of the total content. Tocopherols can inhibit lipid oxidation in biological systems and foods. Tocopherols (δ-tocopherol in particular) delay many angiogenic and inflammatory activities and are potentially useful against many diseases such as cancer, arthritis, psoriasis and cardiovascular disease [56].

Despite the extractions with compressed propane carried out at different temperature and pressures resulted on similar overall extraction yields (Table 1), the total content of tocopherol varied (P < 0.05) (Table 3). Therefore, it could be suggested that tocopherols due to their nonpolar nature have different affinity to compressed propane, according with the combination temperature–pressure applied. The total tocopherol content varied from 2.98 to 8.22 mg/100 g of oil. Average concentrations were higher for the oil samples obtained with nonpolar solvents n-hexane (8.22 mg/100 g of oil) and compressed propane at 60 °C and 2 MPa (5.98 mg/100 g of oil). In case of propane extraction, the highest temperature favored tocopherol recovery. Tocopherols are large molecules and beyond its affinity with these nonpolar solvents, the temperature may have contributed to the tocopherol extraction, increasing the solubility and reducing the viscosity and consequently favoring mass transfer of these compounds. Such values are lower than the values reported by [57] for olive oil (8.6 mg/100 g), which is rich in monounsaturated fatty acid, and also for grapeseed oil (12.1 mg/100 g of oil) [58]. However, higher values (50 mg/100 g and 28.62 mg/100 g of oil) of tocopherol in yellow passion fruit seed oil extracted by Soxhlet and Bligh and Dyer have been reported [41, 59]. This significant differences might be due to genotypes, environmental and cultivation practices and conditions as well as to differences of methods used for extraction and analysis [60]. Total tocopherol content found in our study is approximately 135-fold higher than those found to organic yellow passion fruit pulp [61].

Antioxidant Activity

The antioxidant activity of oils obtained from organic yellow passion fruit seeds was evaluated through DPPH method and results are shown on Table 4. The antioxidant activity measured by DPPH varied with the extraction method. This is possibly due to each solvent ability to extract different compounds with antioxidant activity from the passion fruit seeds, such as polyphenols, carotenoids and phytosterols at distinct conditions. Several studies have demonstrated the presence of these compounds in passion fruit seed oil [62,63,64]. Carotenoids, phenolic compounds like caffeic acid, p-coumaric acid and salicylic acid and phytosterols such as campesterol, stigmasterol, β-sitosterol and stigmastanol were detected in the yellow passion fruit seed by [41]. Those species may play important role in increase of the oxidative stability of the oil as well as can be considered as a valuable bioactive compounds of the final products, for example in the cosmetics industry [8].

The oils obtained with ethanol presented the highest free radical scavenging activity, 82.81% for SE and 80.68% for UAE and these samples differed significantly from each other and from the other oils (P < 0.05). It might be justified by the polarity of the ethanol that can enhance the release of phenols as well as further compounds with bioactivity, suggesting that the highest contribution for antioxidant activity comes from the polar fraction of the oil. For the oils obtained with compressed propane, the highest antioxidant activity was 75.12% at lower temperature (30 °C) and pressure (2 MPa). However, this sample did not differ significantly from that obtained at higher pressure (8 MPa).

All carried out SubFE conditions provided oil samples with free radical scavenging capacity higher than the oil obtained by SE with n-hexane. It may be explained by the long extraction time (4 h) in the SE extraction, in which the oil was kept at the solvent boiling temperature (≈ 68 °C), causing the loss of natural antioxidant compounds. Therefore, the oil obtained by SE may have low concentration of antioxidant phytochemicals responsible for the free radicals scavenging. Ferreira et al. [65] investigated the antioxidant activity of P. edulis seed oil obtained by refined, cold pressed and Soxhlet extraction with petroleum ether. Seed oil from Soxhlet presented lower antioxidant activity and, as expected, a lower phenol content when compared to its correspondent pressed oil, as it is well established that the heat might compromise the polyphenol constituents.

Antimicrobial Activity

The results for the minimum inhibitory concentration (MIC) of the organic yellow passion fruit seed oil obtained by different extraction methods are presented in Table 5. The MIC is defined as the lowest concentration of the antimicrobial agent that inhibits visible growth of the tested microorganism. The MIC results show that all oil samples presented inhibitory effect against the four bacteria tested and were mostly effective against the Gram-negative bacteria (E. coli and S. enteritidis) when compared to the results for the Gram-positive ones (S. aureus and B. cereus). Gram-negative bacteria present higher resistance than Gram-positive. Gram-negative bacteria offer a complex barrier system to antimicrobial agents, specifically to the presence of an outer membrane in the wall structure. The outer membrane is a bilayer structure composed mainly of lipopolysaccharides, responsible for the impermeability of many compounds [66]. The opposite behavior was observed by Oliveira et al. [67], where in their study with yellow passion fruit seed oil obtained by supercritical fluid extraction with CO2 (SFE-CO2), maceration and UAE with a mixture of ethanol and water. As presented by those authors, the extracts obtained by SFE-CO2 did not show antimicrobial activity against E. coli and presented a MIC of 8 mg/mL for L. innocua (Gram-positive).

From the results obtained in this work, the lowest MIC values were presented by the oil samples obtained by SE with n-hexane followed by that obtained by SE with ethanol, mainly for E. coli and S. enteritidis. The lipid fraction easily extracted by SE with n-hexane is more effective against some microorganisms due to the presence of sterols [68]. The oil samples obtained by compressed propane presented highest MIC values and showed more effectiveness for E. coli. No trend was observed for the antimicrobial activity in relation to the pressure or temperature for the oils obtained using compressed propane for all microorganisms. However, the temperature presented a positive effect on the antimicrobial activity of the oils obtained with compressed propane against E. coli.

Ferreir et al. [65] investigated the antimicrobial activity of three types of passion fruit seed oils obtained by refined, cold pressed and Soxhlet extraction against two Gram-positive bacteria (Staphylococcus epidermidis and Staphylococcus aureus) and two Gram-negative bacteria strains (Escherichia coli and Pseudomonas aeruginosa) by the solid medium diffusion technique. As presented by those authors, the oil samples evaluated did not present antimicrobial activity.

Saravanan and Parimelazhagan [69] evaluated the antimicrobial activity of Passiflora subpeltata seed oils extracted by Soxhlet with different solvents (petroleum ether, chloroform, acetone and methanol) and found an effective antibacterial and antifungal property of the oils. For those authors, the strong antimicrobial activity is related to the presence of phenolic compounds.

According to Zheng et al. [70], long-chain unsaturated fatty acids present antimicrobial activity being bactericidal to important pathogenic microorganisms. These antimicrobial actions of fatty acids are usually attributed to long-chain unsaturated fatty acids including linoleic acid, oleic acid and linolenic acid. The high content of polyunsaturated fatty acids (Table 2) can contribute to the strong inhibitory effect presented for all the oils tested.

The organic yellow passion fruit seed oils exhibited antimicrobial properties against Gram-positive and Gram-negative bacteria indicating their potential for use as natural preservatives. However, further studies involving the identification of the compounds responsible for the strong activity against Gram-negative bacteria and the activity against other pathogens are still required.

Conclusions

The results presented in this study showed that high yields of oil from organic yellow passion fruit seeds can be obtained using Soxhlet with n-hexane and compressed propane as solvents. The highest extraction yields obtained were 26.12 and 24.68% for Soxhlet with n-hexane and compressed propane at 30 °C and 8 MPa, respectively. For the compressed propane extractions, the pressure presented a slightly positive effect on the extraction yields. The results showed that propane is a suitable and promising solvent for the extraction of organic yellow passion fruit seed oil, due to the higher yield and relatively low pressure employed for the extraction process.

The oil samples obtained with ethanol as solvent (by Soxhlet and ultrasound-assisted extraction) and compressed propane presented similar physicochemical properties, except in relation to free fatty acids content, that were higher for Soxhlet using ethanol (1.03%) and lower for compressed propane at 30 °C and 8 MPa (0.73%). The oil samples obtained using compressed propane at 30 °C and 2 MPa and at 30 °C and 8 MPa presented a higher unsaturated fatty acids composition (86.65%) and the highest content of the essential linoleic acid (68.99%) at 30 °C and 2 MPa. These results reinforce the high quality of oil obtained using compressed propane. The oil samples obtained in this study can be considered as a premium edible oil due to its predominant constitution in unsaturated fatty acids.

All oil samples (obtained from different techniques and conditions) presented α-, γ- and δ-tocopherol homologues, with predominance of the latter. The highest antioxidant activity determined by the DPPH method was observed for oil obtained with ethanol as solvent by Soxhlet (82.82%) and ultrasound-assisted extraction (80.68%), followed by compressed propane at 30 °C and 2 MPa (75.12%). The oil samples were effective against Gram-positive (S. aureus and B. cereus) and Gram-negative (E. coli and S. enteritidis) bacteria, mainly those samples obtained by Soxhlet with n-hexane and ethanol.

This study indicated that the unconventional compressed propane extraction can be performed to obtain a highly potential nutritious oil with good antioxidant and antimicrobial activities, adding value to this agroindustry waste. The results demonstrate that organic yellow passion fruit seed can be explored as an important raw material to development of functional food ingredients or for nutraceutical applications, adding value to this crop and to the organic production chain.

References

Carr, M.K.V.: The water relations and irrigation requirements of the date palm (Phoenix dactylifera L.): a review. Exp. Agric. 45, 333–371 (2009)

Pacheco, A.L.V., Pagliarini, M.F., de Freitas, G.B., Santos, R.H.S., Serro, J.E., Zanuncio, J.C.: Mineral composition of pulp and production of the yellow passion fruit with organic and conventional fertilizers. Food Chem. 217, 425–430 (2017)

Liu, S., Yang, F., Zhang, C., Ji, H., Hong, P., Deng, C.: Optimization of process parameters for supercritical carbon dioxide extraction of Passiflora seed oil by response surface methodology. J. Supercrit. Fluids 48, 9–14 (2009)

Barrales, F.M., Rezende, C.A., Martínez, J.: Supercritical CO2 extraction of passion fruit (Passiflora edulis sp.) seed oil assisted by ultrasound. J. Supercrit. Fluids 104, 183–192 (2015)

Connor, W.E.: Importance of n-3 fatty acids in health and disease. Am. J. Clin. Nutr. 71, 171S–171S5S (2000)

Tapiero, H., Nguyen Ba, G., Couvreur, P., Tew, K.: Polyunsaturated fatty acids (PUFA) and eicosanoids in human health and pathologies. Biomed. Pharmacother. 56, 215–222 (2002)

Gao, F., Yang, S., Birch, J.: Physicochemical characteristics, fatty acid positional distribution and triglyceride composition in oil extracted from carrot seeds using supercritical CO2. J. Food Compos. Anal. 45, 26–33 (2016)

Siger, A., Dwiecki, K., Borzyszkowski, W., Turski, M., Rudzińska, M., Nogala-Kałucka, M.: Physicochemical characteristics of the cold-pressed oil obtained from seeds of Fagus sylvatica L. Food Chem. 225, 239–245 (2017)

Benitez Benitez, R., Ortega Bonilla, R.A., Franco, J.M.: Comparison of two sesame oil extraction methods: percolation and pressed. Biotecnol. Sect. Agropecu. Agroind. 14, 10 (2016)

Mohammed, N.K., Abd Manap, M.Y., Tan, C.P., Muhialdin, B.J., Alhelli, A.M., Hussin, A.S.M.: The effects of different extraction methods on antioxidant properties, chemical composition, and thermal behavior of black seed (Nigella sativa L.) Oil. Evid.-Based Complement. Altern. Med. (2016). https://doi.org/10.1155/2016/6273817.

Zanqui, A.B., De Morais, D.R., Da Silva, C.M., Santos, J.M., Gomes, S.T.M., Visentainer, J.V., Eberlin, M.N., Cardozo-Filho, L., Matsushita, M.: Subcritical extraction of flaxseed oil with n-propane: composition and purity. Food Chem. 188, 452–458 (2015)

Huang, W., Xue, A., Niu, H., Jia, Z., Wang, J.: Optimised ultrasonic-assisted extraction of flavonoids from Folium eucommiae and evaluation of antioxidant activity in multi-test systems in vitro. Food Chem. 114, 1147–1154 (2009)

Ahmad-Qasem, M.H., Cánovas, J., Barrajón-Catalán, E., Micol, V., Cárcel, J.A., García-Pérez, J.V.: Kinetic and compositional study of phenolic extraction from olive leaves (var. Serrana) by using power ultrasound. Innov. Food Sci. Emerg. Technol. 17, 120–129 (2013)

Esclapez, M.D., García-Pérez, J.V., Mulet, A., Cárcel, J.A.: Ultrasound-assisted extraction of natural products. Food Eng. Rev. 3, 108–120 (2011)

Knorr, D., Zenker, M., Heinz, V., Lee, D.-U.: Applications and potential of ultrasonics in food processing. Trends Food Sci. Technol. 15, 261–266 (2004)

Hernández-Santos, B., Rodríguez-Miranda, J., Herman-Lara, E., Torruco-Uco, J.G., Carmona-García, R., Juárez-Barrientos, J.M., Chávez-Zamudio, R., Martínez-Sánchez, C.E.: Effect of oil extraction assisted by ultrasound on the physicochemical properties and fatty acid profile of pumpkin seed oil (Cucurbita pepo). Ultrason. Sonochem. 31, 429–436 (2016)

Sicaire, A., Abert, M., Fine, F., Carré, P., Tostain, S., Chemat, F.: Ultrasonics sonochemistry ultrasound induced green solvent extraction of oil from oleaginous seeds. Ultrason. Sonochem. 31, 319–329 (2016)

Li, T., Qu, X., Zhang, Q., Wang, Z.-Z.: Ultrasound-assisted extraction and profile characteristics of seed oil from Isatis indigotica Fort. Ind. Crops Prod. 35, 98–104 (2012)

de Azevedo, A.A., Kopcak, U., Mohamed, R.: Extraction of fat from fermented Cupuaçu seeds with supercritical solvents. J. Supercrit. Fluids 27, 223–237 (2003)

dos Santos Freitas, L., De Oliveira, J.V., Dariva, C., Jacques, R.A., Caramão, E.B.: Extraction of grape seed oil using compressed carbon dioxide and propane: extraction yields and characterization of free glycerol compounds. J. Agric. Food Chem. 56, 2558–2564 (2008)

Nimet, G., Antonio, E., Palú, F., Dariva, C., Freitas, S., Medina, A., Cardozo, L.: Extraction of sunflower (Heliantus annuus L.) oil with supercritical CO2 and subcritical propane : experimental and modeling. Chem. Eng. J. 168, 262–268 (2011)

Sparks, D., Hernandez, R., Zappi, M., Blackwell, D., Fleming, T.: Extraction of rice brain oil using supercritical carbon dioxide and propane. J. Am. Oil Chem. Soc. 83, 885–891 (2006)

Liu, Z., Mei, L., Wang, Q., Shao, Y., Tao, Y.: Optimization of subcritical fluid extraction of seed oil from Nitraria tangutorum using response surface methodology. LWT Food Sci. Technol. 56, 168–174 (2014)

Hegel, P.E., Mabe, G.D.B., Pereda, S., Zabaloy, M.S., Brignole, E.A.: Phase equilibria of near critical CO2 + propane mixtures with fixed oils in the LV, LL and LLV region. J. Supercrit. Fluids 37, 316–322 (2006)

Hegel, P.E., Zabaloy, M.S., Mabe, G.D.B., Pereda, S., Brignole, E.A.: Phase equilibrium engineering of the extraction of oils from seeds using carbon dioxide + propane solvent mixtures. J. Supercrit. Fluids 42, 318–324 (2007)

Hegel, P., Mabe, G., Brignole, E.A., Pereda, S.: Phase equilibrium engineering of jojoba oil extraction with mixed-CO2 + propane solvent. J. Supercrit. Fluids 79, 114–122 (2013)

AOCS - American Oil Chemists’ Society.: Official Methods and Recommended Practices of the American Oil Chemists’ Society. AOCS Press, Champaign (1993)

Gomide, R.: Operações com sistemas sólidos granulares. Operações Unitárias, pp. 27–30 (1983) (In Portuguese)

Pereira, M.G., Hamerski, F., Andrade, E.F., Scheer, AdeP., Corazza, M.L.: Assessment of subcritical propane, ultrasound-assisted and Soxhlet extraction of oil from sweet passion fruit (Passiflora alata Curtis) seeds. J. Supercrit. Fluids 128, 338–348 (2017)

Correa, M., Mesomo, M.C., Pianoski, K.E., Torres, Y.R., Corazza, M.L.: Extraction of inflorescences of Musa paradisiaca L. using supercritical CO2 and compressed propane. J. Supercrit. Fluids 113, 128–135 (2016)

Coelho, R., Kanda, L.R.S., Hamerski, F., Masson, M.L., Corazza, M.L.: Extraction of kiwifruit seed (Actinidia deliciosa) oil using compressed propane. J. Food Process. Eng. 39, 335–344 (2016)

AOCS - American Oil Chemists’ Society: Official Methods and Recommended Practices of the American Oil Chemists’ Society. AOCS Press, Champaign (1998)

AOCS - American Oil Chemists’ Society: Method Cd 12be92. Official Methods and Recommended Practices of the American Oil Chemists’ Society. AOCS Press, Champaign (1992)

Tasioula-Margari, M., Okogeri, O.: Simultaneous determination of phenolic compounds and tocopherols in virgin olive oil using HPLC and UV detection. Food Chem. 74, 377–383 (2001)

Brand-Williams, W., Cuvelier, M.E., Berset, C.: Use of a free radical method to evaluate antioxidant activity. LWT Food Sci. Technol. 28, 25–30 (1995)

Wiegand, I., Hilpert, K., Hancock, R.E.W.: Agar and broth dilution methods to determine the minimal inhibitory concentration (MIC) of antimicrobial substances. Nat. Protoc. 3, 163–175 (2008)

Cardoso de Oliveira, R., Rossi, R.M., Gimenes, M.L., Jagadevan, S., Giufrida, M., Davantel, W., de Barros, S.T.: Extraction of passion fruit seed oil using supercritical CO2: a study of mass transfer and rheological property by Bayesian inference. Grasas Aceites 64, 400–406 (2013)

Chemat, F., Rombaut, N., Sicaire, A.G., Meullemiestre, A., Fabiano-Tixier, A.S., Abert-Vian, M.: Ultrasound assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. A review. Ultrason. Sonochem. 34, 540–560 (2017)

De Oliveira, R.C., De Barros, S.T.D., Gimenes, M.L.: The extraction of passion fruit oil with green solvents. J. Food Eng. 117, 458–463 (2013)

Nyanzi, S.A., Carstensen, B., Schwack, W.: A comparative study of fatty acid profiles of Passiflora seed oils from Uganda. J. Am. Oil Chem. Soc. 82, 41–44 (2005)

Silva, A.C., Jorge, N.: Bioactive compounds of oils extracted from fruits seeds obtained from agroindustrial waste. Eur. J. Lipid Sci. Technol. 119, 1–5 (2017)

El-Adawy, T.A., Taha, K.M.: Characteristics and composition of different seed oils and flours. Food Chem. 74, 47–54 (2001)

Youzbachi, N., Trabelsi, H., Elfalleh, W., Khaldi, A., Nasri, N., Tlili, N.: Fatty acids and triacylglycerols composition from Tunisian Acacia species seed oil. Arab. J. Chem. (2015). https://doi.org/10.1016/j.arabjc.2015.08.020

Kostik, V., Memeti, S., Bauer, B.: Fatty acid composition of edible oils and fats. J. Hyg. Eng. Des. 4, 112–116 (2013)

Lawton, C.L., Delargy, H.J., Brockman, J., Smith, F.C., Blundell, J.E.: The degree of saturation of fatty acids influences post-ingestive satiety. Br J. Nutr. 83, 473–482 (2000)

Gutiérrez, L.F., Quiñones-Segura, Y., Sanchez-Reinoso, Z., Díaz, D.L., Abril, J.I.: Physicochemical properties of oils extracted from γ-irradiated Sacha Inchi (Plukenetia volubilis L.) seeds. Food Chem. 237, 581–587 (2017)

Zhang, G., Ni, Y., Churchill, J., Kokot, S.: Authentication of vegetable oils on the basis of their physico-chemical properties with the aid of chemometrics. Talanta. 70, 293–300 (2006)

Bakhshabadi, H., Mirzaei, H., Ghodsvali, A., Jafari, S.M., Ziaiifar, A.M., Farzaneh, V.: The effect of microwave pretreatment on some physico-chemical properties and bioactivity of Black cumin seeds oil. Ind. Crops Prod. 97, 1–9 (2017)

Codex Stan 210: Codex Standard for Named Vegetable Oils (2009)

Noureddini, H., Teoh, B.C., Davis Clements, L.: Viscosities of vegetable oils and fatty acids. J. Am. Oil Chem. Soc. 69, 1189–1191 (1992)

Eromosele, I.C., Eromosele, C.O., Innazo, P., Njerim, P.: Studies on some seeds and seed oils. Bioresour. Technol. 64, 245–247 (1998)

Cho, Y.J., Kim, T.E., Gil, B.: Correlation between refractive index of vegetable oils measured with surface plasmon resonance and acid values determined with the AOCS official method. LWT Food Sci. Technol. 53, 517–521 (2013)

Gharby, S., Harhar, H., Bouzoubaa, Z., Asdadi, A., El Yadini, A., Charrouf, Z.: Chemical characterization and oxidative stability of seeds and oil of sesame grown in Morocco. J. Saudi Soc. Agric. Sci. 16, 105–111 (2017)

Jorge, N., Kobori, C.N.: Caracterização dos óleos de algumas sementes de frutas como aproveitamento de resíduos industriais. Ciênc. Agrotechnol. Lavras 29, 1008–1014 (2005)

Masson, L., Robert, P., Romero, N., Izaurieta, M., Valenzuela, S., Ortiz, J., Dobarganes, M.C.: Comportamiento de aceites poliinsaturados en la preparación de patatas fritas para consumo inmediato: formación de nuevos compuestos y comparación de métodos analíticos. Grasas Aceites 48, 273–281 (1997)

Wells, S.R., Jennings, M.H., Rome, C., Hadjivassiliou, V., Papas, K.A., Alexander, J.S.: Alpha-, gamma- and delta-tocopherols reduce inflammatory angiogenesis in human microvascular endothelial cells. J. Nutr. Biochem. 21, 589–597 (2010)

Fruhwirth, G.O., Wenzl, T., El-Toukhy, R., Wagner, F.S., Hermetter, A.: Fluorescence screening of antioxidant capacity in pumpkin seed oils and other natural oils. Eur. J. Lipid Sci. Technol. 105, 266–274 (2003)

Gliszczyńska-świgło, A., Sikorska, E., Khmelinskii, I., Sikorski, M.: Tocopherol content in edible plant oils. Pol. J. Food Nutr. Sci. 57, 157–161 (2007)

Malacrida, C.R., Jorge, N.: Yellow passion fruit seed oil (Passiflora edulis f. flavicarpa): physical and chemical characteristics. Braz. Arch. Biol. Technol. 55, 127–134 (2012)

Hussain, A., Larsson, H., Olsson, M.E., Kuktaite, R., Grausgruber, H., Johansson, E.: Is organically produced wheat a source of tocopherols and tocotrienols for health food? Food Chem. 132, 1789–1795 (2012)

Pertuzatti, P.B., Sganzerla, M., Jacques, A.C., Barcia, M.T., Zambiazi, R.C.: Carotenoids, tocopherols and ascorbic acid content in yellow passion fruit (Passiflora edulis) grown under different cultivation systems. LWT Food Sci. Technol. 64, 259–263 (2015)

Viganó, J., Coutinho, J.P., Souza, D.S., Baroni, N.A.F., Godoy, H.T., Macedo, J.A., Martínez, J.: Exploring the selectivity of supercritical CO2 to obtain nonpolar fractions of passion fruit bagasse extracts. J. Supercrit. Fluids 110, 1–10 (2016)

López-Vargas, J.H., Fernández-López, J., Pérez-Álvarez, J.A., Viuda-Martos, M.: Chemical: Physico-chemical, technological, antibacterial and antioxidant properties of dietary fiber powder obtained from yellow passion fruit (Passiflora edulis var. flavicarpa) co-products. Food Res. Int. 51, 756–763 (2013)

Santana, F.C., Shinagawa, F.B., Araujo, E.D.S., Costa, A.M., Mancini-Filho, J.: Chemical composition and antioxidant capacity of Brazilian passiflora seed oils. J. Food Eng. 80, 2647–2654 (2015)

Ferreira, B.S., De Almeida, C.G., Faza, L.P., De Almeida, A., Diniz, C.G., Da Silva, V.L., Grazul, R.M., Le Hyaric, M.: Comparative properties of amazonian oils obtained by different extraction methods. Molecules 16, 5874–5885 (2011)

Lambert, P.: Cellular impermeability and uptake of biocides and antibiotics in gram-positive bacteria and mycobacteria. J. Appl. Microbiol. 92, 46S–54S (2002)

Oliveira, D.A., Angonese, M., Gomes, C., Ferreira, S.R.S.: Valorization of passion fruit (Passiflora edulis sp.) by-products: sustainable recovery and biological activities. J. Supercrit. Fluids 111, 55–62 (2016)

Palma, M., Taylor, L.T., Varela, R.M., Cutler, S.J., Cutler, H.G.: Fractional extraction of compounds from grape seeds by supercritical fluid extraction and analysis for antimicrobial and agrochemical activities. J. Agric. Food Chem. 47, 5044–5048 (1999)

Saravanan, S., Parimelazhagan, T.: Total phenolic content, free radical scavenging and Antimicrobial activities of Passiflora subpeltata seeds. J. Appl. Pharm. Sci. 3, 67–72 (2013)

Zheng, C.J., Yoo, J.-S., Lee, T.-G., Cho, H.-Y., Kim, Y.-H., Kim, W.-G.: Fatty acid synthesis is a target for antibacterial activity of unsaturated fatty acids. FEBS Lett. 579, 5157–5162 (2005)

Acknowledgements

The authors are grateful to CNPq (Grant Number 305393/2016-2), CAPES and Fundação Araucária (Brazilian Agencies) for the financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pereira, M.G., Maciel, G.M., Haminiuk, C.W.I. et al. Effect of Extraction Process on Composition, Antioxidant and Antibacterial Activity of Oil from Yellow Passion Fruit (Passiflora edulis Var. Flavicarpa) Seeds. Waste Biomass Valor 10, 2611–2625 (2019). https://doi.org/10.1007/s12649-018-0269-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-018-0269-y