Abstract

In this work, the Q-switched Erbium-doped fiber laser (EDFL) is visualized using Ti2SnC as saturable absorber. The thin layer of Ti2SnC is mechanically exfoliated from a bulk material and pasted onto a fiber ferrule and integrated into EDFL by sandwiched method. The proposed Q-switched EDFL successfully achieved a stable pulse train, and the smallest pulse width of 1.26 µs and the highest pulse energy of 43.76 nJ are obtained at low operational pump power of 110 mW. The pulse energy obtained is comparable to other metal–ceramic based SA, with relatively low pump power. Owing to the strength of thermal shock resistance and oxidation resistant, the proposed saturable absorber is more feasible to cater the commercialization requirements.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

MAX phase is a machinable metal–ceramic material that possesses the strength of both metal and ceramic. Even though MAX phase is more known as precursor to produce MXene, it also exhibits exceptional material characteristic that has attracted a great interest in various applications, including hazardous pollutants removal, nuclear engineering, aerospace, and high temperature applications [1,2,3]. In general, MAX phase materials have excellent electrical, mechanical and thermodynamics properties [4, 5]. Furthermore, they have good structural stability, thermal shock resistance, damage tolerance, lightweight and good oxidation resistant [6].

The titanium tin carbide (Ti2SnC) is one of the early founded MAX phase materials. The Ti2SnC structure was first proposed based on powder diffraction X-ray data (space group: P63/m.m.c.; hexagonal axes a = 0.31626 nm, c = 1.36789 nm) [7]. Inheriting the remarkable properties of MAX phases, Ti2SnC exhibits impressive material self-healing capabilities. For instance, it can be employed as a healing material, effectively restoring electrical and mechanical properties while mending cracks and flaws at relatively low temperatures (as low as 800 °C) [8]. Furthermore, Ti2SnC has displayed promise in energy storage applications. In Li-ion battery, Ti2SnC nanosheets function as anode exhibits an increasing specific capacity with cycling. After 1000 charge–discharge cycles, Ti2SnC nanosheets delivered a high specific capacity of 735 mA h g−1 at a current density of 50 mA g−1, which surpassing the performance of most other MAX phase materials [9]. The exceptional mechanical and electrical properties of Ti2SnC have been widely utilized; however, the exploration of photonic application is still relatively intangible.

In photonics application, pulsed laser is one of the primary research topics due to the feasibility in material processing [10], medical treatment [11, 12] and telecommunication [13, 14]. The development of low-dimensional material spurs the exploration of passively pulsed laser using saturable absorber (SA). Many emerging materials have been reported as SA in pulsed laser system, such as graphene [15], transition metal dichalcogenide (TMD) [16], MXene [17], topological insulator [18] and vanadium pentoxide [19]. Recently, MAX phase has also been reported as SA [20]. From the reported results, the performance of MAX phase SA is comparable to other low-dimensional material. Owing to the nature of ceramic, MAX phase SA could perform better in hazardous environment due to its thermal shock resistance and oxidation resistant. Therefore, it is more feasible to cater the commercialization requirements.

In this work, we report the application of Ti2SnC as SA in Erbium-doped fiber laser (EDFL) system to induce Q-switching operation. The Ti2SnC thin layer is mechanically exfoliated from a bulk material and integrated into EDFL by sandwiched method. The proposed Q-switched EDFL achieved 1.26 µs pulsed width and highest pulse energy of 43.76 nJ at low operational pump power of 110 mW.

2 Preparation and characterization of Ti2SnC

Mechanical exfoliation is a method to physically separate layers from a bulk material using mechanical force. Ti2SnC is a ternary compound that belongs to the family of MAX phases, which are layered materials with a unique combination of metallic and ceramic properties. The most common mechanical exfoliation technique is the "scotch tape" method, which involves repeatedly pressing and peeling a piece of adhesive tape on the surface of the bulk material. As the tape is peeled off, it can pull away thin layers of Ti2SnC and then be transferred onto a substrate for further analysis or device fabrication. The general steps for performing mechanical exfoliation of Ti2SnC using the scotch tape method are shown in Fig. 1. The first step was to obtain a piece of bulk Ti2SnC material, which is clean and free of any contaminants. The next step was to cut a small piece of adhesive tape (such as scotch tape) and stick it onto the surface of the bulk material. The third step was to use a finger to press the tape firmly onto the surface of the bulk material, making sure to apply even pressure across the entire area. The four step was to slowly peel the tape off the surface of the bulk material, taking care not to tear the tape or leave any residue on the surface. Lastly, the previous steps were repeated with a fresh piece of tape each time, pressing, and peeling in different directions and locations on the surface of the bulk material to obtain thinner flakes. Overall, mechanical exfoliation is a relatively simple and low-cost method of processing layered materials.

The presence and quality of the Ti2SnC on the tape were checked by examining its field emission scanning electron microscopy (FESEM) image. As shown in Fig. 2a, the field emission scanning electron microscopy (FESEM) image of Ti2SnC has a high density of microrods and micrograins, which can be clearly viewed and distributed randomly on the substrate surface. These microrods and micrograins are in irregular shapes. The presence of the Ti2SnC layers on the tape was affirmed by analyzing the energy-dispersive X-ray spectroscopy (EDX) of the FESEM image. The EDX spectrum of Ti2SnC is recorded in Fig. 2b. It indicates the presence of 26.38 wt.% titanium (Ti), and 12.54 wt% Carbon (C). The linear absorption of Ti2SnC SA was obtained by utilizing an optical spectrum analyzer (OSA) and a white light source, as shown in Fig. 2c. At the wavelength of 1559.5 nm, the linear absorption was around 1.12 dB. On the other hand, the nonlinear absorption of the Ti2SnC SA was then characterized by utilizing a twin balance detection approach. In the measurement, we used a home-built mode-locked fiber laser as the light source. The output pulse train of the laser worked at a center wavelength of 1557 nm with a repetition rate and pulse duration of 1 MHz and 3.63 ps, respectively. The output port of the laser was connected to optical amplifier and then to the variable optical attenuator (VOA) to tune the output intensity of the laser. A 3 dB coupler was used after the VOA to split the beam power equally into two portions. The first portion was directly connected to the optical power meter as a reference power. While the other portion passed through Ti2SnC SA and the transmission power was recorded by another optical power meter. Figure 2d shows the nonlinear optical profile for the Ti2SnC SA, which was obtained by comparing the output power spectrum with and without the SA. The modulation depth and non-saturable absorption were measured to be about 4.8 and 42.8%, respectively. The saturable intensity of the film was about 10 MW/cm2.

3 Experimental details

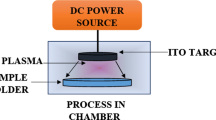

The experimental setup of proposed Q-switched EDFL is illustrated in Fig. 3. A 980 nm pump laser diode is used to excite the population inversion in the 3 m long EDF gain medium. A wavelength division multiplexer is connected between EDF and pump laser diode to couple the C-band signal and 980 nm pump light to co-propagate in the ring cavity. An isolator is incorporated into the ring cavity to ensure unidirectional signal propagation. The Ti2SnC SA is sandwiched into the cavity using two FC/PC ferrule. A 90:10 coupler is used to channel 90% of the signal light to circulate in the cavity. Another 10% of signal is tapped out from the cavity for further analysis using power meter, optical spectrum analyzer (OSA), oscilloscope and RF spectrum analyzer.

4 Results and discussions

Like most of the low-dimensional SA materials, Ti2SnC SA can also self-start Q-switching operation at relatively low pump power. In the proposed cavity, the self-started Q-switched laser was obtained at a pump power as low as 51 mW with repetition rate of 37.17 kHz and pulse width of 2.92 µs. In Q-switched operation, the EDFL is pumped to produce a high population inversion in the gain medium. However, the laser light is initially absorbed by the Ti2SnC SA, preventing it from circulating in the ring cavity. As the laser light intensity builds up, the SA begins to saturate, becoming increasingly transparent to the laser light. Once the Ti2SnC SA reaches its saturation point, the laser light is allowed to circulate in the cavity, producing a high-intensity, short-duration pulses. Successively, the Ti2SnC SA recovers from saturable stage and continue to absorb light. Figure 4a shows the optical spectra obtained from the fiber laser cavity with and without Ti2SnC SA. Without the Ti2SnC SA, the laser cavity generated continuous wave (CW) laser operating at wavelength of 1562 nm. With the incorporation of Ti2SnC SA, the laser operation is red shifted to compensate the additional loss of Ti2SnC SA. Besides, the circulation of short pulses in the cavity induced self-phase modulation (SPM), causing the spectrum broadening as shown in Fig. 4a. As the absorb-saturate-recover processes repeated sequentially, the Q-switched pulse train was realized in time domain as illustrated in Fig. 4b.

The Q-switching operation is observed within the pump power range of 51–110 mW. The details of Q-switched analysis are presented in Fig. 5. In Q-switched operation, the pulse width decreases, and the pulse repetition rate increases with increasing pump power. This is due to the increased energy stored in the laser gain medium, which leads to more efficient and faster population inversion and energy build-up. The result is narrower and more frequent laser pulses with higher energy. The phenomenon is observed in our analysis, as shown in Fig. 5a. With the increase in pump power from 51 to 110 mW, the pulse repetition rate increases from 37.17 to 68.56 kHz, whereas the pulse width decreases from 2.92 to 1.26 µs. The output power and pulse energy exhibit a linear increasing trend with pump power as shown in Fig. 5b. At pump power of 51 mW, the pulse energy and output power are 20.72 nJ and 0.77 mW, respectively. Both parameters increase linearly to 43.76 nJ and 3 mW at pump power of 110 mW. The pulse energy obtained is comparable to other metal–ceramic based SA [20, 21], which were generated with relatively low pump power.

With further increase in pump power, the Ti2SnC SA forced to absorb circulation light while it is not fully recovered from saturation stage. Eventually, the SA becomes transparent (maintain in saturation stage), and the Q-switching operation dismissed. In Fig. 6, we have recorded the signal-to-noise ratio (SNR) at pump power of 110 mW. The RF spectrum is recorded at 68 kHz, which is well agreed with the pulse repetition rate that recorded in time domain (Fig. 4b). The SNR obtained is reported as 55 dB, which indicates the Q-switching operation circulates stably in the EDFL.

5 Conclusion

The Q-switched EDFL was successfully realized using Ti2SnC as SA. The SA was fabricated using a thin layer of Ti2SnC, which was obtained by a mechanical exfoliation method. As the SA is integrated into an EDFL cavity, it produced stable Q-switched pulses operating at 68.56 kHz repetition rate with 1.26 µs pulse width and 43.76 nJ pulse energy at operational pump power as low as 110 mW. Our finding offers exciting prospects for advancements in Q-switched fiber laser technology.

References

Z Ansarian, A Khataee, S Arefi-Oskoui, Y Orooji and H Lin Materials Today Chemistry 24 100818 (2022)

D W Clark, S J Zinkle, M K Patel and C M Parish Acta Materialia 105 130 (2016)

M Radovic and M W Barsoum American Ceramics Society Bulletin 92 20 (2013)

S. Sâad Essaoud and A S Jbara Indian Journal of Physics 97 105 (2023)

M Mebrek, M Zemouli and M Berber Indian Journal of Physics 97 2991 (2023)

F Keramsi, M Berber, M Mebrek and A Mir Indian Journal of Physics 96 3761 (2022)

H Vincent, C Vincent, B F Mentzen, S Pastor and J Bouix Materials Science and Engineering: A 256 83 (1998)

S Li, G Bei, X Chen, L Zhang, Y Zhou, M Mačković, E Spiecker and P Greil Journal of the European Ceramic Society 36 25 (2016)

H Wu, J Zhu, L Liu, K Cao, D Yang, C Gong, H Lei, H Hang, W Yao and J Xu Nanoscale 13 7355 (2021)

X Jia, Y Chen, L Liu and C Wang Optics & Laser Technology 153 108209 (2022)

N E Estrin, A Lesniewski, W Hou and G E Romanos Photomedicine, and Laser Surgery 40 410 (2022)

J Dutta and B Kundu International Journal of Thermal Sciences 172 107346 (2022)

K Zeb, Z Lu, J Liu, Y Mao, G Liu, P J Poole, M Rahim, G Pakulski and P Barrios, W Jiang and X Zhang Optics Express 29 16164 (2021)

S Rommel, D Dodane, E Grivas, B Cimoli, J Bourderionnet, G Feugnet, A Morales, E Pikasis and C Roeloffzen Journal of Lightwave Technology 38 5412 (2020)

A Martinez and Z Sun Nature Photonics 7 842 (2013)

Z C Tiu, S I Ooi, J Guo, H Zhang and H Ahmad Materials Research Express 6 082004 (2019)

J Guo, Z Liu, S Wageh, O A Al-Hartomy, A G Al-Sehemi, Y Ge, W He, S Wei, W Bao and H Zhang Optics & Laser Technology 161 109178 (2023)

X Zhang, X Xing, J Li, X Peng, L Qiao, Y Liu, X Xiong, J Han, W Liu, W Xiao and Y Yao Applied Physics Letters 120 093103 (2022)

Z I Rizman, N F Zulkipli, S Adwan and H Arof, R Apsari and S W Harun Indian Journal of Physics 96 281 (2022)

M M Najm, A S Al-Hiti, B Nizamani, M N Abdullah, A H A Rosol, P Zhang, S M Najm, H Arof, Z C Tiu, M Yasin and S W Harun Optical Fiber Technology 70 102853 (2022)

A M Diblawe, M M Najm, B Nizamani, A H A Rosol, A M Samatar, K Dimyati and M Yasin, Z C Tiu and S W Harun Optik 264 169395 (2022)

Acknowledgements

We acknowledge the INTI IU Research Seeding Grant 2022 (Grant No.: INTI-FEQS-07-03-2022).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Diblawe, A.M., Tiu, Z.C., Rosol, A.H.A. et al. Titanium tin carbide as saturable absorber in C-band fiber laser. Indian J Phys 98, 2147–2152 (2024). https://doi.org/10.1007/s12648-023-02982-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12648-023-02982-8