Abstract

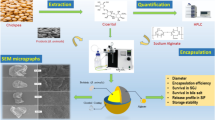

Longevity of probiotic is the main concern for getting maximum benefits when added in food product. Bifidobacterium, a probiotic, tends to lose its viability during gastrointestinal track (GIT) transit and storage of food. Their viability can be enhanced through microencapsulation technology. In this study, Bifidobacterium bifidum (B. bifidum) ATCC 35914 was encapsulated by using two experimental plans. In the first plan, chitosan (CH) at 0.6, 0.8, and 1.0% and sodium alginate (SA) at 4, 5, and 6% were used. Based on encapsulation efficiency, 6% sodium alginate and 0.8% chitosan were selected for single coating of the bacteria, and the resulting micro beads were double coated with different concentrations (5, 7.5, and 10%) of whey protein concentrate (WPC) in the second plan. Encapsulation efficiency and GIT tolerance were determined by incubating the micro beads in simulated gastrointestinal juices (SIJ) at variable pH and exposure times, and their release (liberation of bacterial cells) profile was also observed in SIJ. The microencapsulated bacterial cells showed significantly (P < 0.01) higher viability as compared to the unencapsulated (free) cells during GIT assay. The double-coated micro beads SA 6%–WPC 5% and CH 0.8%–WPC 5% were proven to have the higher survival at pH 3.0 after 90 min of incubation time and at pH 7.0 after 3-h exposure in comparison to free cells in simulated conditions of the stomach and intestine, respectively. Moreover, double coating with whey protein concentrate played a significant role in the targeted (106–9 CFU/mL) delivery under simulated intestinal conditions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Bifidobacteria are gram-positive, non-gas producing anaerobes and belong to the very important group of microorganisms called probiotics [1]. The published literature has revealed that Bifidobacteria play a key role in human health; they can balance the gut microbiota, stimulate the immune system, prevent diarrhea, exhibit anticarcinogenic potential, and also help to alleviate lactose intolerance [2,3,4,5,6,7]. Food and Agriculture Organization (FAO) has suggested/recommended that probiotics should be present in numbers ≥ 106 cells/g in food commodity till the time of consumption [8,9,10,11]. So, to maintain this number of probiotic bacteria is one of the prerequisites for its application [12] in food products. Several factors such as dissolved oxygen content, hydrogen peroxide concentrations, pH, storage time, and temperature affect the viability of probiotics during its utility as food additive (dairy/non-dairy foods) and as therapeutics [10]. Therefore the research work should be conducted to check the viability of the probiotics starting from inoculation to product delivery in the consumer’s gastro intestinal track (GIT) [13].

It has been reported that resistance of sensitive microorganisms to harsh conditions can be improved by incorporating prebiotics to stimulate probiotic growth or by microencapsulation of the beneficial cells into a matrix or shell material before introducing in the final product [13, 14]. Encapsulation is considered as the most effective method to maintain viability of the probiotics confining the bacteria within a protective coating so that they can liberate/release the active cells under specific intestinal conditions at a controlled rate, where, the rapid release of the cells is desirable for their colonization at the targeted site [11, 15]. Choice of coating materials is a critical stage to carry out the encapsulation. The matrices like polysaccharides, lipids, proteins, and their combinations have raised the interest to use them as carrier agents for microencapsulation [13, 16].

It has been observed that among the polysaccharides, alginate and chitosan are the most widely used coating materials for microencapsulation because of the high protection of chitosan for viable probiotic cells [17, 18]. The polycationic nature of chitosan leads to strong interactions between the carboxylic groups of alginate and the amine groups of chitosan, which results in the formation of a membrane. But, it has been observed that the encapsulation of probiotic bacterial cells in alginate-based microbeads was not able to keep the cells alive effectively because calcium alginate microcapsules are chemically prone to disintegrate in the presence of Ca2 +-chelating agents such as citrate phosphate, excess monovalent ions, and being very porous nature of the beads in highly acidic environment [14, 19]. To increase the stability of polysaccharide-based micro bead coating with the polycationic polymers and their derivatives (poly-l-lysine and proteins) are needed. It has been proven that proteins are good carrier agents for microencapsulation, have high nutritional value, and exhibit an excellent functional property [20]. Among proteins, whey proteins are particularly being studied for encapsulation of probiotics [20, 21]. The use of polysaccharide-protein matrices for probiotic cell microencapsulation is a new approach that permits for the targeted delivery of probiotics and can be adopted as a promising alternative (medicinal) strategy for health care management. In current research, an extrusion technique was used for the microencapsulation of B. bifidum with coating material combination. Considering the significance of microencapsulation and particularly its evident role in maintenance of probiotic bacterial viability during their GIT transit, this study was planned to achieve the following objectives: to evaluate protective effect of various polysaccharide-protein matrix for B. bifidum encapsulation and to assess the effect of encapsulating matrices on the cell liberation/release and viability during their incubation in simulated gastrointestinal conditions.

Materials and Methods

Bacterial Strain, Growth Media, and Growth Conditions

Lyophilized B. bifidum ATCC 35914 (Chr. Hansen, Denmark) was used for this study. The organism was inoculated (1%) into de Man Rogosa Sharpe (MRS) broth (Oxoid Ltd., Hampshire, UK), supplemented with 0.05% w/vl-cysteine hydrochloride (Sigma Chemical Co., Castle Hill, Australia), and incubated for 48 h at 37 °C anaerobically [2]. The B. bifidum cells were concentrated at 4 °C by centrifugation at 10090×g for 15 min using high-speed benchtop centrifuge (75005286-EA, Thermo Fisher Sci Inc. USA), and the cell pellet was washed twice with 0.85% of sterilized saline solution. The cell pellet (harvested cell) was then resuspended by physiological saline (0.85%) in one fourth of the original volume to obtain a final cell count of 108–109 colony-forming unit (CFU)/mL.

Microencapsulation of B. bifidum

Microencapsulation was done by preparing beads according to published protocols [22, 23]. B. bifidum was encapsulated following two experimental plans (I and II). In the experimental plan I, polysaccharides at various concentration levels [sodium alginate (SA) 4, 5, 6% w/v and chitosan (CH) 0.6, 0.8, 1% w/v] for single coating were used to prepare micro beads. In experimental plan II, whey protein concentrate (WPC) at levels of 5, 7.5, and 10% were used for double coating over SA 6% and CH 0.8%.

For the preparation of micro beads, the cell suspension (0.1% B. bifidum) was first mixed well with encapsulating material, and the mixture was filled into a syringe (gauge 25) to directly drip the mixture into 250 mL of cooled calcium chloride (0.1 M) (Aldrich Chemical Company Inc., St. Louis, USA) solution at a rate of 1.5 mL/min, which was stirred at 200 rpm by a magnetic stirrer. The distance between the needle and the calcium chloride solution was fixed at 3.0 cm. Particles were immediately formed when the mixture came in contact with the calcium chloride solution. The solution was left to mix for 30 to 120 min to allow for particle hardening. During mixing period, a phase change occurred; the encapsulated micro beads started to precipitate and fell to the bottom. The particles were then collected by filtration using sterilized cheese cloth. The alginate and chitosan micro beads were washed twice with sterile water and kept at 4 °C for further usage. Micro beads thus prepared were then enumerated to calculate the cell count/efficiency of microencapsulation for B. bifidum.

Encapsulation Efficiency of B. bifidum Micro Beads Prepared in Experimental Plan I and II

The efficiency of the encapsulated B. bifidum was measured according to the methods [24, 25] with some modifications. Freshly prepared beads were mechanically disintegrated in 9 mL of phosphate buffer or sterile sodium citrate solution (0.1 M at pH 6.3) in the stomacher (400 Circulator, Seward, UK), subsequently determining the number of entrapped cells by pour plate method (10−1 to 10−7 dilutions), and the counts were expressed as Log CFU/mL and calculated as:

where N represented the total number of viable bacterial cells liberated from the encapsulated micro beads and N0 is the total number of free cells prior to encapsulation added to the biopolymer mixture.

The treatments having the high encapsulation efficiency, SA 6% and CH 0.8%, were selected for further coating with whey protein concentrate (WPC) in experimental plan II. Then, SA 6% and CH 0.8% micro beads were dipped into WPC (100 ml) solutions for double coating with gentle shaking (100 rpm, 30 min) on magnetic stirrer. The beads were then washed and collected for future use. The micro beads containing SA 6%–WPC 5% and CH 0.8%–WPC 5% from experimental plan II were again selected on basis of encapsulation efficiency as described above and were used for gastrointestinal tract (GIT) tolerance assay for evaluating release profile with respect to time and target site.

In-Vitro Gastrointestinal Tract Tolerance

Estimations of acid and bile tolerance of encapsulated micro beads (double coated) in simulated stomach (gastric) and intestinal conditions were assessed following the method described by Pan et al. [14]. The test was performed to compare the bacterial viable counts and their survival rates for free cells as well as for encapsulated SA 6%–WPC 5% and CH 0.8%–WPC 5% micro beads after incubating in simulated gastro intestinal juices for a specific time.

Acidic environments were prepared by adjustment of the pH of MRS broth to different pH values (2.0, 2.5, and 3.0) using sterile (5 M) HCl or (1 M) NaOH solution with the addition of pepsin at a rate of 0.1 to 9.9 mL volume of MRS broth. The interaction time of beads with gastric juice at different pH varied as 0, 30, 60, and 90 min to see the duration of cell’s viability of the tested encapsulated strain. One milligram of SA 6%–WPC 5% and CH 0.8%–WPC 5% micro beads were placed into acidified MRS broth (9 mL) and at 37 °C was incubated (48 h) for pre-determined time intervals (0, 30, 60, and 90 min) and subjected to cell enumerations. Aliquot of 0.1 mL was used for enumeration by pour plating method on MRS agar, anaerobically (Anaerobic Jar, Oxoid Biomass, UAE) incubated (48 h, 37 °C) enumerated and compared with free cell’s survival rate. Survival rate in simulated stomach (gastric) condition was calculated by the following expression:

The simulated small intestine juice (SIJ) was prepared by dissolving pancreatin at a concentration of 5 g/L (Sigma) in sterile saline. Pancreatic solution (0.1 mL) was poured to MRS broth (9.9 mL) adjusted to different pH values (7.0, 7.5, and 8.0) and incubated for various time periods (0, 3, 3.5, and 4 h). The pH of the SIJ was adjusted with 0.1 M NaOH. Survival rate (%) of microencapsulated B. bifidum under SIJ (pH 7.0–8.0) after incubation (up to 4 h) was also checked. For this purpose, micro beads were subjected to enumeration as described above. Viable bacterial enumeration was compared with the survival rate of free cells. The experiment was repeated in triplicate, and values are represented as mean of three observations. Survival rate in simulated intestinal condition was calculated by the following expression:

Liberation/Release of B. bifidum in Simulated Intestinal Fluid (SIF)

The liberation/release behavior of B. bifidum from the SA 6%–WPC 5% and CH 0.8%–WPC 5% micro beads in gastric intestinal fluid (GIF) was determined by adopting the protocol described by Wang et al. [26]. Micro beads 200–250 mg were added to 50 mL SIF solution at various pH values (7.0, 7.5, and 8.0) with the constant agitation of 100 rpm/min under anaerobic conditions at 37 °C. Sampling (aliquots of 1.0 mL) was carried out at 0, 3, 3.5, and 4 h of time periods. The number of viable cells (Log CFU/mL) was determined for each time tested in triplicate after 48 h incubation at 37 °C and subjected to release study.

Statistical Analysis

The experiment design was completely randomized with a three × three and two factorial arrangements between the treatments (pH and incubation time). Analysis of variance (α = 0.05) and mean differences were computed by using the statistical SAS 9.4 software (SAS Institute Inc., Cary, NC, USA) [27] to ascertain the impact of independent variables (pH values and incubation time) on dependent variables (Log CFU/mL). ANOVA (analysis of variance) was used to examine interaction between the factors; however, difference between the means was checked by Tukey’s HSD test.

Results

Encapsulation Efficiency of B. bifidum

High encapsulation efficiency is one of the pre-requisite for successful microencapsulation. In this study, encapsulation significantly (P < 0.01) increased the viability of tested B. bifidum (Fig. 1a). Initially, the total number of viable B. bifidum in aqueous suspension used to prepare the micro beads was about 108–109 CFU/mL. The result of experimental plan I showed that the recovered viable cell number was 9.20 and 9.24 Log CFU/mL for SA 6% and CH 0.8% (single coating). After enumeration, their encapsulation efficiency was calculated as 93.8 and 94.2%, respectively. The treatments (SA 6% and CH 0.8%) were selected for double coating in the next experimental plan II with WPC 5, 7.5, and 10%. It was noticed that changes in total viable count with respect to the changes in chitosan and alginate concentration levels, significantly (P < 0.01) increased with concentration levels of coating material (Fig. 1b). The enumeration results for micro beads using the experimental plan II revealed that the encapsulation efficiency of B. bifidum in SA 6%–WPC 5% was 76.5% and 78.9% for CH 0.8%–WPC 5% micro beads (Fig. 1b). Hence, it was concluded from both experimental plans I and II that functional biological substances, including B. bifidum, exhibit a good compatibility with polysaccharide-protein matrices.

Effect of coating materials on the viability of B. bifidum. a Single coated with sodium alginate (SA 4, SA 5, and SA 6%) and chitosan (CH 0.6, CH 0.8, and CH 1.0%). b Double coated with sodium alginate and whey protein concentrate (SA 6%–WPC 5%, SA 6%–WPC 7.5%, SA 6%–WPC 10%) and chitosan and whey protein concentrate (CH 0.8%–WPC 5%, CH 0.8%–WPC 7.5%, CH 0.8%–WPC 10%). The data was analyzed using two-way ANOVA and the means were separated using Tukey’s HSD test. Each bar represents the mean + SD (n = 3). Different (a-f) lowercase letters are significantly different (P < 0.01)

Viable Count of Free and Encapsulated B. bifidum Cells During GIT Tolerance Transit

Survival of B. bifidum Cells in Simulated Gastric Conditions

Poor viability of probiotic cells under the stomach pH values is a major challenge in efficacy of probiotic food. As per objectives, the encapsulated B. bifidum and free probiotic cells were exposed to artificial stomach and intestinal conditions for various time intervals (Fig. 2a–c). The average initial bacterial count of free probiotic cells decreased from 8.54 Log CFU/mL to 6.6, 3.35, and 3.17 Log CFU/mL after 30, 60, and 90 min of incubation at simulated gastric conditions, respectively at pH of 2.0. Among the three gastric juices used with varying pH values, free cell of B. bifidum showed significant results at pH 3.0. At this pH, the total viable count of free cells was less than 1.87 Log units during 1.5 h incubation time. The data showed that at pH 2.0, free cells of B. bifidum were not resistant to acidic environment and were not found in acceptable limit of probiotic cells (3.35 Log CFU/mL), i.e., less than 106 after 60-min incubation to artificial stomach conditions. On the other side, SA 6%–WPC 5% and CH 0.8%–WPC 5% micro beads were moderately sensitive at this pH 2.0. Higher survival rate of the cells was found when encapsulated B. bifidum micro beads were incubated in SGF at pH 3.0 (Fig. 2c). The SA 6%–WPC 5% and CH 0.8%–WPC 5% micro beads and free cells survived comparatively better (> 106 Log CFU/mL) at pH 3.0 incubating for a period of 0, 30, 60, and 90 min, accordingly. It was concluded that the encapsulated double-layered B. bifidum micro beads showed better protection from simulated gastric juice (SGJ) and showed viability (up to 106 Log CFU/mL) in the pH range 2.0–3.0 (Fig. 2b, c), whereas the free cells of B. bifidum were not resistant to the prescribed acid environment.

Survival of B. bifidum Cells in Simulated Intestinal Conditions

The population of B. bifidum cells, microencapsulated with the mixtures of SA 6%–WPC 5% and CH 0.8%–WPC 5%, during their exposure to simulated intestinal juice was compared with the free ones (Fig. 3a–c). It also illustrates the release profile (time and survival) of SA 6%–WPC 5% and CH 0.8%–WPC 5% micro beads of the B. bifidum in SIF at different pH values (7.0, 7.5, and 8.0) and incubation times (0, 3, 3.5, and 4 h), respectively. The free B. bifidum cells were the most susceptible to intestinal juice after the 4-h incubation, which had a 5.04 and 4.96 Log reduction. The number of free cells declined significantly (P < 0.01) as the incubation time of SIJ increased from 2.5 h at pH > 7.0. However, when compared with the free cells, encapsulated B. bifidum (SA 6%–WPC 5% and CH 0.8%–WPC 5%) survived far better in SIF. After 4 h of incubation at pH 7.0, the viable numbers of B. bifidum encapsulated with treatment descriptions, SA 6%–WPC 5% was slightly reduced from 7.28 to 6.50 Log CFU/mL and CH 0.8%–WPC 5% decreased from 7.67 to 7.19 Log CFU/mL. It was observed that as the pH increases to 7.5 and 8, the cell population reduced by 4–5 Logs after 3 h of incubation in SIJ.

Liberation/Release Profile of B. bifidum in Artificial Intestinal Conditions (AIF)

The liberation of the active probiotic cells from micro beads is indispensable for the colonization resistance at the targeted site (colon). The SA 6%–WPC 5% and CH 0.8%–WPC 5% micro beads were opened to the simulated intestinal fluid at varying pH (7.0, 7.5, and 8.0) to assess the swelling behavior of the coating materials and to determine the cell release potentials. The coated B. bifidum cells liberated to give the viable count of 7.28 ± 0.007, 7.19 ± 0.005, and 7.21 ± 0.01 Log CFU/mL for SA 6%–WPC 5% micro beads at the pH 7.0, 7.5, and 8.0 and the cell counts of 7.67 ± 0.02, 7.23 ± 0.007, and 7.30 ± 0.01 for CH 0.8%–WPC 5%, respectively at the same pH followed by no further release at 0 h. It was observed that the release from the capsules was very slow in the beginning and the rate increased after 2.5 h. The cell count reduced in numbers at 4th-h incubation at pH 7.5 and 8.0 for both SA 6%–WPC 5% and CH 0.8%–WPC 5% micro beads (Fig. 3b, c). It was observed that the complete release of the cells from the capsules was achieved at 4th-h incubation with the significant reduction in the survival rates of the micro beads. Survival was decreased at the rate of 8% for SA 6%–WPC 5% and 1.3% for the CH 0.8%–WPC 5% micro beads at pH 7.0 during 4 h of incubation. Nevertheless, 8 and 13.7% for SA 6%–WPC 5% micro beads at the pH of 7.5 and 8.0, and 13.7 and 4.1% reduction in survival rate was observed for CH 0.8%–WPC 5% micro beads, during 3.5-h incubation in the SIJ.

Discussion

It is reported that encapsulation efficiency is dependent on the nature of coating materials and methods used for the preparation of micro beads. Encapsulation efficiency of micro beads by hydrophilic materials seems to be high as compared to hydrophobics. Two double-coated micro beads (1) 1st layer of 6% sodium alginate and 2nd layer of 5% WPC (SA 6%–WPC 5%) and (2) 1st layer of 0.8% chitosan and 2nd layer of 5% WPC (CH 0.8%–WPC 5%) were prepared in the present research work. The results for microencapsulation efficiency were in accordance with the findings of Babu et al. [28] who investigated the effect of alginate-whey protein as coating material for encapsulation of the yeast and also calculated the microencapsulation efficiency of the prepared micro beads [20, 28]. In another study, the encapsulation efficiency was calculated between 88 and 99.2% by using freeze drying technique [29]. The efficiency of Lactobacillus acidophilus and B. animalis micro beads prepared by spray chilling was also determined as 96 and 97%, respectively [30, 31]. Pedroso et al. [32] noticed that almost all of L. acidophilus and B. lactis in emulsion were protected during spray chilling process. In present study, due to low acid resistance, there was a greater reduction in survival of free B. bifidum in comparison to encapsulated tested SA 6%–WPC 5% and CH 0.8%–WPC 5% micro beads, because these showed the least Log reduction (Log CFU/mL) on their exposure to simulated GIT conditions. The study findings are in agreement with those of Lee et al. [24] and Krasaekoopt et al. [33] who conveyed that B. bifidum ATCC 1994 count was low at pH 2.5 showing simulated gastric pepsin free environment. The results regarding the tolerance of the free and double-layered microencapsulated cells of B. bifidum are coherent with the studies of Shah and Krasaekoopt et al. [2, 33]. However, they observed that count of probiotics was 79.93% higher in all micro beads incubated for 180 min in-vitro gastric digestion test. Nualkaekuet al. [34] assessed the viability of L. plantarum NCIMB 8826 microencapsulated by extrusion in alginate and subsequent coating with two layers of chitosan. They recorded the protective effect of this technique when cells were incubated in simulated gastric solution at pH 1.5 for 2 h. The microencapsulation of L. acidophilus through layer-by-layer self-assembly of chitosan and carboxymethyl cellulose was used to evaluate the survival rate of probiotics under incubation in SGJ and SIJ, for 120 min. These results suggested that double-layered microencapsulation improved protection of probiotics from low acidity in the presence of pepsin and pancreatin [35]. The similar findings are also reported about the low survival rate of the probiotics during their transit [36]. Hypothetically, the greater total viable counts for cells liberated from the micro beads in comparison to free bacterial cells is due to pronounced protective effect of the microencapsulation.

Decline and survival rate (%) of microencapsulated B. bifidum under (i) SGJ (pH 2.0–3.0) after incubation up to 90 min, (ii) SIJ (pH 7.0–8.0) after incubation up to 4 h were investigated. These results are similar to previous study conducted on Lb. Rhamnosus CRL 1505, which conferred greater protection on exposure to acidic conditions after coating with whey protein [28, 37]. The significant increase in viable numbers of encapsulated probiotic micro beads was noticed in SGF at pH 2.0 [18, 38]. Probably, this improvement in total numbers of viable cells can be due to the low porosity on the surface of the micro beads and protein buffering capacity [39]. Finally, it was concluded that encapsulated B. bifidum (up to ~ 106 CFU/mL) can survive in the upper intestine at a low pH (3.0) for at least 90 min (Fig. 2c). From the previous studies, it was confirmed that population of probiotic bacteria enhanced significantly in simulated intestinal conditions when encapsulated with polycationic polymers. Strong ionic interactions between the amino groups of polycationic polymer and carboxylate groups of alginate result in the creation of protective membrane which acts as barrier for viable cells to be dissolved in the stomach and allow for an efficient and controlled release at target site of intestine [2]. Upon facing acid stress, the cells strengthen the cell wall integrity and change the membrane permeability to keep H+ from entering followed by increased activity of F0F1-ATPases. The repair of acid-induced protein and DNA damage is an important response to acid stress in lactic acid bacteria (LABs). This could be a possible reason for revival of the cells observed in survival studies [40]. Similar effects of increased pH on the probiotic population have been previously reported by Shi et al. [41]. The present study suggests that B. bifidum survive better at pH range of 7.0–7.5 in order to remain functional in small and large intestines, which is also in alignment with the findings of Kamalian et al. [42].

An effective liberation/release of metabolically active cells in the intestine is one of the goals of microencapsulation. Delivery of the entrapped cells from hydrogel networks is a mass-transfer-controlled process which depends on the environmental factors such as pH, temperature, and the ionic strength. Alternatively, solute transport through the polymer network can be controlled by numerous physicochemical phenomena, such as polymeric chain relaxation (macromolecule relaxation), gel layer formation, and polymer water uptake (diffusion) [21, 24]. It is reported that alginate gels formed through calcium ion swells slowly at neutral pH and seems to be very rigid due to the electrostatic repulsion between whey proteins and the alginate molecules which dissociate the gel. When the pH of the SIJ solution increased, the strong electrostatic linkages between the protein and polysaccharide matrix (due to presence of the ionizable groups of a carboxyl and amino groups) started to be weakened followed by two ways. Firstly, the deionization of the amino groups and the attraction of the Na+ ions towards carboxyl groups, which results in an increase of the osmotic pressure around the micro beads, allow the network to expand and imbibe water. Secondly, the presence of protease within the AIF is also helpful in dissolution of the micro beads [33, 43].

The study findings are in accordance to Chen et al. [44], who worked on the release profile of alginate-whey protein micro beads and concluded that the encapsulated cells of Lb. bulgaricus completely liberated the active probiotic cells within 3 h with survival rate of 70%. In another study, Mandal et al. [45] also reported that the probiotic cells released progressively with increase of incubation time. The release time of B. bifidum from poly-l-lysine and alginate-based micro beads after their exposure to simulated intestinal fluid was noted at 8 h to obtain 9 Log CFU/g and 8 Log CFU/g required 12 h [46], whereas B. adolescentis bacterium in extruded pea protein–alginate micro beads liberated gradually from 5.5 to 7.0 Log CFU/g in SIF within 3.5 h. It was reported that the release of B. pseudolongum encapsulated in cellulose acetate phthalate subjected to SIF was observed within 20–40 min [36, 47]. Differences in release profile in the above-mentioned studies are due to type of the probiotic strain, micron- vs millimeter-sized micro beads, and chemical nature of the coating material used [48, 49]. Zhang et al. [50] studied the effect of different microencapsulation techniques (coacervation, emulsion, and extrusion) on the total viable count of freeze-dried B. bifidum in comparison to free bacterial cells. They reported that the microencapsulated cells with chitosan and alginate are more resistant than free cells in SGJ and SIF. Therefore, the protective effect of microencapsulation of B. pseudocatenulatum G4 might be due to the deposits of alginate- and chitosan-based multi layers [23, 42]. The active probiotic cells gradually liberated from whey protein-based micro beads in AIF [11, 12]. Similar release profiles were observed by Gerez et al. [51], who worked on the burst release of encapsulated whey protein-hydrogelled caffeine at SIF of pH 7.5. Thus, persistence of Bifidobacterium is highly pH-dependent as they are quite stable at physiological pH > 5.0 but, more susceptible to acidic conditions. The micro beads are tended to be washed out from the body prior to exert beneficial effect, if probiotics are not properly packed during their GIT transit [9, 52].

Conclusively, the results showed that microencapsulation using coating matrixes (polysaccharide-protein matrix) preserve viability of probiotics during GIT transitions and in effector molecules (intestine), which was one of the aims of technology under discussion [45, 53]. The unique property of polysaccharide-protein matrix has encouraged their use as novel coating materials for probiotic-enriched foods [8, 28, 33]. The method used for improving the survival rate of microencapsulated bacteria with whey proteins, as experimented, can be of importance for site-directed (intestine-targeted) drug delivery, alternative therapy to antibiotic for treating GIT disorders and other health care management [35, 54]. However, future studies are still needed to be carried out in order to monitor the effect of polysaccharide-protein-based matrix fate of bacterial entrapment in tested bacterial cells using gut or animal models.

References

Deshpande KG, Dolas CB, Chavan NS (2014) Investigation of tolerance of Lactobacillus casei to the presence of acids, bile salts and deconjugation of bile salts. Int J Curr Microbiol App Sci 3:600–612

Shah D (2007) Functional cultures and health benefits. Int Dairy J 17(11):1262–1277. https://doi.org/10.1016/j.idairyj.2007.01.014

Vieira AT, Rocha VM, Tavares L, Garcia CC, Teixeira MM, Oliveira SC, Cassali GD, Gamba C, Martins FS, Nicoli JR (2016) Control of Klebsiella pneumoniae pulmonary infection and immunomodulation by oral treatment with the commensal probiotic Bifidobacterium longum. Microb Infect 18(3):180–189. https://doi.org/10.1016/j.micinf.2015.10.008

De Freitas Fonseca J (2015) Effect of Bifidobacterium longum on the Weissella paramesenteroides WpK4 328 em giardíase experimental. Available at: http://www.bibliotecadigital.ufmg.br/dspace/handle/1843/BUBD-9WEVXW

Eckert C, Serpa VG, dos Santos ACF, da Costa SM, Dalpubel V, Lehn DN, de Souza CFV (2017) Microencapsulation of Lactobacillus plantarum ATCC 8014 through spray drying and using dairy whey as wall materials. LWT-Food Sci Technol 82:176–183. https://doi.org/10.1016/j.lwt.2017.04.045

Bernucci BS, Loures CM, Lopes SC, Oliveira MC, Sabino AP, Vilela JM, Andrade MS, Lacerda IC, Nicoli JR, Oliveira ES (2017) Effect of microencapsulation conditions on the viability and functionality of Bifidobacterium longum. LWT-Food Sci Technol 80:341–347. https://doi.org/10.1016/j.lwt.2017.02.036

Holkem AT, Raddatz GC, Barin JS, Flores EMM, Muller EI, Codevilla CF, Jacob-Lopes E, Grosso CRF, de Menezes CR (2017) Production of microcapsules containing Bifidobacterium BB-12 by emulsification/internal gelation. LWT-Food Sci Technol 76:216–221. https://doi.org/10.1016/j.lwt.2016.07.013

Carvalho AS, Silva J, Ho P, Teixeira P, Malcata FX, Gibbs P (2004) Relevant factors for the preparation of freeze-dried lactic acid bacteria. Int Dairy J 14(10):835–847. https://doi.org/10.1016/j.idairyj.2004.02.001

Sabikhi D (2010) Enhanced survival of probiotic Lactobacillus aciduphillus by encapsulation with the nano structured polyelectrolyte layers through layer-by-layer approach. J Agri Food Chem 59:11838–11845

Prasanna PH, Grandison AS, Charalampopoulos D (2014) Bifidobacteria in milk products: an overview of physiological and biochemical properties, exopolysaccharide production, selection criteria of milk products and health benefits. Food Res Int 55:247–262. https://doi.org/10.1016/j.foodres.2013.11.013

Coghetto CC, Vasconcelos CB, Brinques GB, Ayub MA (2016) Lactobacillus plantarum BL011 cultivation in industrial isolated soybean protein acid residue. Braz J Microbiol 47(4):941–948. https://doi.org/10.1016/j.bjm.2016.06.003

Tripathi MK, Giri SK (2014) Probiotic functional foods: survival of probiotics during processing and storage. J Funct Foods 9:225–241. https://doi.org/10.1016/j.jff.2014.04.030

Darjani P, Nezhad MH, Kadkhodaee R, Milani E (2016) Influence of prebiotic and coating materials on morphology and survival of a probiotic strain of Lactobacillus casei exposed to simulated gastrointestinal conditions. LWT-Food Sci Technol 73:162–167. https://doi.org/10.1016/j.lwt.2016.05.032

Pan LX, Fang XJ, Yu Z, Xin Y, Liu XY, Shi LE (2013) Encapsulation in alginate-skim microspheres improves viability of Lactobacillus bulgaricus in stimulated gastro-intestinal conditions. Int J Food Sci Nutr 64(3):380–384. https://doi.org/10.3109/09637486.2012.749841

Gbassi GK, Vandamme T, Ennahar S, Marchioni E (2009) Microencapsulation of Lactobacillus plantarum spp in an alginate matrix coated with whey proteins. Int J Food Microbiol 129(1):103–105. https://doi.org/10.1016/j.ijfoodmicro.2008.11.012

Yeung TW, Ucok EF, Tiani KA, McClements DJ, Sela DA (2016) Microencapsulation in alginate and chitosan microgels to enhance viability of Bifidobacterium longum for oral delivery. Front Microbiol 7:34–39

Fahimdanesh M, Mohammadi N, Ahari H, Zanjani MA, Hargalani FZ, Behrouznasab K (2013) Effect of microencapsulation plus resistant starch on survival of Lactobacillus casei and Bifidobacterium bifidum in mayonnaise sauce. Afr J Microbiol Res 6:6853–6858

Zanjani MA, Tarzi BG, Sharifan A, Mohammadi N (2014) Microencapsulation of probiotics by calcium alginate-gelatinized starch with chitosan coating and evaluation of survival in simulated human gastro-intestinal condition. Iran J Pharm Res 13:843–850

Dong QY, Chen MY, Xin Y, Qin XY, Chen Z, Shi LE (2013) Alginate-based and protein-based materials for probiotics encapsulation: a review. Int J Food Sci Technol 48(7):1339–1351. https://doi.org/10.1111/ijfs.12078

Duongthingoc D, George P, Katopo L, Gorczyca E, Kasapis S (2013) Effect of whey protein agglomeration on spray dried microcapsules containing Saccharomyces boulardii. Food Chem 141(3):1782–1788. https://doi.org/10.1016/j.foodchem.2013.04.093

Anandharamakrishnan C, Rielly CD, Stapley AGF (2012) Effects of process variables on the denaturation of whey proteins during spray-drying. Dry Technol 25:799–807

Ayama H, Punnanee S, Songklanakarin SC (2014) Effect of encapsulation of selected probiotic cell on survival in simulated gastrointestinal tract condition. J Adhes Sci Technol 36:291–299

Cook SM, Cho YH, Huh CS, Baek YJ, Park J (2011) Improvement of the stability of Lactobacillus casei YIT 9018 by microencapsulation using alginate and chitosan. J Microbiol Biotechnol 11:376–383

Lotfipour SM, Maghsoodi M (2012) Evaluation of the effect of CaCl2 and alginate concentrations and hardening time on the characteristics of Lactobacillus acidophilus loaded alginate beads using response surface analysis. Afr J Microbiol Res 2:71–78

Lee IC, Tomita S, Kleerebezem M, Bron PA (2013) The quest for probiotic effector molecules-unraveling strain specificity at the molecular level. Pharmacol Res 69(1):61–74. https://doi.org/10.1016/j.phrs.2012.09.010

Wang J, Korber DR, Low NH, Nickerson MT (2014) Entrapment, survival and release of Bifidobacterium adolescentis within chickpea protein-based microcapsules. J Food Res Int 55:20–27. https://doi.org/10.1016/j.foodres.2013.09.018

Montgomery DC (2008) Design and analysis of experiments.7th Ed. John Wiley and sons. Inc. Hookon, NJ, USA. 1-656

Babu G, Rath S, Nithyalakshami V (2011) Probiotic viability of freeze dried symbiotic microcapsules in skim milk powder at ambient storage condition. Int J Food Safety 13:62–68

Dianawati D, Mishra V, Shah NP (2013) Survival of Bifidobacterium longum 1941 microencapsulated with proteins and sugars after freezing and freeze drying. Food Res Int 51(2):503–509. https://doi.org/10.1016/j.foodres.2013.01.022

Bampi GB, Backes GT, Cansian RL, de Matos FE, Ansolin IMA, Poleto BC, Corezzolla LR, Favaro-Trindade CS (2016) Spray chilling microencapsulation of Lactobacillus acidophilus. Food Biopro Technol 9(8):1422–1428. https://doi.org/10.1007/s11947-016-1724-z

Arslan-Tontul S, Erbas M (2017) Single and double layered microencapsulation of probiotics by spray drying and spray chilling. LWT-Food Sci Technol 81:160–169. https://doi.org/10.1016/j.lwt.2017.03.060

de Lara Pedroso D, Thomazini M, Heinemann RJB, Favaro-Trindade CS (2012) Protection of Bifidobacterium lactis and Lactobacillus acidophilus by microencapsulation using spray-chilling. Int Dairy J 26(2):127–132. https://doi.org/10.1016/j.idairyj.2012.04.008

Krasaekoopt W, Bhandari B, Deeth H (2004) The influence of coating materials on some properties of alginate beads and survivability of microencapsulated probiotic bacteria. Int Dairy J 14(8):737–743. https://doi.org/10.1016/j.idairyj.2004.01.004

Nualkaekul S, Lenton D, Cook MT, Khutoryanskiy VV, Charalampopoulos D (2012) Chitosan coated alginate beads for the survival of microencapsulated Lactobacillus plantarum in pomegranate juice. Carbohydr Polym 90(3):1281–1287. https://doi.org/10.1016/j.carbpol.2012.06.073

Falco CY, Sotres J, Rascon A, Risbo J, Cardenas M (2017) Design of a potentially prebiotic and responsive encapsulation material for probiotic bacteria based on chitosan and sulfated β-glucan. J. Colloid Interface Sci 487:97–106. https://doi.org/10.1016/j.jcis.2016.10.019

Sahadeva RPK, Leong SF, Chua KH, Tan CH, Chan HY, Tong EV, Wong SYW, Chan HK (2011) Survival of commercial probiotic strains to pH and bile. Int Food Res J 18:1515–1522

Abbaszadeh S, Gandomi H, Misaghi A, Bokaei S, Noori N (2014) The effect of alginate and chitosan concentrations on some properties of chitosan-coated alginate beads and survivability of encapsulated Lactobacillus rhamnosus in simulated gastrointestinal conditions and during heat processing. J Sci Food Agr 94(11):2210–2216. https://doi.org/10.1002/jsfa.6541

Chandramouli V, Kailasapathy K, Peiris P, Jones M (2004) An improved method of microencapsulation and its evaluation to protect lactobacillus spp. in simulated gastric conditions. J Microbiol Meth 56:27–35

Heidebach T, Först P, Kulozik U (2009) Microencapsulation of probiotic cells by means of rennet-gelation of milk proteins. Food Hydrocoll 23(7):1670–1677. https://doi.org/10.1016/j.foodhyd.2009.01.006

Moumita S, Goderska K, Johnson EM, Das B, Indira D, Yadav R, Kumari S, Jayabalan R (2017) Evaluation of the viability of free and encapsulated lactic acid bacteria using in-vitro gastro intestinal model and survivability studies of symbiotic microcapsules in dry food matrix during storage. LWT-Food Sci Technol 77:460–467. https://doi.org/10.1016/j.lwt.2016.11.079

Shi LE, Zhang ZL, Song YQ, Zhou ML, WM Y, Tang ZX (2013b) Encapsulation of Lactobacillus bulgaricus in carrageenan-locust bean gum coated milk microspheres with double layer structure. LWT-Food Sci Technol 54(1):147–151. https://doi.org/10.1016/j.lwt.2013.05.027

Kamalian N, Mirhosseini H, Mustafa S, Manap MYA (2014) Effect of alginate and chitosan on viability and release behavior of Bifidobacterium pseudocatenulatum G4 in simulated gastrointestinal fluid. Carbohydr Polym 11:700–706

Argin S, Kofinas P, Lo YM (2014) The cell release kinetics and the swelling behavior of physically cross-linked xanthan–chitosan hydrogels in simulated gastrointestinal conditions. Food Hydrocol 40:138–144. https://doi.org/10.1016/j.foodhyd.2014.02.018

Chen MY, Zheng W, Dong QY, Li ZH, Shi LE (2014) Tang ZX activity of encapsulated Lactobacillus bulgaricus in alginate-whey protein microspheres. Braz Arch Biol Technol 57(5):736–741. https://doi.org/10.1590/S1516-8913201402377

Mandal S, Puniya AK, Singh K (2006) Effect of alginate concentrations on survival of microencapsulated Lactobacillus casei NCDC-298. Int Dairy J 16(10):1190–1195. https://doi.org/10.1016/j.idairyj.2005.10.005

Picot A, Lacroix C (2004) Encapsulation of bifidobacteria in whey protein-based microcapsules and survival in simulated gastrointestinal conditions and in yoghurt. Int Dairy J 14(6):505–515. https://doi.org/10.1016/j.idairyj.2003.10.008

Rao AV, Shiwnarain N, Maharaj I (1989) Survival of microencapsulated Bifidobacterium pseudolongum in simulated gastric and intestinal juices. Canadian Int Food Sci Tech J 22(4):345–349. https://doi.org/10.1016/S0315-5463(89)70426-0

Klemmer KJ, Korber DR, Low NH, Nickerson MT (2011) Pea protein-based capsules for probiotic and prebiotic delivery. Int J Food Sci Tech 46(11):2248–2256. https://doi.org/10.1111/j.1365-2621.2011.02743.x

Tian S, Ohta A, Horiuchi H, Fukuda R (2015) Evaluation of sterol transport from the endoplasmic reticulum to mitochondria using mitochondrially targeted bacterial sterol acyl-transferase in Saccharomyces cerevisiae. Biosci Biotechnol Biochem 79(10):1608–1614. https://doi.org/10.1080/09168451.2015.1058702

Zhang L, Zhang X, Liu C, Li C, Li S, Li T, Li D, Zhao Y, Yang Z (2013) Manufacture of cheddar cheese using probiotic Lactobacillus plantarum K25 and its cholesterol-lowering effects in a mice model. World J Microbiol Biotech 29:127–135

Gerez CL, Font de Valdez G, Gigante ML, Grosso CRF (2012) Whey protein coating bead improves the survival of the probiotic Lactobacillus rhamnosus CRL 1505 to low pH. Lett Appl Microbiol 54(6):552–556. https://doi.org/10.1111/j.1472-765X.2012.03247.x

Nieddu M, Rassu G, Boatto G, Bosi P, Trevisi P, Giunchedi P, Carta A, Gavini E (2014) Improvement of thymol properties by complexation with cyclodextrins: in vitro and in vivo studies. Carbohydr Polym 102:393–399. https://doi.org/10.1016/j.carbpol.2013.10.084

de Vos P, Faas MM, Spasojevic M, Sikkema J (2010) Encapsulation for preservation of functionality and targeted delivery of bioactive food components. Int Dairy J 20(4):292–302. https://doi.org/10.1016/j.idairyj.2009.11.008

Cruce PS (2001) Improving probiotic survival rates. Food Tech 55:36–43

Acknowledgements

We acknowledge colleagues and institutions of National Institute of Food Science and Technology, University Faisalabad, HEC, and School of Food Science, UI (University of Idaho) in the College of Agricultural and Life Sciences (CALS) for providing moral, funding, and laboratory support and their contributions. Special thanks are for Dr. Gulhan Unlu and Dr. Boffman, UI, USA and Dr. Tahir Zahoor, Dr. Nuzhat Huma, and Dr. Amer Jamil UAF-Pakistan for providing all guidelines in the field of study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Iqbal, R., Zahoor, T., Huma, N. et al. In-vitro GIT Tolerance of Microencapsulated Bifidobacterium bifidum ATCC 35914 Using Polysaccharide-Protein Matrix. Probiotics & Antimicro. Prot. 11, 830–839 (2019). https://doi.org/10.1007/s12602-017-9384-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12602-017-9384-5