Abstract

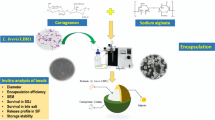

Ciceritol is a prebiotic that improves the gastrointestinal health and viability of probiotics. Ciceritol can be used to improve the structural defects of sodium alginate-based beads and the viability of Bifidobacterium animalis. The present study focused on ciceritol extraction to encapsulate B. animalis in alginate and alginate-ciceritol matrix to enhance the survival of probiotic after exposure to simulated gastric conditions. Ciceritol and sodium alginate were used to encapsulate B. animalis with different formulations i.e.., C0SA2 (0%:2%), C1SA2 (0.5%:2%), C2SA2 (1%:2%), C3SA2 (1.5%:2%) and C4SA2 (2%:2%). Free cells and encapsulated cells were investigated for their survival in gastrointestinal conditions. The addition of prebiotics (ciceritol) significantly (p < 0.05) improved the survival of probiotics. The incorporation of ciceritol in alginate provided better protection and survival (> 106 CFU/mL) as compared to free cells. All the encapsulation treatments showed good storage stability after 30 days and maximum viable count was observed in C4SA2. Results revealed that the efficiency of co-encapsulation to improve the survival of B. animalis in harsh gastrointestinal conditions.

Graphic Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Ciceritol is a trisaccharide extracted from chickpea (Cicer arietinum L.). It has prebiotic potential to improve the survival of probiotics and to inhibits the proliferation of pathogenic bacteria. It produces short chain fatty acids e.g. acetic acid, butyric acid and propionic acid. Butyric acid improves the differentiation process of cells to nourish mucosal lining of colon and decreases the risk of colon cancer. Propionic acid acts as a precursor for gluconeogenesis and decreases hepatic cholesterol synthesis. Acetic acid modulates lipogenesis and gluconeogenesis processes. Ciceritol is a non-digestible oligosaccharide which can improve gut health and viability of probiotics. The regular intake of oligosaccharides (ciceritol, inulin and fructooligosaccharide) improve probiotic population in colon [1, 2].

Probiotics are the microbes which are beneficial for human health. They can modulate immune system to decrease the risk of disease. Probiotics produce enzymes like beta-galactosidase which can improve digestion. B. animalis is a probiotic which is reported to provide different health benefits i.e.. improves immune system, limits lactose malabsorption, anticancer effect, anti-inflammatory effect, improves gut microflora and inhibits the growth of pathogens due to the production of bacteriocins. The study of [3] reported the impact of oligosaccharides on the probiotics. The bifidogenic effect can be enhanced with the uptake (10 g/day) galactooligosaccharides or fructooligosaccharides. The addition of these prebiotics improves viability of bifidobacteria which can ultimately improve the gut health. Prebiotic utilization is fundamental attribute of probiotics. Probiotics survival decreases in harsh gastrointestinal conditions (low pH and bile salt). Therefore, it is important to encapsulate probiotics for maintenance of their viability (> 107 CFU/mL) [4]. The use of prebiotics as encapsulating material are helpful to protect and improve the viability of probiotics.

Alginate is a polymer having good gelling properties. It is commonly used as an encapsulation agent due to low cost, non-toxicity and biocompatibility [5]. Although alginate has been used in various studies as encapsulating material. It could not withstand harsh conditions (low pH and bile salt) [6]. The main disadvantages using alginate are the presence of pores, loss of viability and uncontrolled release of bioactive component. The incorporation of different polymers may be effective to overcome these issues. The challenging task in the microencapsulation of the probiotics is the selection of wall material to protect and improve the viability of probiotics in harsh conditions. Recently, there is an increasing interest to use prebiotic based encapsulating materials for probiotics as they can improve the survival of probiotics. Oligosaccharides as encapsulation material have been reported to improve the viability of probiotics [7]. However, the matter of concern is their solubility and low glass transition temperature [8].

Ciceritol and alginate can be used to develop microbeads for encapsulation of B. animalis. The combination of ciceritol and alginate can help to form a stable bead for improved survival of B. animalis. Keeping in view the above details, the present study was designed to develop a prebiotic based encapsulation matrix for improved survival of B. animalis. The encapsulated probiotics were further studied for their survival in unfavorable conditions (low pH and bile salt), release profile and storage stability.

Materials and methods

B. animalis subsp. animalis (ATCC 25,527) was received from the American Type Culture Collection. Chickpea was procured from the local market of Faisalabad, Pakistan. Alginate, simulated gastric fluid and simulated intestinal fluid were obtained from Sigma Aldrich (St. Louis, MO, USA). Pepsin was procured from Merck (Germany). MRS agar (De Man Rogosa and Sharpe) and MRS broth were procured from Difco (Sparks, USA). All other chemicals were of analytical grade procured from Sigma Aldrich (St. Louis, MO, USA).

Extraction and quantification of ciceritol

Grinding of chickpeas was performed in an electric blender to make powder. The fat was removed from the powder using petroleum ether. The defatted meal was suspended with ethanol and water (1:10 w/v) and incubated at 50 °C for 30 min. The mixture was centrifuged at 2000 rpm for 25 min and the supernatant was collected through the rotary evaporator. This extract was used for the extraction of ciceritol [9].

Ciceritol was quantified by the method provided by [9]. A column (3 × 50 cm) filled with charcoal-celite (1:1, w/w) was used to separate ciceritol from the concentrated extract. The column was successively eluted with water and ethanol (5–30%). The colorimetric method was used to determine sugars and, the fractions that contained sugars were further detected through HPLC with a refraction index detector (RID) (Agilent Technologies, Santa Clara, CA, USA). Briefly, the separation of sugars was completed on a Cosmosil Sugar-D column (4.6 × 250 mm, 5 µm, Nacalai Tesque Inc., Kyoto, Japan) using acetonitrile-water (75:25, v/v) as the mobile phase at a flow rate of 1.0 mL/min and the injection volume was 20 µL. The fractions containing ciceritol were collected, concentrated and purified by gel chromatography of the Biogel P-2 column (1.5 × 100 cm). The column was eluted with degassed water at a flow rate of 20 mL/h. The fractions containing pure ciceritol were collected, concentrated and freeze-dried (purity > 95%).

Prebiotic potential of ciceritol

To assess the prebiotic effect of ciceritol, the suspension was prepared in saline buffer at pH 7.2, 0.1 M PBS. Fermentation was carried out in basal media, and the media supplemented with ciceritol using microbial culture. These formulations were used for the experiment BM1C0 (1%:0%), BM1C1 (1%:0.5%), BM1C2 (1%:1.0%), BM1C3 (1%:1.5%) and BM1C4 (1%:2%). In control, ciceritol was not added. Fermentation was done in an anaerobic incubator (37 °C) and samples were withdrawn after 0 h, 6 h, 12 h and 24 h [10].

Encapsulation of B. animalis using ciceritol and alginate

Activation of probiotic culture

The probiotic culture B. animalis (ATCC 25,527) was activated before use. The lyophilized probiotic culture was reactivated thrice and purity was determined using streak plate method. The culture was inoculated into 10 mL of MRS broth and incubated at 37 °C for 18 h. The culture (1 mL) was inoculated again into 10 mL of MRS broth and incubated at 37 °C for 18 h. From this sample 1 mL of culture was transferred into 200 mL MRS broth and incubated under the same conditions. The biomass was harvested through centrifugation (4816×g at 4 °C) for 10 min (Sorvall Legend XTR centrifuged, USA). The cells were washed three times in 0.85% (w/v) sterile saline solution and re-suspended into 50 mL of sterile saline solution to get final concentration 108 to 109 CFU/mL [11].

Beads preparation

B. animalis (1%, 1011 CFU/g) was mixed with different concentrations of ciceritol and sodium alginate for beads formation. Different formulations were as C0SA2 (0%:2%), C1SA2 (0.5%:2%), C2SA2 (1%:2%), C3SA2 (1.5%:2%) and C4SA2 (2%:2%). The beads were extruded with encapsulator (Buchi, B-390, Switzerland) in 0.1 molar calcium chloride solution. The agitation of obtained gelled particles was performed for 30 min [12]. The particles were washed with Milli Q water, filtrated and freeze dried. Glass vacuum desiccator (6 °C) was used to maintain dried particles.

Diameter and encapsulation efficiency

The diameter of microbeads was measured using an optical microscope (Nikon, Japan). The diameter was obtained in three different directions and represented as average size ± standard deviation (SD).

The viable cell count was determined before and after microencapsulation. The microcapsules were dissolved in 9 mL of 2% (w/v) sodium citrate solution (pH 7.0). The released cells were serially diluted and plated for enumeration. The colonies were counted using colony counter. The encapsulation efficiency (EE) was calculated using Eq. (1).

EE = Encapsulation efficiency.

N = Viable cells released from the microcapsules.

N0=Free cells in the polymer mixture during microcapsules production.

Characterization of encapsulated bead B. animalis

Morphology of beads

The morphology of beads was observed through scanning electron microscopy (SU1510, Hitachi, Tokyo, Japan). Triplicate samples of respective treatments were selected for morphological analysis. The freeze dried beads were coated with gold to improve conductance and placed on carbon tapped sample holder. The images were taken under vacuum (9.75 × 10− 5 Torr) using 15 KV accelerating voltage at low( ≥ × 45) and high magnification ( ≥ × 1000) for surface and cross sectional images, respectively [13].

Survival in simulated gastrointestinal fluid (SGF)

Free and encapsulated B. animalis survival were determined at low pH (pH 2.0 and 2.5). Ciceritol and sodium alginate beads containing B. animalis (0.5 g) were added into the tubes containing 4.5 mL of SGF (pH 2.0 or 2.5), incubated at 37 °C for 10, 30, 60, 90 and 120 min. Free B. animalis were platted on MRS agar for enumeration. Microbeads containing B. animalis were recovered from SGF, and then dissolved in 4.5 mL SGF, 50 mM sodium citrate solution at pH 7.5. Released B. animalis were determined using the method described above [14].

Bile salt tolerance

The stability of encapsulated and free B. animalis was determined in porcine bile salt solution. Suspensions of free B. animalis (0.5 mL) and encapsulated cell were incubated at 37 °C for 1 and 2 h respectively. Free and encapsulated B. animalis were collected at each time interval. Free B. animalis were determined using the method described above. The microbeads were broken in sodium citrate solution for enumeration of B. animalis [14].

Release profile

The release profile of encapsulated B. animalis in ciceritol-alginate microspheres was investigated in simulated intestinal fluid (SIF) for 70 min. Ciceritol-alginate microspheres (0.5 g) were added to conical plastic tubes containing pre-warmed SIF (pH 6.8, 50 mM KH2PO4) and placed in shaking incubator at 37 °C with 100 rpm. Enumeration of released B. animalis was carried out according to the method described by [15].

Storage stability

The stability of free and encapsulated B. animalis was determined for 0, 10, 20 and 30 days of storage at 4 °C. The encapsulated B. animalis were released in sodium citrate solution (pH 7.5, 50 mM) and enumerated using pour plate method [15].

Statistical analysis

The acquired data were subjected to two factor factorial under completely randomized design (CRD) for statistical analysis using Statistix 8.1 (Statistix 8.1., Chicago, USA). The analysis of variance (ANOVA) was performed using (p < 0.05) level of significance to assess the effect of encapsulation materials on the viability of B. animalis. Tukey’s test was used at 95% confidence level to determine differences among the treatments. The mean values of triplicate analyses were expressed with standard deviation [16].

Results and discussion

Extraction and quantification of ciceritol

Ciceritol was successfully extracted from chickpea and quantified by HPLC. Chromatograms exhibited different oligosaccharides with specific retention time (Table 1). Ciceritol, raffinose and stachyose have distinct elution time i.e.. 8.6 min, 7.5 min and 11.4 min, respectively. Furthermore, these compounds were quantified as ciceritol (68.4 ± 0.12 mg/g), raffinose (49.2 ± 0.07 mg/g) and stachyose (26.1 ± 0.09 mg/g). Ciceritol can be extracted from different plants of Leguminous family such as linseed. However, chickpea is a good source of oligosaccharides especially ciceritol (45%). The study of [17] characterized cyclitol glycosides by gas chromatography and successfully extracted ciceritol from chickpea. The ciceritol was amongst the top constituents in chickpea (2.51–2.78 g/100 g) as compared to other oligosaccharides. The results were consistent with the finding of [18] who quantified different disaccharides and oligosaccharides from various cultivars of chickpea. The quantification was based on the elution time of the components.

Prebiotic potential of ciceritol

The impact of ciceritol was investigated for its effect to improve the viability of probiotics. The microbial growth showed a significant result (8.23 ± 0.03 to 9.62 ± 0.06 CFU/mL) among treatments with time (Fig. 1). Maximum viability (9.62 ± 0.06 CFU/mL) was observed for BM1C5 after 24 h of fermentation. However, the minimum viability (8.23 ± 0.03 CFU/mL) was observed for BM1C0 at the start of incubation. Probiotic growth was enhanced by the addition of ciceritol. The viable cells were increased significantly (p < 0.05) with increasing concentration of ciceritol and incubation time. The results are comparable with the findings of [9], who probed the effects of ciceritol on human colonic microflora. The ciceritol as prebiotics improved the viability of probiotics due to the increase in the production of short-chain fatty acids. The results are in close agreement with the findings of [19], who investigated the lentil flour water soluble carbohydrates prebiotic effect.

Microencapsulation of B. animalis

Diameter and encapsulation efficiency

Ciceritol-sodium alginate beads were made by extruding the mixture of ciceritol, sodium alginate and B. animalis (Fig. 2). The diameter of beads varied significantly as the concentration of ciceritol increased. C2SA2 have a maximum diameter (1.57 ± 0.09 mm) and C0SA2 beads have the lowest (1.26 ± 0.08 mm) (Table 2). The diameter of beads increased due to the inclusion of ciceritol in the formulation. The diameter was increased due to the increase in the concentration of ciceritol up to certain limit (0.5–1.5%), after that the diameter decreased because oligosaccharides are water-soluble and cannot form a strong linkage with other carbohydrates. That’s why when 2% of ciceritol concentration was used, comparatively smaller size beads produced (1.41 ± 0.07 mm). Sodium alginate beads have the lowest encapsulation efficiency (70.06 ± 0.11%), but the beads supplemented with ciceritol have better encapsulation efficiency (> 80%). C2SA2 beads have the highest encapsulation efficiency (93.54 ± 0.08%) followed by C3SA2 (88.94 ± 0.09). The addition of ciceritol improved the structure of beads and viability of B. animalis. Similarly, [12] encapsulated B. longum in alginate-pectin-whey protein concentrate. The results revealed that the increase in concentration of polymer resulted in the increased encapsulation efficiency.

Characterization of encapsulated B. animalis

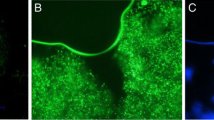

Morphology of microbeads

SEM depicted structural traits of beads with different concentrations of ciceritol and sodium alginate (SA) (Fig. 3). The addition of ciceritol significantly (p < 0.05) reduced the porosity of microbeads. The increased concentration of ciceritol (C4SA2) decreased porosity and spherical shape of microbeads. The beads with higher concentration of ciceritol were de-shaped and shriveled (C4SA2). The SA beads (C0SA2) presented better spherical shapes. The dents were observed in each bead formulation. The addition of cicerritol resulted in less noticeable pores as compared to C0SA2 and C1SA2.

Ciceritol is water soluble carbohydrate which results in loss of water from beads. The resulted beads were shriveled. Comparatively, SA has better gel forming ability which helps to form round shape beads. The addition of ciceritol improved the structure of beads through better polymeric distribution of components. It eventually helped to fill the pores in SA beads. The better structure of beads ensured improved survival of probiotics. The study of [20] had encapsulated L. rhamnosus in oligosaccharide based prebiotic. The dents were present in freeze dried beads due to the loss of water [11]. Similarly, [21] had encapsulated probiotics in alginate and inulin. The combination of both enhanced polymeric distribution and survival of probiotics. The oligosaccharides have better stickiness and low glass transition temperature. The addition of higher molecular compound (alginate, whey protein) can improve the glass transition temperature [13].

Stability in SGF

The stability of free and encapsulated B. animalis was investigated at pH 2 and 2.5 in SGF (Fig. 4). The viability of B. animalis ranged from 4.03 ± 0.07 to 9.87 ± 0.1 CFU/mL. Free cells were not stable at pH 2 and 2.5. It was observed that the free cells were unable to resist unfavorable conditions and almost all the cells lost their viability. Their viability decreased from 9.87 ± 0.1 to 4.03 ± 0.07 CFU/mL (Fig. 2). However, all the encapsulated formulations were able to maintain the recommended viable cell count > 106 CFU/mL. The maximum stability was observed for C2SA2 with minimal loss of probiotics. The improved cell viability is due to the established hydrogel barrier of alginate and ciceritol. The stability was observed due to the addition of ciceritol as it acts as prebiotic and provides structural rigidity to the beads. The continual increase in ciceritol may disrupt bead structure and can cause a decrease in viability as it was observed in C3SA2 and C4SA2. Alginate has been used for the encapsulation of probiotic and proved by various researchers that it improves survival as compared to free cells [7, 22]. Alginate does not swell in acidic media. However, the release was observed due to the erosion of alginate hydrogel which was the real challenge of current study. To overcome this problem, alginate was mixed with ciceritol to increase the protection of probiotics. Similar results were described by [23] who worked on the microencapsulation of probiotics with alginate and prebiotics. They found that the inclusion of prebiotics improves the cell viability and promotes cell proliferation. The utilization of ciceritol with alginate improved the cell viability. Herein, current research preliminarily studied the efficiency of sodium alginate with ciceritol for protection of probiotics. It was observed that the free cells (control) significantly lost their viability after exposure to SGJ (< 3 logs CFU/mL). However, no obvious changes were observed for the viability of encapsulated cells in alginate-ciceritol microbeads.

Bile salt tolerance of B. animalis

The stability of free and encapsulated B. animalis was investigated in bile salt solution (Fig. 5). The viability of free and encapsulated cells varied significantly (p < 0.05). Free cells were not able to withstand the bile salt solution and after 2 h of incubation, the viable cell count was < 5 logs CFU/mL (Fig. 3). All the encapsulated formulations have viable cell count > 6 log CFU/mL, implying that the encapsulation of probiotics provides protection to free cells. The microencapsulation of B. animalis using ciceritol and alginate increased the survival of cells in the unfavorable conditions of the intestine as compared to alginate alone. Maximum stability was observed in C4SA2 with minimal loss of viability even after 2 h of incubation. This approach is very useful for the delivery of probiotics to the human intestinal tract along with prebiotics. A similar finding was revealed by [24], who encapsulated L. fermentum L7 with a combination of alginate galactooligosaccharides, isomalto-oligosaccharides, fructooligosaccharides, and xylooligosaccharides. The work of [8] worked on the microencapsulation of B. animalis and observed that the addition of prebiotic improved cell viability. These results revealed that microencapsulation with prebiotics provides maximum cell viability > 108–109 CFU/mL.

Release profile B. animalis

The release rate of encapsulated B. animalis significantly affected by bead formulations and incubation time (Fig. 6). A maximum release was observed for C1A1 (100 ± 2%) and the minimum was observed for C4A4 (18 ± 1%). The fastest release was observed for C1A1. The release of B. animalis was completed within 70 min of exposure. The exposure of sodium alginate and ciceritol beads to simulated intestinal fluid resulted in the exchange of the carboxylic group of sodium alginate to release the probiotic cells. However, the addition of prebiotics helped to fill up the pores present in alginate beads. The higher the concentration of ciceritol, the slower will be the release of cells. Similar results were reported by [25], who encapsulated L. plantarum with prebiotics and alginate. The improvement in the bead structure resulted in a decrease of release rate. Whey protein and prebiotic improve the viability of probiotics and decrease the rate of release [13].

Storage stability of B. animalis

The viability of B. animalis during one month of storage ranged from 3.24 ± 1.0 to 9.78 ± 0.61 log CFU/mL (Fig. 7) with bead formulation and storage time. The variation in concentration of ciceritol and alginate significantly affected their viability. Minimum storage stability was recorded for C0A0 (3.24 ± 1.0 CFU/mL) after 28 days while maximum storage stability was observed just after encapsulation C4A1 (9.78 ± 0.61 CFU/mL) at 0 day. However, increasing the time of storage resulted in a decrease in viability of B. animalis. The addition of ciceritol improved the structure of beads and helped the probiotics cells to stay alive. The recommended amount of viable cells was > 107 CFU/mL after 1 month of storage. The free cells were more prone to environmental conditions and their viability significantly (p < 0.05) decreased as compared to the encapsulated B. animalis. Metabolite production and storage temperature significantly reduced their viability. The viability of B. animalis was maintained due to the addition of ciceritol, which is prebiotic. The addition of prebiotics improves the viability of probiotics. The study of [26] explained similar results during the encapsulation of phycocyanin with polysaccharides and prebiotics. The combination of prebiotics and polysaccharides improved the structure of beads. In another study, the improved viability of encapsulated L. acidophilus was observed with the addition of fructooligosaccharides in the beads of alginate and gelatin [27].

Conclusions

Prebiotics are non-digestible materials which help to promote the growth of probiotics. B. animalis was encapsulated through the extrusion technique using ciceritol and alginate in different formulations. The ciceritol was extracted from chick pea, quantified and assessed for its prebiotic potential. The addition of ciceritol contributed to the improvement of structural integrity of beads and improved the viability in different gastrointestinal conditions. The co-encapsulation exhibited better performance in acidic and bile salt conditions compared to the free cells. The results paved the way for the use of ciceritol as wall material for encapsulation of probiotics.

References

C. Arribas, B. Cabellos, C. Cuadrado, E. Guillamon, M. Pedrosa, Foods 9, 415 (2020)

M. Ciudad-Mulero, V. Fernandez, C. Cuarado, C. Arribas, M.M. Pedrosa, J.J. De Berrios, J. Pan, P. Morales, Food Chem. 315, 126175 (2020)

S.H. Al-Sheraji, A. Ismail, M.Y. Manap, S. Mustafa, R.M. Mustafa, F.A. Hassan, J. Funct. Foods 5, 1542–1553 (2013)

I. Yasmin, M. Saeed, W.A. Khan, A. Khaliq, M.F.J. Chughtai, R. Iqbal, S. Tehseen, S. Naz, A. Liaqat, T. Mehmood, S. Ahsan, S. Tanwweer, Microorganisms 8, 354 (2020)

M. de Araújo Etchepare, G.L. Nunes, B.R. Nicoloso, J.S. Barin, E.M.M. Flores, R.O. Mello, C.R. Menezes, LWT 117, 108601 (2020)

S.S. Dehkordi, I. Alemzedah, A. Vossoughi, Appl. Biochem. Biotechnol. 190, 182–196 (2020)

M. Yao, J. Xie, H. Du, D.J. Mcclements, H. Xiao, L. Li, Compr. Rev. Food Sci. Food Saf. 19, 857 (2020)

A.G. Peredo, C.I. Beristain, L.A. Pascuel, E. Azuara, M. Jimenez, LWT 73, 191–196 (2016)

Y. Zhang, D. Su, Z. Dai, R. Asad, S. Ou, X. Zeng, LWT-Food Sci. Technol. 79, 294–299 (2017)

H. Hussein, S. Awad, I. EI-Sayed, A. Ibrahim, Ann. Agric. Sci. 65, 49–58 (2020)

I. Yasmin, M. Saeed, I. Pasha, M.A. Zia, Indian J. Plant Physiol. 11, 413–426 (2019)

W.A. Khan, M.S. Butt, I. Pasha, A. Jamil, J. Food Meas. Charact. 14, 1–11 (2020)

R. Rajam, C. Anandharamakrishnan, LWT-Food Sci. Technol. 60, 773–780 (2020)

H.-Y. Chen, X. Li, X.-H. Meng, J. Funct. Foods 29, 248–255 (2017)

T. Riaz, M.W. Iqbal, M. Saeed, I. Yasmin, H.A.M. Hassanin, S. Mahmood, A. Rehman, J. Microencapsul. 36, 192–203 (2019)

D.C. Montgomery, Design and Analysis of Experiments (Wiley, New York, 2017).

L. Ruiz-Aceituno, C.C. Carralero, A.I. Ruiz-Matuate, L. Ramos, M.L. Sanz, I. Martinez-Castro, J. Chromatogr. A 1484, 58–64 (2017)

X. Xiaoli, Y. Liyi, H. Shuang, L. Wei, S. Yi, M.A. Hao, Z. Jusong, Z. Xiaoxiong, Food Chem. 111, 215–219 (2008)

D. Portman, C. Blanchad, P. Mahajan, M. Naiker, J. F. Panozzo Cereal Chem. 96, 447–455 (2019)

M. Azam, M. Saeed, I. Pasha, M. Shahid, Food Biosci. 37, 100679 (2020)

A. Atia, A. Gomaa, I. Fliss, E. Beyssec, G. Garrait, M. Subirade, J. Microencapsul. 33, 89–101 (2016)

K. Feng, R.J. Linhrdt, H. Wu, R. Huang, R. Wu, Y. Wei, M. Zong, Food Chem. 310, 125977 (2020)

S. Sathyabama, M.R. Kumar, P.B. Devi, R. Vijayabharathi, V.B. Priyadharisini, LWT-Food Sci. Technol. 57, 419–425 (2014)

N. Liao, B. Luo, J. Gao, X. Li, Z. Zhao, Y. Zhang, Y. Ni, F. Tian, Biotechnol. Lett. 41, 263–272 (2019)

Y. Wu, G. Zhang, LWT 93, 135–141 (2018)

Y. Wen, PWen Hu T., R.J. Linhrdt, M. Zong, H. Wu, Int. J. Biol. Macromol. 149, 672–681 (2020)

K.C.G. Silva, E.C. Cezarino, M. Michelon, A.C.K. Sato, LWT. 89, 503–509 (2018)

Acknowledgements

The authors are grateful to the National Institute of Food Science and Technology, University of Agriculture Faisalabad, Pakistan for providing a conducive environment for research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Azam, M., Saeed, M., Yasmin, I. et al. Microencapsulation and invitro characterization of Bifidobacterium animalis for improved survival. Food Measure 15, 2591–2600 (2021). https://doi.org/10.1007/s11694-021-00839-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-021-00839-4