Abstract

Aspergillus nomius is a potent producer of aflatoxins B and G and is one of the most common species of fungi found in Brazil nuts. Temperature is considered a major abiotic factor that influences fungal colonization and aflatoxin production in nuts during pre- and post-harvest. Therefore, assessment of the response of aflatoxigenic species to different temperatures is important to add information about the understanding of aflatoxin production by Aspergillus nomius and may help in the development of new strategies to prevent aflatoxin contamination. The aim of this study was to evaluate the effect of temperature (25, 30, and 35 °C) on the radial growth, aflatoxin production (B and G), and aflatoxin gene expression of seven A. nomius strains isolated from Brazil nuts. The optimal temperature for growth was 30 °C and was also the best condition for the expression of the aflR, aflD, and aflQ genes. However, maximum production of aflatoxins B and G occurred at 25 °C. Interestingly, high expression of the structural gene aflQ was observed in the maximum aflatoxin production condition (25 °C). The present study demonstrates that temperature may influence aflatoxin production by A. nomius. The combination of molecular and physiological data aids the understanding of the aflatoxigenic species response to different temperatures and can assist in predicting the driving environmental factors that influence aflatoxin contamination of Brazil nuts.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Brazil nuts are the second most profitable extractivist food in the Amazon region, losing only to acai, a berry fruit, with a production of 26,191 t and a value close to R$ 104.1 million (IBGE 2017). These nuts have a high nutritional value and contain selenium, an important antioxidant agent (Pacheco and Scussel 2007). In addition, Brazil nuts are used for the development of cosmetics (CONAB 2017). Brazil is currently the second largest producer in the world (34.8%) after Bolivia (42.9%) (Avramenko 2017). The main importing countries of these seeds are the USA (25%), members of the UK (17%), Germany (17%), and the Netherlands (5%) (Kosikova 2016).

One of the major concerns of food safety in the production chain of Brazil nuts is the contamination with toxigenic fungi, especially those of the genus Aspergillus. These fungi are often recovered from several edible seeds such as peanuts, sorghum, corn, walnuts, hazelnuts, pistachios, almonds, and other oilseeds around the world (Bennett and Klich 2003; Passone et al. 2012; Gallo et al. 2016).

There are many reports of fungal contamination throughout the production chain of Brazil nuts with Aspergillus nomius, a toxigenic species (producer of aflatoxins B and G) that belongs to section Flavi, considered a common contaminant (Kurtzman et al. 1987; Klich 2002). The presence of this species has been reported in several studies conducted in Brazil (Costa et al. 2009; Baquião et al. 2013; Reis et al. 2012, 2014; Gonçalves et al. 2012; Calderari et al. 2013; Luo et al. 2014; Massi et al. 2014; Midorikawa et al. 2014; Taniwaki et al. 2017). However, to the best of our knowledge, there are no data about the ecophysiology of A. nomius related to aflatoxin production.

It is well-known that several biotic and abiotic factors exert direct effects on mycotoxin production, including humidity, temperature, substrate composition (Ciegler 1978; Arrus et al. 2005; FIB 2009), water activity, aeration, microbial population and competition, stress factors, insects, and substrate (Ciegler 1978; Bhatnagar et al. 2002). Among them, temperature is considered one of the most critical determinants (Arrus et al. 2005; Freitas-Silva et al. 2013).

The consumption of contaminated food and feed, especially with aflatoxins, can pose health risks to humans and animals, causing disorders such as tumors, immunosuppression, and liver problems (Bennett and Klich 2003; CAST 2003). Aflatoxin B1 (AFB1), classified as a class 1 carcinogenic compound for humans by the IARC (1993), has received special attention by food safety authorities, and restrictions have been applied worldwide to products contaminated with aflatoxins (EC 2010; CAC 2010; ANVISA 2011).

The biosynthetic pathway of aflatoxins comprises 30 genes that are located in the same order in all aflatoxigenic fungi of the Flavi section (Ehrlich et al. 2005; Yu et al. 2011). The cluster is controlled in a coordinated way, and norsolorinic acid is the first stable precursor of aflatoxins (Bennett 1981; Trail et al. 1994), which is then converted to averantin by a reductase encoded by the aflD gene (Trail et al. 1994; Yu 2012). The aflR gene acts as a positive regulator of gene expression (Flaherty and Payne 1997; Abdel-Hadi et al. 2012; Yu 2012). This gene encodes a specific protein containing a zinc finger motif that binds to DNA and is necessary for the transcriptional activation of all or nearly all of the structural genes of this pathway (Flaherty and Payne 1997; Yu 2012). At the end of the pathway, the aflQ gene encodes a monooxygenase that converts O-methylsterigmatocystin to AFB1 by oxidation (Frisvad et al. 2007), as well as dihydro-O-methylsterigmatocystin to AFB2, also by oxidation (Carbone et al. 2007; Do and Choi 2007; Yu 2012). Other genes are involved in the conversion of these substances to AFG1 and AFG2 (Yu et al. 2000; Carbone et al. 2007; Yu 2012).

Previous studies have shown that higher temperatures (above 36 °C) are associated with a decrease in the expression of aflatoxin biosynthetic pathway genes, including the transcriptional factors aflR and aflS, therefore, inhibiting aflatoxin production in A. flavus (OBrian et al. 2007; Yu et al. 2011). Despite the studies on abiotic factors that affect aflatoxin production and gene expression in A. flavus, there is a lack of information about the expression of aflatoxin genes in A. nomius, a species involved in the aflatoxin B and G contamination of Brazil nuts, a worldwide consumed food product. Knowledge about the ecophysiology of this fungus will allow us to contribute to the prevention and control of aflatoxins.

The objective of this study was to evaluate the ecophysiological response (mycelial growth, gene expression, and aflatoxin production) of A. nomius strains isolated from Brazil nuts to different temperatures (25, 30, and 35 °C).

Materials and methods

Fungal strains and culture conditions

Seven strains of Aspergillus nomius and one standard strain (A. nomius - INCQS 40010) were used in this study. The strains were previously isolated from Brazil nuts collected in the Amazon region and were identified by sequencing of the internal transcribed spacer (ITS) region (rDNA) and β-tubulin gene (TUB). The strains are maintained in 60% glycerol at − 80 °C in the Department of Microbiology at the University of São Paulo.

DNA extraction, amplification, and sequencing

The isolates were incubated for 3 days on yeast extract sucrose (YES) agar at 25 °C. A fragment of the mycelium was collected from these cultures and transferred to a microtube containing PrepMan Ultra® to extract the genomic DNA according to the manufacturer’s instructions (Applied Biosystems, Carlsbad, CA, USA). The DNA concentration was measured in a NanoDrop 2000 spectrophotometer (Thermo Fisher Scientific, Wilmington, DE, USA). Fragments of the ITS region and β-tubulin gene (TUB) were amplified under the following thermal cycling conditions: heating at 94 °C for 3 min, followed by 35 cycles at 94 °C for 1 min, 57 °C (TUB) or 49 °C (ITS) for 1 min, and 72 °C for 1 min, and a final incubation step of 5 min at 72 °C. The amplicons were purified with the QIAquick PCR Purification Kit (Qiagen, Hilden, Germany) as described in the kit’s protocol. These fragments were sequenced in a 3100 DNA sequencer (Applied Biosystems, USA) using the Big Dye® Terminator v 3.1 Cycle Sequencing Kit (Applied Biosystems). The sequences were edited with the Sequencher DNA Sequence Assembly 4.1.4 Software (Gene Codes Corporation, USA), and consensus sequences were used to perform BLASTn searches for species identification in the NCBI (http://blast.ncbi.nlm.nih.gov) and MycoBank (http://www.mycobank.org) databases. The nucleotide sequence from each isolate was deposited in GenBank (Table 1).

Ecophysiological study

For the physiological study (growth, gene expression, and aflatoxin production), fungal spore suspensions (8 × 106/mL) were prepared from each strain, and 10 μL of the suspension was centrally inoculated onto plates containing coconut agar (200 mL coconut milk and 20 g bacteriological agar in 1 L ultrapure water) (Lin and Dianese 1976). The plates were incubated at 25, 30, and 35 °C for 7 days. The experiments were performed in quadruplicate.

Growth rate

Radial growth was assessed daily by measuring the diameters of the colonies using a millimeter ruler in eight orthogonal directions (Patriarca et al. 2001). The radial growth was plotted against time, and the slope was calculated by linear regression. The results were expressed as radial growth rate (mm d−1).

RNA extraction and cDNA synthesis

Total RNA was extracted using the RNeasy Plant Mini Kit (Qiagen, Hilden, Germany) from frozen mycelial fragments of each strain and stored in RNA later (Ambion, Thermo Fisher Scientific, Waltham, MA, USA). The total RNA was treated with RNAse-free DNAse-l Kit (Promega, Madison, WI, USA), and its concentration and purity were analyzed in a Nano Drop 2000c spectrophotometer (Applied Biosystems). The RNA was diluted to 6 ng/μL. cDNA from each sample was synthesized in triplicate using the High Capacity cDNA Reverse Transcription Kit (Applied Biosystems) under the following thermocycling conditions in a Gene APP PCR system 9700 thermocycler (Applied Biosystems): 10 min at 25 °C, 120 min at 37 °C, and 5 min at 85 °C. The cDNA was stored at − 20 °C. All kits were used according to the manufacturer’s protocol.

Transcriptional analysis

The transcription profiles of three aflatoxin biosynthetic genes (aflR, aflD, and aflQ) and of calmodulin (CAL) as the reference gene were analyzed by the quantitative real-time polymerase chain reaction (qRT-PCR) performed in a Step One Plus RT-PCR system (Applied Biosystems). The primer pairs used in this study were designed with the Primer 3 software (Institute for Biomedical Research) from sequences deposited in GenBank (NCBI) and are listed in Table 1.

The reactions were prepared in triplicate using the 2X Power SYBR Green PCR Master Mix (Invitrogen, Thermo Fisher, Carlsbad, CA) according to the manufacturer’s protocol. The concentration of the primer pairs was 100 nM. Two replicates of the negative control were included in all runs to rule out contamination. All amplifications were carried out in MicroAmp Optical 96-Well Reaction Plates sealed with optical adhesive covers (Applied Biosystems). The amplification conditions were an initial incubation step of 20 s at 95 °C, followed by 40 cycles at 95 °C for 3 s and 60 °C for 30 s, and a final cycle at 95 °C for 15 s, 60 °C for 1 min, and 95 °C for 15 s.

Relative gene expression was conducted by using the comparative ΔΔCT method, and the expression levels of the genes were evaluated by comparing Ct values (Pfaffl 2001; Schmittgen and Livak 2008). The amplification curves for all genes were specific, showing a single peak by melting curve analysis (Supplementary File S1). The amplification efficiency was evaluated by constructing a standard curve with serial dilutions of cDNA from one sample (RNA: 80 ng/μL) (1, 1:4, 1:16, 1:64, 1:256) for each gene in quintuplicate using the formula: E = 10(− 1/slope) - 1. The efficiency calculated from each linear regression of the standard curves was satisfactory for the parameters established for all genes (90 to 110%).

Production of aflatoxins by Aspergillus nomius

The toxigenic potential was analyzed by high-performance liquid chromatography (HPLC) (Tanaka et al. 2000; Lebret et al. 2004). Aflatoxins were extracted from fungal cultures after 7 days of incubation. The methods described by Reis et al. (2012) were used for extraction and evaluation of the aflatoxigenic potential, as well as for determination of the limit of detection (LOD), limit of quantification (LOQ), coefficients of the calibration curves, recovery rates, and retention times.

The LOD for total aflatoxins was 0.75 μg/kg and the LOQ was 1.5 μg/kg. The coefficients of the calibration curves were 0.999 for all toxins. Average recovery rates of aflatoxins from the samples, considering three replicates of them, were 80% for AFB1, 83% for AFB2, 116% for AFG1, and 84% for AFG2, and the coefficients of variation were 6.4%, 3.5%, 4.7%, and 6.7%, respectively. Retention times were 5, 7.5, 11, and 17 min (± 5%) for AFG1, AFB1, AFG2, and AFB2, respectively.

Statistical analysis

All experiments were analyzed statistically using the OriginPro 8.5 software. The tests performed were exploratory analysis and one-way analysis of variance (ANOVA). The differences among mean values were ranked by the Tukey Test (P < 0.05).

Results

Growth assessment

Figure 1 shows the radial growth rate of the A. nomius strains on coconut agar in response to different temperatures (25, 30, and 35 °C). The results indicated that mycelial growth occurred over the temperature range investigated. The optimum growth condition (mm/day) occurred at 30 °C (P < 0.05), with an average of 4.7 mm/day. No significant differences were found between the two other temperatures.

Radial extension rates (mm/day) growth of A. nomius at different temperatures. The boxplot analysis reveals the interquartile range of each evaluated temperature (box), the median (line), and minimum and maximum values (whiskers); circles represent values 1.5–3 times outside the interquartile range; squares represent values more than 3 times outside the interquartile range *There was statistical difference at 30 °C in relation to temperature of 25 and 35 °C (P < 0.05)

Analysis of aflatoxin gene expression

Species identification data in NCBI shown identities of strains above 99% with A. nomius (Supplementary File S2).

The results of aflatoxin gene expression (aflR, aflD, and aflQ) by the A. nomius strains grown on coconut agar at different temperatures (25, 30, and 35 °C) are shown in Fig. 2. All A. nomius strains showed considerable expression of these genes. In general, the expression of aflR and aflD was higher at 30 and 35 °C. An interesting finding was the high levels of expression of the structural aflD gene at 25 °C in one strain. The structural aflQ gene was the most expressed gene at all temperatures evaluated. However, the highest levels were observed at 25 and 30 °C (P < 0.05).

Mycotoxin production potential

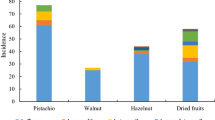

Figure 3 shows the aflatoxin production by the A. nomius strains on coconut agar after 7 days in response to different temperatures (25, 30, and 35 °C). All strains produced aflatoxins under all conditions evaluated. However, the highest toxin levels were found at 25 °C, with a mean AFB level of 154.32 μg/kg and AFG level of 86.50 μg/kg. The production of aflatoxins decreased at 30 °C, and the strains exhibited a similar production of AFB and AFG. Aflatoxin production was inhibited at 35 °C. A significant difference in AFB levels was observed between all temperatures tested, while there was no difference in AFG levels between 25 and 30 °C (P < 0.05).

Discussion

Contamination with mycotoxins is a recurrent problem in Brazil nuts and is caused mainly by post-harvest infection with Aspergillus section Flavi species. In general, the temperature remains between 25 and 30 °C throughout the Amazonia region (Arrus et al. 2005; Freitas-Silva et al. 2013) and is higher than 30 °C post-extractivism (Silva et al. 2016). Temperature is a key environmental factor that may favor the growth of these fungi and aflatoxin production (Arrus et al. 2005).

This study showed that A. nomius could thrive in coconut agar for all of the tested temperatures, with the optimum radial growth rate at 30 °C. Similar results have been reported in the literature (Doster et al. 2009; Zafra et al. 2015). Another species belonging to the Flavi section, Aspergillus bombycis, described by Peterson et al. (2001) as sister group of A. nomius, exhibits optimum growth at 25 °C, significative growth reduction at 37 °C, and no growth at 42 °C (Peterson et al. 2001), whereas A. nomius can grow well at different temperatures, as demonstrated previously by Peterson et al. (2001) and the current study. These findings may aid taxonomic identification of these two species based on different temperatures and specific culture medium.

The ability to produce aflatoxins by A. nomius strains used in the current study corroborates with other findings based on aflatoxin-producing potential of Aspergillus section Flavi species isolated from Brazil nuts (Olsen et al. 2008; Gonçalves et al. 2012; Calderari et al. 2013; Moore et al. 2015). Nevertheless, in contrast to the present research in which higher levels of AFB were detected, the other studies found higher production of AFG than AFB at 25 °C (Doster et al. 2009; Baquião et al. 2013; Reis et al. 2014). Peterson et al. (2001) analyzed A. bombycis at 27 °C and detected high levels of both groups of aflatoxins. In fact, according to Liu et al. (2017), aflatoxin production in seeds can occur over a wide temperature range.

The biosynthetic pathway of mycotoxin production is regulated by clustered genes and by environmental conditions, highlighting that the latter may affect the expression of the former, therefore influencing mycotoxin production by fungi. Changes in temperature may stimulate or inhibit the production of these toxic secondary metabolites (Ciegler 1978; Arrus et al. 2005; FIB 2009; Freitas-Silva et al. 2013). This is the first study to evaluate aflatoxigenic expression data of A. nomius. We investigated the expression profile of a regulatory gene, aflR, and of two structural genes, aflD and aflQ, in response to different temperatures (25, 30, and 35 °C) found during the Brazil nut production chain (Arrus et al. 2005; Freitas-Silva et al. 2013; Silva et al. 2016). Our analyses showed that 30 °C was the optimal condition for gene expression; however, the highest AFB levels were produced at 25 °C. This should be further investigated, because previous studies have shown a positive correlation between aflR expression and AFB production in A. flavus strains (Chang et al. 2007). Moreover, the aflQ gene was highly expressed at all temperatures. Studies on A. flavus also demonstrated high levels of transcription of this gene (Abdel-Hadi et al. 2012; Liu et al. 2017). According to Abdel-Hadi et al. (2012), the study of this pathway may help the understanding of the interaction between these genes and the production of aflatoxins. The application of genetic technologies enables early detection of these compounds, thus ensuring the safety and quality of food (Baquião et al. 2016). Nevertheless, several studies on A. flavus and A. parasiticus have shown variable expression of the same genes subjected to these temperatures (Chang et al. 2007; Al-Hmoud et al. 2012; Davari et al. 2015; Baquião et al. 2016). This variability is plausible, considering that mRNA cannot persist for long periods; therefore, depending on the time of the analysis, mRNA could be detected in lower or higher concentrations. For this same reason, we could possibly explain the absence of an association between aflatoxin production and aflR, aflD, and aflQ expression in the current study, even though Chang et al. (2007) observed a positive correlation between the biosynthetic genes and aflatoxin production in A. flavus.

The present research showed that the optimal temperature for aflatoxin production coincides with those found in the Amazon region, the most important Brazilian area of production. The overall conclusion of this study was that high temperatures (> 25 °C) pose a risk for aflatoxin contamination by A. nomius. These results enhance our current understanding of ecophysiological aspects of this species and may contribute to improve strategies for the management of aflatoxins in food and feed.

References

Abdel-Hadi A, Schmidt-Heydt M, Parra R, Geisen R, Magan N (2012) A systems approach to model the relationship between aflatoxin gene cluster expression, environmental factors, growth and toxin production by Aspergillus flavus. J R Soc Interface. https://doi.org/10.1098/rsif.2011.0482

Al-Hmoud N, Ibrahim MA, l-Rousan H, Alseyah A (2012)A The prevalence of aflatoxinogenic Aspergillus parasiticus in Jordan. Int J Food Microbiol https://doi.org/10.1155/2012/675361

ANVISA - Brazilian Health Regulatory Agency (2011) Resolutions of the Collegiate Board of Directors - RDC No. 7, of February 18, 2011. In: Dispõe sobre limites máximos tolerados para micotoxinas em alimentos. Available from: http://portal.anvisa.gov.br/documents/10181/2968262/RDC_07_2011_COMP.pdf/afe3f054-bc99-4e27-85c4-780b92e2b966

Arrus K, Blank G, Abramson D, Clear R, Holley RA (2005) Aflatoxin production by Aspergillus flavus in Brazil nuts. J Stored Prod Res. https://doi.org/10.1016/j.jspr.2004.07.005

Avramenko S (2017) Which Country Produces the Most Brazil Nuts in the World? IndexBox Marketing & Consulting. http://www.indexbox.co.uk/blog/which-country-produces-the-most-brazil-nuts-in-the-world. Accessed 11 Jan 2018

Baquião AC, De Oliveira MM, Reis TA, Zorzete P, Atayde DD, Correa B (2013) Polyphasic approach to the identification of Aspergillus section Flavi isolated from Brazil nuts. Food Chem. https://doi.org/10.1016/j.foodchem.2013.01.007

Baquião AC, Guedes AR, Lopes EL, Tralamazza SM, Zorzete P, Correa B (2016) Expression of genes by aflatoxigenic and nonaflatoxigenic strains of Aspergillus flavus isolated from Brazil nuts. Foodborne Pathog Dis. https://doi.org/10.1089/fpd.2015.2111

Bennett JW (1981) Loss of norsolorinic acid and aflatoxin production by a mutant of Aspergillus parasiticus. J Gen Microbiol. https://doi.org/10.1099/00221287-124-2-429

Bennett JW, Klich M (2003) Mycotoxins. Clin Microbiol Rev. https://doi.org/10.1128/CMR.16.3.497-516

Bhatnagar D, Yu J, Ehrlich KC (2002) Toxins of filamentous Fungi. In: Breitenbach M, Crameri R, Lehrer SB (ed) Fungal allergy and pathogenicity. Chem Immunol https://doi.org/10.1159/000058867

CAC - Codex Alimentarius Commission (2010) Proposed Draft Maximum Level for Total Aflatoxins in Brazil Nuts. In: Distribution of the report of the fourth session of the Codex Committee on Contaminants in foods. ALINORM 10/33/41. Appendix V Joint. Available from: https://www.nutfruit.org/files/llei/102905.pdf

Calderari TO, Iamanaka BT, Frisvad JC, Pitt JI, Sartori D, Pereira JL, Fungaro MHP, Taniwaki MH (2013) The biodiversity of Aspergillus section Flavi in Brazil nuts: from rainforest to consumer. Int J Food Microbiol. https://doi.org/10.1016/j.ijfoodmicro.2012.10.018

Carbone I, Ramirez-Prado JH, Jakobek JL, Horn BW (2007) Gene duplication, modularity and adaptation in the evolution of the aflatoxin gene cluster. BMC Evol Biol 7:1–12. https://doi.org/10.1186/1471-2148-7-111

CAST - Council for Agricultural Science and Technology (2003) In: Richard JL, Payne GA (eds) Mycotoxins: Risks in Plant, Animal and Human Systems. Task Force Report, Ames, p 139 Available from: https://www.international-food-safety.com/pdf/Mycotoxins - Risks in Plant, Animals and Human Systems.pdf

Chang PK, Wilkinson JR, Horn BW, Yu J, Bhatnagar D, Cleveland TE (2007) Genes differentially expressed by Aspergillus flavus strains after loss of aflatoxin production by serial transfers. Appl Microbiol Biotechnol 77:917–925. https://doi.org/10.1007/s00253-007-1224-1

Ciegler A (1978) Fungi that produce mycotoxins: condition and occurrence. Mycopathology. 65:5–11. https://doi.org/10.1007/BF00447169

CONAB - Brazilian National Supply Company (2017) Monthly report. October. Roraima Regional Superintendence - Sureg/RR

Costa AKF, Freire FCO, Vieira IGP, Andrade JÁ, Mendes FNP (2009) Fungos associados à castanha-do-Brasil (Bertholletia excelsa Humb. & Bompl) e ao amendoim (Arachis hypogaea L.) comercializados em Fortaleza (Ceará). Rev Ciênc Agron. https://ainfo.cnptia.embrapa.br/digital/bitstream/CNPAT-2010/11636/1/PB09017.pdf. Accessed 14 Set 2017

Davari E, Mohenzadeh M, Mohammadi G, Rezaeian-Doloei R (2015) Characterization of aflatoxigenic Aspergillus flavus and A. parasiticus strain isolates from animal feedstuffs in northeastern Iran. Iran J Vet Res http://europepmc.org/backend/ptpmcrender.fcgi?accid=PMC4827679&blobtype=pdf. Accessed 24 July 2017

Do JH, Choi DK (2007) Aflatoxins: detection, toxicity, and biosynthesis. Biotechnol Bioprocess Eng 12:585–593. https://doi.org/10.1007/BF02931073

Doster MA, Cotty PJ, Michailides TJ (2009) Description of a distinctive aflatoxin-producing strain of Aspergillus nomius that produces submerged sclerotia. Mycopathologia. 168:193–201. https://doi.org/10.1007/s11046-009-9214-8

EC - European Commission (2010) Commission regulation (EC) no 165/2010 of 26 February 2010 amending regulation (EC) no 1881/2006 setting maximum levels for certain contaminants in foodstuffs as regards aflatoxins. Off J Eur Union L 50:8–12 Available from: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2010:050:0008:0012:EN:PDF

Ehrlich KC, Yu J, Cotty PJ (2005) Aflatoxin biosynthesis gene clusters and flanking regions. J Appl Microbiol. https://doi.org/10.1111/j.1365-2672.2005.02637.x

FIB - Food Ingredients Brazil (2009) Micotoxinas. Available from: http://www.revista-fi.com/materias/90.pdf. Accessed 12 out 2017

Flaherty JE, Payne GA (1997) Overexpression of aflR leads to upregulation of the pathway gene transcription and increased aflatoxin production in Aspergillus flavus. Appl Environ Microbiol https://aem.asm.org/content/aem/63/10/3995.full.pdf. Accessed 14 out 2017

Freitas-Silva O, Morales-Valle H, Venâncio A (2013) Potential of aqueous ozone to control aflatoxigenic fungi in Brazil nuts. ISRN Biotechnol. https://doi.org/10.5402/2013/859830

Frisvad JC, Larsen TO, Vries R, Meijer M, Houbraken J, Cabañes FJ, Ehrlich K, Samson RA (2007) Secondary metabolite profiling, growth profiles and other tools for species recognition and important Aspergillus mycotoxins. Stud Mycol. https://doi.org/10.3114/sim.2007.59.04

Gallo A, Solfrizzo M, Epifani F, Panzarini G, Perrone G (2016) Effect of temperature and water activity on gene expression and aflatoxin biosynthesis in Aspergillus flavus on almond medium. Int J Food Microbiol. https://doi.org/10.1016/j.ijfoodmicro.2015.10.026

Gonçalves JS, Ferracin LM, Vieira MLC, Iamanaka BT, Taniwake MH, Fungaro MHP (2012) Molecular analysis of Aspergillus section Flavi isolated from Brazil nuts. World J Microbiol Biotechnol 28:1817–1825. https://doi.org/10.1007/s11274-011-0956-3

IARC - International Agency for Research on Cancer (1993) some naturally occurring substances: food items and constituents, heterocyclic aromatic amines and mycotoxins. IARC Monogr Eval Carcinog Risk Hum 56:571 Avaliable from: https://monographs.iarc.fr/wp-content/uploads/2018/06/mono56.pdf

IBGE - Brazilian Institute of Geography and Statistics (2017) Produção da Extração Vegetal e da Silvicultura 32: 1–8. Avaliable from: https://biblioteca.ibge.gov.br/visualizacao/periodicos/74/pevs_2017_v32_informativo.pdf

Klich MA (2002) Identification of common Aspergillus species. Centraalbureau voor Schimmelautures, Utrecht

Kosikova D (2016) Brazil nut market - globalization on the Brazil nut market. IndexBox Marketing & Consulting. http://www.indexbox.co.uk/news/Globalization-on-the-Brazil-Nut-Market. Accessed 11 Jan 2018

Kurtzman CP, Horn BW, Hesseltine CW (1987) Aspergillus nomius, a new aflatoxin- producing species related to Aspergillus flavus and Aspergillus tamarii. Antonie Van Leeuwenhoek. https://doi.org/10.1007/BF00393843

Lebret DT, Martins JR, HD A, Wang A, Bustillos OV (2004) Rapid method to determinate of mycotoxins compounds in food samples using high-performance liquid chromatography with APCI ionization tandem mass spectrometry (LC-APCI-MS/MS) in simultaneous positive and negative ion mode. 10th Latin American congress on chromatography and related techniques – COLACRO X, Campos de Jordão, São Paulo, Brazil

Lin MT, Dianese JC (1976) A coconut-agar medium for rapid detection of anatoxin production by Aspergillus spp. Phytopathology. https://doi.org/10.1094/Phyto-66-1466

Liu X, Guan X, Xing F, Lv C, Dai X, Liu Y (2017) Effect of water activity and temperature on the growth of Aspergillus flavus, the expression of aflatoxin biosynthetic genes and aflatoxin production in shelled peanuts. Food Control. https://doi.org/10.1016/j.foodcont.2017.07.012

Luo J, Taniwake MH, Iamanaka BT, Vogel RF, Niessen L (2014) Application of loop-mediated isothermal amplification assays for direct identification of pure cultures of Aspergillus flavus, A. nomius, and A. caelatus and for their rapid detection in shelled Brazil nuts. Int J Food Microbiol. https://doi.org/10.1016/j.fm.2014.06.004

Massi FP, Vieira MLC, Sartori D, Penha RES, Munhoz CF, Ferreira JM, Iamanaka BT, Taniwaki MH, Frisvad JC, Fungaro MHP (2014) Brazil nuts are subject to infection with B and G aflatoxin-producing fungus, Aspergillus pseudonomius. Int J Food Microbiol. https://doi.org/10.1016/j.ijfoodmicro.2014.06.006

Midorikawa GEO, Sousa MLM, Silva OF, Dias JSA, Kanzaki LIB, Hanada RE, Mesquita RMLC, Gonçalves RC, Alvares VS, Bittencourt DMC, Miller RNG (2014) Characterization of Aspergillus species on Brazil nut from the Brazilian Amazonian region and development of a PCR assay for identification at the genus level. BMC Microbiol 14:1–9. https://doi.org/10.1186/1471-2180-14-138

Moore GG, Mack BM, Beltz SB (2015) Genomic sequence of the aflatoxigenic filamentous fungus Aspergillus nomius. BMC Genomics. https://doi.org/10.1186/s12864-015-1719-6f

OBrian GR, Georgianna DR, Wilkinson JR, Yu J, Abbas HK, Bhatnagar D, Cleveland TE, Nierman WC, Payne GA (2007) The effect of elevated temperature on gene transcription and aflatoxin biosynthesis. Mycologia. https://doi.org/10.1080/15572536.2007.11832583

Olsen M, Johnsson P, Möller T, Paladino R, Lindblad M (2008) Aspergillus nomius, an important aflatoxin producer in Brazil nuts? World Mycotoxin J. https://doi.org/10.3920/WMJ2008.1032

Pacheco AM, Scussel VM (2007) Selenium and aflatoxin levels in raw Brazil nuts from the Amazon Basin. J Agric Food Chem. https://doi.org/10.1021/jf072434

Passone MA, Rosso LC, Etcheverry M (2012) Influence of sub-lethal antioxidant doses, water potential and temperature on growth, sclerotia, aflatoxins and aflD (= nor-1) expression by Aspergillus flavus RCP08108. Microbiol Res. https://doi.org/10.1016/j.micres.2011.11.004

Patriarca A, Vaamonde G, Pinto VF, Comeiro R (2001) Influence of water activity and temperature on the growth of Wallemia sebi: application of a predictive model. Int J Food Microbiol. https://doi.org/10.1016/S0168-1605(01)00470-6

Peterson SW, Ito Y, Horn BW, Goto T (2001) Aspergillus bombycis, a new aflatoxigenic species and genetic variation in its sibling species, A nomius. Mycologia. https://doi.org/10.2307/3761823

Pfaffl MW (2001) A new mathematical model for relative quantification in real time RT-PCR. Nucleic Acids Res. https://doi.org/10.1093/nar/29.9.e4

Reis TA, Oliveira TD, Baquião AC, Gonçalves SS, Zorzete P, Corrêa B (2012) Mycobiota and mycotoxins in Brazil nut samples from different states of the Brazilian Amazon region. Int J Food Microbiol. https://doi.org/10.1016/j.ijfoodmicro.2012.08.005

Reis TA, Baquião AC, Atayde DD, Grabarz F, Corrêa B (2014) Characterization of Aspergillus section Flavi isolated from organic Brazil nuts using a polyphasic approach. Food Microbiol. https://doi.org/10.1016/j.fm.2014.02.012

Schmittgen TD, Livak KJ (2008) Analyzing real-time PCR data by the comparative Ct method. Nat Protoc. https://doi.org/10.1038/nprot.2008.73

Silva AC, Sarturi HJ, Dall’Oglio EL, Soares MA, Sousa PT, Vasconcelos LG, Kuhnen CA (2016) Microwave drying and disinfestation of Brazil nut seeds. Food Control. https://doi.org/10.1016/j.foodcont.2016.04.049

Tanaka F, Fukuse T, Wada H, Fukushima M (2000) The history, mechanism and clinical use of oral 5-fluorouracil derivative chemotherapeutic agents. Curr Pharm Biotechnol. https://doi.org/10.2174/1389201003378979

Taniwaki MH, Frisvad JC, Ferranti LS, Lopes AS, Larsen TO, Fungaro MHP, Iamanaka BT (2017) Biodiversity of mycobiota throughout the Brazil nut supply chain: from rainforest to consumer. Food Microbiol. https://doi.org/10.1016/j.fm.2016.08.002

Trail F, Chang PK, Cary J, Lin JE (1994) Structural and functional analysis of the nor-1 gene involved in the biosynthesis of aflatoxins by Aspergillus parasiticus. Appl Environ Microbiol https://www.ncbi.nlm.nih.gov/pmc/articles/PMC201939/pdf/aem00028-0188.pdf. Accessed 12 Jan 2018

Yu J (2012) Current understanding on aflatoxin biosynthesis and future perspective in reducing aflatoxin contamination. Toxins. https://doi.org/10.3390/toxins4111024

Yu J, Chang PK, Bhatnagar D, Cleveland TE (2000) Cloning of a sugar utilization gene cluster in Aspergillus parasiticus. Biochim Biophys Acta. https://doi.org/10.1016/S0167-4781(00)00148-2

Yu J, Fedorova ND, Montalbano BG, Bhatnagar D, Cleveland TE, Bennett JW, Nierman WC (2011) Tight control of mycotoxin biosynthesis gene expression in Aspergillus flavus by temperature as revealed by RNA-Seq. FEMS Microbiol Lett. https://doi.org/10.1111/j.1574-6968.2011.02345.x

Zafra G, Absalón AE, Cortés-Espinosa DV (2015) Morphological changes and growth of filamentous fungi in the presence of high concentrations of PAHs. Braz J Microbiol. https://doi.org/10.1590/S1517-838246320140575

Funding

This research was supported by Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES), Brazil.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that there is no conflict of interest.

I have full control of all primary data, and I agree to allow the journal to review the data if requested.

The experiments comply with the current laws of the country in which they were performed.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yunes, N.B.S., Oliveira, R.C., Reis, T.A. et al. Effect of temperature on growth, gene expression, and aflatoxin production by Aspergillus nomius isolated from Brazil nuts. Mycotoxin Res 36, 173–180 (2020). https://doi.org/10.1007/s12550-019-00380-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12550-019-00380-w