Abstract

Response surface methodology (RSM) was employed to optimize medium components including oxygen vector of n-dodecane of a mutant strain GC-63 of Streptomyces roseosporus NRRL 11379. The two-level Plackett–Burman design (PB factorial design) with fourteen variables including oxygen vector was used to screen the most significant factors affecting antibiotic production. Then, the RSM based on center composite design was used to identify the optimum levels of the significant variables to generate optimal response. Glucose, soybean meal, asparagine and n-dodecane were screened to significantly influence the daptomycin production. The medium composition optimized with response surface methodology was (g/L): glucose, 9.46; soluble starch, 25; dextrin, 12.5; yeast extract, 12.5; soybean meal, 21.34; peptone, 25; casein, 5; asparagine, 2.68; K2SO4, 6; (NH4)2Fe(SO4)2, 2; MgSO4, 1; CaCO3, 5; MnCl2, 0.5; n-dodecane, 7.47 % (v/v). The maximum daptomycin concentration reached 979.36 mg/L which was nearly 2.2-fold higher compared to that in the basal medium, with predicted optimal concentrations in a 7.5-L fermentor.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Daptomycin is a member of the A21978C family of the cyclic anionic 13-amino acid lipopeptide, produced by a non-ribosomal peptide synthetase (NRPS) mechanism in Streptomyces roseosporus against a broad range of gram-positive pathogens, including methicillin- and vancomycin-resistant Staphylococcus aureus [1]. However, the yield needs to be further improved and cost of industrial production needs to be further reduced. Yet, there was little information available regarding enhancement of daptomycin productivity by medium optimization.

RSM was a collection of statistical techniques for evaluating the effective factors, building models to study the interaction between the variables, and selecting the optimum conditions of variables or desirable responses [2]. Using this technique, a few experimental trials were needed and significant interactions between the factors could be identified and quantified. Thus, RSM has been widely proved to be very effective for the applications on the optimization of medium compositions for fermentation processes [3, 4].

One of the major problems in industrial production of antibiotics was the inadequate supply of dissolved oxygen, which does not meet the demand of the cultures by only increasing the agitation speed. The addition of non-aqueous solvent called oxygen vector was one of the most effective approaches to improve oxygen transfer rate in aerobic fermentation [5].

In summary, the present investigation was aimed to enhance daptomycin production of strain GC-63 of S. roseosporus by optimizing medium components including oxygen vector of n-dodecane using the RSM method. The factorial design of Plackett–Burman (PB) was used to screen the most significant factors affecting antibiotic production. Center composite design (CCD) was used to identify the optimum levels of the significant variables to generate optimal response.

2 Materials and Methods

2.1 Microorganism

The mutant strain GC-63 (He–Ne Laser and NTG induced mutants) of S. roseosporus NRRL 11379 used in the study was stored in 20 % glycerol at −80 °C.

2.2 Medium and Culture Conditions

Seed medium, fermentation medium and culture conditions both in flasks and in a 7.5-L bioreactor were same as previous research [6].

2.3 Analytical Methods

The analysis methods of the daptomycin, dry cell weight (DWC) and reducing sugar concentrations were same as previous research [6]. The pH and dissolved oxygen values were monitored by the digital electrode on-line.

2.4 Experimental Design and Optimization by RSM

2.4.1 Screening of Factors Affecting Daptomycin Production

The PB factorial design was employed for selecting factors that significantly influenced daptomycin production. In the present study, fourteen assigned variables were screened in twenty experimental runs (Tables 1, 2).

2.4.2 Path of Steepest Accent (Descent) Experiment Design

According to the first-order model equation obtained and the three important effect factors above, we moved in the three most important effect factors directions, respectively. The path of steepest ascent (descent) was determined to find proper direction of changing variables increasing or decreasing the concentration according to the sign of the main effects to improve daptomycin production. The design of the path of steepest ascent experiments is shown in Table 3.

2.4.3 Response Surface Methodology and Central Composite Design

RSM was used to optimize the screened variables for enhanced daptomycin production based on CCD. Glucose, soybean meal, asparagine and n-dodecane were major variables for daptomycin production using CCD and RSM. The four-factor, five-level CCD was used to optimize the response of four variables. The range and levels of experimental variables investigated in this study are listed in Table 4.

The analysis of all the data was conducted by Design Expert software package 7.0.

3 Results and Discussion

3.1 PB Method for Selection of Significant Factors Affecting Daptomycin Production

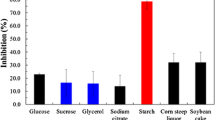

To evaluate which factors play significant effects on the daptomycin production, the PB design was employed. The previous studies indicated that the factors such as K+, Mg2+, Mn2+, Fe2+ and Ca2+ exerted important effects on the production of daptomycin through fermentation by S. roseosporus (data no shown). In addition to these factors, others including yeast extract, peptone, casein, soybean meal, glucose, soluble starch and dextrin were also investigated in our experiment. Furthermore, n-dodecane was used in this investigation as a dissolved oxygen vector in the media. Based on the above results, the upper and lower limits of the variables for each factor were then chosen as shown in Table 1. The PB design for 20 trials with two levels for each variable and corresponding daptomycin production is presented in Table 2. To approach the neighborhood of the optimum response, a fitted first-order model for daptomycin production was obtained from the PB design as follows:

The coefficient of each variable in Eq. (1) represents the effect extent of this variable on the daptomycin yield. The linear regression coefficient R 2 was 0.9411 and the adjusted determination coefficient (Adj R 2) was 0.7763 for the model, which indicated that the model was reasonable for the PB design. And glucose (X 1), soybean meal (X 4), asparagine (X 6) and n-dodecane (X 8) were found to be the most significant variables affecting daptomycin production.

According to reports, the synthesis of many antibiotics and other secondary metabolites was often affected by carbon catabolic inhibition [7]. Daptomycin production could suffer from carbon catabolic repression which explained the negative effect of glucose. And the soybean meal was also known to play a major role by supplying various amino acids and cofactors. As one of amino acids, addition of asparagine could increase the precursors for daptomycin production, which may account for the positive effect. For the oxygen vector n-dodecane, the results showed that dissolved oxygen plays an important role for the synthesis of daptomycin, as the research results of Wang [8].

3.2 The Path of Steepest Ascent

The path of steepest ascent was determined by Eq. (1). The coefficients of the X 4, X 6 and X 8 in the refined model were positive, which indicated a positive impact on daptomycin production. The X 1 was negative and generated an opposite effect. Table 3 exhibits the results of the experiment and the directions which the variables changed. The concentrations of the other factors were fixed at the center of the fractional factorial design, because they were not significant at the probability level of 95 %. Regarding the results from the path of steepest ascent, it was clearly seen that the daptomycin concentration profile showed a maximum for the run four (Table 3). Consequently, this point was chosen for further optimization.

3.3 CCD and RSM

The optimum levels of significant independent variables (glucose, soybean meal, asparagine and n-dodecane) were determined based on the above results by CCD. The CCD with four-factor and five-level, including six replicates at the center point, was used for fitting a second-order response surface. The design matrix and the corresponding experimental data are presented in Table 4. The results were analyzed by standard analysis of variance (ANOVA), and the following quadratic regression equations were obtained in terms of daptomycin production (Table 5). Using the designed experimental data, the polynomial model for daptomycin yield Y was regressed by only considering the significant terms and is shown below:

where Y was the predicted response, A, B, C, D were coded values of glucose, soybean meal, asparagine and n-dodecane, respectively.

As shown in Table 5, the model F value was 26.82 and the F value for lack of fit was 3.04. The F value and nonsignificant lack of fit indicated that the model was a good fit. The P values of the model (<0.0001) and the lack of fit (0.1155) also suggested that the obtained experimental data were good fit with the model. The fit of the model was also checked by determination of coefficient (R 2). The value of determination coefficient R 2 = 0.9616 for daptomycin yield, indicating that about 96.16 % of the total variations could be explained by the model. This value indicated that the accuracy and general ability of the polynomial model was good. The adjusted determination coefficient (Adj R 2 = 0.9257) could be used to verify the significance of the model. Analysis of the response trends using the model was considered to be reasonable.

The model coefficients calculated by regression analysis for each variable are also given in Table 5. The P value <0.05 indicates that the model terms were significant. In this case, the A, B, C, D, AC, AD, CD, A2, B2, C2, D2 were significant model terms. They were proved to have important effects for daptomycin production.

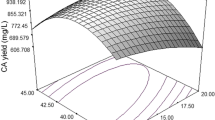

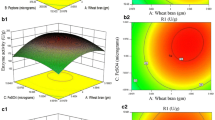

The three-dimensional response surfaces plot is shown in Fig. 1. There was a clear elongated hill running along the concentration axis on the plot of the three-dimensional response surfaces of the quadratic model (Fig. 1b, c, e, f), which indicated a significant interactive effect on daptomycin between the two independent variables. On the other hand, three-dimensional response surface of glucose and soybean meal, soybean and asparagine had a slightly circular nature, suggesting that their interactive effects were not significant (Fig. 1a, d) [4, 9, 10].

Response surface plot for daptomycin production by S. roseosporus. a Effects of glucose and soybean meal, b effects of glucose and asparagine, c effects of glucose and n-dodecane, d effects of soybean meal and asparagine, e effects of soybean meal and n-dodecane, f effects of asparagine and n-dodecane. Each figure shows the effect of two variables on the production of daptomycin, while other two variables were held at zero level

According to the canonical analysis, the results predicted by the model showed that the maximum daptomycin production could be achieved when the glucose, soybean meal, asparagine and n-dodecane were set at 9.46, 21.34, 2.68 g/L and 7.47 % (v/v), respectively. The maximum predicted value of daptomycin yield obtained was 1001.24 mg/L.

3.4 Experimental Validation of the Optimized Condition

In order to verify the model adequacy for predicting the maximum daptomycin production, three verification experiments in shake flasks under this optimum medium composition were performed. The mean value of daptomycin concentration was 918.87 mg/L, which was coincident with the predicted value (1001.24 mg/L), indicating that the model was proved to be adequate.

After optimization of medium components, scale-up studies were carried out in a 7.5-L laboratory bioreactor. The batch-fermentation profile of daptomycin production, including reducing sugar, DWC and dissolved oxygen concentration, with the optimized medium is shown in Fig. 2. And the daptomycin yield reached 979.36 mg/L. The ranges of DWC were from 1.35 g/L at the lag phase to 13.89 g/L at the end of the exponential phase. The reducing sugar decreased to 0.1–0.2 % when the cells reached the stationary phase. The results indicated that the optimum medium components obtained by statistical experimental design in shake flasks were equally effective to the overproduction of daptomycin by bioreactor fermentation. The addition of n-dodecane enhanced the dissolved oxygen with the constant agitation speed, which enhanced the cell growth and daptomycin biosynthesis.

4 Conclusions

Response surface methodology (RSM) was employed to enhance daptomycin production by a mutant strain GC-63 of S. roseosporus NRRL 11379. The glucose, soybean meal, asparagine and n-dodecane were screened to significantly influence the daptomycin production. The predicted optimized concentration of glucose, soybean meal, asparagine and n-dodecane were 9.46, 21.34, 2.68 g/L and 7.47 % (v/v), respectively, by CCD. Furthermore, the validation experiments were carried out to prove the adequacy and the accuracy of the model, and the maximum daptomycin concentration reached 979.36 mg/L which was nearly 2.2-fold higher compared to that in the basal medium, with predicted optimal medium concentrations in a 7.5-L fermentor. The study had certain guiding significance for improvement of antibiotic production in other Streptomyces.

References

Steenbergen JN, Alder J, Thorne GM, Tally FP (2005) Daptomycin: a lipopeptide antibiotic for the treatment of serious Gram-positive infections. J Antimicrob Chemother 55:283–288

Piyushkumar M, Kiran D, Lele SS (2007) Application of response surface methodology to cell immobilization for the production of palatinose. Bioresour Technol 98:2892–2896

Chen H, Huang H, Wu H (2009) Process optimization for PHA production by activated sludge using response surface methodology. Biomass Bioenerg 33:721–727

Ghosh D, Hallenbeck PC (2010) Response surface methodology for process parameter optimization of hydrogen yield by the metabolically engineered strain Escherichia coli DJT135. Bioresour Technol 101:1820–1825

Xu F, Yuan QP, Zhu Y (2007) Improved production of lycopene and β-carotene by Blakeslea trispora with oxygen-vectors. Process Biochem 42:289–293

Yu GH, Jia XQ, Wen JP, Lu WY, Wang GY, Caiyin Q (2011) Strain Improvement of Streptomyces roseosporus for daptomycin production by rational screening of He–Ne laser and NTG induced mutants and kinetic modeling. Appl Biochem Biotech 163:729–743

Colombié V, Bideaux C, Goma G, Uribelarrea JL (2005) Effects of glucose limitation on biomass and spiramycin production by Streptomyces ambofaciens. Bioprocess Biosyst Eng 28:55–61

Wang JL (2000) Enhancement of citric acid production by Aspergillus niger using n-dodecane as an oxygen-vector. Process Biochem 35:1079–1083

Li Y, Jiang H, Xu Y, Zhang X (2008) Optimization of nutrient components for enhanced phenazine-1-carboxylic acid production by gacA-inactivated Pseudomonas sp. M18G using response surface method. Appl Microbiol Biotechnol 77:1207–1217

He L, Xu YQ, Zhang XH (2008) Medium factor optimization and fermentation kinetics for phenazine-1-carboxylic acid production by Pseudomonas sp. M18G. Biotechnol Bioeng 100:250–259

Acknowledgments

This work was supported by 21506048 and 51408396 from the National Natural Science Foundation of China. And the authors also wished to acknowledge the financial support provided by Excellent Talents Project of Henan University of Technology (2011BS037).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declared that no potential conflict of interest existed in this study.

Rights and permissions

About this article

Cite this article

Yu, G., Wang, G. Optimization of the Biosynthesis Conditions of Daptomycin by the Biostatistical Methodology. Interdiscip Sci Comput Life Sci 9, 80–87 (2017). https://doi.org/10.1007/s12539-015-0133-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12539-015-0133-8