Abstract

This is a mineralogical and chemical study of samples from selected carbonate rock deposits in South Africa, to test their suitability for the production of cement for local infrastructure projects. The sites are located on Rietfontein, Rooikop, and Wiedouw farms. The study has been carried out using petrographic, X-ray diffraction, and X-ray fluorescence techniques. The results show that material from Rietfontein is composed of calcrete, while that at Rooikop is composed of recycled micrite. At Wiedouw, the carbonate is a low metamorphic grade marble with classic metamorphic polygonal grains and grain boundaries. The study shows that the carbonate material from the selected sites is suitable, not only for cement manufacture but, due to their purity, also for the production of calcium oxide for use in various industrial processes requiring high-grade lime or limestone. Future development should, therefore, consider exploitation of these deposits as raw material for cement production, as well as limestone and lime production. While the Wiedouw marble and the Rooikop limestone form compact and tough rocks requiring higher costs for blasting, crushing, and grinding for the small quarry, the Rietfontein calcrete, being of secondary surface origin, is softer and is therefore preferred ahead of the other two.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

This work is in support of an initiative aimed at contributing towards infrastructure development in regions far from urban centres and existing large-scale cement plants. The primary investigation focuses on simplifying and miniaturizing the cement-manufacturing process. Another part of this innovation is to create a plant that can be assembled and used at one site, get dismantled, and conveyed to another site, where it is reassembled and reused. It, therefore, intended that the plant be modular, to enable the cycles of dismantling and assembly. The benefit of such a set-up is that the capital costs paid to enable operations are at the first site would enable production at additional locations. This would have the advantage of reducing the total capital costs for working several deposits, as well as enable exploitation of carbonate deposits that may have been too small to justify a capital outlay on their own.

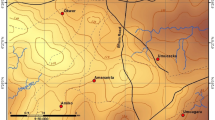

Naturally occurring carbonate occurs mainly as deposits of limestone, marble, or carbonatite deposits. It may also occur as secondary deposits of tufa, calcrete, travertine, and cave limestone, produced by soil or near-surface chemical rock dissolution and reprecipitation of some of the solute, during weathering. It is, by mass, the single most important input in the cement manufacturing process. To be suitable for this, it must have a CaCO3 content of at least 75% (CaO>47%), a MgCO3 no more than 6% (MgO<4%), SiO2 less than 15%, and Fe2O3+Al2O3 no more than 16% ASTM 1998; BGS 2005). K2O+Na2O must also be less than 0.66%. Thus, as a first step, the rock carbonate resources of South Africa, the authors’ host country, were reviewed. Carbonate deposits with the chemical composition suitable for use as an input during Portland cement manufacture, but not already being exploited, were earmarked as potential targets for the envisaged plant. Of these, deposits close to main roads; a rail track; main electricity supply line; a source of water such as a lake, dam, or major river; and, finally, a human population cluster were prioritized. Four deposits passed all the foregoing tests and are named after the farms on which they fall, these being Cyferfontein and Rietfontein in the Limpopo Province, Rooikop in the Free State Province, and Wiedouw in the Western Cape Province (Senzani and Mulaba-Bafubiandi 2019).

Because the above review was conducted only as a desktop study, field investigations were conducted at the selected sites to confirm the existence of the carbonate. Reconnaissance mapping and sampling were involved. Chemical and petrological analyses of carbonate specimens taken during the field investigation of the deposits constitute the main subject of study. The results were also used to assess if, as reported previously (Martini 1987; Vorster 2003; Wybergh and Du Toit 1918; Wybergh 1920), they met the chemical criteria for cement manufacture. They were also used to compare the characteristics of the carbonate materials from the different sites, as regards cement manufacture. This also enabled a determination as to which deposit would be the easiest to exploit.

South Africa

Located at the southern tip of the continent after which it is named, the country stretches over 1,221,037 km2. The country’s neighbours are, from west to east, Namibia, Botswana, Zimbabwe, Mozambique, and Eswatini, the last being formerly known as the Kingdom of Swaziland. Lesotho, another kingdom, is surrounded on all sides by the country of study. South Africa’s coastline stretches over 2798 km, with the Atlantic Ocean to the west and the Indian Ocean to the east (Readers Digest Association 1984; britannica.com/place/South-Africa, 2020; Fig. 1). Its population is 58 million and, with a per capita income of US$12,393 (statssa.gov.za/?s=per+capita+income; data.worldbank.org/country/ZA), has been classified as an upper-middle-income economy. South Africa has the greatest difference in the distribution of wealth between the rich and the poor. A Gini coefficient from 0.66 to 0.7, with the top decile accounting for 58% of income, while the bottom decile accounts for 0.5%, confirms the assertion. In addition, the lower half of the population earns only 8% of national income, while the unemployment rate is 40% in general and over 60% among the youth (data.worldbank.org/indicator/SP.POP.TOTL?locations=ZA; worldbank.org/en/country/southafrica/overview#:~:text=South%20Africa%20remains%20a%20dual,increased%20from%200.61%20in%201996).

This report is the second in a series, on a project which attempts to contribute towards the development of technology suitable for the manufacture of Portland cement at an artisanal to small scale. The target users are small rural communities, located far from present major factories, making cartage of the product prohibitively costly. While South Africa is the location of the present study, the successful completion of the investigation would benefit any similar communities, anywhere. As the technology is being developed so that it will be simple and low in capital outlay, it will also enable exploitation of low-tonnage raw material deposits of limestone, silica sand, clay, shale, bauxite, and ironstone. Such deposits are too small to be of interest to large cement corporations and are therefore idle at present. Labour-intensive methods are also envisaged, and thus successful completion of the broader investigation will help absorb some of the readily available and currently idle manpower.

Portland cement

When Portland clinker, gypsum (CaSO4·2H2O), and water are mixed, Portland cement paste is produced. When river sand is added, mortar, commonly used as a binder for bricks, masonry, or stones during construction, is produced. If coarse sand, gravel, or other coarse aggregate is added in certain proportions, the paste + solid mixture is concrete, globally the single most important building material in volume terms. Portland clinker is the main constituent (91%) and is itself composed of a fused mixture of calcitic limestone, sand, clay, and some form of ironstone. Shale or bauxite may be used in place of clay. The limestone, the sand, and the ironstone supply CaO, SiO2, and Fe2O3 component, respectively, while the clay, shale, or bauxite supply Al2O3 (Gwosdz 1981; Lapidus 2003; Manning 1995; Wright 1974). The raw materials are blended to comply with the so-called Lime Saturation Factor (LSF), in which

The mixture is heated to 14500C, which leads to its dehydration, calcining, melting, and some tumbling, if rotary kilns are used. It is then cooled rapidly, whereupon forms nodules of the clinker, composed of the four minerals alite, belite, calcium aluminate, and calcium-ferrite (Table 1; Gwosdz 1981; Manning 1995; Wright 1974). Gypsum, to the amount of 9.89% of the clinker, is then added and the mixture milled to a fine powder. Strictly, Portland cement is the paste formed only after addition of water to the powder. However, it is common to refer to the dry powder as Portland cement. This is a convention which is adopted in the rest of this article.

Cement production in South Africa

In 2014, Portland cement consumption was 12.07 Mt in South Africa, down to 8% from the 12.17 Mt sold in 2013. This gives a per capita consumption of 216 kg for 2014. The amount included 1.3 Mt of imports, which were mostly from Pakistan. The imports rose from 0.76 in 2012 and 1.1 Mt in 2013 (ICR 2017). The amount produced by each South African plant is unclear due to mixing up of capacities, retired or suspended capacities, as well as the splits between integrated plants, which carry the whole process from raw materials to the final Portland cement product and those that supply clinker to separate grinding units, thereby carrying out the last production steps. Single plant capacity in the country averages 1.18 Mt for 2014. This is based on the reported consumption of 12.07 Mt, 1.3 Mt of imports, and the 10 integrated and 8 downstream plants in the country (Table 2). The widespread presence of high tonnage bodies of carbonate, the high-energy cost per ton of small-scale operations, and the benefit brought on board by the economies of scale have militated against any low-capacity plants. Even the technical complexity and high capital outlay have not been adequate to discourage the large-scale operations or conversely to encourage small-scale production approaches. It would seem, therefore, that the country may have no need for small-scale cement operations at present. However, the economic case for the small-scale operations is being argued in a separate publication (Senzani and Mulaba-Bafubiandi, in preparation). The focus is in locations where the market is located far from current plants and is close to the required resources and on primarily carbonate deposits. It also targets deposits which are also difficult of access by the large means of transportation required to convey high bulk items, of which Portland cement is an example.

Materials and methods

Samples were taken from three different sites determined in an earlier study, namely, Rietfontein, Rooikop, and Wiedouw farms (Senzani and Mulaba-Bafubiandi 2019). The farms are located in the Limpopo, Free State, and Western Cape provinces, respectively (Martini 1987; Vorster 2003). Reconnaissance mapping was conducted at the farm sites (Figs. 2, 6, and 10). Samples were analysed using petrographic, X-ray diffraction, and X-ray fluorescence techniques. Petrographic investigations were carried out using an Olympus BX51 petrographic microscope. The XRD determination was conducted using a Rigaku, Ultima IV, at 40 kV, a 30 Ma copper source and a K-beta filter, with a scintillation counter detector. The scan mode was continuous and at 0.500° per minute and a step width of 0.01°. The scan axis was 2θ/θ, while the scan range was 5.000 to 90.0000°. The receiving slit #1 was open, and the receiving slit #2 was set at 0.60 mm.

A Rihaku ZXS Primus II was utilized for the XRF analysis by the scatter FP method. This has an elemental coverage from 4Be to 92U. The wavelength was dispersive and sequential, while the wave was generated using an X-ray tube, with the power at 3 kW and 60 kV. The sample rotation speed was at 30 rpm, with primary filters of Al, Ti, Cu, and Zr. It was equipped with a beam collimator with 6 auto-selectable diameters, 35 mm, 30 mm, 20 mm, 10 mm, 1 mm, and 0.5 mm, and three divergence slits, also auto-selectable resolutions, namely, standard, high, and course. The receiving slit was set up for scintillation counter (SC) for heavy element detection and a flow proportional counter (F-PC) for light elements. The goniometer is set up with a θ to 2θ independent drive mechanism. The angular range is, for SC, 5° to 118° and for F-PC, 13° to 148°. The temperature was stabilized at 36.5±.1 °C. Results were then compared with the characteristics of carbonate material utilized at selected Portland cement plants.

Results

Rietfontein

Regional geology

The area around Rietfontein Farm is underlain by the Daspoort Quartzite Formation and the Mackekaan Formation composed mainly of arenites (sandstone, greywacke, arkose, orthoquartzite, feldspathic sandstone) and micaceous siltstone. Both formations constitute part of the Pretoria Group, which is in turn part of the Transvaal Supergroup, with a Vaalian age. There are also Bushveld (igneous) Complex bodies of pyroxenite, melanorite, and granite. In addition there are Karoo Supergroup rocks, namely, Ecca Group shale, shaly sandstone, sandstone, grit, tillite, conglomerate, or coal near the base. It is capped by the Letaba dolerite. Also present is also loose, cream to reddish-brown Kalahari sand occurring as superficial cover of the above units. The Rietfontein Farm deposit occurs at the southwest end of a post-Karoo fault precipitated (Fig. 3; CGS 1978), which may be have acted as a conduit for fluid from which the carbonate was precipitated.

Outcrops and dugouts of calcrete at Rietfontein Farm, Limpopo Province, South Africa. (a) Wall of dugout capped by topsoil, underlain by loose top calcrete, a middle thick hardpan, underlain by the lower soft calcrete. Lower hard calcrete is not exposed in the cutting. (b) Quarry wall of soft calcrete underlain by hardpan calcrete forming the quarry floor

Deposit geology and petrography

On the farm, the carbonate material consists of light-brown to cream calcrete composed of three main categories of very fine grains. Four layers were identified, beneath a loose, pale orange to reddish brown sandy calcrete soil layer with some decomposed plant remains. Below this was a 0.5-m to 1-m-thick layer of the first proper calcrete, which was composed of loose cream to pale yellow fine material. It was underlain by a 0.5-m-thick zone of hardpan calcrete which sticks out as a bed in the wall of the dugout (Fig. 4a). Below this was a 2-m-thick bed, also of loose calcrete in the mode of the first proper calcrete layer. This main calcrete is underlain by rock hard calcrete surface which forms the base of the whole deposit. Its lower limit is not exposed on the farm, with the previous excavations having been stopped at this surface (Fig. 4b).

Photomicrographs of calcrete from Rietfontein Farm, Limpopo Province, South Africa. (a) Plane-polarized microphotograph of calcrete from Rietfontein Farm - composed of fine micritic calcite lumps (light brown) surrounding quartz grains (white), and in turn surrounded by more micritic calcite mixed with fine iron-hydrooxide (dark brown). The latter is cut by calcite veins (white). Field of view = 3 mm. (b) Cross-polarised micrograph of part of a veinlet of carbonate hosted by calcrete (Field of view: 200 μm across)

Examination using a petrological microscope reveals very fine carbonate, composed of micrite grains, held in even finer micrite cement. In both the grains and cement are small sparite grains. Multiple cycles of carbonate precipitation are indicated by the presence of earlier micrite grains inside subsequent ones (Fig. 5a). These are cut by later microscopic veinlets, also of crystalline calcite, which is shown at higher magnification. The veinlets are enveloped by iron hydroxide (Fig. 4b).

X-ray diffraction and X-ray fluorescence data

The petrographic results are supported by XRD analysis, which shows a high content of high calcite, with negligible magnesian calcite as the only minerals present in the Rietfontein calcrete (Fig. 5). The high calcite content of the deposit is borne out by the XRF data, which shows average contents, on a volatile-free basis, of CaO, MgO, SiO2, and Al2O3+Fe2O3 of, respectively, 78%, 1%, 6.6%, 1.9%, and a silica ratio of 3.5% (Fig. 6, Table 4; Appendix 1). The purity of the deposit suggests a deep source of the carbonate-rich liquid from which calcite was deposited. This is because calcrete derived from alkaline weathering of any of the rocks in the vicinity of the farm (Fig. 2) would have yielded higher percentages of alumina, magnesia, silica, and iron oxide.

Rooikop

Regional geology

Rooikop Farm falls in an area underlain by two main stratigraphic units, both forming part of the Karoo Supergroup. The first is the Estcourt Formation, which is composed of fine to coarse-grained sandstone and grey shale. The other is a dolerite sill which caps most of the hills in the region. Recent alluvium occupies the valleys in the area (Fig. 6; CGS 1992). Only khaki portions of the grey shale were observed during the reconnaissance study being reported here. Outcrop of this is rare as it weathers readily of black clay.

Deposit geology and petrography

In detail, the Rooikop Farm resource is a compact limestone, composed of grey micrite when fresh, but brown on exposed surfaces (Fig. 7), with sparite spots and micro-veining. The veins are composed of an outer (earlier), ferruginous phase, and an inner (later) phase of microcrystals of calcite (Fig. 8).

Plane-polarized micrographs of micritic limestone from Rooikop Farm, Free State Province, South Africa. (a) Micritic limestone with veinlet of calcite, bordered by iron-hydroxide. Field of view 3 mm. (b) Micritic limestone with developing cracks filled by sparry calcite, with clots of iron-hydroxide. Field of view = 1 mm

X-ray diffraction and X-ray fluorescence data

The mineral spectra show a high proportion of magnesian calcite (88%), with subordinate graphite (7%), and negligible ankerite, pyrolusite, and haematite (Fig. 9). The XRF determinations show ranges 68.92 to 83.9% with an average of 77.35% for CaO, 0.76 to 1.17% with an average of 0.99% for MgO, 6.88 to 15.84% but an average 11.27% for SiO2, 1.89% to 4.21%, with an average of 2.96% for Al2O3, 2.97 to 3.58%, with an average of 3.17% for Fe2O3, and 0.60 to 1.35% and an average 0.89% for Na2O+K2O.

While magnesian calcite, shown as the dominant mineral, may range in MgCO3 content from 5 to 18%, it is clear from the accompanying XRF analyses, which show an average compositions of 77.35% CaO and 0.99% MgO, that the Rooikop Farm material is hardly magnesian.

Wiedouw

Regional geology

Rocks underlying the area in which Wiedouw Farm falls constitute parts of the Namibian era Gifberg Group, itself a constituent of the Gariep Supergroup. The oldest is the Karoeskop Formation, which is composed of quartzite, conglomerate, diamictite, biotite, and sericite schist. This was succeeded by Wiedouw Formation limestone, dolomite, marble, greywacke, biotite, and sericite schist. In turn, Wiedouw Formation was overlain by the Aties Formation graphitic and sericitic schist, phyllite, greywacke, quartzite, impure dolomite, limestone, and marble. Loose Kalahari sand forms the recent cover (Fig. 10; CGS 2001).

Deposit geology and petrography

On closer examination, the Wiedouw carbonate is in fact a low-grade marble composed of lighter-grey calcitic units, interbedded with darker-grey dolomite (Fig. 11a). Intraformational folding is evident at the sub-decimetre scale (Fig. 11b). Classic polygonal grains, forming high-angle contacts, and thus revealing the low-grade metamorphism, are uniformly 1mm across in Sample WD001 (Fig. 12a). There are also zones where shear movement has flattened or ground the grains (Fig. 12b). There is no development of new metamorphic minerals, however.

Photomicrographs of Wiedouw Farm marble, Western Province, South Africa. (a) Plane-polarised photomicrograph of calcitic Wiedouw marble, with characteristic low-grade metamorphic polygonal grain contacts. (b) Plane-polarised photomicrograph (top) of calcitic Wiedouw marble, with flattening in parts, and tight flow folding and interpretation (bottom)

X-ray diffraction and X-ray fluorescence data

The XRD spectra indicate the Wiedouw marble to be composed mainly of 70% magnesian calcite and significant dolomite of just over 30%. Quartz and graphite form an insignificant proportion (Fig. 13). The mineralogical data is borne out by the XRF data for the same sample, which shows, on a dry basis, 74.47 % CaO and 24.12% MgO. In more detail, the CaO content ranged from 74.17 to 96.68, with an average of 87.87%; MgO from 0.51 to 24.12%, average 9.39%; SiO2 from 0.35 to 4.55% and an average of 1.37%; Al2O3 from 0.15 to 0.74% and a mean of 0.41%; Fe2O3 from 0.01 to 0.02% and an average of 0.02; and, finally, a Na2O+K2O ranging from 0.06 to 0.19% and an average of 0.12% (Appendix 3).

Summary and conclusion

When compared with the chemical content of the oxides of carbonate suitable for Portland cement production from around the world, the material from the target sites lies within the satisfactory range (Table 3). While the average MgO content for the Wiedouw samples is above the required range, there is local low-magnesia carbonate that could be blended with the high-magnesia material (Appendix 3).

The Rietfontein carbonate is fine-grained and friable and therefore easy to grind during preparation. While the Rooikop limestone is also fine-grained, it is hard, compact, and well cemented and will therefore require more energy for comminution. Due to the low-grade metamorphism, the Wiedouw marble will, of the three sites, demand the most energy to crush and mill. The constituent calcite crystals are also the largest.

Conclusions

Microscopic petrographic study, as well as X-ray diffraction and X-ray fluorescence analysis of carbonate samples from Rietfontein, Rooikop, and Wiedouw farms in South Africa, shows that the minerals have a high content of calcite. The investigation also shows that the material has levels of MgO, Fe2O3, Al2O3, SiO2, Na2O, and K2O and silica ratios within the accepted range for cement production, as well as various industrial processes requiring high-purity lime or limestone (Table 3). The Rietfontein material is concluded to have the best potential as, in addition to its purity, the material is very fine-grained and friable.

References

ASTM (American Standards Test Methods) (1998) Annual book of ASTM standards, vol 04.01 (Cement, Lime, Gypsum) ASTM. Pasadena, USA

BGS (British Geological Survey) (2005) Mineral profile: cement raw materials. Natural Environment Research Council. Office of the Deputy Prime Minister, London, 20p

CGS (Council for Geoscience) (1978) 1:250 000 Geological map series, Nylstroom 2428. Government Printer, Republic of South Africa. Pretoria

CGS (Council for Geoscience) (1992) 1:250 000 Geological map series, Frankfurt 2728. Government Printer, Republic of South Africa. Pretoria

CGS (Council for Geoscience) (2001) 1:250 000 Geological map series, Calvinia 3118. Government Printer, Republic of South Africa. Pretoria

Gwosdz W (1981) Report on the Nakala-Phala carbonate deposit (QDS2226D1). Geological Survey of Botswana Report No. WG/21/81

ICR (International Cement Review) (2017) Global cement report, 12th edn. Tradeship Publications Ltd, Surrey, United Kingdom

Lapidus DF (2003) Collins dictionary of geology. Caledoninan International Book Manufacturing Limited, Glasgow, Great Britain, pp 576

Manning DAC (1995) Industrial minerals. Springer, Netherlands, 276p

Martini JEJ (1987) Limestone and dolomite resources of the republics of South Africa, Bophuthatswana, Ciskei, Transkei and Venda. Geological Survey, Department of Mineral an Energy Affairs, Handbook 9. Government Printer, Pretoria, 112p

Readers Digest Association (1984) Atlas of Southern Africa. Cape Town, South Africa

Senzani FED, Mulaba-Bafubiandi (2019) Site determination for artisanal rock carbonate processing using qualitative multifactor analysis – case studies: Malawi and South Africa. Transactions of the Royal Society of South Africa 74(1):55–66. https://doi.org/10.1080/0035919X.2018.1564400

Vorster CJ (2003) Limestone and dolomite deposits of South Africa, Lesotho and Swazilansd. SAMINDABA. Council for Geoscience, Pretoria

Wright JB (1974) Constructional and other bulk materials. The Open University Press. Milton-Keynes, UK, 88p

Wybergh W (1920) The limestone resources of the Union. Volume 2 – the limestone resources of Natal, Cape and Orange Free State Provinces: Memoir of the Geological Survey of South Africa, 11(2), 149p

Wybergh W and Du Toit AL (1918) The limestone resources of the Union, Volume 1 – the limestone resources of the Transvaal and portions of Bechuanaland and Zululand: Memoir of the Geological Survey of South Africa, 2, 122p.

Acknowledgements

The authors gratefully acknowledge the funding support for the study from the National Research Foundation through the Centre of Excellence for Integrated Mineral and Energy Analysis. They are also very grateful to Dr. Yuegao Liu from the Institute of Deep-Sea Science and Engineering, Chinese Academy of Sciences, and an anonymous reviewer for their great help in improving this manuscript and constructive opinions. We thank the editor Dr. Abdullah M. Al-Amri and the associate editor Dr. Emanuela Schingaro for their suggestions to amend the manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Responsible Editor: Domenico M. Doronzo

Appendices

Appendix 1

Appendix 2

Appendix 3

Rights and permissions

About this article

Cite this article

Senzani, F.E.D., Mulaba-Bafubiandi, A.F. Mineralogical and chemical comparison of carbonate from sites selected for cement production with limestone used in commercial operations. Arab J Geosci 14, 1301 (2021). https://doi.org/10.1007/s12517-021-07021-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-021-07021-6