Abstract

Glass transition temperature (Tg) and degree of caking for maltodextrin with added plasticizers (glucose, maltose, and sorbitol) were investigated. Onset and offset Tgs were evaluated by differential scanning calorimetry. From the onset and offset Tg-curves and water sorption isotherm, each critical water activity (awc) value was determined (water activity at each Tg = 25 °C). The awc range between onset Tg and offset Tg was extended by the addition of plasticizers. The degree of caking increased at a water activity just above awc of onset Tg, and completely caked at a water activity just below awc of offset Tg. Effect of aw on the degree of caking became more gradual with the addition of plasticizers because of the extended awc range. According to the dependence of viscosity on temperature and water activity, a predictive model for the caking of amorphous powders was proposed based on the onset and offset Tg curves.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Amorphous food powders show glass-to-rubber transition (glass transition) upon changes in temperature and water content. Glass transition is characterized by the glass transition temperature (Tg) [1]. Glassy amorphous powders (T < Tg) have a solid-like property based on the extremely low molecular mobility and/or high viscosity [2]. Thus, physical stability is expected for the amorphous powder, and caking [3] and re-crystallization [4] are prevented. Rubbery amorphous powders (T > Tg), on the other hand, have a liquid-like property, and physical deteriorations may occur depending on the storage time. Since the Tg of amorphous food powders decreases with an increase in water content, glass transition is caused by water sorption even at a constant temperature; when the Tg becomes lower than ambient temperature (typically 25 °C) as a result of water sorption, the glassy material changes to a rubbery material. The effect of water content on Tg has been described as the Tg curve. From the Tg curve, the water content at Tg = 25 °C can be determined as critical water content (wc) [5]. In addition, wc is converted to critical water activity (awc) through the effect of water activity (aw) on the equilibrium water content of materials (water sorption isotherm). The values of wc and awc help to characterize resistance to the physical deteriorations induced by water sorption [5, 6].

Caking is a physical phenomenon in which free-flowing powders are transformed into lumps, attributable to deformation and bridging of sticky particles as a result of plasticization and a decrease of surface viscosity [6, 7]. Caking requires relatively high molecular mobility and/or low viscosity to promote viscous flow; therefore, the Tg curve is useful to predict the caking of amorphous food powders [6,7,8]. Caking of amorphous food powders, however, does not always change drastically just at Tg. In our previous study [9], the caking behavior of maltodextrin (MD) and maca (Lepidium meyenii Walp.) powder was compared; the MD was a water-soluble carbohydrate polymer, and the maca powder was a mixture of protein (14.8%), fat (2%), and carbohydrate (69%). As expected, the degree of caking for MD powder was negligible below the awc (0.575) and increased drastically up to 100% above the awc. The degree of caking for maca powder, on the other hand, gradually increased from a slightly lower aw than the awc (0.258), and the degree of caking drastically increased at higher aw than 0.576. Two reasons why MD and maca powder showed completely different caking behavior were suggested. One reason is the dispersions (typically 23% starch and 23% water-insoluble fiber) that exist in maca powder [10]. When amorphous powder forms a fragile cake, the cake will be destroyed by sieving, and as a result the degree of caking cannot be determined. Since some dispersion contained in maca powder would have prevented the construction of a hard cake [8], there was no drastic increase in the degree of caking above awc. The other reason is the difference in the dependence of molecular mobility and/or viscosity on aw in the rubbery state. Maca powder showed a continuously distributed glass transition behavior in the differential scanning calorimetry (DSC) thermogram. Taking into account the fact that glass transition occurs in a temperature range depending on the molecular mobility and/or viscosity change [11], it was suggested that the molecular mobility and/or viscosity required for caking was provided incrementally by the increase in aw above awc. Similar caking behavior to maca powder has been reported in complex food powders such as fish protein hydrolysate [12], dairy-based infant formulas [13], skim milk [8, 14], spray-dried coffee [15], and spray-dried MD–lemon juice mixtures [16].

Glass transition occurs in a temperature range that is determined by the temperature dependence of molecular mobility and/or viscosity. That is, the temperature difference between the onset point of glass transition (Tgon) and the offset point of glass transition (Tgoff) reflects the dependence of molecular mobility and/or viscosity on temperature [11, 17]. It is known that the Tg range of carbohydrate polymers becomes broader with the incorporation of carbohydrate-based plasticizers [18, 19]. In this study, thus, freeze-dried water-soluble maltodextrin (MD) and carbohydrate-based plasticizers including glucose, maltose, and sorbitol blend powders were employed as model food samples, and the effect of Tg range on caking behavior was investigated. Since there was no water-insoluble material (dispersions) in the model samples, it was expected that the effect of Tg range on the caking behavior of the amorphous food powder could be focused. In addition, the Tg range corresponded to the dependence of molecular mobility and/or viscosity on temperature and aw, and a predictive model for the caking of water-soluble amorphous powders was proposed based on the dependence of viscosity on aw. Caking is a deteriorative phenomenon in the powder food industry as it negatively affects food processing and handling. This study is expected to be a better predictive approach for the caking of amorphous food powders.

Material and Methods

Materials

Maltodextrin (MD) with a dextrose equivalent (DE) of 17–21 and glucose monohydrate were provided by San-ei Sucrochemical Co., Ltd. (Aichi, Japan). Maltose monohydrate and sorbitol (d-glucitol) were purchased from Nacalai Tesque Inc. (Kyoto, Japan).

Sample Preparation

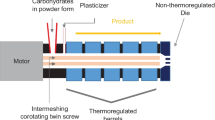

The MD and glucose were mixed at dry weight fractions of glucose = 0.1 and 0.2, maltose = 0.1, and sorbitol = 0.1. Samples are identified by the dry weight fraction and the initial character of the plasticizers hereafter. For example, MD:glucose = 0.8:0.2 and MD:maltose = 0.9:0.1 are referred to “G0.2” and “M0.1,” respectively. The mixtures and MD (non-additive sample) were dissolved in 35% (w/w) aqueous solutions by the addition of distilled water. The solution was distributed to an aluminum container and frozen in a freezer at − 20 °C. The frozen samples were then transferred to a pre-cooled chamber and freeze-dried at approximately 11 Pa as the temperature was increased from − 35 to 5 °C in a stepwise fashion over a 48-h period. The freeze-dried solids were powdered using a mixer.

Water Sorption Isotherm

Freeze-dried powder samples (0.5 g) were placed in an aluminum dish (40 mm diameter), and residual moisture of the samples was removed by vacuum-drying at 80 °C (stage temperature) for 6 h. The fully dried samples were equilibrated at 25 °C for longer than 7 days in a desiccator with saturated salts: LiCl (aw = 0.113), CH3COOK (aw = 0.225), MgCl2 (aw = 0.328), K2CO3 (aw = 0.432), Mg(NO3)2 (aw = 0.529), NaBr (aw = 0.576), KI (aw = 0.688), and NaCl (aw = 0.753). Equilibrium water content of the samples was determined gravimetrically by oven-drying at 105 °C for 16 h. Measurements were obtained in triplicate and the results averaged.

The water sorption isotherm behavior (equilibrium water content versus aw) was analyzed using the Guggenheim, Anderson, and De Boer (GAB) equation:

where W is the equilibrium water content (g-water/g-solid), Wm is the amount of water strongly adsorbed to specific sites at the material surface (g-water/g-solid), and C and K are factors that correct the sorption properties of the monolayer with respect to the bulk liquid, and the properties of the multilayer with respect to the bulk liquid, respectively [20]. The Wm, C, and K values were determined as fitting parameters using the KaleidaGraph software (version 3.6; Hulinks Inc., Tokyo, Japan).

Glass Transition Temperature

Glass transition temperature (Tg) of the samples was determined using a DSC (DSC 60, Shimadzu Instruments Inc., Tokyo, Japan). Alumina powder was used as a reference, and temperature and heat flow were calibrated with indium and distilled water, respectively. The sample (10~30 mg) was hermetically sealed into a DSC aluminum pan. The DSC measurement was carried out at 5 °C/min. To reset the thermal history of glassy samples, the DSC scan was repeated two times [21]. In the first scan, DSC measurement was stopped at a slightly higher temperature than the endothermic shift expected as glass transition, and then cooled down. In the second scan, DSC measurement was stopped at a much higher temperature than the Tg suggested by first scan. The DSC thermogram was analyzed using software interfaced with the DSC, and the Tg value was determined from the onset and offset points of the endothermic shift observed in the second scan. The measurements were performed in triplicate and the results averaged.

Isothermal Mechanical Relaxation

To confirm the validity of awc evaluated from the water sorption isotherm and Tg curve, isothermal mechanical relaxation measurements were carried out [9, 22]. The powder samples (20~30 mg) equilibrated at aw conditions (aw = 0.113~0.753) were placed in a stainless sample holder (diameter = 3 mm). The sample holder was placed on the heating stage (25 °C) of a texture meter (CR-150; Sun Scientific Co., Ltd., Tokyo, Japan) and compressed at 80 N (2.83 MPa) for 3 min with a plunger tightly fitted in the sample holder. The force-drop (ΔF) between the initial force (approximately 80 N) and the force after 3 min was evaluated as the degree of isothermal mechanical relaxation under a given condition. Measurements were obtained in triplicate and the results averaged.

Degree of Caking

The degree of caking was investigated as described previously [23] with minor modifications [9, 24]. Mixed powders were filtered through a 1.4-mm sieve with a vibration amplitude of 4.5 mm using a mechanical shaker (MVS-1; As One Instruments Co., Tokyo, Japan). Powder samples (approximately 0.5 g) were placed in an aluminum dish (diameter = 40 mm) and vacuum-dried at 80 °C for 6 h. The samples were equilibrated at 25 °C for 7 days in a desiccator with saturated salts as mentioned above. The equilibrated samples were vacuum-dried at 25 °C for 6 h. The dried sample was weighed and then sieved under the same conditions as the first treatment. After weighing the amount of sample retained on the sieve, the degree of caking was evaluated as follows:

where Wr and Wi are the weight of retained and initial (pre-sieved) samples, respectively. The measurements were performed in triplicate and the results averaged.

Statistical Analysis

Analysis of variance (ANOVA) was performed using Tukey’s HSD test (p < 0.05) with the KaleidaGraph software (Version 3.6; Hulinks Inc.).

Results and Discussion

Water Sorption Behavior

The water sorption behavior of the samples is shown in Fig. 1. The values with the results of the statistical analysis are also listed in Table S1 (supplemental data). The samples showed a sigmoidal curve typically observed in amorphous powders. Since amorphous glucose, maltose, and sorbitol readily crystallize [5], it is possible that the plasticizers may have crystallized during water sorption under a high aw condition. However, it is thought that the plasticizers remained in an amorphous state, because the water content of the samples did not decreased drastically as observed in the crystallization of maltose [25]. MD will have prevented the crystallization of amorphous plasticizers because of the formation of intermolecular hydrogen bonds between MD and plasticizers; the plasticizers are dynamically trapped in the amorphous MD matrix [26]. The water sorption isotherms could be analyzed using the GAB model (Eq. 1) with good regression parameters as listed in Table 1. The Wm and C decreased, and K increased by the addition of plasticizers (except for C in M0.1). Similar behavior was also reported for MD with DE = 12 [27], mixtures of maltopolymer–maltose [26], and hydrophobically modified starch–sucrose mixtures [28]. A comparison of Wm (monolayer water content) among MD, G0.1, and G0.2 revealed that the Wm decreased with increases in glucose content. At the same weight fraction of plasticizers, the Wm values were higher in the order of glucose > maltose > sorbitol. The reduction of Wm by the addition of plasticizers can be explained by the anti-plasticizing effect; plasticizers fill defects in the polymer, and thus, the hardness of the polymer can be mechanically strengthened [29,30,31]. Defects filled by plasticizers cause a reduction of water-binding sites in the polymer; consequently, Wm will be decreased by the addition of plasticizers to MD. The GAB parameters, however, are sensitive to the equilibrium water content at each aw; a small deviation in experimental data causes a large difference in the GAB parameters [24, 32]. Taking this fact into consideration, further discussion based on the GAB parameters was avoided in this study, and the GAB parameters were used to convert water content to aw in the following section.

Glass Transition Behavior

As typical results, DSC thermograms (second scan) for MD, G0.1, and G0.2 having aw = 0.328 are shown in Fig. 2. A clear endothermic shift due to glass transition was observed, and thus, Tgon and Tgoff were determined from the onset and offset of the shift. At the aw condition, the Tgon decreased with increases in glucose content. This indicates that MD was plasticized by glucose because of the formation of intermolecular hydrogen bonds between MD and glucose; glucose partially cut the hydrogen bonds in amorphous MD matrix, and macroscopic molecular mobility increases [33]. In addition, the Tg range (temperature difference between Tgon and Tgoff) increased with increases in glucose content. This suggests that distribution of the molecular mobility for MD was extended by glucose as a result of the heterogeneous formation of intermolecular hydrogen bonding [18, 19, 34, 35].

The effect of water content on the Tgon and Tgoff of the samples is shown in Fig. 3. The values with the results of the statistical analysis are also listed in Tables S2 and S3 (supplemental data). From the results, it was confirmed that the Tg values decreased with increases in the water content because of the water plasticizing effect. The Tg curves (solid lines) were obtained by fitting of the Gordon-Taylor (GT) equation (Eq. 3) to the data:

where Xw is the weight fraction of water, Tg(as) and Tg(w) are the Tg for anhydrous solute and pure water, respectively, and k is a constant. The Tg(w) was set as 136 K in reference to previous reports [36, 37]. The Tg(as) and k were provided as fitting parameters, and then, each Tg curve was obtained. From the Tg curve, the water content at Tg = 25 °C was determined as the critical water content (wc). In addition, the wc value was converted to critical water activity (awc) using the GAB equation (Fig. 1 and Table 1). These values (Tg(as), k, wc, and awc) were evaluated from Tgon and Tgoff as listed in Table 2.

Isothermal Mechanical Relaxation

Isothermal mechanical relaxation measurement at 25 °C is useful to validate the awc determined by the fitting analysis mentioned above [9, 22]. In addition, the degree of mechanical relaxation reflects the molecular mobility [38]. Typical isothermal mechanical relaxation curves are shown in Fig. 4. MD having aw = 0.113 showed a small mechanical relaxation because of its high elasticity, which is characteristic of the glassy state. In contrast, MD having aw = 0.753 showed a large mechanical relaxation, suggesting a rubbery state. From the isothermal mechanical relaxation curve, ΔF (the force difference between the initial compression and compression after 3 min) was evaluated.

The effect of aw on the ΔF of samples is shown in Fig. 5. The vertical solid and dotted lines are awc values determined from Tgon and Tgoff, respectively, hereafter referred to as awcon and awcoff, respectively. The values with the results of the statistical analysis are also listed in Table S4 (supplemental data). The ΔF values of MD were low and almost constant (lower than 10 N) below awcon, but increased drastically above awcon and reached approximately 70 N at awcoff. These observations support that glass transition was caused by water sorption at awcon and that molecular mobility remarkably increased under a rubbery state. Also, the ΔF values of G0.1, M0.1, and S0.1 showed almost similar behavior to those of MD; the ΔF values were lower than 10 N below awcon, and increased above awcon, and reached approximately 60 N at awcoff. It should be noted that the slopes of the ΔF-aw plot between awcon and awcoff for G0.1, M0.1, and S0.1 were lower than that for MD. This result indicates that the distribution of molecular mobility for MD is extended by the addition of plasticizers. The tendency given by the plasticizers became even more remarkable in G0.2. This is supported by the recent rheological study of Dupas-Langlet et al. [39] who investigated the viscosity change above Tg for amorphous maltopolymer-maltose blends and reported that plasticizers extended the viscosity change depending on the amount of addition.

Caking Behavior

Although caking behavior depends on experimental conditions such as the mass, size, and shape of powder particles, temperature and time of storage, and speed and amplitude of sieving [7, 40,41,42,43,44], caking behavior under identical conditions gives valuable knowledge on the physical stability of amorphous food powders [9, 24]. The effect of aw on the degree of caking for the samples is shown in Fig. 6. The vertical solid and dotted lines indicate awcon and awcoff, respectively. The values with the results of the statistical analysis are also listed in Table S5 (supplemental data). The degree of caking for MD was negligible below awcon, but increased drastically above awcon and reached 100% at an aw that was close to awcoff. The degree of caking for G0.1, M0.1, and S0.1 was also negligible below their awcon, but increased remarkably above awcon and reached 100% at around awcoff. The dependence of the degree of caking on aw became slightly broader because of the large aw range between awcon and awcoff. This observation was emphasized for G0.2. Taking the ΔF–rising behavior into account, the caking behavior for plasticizer-added samples can be corresponded to the extended distribution of molecular mobility. The present results corroborate the fact that caking occurs at T and aw conditions above Tgon [6,7,8,9, 13, 16, 24, 40]. However, Tgon is not always a critical indicator of the caking behavior because of heterogeneous molecular mobility. Tgoff and awcoff can be applied to better predict caking as discussed in the following section.

Predictions of Viscosity and Caking Behavior Based on T g Range

It is known that the Tg range reflects the distribution of molecular mobility [45]; the larger the Tg range, the broader the expected distribution of molecular mobility. The broad distribution of molecular mobility reflects a gradual dependence of viscosity (η) on temperature near Tg [11]. The dependence of η on temperature can be described by the Vogel–Fulcher–Tamman (VFT) equation (Eq. 4):

where η0 (Pa·s) is the viscosity at infinite temperature, T0 (K) is the temperature of viscosity divergence, and D (dimensionless) is a constant described as “strength parameter” [46]. D characterizes the dependence of η on temperature; the higher the D, the broader the dependence of η on temperature. When Tgon and Tgoff are applied to Eq. 4, Eq. 4 can be described as:

where ηgon and ηgoff are η at Tgon and Tgoff, respectively. It is known that η0 and ηgon can be empirically applied as 10−5 Pa·s and 1012 Pa·s, respectively [46]. The ηgoff, on the other hand, depends both on the temperature dependence of η and on the heating rate in DSC measurement [11]. The greater the dependence of η on temperature and the higher the DSC heating rate, the higher the Tgoff (the lower the ηgoff). When ηgoff is regarded as a constant at each DSC heating rate, T0 can be estimated from the experimentally determined Tgon and Tgoff from Eq. 5. On the other hand, when η0 = 10−5 Pa·s and ηgon = 1012 Pa·s are applied to Eq. 4, Eq. 4 can be described as:

From the experimentally determined Tgon and the calculated T0, D can be estimated by Eq. 6. As a result, the dependence of η on temperature can be predicted by Eq. 4.

It is reported that anhydrous sucrose has approximately D ≈ 6.0 [46]. In our preliminary study, the Tgon and Tgoff for anhydrous sucrose observed at 5 °C/min (same DSC scanning condition as this study) were determined to be 341.4 K and 348.0 K, respectively (data not shown). When η0 = 10−5 Pa·s and ηgon = 1012 Pa·s were applied to Eq. 5, ηgoff was estimated to be 109.8 Pa·s. This value was in good agreement with the ηgoff for inorganic glasses reported previously [11].

Based on the ηgoff value, the dependence of η on temperature could be calculated for the MD–plasticizer blend powders. The Tgon and Tgoff were described as a function of water content by the GT equation (Eq. 3) according to Fig. 3. In addition, water content was converted to aw using the GAB equation (Eq. 1) according to Fig. 1. Combining Eqs. 1, 3, and 4, the dependence of η on aw at 25 °C was calculated as shown in Fig. 7a. The slope of log η versus the aw curve is affected by the Tg range. Notably, G0.2 has a crossover aw point with S0.1 because of the difference in the Tg range. The effect of the predicted η on the degree of caking for the samples is shown in Fig. 7b. The degree of caking linearly increases with decreases of the predicted log η in the η range between approximately 1012 Pa·s and 1010 Pa·s. From the linear regression, an empirical formula (Eq. 7) could be obtained with a good coefficient of determination (R2 = 0.8475) as follows:

The degree of caking (%) and log η (Pa·s) ranged between 0 and 100, and 9.64 and 12.36, respectively. According to Eq. 7, the degree of caking could be described as a function of aw as shown in Fig. 7c. The proposed approach is unique in that it demonstrated that the dependence of η on temperature and aw is characterized by the Tg range. This will be useful as a better predictive approach for caking of carbohydrate blend powders based on Tgon and Tgoff.

It should be pointed out that caking is a time-dependent phenomenon [6, 41, 42]. Although the degree of caking was evaluated at the storage time of 1 week in this study, the values will increase more or less with longer storage times. In addition, particle size and shape (contact between particles) affect caking [13, 14, 47, 48]. As mentioned above, dispersions (semi-crystalline starch and water-insoluble fiber) undermine the hardness of the cake structure. The effect of these factors on the proposed predictive approach will be investigated in the next study.

Conclusion

The water sorption, glass transition, and caking behaviors of freeze-dried MD–carbohydrate plasticizer blend powders were investigated. In order to characterize the viscosity change at a higher temperature than Tgon, Tgon and Tgoff were evaluated from DSC thermograms. In addition, Tgon and Tgoff were corresponded to awon and awoff, respectively, through the water sorption behavior. It was suggested that the temperature difference between Tgon and Tgoff and the aw difference between awon and awoff reflected the distribution of molecular mobility above the Tg. Isothermal mechanical relaxation behavior supported this suggestion. The distribution of molecular mobility affected the degree of caking. In reference to a previously suggested approach, Tgon and Tgoff were converted to viscosity, and a predictive approach in consideration of the dependence of viscosity on water activity was proposed. For better prediction, it is necessary to understand the effects of storage time, particle size and shape, and water-insoluble materials (dispersions) on the degree of caking. These are future subjects of study.

References

Fan F, Roos YH (2017) Glass transition-associated structural relaxations and applications of relaxation times in amorphous food solids: a review. Food Eng Rev 1–14. https://doi.org/10.1007/s12393-017-9166-6

Hancock BC, Zografi G (1997) Characteristics and significance of the amorphous state in pharmaceutical systems. J Pharm Sci 86:1–12. https://doi.org/10.1021/js9601896

Karel M, Anglea S, Buera P et al (1994) Stability-related transitions of amorphous foods. Thermochim Acta 246:249–269. https://doi.org/10.1016/0040-6031(94)80094-4

Roos YH, Karel M (1991) Plasticizing effect of water on thermal-behavior and crystallization of amorphous food models. J Food Sci 56:38–43. https://doi.org/10.1111/j.1365-2621.1991.tb07970.x

Roos YH (1995) Time-dependent phenomena. In: Phase transitions in foods. Academic Press, San Diego, pp 193–245

Palzer S (2005) The effect of glass transition on the desired and undesired agglomeration of amorphous food powders. Chem Eng Sci 60:3959–3968. https://doi.org/10.1016/j.ces.2005.02.015

Aguilera JM, del Valle JM, Karel M (1995) Caking phenomena in amorphous food powders. Trends Food Sci Technol 6:149–155. https://doi.org/10.1016/S0924-2244(00)89023-8

Fitzpatrick JJ, Hodnett M, Twomey M et al (2007) Glass transition and the flowability and caking of powders containing amorphous lactose. Powder Technol 178:119–128. https://doi.org/10.1016/j.powtec.2007.04.017

Alvino Granados AE, Fongin S, Hagura Y, Kawai K (2019) Continuously distributed glass transition of maca (Lepidium meyenii Walpers) powder and impact on caking properties. Food Biophys 14:437–445. https://doi.org/10.1007/s11483-019-09593-z

Rondán-Sanabria GG, Finardi-Filho F (2009) Physical-chemical and functional properties of maca root starch (Lepidium meyenii Walpers). Food Chem 114:492–498. https://doi.org/10.1016/j.foodchem.2008.09.076

Moynihan CT (1993) Correlation between the width of the glass transition region and the temperature dependence of the viscosity of high-Tg glasses. J Am Ceram Soc 76:1081–1087. https://doi.org/10.1111/j.1151-2916.1993.tb03724.x

Aguilera JM, Levi G, Karel M (1993) Effect of water content on the glass transition and caking of fish protein hydrolyzates. Biotechnol Prog 9:651–654. https://doi.org/10.1021/bp00024a013

Chuy LE, Labuza TP (1994) Caking and stickiness of dairy-based food powders as related to glass transition. J Food Sci 59:43–46. https://doi.org/10.1111/j.1365-2621.1994.tb06893.x

Silalai N, Roos YH (2010) Roles of water and solids composition in the control of glass transition and stickiness of milk powders. J Food Sci 75:285–296. https://doi.org/10.1111/j.1750-3841.2010.01652.x

Saragoni P, Aguilera JM, Bouchon P (2007) Changes in particles of coffee powder and extensions to caking. Food Chem 104:122–126. https://doi.org/10.1016/j.foodchem.2006.11.029

Paterson AHJ, Bröckel U (2015) Caking development in lemon juice powder. Proc Eng 102:142–149. https://doi.org/10.1016/j.proeng.2015.01.117

Hancock BC, Dalton CR, Pikal MJ, Shamblin SL (1998) A pragmatic test of a simple calorimetric method for determining the fragility of some amorphous pharmaceutical materials. Pharm Res 15:762–767

Kawai K, Hagura Y (2012) Discontinuous and heterogeneous glass transition behavior of carbohydrate polymer-plasticizer systems. Carbohydr Polym 89:836–841. https://doi.org/10.1016/j.carbpol.2012.04.018

Tedeschi C, Leuenberger B, Ubbink J (2016) Amorphous-amorphous phase separation in hydrophobically-modified starch-sucrose blends I. Phase behavior and thermodynamic characterization. Food Hydrocoll 58:75–88. https://doi.org/10.1016/j.foodhyd.2016.02.021

Quirijns EJ, Van Boxtel AJB, Van Loon WKP, Van Straten G (2005) Sorption isotherms, GAB parameters and isosteric heat of sorption. J Sci Food Agric 85:1805–1814. https://doi.org/10.1002/jsfa.2140

Kawai K, Hagiwara T, Takai R, Suzuki T (2005) Comparative investigation by two analytical approaches of enthalpy relaxation for glassy glucose, sucrose, maltose, and trehalose. Pharm Res 22:490–495. https://doi.org/10.1007/s11095-004-1887-6

Jothi JS, Ebara T, Hagura Y, Kawai K (2018) Effect of water sorption on the glass transition temperature and texture of deep-fried models. J Food Eng 237:1–8. https://doi.org/10.1016/j.jfoodeng.2018.05.014

Farahnaky A, Mansoori N, Majzoobi M, Badii F (2016) Physicochemical and sorption isotherm properties of date syrup powder: antiplasticizing effect of maltodextrin. Food Bioprod Process 98:133–141. https://doi.org/10.1016/j.fbp.2016.01.003

Fongin S, Alvino Granados AE, Harnkarnsujarit N et al (2019) Effects of maltodextrin and pulp on the water sorption, glass transition, and caking properties of freeze-dried mango powder. J Food Eng 247:95–103. https://doi.org/10.1016/j.jfoodeng.2018.11.027

Fukami K, Kawai K, Takeuchi S et al (2016) Effect of water content on the glass transition temperature of calcium maltobionate and its application to the characterization of non-arrhenius viscosity behavior. Food Biophys 11:410–416. https://doi.org/10.1007/s11483-016-9455-2

Ubbink J, Giardiello MI, Limbach HJ (2007) Sorption of water by bidisperse mixtures of carbohydrates in glassy and rubbery states. Biomacromolecules 8:2862–2873. https://doi.org/10.1021/bm0701898

Kilburn D, Claude J, Mezzenga R et al (2004) Water in glassy carbohydrates: opening it up at the nanolevel. J Phys Chem B 108:12436–12441. https://doi.org/10.1021/jp048774f

Ubbink J, Zwick T, Hughes D, Bönisch GB (2018) Water vapor sorption and glass transition temperatures of phase-separated amorphous blends of hydrophobically-modified starch and sucrose. Data Br 20:1884–1889. https://doi.org/10.1016/j.dib.2018.08.105

Figueroa Y, Guevara M, Pérez A et al (2016) Effect of sugar addition on glass transition temperatures of cassava starch with low to intermediate moisture contents. Carbohydr Polym 146:231–237. https://doi.org/10.1016/j.carbpol.2016.03.054

Lourdin D, Bizot H, Colonna P (1997) ‘“Antiplasticization”’ in starch – glycerol films? J Appl Polym Sci 63:1047–1053

Ubbink J (2018) Plasticization and antiplasticization in amorphous food systems. Curr Opin Food Sci 21:72–78. https://doi.org/10.1016/j.cofs.2018.05.007

Rahman MS, Al-Belushi RH (2006) Dynamic isopiestic method (DIM): measuring moisture sorption isotherm of freeze-dried garlic powder and other potential uses of DIM. Int J Food Prop 9:421–437. https://doi.org/10.1080/10942910600596134

Sperling LH (2006) Glass-rubber transition behavior. In: Introduction to physical polymer science, Fourth edn. Wiley and Sons, New Jersey, p 361

Hughes DJ, Bönisch GB, Zwick T et al (2018) Phase separation in amorphous hydrophobically modified starch–sucrose blends: glass transition, matrix dynamics and phase behavior. Carbohydr Polym 199:1–10. https://doi.org/10.1016/j.carbpol.2018.06.056

Ubbink J (2016) Structural and thermodynamic aspects of plasticization and antiplasticization in glassy encapsulation and biostabilization matrices. Adv Drug Deliv Rev 100:10–26. https://doi.org/10.1016/j.addr.2015.12.019

Johari GP, Hallbrucker A, Mayer E (1987) The glass-liquid transition of hyperquenched water. Nature 330:552–553. https://doi.org/10.1038/330552a0

Sastry S (1999) Supercooled water: going strong or falling apart? Nature 398:467–470. https://doi.org/10.1258/mi.2010.010040

Lourdin D, Colonna P, Brownsey GJ et al (2002) Structural relaxation and physical ageing of starchy materials. Carbohydr Res 337:827–833. https://doi.org/10.1016/S0008-6215(02)00064-2

Dupas-Langlet M, Meunier V, Pouzot M, Ubbink J (2019) Influence of blend ratio and water content on the rheology and fragility of maltopolymer/maltose blends. Carbohydr Polym 213:147–158. https://doi.org/10.1016/j.carbpol.2019.02.066

Li R, Roos YH, Miao S (2016) The effect of water plasticization and lactose content on flow properties of dairy model solids. J Food Eng 170:50–57. https://doi.org/10.1016/j.jfoodeng.2015.09.014

Schulnies F, Kleinschmidt T (2018) Time consolidation of skim milk powder near the glass transition temperature. Int Dairy J 85:105–111. https://doi.org/10.1016/j.idairyj.2018.05.005

Hartmann M, Palzer S (2011) Caking of amorphous powders - material aspects, modelling and applications. Powder Technol 206:112–121. https://doi.org/10.1016/j.powtec.2010.04.014

Juliano P, Muhunthan B, Barbosa-Cánovas GV (2006) Flow and shear descriptors of preconsolidated food powders. J Food Eng 72:157–166. https://doi.org/10.1016/j.jfoodeng.2004.11.032

Petit J, Michaux F, Jacquot C et al (2017) Storage-induced caking of cocoa powder. J Food Eng 199:42–53. https://doi.org/10.1016/j.jfoodeng.2016.12.005

Sartor G, Mayer E, Johari GP (1994) Calorimetric studies of the kinetic unfreezing of molecular motions in hydrated lysozyme, hemoglobin, and myoglobin. Biophys J 66:249–258. https://doi.org/10.1016/S0006-3495(94)80774-X

Angell CA, Bressel RD, Green JL et al (1994) Liquid fragility and the glass transition in water and aqueous solutions. J Food Eng 22:115–142. https://doi.org/10.1016/0260-8774(94)90028-0

Haider CI, Hounslow MJ, Salman AD et al (2014) Influence of environmental conditions on caking mechanisms in individual amorphous food particle contacts. AIChE J 60:2774–2787. https://doi.org/10.1002/aic

Haider CI, Niederreiter G, Palzer S et al (2018) Unwanted agglomeration of industrial amorphous food powder from a particle perspective. Chem Eng Res Des 1–10. https://doi.org/10.1016/j.cherd.2018.02.023

Acknowledgments

We acknowledge San-ei Sucrochemical, Co., Ltd. (Aichi, Japan) for providing MD and glucose.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

Kiyoshi Kawai (corresponding author) received a collaborative research fund from San-ei Sucrochemical Co., Ltd. (Aichi, Japan) for a different purpose from this study.

Additional information

Disclaimer

The sponsor had no control over the interpretation, writing, and publication of this work.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(PDF 96.9 kb)

Rights and permissions

About this article

Cite this article

Alvino Granados, A.E., Mochizuki, T. & Kawai, K. Effect of Glass Transition Temperature Range on the Caking Behavior of Freeze-dried Carbohydrate Blend Powders. Food Eng Rev 13, 204–214 (2021). https://doi.org/10.1007/s12393-020-09226-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12393-020-09226-z