Abstract

Non-Centrifugal Sugar commonly known as jaggery is a famous sweetening agent derived from sugarcane juice. The sugarcane juice undergoes enzymatic reactions during jaggery production, resulting in the darkening of its color. The study presents enzymatic inactivation of sugarcane juice, which was extracted from blanched sugarcane stalks and also the effect of organic clarificants on the quality of jaggery. Blanching of sugarcane stalks at 80 °C for 5 min inhibited enzymatic browning up to 53–55%. Clarification of juice was carried out using organic clarificants such as aloe vera leaf extract, moringa leaf extract at 0.1%, 0.2% and 0.3% v/v concentrations and chemical clarificant (Hydros). The jaggery prepared using organic clarificants, either using aloe vera or moringa leaf extract at 0.3% concentration was found to be superior in terms of insoluble solids, sucrose content, total phenols and total flavonoids. The jaggery prepared using chemical clarificants is brighter in color with low microbial load, however, it is inferior in quality parameters such as total phenols and flavonoids compared to jaggery prepared using organic clarificants. Hence, the technology of jaggery making from blanched canes using organic clarificants may be recommended as an alternative to chemical clarification to produce organic jaggery rich in bioactive compounds.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Non-Centrifuged Sugar (NCS) commonly known as jaggery, is a famous sweetening agent, derived from sugarcane without undergoing chemical processing as made in sugar production. Jaggery making is an age-old small-scale industry flourishing in rural India creating livelihood for many farmers. India is the world’s largest producer of jaggery contributing about 70% of total world jaggery production (Dilip et al. 2017). The chemical composition of jaggery consists of sucrose (65–85%), reducing sugars including glucose and fructose (10–15%), non-sugars such as calcium (0.4%), magnesium and phosphorous (0.045%), protein (0.25%) and fat (0.05%) (Rao et al. 2007). The minerals and vitamins present in jaggery help in purification of blood, prevents rheumatic and bile disorders, helps to cure jaundice etc. (Singh et al. 2013). Owing to its high therapeutic value, jaggery is called as medicinal sugar as it was extensively used in traditional medicine from ancient times (Karthikeyan and Samipillai 2010).

The sequential operations during jaggery preparation include pre-cleaning of canes, juice extraction, clarification, boiling of juice, concentration, cooling and moulding. Of all the operations pre-cleaning of canes and clarification of the juice are the crucial operations to maintain quality standards. The cane after harvest consists of impurities such as mud, roots and waxy materials on its surface. More often, the pre-cleaning of canes is neglected by the farmers which adversely affect the quality and color of jaggery. Further, during jaggery making, the sugarcane juice undergoes both enzymatic and non-enzymatic browning reactions resulting the end product darker in color. The polyphenol oxidase and peroxidase enzymes present in sugarcane juice contribute for enzymatic browning (Eq. 1) (Tomasik et al. 1989). Immediately after extraction of juice, enzymatic oxidation starts and continues during boiling until the enzyme is inactivated by heat (<50 °C). As the temperature of the juice rises, the enzymatic activity stops and non-enzymatic reactions starts due to formation of darker compounds such as melanoid through caramelization and maillard reaction (Eq. 2 and 3) (Tomasik et al. 1989). Hence, to obtain jaggery of brighter color, these browning reactions has to be arrested.

It has been reported that, blanching of sugarcane stalks reduce enzymatic browning and maintains the quality of juice for longer period (Mao et al. 2007; Jittanit et al. 2011). Blanching of canes not only inhibits enzymatic browning but also helps in efficient cleaning of canes. The fresh sugarcane juice contains colloidal inorganic and organic suspensions, non-sugars which are to be removed during jaggery making by clarification process to impart golden yellow colour to jaggery (Gangwar et al. 2015). The efficiency of clarification affects quality as well as color of jaggery. Generally, farmers use sodium hydrosulphite (Hydros) as chemical clarificants, which has bleaching action and enhances color (Rao et al. 2007). However, many of the desired components such as polyphenols, minerals and vitamins present in juice are lost (Hussain et al. 2012). Moreover, the residual effect of the chemical clarificants in jaggery poses health problems. The natural taste and aroma of jaggery is lost due to the chemical clarification and deteriorates faster due to inversion of sucrose during storage (Baboo and Solomon 1995). Hence, preparation of chemical free jaggery with brighter color is a challenging task in the present situation. Organic clarificants of plant origin such as mucilage of white wild musk mallow (Hibiscus ficulneus), Okra (Hibiscus esculentus), Castor (Recinus communis), Groundnut (Arachis hypogea), Soybean (Glycine max), Phalsa (Grewia asiatica), and Kydia(Kydia calycina) had improved the quality of jaggery (Chauhan et al. 2012; Chauhan 1972; Shakunthala and Devraj 1991; Chikkappaiah et al. 2017a), moreover they are eco-friendly, easily available with low cost. It was reported that, mucilage of organic clarificants is a polysaccharide complex, possessing many biological activities and hence, widely used in pharmaceuticals, therapeutics, food and cosmetic industry (Chikkappaiah et al. 2017b). A lot of literature is available on effect of organic clarificants on jaggery quality; however, no scientific studies justifies the effect of both blanching and organic clarification on jaggery quality. Hence, the present study has been conducted to explore the quality parameters of jaggery prepared from blanched canes and using organic clarificants to recommend farmers for production of nutritional enriched chemical free jaggery with bright colour.

Materials and Methods

Blanching and Juice Extraction

Freshly harvested canes were blanched in hot water at 80 °C for 5 min (Mao et al. 2007) allowed to cool to room temperature and juice was extracted using three roller horizontal sugarcane juice extractor (Model: Sharat 2A; Make: Kirlosker Brother, Ltd., India). The weight of cane before and after blanching was recorded; the juice yield was calculated as amount of juice extracted to the weight of sugarcane stalks. The total soluble solids (TSS) of sugarcane juice were measured using portable hand refractometer (Models PAL-1, 0–53°Brix; PAL-2, 45–93°Brix, make: Atago, Japan) having resolution of 0.1°Brix and expressed in °Brix.

Organic Clarificants Preparation

The organic clarificants selected for the study were aloe vera leaf extract and moringa leaf extract. The clarificants from aloe vera leaf and moringa leaf were extracted following the method standardized (Chikkappaiah et al. 2017b; Anonymous 2011). The extract was filtered through muslin cloth and kept at 4 °C for further use in jaggery preparation.

Jaggery Preparation

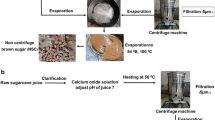

Matured sugarcane (Variety: 93 A 145) was selected from the experimental plots of Regional Agricultural Research Station, Anakapalle for preparation of jaggery (Fig. 1). About 10 L of sugarcane juice was taken from the blanched sugarcane stalks, filtered using muslin cloth to remove coarse impurities and used for jaggery making. Milk of lime was added as basic clarificant to separate the scum and also to adjust the pH of the juice from 5.2 to 5.8 while boiling. For preparation of milk of lime, about one kg of lime with 80–90% purity is mixed with 4 L of water and added to the sugarcane juice at the rate of 0.6 g/l of sugarcane juice until the required pH is reached during jaggery making (Rao et al. 2007). When milk of lime is added, the chemical reaction takes place between calcium and phosphates present in the juice to form calcium phosphate and this molecule carries insoluble (earth) and soluble (chlorophyll and Xanthophylls) impurities which are removed as scum. In order to improve the settling and compaction of these coagulates, natural or synthetic flocculants are added in addition to milk of lime. Instead of using synthetic flocculants which may be toxic, organic clarificants were identified and added at different concentrations (0.1%, 0.2% and 0.3%). The moringa leaf and seed extract are widely used for the treatment of water to precipitate soluble and insoluble impurities and reduces microbial load (Costa et al. 2014). Similarly, many scientific studies reported the application of aloe vera in cosmetic-moisturizers, toothpastes and in food industry as flavoring compounds or preservative of fresh products and in medicine of humans or animals (Christaki and Florou-Paneri 2010). Aloe vera also possess many properties such as anti-inflammatory, immunity, antidiabetic, antioxidant, laxative, antibacterial, antifungal, antiviral and antitumor effects. The aloe vera juice extract forms as mucilage and added to juice during boiling, the albumins present in the mucilage, coagulates and carries the colloidal and suspended impurities present in the juice to form as scum. Hence, the organic clarificants, i.e., moringa leaf extract and aloe vera leaf extract, were selected during jaggery production. During jaggery prepartion, milk of lime is added in two splits, the first split being added during initial juice boiling and the second split after one hour of boiling. The impurities present in the juice will float to the surface as scum and removed manually time to time. To further accelerate the coagulation of impurities, the organic clarificant at different concentrations (0.1%, 0.2% and 0.3%) was added to the juice in the last stage of boiling, i.e., two hours after boiling. The juice was allowed to boil until the water in the sugarcane juice gets evaporated to get concentrated product of brix 85° and temperature of 118 °C was attained. The concentrated jaggery syrup was unloaded and allowed to cool and moulded into desired shapes. In the entire process, the amount of scum removed and jaggery recovery for each boiling was recorded. For preparation of jaggery using chemical clarificant, in addition to lime, sodium hydrogen sulphite is added (@ 5 g per 10 L of juice. For control sample, jaggery is prepared from unblanched canes and lime alone was added as clarificant. The jaggery obtained from all treatments (Fig. 2) was used for quality analysis.

Measurement of Physico-Chemical Properties

Determination of Enzymatic Activity

The estimation of polyphenol oxidase (PPO) and peroxidase (POD) enzymes contributing enzymatic browning of sugarcane juice was done using the extract obtained from the sample. The extraction solution was prepared by the method suggested by Sreedevi et al. (2018) PPO assay was performed by adding 1.55 ml of 0.05 M potassium phosphate buffer (pH-7.0) to a mixture containing 1.25 ml of 0.1 M catechol and 200 µl of sugarcane juice extract. The absorbance of the assay mixture was measured at 420 nm for 10 min. using UV–visible spectrophotometer (Model: UV1700; Make: Shimadzu Corp, Kyoto, Japan). The rate of reaction was calculated from the linear slope of activity curves.

POD assay was performed by adding 2.42 ml of 0.05 M potassium phosphate buffer (pH-7.0) to a mixture containing 320 µl of 5% catechol, 160 µl of 0.5% H2O2 and 100 µl of enzyme extract. The absorbance of the mixture was measured for 10 min at 420 nm and percent inactivation of POD was calculated similar to PPO inactivation calculations.

Color Determination

The color of the sugarcane juice and jaggery was measured using portable colorimeter (Model: Spectro-guide 45/0 gloss; Make: BYK Gardner, Geretsried, Germany) calibrated against a white and black tile. The values of L*, a* and b* were taken at three different places of the jaggery samples and the average of the three readings was recorded. The color of the sample is expressed in CIE scale (Commission Internationale de I’Echairages) in terms of L*, a* and b*, where L* denotes lightness, a* indicates red/green value and b* denotes yellow/blue value.

Estimation of Insoluble Solids

The insoluble solids of jaggery were determined as per procedure given by Ranganna (1986). About ten grams of jaggery was mixed with 100 ml of distilled water and heated. When boiling starts, the heating was stopped; solution was cooled and filtered through sintered glass filter. The filtrate was dried in an oven at 135 °C and weighted until constant weight is obtained. Then, the weight of insoluble solids was expressed on percentage dry basis.

Determination of Moisture Content

The moisture content of jaggery samples were determined by gravimetric method as per AOAC (1990). About 5 g of jaggery sample was taken in aluminum box and the sample is dried in oven at 70 °C for 6–8 h. The sample is taken out and cooled in desiccator and loss in weight is reported. The process is repeated until constant weight of the sample is obtained. The loss in weight was calculated as moisture content of the sample expressed in percentage dry basis.

Estimation of Sulphur Content

The sulphur content of jaggery samples were estimated by titration method (Henshall 2012). About 22.4 g of jaggery was dissolved in 250 ml of distilled water to prepare N/2 jaggery solution. Then 10 mL of N/2 jaggery solution was dissolved in 40 ml of distilled water and titrated with 0.1 N potassium iodide solution until the end point of bluish color appears.

SO2 (ppm) = 123.075 × Titration value.

Estimation of Sucrose and Reducing Sugars

The percent sucrose of samples was recorded using polarimeter (Antanpaar, Model: MCP 500 Sucromat). The percent reducing sugars are estimated by Lane and Eynon method using Fehling A and Fehling B solutions based on the principle of reduction of Fehling’s solution by reducing sugars (Lane and Eynon 1923).

Estimation of Phenol Content

Total phenol content of the jaggery samples were estimated using Folin-Ciocalteu method (Singleton et al. 1999). About 100 µl of 5% of jaggery sample was mixed with 900 µl of distilled water and 1 ml of FCR reagent (1:2 v/v), then 2 mL of 10% sodium carbonate was added. The solution was mixed well using vortex meter and kept in dark for 30 min for incubation, then the absorbance of the solution was noted using Spectrophotometer (Make: Elico, Model:SL27VIS spectrophotometer) at 765 nm. The standard curve is prepared using Gallic acid at different concentrations and the total phenol content was expressed in Gallic acid equivalent in microgram per gram of jaggery.

Estimation of Total Flavonoid Content

Total flavonoid content of jaggery samples were estimated using aluminium chloride following the method of Chang et al. (2002). About 200 µl of 5% jaggery sample was made up to 2 ml with distilled water. To it 100 µl of 10% sodium chloride and 100 µl of 0.5 ml of 1 M potassium acetate were added followed by vortex. The solution is then incubated for 30 min and the transmittance was recorded using spectrophotometer at 415 nm. The standard curve using quercetin at different concentrations was prepared, and then total flavonoid content of the sample is then expressed as quercetin equivalent (QE) micrograms/g of jaggery.

Microbial Analysis

The microbial analysis of jaggery samples was evaluated for aerobic mesophiles (AM), yeasts and mold (YM) counts using the serial dilution pour plate method (APHA 2001). The nutrient agar and potato dextrose agar were used as the growth media for the AM and YM, respectively. All the media were procured from HIMEDIA®, India (HiMedia Laboratories Pvt. Ltd., India). The corresponding incubation conditions for the microbial growth (AM and YM) were 37 °C/24–36 h, 37 °C/18–24 h, respectively. All the samples were analyzed in triplicate and the mean (n = 3) data expressed as total count.

Statistical Analysis

The jaggery was prepared at different concentrations of clarificants and for each treatment was repeated three times and the quality parameters were recorded. The average of three reading was calculated and expressed as mean ± standard deviations. SPSS software version 2.0 (IBM SPSS Statistics, USA) is used to carry out the significance tests viz. Fisher’s least significance difference (LSD) and Tukey’s HSD test at 95% confidence interval for all the attributes under study.

Results and Discussion

Effect of Blanching on Quality of Sugarcane Juice

The color and enzymatic activity of sugarcane juice after blanching the sugarcane stalks is tabulated in Table 1. There is insignificant difference in TSS and juice yield due to blanching. However, there is significant improvement in juice color after blanching as observed from L*, a* and b* values. The L* value represents lightness of the juice, has increased two folds after blanching compared to unblanched cane juice. Decrease in a* and increase in b* values of juice from blanched cane represents improvement in green and yellow color, respectively. This might be due to inactivation of PPO and POD enzymes which causes browning effect in juices (Mao et al. 2007). The blanching of sugarcane stalks has reduced the PPO and POD activity to 55 and 53%, respectively (Table 1). Of the two enzymes, POD is reported to be heat resistant enzyme compared to PPO. Blanching of canes thus not only improved the color but also helps cleaning the cane for hygienic production of jaggery.

Jaggery Recovery and Scum Removed

The jaggery recovery and scum removed during jaggery preparation using different clarificants are presented in Table 2. It was observed that, the scum removal is high in all treatments where organic clarificants were used when compared to control and chemical clarification. However, no significant difference was observed in scum removal among the organic clarification treatments. The jaggery prepared using aloe vera with 0.3% recorded highest scum removal (4.06%), whereas lowest is recorded for chemical clarificant (2.69%). Addition of organic clarificants during boiling causes coagulation of colloidal and suspended impurities present in the juice and forms as scum on the surface which was removed. During chemical clarification, due to bleaching action of hydros, bright color is obtained and the impurities got dissolved in to the juice resulting low scum yield. Similar results of high scum removal with addition of organic clarificants were reported by Chikkappaiah et al. (2017b) during jaggery preparation using plant mucilage as clarificants. The quality of jaggery directly depends on the quantity of scum removed during clarification, more the scum removal; the brighter will be jaggery color. The jaggery recovery varied from 9.81 to 10.75% in different treatments under study. However, jaggery yield under different treatments was insignificant at 5% confidence level. It was observed that the addition of organic clarificants has reduced the processing time significantly during jaggery preparation compared to control (Table 2). However, no change in consistency of juice is recorded with addition of these clarificants. The organic clarificant accelerates the coagulation of impurities resulting in more scum removal and enhanced vigorous juice heating thus reducing the jaggery processing time. Also, reduction in processing time avoids caramelization of sugars which adversely affect the color and quality of jaggery.

Variation in Physical Properties of Jaggery

The physical properties such as color, total insoluble solids and moisture content of jaggery prepared using different clarificants are presented in Table 3. Color of the jaggery plays vital role as consumer’s preference and marketability of jaggery mainly depends on it. The values of L* and b* increased significantly with increase in concentration of both the organic clarificants. It was observed that, the L* representing lightness was recorded high in chemically clarified jaggery (51.2) followed by organic clarified jaggery with 0.3% aloe vera (48.5). Also, the L* values increased significantly in organic clarified jaggery compared to control. The higher values of b* indicating yellowness of the jaggery, was recorded high in chemical clarified jaggery (23.4). Thus, it can be reported that, the jaggery prepared using chemical clarificant possess yellow color which may be due to the bleaching action of sodium hydro sulphite. It was reported that hydros which was added as chemical clarificant is a strong reducing agent and reduces colored quinones into colourless phenols (McEvily et al. 1992; Lambrecht 1995).

The insoluble solids percent was recorded less than 2% in jaggery prepared using organic clarificants. Addition of organic clarificants helps in effective removal of insoluble solids from the sugarcane juice compared to control (2.75%) and chemical clarificant (2.86%). According to Bureau of Indian Standards (1990), the insoluble solids should be less than 1.5% for Grade-I and less than 2.0% for Grade-II jaggery. It was also observed that, the total insoluble solids in jaggery decreased significantly with increase in concentration of organic clarificants which is similar to results reported by Chikkappaiah et al. (2017a). The high concentration of organic clarificants helped in removal of more impurities and hence recorded low insoluble solids in jaggery. The moisture content plays vital role in shelf-life enhancement during storage and varied from 3.75 to 4.81 (%, d.b.) with highest value recorded for jaggery prepared using chemical clarificant. Among the treatments, the jaggery prepared using aloe vera (0.3%) recorded lowest moisture content (3.75%) indicating the more shelf life. Impurities present in the jaggery enhances the moisture holding capacity hence, reported the higher moisture content in control and chemical clarificant treatments.

Variation in Biochemical Parameters of Jaggery

The biochemical parameters such as sucrose, reducing sugars and SO2 present in jaggery were studied (Table 4). The sucrose and reducing sugars are important factors that govern the grading of jaggery. Reducing sugars of the jaggery varied from 7.9 to 11.8%. It was observed that, the organic clarified jaggery falls under grade-I as the reducing sugar are below 10% according to Bureau of Indian Standards (1990), whereas the corresponding value for the chemical clarificant jaggery is 11.8 (Table 4). Similar results were reported by Chikkappaiah et al. (2017a) during jaggery preparation using plant mucilage. The reducing sugars will adversely affect the quality due to its hygroscopic nature and cannot be stable for longer period (Verma and Narain 1990). There was insignificant effect on sucrose content of jaggery due to blanching and organic clarification. The sucrose content of jaggery prepared using organic clarificants was in the range of 81.2–84.6%, indicating Grade-I jaggery (Bureau of Indian Standards 1990). Among all treatments, the chemically clarified jaggery noticed low sucrose content (78.5%) which falls under Grade-II, while jaggery prepared with aloe vera (0.3%) noticed high sucrose content (84.6%). Hence, it is clearly evident that addition of organic clarificants improved the purity of jaggery as indicated by high values of sucrose content which was due to effective removal of impurities.

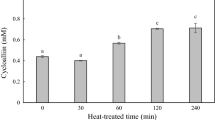

The sulphur dioxide content in the jaggery varied from 30.1 to 93.5 ppm. Among the treatments, the jaggery prepared using organic clarificants and control sample has sulphur dioxide content within the permissible limit of 50 ppm according to Indian standards, whereas the chemically clarified jaggery recorded higher sulphur dioxide of 93.5 ppm. This might be due to addition of sodium hydrogen sulphite as clarificant. It was already reported that, the excess use of chemicals during jaggery preparation results in salty taste with low shelf-life and the residual sulphur is harmful to health (Rajesh et al. 2016). The total flavanoid content of jaggery prepared from organic clarificants recorded high compared to chemically clarified jaggery and control (Fig. 3a). The total flavonoids content of the jaggery has increased significantly with increase in concentration of clarificant. The highest value of total flavonoids was recorded for jaggery treated with 0.3% aloe vera (1220 µg QE/g), whereas lowest values observed with chemical clarified jaggery (320 µg QE/g). The results were in agreement with Nayaka et al. (2018a) reporting high flavonoid content in jaggery prepared using organic clarificants. Similarly, the total phenols were reported to be high in jaggery prepared using organic clarificants compared to chemically clarified jaggery (Fig. 3b). The total phenols of the jaggery under study ranged from 5976 to 6584 µg GAE/g with highest value recorded for jaggery prepared using moringa leaf extract (0.3%). Moringa tree is considered to be the miracle tree in the world as each part of it was well utilized for food, medical and industrial purpose. It was reported that moringa leaf extract has antioxidant activity both in vitro and in vivo due to the presence of phenolic acids and flavonoids (Vongsak et al. 2013). Similarly, different parts of aloe vera, namely peel, gel, flowers and roots, were rich in phenolic compounds and several flavonoids (Quispe et al. 2018). This might be the reason for high values of flavonoids and phenols in jaggery prepared with aloe vera and moringa leaf extract as clarificants. Also, aloe vera leaf gel was reported to be a natural flocculant and eliminates turbidity and suspended solids with efficiency of 72 and 91%, respectively, in surface water clarification as reported by Nougbode et al. (2016). Hence, clarification of sugarcane juice with aloe vera leaf extract resulted in effective removal of insoluble solids.

The jaggery prepared using chemical clarificants exhibited pale yellow color which is a temporary enhancement in physical appearance but indiscriminate use of this chemical resulted in deposition of residual sulphur which is very much harmful. Also, the use of chemical clarificant resulted in inefficient removal of impurities with low sucrose percent and comes under Grade –II. Polyphenols have proved to affect the health positively (Jaffe 2012). However, addition of hydros during jaggery making has significantly reduced the polyphenol content. Similar results of reduction in polyphenols and flavonoids were reported for jaggery prepared using hydros as clarificant (Verma et al. 2019). The addition of organic clarificant not only improves the efficiency in clarification of juice during jaggery production but also increased bioactive compounds such as flavonoids and total phenols.

The microbial analysis of jaggery showed that jaggery prepared using organic clarificants recorded low bacterial count compared to control (Table 4). No fungal growth is observed in jaggery samples prepared with or without organic clarificant. Blanching of canes leads to microbial safe and clean juice during jaggery production. Hence, blanching of canes by mechanical means can be recommended for large scale production of jaggery. Among all treatments, jaggery prepared using hydros as clarificant recorded lowest bacterial count. It was reported that hydros is used in food and beverage industries as a preservative against microbial growth and helps in inhibiting browning reactions, such as phenol oxidation and Maillard reactions (Verma et al. 2019). Hence, the chemical clarified jaggery recorded low microbial load with bright color. However, the high SO2 content and low phenolic and flavonoids recorded in chemically clarified jaggery leads to production of inferior quality jaggery. Hence, for quality jaggery making, blanching of canes followed by clarification either with aloe vera or moringa leaf extract at 0.3% was recommended. The use of aleo vera in functional foods especially for the preparation of health drinks including milk, ice cream, confectionery, etc. with no laxative effects has been increasing. The high protein content and richness in vitamins and minerals in, Moringa oleifera is often promoted as a promising plant to fight against malnutrition. With changing times and conditions due to covid pandemic, the perception and awareness of the people towards usage of chemical free, nutritional rich products is gaining wide popularity worldwide. This paves a way for introduction of organic clarificants such as moringa and aloe vera leaf extract in the production of jaggery which not only enhances nutritional value but also fetches premium price to the farmers. However, further studies need to be done to access the shelf-life of jaggery prepared using organic clarificants. It was already reported that jaggery prepared using aloe vera, malabar spinach and purslane plant mucilage clarificants showed lesser changes in physicochemical, microbial as well as sensory characteristics compared to control jaggery during shelf-life studies for 6 months (Nayaka et al. 2018b). The Food Safety and standard authority of India (FSSAI) has mentioned the regulatory standards for jaggery making and specified the limit for usage of chemical clarificant. However, the usage of organic clarificants during jaggery making was not specified in FSSAI standards which need to be studied further and implemented. Hence, it is very much essential to renew the traditional method of jaggery production using hazardous chemical clarificants with plant based clarificants.

Conclusion

Blanching of sugarcane stalks resulted in controlling enzymatic browning and removal of extraneous impurities in sugarcane juice. Jaggery prepared using organic clarificants resulted in efficient removal of impurities and comes under Grade-I, whereas chemical clarified jaggery falls under Grade-II. The jaggery prepared using aloe vera or moringa leaf extract (0.3%) resulted rich in bioactive compounds such as phenols and flavonoids. Though chemically clarified jaggery exhibits yellow color, it is inferior to organic clarified jaggery in terms of quality parameters. The study supplements the standardization of process technology for jaggery making using organic clarificants. The future work will concentrate on the stability of jaggery prepared using organic clarificants during storage.

References

American Public Health Association (APHA). 2001. Culture methods for enumeration of microorganisms. In Compendium of methods for the microbiological examination of foods, ed. P.D. Frances and I. Keith, 53–67. Washington, DC: APHA.

Anonymous. 2011. Acharya N.G. Ranga agricultural university, annual report.

AOAC. 1990. Official methods of analysis, 15th ed. Washington, DC: Association of Official Analytical Chemist.

Baboo, B., and S. Solomon. 1995. Nutritive sweeteners from sugar crops: development of jaggery khandsari and syrup industry in India. In Sugarcane agro-industrial alternatives, ed. G.B. Singh and S. Solomon, pp. 289–312. New Delhi: IBH Publishing Co Pvt Ltd.

Bureau of Indian standards IS 12923, (Clause 4.3 and 6.1). 1990. New Delhi, India.

Chang, C.C., M.H. Yang, H.M. Wen, and J.C. Chern. 2002. Estimation of total flavonoid content in propolis by two complementary colorimetric methods. Journal of Food and Drug Analysis 10 (3): 178–182.

Chauhan, D.V.S. 1972. Vegetable production in India, 3rd ed., 28–30. Agra: Ram Prasad and Sons.

Chauhan, A.K., S. Sharma, P. Sharma, and R. Maheshwari. 2012. Production of organic sugar employing vegetable agent for sugarcane juice. International Journal of Institutional Pharmacy and Life Sciences 2 (2): 312–315.

Chikkappaiah, L.A.V.A., M.A.H. Nayaka, and P.K.G. Mahadeviah. 2017a. Preparation of plant mucilage clarificants and their effect on jaggery processing of sugarcane variety Co 86032. International Journal of Pharmacy and Pharmaceutical Sciences 9: 32–36.

Chikkappaiah, L.A.V.A., M.A.H. Nayaka, M.P. Manohar, and P. Kumar. 2017b. Effect of plant mucilage clarificants on physical and chemical properties of jaggery. International Journal of Recent Scientific Research 8 (10): 20663–20669.

Christaki, E.V., and P.C. Florou-Paneri. 2010. Aloe vera: A plant for many uses. Journal of Food Agriculture and Environment 8 (2): 245–249.

Costa, G.H.G., I.D.S. Masson, L.A.D. Freita, J.P. Roviero, and M.J.R. Mutton. 2014. Use of moringa oleífera lamarck leaf extract as sugarcane juice clarifier: Effects on clarified juice and sugar. Food Science and Technology 34: 204–209.

Dilip, P.A., A.S. Maruthi, and N.A. Charudatta. 2017. Techniques and advances in jaggery processing: A review. Research Journal of Chemical and Environmental Sciences 5 (2): 14–20.

Gangwar L.S., Solomon S., and Anwar S.I. 2015. Technological and policy options for modernization of jaggery industry in India. ICAR Policy Brief, 1–6. https://iisr.icar.gov.in/iisr/download/publications/report/policypaper_gangwar.pdf.

Henshall, J.D. 2012. Food safety and standards authority of India ministry of health and family welfare government of India New Delhi. Manual of Methods of Analysis of Foods Fruit and Vegetable Products 5: 1–59.

Hussain, Z., M. Islam, Z. Mohammad, K.M. Khan, S. Perveen, and M. Afzal. 2012. The effect of pretreatment of juice on the properties and composition of jaggery. Sugar Tech 14: 291–294.

Jaffe, W.R. 2012. Health effects of non-centrifugal sugar (NCS): A review. Sugar Tech 14: 87–94.

Jittanit, W., S. Wiriyaputtipong, H. Charoenpornworanam, and S. Songsermpong. 2011. Effects of varieties, heat pretreatment and UHT conditions on the sugarcane juice quality. Chiang Mai Journal of Science 38 (1): 116–125.

Karthikeyan, J., and S.S. Samipillai. 2010. Sugarcane in therapeutics. Journal of Herbal Medicine and Toxicology 4 (1): 9–14.

Lambrecht, H.S. 1995. Sulfite substitutes for the prevention of enzymatic browning in foods. ACS Symposium Series 600: 313–323.

Lane, J.H., and L. Eynon. 1923. Methods for determination of reducing and nonreducing sugars. Journal of Science 42: 32–37.

Mao, L.C., Y.Q. Xu, and F. Que. 2007. Maintaining the quality of sugarcane juice with blanching and ascorbic acid. Food Chemistry 104 (2): 740–745.

McEvily, A.J., R. Iyengar, and W.S. Otwell. 1992. Inhibition of enzymatic browning in foods and beverages. Critical Reviews in Food Science & Nutrition 32 (3): 253–273.

Nayaka, H.M.A., L.A.V.A. Chikkappaiah, M.P. Manohar, and B.S. Gunashree. 2018. Storage studies of jaggery prepared using aloe vera, pursalane and malabar spinach mucilage clarificants. International Journal of Biosciences 13 (1): 196–205.

Nayaka, H.M.A., L.A.V.A. Chikkappalah, K.S. Venkatesh, B.S. Gunashree, and S. Sudharshan. 2018. Evaluation of bioactivity of jaggery prepared using plant mucilage as clarificant. Asian Journal of Pharmaceutical and Clinical Research 11: 294–299.

Nougbode, A.E.I., P. Sessou, A.K. Youssao, C.P. Agbangnan, D. Mama, and K.C.D. Sohounhloue. 2016. Evaluation de gel dAloevera en feuilles comme un floculant naturel: Criblage phytochimique et elimination de la turbidite des essais deau par coagulation flocculation. Research Journal of Recent Sciences 5 (1): 9–15.

Quispe, C., M. Villalobos, J. Borquez, and M. Simirgiotis. 2018. Chemical composition and antioxidant activity of aloe vera from the Pica Oasis (Tarapaca, Chile) by UHPLC-Q/Orbitrap/MS/MS. Journal of Chemistry 2018: 1–16. https://doi.org/10.1155/2018/6123850.

Rajesh, C.K., M.A. Shajahan, and S. Hameed. 2016. Analytical study of different samples of guda (jaggery) collected from Thrissur, Kerala. Ayurpharm: International Journal of Ayurveda and Allied Sciences 5: 52–58.

Ranganna, S. 1986. Manual of analysis of fruit and organic products, 2nd ed. New Delhi: Tata McGraw Hill Publishing Company Limited.

Rao, P.V.K., M. Das, and S.K. Das. 2007. Jaggery–a traditional Indian sweetener. Indian Journal of Traditional Knowledge 6: 95–102.

V.A. Shakunthala, and G. Devraj. 1991. Hibiscus abelmoschus L.-A vegetable clarificant in gur making. In National Seminar on Increasing Productivity, Quality and Storability of Jaggrey (gud) at Indian Institute of Sugarcane Research, Lucknow, India, 30th November–1st December.

Singh, J., S. Solomon, and D. Kumar. 2013. Manufacturing jaggery, a product of sugarcane, as health food. Agro Technology S11 (7): 1–3.

Singleton, V.L., R. Orthofer, and R.M. Lamuela-Raventos. 1999. Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. Methods in Enzymology 299: 152–178.

Sreedevi, P., L.E. Jayachandran, and P.S. Rao. 2018. Browning and bioactive composition of sugarcane juice (Saccharum officinarum) as affected by high hydrostatic pressure processing. Journal of Food Measurement and Characterization 12: 1962–1971.

Tomasik, P., M. Pałasinski, and S. Wiejak. 1989. The Thermal decomposition of carbohydrates. Part I. The decomposition of mono-, di and oligo-saccharides. Advances in Carbohydrate Chemistry and Biochemistry 47: 203–278.

Verma, V.K., and M. Narain. 1990. Moisture absorption isotherms of jaggery. Journal of Stored Products Research 26: 61–66.

Verma, P., N. Shah, and S. Mahajani. 2019. Effect of sodium hydrosulphite treatment on the quality of non-centrifugal sugar: Jaggery. Food Chemistry 299: 1–8.

Vongsak, B., P. Sithisar, S. Mangmool, S. Thongpraditchote, Y. Wongkrajang, and W. Gritsanapan. 2013. Maximizing total phenolics, total flavonoids contents and antioxidant activity of Moringa oleifera leaf extract by the appropriate extraction method. Industrial Crops and Products 44: 566–657.

Acknowledgements

The authors are grateful to ICAR for providing funds to AICRP on Post-Harvest Engineering and Technology and the Director of Research, Acharya N.G.Ranga Agricultural University for the encouragement and providing facilities to carry out the experiment.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sreedevi, P., Madhava, M. Quality Improvement of Non-Centrifugal Sugar as Affected by Blanching and Organic Clarification. Sugar Tech 24, 1867–1876 (2022). https://doi.org/10.1007/s12355-022-01158-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12355-022-01158-8