Abstract

In Thailand, non-centrifugal sugar (NCS) product is not yet processed on an industrial scale and all of it is produced by famers on a small scale using a traditional evaporation process with open iron pans. Since the whole sugarcane stalk is directly pressed by a milling machine, impurities from the rind contaminate the raw juice. Therefore, subsequent clarification of the raw juice is a crucial step to produce the high-quality NCS product. The farmers normally use traditional filtration, and sometimes non-food-safe additives to remove suspended impurities from the raw juice. This study examined and analysed the effects of the food additives calcium oxide (CaO) and sodium hydrogen carbonate (NaHCO3) on the physicochemical properties of NCS, and the results will be used to guide and improve traditional-level production. Clarifying the juice at pH 8.5 with CaO gave the greatest mud weight (47.52 g) and the lowest sediment value of NCS (0.68%), while clarifying the juice with the maximum studied level (0.1% w/v) of NaHCO3 gave the mud weight and sediment values of 30.28 g and 0.71%, respectively. The higher the amount of clarifier, the cleaner the juice obtained. Clarification by NaHCO3 or CaO caused different effects on the moisture content, water activity and colour of the NCS, but had no impact on its solubility. Total phenolic content and total flavonoid content were positively correlated with antioxidant activity by the ABTS radical scavenging assay. Clarifying the juice with CaO or sodium NaHCO3 caused loss of policosanol and tricin contents.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Non-centrifugal cane sugar (NCS) product classified as a traditional minimally processed sweetener, and it is available in many countries under different local names like “Kokuto” in Japan, “Panela” in Colombia, and “Nam-Tan-Oy” in Thailand (Asikin et al. 2014). Since NCS product does not require an intense refining process, it is full of nutrients and phytochemicals naturally found in sugarcane and has a unique flavour and aroma (Weerawatanakorn et al. 2016; Asikin et al. 2017). NCS also has many environment benefits over refined sweeteners. Many health-promoting properties of NCS have been reported, including immuno-protective effects, anti-toxicity, cytoprotective effects, anti-carcinogenic effects and protective effects against diabetes and hypertension (Jaffé 2012). Previous research has identified bioactive compounds, both nutrients and phytochemicals, in NCS. It contains high amounts of minerals (1648–2972 mg/100), as well as 19 amino acids, including 10 essential amino acids. Citrulline and γ-aminobutyric acid (GABA) were also found (Asikin et al. 2017). The main phytochemicals identified in NCS were flavanones such as naringin and flavones including tricin, apigenin and luteolin (Takara et al. 2002). Tricin in sugarcane juice and brown sugar products were reported at 0.59 mg/100 g and 0.31 mg/100 g, respectively (Duarte-Almeida et al. 2011). It inhibits the growth of human malignant breast tumour cells and protects against murine gastrointestinal carcinogenesis (Cai et al. 2005; Verschoyle et al. 2006). Policosanols (PCs) are a group of long-chain (C20–C30) aliphatic primary alcohols derived mainly from the wax found on sugarcane rind. PC can reduce blood levels of low-density lipoprotein and inhibit cholesterol synthesis, thereby protecting against atherosclerosis (Noa and Mas 2005; Singh et al. 2006). The PC content of Japanese NCS, known there as “Kokuto”, ranged from 7.0 to 85.7 mg/100 g (Asikin et al. 2008).

The process of NCS prodcuts is basically based on thermal evaporation process, and the main chemical reaction involved in the process is non-enzymatic browning through the Maillard reaction as well as caramelization, generating the brown colouration and characteristic aroma and taste of NCS products (Takahashi et al. 2016; Weerawatanakorn et al. 2016). The process can be divided into traditional and industrial production scales, and the most important step of NCS process in both production levels is the clarification of the raw cane juice to remove the impurity of the juice including a variety of insoluble and suspended matters such as soil, sand, clay, starch and mud contaminated mostly from the rind during harvesting and pressing process (Binkley and Wolform 1953). In Thailand, non-centrifugal sugar (NCS) product is still not processed on an industrial scale and it is produced by farmers on a small scale using a traditional evaporation process in the open pan. The impurities of raw juice will naturally move to the top of the pan during boiling the juice, and then they are manually removed out at the top of the syrup during the evaporation process. In some areas, they use only conventional filtration, while others use toxic chemicals to clarify the raw juice prior to the evaporating process. Therefore, there are controversial issues on the quality of the obtained products from this traditional process, particularly where the food laws and regulation of brown sugar products are over looked in the clarification of raw juice. Mungare et al. (2000) reported that clarificants were important to remove impurities for production of good qualities jaggery. However, excessive use of synthetic chemical clarifier causes serious health problem in the long term (Mungare et al. 2000). Patil et al. (2005) reported that bhendi plant better effect on quality of jaggery and also helped in maintaining better colour jaggery during storage.

Calcium oxide (CaO) together with centrifuge filtration and high-pressure filtration is principally applied to clarify the raw juice for the industrial production level (Doherty and Edye 1999). Sodium hydrogen carbonate (NaHCO3), a food additive, is mainly used in baking products as part of the leavening step via carbon dioxide gas generation in acidic conditions. It is safe and widely available on the market. To improve the clarification of the raw juice, we suspect that CO2 gas produced due to the acidic property of cane juice helps removing higher amounts of suspended impurities to the top of the open pan during boiling. The impurities can be manually removed. The NCS world consumption has increased by improving the end-product quality in terms of purities, physicochemical properties and nutritional components. Consequently, this study aims to investigate the effect of the clarification method with CaO and NaHCO3 on the quality of the obtained NCS products from the traditional process production. The physicochemical properties of products and nutraceuticals are used to evaluate the effectiveness of the clarification process.

Materials and Methods

Preparation of NCS Products

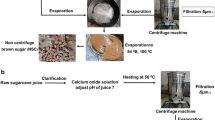

Whole stalks of the LK92-11 sugarcane cultivar were manually harvested at maturity stage (February–March, 2017) at the Sukhothai Agricultural Research and Development Centre, Sukhothai Province, Thailand. Raw cane juice was extracted from whole stalks by pressing machine (C.H.H, Bangkok, Thailand). The pH, total soluble solid content, total acidity, total sugar and yield of each juice were recorded. The obtained juices were divided to eight conditions as Table 1. NCS products were processed as the processing flow chart in Fig. 1. For CaO clarification, the raw juices were adjusted pH to 6, 7 and 8.5 using CaO solution (5:50 w/v) and heated at 50 °C, followed by cooling to 30 °C and centrifuging (5 µm) process to remove the impurities out of the juice. The clarified juice was concentrated by heating in an open pan with manual stirring until the final total soluble solid (TSS) of 84 °Brix (100 °C). The obtained syrup was processed into shaping blocks to solidify into an NCS products. For NaHCO3 application, the direct addition of NaHCO3 powder into the juice at the level of 0.05% (pH 6), 0.07% (pH 6.36) and 0.1% (pH 6.56) was used following evaporation till TSS reached 84 °Brix (100 °C). The syrup was then processed as the same step as mentioned above. During evaporation, the mud as suspended impurities material, manually removed from the top of the pan, was also corrected for mud weight analysis. The mud weight of NCS products made from CaO clarification also included the mud from the filtered bag of the centrifuge machine. The two types of NCS samples made from raw juice without any addition of food additives and with only centrifugation (5 µm) were used to compare as the control samples. All NCS products made were finally stored at − 18 °C until further analysis.

Physicochemical Analysis

Moisture Content, Water Activity and Colour Analyses

Moisture content was determined based on the loss of sample weight (2 g) by an oven drying at 105 °C for 3 h and water activity (aw) was measured using an IC-5000 AW-LAB water activity analyser (Novasina AG, Lachen, Switzerland. The colour was determined according to the International Commission for Uniform Methods of Sugar Analysis (ICUMSA, 2003), and the colour value was calculated following ICUMSA and expressed as a colour unit (Asikin et al. 2014).

Sugar Composition Analysis

The sugar component was evaluated using a high-performance liquid chromatography (HPLC) (Xu, Niimi and Han 2006) with modifications. The column used was Inertsil NH2 (4.6 mm × 250 mm) with a refractive index (RI) detector. The mobile phase was a solution of acetonitrile and water in a ratio of 75:25 (v/v).

Determination of Mud Weight

All of the mud collected from each treatment was dried in a hot air oven (UMAC, UM-Oven 120L, USA) at 60 °C for 24 h. The received weight was recorded as the mud weight (g).

where a is the weight of aluminium dish before oven (g) and b is the weight of aluminium dish and sample after oven (g).

Solubility Value Analysis

The samples were dissolved in distilled water (15 ml) with stirring for 5 min followed by centrifugation at 8000 rpm for 15 min. The supernatant (5 ml) was added into the moisture can and processed to oven at 105 °C for 12 h. (Shittu and Lawal 2007). After cooling down in desiccator for 30 min, the weight was recorded and the solubility was calculated according to the following equation:

where a is the weight of moisture can before oven (g), b is the weight of moisture can and sample after oven (g), and w is the weight of sample (g).

Sediment Value

Sugar sample (10 g) was dissolved in distilled water (100 ml) with continues stirring. After filtration, the samples were dried by hot air oven at 105 °C for 60 min (Khuenpet et al. 2016). Sediment value was calculated with the below formula.

where Wt is the weight of filter paper and sample after oven (g), W1 is the weight of filter paper (g), and W2 is the weight of sample (g).

Antioxidant Activities Determination

Sample Extraction for Antioxidant Test

The sugar samples (20 g) were extracted with MeOH solution (1:1v/v) 70 ml with continuous stirring for 60 min following filtration through filter paper (No. 4). The solvent was removed by rotary evaporator, and then the extract was adjusted with MeOH to the final volume of 50 ml.

Total Phenolic Content (TPC) Analysis

The TPC was determined based on the Folin–Ciocalteu method (Weerawatanakorn et al. 2016) and was calculated from a calibration curve of gallic acid (standard) and expressed as mg GAE/100 g.

Total Flavonoid Contents (TFC)

The TFC was performed as described by the method of Weerawatanakorn et al. (2016), and the results were expressed as mg rutin equivalent/100 g.

DPPH Radical Scavenging Activity Analysis

The ability of antioxidants in the sample to scavenge DPPH radicals was examined following Weerawatanakorn et al. (2016), and the antioxidant activity was calculated as a percentage of DPPH radical inhibition.

ABTS Radical Scavenging Assay (2,2-Azino-bis (3-Ethylbenzthiazoline-6-Sulphonic Acid))

ABTS (2,2-azino-bis (3-ethylbenzthiazoline-6-sulphonic acid)) radical scavenging assay was performed using a method explained by Rael et al. (2004), and the ABTS radical scavenging was presented as g TE/100 g.

Policosanol Content Analysis

Policosanol Extraction and Derivatization

Policosanol (PC) extraction was modified from the method of Asikin et al. (2012). The sample (9 g) was extracted by a Soxhlet apparatus for 18 h. The solvent used was the mixture of hexane and methanol (20:1v/v). The solvent solution was completely removed from the extract using a rotary evaporator under 40 °C. The extracted dried residue was diluted with toluene to a final volume of 2 ml. The mass spectra of PC and PC contents were examined by silylated derivatization. Policosanol standard and sample solution was derivatized with a silylation reagent MSTFA (2:1 v/v) at 50 °C for 30 min for mass spectra identification. The PC standards included docosanol (C-22), tetracosanol (C-24), hexacosanol (C-26), octacosanol (C-28) and triacontanol (C-30). The content of the derivatized PC was examined by GC–MS.

GC–MS Condition for Policosanol Analysis

Samples were analysed using an Agilent GC–MS 6890 N with a fused capillary column (DB-5 ms, 0.25 mm id × 30 m), and the temperature of GC injector and the MS was set at 280 °C. The injection volume was 1 µL with a split ratio of 1:10 ml/min. The oven temperature originally set at 150 °C was raised to 320 °C at a rate of 4 °C/min, and was then kept at 320 °C for 15 min. Helium was used as the carrier gas. For MS detection, the electron impact (EI) ion source and transfer line temperature were at 280 °C and the ionization energy was generated at 70 eV. The mass acquisition scan range and rate were (m/z) 30–500 amu and 2 scans/s, respectively (Asikin et al. 2012).

Tricin Content Analysis

Tricin Extraction

The tricin extraction was modified from the method of Colombo et al. (2005). The sample (1 g) was extracted with 10 ml of methanol following sonication for 2 min and filtration (0.42 µm). The tricin purification of the extracts was performed by solid-phase extraction using Oasis HLB cartridges (6 cc, (200 mg), 30 µm particle size) (Waters, Milford, USA), the methanol extract solution (1 ml) was loaded into the cartridges, and the interfering compounds were removed by water (1 ml). The 1 ml of methanol was used to elute the flavonoid from the column tree times. The purified tricin (40 µL) of NCS products was injected into the LC-MC.

LC–MS Condition for Tricin Content Analysis

Analyses were performed using an Agilent technologies 1100 (Germany), C-18 Column LiChroCART RP-18e (150 × 4.6 mm, 5 µm) (Purospher STAR Merk, USA), and the temperature of oven was set at 40 °C. The mobile phase was a linear gradient of acetonitrile (solvent A) and 7% MeOH (0.1% formic acid) (solvent B) kept at a flow rate of 1.0 mL/min. The gradient elution programme was set at the constant ratio between solvent A and B (30:70%.). For mass detection, the N2 nebulizer gas pressure was set at 60 psi with dry gas flow at 13 L/min and dry temperature of 320 °C. The tricin was analysed in positive and negative ion modes with the following settings: capillary voltage 4000 and − 3500 V. Analyses were made in the SIM mode (329, 330 and 331 m/z).

Statistical Analyses

All measurements were conducted in triplicate, and the results are expressed as mean ± SD. Data were analysed by completely randomized design (CRD). Significant differences were compared using Duncan’s new multiple range test and a probability of p < 0.05.

Results and Discussion

In Thailand, some farmer producers used traditional muslin to filter the raw juice, while others used toxic non-food additives to remove the impurities from the raw juice. There is still no food standard or regulation of raw cane juice clarification. The research study on suitable food additives to clarify the raw juice is very important, especially for small-scale production including traditional processes. However, the different conditions of raw juice clarification affect its physical and chemical properties, such as colour, water activity, and nutritional and bioactive compositions (Payet et al. 2005; Asikin et al. 2017). Therefore, the current study aims to evaluate the effect of clarifying conditions with food additives on the physicochemical properties of NCS products.

Effect of Food Additives on the Sugarcane Juice Clarification

Table 2 shows the parameters used to indicate the effectiveness of clarification processes by CaO and NaHCO3. The initial pH, total soluble solid and total solid content of cane juice were 5.35, 20 oB and 21.56%, respectively. This study purposed to investigate effect of CaO and NaHCO3 on the removal of the suspended and insoluble impurities out of the raw sugarcane juice, which were related to the removed mud weight, total solid of clarified juice and sediment value of NCS products. The highest adjusted pH (8.5) of juice by CaO gave the greatest mud weight (47.52 g) and the lowest total solid of juice (35.68%), sediment value (0.68%) and the yield percentage of product (9.6%). As expected, the mud weight removed out from the boiled juice during the evaporation process and from the filtered bag of centrifuge machine, significantly increased when the pH of cane juice was increased by the treatment of CaO and NaHCO3 for clarifying the raw juice. The application of CaO and NaHCO3 increased the mud weight and decreased the total solid of juice and sediment value of sugar products, suggesting that the obtained juice was more clarified compared with the control sample. The sediment value (0.68–0.83%) of NCS products with food additives clarification was also comparable with commercial Japanese NCS, Kokuto, produced at industrial level (0.82 and 0.95%) (data not shown). Since the raw juice was more clarified when food additives were applied, the yield percentage of the sugar products was reduced. Clarifying the juice using filtration (5 µm) by centrifuge machine was effectively compared with the control sample, but was not more effective than clarifying the raw juice by CaO and NaHCO3. The suspended and insoluble materials in the raw sugarcane juice have a negative charge (Doherty and Edye 1999). Based on the principle of aggregation of charge by the food additive containing positive ion Ca2+ and Na+, they combine with negative ions of the suspended materials in the raw juice (Steindl 2010). Consequently, clarifying the raw juice with CaO and NaHCO3 reduced the impurities in the juice, leading to reduction in total solids in the juice and sediment value of the products (Fig. 2).

Effect of CaO and NaHCO3 in Juice Clarification Process on Characteristics of NCS Products

The physical characteristics of NCS products, comprising in Table 3, included moisture content, aw, total acidity colour and soluble index, as the major quality factors of food products, which have a strong impact on consumer acceptability and shelf life storage (Takahashi et al. 2016). Higher amounts of CaO use decreased water activity (0.60, 0.56 and 0.54) and moisture content (5.41, 4.15, and 3.64%) due to the desiccant properties of CaO. NaHCO3 treatment at the level of 0.05 and 0.07% also caused the reduction in aw and the moisture content of sugar products but not at the highest level used (0.1%). CO2 gas and water are generated from the chemical reaction when NaHCO3 is heated in acidic conditions. This might help to reduce moisture content and water activity by heat dissipation during the evaporation phase (Tang et al. 2018).

In contrast, the higher water amount released from the chemical reaction at high levels of NaHCO3 used (0.1%) results in higher amounts of water found in the NCS product compared with the levels of 0.05 and 0.07%. Total acidity of NCS products decreased as the pH of NCS products increased because NaHCO3 and CaO were the basic agents. Although the solubility index of NCS products from clarifying juice at pH 8.5 with CaO solution was the highest value (34.18%), clarification of juice with CaO and NaHCO3 had no significant effect on solubility index of NCS products. The reason might be that the clarified cane juice obtained has the lowest moisture content (Khuenpet et al. 2016). The colour value (8500 IU) of NCS products from juice clarified with CaO at a level of pH 8.5 was found to be the highest, suggesting that the darker products are due to the development of a brown colour with the progress of the Maillard reaction. NaHCO3 is known as a mild bleaching agent, so the clarifying of the raw juice with NaHCO3 reduced the colour value of products but not in a dose-dependent manner (Ahrari et al. 2017).

NCS products mainly composed of sucrose (> 93%), while glucose and fructose were minor composition (Supplementary data). The total sugar contents of NCS products increased when CaO and NaHCO3 were applied to clarify the raw juice (from 80.88 g/100 g to maximum content of 94.38 g/100 g). This increasing phenomenon was in accordance with the sucrose level of NCS products. Since the more degree of juice clarification, the higher purified raw juice obtains, leading to high sugar concentration (total sugar and sucrose contents).

Effect of CaO and NaHCO3 in Juice Clarification on Total Phenolic Compound (TPC), Flavonoid Contents (TFC) and Antioxidant Capacity of NCS Products

NCS products contain not only the nutrients, but also the important nutraceutical, especially phenolic compounds such as flavonoids (Asikin et al. 2017). This study revealed how the clarifying raw cane juice by CaO and NaHCO3 had impact on the phenolic compound and their antioxidant activities as demonstrated in Table 4. For clarifying the raw cane juice with different amounts of NaHCO3, the highest TPC (1664.9 mg GAE/100 g) and TFC (92.66 mg RUE/100 g) were found at the highest level of NaHCO3 used (0.1%). Statistical analysis indicated that clarifying juice with NaHCO3 caused significantly increasing TPC, but had no significant effect on TFC except for the level of 0.1%. For clarifying juice with CaO, the highest TPC (1483.2 GAE/100 g) and TFC (95.64 RUE/100 g) were found at the CaO solution used to adjust cane juice at pH 8.5, and the clarification of juice by CaO significantly increased both TPC and TFC. TPC showed a high correlation (p < 0.01) with TFC (Table 5). Feng et al. (2014) also found the high correlation between TPC and TFC of cane juice grown in China. Phenolic and flavonoid components exhibit hydrophilic properties. Therefore, the more clarifying the juice to remove the suspended insoluble materials, the higher the concentration of those hydrophilic components obtained.

TPC values of NCS products found were much higher than the TPC values reported by Payet et al. (2005) for commercial brown sugars produced in different countries (117.4–418.1 mg GAE/100 g), Nayaka et al. (2009) for jaggery, an Indian commercial brown sugar (383 mg GEA/100 g), and Takahashi et al. (2016) for Kokuto, Japanese NCS product, (92.88–154.92 mg GAE/100 g). It might be due to the difference in phenolic and flavonoid extraction methods such as extraction duration, solvent, extraction time and the sugarcane varieties.

DPPH and ABTS assay were used for determining antioxidant abilities in recent studies. The DPPH radical scavenging activity significantly decreased, while the ABTS radical scavenging activity significantly increased as clarification by CaO and NaHCO3 was applied. These results agree with the correlation results in Table 5, showing that the DPPH inhibition was a high negative correlation with TPC (r = − 0.937) and TFC (r = − 0.973). The ABTS value showed a positive correlation with TPC (r = 0.587) and TFC (r = 0.427). The result suggests that flavonoids are the most important contributors to the antioxidant activity of NCS products. The data indicated that the pH value had an association with the total acidity of NCS products due to the basic agent clarifier used. The pH value and antioxidant activity by DPPH assay of NCS products had a high negative correlation with r = − 0.899, suggesting that antioxidant activity by DPPH assay is not suitable to use to compare products with a high range of the differences in pH (5.71–7.58) and total acidity (0.19–0.70%). Feng et al. (2014) also found that there was a high positive correlation of DPPH value and TPC (r = 0.8806) and TFC (r = 0.9072) of cane juice from different cultivars. The difference of the recent study and Feng et al. (2014) may be the difference of samples used in this study which are the NCS products clarified by food additives with basic properties. It is also showed that clarifying the juice by filtration has no effect on TPC, TFC, DPPH and ABTS value of NCS products.

Effect of CaO and NaHCO3 in Juice Clarification on Policosanol and Tricin Contents of NCS Products

Policosanol is a group of long-chain C22–C30 aliphatic primary alcohols normally found in sugarcane wax and is a characteristic nutraceutical in cane since it exhibits health promotion in terms of reducing platelet aggregation as well as low-density lipoprotein levels in blood, leading to the prevention of atherosclerosis. The flavonoid tricin is a nutraceutical not normally found in plant food. It had been reported in rice and sugarcane (Irmak et al. 2006) and showed the chemopreventive properties as the inhibition of the growth of human malignant breast tumour cells and protection of murine gastrointestinal carcinogenesis (Cai et al. 2005; Verschoyle et al. 2006). The clarification by CaO and NaHCO3 effect on policosanol and tricin contents of NCS is registered in Table 6. The composition of the policosanol content of all NCS products showed that octacosanol (C28–OH) and triacosanol (C30–OH) were the main policosanol components. Clarification of raw juice by NaHCO3 significantly reduced PC contents except for NaHCO3 at a level of 0.07%, but had no significant effect on tricin contents. Manually removing impurities during the evaporation process might affect the result found here due to the water-insoluble property of PC. Clarification by CaO solution also reduced PC contents and tricin content. The high content of tricin is at pH 6 (143.72 µg/100 g) because of variation and manual removal of the impurities during the evaporation process.

PCA (Fig. 3) was graphically performed to understand the inter-relationships of some physicochemical properties and phenolic components and the similarities and the difference of raw cane juice clarification. Two principle components can explain 64.37% of total variances. The clarification by NaHCO3 0.07% and CaO at pH 7 was highly correlated with policosanol content (PC), total phenolic content (TPC) and total flavonoid content (TFC).

Principal component analysis bioplot of active variable including colour, sucrose (suc), glucose (glu), fructose (fru), total sugar (Tsug), DPPH, ABTS, TPC, TFC and PC content. Active observations are NCS products made from different clarification conditions including control (CTS), centrifuge filtration (FTTS), NaHCO3 clarification (NaS1–3) and CaO clarification (CaS1–3)

Conclusion

Clarifying raw juice by CaO and NaHCO3 with basic properties causes the obtained juice to be clearer than the control. NaHCO3 caused the lighter colour compared with control products, whereas CaO gave the darker coloured products. TPC, TFC and ABTS radical inhibition increased when either the CaO or NaHCO3 was applied to clarify the raw juice. The maximum PC and tricin loss were 15.16 and 79.86%, respectively, from the CaO clarification. The NaHCO3 clarification had no effect on tricin content. Thus, the clarification of sugarcane juice by CaO to obtain final pH at 7 and NaHCO3 at the level of 0.07% offers a new alternative clarification process to NCS product production for farmer producers in Thailand.

References

Asikin, Y., T. Chinen, K. Takara, and K. Wada. 2008. Determination of long-chain alcohol and aldehyde contents in the non-centrifuged cane sugar Kokuto. Food Science and Technology Research 14: 583–588.

Asikin, Y., M. Takahashi, N. Hirose, D.X. Hou, K. Takara, and K. Wada. 2012. Wax, policosanol, and long-chain aldehydes of different sugarcane (Saccharum officinarum L.) cultivars. Lipid Science Technology 114: 583–591.

Asikin, Y., A. Kamiya, M. Mizu, K. Takara, and H. Tamaki. 2014. Changes in the physicochemical characteristics, including flavor components and Maillard reaction products, of non-centrifugal cane brown sugar during storage. Food Chemistry 149: 170–177.

Asikin, Y., W. Takahara, M. Takahashi, N. Hirose, S. Ito, and K. Wada. 2017. Compositional and electronic discrimination analyses of taste and aroma profiles of non-centrifugal cane brown sugars. Food Analytical Methods 6: 1844–1856.

Ahrari, F., N. Hasanzadeh, O. Rajabi, and Z. Forouzannejad. 2017. Effectiveness of sodium bicarbonate combined with hydrogen peroxide and CPP-ACPF in whitening and microhardness of enamel. Journal of Clinical and Experimental Dentistry 9: e344–e350.

Binkley, W.W., and M.L. Wolform. 1953. Composition of came juice and cane final molasses. Advances in Carbohydrate Chemistry 8: 291–314.

Cai, H., W.P. Steward, and A.J. Gescher. 2005. Determination of the putative cancer chemopreventive flavone tricin in plasma and tissue of mice by HPLC with UV–visible detection. Biomedical Chromatography 19: 518–522.

Colombo, R., J.H. Yariwake, E.F. Queiroz, K. Ndjoko, and K. Hostettmann. 2005. On-line identification of sugarcane (Saccharum officinarum L.) methoxy flavones by liquid chromatography–UV detection using post-column derivatization and liquid chromatography–mass spectrometry. Chromatography 1082: 51–59.

Duarte-Almeida, J.M., A. Salatino, M.I. Genovese, and F.M. Lajolo. 2011. Phenolic composition and antioxidant activity of culms and sugarcane (Saccharum officinarum L.) products. Food Chemistry 125: 660–664.

Doherty, W., and L.A. Edye. 1999. An overview on the chemistry of clarification of cane sugar juice. Proceedings: International Society of Sugar Cane Technologists 21: 381–388.

Feng, S., Z. Luo, Y. Zhang, Z. Zhong, and B. Lu. 2014. Phytochemical contents and antioxidant capacities of different parts of two sugarcane (Saccharum officinarum L.) cultivars. Food Chemistry 151: 452–458.

Irmak, S., N.T. Dunford, and J. Milligan. 2006. Policosanol contents of beeswax, sugar cane and wheat extracts. Food Chemistry 95: 312–318.

Jaffé, W.R. 2012. Health effects of non-centrifugal sugar (NCS): A review. Sugar Tech 14: 85–94.

Khuenpet, K., N. Charoenjarasrerk, S. Jaijit, S. Arayapoonpong, and W. Jittanit. 2016. Investigation of suitable spray drying conditions for sugarcane juice powder production with an energy consumption study. Agriculture and Natural Resources 50: 139–145.

Mungare, T.S., H.D. Jadhav, J.P. Patil, R.R. Hasure, B.S. Jadhav, and Jaswant Singh. 2000. Clarification technique for producing quality jaggery. Cooperative Sugar 32: 283–285.

Noa, M., and R. Mas. 2005. Protective effect of policosanol on atherosclerotic plaque on aortas in monkeys. Archives of Medical Research 36: 441–447.

Nayaka, M.A.H., U.V. Sathisha, M.P. Manohar, K.B. Chandrashekar, and S.M. Dharmesh. 2009. Cytoprotective and antioxidant activity studies of jaggery sugar. Food Chemistry 115: 113–118.

Patil, J.P., U.S. Shinde, G.S. Nevkar, and J. Singh. 2005. Clarification efficiency of synthetic and herbal clarificants in quality jaggery production. Sugar Tech 7: 77–81.

Payet, B., A.S. Cheong, and J. Smadja. 2005. Assessment of antioxidant activity of cane brown sugars by ABTS and DPPH radical scavenging assays: Determination of their polyphenolic and volatile constituents. Agricultural and Food Chemistry 53: 10074–10079.

Rael, L.T., G.W. Thomas, M.L. Craun, C.G. Curtis, R. Bar-Or, and D. Bar-Or. 2004. Lipid peroxidation and the thiobarbituric acid assay: Standardization of the assay when using saturated and unsaturated fatty acids. BMB Report 37: 749–752.

Singh, D.K., L. Li, and T.D. Porter. 2006. Policosanol inhibits cholesterol synthesis in hepatoma cells by activation of AMP-kinase. Pharmacology and experimental 318: 1020–1026.

Steindl, R.J. 2010. Clarification of cane juice for fermentation. Proceedings International Society of Sugar Cane Technologists 27: 1–10.

Shittu, T.A., and M.O. Lawal. 2007. Factors affecting instant properties of powdered cocoa beverages. Food Chemistry 1: 91–98.

Xu, R.Y., Y. Niimi, and D.S. Han. 2006. Changes in endogenous abscisic acid and soluble sugars levels during dormancy-release in bulbs of Lilium rubellum. Scientia Horticulturae 111: 68–72.

Takara, K., A. Kinjyo, D. Matsui, K. Wada, Y. Nakasone, and S. Yogi. 2002. New antioxidative phenolic glycosides isolated from kokuto, non-centrifuged cane sugar. Bioscience, Biotechnology, and Biochemistry 66: 29–35.

Tang, Y., J. Min, and X. Wu. 2018. Selection of convective moisture transfer driving potential and its impacts upon porous plate air-drying characteristics. International Heat and Mass Transfer 116: 371–376.

Takahashi, M., M. Ishmael, Y. Asikin, N. Hirose, M. Mizu, T. Shikanai, H. Tamaki, and K. Wada. 2016. Composition, taste, aroma, and antioxidant activity of solidified noncentrifugal brown sugars prepared from whole stalk and separated pith of sugarcane (Saccharum officinarum L.). Journal of Food Science 81: C2647–C2655.

Verschoyle, R.E., P. Greaves, H. Cai, B. Arndt, M. Broggini, M. D’Incalci, E. Riccio, R. Doppalapeed, I.M. Kapetanovic, W.P. Stewand, and A.J. Gescher. 2006. Preliminary safety evaluation of the putative cancer chemo preventive agent tricin, a naturally occurring flavone. Cancer Chemotherapy and Pharmacology 57: 1–6.

Weerawatanakorn, M., Y. Asikin, M. Takahashi, H. Tamaki, K. Wada, C.T. Ho, and R. Chuekittisak. 2016. Physico-chemical properties, wax composition, aroma profiles, and antioxidant activity of granulated non-centrifugal sugars from sugarcane cultivars of Thailand. Food Science and Technology 53: 4084–4092.

Acknowledgements

This study was financially supported by Naresuan University and the National Research Council of Thailand for research Project Numbers R2560B031, RDG5950040, and the thesis grant for master degree student of Naresuan University, 2018. The authors also thank the NULC Writing Clinic for reviewing the language of the paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meerod, K., Weerawatanakorn, M. & Pansak, W. Impact of Sugarcane Juice Clarification on Physicochemical Properties, Some Nutraceuticals and Antioxidant Activities of Non-centrifugal Sugar. Sugar Tech 21, 471–480 (2019). https://doi.org/10.1007/s12355-018-0646-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12355-018-0646-7