Abstract

This study explores the application of 3-chloro-2-hydroxypropyl trimethyl ammonium chloride as a cationizing agent to modify viscose rayon fabric by the pad-batch method. This modification overcomes the electrostatic repulsion between negatively charged cellulose and acid dyes during dyeing, enabling dyeing without the need for electrolytes. Thus the dyeing of the cationized viscose rayon fabric is achieved with the negatively charged acid dyes without any electrolyte. The dyeing properties of unmodified and modified fabric samples with three different acid dyes (Lanasyn Orange NLI, Brillion Brill Red MF/3B 140, and Nyloson Navy NRBL 220) with the shade depths as 1%, 2%, 4%, and 6% owf by exhaust method are examined. The results indicate that modified viscose rayon fabric offers significant color yield values and improved fastness properties such as washing, light, perspiration, and rubbing. The novelty of this research lies in the ability to dye cellulosic fibers such as viscose in this case with acid dyes, while originally these dyes are typically used to color polyamide fibers.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Viscose rayon, a regenerated cellulosic fiber, is the oldest commercially available manmade fiber [1]. Its properties are more similar to the natural cellulosic fibers [2]. Upon immersion in an aqueous medium, the cellulosic fibers develop a partial negative charge on their surfaces owing to the presence of hydroxyl groups [3]. Most of the dyes used for the dyeing of cellulosic fibers are anionic in nature which causes electrostatic repulsion between the negatively charged cellulosic fibers and anionic dye molecules [4, 5]. It leads to the reduced exhaustion of the dyestuffs from the dye bath into the fiber. The electrostatic repulsion can be overcome through the addition of salt that neutralizes the negatively charged surface of the fabric and increases dye exhaustion [6, 7]. It is not usual that all the dye penetrates inside the fiber even after adding salt. The remaining dyestuffs find their way into the effluents after dyeing and washing. These effluents lead to rivers and oceans polluting the whole environment. The added salt also becomes the part of wastewater during the washing process [8,9,10].

Acid dyes are used for the dyeing of polyamide fibers such as wool, silk, and nylon [11]. They are not used to dye the cellulosic fibers because of the lack of affinity. To seek an alternative to reactive and direct dyes, the modification of cellulosic fibers can be carried out to enhance their affinity for acid dyes. Further, acid dyes are relatively cheaper, especially than reactive dyes. These dyes nearly offer full-color range with bright shades [12, 13].

The modification of cellulose to alter the affinity towards anionic dyes has been reported by many researchers in the literature [14]. Ticha et al. modified the cotton fabrics using cationic agents for enhanced dyeability using natural dyes using ultrasonic energy [15]. Acharya et al. cationized the cotton fabrics using 3-chloro-2-hydroxypropyl trimethyl ammonium chloride (CHPTAC) followed by dyeing with reactive dyes. The cationized cotton exhibited significantly higher exhaustion without the addition of any electrolyte [16]. Salt-free reactive dyeing can also be achieved by the modification of cotton through a chitosan-poly(propylene imine) dendrimer hybrid [17]. The nanospheres of poly[styrene-butyl acrylate-(p-vinylbenzyl trimethyl ammonium chloride)] are also used to cationize the cotton fabrics for enhanced color strength and dye fixation [18]. Lei and Lewis introduced the amino groups on cotton fabrics to dye without electrolytes [19]. Further, very limited studies are available regarding the modification of viscose rayon to dye with acid dyes [20].

Previous research has explored cationization methods using 3-chloro-2-hydroxypropyl trimethyl ammonium chloride for low salt to salt-free dyeing with reactive dyes on cotton and viscose [21, 22]. However, to date, no studies have examined the application of acid dyes on viscose using this method. Additionally, recent research has investigated low-salt dyeing of cotton fabric through the use of a pH-responsive cationic polymer of polyelectrolyte 2-(N, N-dimethylamino) ethyl methacrylate [23].

Despite several studies available regarding the cationization of the cotton and dyeing with different anionic dyes but the modification of viscose rayon followed by the dyeing with acid dyes has not been reported yet to the best of our knowledge. Our work has proved to enhance dye uptake or coloration yield of viscose rayon by cationization successfully. This significant improvement will lead to a sustainable dyeing process creating minimal dye in wastewater leading to zero waste discharge upon further modification and optimization. This has also been supported by statistical analysis of the results of shade depth to dye uptake.

In this research work, the modification of viscose rayon was carried out using CHPTAC to alter the negative charge and to introduce the cationic sites on the fiber. The modified viscose rayon fabric was dyed using acid dyes through the exhaust method. The dyed fabric was characterized by the color yield and also evaluated with wash fastness, perspiration fastness, rubbing fastness, and light fastness.

2 Experimental

2.1 Materials

Plain weave viscose rayon fabric (desized, scoured, and bleached) with a warp count of 58, weft count of 56, ends/inch of 84, and picks/inch of 84 were used in this experiment. The cationizing agent 3-chloro-2-hydroxypropyl trimethyl ammonium chloride with a concentration of 65% was purchased from Sigma Aldrich, USA. The acid dyes used in this experiment were Lanasyn Orange NLI, Brillion Brill Red MF/3B 140, and Nyloson Navy NRBL 220 supplied by Archroma. Sodium hydroxide, acetic acid, wetting agent, and detergent were all laboratory-grade reagents.

2.2 Modification of Viscose Rayon Fabric

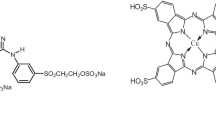

The cationization of viscose rayon fabric was conducted using the cold pad batch method. The solution consisting of 20 g/L of 3-chloro-2-hydroxypropyl trimethyl ammonium chloride (CHPTAC) with a concentration of 65% and 20 g/L of sodium hydroxide (50%) was applied to the well-prepared viscose rayon fabric keeping the wet pick-up of 100%. To minimize the hydrolysis of the cationizing agent, the alkali (NaOH) was added as the equipment was ready to use. Dropwise adding the sodium hydroxide in the solution of CHPTAC with stirring for about 15–20 min converts CHPTAC to its active epoxide form as shown in Fig. 1. Later on, this active epoxide form reacts with cellulose as shown in Fig. 2.

Then the viscose rayon fabric was padded with this solution of CHPTAC which is in its epoxide form and ready to be covalently bonded to viscose rayon cellulose during batching overnight. The fabric padded with the CHPTAC solution was wrapped onto the tube and then this tube was wrapped with the cling film making sure this is airtight to avoid the water evaporation of the solution of the fabric which might cause uneven cationization or modification of viscose rayon fabric. This fabric was stored at room temperature for 18 h. And then on the next day, it was washed five times each with minimum of 5 min under the tap water making sure the hydrolyzed or unfixed CHPTAC and other chemicals are washed away. Then the fabric was neutralised with the dilute solution of acetic acid (1 g/L) so that the pH of the fabric is about 7.2.

As a result, the viscose rayon fabric has cationic dye sites covalently bound to the cellulose. Due to these positively charged dye sites on the viscose rayon fabric, it became possible to apply the anionic acid dyes onto the viscose rayon fabric without using any electrolyte.

2.3 Dyeing of Unmodified and Modified Viscose Rayon

The dyeing of the unmodified and the modified fabric samples with the acid dyes was carried out by exhaust method using high-temperature dyeing machine at 100 °C for 60 min keeping the liquor ratio at 40:1. The pH of the dye bath was kept neutral around 7. The unmodified and the modified viscose rayon fabrics were dyed with the shade depths of 1%, 2%, 4%, and 6% using Lanasyn Orange NLI, Brillion Brill Red MF/3B 140, and Nyloson Navy NRBL 220 dyes. After the dyeing, the dyed samples were washed with the detergent 2 g/L at 70 °C for 15 min.

2.4 Analytical Testing

The dyed samples were tested according to AATCC and ISO standards. The color strength values (K/S) were determined using CIE Lab: D-65 10 standard. The ISO-CO6 D1M was used to determine the color-fastness to laundering. The color fastness to laundering, color fastness to perspiration, and color fastness to rubbing were measured using AATCC-15, AATCC-8, and AATCC-16 standards, respectively.

3 Results and Discussion

3.1 Color Strength

Color strength is the most important parameter to test the quality of the sample in terms of the depth of the dyed fabric. As shown in Fig. 3, the color yield values of cationized viscose rayon fabric samples are higher than uncationized fabric. It has been attributed to the electrostatic attraction between the surface of viscose rayon and acid dye molecules. The cationized surface of viscose rayon attracts the anionic acid dye molecules. Due to this force of attraction, a greater number of negatively charged dye molecules are attracted toward the fabric surface followed by enhanced absorption and dye uptake resulting in deeper shades and higher color yield values. It can be observed in Fig. 3 that the K/S values of modified samples dyed with Brillion Brill Red in the case of 1% shade are around 20 times higher than the unmodified samples dyed with the same dye. Similarly, the K/S values of modified samples dyed with 1% shade Lanasyn Orange LNI are 4 times while for 6% shade are 8 times higher than the unmodified samples dyed with the same dye. Likewise, the case is for Nyloson Navy NRBL 220 which can also be observed that the K/S values of the cationized sample dyed with Nyloson Navy NRBL 220 are 10 to 20 times higher than that of cationized samples dyed with Lanasyn Orange LNI and Brillion Brill Red MF/3B 140.

3.2 Wash Fastness

Tables 1, 2, and 3 show the washing fastness of uncationized and cationized fabric samples dyed with the Lanasyn Orange LNI, Brillion Brill Red MF/03 140, and Nyloson Navy NRBL 220, respectively. The results showed that the washing fastness of uncationized fabric samples dyed with acid dyes is better in case of color change than that of cationized fabric samples. This could be due to the removal of unfixed dye from the cationized dyed samples. Moreover, it can be observed that the wash fastness of uncationized and cationized samples is almost equal in the case of staining on acrylic, polyester, and acetate, but wool and nylon stripes get stained significantly, especially on nylon. This is due to the removal of surplus acid dye during the washing test which has more substantivity for wool and nylon. In addition, more staining on wool and nylon may be due to higher affinity of acid dyes to these fibers that that for cationized cotton fibers.

It is possible that the increased staining observed on wool and nylon fabrics is due to the higher affinity of acid dyes for these fibers compared to cationized cotton fibers.

3.3 Perspiration Fastness

Table 4 shows the results of color change and staining upon contact with the acid perspiration solution during the perspiration test for both uncationized and cationized fabric samples. The results show that color fastness to perspiration of uncationized samples and cationized samples is significant to excellent in case of color change while in case of staining, the cationized dyed samples have poor fastness as compared to uncationized samples. This can be attributed to the higher shade depth that can cause the removal of more dye molecules during interaction with the perspiration solution. The significant amount of dye molecules on cationized fabric leaves the substrate and stains the adjacent white fabric while uncationized fabric gives good perspiration fastness.

3.4 Rubbing Fastness

Table 5 shows the rub fastness of cationized and uncationized samples. The results show that dry rub fastness of both cationized and uncationized fabric samples dyed with Lanasyn Orange NLI, Brillion Brill Red MF/3B 140, and Nyloson Navy NRBL 220 is good to excellent. The acid dyes usually do not have an affinity towards cellulosic fibers so apparently, the acid dye molecules would not retain or stay onto the viscose rayon fabric. So there is hardly any dye or very little staining of acid dye molecules onto the fabric. As a result, the dye hardly comes off in the case of dry rubbing while during wet rubbing very little staining has been noticed in the case of deep shades. In Table 5, it has been found that the rubs off from the cationized dyed cotton with shade depths of 4% and 6% of.

3.5 Light Fastness

Table 6 shows the light fatness of uncationized and cationized fabric samples. The results show that the light fastness of uncationized samples is better than that of cationized samples. This is so because of the pale shade on uncationized samples and a darker shade on cationized samples. As there is a little number of dye molecules on uncationized fabric, the effect of light on the lighter shade will be less as compared to the darker shades exhibiting relatively less fastness to light of the cationized fabric samples. The light fastness of dyed samples depends on the dye structure and resonance in the dye molecules. The difference in the light fastness can be due to the shade depth. Also, the cationic agent generally get yellowed on exposure to light, thereby reducing the overall light fastness of dyed fabrics.

It is worth noting that cationic agents can be susceptible to yellowing upon exposure to light, potentially leading to decreased light fastness of dyed fabrics. The analysis of variance of uncationized and cationized fabric dyed with Lanasyn Orange NLI, Brillion Brill Red MF/3B 140 and Nyloson Navy NRBL 220 supplied by Archroma. and their regression analysis factors are shown in Tables 7, 8, 9, 10, 11 and 12 with odd numbered tables being uuncationized samples and even number tables with cationed samples respectively.

3.5.1 Regression Analysis of Color Strength of Uncationized and Cationized Dyed Samples

Study of regression analysis of color strength of all 6 shades (Dyed samples 1–6%) for uncationized and catinized samples of each Lanasyn Orange NLI, Brillion Brill Red MF/3B 140, and Nyloson Navy NRBL 220 was evaluated. Figure 4 is given showing regression curves in between shade percent versus color strength values. The cationized samples clearly shown significantly improved in color strength after cationization. The highest improvement in color strength of samples dyed with Nyloson Navy NRBL 220 is observed while Brillion Brill Red MF/3B 140 shows the second highest improvement in color strength values. The lowest value of color strength improvement was found in Lanasyn Orange NLI. This could be because of different chemistry of dyes as well as because of absorbance of light waves at different wave lengths.

3.5.2 Regression Analysis of Color Strength: Un-cat. (Lanasyn Org LNI) Versus Shade

The regression calculations of the above samples have been incorporated depicting the best fitting of the regression model. The R-Sq value of each model represents the adequacy of the model. In our case, the highest R-Sq value was found for Lanasyn Org LNI uncationized while that of cationed gave a little lesser value. This means the fixation of dye has been found with the same amount from (1–6)% shade.

The regression equation of uncationized fabric dyed with Lanasyn Org LNI is given below:

or

The value of S is 0.0479213, while that of R-Sq is 99.7% and the R-Sq (adj) = 99.6%.

Where DF is the degree of freedom, SS is the sum of squares, MS is the mean square, F is the variation between sample means/variation within the samples, and P is the probability value.

3.5.3 Regression Analysis of Color Strength: Cat. (Lanasyn Org LNI) versus Shade

The regression equation is

The R-Sq value of Brillion Brill Red MF/3B 140 for uncationized fabric was found little lesser than for cationized one. However, the values remain between 82.5 and 83.9%. This shows the fixation is not as much stronger as that in the previous case. Thus the wastage of dye in a dye bath is prominent.

3.5.4 Regression Analysis of Color Strength: Un-cat. (BBR Red MF/3B140) Versus Shade

The regression equation is

3.5.5 Regression Analysis of Color Strength: Cat. (BBR MF/3B140) Versus Shade

The regression equation is

The R-Sq value of Brillion Brill Red MF/3B 140 for cationized fabric was found little lesser than for uncationized one. However, the values remain between 87.5 and 89.2%. This shows the fixation is much better than the red-dyed samples. Thus the wastage of dye in the dye bath is considerable.

3.5.6 Regression Analysis of Color Strength: Un-cat. (Nyloson Navy220) Versus Shade

The regression equation is

3.5.7 Regression Analysis of Color Strength: Cat. (Nyloson Navy220) Versus Shade

The regression equation is

Table 13 given below shows observed and expected model-generated values. The values show minimum differences in observed and expected models. Furthermore, the values are predicted for 8% and 10% shades which can be further extended practically if needed.

4 Conclusions

The viscose rayon fabric is modified with CHPTAC to provide cationic dye sites which can be dyed with the anionic acid dyes without using any electrolyte. The environment-friendly dyeing process can be carried out for the dyeing of cellulosic fibers with acid dyes using this technique. It is diversified for the coloration of cellulosic fibers such as viscose rayon to be dyed with acid dyes by chemically modifying with cationizing agent without adding the auxiliaries such as electrolytes or alkali which is an additional polluting load for the dye effluents.

Chemical modification of cellulose fibers, such as viscose rayon, with cationizing agents offers a means of achieving effective coloration with acid dyes, without the need for additional auxiliaries such as electrolytes or alkalis. This approach offers the advantage of reducing the overall polluting load of dye effluents.

The color yield, rub fastness, washing fastness, perspiration fastness, and light fastness properties are evaluated for both modified and unmodified viscose rayon fabrics. The washing fastness, rub fastness, perspiration fastness, and light fastness properties of the modified fabric are better than that of unmodified fabric because of low color yield. This is so because the acid dyes have a very low affinity towards the cellulosic fibers. However, it is found that the color yield of modified fabric is far better than unmodified fabric due to ionic attraction between the positively charged fabric and anionic dye molecule. This shows that the maximum exhaustion of the acid dyes can be achieved by cationizing the viscose rayon fabric. Regression analysis of color strength also showed improvement by model fitting for cationzied dyed samples showing the best result for the orange shade. This is evidenced by lowest p-value of 0.001 un-cationized dyed orange shade and that of cationized p-value of 0.01.

References

A. S. Lawal, and John, A. C, IJAST, 4, 268 (2014) => It cannot be searched due to wrong citation information. Correct it

T. Shaikh, S. Chaudhari, and A. Varma, IJERGS, 2, 675 (2012) => It cannot be searched due to wrong citation information. Correct it.

A.K.R. Choudhury, AATCC J. Res. 1(3), 11 (2014)

M.F. Shahin, Int. J. Eng. Res. Appl. 5(8), 62 (2015)

P.J. Hauser, A.H. Tabba, Color. Technol. 117(5), 282 (2001)

S. Park, H. Choi, Cellul. Chem. Technol. 52, 311 (2018)

J. Ru, X. Qian, Y. Wang, Sci. Rep. 8, 13045 (2018)

U.H. Siddiqua, S. Ali, T. Hussain, H.N. Bhatti, M. Asghar, Pol. J. Environ. Stud. 26, 2215 (2017)

D.M. Lewis, K.A. McIlroy, Rev. Prog. Color. Relat. Top. 27, 5 (1997)

R.M. El-Shishtawy, S.H. Nassar, Color. Technol. 115, 118 (2002)

Z. Akhtar, S.I. Ali, M. Farooq, S. Zubair, R. Parveen, K.M. Khan, J. Chem. Soc. Pak. 40, 283 (2018)

H. Musa, A. Abdulmumini, M.O. Folashade, B. Usman, H. Abba, IOSR J. Appl. Chem. 5, 11 (2013)

E. Atherton, D.A. Downey, R.H. Peters, Text. Res. J. 25, 977 (1955)

H. Wang, D.M. Lewis, Color. Technol. 118, 159 (2002)

M. Ben Ticha, W. Haddar, N. Meksi, A. Guesmi, M.F. Mhenni, Carbohydr. Polym. 154, 287 (2016)

S. Acharya, N. Abidi, R. Rajbhandari, F. Meulewaeter, Cellulose 21, 4693 (2014)

M. Sadeghi-Kiakhani, S. Safapour, Fibers Polym. 16, 1075 (2015)

K. Fang, D. Shu, X. Liu, Y. Cai, F. An, X. Zhang, Polymers 10, 564 (2018)

X.P. Lei, D.M. Lewis, J. Soc. Dye. Colour. 106, 352 (1990)

M. Kamel, M.M. Kamel, B.M. Youssef, G.M. Shokry, J. Soc. Dye. Colour. 114, 101 (1998)

S. Zhai, Y. Li, W. Dong, H. Zhao, K. Ma, H. Zhang, H. Wang, Y. Zhao, X. Li, Z. Cai, Cellulose 29, 633 (2022)

Y. Li, S. Zhai, W. Dong, C. Yao, Z. Fan, K. Jin, H. Zhao, M. Wang, Z. Cai, Color. Technol. 138, 378 (2022)

W. Dong, M. Zhou, Y. Li, S. Zhai, K. Jin, Z. Fan, H. Zhao, W. Zou, Z. Cai, Coll. Surf. A 594, 124573 (2020)

Acknowledgements

The improvement in English language technical writing of this article is rechecked and suggested by Ms. Hina Bashir, Lecturer in English language at National Textile University Karachi Campus, Pakistan.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

We have no conflicts of interest to disclose.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rehman, A., Abid, H.A., Hassan, D. et al. Modification of Viscose Rayon Fabric with 3-Chloro-2-Hydroxypropyl Trimethyl Ammonium Chloride (CHPTAC) to Enable its Sustainable Dyeing with Acid Dyes. Fibers Polym 24, 2315–2323 (2023). https://doi.org/10.1007/s12221-023-00237-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-023-00237-1