Abstract

The present study demonstrates that the albedo (AP) and flavedo (FP) portions of Citrus maxima, are often discarded as agricultural waste that has the potential to manufacture high-quality pectin. The efficacy of green microwave aided extraction (MAE) technology for pectin extraction yield from both the portions of citrus peels was examined using a response surface technique. However, further advancement has to be made in improving the functional parameters required for MAE. The optimal conditions for increased pectin yields for albedo (YAP %) and flavedo (YFP %) were found to be solid to solvent ratio (1:15), time (95 s) and power (450 watt). The predicted values of YAP (5.35%) and YFP (3.13) were in accordance with experimental values of YAP (5.57 %) and YFP (3.09 %) with small error % i.e., 3.90 % and 1.29 % for AP and FP respectively. The AP and FP extracted at optimum conditions were compared with commercial pectin (Cp) based on physicochemical properties, color, FT-IR, FE-SEM/EDX, XRD, and particle size analysis. Experimental result shows that AP and FP were classified as high methoxy pectin due to high DE values 72.76 % and 74.98 % respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Citrus peels are the most prevalent commercial source of pectin owing to their high pectin concentration of 25-30 % in dry peel mass (Bagherian et al. 2011; Quoc et al. 2015). Pomelo, also known as "pummelo" or Citrus maxima (Burm.) Merr, is the largest citrus fruit of the Rutaceae (citrus) family, and its peels have been stated to be rich in numerous nutrients and functional compounds (Xiao et al. 2021). According to FAO (Food and Agriculture Organization of United Nations), over 9.3 million metric tonnes of pomelo are produced globally each year. The use of pomelo peels might result not only in value-added products/ingredients, but also in reduced environmental hazards (Xiao et al. 2021). Pectin, a complex polysaccharide predominantly consisting of α-1-4 d-galacturonic acid (GalA), has long been utilized as an important food additive, with a global demand of around 45,000 metric tonnes per year and a 4-5 % yearly growth rate (Jeong et al. 2013; Raji et al. 2017). This polysaccharide finds applications in the culinary, cosmetic, and pharmaceutical sectors for its thickening, stabilizing and gelling properties (Mahmud et al. 2020). According to FAO regulations, pectin should contain more than 65% GalA to be regarded "desirable" in terms of quality (Adetunji et al. 2017). The most frequent techniques of generating pectin are extraction, purification, and drying. The selection of an appropriate extraction technique is one of the most crucial variables impacting pectin quality and quantity.

The conventional hot-acidified water extraction method employed to extract pectin is tedious, laborious, and thermally hazardous. The process additionally necessitates high utilization of solvent while possesses low efficiency (Liew et al. 2016). Alternative non-conventional techniques, such as the MAE approach, also known as green extraction technology, has recently escalated to address the aforementioned constraints. MAE technique partitioned analytes from several sample matrices by combining non-ionizing microwave and heat solvent energy by ionic conduction and dipole rotation (Wang et al. 2007; Mahmud et al. 2020). During MAE, microwave radiation causes the moisture inside cells to heat and evaporate, resulting in a massive rise in pressure on the cell walls. As a result, it ruptures plant tissue and releases the targeted compounds into the surrounding solvent. Microwave interaction between pectinesterase and pectic compounds elevates pectin extraction (Kute et al. 2015).

MAE has recently been employed to extract pectin from a wide range of citrus resources, including sweet lemon peel, orange peel, and pomelo peel (Liew et al. 2016; Rahmani et al. 2019; Kute et al. 2020). MAE improves both the capillary-porous components and the water absorption capacity of the cell wall (Maran and Prakash 2015). These changes provide the possibility of increasing the extraction yield of various analytes from the plant cell wall, including pectin, cellulose, and hemicellulose (Maran and Prakash 2015). Furthermore, the energy promotes temperature rise by inducing polar molecules to vibrate, enhancing extraction yield (Rodsamran et al. 2019). When compared to conventional methods, it protects thermolabile components and efficiently extracts the target bioactive compounds from raw materials in a short period of time (Mandal et al. 2007; Karbuz and Tugrul 2021).

There is no comprehensive study on microwave aided pectin extraction from sole albedo and flavedo sections. Thus, the current study aims to accelerate the extraction processes and yield higher quality pectin from both portions of the pomelo peels while avoiding potential thermal degradation through optimization using a Box-Behnken design (BBD) with the assistance of MAE, to characterize the extracted pectin and compare its potentiality with commercial pectin.

Material and Methods

Materials

Fully grown Citrus maxima fruits were collected from the premises of the Graphic Era (Deemed to be University), Dehradun, Uttarakand. All the analysis of this study was investigated using analytical grade chemicals which were procured from Hi-Media, India. The chemicals NaOH, HCl, H2SO4, Gallic acid, Na2CO3, CuSO4, K2SO4, Boric acid, Folin–Ciocâlteu reagent etc. were purchased from local suppliers.

Sample Preparation

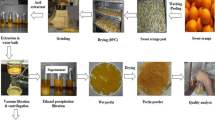

To eliminate surface contamination, the fruits were washed thrice with tap water. The flavedo and albedo sections were manually separated and dried in a hot air oven at 55 ± 5 °C for 6-8 h. Dried flavedo and albedo were grounded in mixer (Sujata, 900 W) and stored at 4°C in an airtight container.

Microwave Extraction of Pectin

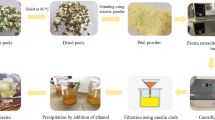

For pectin extraction, a household microwave oven (Samsung, MC28H5025VK/TL4) was employed. Flavedo and albedo powder were placed in 500 mL separate beakers and extraction process was performed according to the parameters listed in Table S1. The extraction was carried out with deionized water as the solvent, and the pH was lowered to 2.0 using HCl. After the completion of extraction process, the mixture was allowed to cool at 28 ± 2 °C. After cooling, the mixture was separated to biomass and supernatant by centrifugation (25 min at 5000 rpm), the supernatant was precipitated using 100 % (v/v) ethyl alcohol, and the purified pectin was dried in a hot air oven at 50 °C to a constant weight. After cooling the pectin was kept in an airtight container till further analysis. The flow diagram (Fig. 1) represents the methodology of microwave assisted extraction of pectin.

Experimental Methodology

The experiments were conducted using Box Behnken (BBD) model of response surface methodology (RSM) with three process parameters, each with three levels including solid to solvent ratio (1:10, 1:15 and 1:20), time (80, 95 and 110s), and microwave power (300, 450, 600 watt) (Table S1). Total 17 experiments were performed and response i. e., yield (%) was measured. The experimental data was put into the second order model equation (Eq. 1).

Where,

Y = Dependent variable

β 0, βa, βaa and βab are coefficients

Xa and Xb denotes independent variables (Where, a = 1, 2………n and b = 1, 2.…n)

Quality Characteristics of Pectin

Pectin Yield

Rodsamran and Sothornvit (2019) method was adopted to estimate the pectin yield (%) using Eq (2):

Where, Wdp = weight of dried pectin, Ws = Weight of sample

Equivalent weight (%) was calculated using Eq (3) given by Shubham et al. (2023)

Where, Ws = Weight of sample, Va= mL of alkali solution, Na = naoramilty of alkali solution

Solubility, Methoxyl Content (MeC), Anhydrouronic acid (AUA) and Degree of Esterification (DE)

The modified technique reported by Wang et al. (2019) was adopted to measure pectin solubility (%). MeC was determined by the method outlined by Zakaria et al. (2021). AUA was determined using the method provided by Mahmud et al. (2020), and DE was estimated using the method described by Zakaria et al. (2021), which included the use of MeC and AUA. Eq 4, 5 and 6 were used to calculate MeC, AUA and DE.

Where, Mw = molecular weight of MeO, Va= mL of alkali solution, Na = naoramilty of alkali solution, V1 & V2 are the volume of alkali in equivalent weight and in methoxy content respectively and 176 is the molecular weight of AUA.

Proximate Analysis

Proximate analysis i.e., moisture content, ash content, and protein content of pectin was determined according to the standard procedure AACC (2002).

Total Phenolic Content (TPC)

TPC of pectin was determined using a modified technique developed by Kumar et al. (2022). In brief, 1 mL of ethanolic pectin extract was added to 0.5 mL Folin Ciocalteu (10%), 2.5 mL Na2CO3 (20 %), and vortexed for 1 min. The absorbance was measured at 725 nm using a UV Spectrophotometer (Shimadzu 1900) after 45 min of incubation in the dark. TPC (μg GAE/mg) was calculated using the Gallic Acid standard curve.

Color Analysis

The colour index for lightness (L), hue (a), chroma (b) was determined by the colorimeter (Colour Flex EZ, Hunter's colour lab, Virginia, USA). Total colour difference (ΔΕ), brown index (BI), yellow index (YI), white index (WI), Chroma (C) and hue angle (h) of pectin were determined according to Ataei and Hojjatoleslamy (2017).

Particle Size

Particle size analyzer (ZEN1690, Malvern Instruments Ltd) was used to determine the size of pectin particles.

FT-IR

PerkinElmer FT-IR spectrophotometer was used to analyze functional groups of pectin. The KBr pellet technique previously described by Jaiswal et al. (2021) was employed. Briefly, the powdered pectin sample mixed with potassium bromide powder (KBr) and pulverized to prepare pellets at high pressure. The FT-IR analysis of extracted pectin were measured in the range of range of 500-4000cm−1.

FE-SEM Analysis

The morphology of extracted pectin was examined using a FE-SEM (Aperio 2 Thermofisher) at 10 kV operating voltage. Secondary electron (SE) imaging method was used to get the images.

X-ray Diffraction Spectra Analysis

The phase evaluations as well as structural properties of pectin like crystallinity were analyzed by the XRD (Rigaku X-ray diffractometer) pattern of pectin. In this study diffraction angle range was from 10° to 80°, and the scanning rate was 20/min.

Statistical Analysis and Model Validiation

The experimental data obtained in this study were analyzed for numerical optimization of the processing factors in terms of responses using Design Expert Software (Version 13.0.1). The analysis of variance was performed to determine the significance (p <0.05) of model terms such as coefficient of determination (R2), F-values, p-values, and lack of fit. To assess statistical significance (p < 0.05), the F value was utilized at numerous significance levels to estimate the statistical significance of all terms in the second order model Eq (1). R2 should be more than 90% for a good fit model. To validate the results, the designed model was validated with optimized parameters. The (%) error was used to determine the fit of the design model using Eq. (7).

For physicochemical analysis, the experiments were carried out in triplets and results were indicated as mean ± SD.

Results and Discussion

Model Fitting and Experimental Data Analysis

The effect of process variable i.e., solid to solvent ratio (X1), time (X2), and microwave power (X3) on YAP % and YFP % have been investigated and assessed in this study. Table 1 shows the experimental findings of pectin yield (%) for various combinations of independent variables. Design Expert was used to compute analysis of variance (Table 2) for model fitting and validation of experimental data.

Impact of Independent Variables on YAP and YFP

Based on the results, the experimental data of YAP and YFP were ranged from 0.48 to 5.7 % and 0.69 to 3.3 %, respectively over the entire range of experimental condition (Table 1). Furthermore, according to the statistical analysis, the proposed model was appropriate and significantly fit (p<0.05) fitting all statistics (R2 = 0.95; 0.96, R2adj = 0.89; 0.91) and met the intended model adequacy values in both YAP and YFP, respectively. There was also non-significant (p>0.05) lack of fit, which improved the model's reliability. To fit the empirical relationship shown by Equation (5) and (6), a second order polynomial model were attempted:

From Eq. (5) & (6), high value of coefficient has a greater effect on the YAP and YFP. In Eq. (5), interactive term (X1X2, X2X3) showed a positive effect whereas linear terms (X1, X2 and X3), interactive term (X1X3) and quadratic terms (X12, X22 and X32) showed a negative effect on YAP (Table S2). From Eq. (6), it was observed that linear terms (X1 and X3), interactive terms (X1X2 and X2X3) showed a positive effect whereas linear term (X2), interactive term (X1X3) and quadratic terms (X12, X22 and X32) had a negative impact on YFP (Table S2). According to the findings, the positive coefficient of independent factors implies that as its level increased, YAP and YFP also increased, but the negative coefficient shows that YAP and YFP declined dramatically as independent variables increased.

To visualize the impact of independent variables on YAP and YFP response surface (3D) plot (Fig. 1 a, b & c) and (Fig. 2 a, b & c) were developed. Fig 1 (a) – (c) and Fig. 2 (a) – (c) depicted the impact of solid to solvent ratio (1:15), time (95s) and power (450 watt) on YAP and YFP at central points. Attributing to Fig. 1 (a) & (b) and Fig. 2 (a) & (b), YAP and YFP increased significantly from low solid to solvent ratio (1:10) to maximum value at central point (1:15) and further decreased as solid to solvent ratio increased (1:20). The addition of solvent may effectively absorb microwave energy by albedo and flavedo matrices, leading to swelling of cells and breaking of cell walls, which is beneficial to increasing the contact surface area between both the matrix and the solvent, resulting in an increase in pectin extraction yield to solid to solvent ratio of 1:15 (Maran et al. 2015; Zakaria et al. 2023). Higher solvent concentrations, on the other hand, would reduce microwave adsorption of material since the solvent absorbed more energy. As a result, the break of the material cell wall and mass transmission may be adversely impacted, resulting in a drop in pectin yield (Li et al. 2010). Our findings were consistent with the results reported by Shams et al. (2020) and Su et al. (2019), who investigated the MAE of pectin from faba bean dried hull and orange peel and found a reduction in pectin production when the solid to solvent ratio was high.

From Fig. 2 (a) & (c) and Fig. 3 (a) & (c) it was observed that YAP and YFP increased significantly from shorter exposure time (80 s) to maximum value at central point (95 s) and further decreased as exposure time increased (110 s). The entire process explains the phenomenon of thermal accretion into the mixture as a result the absorption of microwave energy, which increased pectin dissolution into solid and solvent mixture till 95s (central point) and subsequently reduced the YAP and YFP to 110 s. This finding is in close agreement with Maran and Prakash (2015); Shams et al. (2020) and Zakaria et al. (2021) who reported that longer exposure time may cause breakdown of pectin molecules thus affecting pectin extraction rate.

Figures 2 (b) & (c) and Fig. 3 (b) & (c) depicts that YAP and YFP increased significantly from less microwave power (300 watt) to maximum value at central point (450 watt) and further decreased as the microwave power increased (600 watt). The entire process explicates the phenomenon of polar solvent penetration that can efficiently absorb microwave power causing efficient heating and thereby increasing the solvent penetration rate into solid matrix, resulting in effective transport of materials via molecular interaction with the electromagnetic field and therefore offering a rapid transfer of energy to the solid-solvent matrix, allowing the extraction of components (Yan et al. 2010; Latorre et al. 2013). Furthermore, microwave power also accelerates cell rupture by triggering a sudden temperature and internal pressure rise within the sample, promoting the destruction of the sample surface which in turn results in the exudation of pectin within the plant cells into the surrounding solvents (Zhang et al. 2008) and thus increasing the extraction yield. Intense microwave power, on the other hand, may reduce YAP and YFP due to thermal breakdown of the released pectin. The results of this study are consistent with those of Zakaria et al. (2021) and Zakaria et al. (2023), who investigated microwave aided extraction of pectin from pineapple peel and ananas comosus peel and concluded that microwave power ranging from 450 watt to 550 watt is best for pectin extraction.

Numerical Optimization and Validation of Microwave Assisted Extraction Process Conditions

Numerical optimization was performed using design expert software (ver. 13.0.1) to achieve the highest YAP and YFP. The constraints selected to the independent variables and response for optimization has been provided in Table S3. Based on statistical analysis of experimental data, independent variables that provided the desired YAP and YFP were solid to solvent ratio (1:15), time (95s) and power (450 watt) respectively. Table S3 depicts that the predicted and experimental values are in reasonable agreement with non-significant difference and low error % between the means.

The graphical representation of predicted and actual values of YAP and YFP are shown in Fig. S1 (a) & (c), and it can be easily observed that actual values of YAP and YFP are adjacently merged in predicted values of YAP and YFP. Fig. S1 (b) & (d) represents that all the experimental data selected were placed within the permissible limits (-2 to +2), showing that the generated model is a good fit for the experiments (Saikumar et al. 2023).

Physico-Chemical Properties of Extracted Pectin from AP and FP at Optimum Condition

The moisture content (MC) of pectin recovered from MAE of the CP (6.96 %) was greater than that of the AP (4.8 %), and the FP (3.53 %) (Table 3). The MC of CP, AP, and FP were within the IPPA (2002) with a permitted limit of less than 12 %. The MC of AP and FP lies within the range (5.2 % - 7.6 %) of the MC of citrus peel pectin (Devi et al. 2014). Dananjaya et al. (2020) and Raftani Amiri et al. 2023 reported 10.35 % and 9.21 % MC in purified pectin obtained from pomelo peel and pomegranate peel respectively which were higher than the moisture content of CP, AP and FP. This research demonstrated that pectin from MAE had lower water holding capacity than that extracted by traditional extraction, which is preferable for safe storage and prevents deterioration of pectin quality owing to pectinase generation as a result of microorganism growth (Ismail et al. 2012; Koh et al. 2014).

Ash content in pectin varies with different maturity index of different samples. The ash content of the extracted pectin was found to be within the permissible limit (< 10 %) suggested by IPPA (2002) i.e., CP (1.38 %) followed by FP (2.22 %) and CP (3.41 %), thereby more supportive for gel formation (Begum et al. 2014) and thus might be indicative of pre-mature samples. When the above-mentioned results were compared to other studies done on conventional extraction, the ash content of extracted pectin was much higher than that of MAE (Koh et al. 2014). The ash level of pomelo peel pectin extracted with ethanol and water was 3.56% and 4.14%, respectively (Dananjaya et al. 2020; Sotanaphun et al. 2012). Sönmez and Giray (2011) postulated that the low ash content was due to the short extraction duration of MAE for pectin extraction. In another study Raftani Amiri et al. 2023 reported 3.30 % ash content in pomegranate peel pectin which is higher than CP and FP while almost near to the ash content of AP of the present study.

Citrus pectin's emulsifying powers are dependent on protein content. Since protein is amphipathic, it may improve the emulsifying properties of citrus pectin by binding to the water-oil interface and decreasing interfacial tension (Chen et al. 2018). According to Table 3, AP has superior emulsifying properties due to its high protein content (11.36%) when compared to CP (10.6 %) and FP (5.76 %). In this study, the protein concentration of AP, CP, and FP was greater than the citrus pectin protein (3.67 %) reported by Chen et al. (2018) and eggplant peel pectin (2.53 %) reported by Kazemi et al. (2019).

Equivalent weight of pectin depends on method of extraction and raw material used (Shams et al. 2020). The highest equivalent weight was noted for AP (294.08) while lowest for FP (81.64) (Table 3). High equivalent weight represents the higher gel forming capacity of pectin. In a previous study conducted by Dananjaya et al. (2020) reported higher equivalent weight (1245.26) of purified pomelo pectin.

Pectin is classified into two types based on DE: low methoxyl pectin (DE 50%) and high methoxyl pectin (DE > 50%). Methoxy content is a significant measure in defining gel capacity and influencing pectin setting time, and it varies between 0.2 % and 12 % depending on the technique of extraction and raw material utilized (Huang et al. 2014). Pectin influences the emulsifying, texturing, and gelling qualities of foods (Mellinas et al. 2020; Spinei and Oroian 2022). The esterification level in FP is much greater than in AP and CP (Table 3). The methoxy content value in this investigation also depicted the similar results (Table 3), which might be attributable to the pre-mature samples carrying high methoxyl pectin class (> 7%). Because of the high DE value, the recovered pectin in this investigation represents under high methoxyl pectin (Table 3), which is closely linked to findings of Wang et al. (2015), Quoc et al. (2015), and Van Hung et al. (2021). These methoxy content findings were comparable to those found for mango peel (7.33%), banana peel (7.03%), pomelo peel (8.57%), lime (9.92%), passion (8.81%-9.61%), and dragon fruit pectin (2.98% to 4.34%) (Ismail et al. 2012). The methoxy content of pectin increases its spreading quality and sugar binding ability (Madhav and Pushpalatha, 2002). The value of AUA (%) determines the purity of pectin. According to AOAC (1995), the AUA% of pectin should be greater than 65 %. The AUA value for CP, AP, and FP in this study is higher than the recommended value. Our findings are consistent with prior research by Sotanaphun et al. (2012), Kanmani et al. (2014), and Dananjaya et al. (2020), who reported 74.12 %, 85.57 %, and 68.27 % AUA in pomelo peel pectin, respectively.

TPC was found to be highest in AP, followed by FP and CP (Table 3) than pectin extracted from similar peel waste using ultrasonic assisted extraction (Wang et al. 2015).

Color Analysis

Pectin colour has a significant impact on the presentation of gel formed (Kute et al. 2020). Color index of CP, AP, and FP are tabulated in Table 3. The highest lightness value was observed in CP (67.11) and lowest for FP (49.20). It was observed that CP has lighter than AP, and FP in color. The negative value of a in CP and positive values in AP, and FP indicated that CP, AP, and FP were characterized by greenness and redness respectively. The positive b value is highest for FP and lowest for CP, which represents that FP and AP shows more yellowness compared to CP which is confirmed by highest YI for FP followed by AP and CP. The highest ΔE was noted for FP and lowest for AP compared to CP. Highest WI and BI were observed in CP and FP respectively. The brown color of FP may be attributed to the presence of carotenoids (Kute et al. 2020). Among CP, AP, and FP, the highest chroma and h value was predicted in AP and FP, respectively. The comparable color propensity was reported for apple peel pectin (Zheng et al. 2021) and lime peel pectin (Rodsamran and Sothornvit 2019).

Characterization of CP, AP, and FP

FT-IR Analysis

The absorption band arises in the 3828 cm-1 and 3863 cm-1 regions for AP and CP, respectively correlates to O-H group stretching (Fig. 4). The peak depicted at 3415 cm-1 is attributed to the C-H stretching of the CH2 group (Pasandide et al. 2017). The peak emerging at 2838 cm-1 corresponds to bending vibration of O-H bond. Peak observed at 1624 cm-1, 1625 cm-1 and 1641 cm-1 for AP, FP, and CP, respectively is most likely caused by C=O stretching vibrations of the free (non-methyl-esterified) carboxyl group (Hosseini et al. 2019; Mamiru and Gonfa 2023). AP has a peak at 1053 cm-1, FP has a peak at 1064 cm-1, and 1057 cm-1 for CP confirms the presence of polysaccharide in all the pectin (Lasunon and Sengkhamparn 2022).

FE-SEM/EDX Analysis

The FE-SEM micrograph of the CP, AP and FP is depicted in the Fig. 5. The morphological analysis of the isolated pectin was done using FE-SEM micrograph analysis. The FE- SEM images of both AP and FP show flat surfaces with some roughness and wrinkles on the flat surface whereas CP has more roughness and wrinkles on the flat surface. Similar results were reported by Kazemi et al. 2020 and Raftani Amiri et al. 2023 who stated that microwave and ultrasound assisted pectin has smooth surface.

The elemental composition of CP, AP, and FP is determined by EDX analysis (Fig. 6). EDX results revealed that carbon % in CP is substantially greater than in AP and FP, but oxygen % in AP and FP is higher than in CP. Furthermore, CP has a trace of sodium, whereas AP and FP have a trace of calcium. Our findings are in reasonable agreements with Salima et al. (2022) who also reported high oxygen content in pumpkin pectin.

XRD Analysis

The XRD pattern employed to evaluate the type (crystalline or amorphous) of CP and extracted AP and FP under ideal conditions (Fig. 7). The XRD pattern of CP shows crystalline structure, whereas the AP and FP XRD spectrum suggests amorphous nature. The results of this investigation matched the XRD spectrum of sour orange peel pectin (Hosseini et al. 2019), pomelo peel pectin (Dananjaya et al. 2020), watermelon rind pectin (Mamiru and Gonfa 2023) and pomegranate peel pectin (Raftani Amiri et al. 2023).

Particle Size Analysis

Particle size is critical in food component compositions, material handling, and processing. The rate of diffusion is related to particle size (Rivadeneira et al. 2020). DLS was used to compute the average particle size of the CP, AP, and FP. Figure 8 depicts the spectra of the DLS investigation. The average particle size of AP is 0.95 nm, whereas some particles have an average particle size of 1200 nm. The particle size of the AP was found to be substantially smaller than that of the CP within the range of 8 nm, with some particles reaching a size of 85 nm. Furthermore, the size of FP was found to be around the 14 nm. The average particle size of the FP has been found to be variable.

Conclusions

Extraction of pectin from AP and FP portion of Citrus maxima using Box- Behnken design with three independent variables i.e., solid to solvent ratio, time and power were performed through green microwave extraction technology (MAE). The optimal conditions responsible for higher YAP % and YFP % were solid to solvent ratio (1:15), time (95 s) and power (450 watt). Experimental values of YAP (5.57 %) and YFP (3.09 %) were observed at optimal values. The results of physicochemical properties, color, FT-IR, FE-SEM/EDX, XRD, and particle size analysis showed that AP and FP have similar properties of commercial grade pectin. From the results it could be concluded that high quality pectin from albedo (AP) and flavedo (FP) portions of Citrus maxima can be extracted using green microwave extraction technology in short processing time.

Data availability

All the data is available in the manuscript.

References

A.A.C.C (2002) Approved Method of American Association of Cereal Chemists. Approved Methods the A.A.C.C. published by the American Association of Cereal Chemists. 13th Ed., St. Paul, Minnesota, USA

Adetunji LR, Adekunle A, Orsat V, Raghavan V (2017) Advances in the pectin production process using novel extraction techniques: A review. Food Hydrocoll 62:239–250

AOAC (1995) Official Methods of Analysis, vol. 37. 16th ed. Association of Official, Analytical Chemists, Washington. pp. 1–10

Ataei F, Hojjatoleslamy M (2017) Physicochemical and sensory characteristics of sponge cake made with olive leaf. J Food Measure Character 11(4):2259–2264

Bagherian H, Zokaee Ashtiani F, Fouladitajar A, Mohtashamy M (2011) Chemical Engineering and Processing: Process Intensification Comparisons between conventional, microwave-and ultrasound-assisted methods for extraction of pectin from grapefruit. Chem Eng Process 50:1237–1243

Begum R, Aziz MG, Uddin MB, Yusof YA (2014) Characterization of jackfruit (Artocarpus heterophyllus) waste pectin as influenced by various extraction conditions. Agric Agric Sci Procedia 2:244–251

Chen H, Qiu S, Liu Y, Zhu Q, Yin L (2018) Emulsifying properties and functional compositions of sugar beet pectins extracted under different conditions. J Dispers Sci Technol 39(4):484–490

Dananjaya SHS, Chandrarathna HPSU, Nayanaransi LAU, Edussuriya M, Dissanayake AS, Whang I, De Zoysa M (2020) Pectin purified from pomelo (Citrus maxima) peel as a natural hatching agent for fish embryos. Aquac Res 51(8):3109–3118

Devi EW, Shukla RN, Bala KL, Kumar A, Mishra AA, Yadav KC (2014) Extraction of pectin from citrus fruit peel and its utilization in preparation of jelly. Intl J Eng Res Technol 3(5):1925–1932

Hosseini SS, Khodaiyan F, Kazemi M, Najari Z (2019) Optimization and characterization of pectin extracted from sour orange peel by ultrasound assisted method. Int J Biol Macromol 125:621–629

Huang R, Cao M, Guo H, Qi W, Su R, He Z (2014) Enhanced ethanol production from pomelo peel waste by integrated hydrothermal treatment, multienzyme formulation, and fed-batch operation. J Agric Food Chem 62:4643–4651. https://doi.org/10.1021/jf405172a

Ismail NSM, Ramli N, Hani NM, Meon Z (2012) Extraction and characterization of pectin from dragon fruit (Hylocereus polyrhizus) using various extraction conditions. Sains Malaysiana 41(1):41–45

Jaiswal KK, Kumar V, Verma R, Verma M, Kumar A, Vlaskin MS, Kim H (2021) Graphitic bio-char and bio-oil synthesis via hydrothermal carbonization-co-liquefaction of microalgae biomass (oiled/de-oiled) and multiple heavy metals remediations. J Hazard Mater 409:124987

Jeong HS, Kim HY, Ahn SH, Oh SC, Yang I, Choi IG (2013) Effects of combination processes on the extraction of pectins from rapeseed cake (Brassica napus L.). Food Chem 139:9–15

Kanmani P, Dhivya E, Aravind J, Kumaresan K (2014) Extraction and analysis of pectin from Citrus peels: Augmenting the yield from Citrus limon using statistical experimental design. Iranica J Energy Environ 5(3):303–312. https://doi.org/10.5829/idosi.ijee.2014.05.03.10

Karbuz P, Tugrul N (2021) Microwave and ultrasound assisted extraction of pectin from various fruits peel. J Food Sci Technol 58:641–650

Kazemi M, Khodaiyan F, Hosseini SS (2019) Utilization of food processing wastes of eggplant as a high potential pectin source and characterization of extracted pectin. Food Chem 294:339–346

Kazemi M, Khodaiyan F, Labbafi M, Hosseini SS (2020) Ultrasonic and heating extraction of pistachio by-product pectin: physicochemical, structural characterization and functional measurement. Food Measure 14:679–693

Koh PC, Leong CM, Noranizan MA (2014) Microwave-assisted extraction of pectin from jackfruit rinds using different power levels. Int Food Res J 21(5):2091

Kumar S, Krishali V, Purohit P, Saini I, Kumar V, Singh S, Upadhyay S, Joshi HC, Wilson I, Singh Tomar M (2022) Physicochemical properties, nutritional and sensory quality of low-fat Ashwagandha and Giloy-fortified sponge cakes during storage. J Food Process Preserv 46(2):e16280. https://doi.org/10.1111/jfpp.16280

Kute AB, Mohapatra D, Babu B, Sawant BP (2015) Optimization of microwave assisted extraction of pectin from orange peel using response surface methodology. J Food Res Technol 3(2):62–70

Kute AB, Mohapatra D, Kotwaliwale N, Giri SK, Sawant BP (2020) Characterization of pectin extracted from orange peel powder using microwave-assisted and acid extraction methods. Agric Res 9:241–248

Lasunon P, Sengkhamparn N (2022) Effect of ultrasound-assisted, microwave-assisted and ultrasound-microwave-assisted extraction on pectin extraction from industrial tomato waste. Molecules. 27(4):1157

Latorre ME, de Escalada Plá MF, Rojas AM, Gerschenson LN (2013) Blanching of red beet (Beta vulgaris L. var. conditiva) root. Effect of hot water or microwave radiation on cell wall characteristics. LWT-Food Sci Technol 50(1):193–203

Li J, Zu YG, Fu YJ, Yang YC, Li SM, Li ZN, Wink M (2010) Optimization of microwave-assisted extraction of triterpene saponins from defatted residue of yellow horn (Xanthoceras sorbifolia Bunge.) kernel and evaluation of its antioxidant activity. Innovative Food Sci Emerg Technol 11(4):637–643

Liew SQ, Ngoh GC, Yusoff R, Teoh WH (2016) Sequential ultrasound-microwave assisted acid extraction (UMAE) of pectin from pomelo peels. Int J Biol Macromol 93:426–435

Mahmud MM, Belal M, Ahmed S, Hoque MM, Zzaman W (2020) Microwave-assisted extraction and characterization of pectin from citrus fruit wastes for commercial application. 10.26656/fr.2017.5(5).52

Mamiru D, Gonfa G (2023) Extraction and characterization of pectin from watermelon rind using acetic acid. Heliyon. 9(2):e13525

Mandal V, Mohan Y, Hemalatha S (2007) Microwave assisted extraction – an innovative and promising extraction tool for medicinal plant research. Pharmacogn Rev 1(1):7–18

Maran JP, Prakash KA (2015) Process variables influence on microwave assisted extraction of pectin from waste Carcia papaya L. peel. Int J Biol Macromol 73:202–206

Maran JP, Swathi K, Jeevitha P, Jayalakshmi J, Ashvini G (2015) Microwave-assisted extraction of pectic polysaccharide from waste mango peel. Carbohydr Polym 123:67–71

Mellinas C, Ramos M, Jiménez A, Garrigós MC (2020) Recent trends in the use of pectin from agro-waste residues as a naturalbased biopolymer for food packaging applications. Materials (Basel) 13:673

Pasandide B, Khodaiyan F, Mousavi ZE, Hosseini SS (2017) Optimization of aqueous pectin extraction from Citrus medica peel. Carbohydr Polym 178:27–33

Quoc LPT, Huyen VTN, Hue LTN, Hue NTH, Thuan NHD, Tam NTT et al (2015) Extraction of pectin from pomelo (Citrus maxima) peels with the assistance of microwave and tartaric acid. Int Food Res J 22(4):1637–1641

Raftani Amiri Z, Gholizadeh A, Farahmandfar R, Gorjian H (2023) Characterization of aqueous extracted pectin from pomegranate peel at optimized condition using response surface optimization. Food Measure. 1-15

Rahmani Z, Khodaiyan F, Kazemi M, Sharifan A (2019) Optimization of microwave-assisted extraction and structural characterization of pectin from sweet lemon peel. Intl J Biol Macromol

Raji Z, Khodaiyan F, Rezaei K, Kiani H, Hosseini SS (2017) Extraction optimization and physicochemical properties of pectin from melon peel. Int J Biol Macromol 98:709–716

Rivadeneira JP, Wu T, Ybanez Q, Dorado AA, Migo VP, Nayve FRP, Castillo-Israel KAT (2020) Microwave-assisted extraction of pectin from “Saba” banana peel waste: Optimization, characterization, and rheology study. Intl J Food Sci. 2020

Rodsamran P, Sothornvit R (2019) Microwave heating extraction of pectin from lime peel: Characterization and properties compared with the conventional heating method. Food Chem 278:364–372

Saikumar A, Singh A, Kaur K, Kumar N, Sharma S, Dobhal A, Kumar S (2023) Numerical optimization of hypochlorous acid (HOCl) treatment parameters and its effect on postharvest quality characteristics of tomatoes. J Agric Food Res 14:100762

Salima B, Seloua D, Djamel F, Samir M (2022) Structure of pumpkin pectin and its effect on its technological properties. Appl Rheol 32(1):34–55. https://doi.org/10.1515/arh-2022-0124

Shams R, Masih D, Ashraf G, Dar AH, Rizvi QH (2020) Microwave assisted extraction of pectin from dried hull of faba bean. J Postharvest Technol 8(1):13–22

Shubham K, Shubham B, Hritika B, Ali SM, Hassan MN, Arya (2023) Pectin extraction from orange peels with microwave assisted extraction technique & its characterization. Pharma Innov J 2023 12(2):2861–2867

Sönmez O, Giray ES (2011) Producing ashless coal extracts by microwave irradiation. Fuel 90(6):2125–2131

Sotanaphun U, Chaidedgumjorn A, Kitcharoen N, Satiraphan M, Asavapichayont P, Sriamornsak P, Silpakorn U (2012) Preparation of Pectin from Fruit Peel of Citrus maxima. Sci Technol J 6:42–48. https://doi.org/10.14456/sustj.2012.3

Spinei M, Oroian M (2022) Microwave-assisted extraction of pectin from grape pomace. Sci Rep 12(1):12722

Su DL, Li PJ, Quek SY, Huang ZQ, Yuan YJ, Li GY, Shan Y (2019) Efficient extraction and characterization of pectin from orange peel by a combined surfactant and microwave assisted process. Food Chem 286:1–7

Van Hung P, Anh MNT, Hoa PN, Phi NTL (2021) Extraction and characterization of high methoxyl pectin from Citrus maxima peels using different organic acids. J Food Measure Character 15:1541–1546

Wang RS, He XH, Lin H, Liang RH, Liang L, Chen J, Liu CM (2019) Solubility difference between pectic fractions from creeping fig seeds. Polymers 11(1):159

Wang S et al (2007) Optimization of pectin extraction assisted by microwave from apple pomace using response surface methodology. J Food Eng 78:693–700

Wang W, Ma X, Xu Y, Cao Y, Jiang Z, Ding T, Liu D (2015) Ultrasound-assisted heating extraction of pectin from grapefruit peel: Optimization and comparison with the conventional method. Food Chem 178:106–114

Xiao L, Ye F, Zhou Y, Zhao G (2021) Utilization of pomelo peels to manufacture value-added products: A review. Food Chem 351:129247

Yan M-M, Liu W, Fu Y-J, Zu Y-G, Chen C-Y, Luo M (2010) Optimisation of the microwave-assisted extraction process for four main astragalosides in Radix Astragali. Food Chem 119:1663–1670

Zakaria NA, Abd Rahman NH, Rahman RA, Zaidel DNA, Hasham R, Illias RM, Ahmad RAA (2023) Extraction optimization and physicochemical properties of high methoxyl pectin from Ananas comosus peel using microwave-assisted approach. Journal of Food Measurement and Characterization. 1-14

Zakaria NA, Rahman RA, Zaidel DNA, Dailin DJ, Jusoh M (2021) Microwave-assisted extraction of pectin from pineapple peel. Malays J Fundam Appl Sci 17(1):33–38

Zhang B, Yang R, Liu CZ (2008) Microwave-assisted extraction of chlorogenic acid from flower buds of Lonicera japonica Thunb. Sep Purif Technol 62:480–483

Zheng J, Li H, Wang D, Li R, Wang S, Ling B (2021) Radio frequency assisted extraction of pectin from apple pomace: Process optimization and comparison with microwave and conventional methods. Food Hydrocoll 121:107031

Acknowledgements

The authors are grateful to the Department of Food Science & Technology, Graphic Era (Deemed-to-be) University, Dehradun, Uttarakhand, India, for providing the necessary infrastructure for this research work. The authors acknowledge the generous support from the researchers supporting project number (RSPD2023R980) King Saud University, Riyadh, Saudi Arabia. This paper has been supported by the RUDN University scientific projects grant system, project No. 2027042000.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Investigation and project administration was carried out by S.A., P.K. and A.H. Conceptualization and Supervision was carried out by S.K. and V. K. The first draft of the manuscript was written by S. K. Methodology and analysis by W.A., and S.A. Review and editing were performed by A. D., R.M., B.B. and S. U. and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethical statement

Not Applicable

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

ESM 1

(DOCX 101 kb)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Arora, S., Kataria, P., Ahmad, W. et al. Microwave Assisted Green Extraction of Pectin from Citrus maxima Albedo and Flavedo, Process Optimization, Characterisation and Comparison with Commercial Pectin. Food Anal. Methods 17, 105–118 (2024). https://doi.org/10.1007/s12161-023-02547-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-023-02547-9