Abstract

Pectin extracted from dried orange peel powder by microwave extraction method (MAE) and conventional acid extraction method (CE) were compared based on their yield, color, solubility in cold and hot water, equivalent weight, degree of esterification (DE), methoxyl percentage, and gelling properties. The raw orange peel powder of 98.95 µm size had moisture 8.33%, carbohydrate 80.06%, crude protein 5.6%, fat 2.3%, ash 3.62%, L* value 66.26 ± 0.05, a* value 11.89 ± 0.02, and b* value 60.56 ± 0.15, and poor flowability. The pectin yield in MAE (15.79%) was significantly higher than CE (8.78%); time taken for processing operation was 90 s and 15 min in MAE and CE, respectively. The equivalent weight of MAE and CE pectin were 485 mg/mL and 381 mg/mL, respectively. DE and methoxyl content of MAE and CE pectin were 42.85%, 35.48%, and 6.99% and 5.75%, respectively. The CIE L*, a* and b*, values of the MAE and CE pectin powders were 41.27, 7.11, and 31.41, and 37.54, 10.96, 24.34, respectively. Complex viscosity, storage modulus, and loss modulus of CE pectin was higher than that of MAE but were not significantly different (p > 0.05). The pectin gel obtained through both the methods showed a good stability.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Citrus fruits are widely grown throughout the tropical and subtropical climates and oranges (Citrus sinensis) accounts for about 65% of the total citrus fruit production [26]. The world production of oranges was 73,187,570 tonnes, and Brazil ranked first, followed by mainland China, and India in the year 2016 [7]. In India, annual production of citrus fruits from 1996 to 2016 has seen a substantial growth from 2,041,300 tonnes to 7,503,000 tonnes [7]. Oranges are not only consumed as a table fruit, but also various value-added products are developed from it. Indian fruit-processing industry mainly focuses on producing juices from the pulpy mass of the fruit, thus generating a great amount of wastes. The wastes generated from citrus processing industries are pomace, seeds, and peels. These fruit wastes are highly perishable and pose a problem to the processing industries and pollution monitoring agencies, being rich in antioxidants and other nutrients. Moreover, some of the components of orange peel have antiseptic [34, 35] and anti-insecticidal [22] properties, which makes them difficult to be biodegraded.

The orange waste contains 16.9 g 100 g−1 soluble sugar, 9.21 g 100 g−1 cellulose, 10.5 g 100 g−1 hemicelluloses, and 42.5 g 100 g−1 pectin [30]. Valuable by-products such as pectins, pigments, essential oil, and dietary fiber can be extracted from the orange peels. Orange peel, which constitutes approximately 40–45% of the total bulk of the processed citrus fruit, is a good source for the extraction of pectin [37]. It contains about 25–30% (db) pectin [1]. Utilization of orange peel through extraction of valuable compounds like pectin can increase the economic value of the orange peel and reduce the cost of waste disposal.

Pectin has extensive use in the food industry as a thickener, texturizer, emulsifier, stabilizer, gelling agent, fat replacers in spreads, salad dressings, ice cream, and emulsified meat products [25]. The quality of pectin depends on the adopted extraction method. Pectin is obtained commercially by direct boiling of the acidified pectin solution [23]. However, this extraction method is a time-consuming process, generally required over 1 h. Moreover, the pectin extracted using traditional method is not only poor in terms of quantity but also in quality due to the prolonged exposure of pectin to the heat during extraction, which leads to pectin degradation and associated undesirable changes in physicochemical and functional properties [25]. Several extraction methods like enzymatic [6, 32], ultrasound [4], ultra-high pressure treatment [11], ultra-high electric field treatment [19], and microwave-assisted extraction (MAE) [37, 38] processes have been developed to increase the extraction efficiency. Extraction of pectin from different sources using MAE method had been investigated thoroughly. MAE that works on the principle of dielectric heating is faster and thus it is a energy-saving process and also causes no environmental pollution [8, 20]. Since conventional extraction of pectin is time-consuming, it is essential to investigate alternate potential extraction method such as MAE method in obtaining higher yield and quality pectin.

Considering the merits of MAE method, the investigation was undertaken to characterize the pectin extracted from orange peel powder using MAE and Acid extraction methods.

Materials and Methods

Orange (Citrus sinensis, c.v. Nagpur mandarin) fruits were obtained from local fruit market Bhopal, India. The peels were removed, coarsely chopped (4–5 mm) and dried in a tray dryer (NSW, India) at 50 °C for 5 h [9]. The dried peels were ground in a domestic mixture grinder for 15 s to obtain a powdered sample. The powder was stored in aluminum-laminated pouches in a refrigerated condition.

Characteristics of Orange Peel

Moisture Content

Moisture content of the orange peel was determined by standard AOAC method 2001.12 [3] method using hot air oven (Jyothi Scientific Industries, Gowalior, M.P India), by keeping 3 g sample at 105 ± 1 °C for 3 h till constant weight was achieved. The sample was then kept in a desiccator for cooling down, after which the final weight was noted and the moisture content was determined gravimetrically.

Fat Content

Fat content was determined by the ether extraction method using AOAC method no. 945.44, using Soxhlet’s apparatus (SCS-8, Pelican equipment, India) by taking 5 g dry orange peel powder. The extract was then dried on a water bath and then at 100 °C for 1 h in a hot air oven, cooled, and weighed. The extract was filtered to remove residues from the fat sample. Percent fat content in the sample was calculated using the following formula [2]:

Protein Content

The protein content was determined following AOAC method no 991.20 by Micro-Kjeldahl’s apparatus (Kel plus, Pelican, India). About 0.2 g defatted orange peel powder was digested in a mixture of catalyst (1 g) and 5 mL each of H2O2 and conc. H2SO4. The digested sample was allowed to boil and distillate of ammonia liberated in boric acid was collected. The distillate was titrated with hydrochloric acid until blue color disappeared. Protein content was calculated using the following formula [2].

where S = mL of HCl required for sample titration, B = mL of HCl required for blank titration, N = Normality of HCl (0.02 N)

Ash Content

Ash content was determined by carbonizing the 2 g sample at 550 for 6 h in the muffle furnace following AOAC method no 923.03 (ATE/Muffla, India). The ash content was calculated using following formula [2]

Carbohydrate Content

Carbohydrates were calculated by difference method as follows [2] as

Flow Properties

The bulk density of orange peel powder was determined by weighing sample filled in a 10-mL volumetric flask and expressed as the weight per volume of sample. Tap bulk density of the orange peel powder was determined by filling, the graduated cylinder with orange peel powder and gently tapping it for 100 times; the final volume was noted and tap bulk density was calculated as the final weight divided by the volume of the sample.

Carr’s index, which is an indication of flowability of the powdered sample, was calculated as per the following equation [32]:

Hausner ratio is also used to define the flow behavior of the powdered material. It was determined using the following formula [11]:

where Vo = unsettled apparent volume, Vf = final tapped volume

Particle Size

The particle size of orange peel powder was determined using a particle size analyzer (Mastersizer 2000, Malvern Instruments Ltd., UK). About 2–3 g dry powder was used for the experimentation. The volume mean diameter of the powdered samples was noted down as obtained from a factory installed algorithm. All the experiments were done six times, and the average value was considered for analysis.

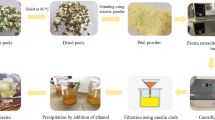

Microwave-Assisted Extraction of Pectin from Orange Peel

Extraction of pectin was performed according to the method described by [37] with the help of a domestic microwave equipment (CE11111TL Samsung, Thailand), at working frequency 2450 MHz and maximum power output 900 W, with adjustable microwave power and irradiation time. The pectin powder obtained through the optimized processing conditions obtained from our earlier studies [23] was considered for characterization. A mixture of 5 g of dried orange peel powder and 100 mL distilled water (pH 1.5) was exposed to microwave heating at 540 W for 90 s. The sample was then cooled down to room temperature and centrifuged in a refrigerated centrifuge (RSMI G-12 plus, India) at 4 °C, 8000 rpm for 10 min [37]. The insoluble residue was recovered, and the supernatant was precipitated with an equal volume of 95% (v/v) ethanol. The coagulated pectin mass was three times washed with 95% (v/v) ethanol to remove the mono and disaccharides [27].

The coagulated pectin was then subjected to freeze drying in a laboratory freeze dryer (OD-12, Delvac pumps, Pvt Ltd, Chennai, India) at − 40 °C for 24 h, till constant weight was achieved. Samples were then weighed and the pectin yield was calculated. The dry pectin was milled in an analytical mill and packed in aluminum-laminated pouches and sealed. The sealed packs were stored at 6 °C in a refrigerator until further analysis.

Extraction of Pectin from Orange Peel by Conventional Method

The pectin yield (PY) determined using a method by Li et al. [24]. In a 100-mL Pyrex beaker, 5 g of dried orange peel powder and 100 mL acidified water of pH 1.5 was taken. The pH was adjusted to 1.5 by the addition of 1 M HNO3. The solution was then boiled in a constant temperature water bath (TH-6000, Serelogical water bath, India) at 80 °C for 10 min. The mass was then centrifuged at 4 °C, 8000 rpm for 10 min; supernatant coagulated with ethanol, freeze-dried, and stored in sealed aluminum-laminated pouches till further experimentation. The pectin yield (PY) was calculated from the following equation proposed by Li et al. [24].

where mo (g) is the weight of dried pectin, m (g) is the weight of dried orange peel powder.

Characterization of Pectin Powder

Equivalent Weight

Equivalent weight of the pectin was determined by method by Liew et al. [25]. Pectin sample (0.5 g) was weighed into a 250-mL conical flask and 5 mL ethanol was added to it followed by addition of 1.0 g NaCl, 100 mL distilled water and few drops of phenol red indicator. The dissolved solution was slowly titrated (to avoid possible de-esterification) with 0.1 M NaOH to a pink color at the endpoint.

Equivalent weight was calculated using the equation below [25].

Degree of Esterification (DE)

The degree of esterification, DE, is defined as the ratio of esterified galacturonic acid groups to the galacturonic acid groups present and was determined by a titration method by Liew et al. [25]. About 0.2 g of dried pectin sample was soaked in 2 mL ethanol, and the mass was then dissolved in 20 mL distilled water and placed in an automatic shaking water bath at 45 °C until the pectin dissolved completely. The solution was titrated with 0.1 N NaOH after addition of three drops of phenolphthalein, till some pink color appeared. The number of free carboxy group was calculated from the volume of 0.1 N NaOH solution spent for initial titration. Then, 10 mL of 0.1 N NaOH was added to neutralize the polygalacturonic acid. The sample was plugged with a stopper and shaken vigorously, then allowed to stand at room temperature for 2 h to de-esterify pectin. Ten milliliters of 0.1 N HCl was added to neutralized NaOH and the sample was shaken until its pink color disappeared. Three drops of phenolphthalein were added into the sample and the sample was further titrated with 0.1 N NaOH. The volume of titration was recorded as final titration volume once some pink color appeared. The number of the esterified carboxy group was calculated from the volume of 0.1 N NaOH solution spent for final titration.

The DE was calculated from the following formula [25]:

Methoxyl Percentage (MeO%)

The methoxyl percentage (MeO%) was determined according to the procedure of Zouambia et al. [39]. Since the amount of methoxyl in 100% of esterified pectin is 16.32%, the methoxyl percentage was calculated from the following equation.

Solubility of Dry Pectin in Cold and Hot Water

The solubility of the pectin powder was determined by following the method of Fishman et al. [8]. The cold water solubility of the pectin powder was determined by mixing 0.25 g pectin with 10 mL 95% ethanol and 50 mL distilled water. The mixture was vigorously shaken, and any amount of insoluble material in the solution was weighed to find out the solubility. The suspension was then heated at 85–95 °C for 15 min to find out the presence of any insoluble material.

Gelling Properties

The flow behavior of microwave-treated and conventionally obtained pectin solution (5% w/w) was investigated by referring the method of Singthong et al. [33]. For the rheological tests, 5% (w/w) pectin solution was prepared by mixing 0.5 g pectin with 10 mL distilled water and heated at 80 °C in a water bath for 15 min. The solution was cooled down before conducting the rheological tests in a rheometer (Anton Paar, Physica MCR 51, Germany), under plate–plate configuration, using 50-mm probe and 1-mm gap. In frequency sweep test, viscoelasticity moduli (storage modulus G′—elastic components, loss modulus G′′—viscous component, η—complex viscosity) were determined at a constant strain of 2% and linearly ramping, angular frequencies between 0.1 and 20 Hz. All the samples were maintained at 25 °C for this test by using a built-in Peltier temperature control (Accuracy ± 0.1 °C). The loss angle (G′/G′′) was calculated. Average of five replications was considered for the analysis.

Color Measurement

The hunter Lab color values of the orange peel powder and pectin obtained from MAE and acid extraction methods were estimated using CIE color Lab (Lab scan). The instrument was calibrated against white and black tiles. The parameter a takes positive values for reddish color and negative values for the greenish ones, whereas b takes positive values for yellowish color and negative values for the bluish ones. L is an approximate measurement of luminosity, which is the property according to which each color can be considered as equivalent to a member of the grayscale, between black and white [ ].

Results and Discussion

Characteristics of Orange Peel Powder

Chemical Composition

The dried orange peel powder had moisture 8.33 ± 1.14% (wb), carbohydrate 80.06 ± 0.9%, crude protein 5.6 ± 0.16%, fat content 2.3 ± 0.15%, and ash 3.62 ± 0.01% on dry basis. The results were similar to those reported by Kar and Arslan [17], for dried orange peel powder having 2.68% ash, 6.08% crude protein, 17.60% crude fiber, and 71.40% carbohydrate. Hosni et al. [12] reported that the oil content of the different varieties of sweet oranges varied from 1.49 to 2.31%. The result obtained in this study corroborates the earlier reports.

Particle Size

The particle size of orange peel powder was found to be 98.95 ± 5.46 µm. Pectin yield is significantly affected by the particle size. Schemin et al. [31] reported that pectin yield from apple pomace was significantly higher with the use of flour having a particle size less than 80 µm raw materials (9.73%); however, when the extraction was made from the pomace having particle size ranging from 1 mm to 106 µm, the yield was 6.13%. As particle size reduces, the specific surface area of the powdered particles increases. This provides more area to be bonded with acidified water during the heat treatment. It was postulated that since protopectin is more available in small particles than in large ones, when extraction is made from the powder of smaller particle size, the pectin yield would be higher. Therefore, in the current investigation, dried orange peels were made to powder below 100 µm size, so as to have a better recovery.

Color

The color of dried orange peel powder as denoted by the hunter Lab values were observed to be 66.26 ± 0.05, 11.89 ± 0.02, and 60.56 ± 0.15, respectively. The high and positive value of b indicates the orange peel powder had predominately yellow color. Color of pectin was important as it affects the appearance of the gel produced. The lighter color having little effect on the final appearance of a food product would be preferred.

Flow Properties

The bulk density of orange peel powder was 0.391 ± 0.012 (g/cm3) and tap bulk density of orange peel powder was 0.559 ± 0.010 (g/cm3). The tap density of a material can be used to predict both its flow properties and its compressibility. The Carr’s Index and Haustner ratio as derived from the bulk density and tap bulk density shows that the powder has poor flow property. The Carr’s Index of orange peel powder was 37.31 ± 1.24 (%). Carr Index is used as an index of the ability of the powder to flow. In a free-flowing powder, the bulk density and tapped density would be close in value; therefore, the Carr index would be small. On the other hand, in a poor-flowing powder where there are greater interparticle interactions, the difference between the bulk and tapped density would be greater; therefore, the Carr index would be larger. A Carr index greater than 25 is considered to be an indication of poor flowability, and below 15, of good flowability [5]. The Hausner ratio of orange peel powder was 1.60 ± 0.02. A Hausner ratio greater than 1.25 is considered to be an indication of poor flowability [10, 13]. The poor flowability of the orange peel powder may be due to the presence of oil and moisture.

Characteristics of Pectin Obtained Through MAE and Conventional Method

Comparison of Extraction Yield Of MAE and CE

Comparative analysis of pectin yield between two methods, i.e., microwave-assisted extraction (MAE) and conventional extraction (CE) method was carried out. The yield of MAE (15.79%) was significantly higher than CE (8.78%). Similar results were reported by Guo et al. [11]. Microwaves disrupt the water-containing cells through the rapid dielectric heating process, which results in better extractability of biomolecules.

The time taken for MAE process at 540 W microwave powers was 90 s for 5 g sample, whereas the time taken for the conventional process at 80 °C was 15 min, which could be achieved only after the water bath reached a constant temperature of 80 °C in the finite time period. This result corroborates with the reports of Guo et al. [11], who had also compared the pectin extraction process for conventional and microwave method. The conventional process took about 1 h at 80 °C; microwave treatment was only for 21 min at 500 W for 50 g sample at the same temperature. Since microwaves work on dipole movement of water, the heating of sample was rapid in acidified water, which required lesser treatment time as compared to conventional heating process.

Solubility of Dry Pectin in Cold and Hot Water

The pectin powders obtained through both the methods were insoluble in cold water, whereas they were soluble in hot water. In hot water, the pectin cells imbibe water and swells. The reason for being soluble in hot water could be the distributions of hydrophilic and hydrophobic groups in the pectin molecule. During hot water treatment, the hydrophobic bonds might be weakening, paving the way for the hydrophilic groups to be attached with water, which might have led to solubility. Partial de-methoxylation of pectin lowers its solubility in water [14].

Equivalent Weight

The equivalent weight of MAE pectin (485 mg/mL) was higher than that obtained through CE (381 mg/mL). The lower equivalent weight in the case of acid extraction may be due to partial degradation of pectin as a result of prolonged heating. The equivalent weight of pectin is of significance as higher equivalent weight pectin would have higher gel-forming ability. Kulkarni and Vijayanand [21] also observed the effect of increasing heating time on the decrease in equivalent weight of pectin obtained from passion fruit peel.

Degree of Esterification (DE)

The ratio of esterified galacturonic acid to the total galacturonic acid is called the degree of esterification (DE). In this study, microwave-assisted extracted pectin DE was estimated to be 42.85%, whereas conventionally extracted pectin DE was 35.48%, and hence both the pectin can be considered as low ester pectin of low molecular weight or less rigid molecule. It is also reported that with increase in DE, the gel rigidity decreases [29]. These types of pectin can have varied end uses as their structures will yield a variety of gelling and texturizing abilities under differing conditions.

Methoxyl Percentage (MeO%) of Pectin

It was observed that the MAE pectin powder had methoxyl content of 6.99% and that of acid extraction method was 5.75%. Methoxyl content is an important factor in controlling the setting time of pectins, their combining power with metallic ions and the ability of the pectin to form gels. It is reported that methoxyl content of extracted pectin varies from 0.2 to 12% [16] depending on the source and mode of extraction, and thus, the percentage methoxyl content obtained in this investigation falls well within the range. The pectins obtained from orange peel by both the methods were less than 7% which is classified under low methoxy content pectin.

Color of Pectin

Color of pectin is an important factor affecting the appearance of gel formed. It was observed that the L, a and b, the value of the pectin powder obtained through MAE and CE were 41.27 ± 0.05, 7.11 ± 0.02, and 31.41 ± 0.0.06, and 37.54 ± 0.04, 10.96 ± 0.02, 24.34 ± 0.05, respectively. It is evident that MAE method pectin has a higher L value than that obtained through conventional extraction method. The redness value of the CE was more than that of MAE, whereas the yellow value is more in the MAE sample. Visually the pectin powder obtained in CE methods was darker in color. The gel color of pectin powder obtained through conventional method was found to be brownish orange, whereas samples extracted MAE had yellowish in color, which might be due to the presence of carotenoids in extracted pectin, as the carotenoids have not been analyzed in the present research work.

Gelling Properties

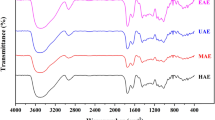

The viscosity of pectin solutions depends on molar mass and structural parameters such as stiffness and charge of the molecules and degree of esterification [18, 29]. The viscoelastic properties of orange peel pectin were examined by oscillatory experimental measurement. In this study, frequency sweep test was conducted which measured storage modulus (G′), loss modulus (G′′) and complex viscosity (η) of both MAE and conventional extraction method.

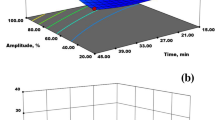

Pectin solution showed shear-dependent flow behavior, as the complex viscosity (η) decreased polynomially with an increase in angular frequency as shown in Fig. 1. This behavior indicates that there is loss of microstructure of the gel as the shear rate increases, thus showing a shear thinning behavior. At the initial stages of measurement of frequency, no viscosity value could be observed, indicating that the solution was very thin to indicate any value during the initial phase of shear. The complex viscosity of the pectin extracted by acid extraction method was higher than that of the MAE, which was due to the fact that the DE in the MAE method was higher as compared to AE process. As DE increases, the intrinsic viscosity decreases [28]. This result is in line with that reported by Morris et al. [29].

The relationship between storage modulus (G′) and loss modulus (G′′) of pectin solutions for different angular frequency is shown in Fig. 2. Storage module (G′) value is a measure of elastic behavior of a sample, while loss modules G′′ value represents the viscous behavior of a sample [36]. It was observed that the loss modulus G′′ was always higher than the storage modulus (G′) for MAE and conventionally extracted pectin within the experimental range of frequency (0.1–20 Hz) and no crossover point occurred. A higher value of G′′ indicated the viscous behavior of both the pectin solutions. For chemical gels, strong gel usually has G′ < G′′. This indicated that viscous properties were predominant because of the dynamic balance between pectin molecular entanglements and shearing. The acid extracted pectin has higher G′ and G′′ value indicating higher gel strength than the MAE pectin solution. The reason could be some molecular disruption of pectin due to microwave heating, as microwave energy tends to disrupt polar bonds, thus affecting the rheological properties [8].

Gels with higher G′/G′′ (loss angle) are brittle gels with a high breaking strength. The gel is sensible to mechanical processing and shows a tendency to syneresis. On the other hand, gels with low G′/G′′ values are soft and show better extensibility. They are more stable during mechanical processing and show less syneresis [15]. In this case, higher loss modulus and less storage modulus, the loss angle being 0.002, indicated that the gels are more stable during processing.

Conclusions

Pectin is a natural food additive used extensively in the food industry. MAE method took less time to have higher pectin yield. The MAE pectin had higher equivalent weight suggesting lesser thermal degradation, higher DE, better lightness compared to that of the conventional method. The MAE pectin had comparable gelling properties as a conventionally extraction method. Both the pectins had low methoxy content (less than 7%) and low loss angle value indicating good gel behavior.

References

Akhtar N, Uddin M (1971) Fractionation of pectins. Pak J Sci Ind Res 14(4/5):346–349

AOAC (ed) (1995) Official methods of analysis. Association of official analytical chemists, 12th edn. AOAC, Washington D.C

AOAC (ed) (2000) Official methods of analysis, 17th edn. Association of Official Analytical Chemists, Washington DC. ISBN: 0935584870

Bagherian H, Ashtiani FZ, Fouladitajar A, Mohtashamy M (2011) Comparisons between conventional, microwave-and ultrasound-assisted methods for extraction of pectin from grapefruit. Chem Eng Process Process Intensif 50(11):1237–1243

Carr RL (1965) Evaluating flow properties of solids. Chem Eng 72:163–168

Donaghy JA, McKay AM (1994) Pectin extraction from citrus peel by polygalacturonase produced on whey. Bioresource Tech 47(1):25–28

FAO (Food and agricultural organization) (2015). http://www.fao.org/news/archive/news-by-date/2015/en/. Accessed 10 June 2015

Fishman ML, Chau HK, Hoagl PD, Hotchkiss AT (2006) Microwave-assisted extraction of lime pectin. Food Hydrocoll 20(8):1170–1177

Garau MC, Simal S, Rossell C, Femenia A (2007) Effect of air-drying temperature on physico-chemical properties of dietary fibre and antioxidant capacity of orange (Citrus aurantium v. Canoneta) by-products. Food Chem 104(3):1014–1024

Grey RO, Beddow JK (1969) On the Hausner ratio and its relationship to some properties of metal powders. Powder Tech 2(6):323–326

Guo X, Han D, Xi H, Rao L, Liao X, Hu X, Wu J (2012) Extraction of pectin from navel orange peel assisted by ultra-high pressure, microwave or traditional heating: a comparison. Carbohydr Poly 88(2):441–448

Hosni K, Zahed N, Chrif R, Abid I, Medfei W, Kallel M, BenBrahim N, Sebei H (2010) Composition of peel essential oils from four selected Tunisian Citrus species: evidence for the genotypic influence. Food Chem 123(4):1098–1104

Hausner HH (1967) Friction conditions in a mass of metal powder. Int J Powder Metall 3:7–13

Hsu CP, Deshpande SN, Desrosier NW (1965) Role of pectin methylesterase in firmness of canned tomatoes. J Food Sci 30(4):583–588

Iglesias MT, Lozano JE (2004) Extraction and characterization of sunflower pectin. J Food Eng 62(3):215–223

Kanmani P, Dhivya E, Aravind J, Kumaresan K (2014) Extraction and analysis of pectin from citrus peels: augmenting the yield from citrus lemon using statistical experimental design. Iran J Energy Environ 5(3):303–312

Kar F, Arslan N (1999) Effect of temperature and concentration on viscosity of orange peel pectin solutions and intrinsic viscosity–molecular weight relationship. Carbohydr Poly 40(4):277–284

Kim WC, Lee DY, Lee CH, Kim CW (2004) Optimization of narirutin extraction during washing step of the pectin production from citrus peels. J Food Eng 63(2):191–197

Kratchanova M, Panchev I, Pavlova E, Shtereva L (1994) Extraction of pectin from fruit materials pretreated in an electromagnetic field of super-high frequency. Carbohydr Poly 25(3):141–144

Kratchanova M, Pavlova E, Panchev I (2004) The effect of microwave heating of fresh orange peels on the fruit tissue and quality of extracted pectin. Carbohydr Poly 56:181–185

Kulkarni SG, Vijayanand P (2010) Effect of extraction conditions on the quality characteristics of pectin from passion fruit peel (Passiflora edulis f. flavicarpa L.). LWT-Food Sci Tech 43(7):1026–1031

Kumar P, Mishra S, Malik A, Satya S (2012) Insecticidal evaluation of essential oils of Citrus sinensis L. (Myrtales: Myrtaceae) against housefly, Musca domestica L. (Diptera: Muscidae). Parasitol Res 110(5):1929–1936

Kute A, Mohapatra D, Babu VB, Sawant BP (2015) Optimization of microwave assisted extraction of pectin from orange peel using response surface methodology. J Food Res Tech 3(2):62–70

Li D, Jia X, Wei Z, Liu Z (2012) Box-behnken experimental design for investigation of microwave-assisted extracted sugar beet pulp pectin. Carbohydr Poly 88(1):342–346

Liew SQ, Chin NL, Yusof YA (2014) Extraction and characterization of pectin from passion fruit peels ST26943. In: 2nd International conference on agricultural & food engineering, CAFEi2014” agriculture & agricultural science procedia, vol 2, pp. 231–236

Liu Y, Shi J, Langrish TAG (2006) Water-based extraction of pectin from flavedo & albedo of orange peels. Chem Eng J 120(3):203–209

Maran JP, Sivakumar V, Thirugnanasambham K, Sridhar R (2013) Optimization of microwave assisted extraction of pectin from orange peel. Carbohydr Poly 97(2):703–709

Min B, Lim J, Sanghoon K, Kwang GL, Sung HL, Suyong L (2011) Environmentally friendly preparation of pectins from agricultural byproducts and their structural/rheological characterization. Bioresource Tech 102:3855–3860

Morris GA, Foster TJ, Harding SE (2000) The effect of the degree of esterification on the hydrodynamic properties of citrus pectin. Food Hydrocoll 14(3):227–235

Rezzadori K, Benedetti S, Amante ER (2012) Proposals for the residues recovery: orange waste as raw material for new products. Food Biol Prod Process 90:606–614

Schemin MHC, Fertonani HCR, Waszczynskyj N, Wosiacki G (2005) Extraction of pectin from apple pomace. Brazil Arch Biol Tech 48:259–266

Shkodina OG, Zeltser OA, Selivanov NY, Ignatov VV (1998) Enzymic extraction of pectin preparations from pumpkin. Food Hydrocoll 12(3):313–316

Singthong J, Ningsanond S, Cui SW, Goff HD (2005) Extraction & physicochemical characterization of Krueo Ma Noy pectin. Food Hydrocoll 19(5):793–801

Srivastava P, Malviya R (2011) Extraction, characterization and evaluation of orange peel waste derived pectin as a pharmaceutical excipient. Nat Prod J 1(1):65–70

Subba MS, Soumithri TC, Rao RS (1967) Antimicrobial action of citrus oils. J Food Sci 32(2):225–227

Tabilo-Munizaga G, Barbosa-Canovas GV (2005) Rheology for the food industry. J Food Eng 67:147–156

Wang S, Chen F, Wu J, Wang Z, Liao X, Hu X (2007) Optimization of pectin extraction assisted by microwave from apple pomace using response surface methodology. J Food Eng 78(2):693–700

Yeoh S, Shi J, Langrish TAG (2008) Comparisons between different techniques for water-based extraction of pectin from orange peels. Desalination 218(1):229–237

Zouambia YK, Youcef E, Mohamed K, Nadji MM (2014) A new approach for pectin extraction: electromagnetic induction heating. Arab J Chem 10:480. https://doi.org/10.1016/j.arabjc.2014.11.011

Acknowledgements

The authors are grateful to Dr. K. K. Singh, Director, ICAR—Central Institute of Agricultural Engineering, Dr. Punit Chandra, Dr. Sumedha S. Deshpande, and Dr. Dipika Agrahar-Murugkar for providing laboratory facilities. The authors also wish to acknowledge the help and support received from the Dean of College of Agricultural Engineering & Technology, Vasantrao Naik Marathwada Krishi Vidyapeeth, Parbani.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kute, A.B., Mohapatra, D., Kotwaliwale, N. et al. Characterization of Pectin Extracted from Orange Peel Powder using Microwave-Assisted and Acid Extraction Methods. Agric Res 9, 241–248 (2020). https://doi.org/10.1007/s40003-019-00419-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40003-019-00419-5