Abstract

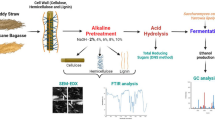

Biological pretreatment was investigated to increase ethanol production from lignocellulosic biomass, like sugarcane bagasse. Enzyme secretion, changes in substrate composition, enzymatic hydrolysis, and ethanol yield after pretreatment by different basidiomycetes were evaluated. Analysis by Fourier transform infrared spectroscopy showed that Pleurotus pulmonarius PS2001 and Trametes villosa 82I6 promoted more extensive selective modifications in the lignin content. Glucose release during enzymatic hydrolysis of samples pretreated with P. pulmonarius PS2001 for 35, 42, and 49 days and with T. villosa 82I6 for 21, 28, and 49 days were higher than the control (48.5 ± 2.38 mg/g), i.e., 68.4 ± 0.7, 76.3 ± 1.6, and 76.5 ± 2.1 mg/g and 70.9 ± 8.3, 77.8 ± 5.8, and 77.6 ± 4.2 mg/g, respectively. During the fermentation of hydrolysates of samples pretreated with T. villosa 82I6 for 14, 28, and 49 days, a maximum ethanol yield of 17.8 ± 1.9, 19.1 ± 2.8, and 20.2 ± 0.5 mg/g, respectively, was achieved. A positive effect of biological pretreatment on hydrolysis and fermentation was demonstrated.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The lignocellulosic materials has become increasingly attractive due to its potential for the production of sugars and fuels [1]. Cellulosic biomass, derived from non-food sources such as trees and grasses, is being exploited as a feedstock for cellulosic ethanol production. All lignocellulosic materials are, in principle, suitable for the production of ethanol or other biotechnological products [2,3,4,5].

There are many sources of lignocellulosics that have potential for energy generation and among these crops is sugarcane. Brazil is the world’s largest producer of sugarcane, and it is estimated that the production of sugarcane in the 2020/21 harvest was 654.5 million tons. Bagasse, a fibrous material remaining after the extraction of sugarcane juice, corresponds to one-third of the energy content of sugarcane [6]. Sugarcane bagasse is low cost since it does not find many applications. However, due to abundant quantities, it is important to find its applications [7].

The base structure of all lignocellulosic biomass consists of three main components: cellulose, hemicellulose and lignin, as well as small amounts of extractives and minerals [8]. These constituents are linked together, forming a complex network resistant to microbial attacks [9]. Biomass transformation to second-generation ethanol is composed of four main operation units: pretreatment, hydrolysis, fermentation, and product separation [10]. Pretreatment and the production of the enzymes used in the hydrolysis step are the factors that contribute most to the cost of processing second-generation ethanol [11, 12] and have attracted much attention in recent years [13].

Pretreatment is among the great challenges associated with converting lignocellulosic biomass to ethanol and is one of the most crucial steps in the process [14,15,16]. The main objective is to remove or minimize the physical and chemical barriers caused by the close association of the main components of lignocellulosic biomass, increasing the accessibility of cellulose to enzyme [17, 18]. Since physical, chemical, and physicochemical methods require higher energy demand, high reagent costs, and the treatment of process residues, which are often highly polluting, in addition to forming compounds that inhibit the hydrolysis and fermentation stages, biological pretreatment had emerged as an alternative technology [19].

Biological pretreatment has been considered an ecofriendly method, that consists of the disorganization of lignocellulosic biomass by enzymes produced by microorganisms, especially basidiomycetes fungi, making the sugars accessible to the hydrolysis and fermentation stages for ethanol production. In contrast to chemical and physical–chemical pretreatment methods, there is no need to use chemicals or high amounts of energy and there is no generation of toxic compounds which could compromise the subsequent steps of hydrolysis and fermentation [20, 21]. However, there are authors who indicate that this type of pre-treatment requires long times [22], but this can be overcome if performed during the storage of the material.

Enzymes are necessary for the biological pretreatment; among these enzymes, four enzymes stand out because can depolymerize lignin, namely laccases, manganese peroxidases, lignin peroxidases, and versatile peroxidases [22], whose catalytic efficiencies and structures differ between different microorganisms of different species [23].

Fungi have two extracellular enzyme systems: the hydrolytic system, which produces hydrolases responsible for the degradation of polysaccharides, and the oxidative system, which degrades lignin and opens phenyl rings [23, 24]. Based on these considerations, in the present study, sugarcane bagasse was pretreated with seven basidiomycetes, namely Pleurotus pulmonarius PS2001, Trametes villosa 82I6, Schizophyllum commune VE07, Pleurotus albidus 78F-13, Pycnoporus sanguineus OU-04, Pycnoporus sanguineus PR-32, and Marasmiellus palmivorus VE111. The main purpose was to select the species most appropriate for improving the subsequent enzymatic hydrolysis and fermentation to produce second generation ethanol.

Material and methods

Microorganisms

The strains used as biological agents in the biomass pretreatment stage (belonging to the collection of the Laboratory of Enzymes and Biomasses of the Biotechnology Institute of the University of Caxias do Sul) are listed in Table 1, with the collection and access code of the library of the University of Caxias do Sul. The strains were grown on sawdust medium for up 15 days at 28 °C, and then stored at 4 °C. These strains were selected considering previous screening, searching for strains that produce enzyme-producing strains involved in lignin degradation.

For glucose fermentation, Saccharomyces cerevisiae strain CAT-1 was used. The strain was grown on yeast extract peptone dextrose (YPD) medium for up to 2 days at 28 °C, and then stored at 4 °C until use.

Substrate

The sugarcane bagasse was used dry and previously ground, kindly provided the National Laboratory of Science and Technology of Bioethanol, Campinas, SP, Brazil.

Biological pretreatment of sugarcane bagasse with basidiomycetes

The biological pretreatment (BPT) was performed using previously dried ground sugarcane bagasse as the major compound of the culture medium. Wheat bran 2.5% (w/v) and calcium carbonate (CaCO3 1% w/v) were added to the biomass and the humidity was adjusted to around 66%, as described by Gambato et al. [25]. These were autoclaved (Autocle Phoenix 75 L®) for 30 min, respectively, at 1 atm. The bag gas exchange system was made with a polyvinyl chloride-type cylinder (1.5 cm in diameter and 4 cm in length) attached to the bag opening, which was filled with gauze and cotton.

As inoculum, mycelial discs 1.5 cm in diameter were used, one disc in each bag. To obtain these disks, each strain of basidiomycete was propagated in Petri dishes containing sawdust medium, constituted of (w/v) 2% ground sawdust (Pinus sp.), 2% ground wheat bran, 2% of agar–agar, and 0.2% CaCO3 [26], completed with distilled water, for 15 days at 28 °C, until total colonization of the medium surface. Then, in a sterile manner, discs were cut using a glass tube. Each bag containing sterile medium received a disc of mycelial mass as the inoculum. Each basidiomycete was considered as a pretreatment, performed in triplicate for each sampling time point, i.e., 7, 14, 21, 28, 35, 42, and 49 days. These samples were collected for measurements of cell growth, medium characterization, and enzyme production.

Estimate of fungal growth

Fungal biomass was determined indirectly via the enzymatic hydrolysis of cell wall chitin. For the determination of the N-acetyl-d-glucosamine content resulting from the hydrolysis of chitin, the methodology was described by Novello et al. [3].

Determination of enzymatic activities

Extraction of the enzymes was performed by suspending the sample in distilled water at 4 °C in a solid/liquid ratio of 1:2, then shaking manually for 30 min. After, the samples were centrifuged (30 min, 2862 × g, 4 °C) (Eppendorf® 5810R) and the supernatant was stored under refrigeration (4 °C) for further analysis [26].

The activity of laccases was determined according to Schneider et al. [27] and the activity of total peroxidases was assessed according to Heinzkill et al. [28], by quantifying the oxidation product of the 2,2′-azino-bis (3-ethylbenzothiazoline-6-sulfonate) (ABTS) used as the substrate. For the determination of the activity of manganese peroxidases, phenol red was used as the substrate, according to the method proposed by Kuwahara et al. [29].

The determination of xylanase activity was performed according to Bailey et al. [30]. The analysis of enzymatic activity on filter paper (FPA) was determined according to Ghose [31], with modifications proposed by Camassola and Dillon [32]. The determination of endoglucanase activity was performed according to the methodology described by Ghose [31], with modifications. The determination of β-glucosidase activity was performed using the methodology adapted from Daroit et al. [33]. The readings were taken in a spectrophotometer Spectramax 190, Molecular Devices®.

Chemical analysis of the cellulosic substrates

The chemical composition of the samples was determined according to the methodology proposed by the National Renewable Energy Laboratory (NREL-TP-510–42,618, NREL-TP-510–42,619, and NREL-TP-510–42,621) [34, 35].

Characterization of sugarcane bagasse before and after biological pretreatment

Scanning electron microscopy (SEM) (Shimadzu SSX-550 Superscan) was used to characterize the sugarcane before and after biological treatment. As part of the imaging procedure, the samples were sputter coated with gold layers [36].

Fourier transform infrared (FTIR) spectroscopy (Nicolet IS10 Termo Scientific) was performed according to ASTM E1252-98 (Reapproved 2013) or ASTM E573-01 (Reapproved 2013). Sample spectra were obtained in duplicate using an average of 128 scans in the range between 850 and 2000 cm−1 with a spectral resolution of 2 cm−1. Peak heights and areas of FTIR spectra were determined using Origin software version 6.0. The influence of the biological pretreatment was analyzed in terms of the percent diminution in the intensity of the lignin (1427 and 1515 cm−1) and carbohydrate peaks (1395, 1098, and 898 cm−1) [2, 37, 38].

Enzymatic hydrolysis of sugarcane bagasse

Enzymatic hydrolysis was carried out using the Penicillium echinulatum S1M29 enzyme complex, mainly composed of endoglucanases, cellobiohydrolases, and β-glucosidases, produced in the Laboratory of Enzymes and Biomass (IB-UCS) [39,40,41].

The procedure was conducted in 50 mL Duran® flasks, containing 5% (w/v) of biomass biologically pretreated with basidiomycetes. This percentage of biomass was used to evaluate the reactivity of the fibers, before and after pretreatment. The enzyme loading was 20 FPU/g of dry biomass, suspended in 50 mmol/L citrate buffer, pH adjusted to 4.8, which was added until reaching a final volume of 50 mL. The flasks were kept at 50 °C under reciprocal shaking at 150 rpm for 24 h. Enzymatic hydrolysis occurred according to the sampling time of the culture of the basidiomycetes. As controls, the enzymatic hydrolysis of non-pretreated sugarcane bagasse was carried out under the same conditions. Samples of the hydrolyzate for the determination of reducing sugars and glucose were collected at 0, 6, 12, and 24 h. A 1 mL volume was withdrawn at each sampling time, centrifuged (2862 × g) and frozen (− 4 °C) for further analysis. The enzymatic hydrolysis of the biomass was carried out in triplicate.

It should be noted that the amount of enzyme used was standardized according to FPA, but in the volume used that contained 20 FPU there was also 49.48 U of endoglucanases, 3.84 U of cellobiohydrolases, 82.56 U of xylanases, and 1.28 U of β-glucosidases.

Cellulose digestibility (Dc) was calculated using the Eq. (1), as the quotient between the percentage of glucose (Gr) released from either the pretreated solid fraction and the theoretical maximum amount of glucose (Gs), according to Salvachúa et al. [16].

Alcoholic fermentation

The alcoholic fermentation of sugars released from sugarcane bagasse was carried out using a S. cerevisiae CAT-1 at a concentration of 108 viable cells/mL for 24 h. Ethanol production was performed by a saccharification and fermentation process, carried out separately [35].

The experiments were performed in 2 mL tubes containing a suspension of sugarcane bagasse submitted to hydrolysis and supplemented to obtain a final concentration of 4 mg/mL of Prodex® (crude yeast extract) and 1 mg/mL of (NH4)2SO4 [34] at 28 °C under static conditions. Samples were taken to determine the consumption of glucose and xylose and ethanol production by high performance liquid chromatography (HPLC—Shimadzu® LC-20AD Prominence). Samples were analyzed using a Shimadzu chromatography system. The analysis was performed on an Aminex HPX-87H column (Bio-Rad®) by the refractive index detector at 60 °C, with 5 mmol/L H2SO4 (mobile phase) and a flow rate of 0.6 mL/min. The ethanol yield was calculated according to Menegol et al. [35].

Statistical tests

To determine the efficiency of the metabolism action of different fungi on the chemical composition of sugarcane bagasse biomass, as well as to evaluate the potential of these fungi for the preparation of biomass for enzymatic hydrolysis and alcoholic fermentation, the data obtained in the experiments were subjected to analysis statistic. All statistical tests were performed by analysis of variance (one-way ANOVA) and a post-hoc Tukey test, using a probability level below 5% (p < 0.05).

Results and discussion

Evaluation of the growth and production of enzymes in sugarcane bagasse

The goal of this study was to select fungal species for the production of second generation ethanol from untreated sugarcane bagasse. In Fig. 1, the growth profiles of the different species in sugarcane bagasse medium are shown as a function of incubation time. It was found that all basidiomycetes species tested were able to colonize the medium.

It was observed that the species that apparently presented the greatest formation of mycelium were S. commune VE07, reaching about 0.25 ± 0.004 g of mycelium per g of dry biomass (g/g), followed by P. sanguineus OU04, M. palmivorus VE111, P. sanguineus PR32, and T. villosa 82I6, which reached, respectively, 0.18 ± 0.005, 0.16 ± 0.001, 0.13 ± 0.012, and 0.11 ± 0.005 g/g. The two species that presented the lowest growth were P. albidus 88F-13 (0.07 ± 0.006 g/g) and P. pulmonarius PS2001 (0.05 ± 0.003 g/g). As an indirect method was used to determine the growth, perhaps there may be some other component produced by S. commune VE07 that may have interfered in the analysis, since for the other fungi evaluated the values are more adequate.

When comparing the growth data of P. albidus 88F-13 in other lignocellulosic residues, Stoffel et al. [42] detected growth of 0.13 g/g of mycelium when grown in brewer spent grain and 0.03 g/g in grape bagasse. Although Stoffel et al. [42] used the determination of indirect growth through the dosage of ergosterol, it is noticed that there is coherence between the growth data, indicating that the growth is variable according to the substrate used for the cultivation of the fungi.

The differences observed during growth may be due to several factors, among others firstly to the characteristics of the strain, the presence of macronutrients and micronutrients required for the species, the type of substrate, and the pH of the medium [25, 26]. Biological pretreatment has been associated with modifications to the biomass via the action of enzymes produced during colonization. These enzymes act at specific substrate locations, and may degrade polyphenols in the lignin and also degrade the structure of the hemicellulose heteropolysaccharide, in addition to reaching cellulose fibers [16, 21]. The enzymatic complex responsible for the degradation of lignin is composed of laccases and peroxidases [43]. The lignin peroxidase degrades non-phenolic units and manganese peroxidase acts on phenolic and non-phenolic lignin units [44]. Laccases are phenol-oxidases that act together with the peroxidases to oxidize phenolic components, leading to the complete degradation to CO2 and H2O [45].

The hydrolysis of hemicellulose, a polysaccharide that forms a reticulated structural network and contributes to the integrity of the vegetal cell wall, is catalyzed by xylanases. Endoglucanases act at randomly at various sites in the amorphous regions of the cellulose fiber, reducing the degree of polymerization and opening sites for the further action of cellobiohydrolases [46]. Endoglucanases and cellobiohydrolases act in synergy in cellulose hydrolysis and β-glucosidases hydrolyze cellobiose and cellulose oligosaccharides to glucose. The presence of these enzymes during pretreatment may be favorable to the process, provided that the microorganism does not use the sugars resulting from the action of this set of enzymes in its metabolism, since all sugars are important to the fermentation process. Therefore, it is necessary to evaluate the species of basidiomycetes in order to identify those that are able to promote the delignification of the biomass, but that have little or no metabolic activity for the use of cellulose and hemicellulose. Thus, the production of different enzymes that act on these biomass components was evaluated.

Figure 2 shows the data on the production of laccases, manganese peroxidases, total peroxidases, β-glucosidases, endoglucanases, and xylanases, as well as filter paper activity (FPA) by basidiomycete species as a function of incubation time. Regarding the production of laccases, it was observed that M. palmivorus VE111 stood out, showing increasing activity until day 42 of the process, with a peak of 1985 ± 235 U/g. The species P. pulmonarius PS2001 and P. sanguineus PR32, followed by P. albidus 88F-13, achieved activities of 1256 ± 65, 1185 ± 89, and 785 ± 72 U/g, respectively, at 35 days of culture (Fig. 2A).

It was observed that the species that produced the highest amounts of manganese peroxidases were P. albidus 88F-13 (21.3 ± 2.6 U/g), presenting increasing activities in up to 21 days of cultivation, and P. pulmonarius PS2001 (21 ± 3.7 U/g) and T. villosa 82 I6 (17 ± 1 U/g), which showed increasing activities in up to 14 days of cultivation (Fig. 2B).

The species that excelled in the production of total peroxidases were M. palmivorus VE111, which presented an enzymatic peak of 518 ± 31 U/g after 28 days of the process, followed by P. pulmonarius PS2001 (472 ± 48 U/g in 42 days) and P. albidus 88F-13 (423 ± 35 U/g in 21 days). P. pulmonarius PS2001, P. albidus 88F-13, and T. villosa 82I6 showed low β-glucosidase activities throughout the entire culture period. P. sanguineus strains PR32 and P. sanguineus OU04 presented the maximum activity of β-glucosidase, i.e., 7.1 ± 1.0 and 6.0 ± 0.4 U/g, respectively, after 35 days. S. commune VE07 and M. palmivorus VE111 had an enzymatic peak of 3.9 ± 0.4 and 3.9 ± 0.9 U/g, respectively, after 21 days (Fig. 2D).

The endoglucanase activities were low for all evaluated species; M. palmivorus VE111 was the species that presented the lowest activity of this enzyme, reaching only 0.09 ± 0.005 U/g. P. albidus 88F-13 showed an enzymatic peak of 0.2 ± 0.05 U/g after 7 days of culture. At 21 days, S. commune VE07 had maximum activity of 0.3 ± 0.03 U/g. For the other species, the activities increased throughout the process, reaching values close to 0.3 U/g at the end of 49 days (Fig. 2E).

The species that presented the highest FPA activity at the end of 49 days of cultivation was T. villosa 82I6 (2.3 ± 0.1 U/g), followed by P. sanguineus OU04, which had a peak activity of 1.4 ± 0.1 U/g after 35 days of incubation. In general, the tested species showed low values of this enzyme activity (Fig. 2F).

In relation to xylanase production, S. commune VE07 showed the highest activity of 6.5 ± 0.2 U/g after 21 days of culture, followed by P. albidus 88F-13, which presented an activity of 6.0 ± 1.1 U/g at 35 days. T. villosa 82I6 presented an enzymatic peak of 5.5 ± 1.2 U/g after 42 days of processing. After the maximum activities were reached, these species sustained activities on the order of 4.5 U/g until the end of the process (Fig. 2G).

It was evident that the studied species secreted different enzymatic complexes, which resulted in differences in the degradation of the components of the sugarcane bagasse. However, when cell growth was related to the production of enzymes by P. pulmonarius PS2001, P. albidus 88F-13, and T. villosa 82I6, these species showed lower mycelial formation and produced high amounts of laccases and peroxidases. However, according to Leisola et al. [47], the secretion of enzymes capable of degrading lignin by white rot fungi has some peculiarities. Among them is the fact that lignin is degraded only after nutrient depletion, which triggers the secondary metabolism of the microorganism.

Evaluation of basidiomycetes biodegradation patterns

FTIR spectroscopy was performed focusing on the bands corresponding to cellulose, hemicelluloses, and lignin (Table 2). Five bands were evaluated: 1515 cm−1 (aromatic skeletal vibrations in lignin), 1427 cm−1 (syringyl and guaiacyl condensed nuclei), 1375 cm−1 (cellulose and hemicelluloses), 1098 cm−1 (crystalline cellulose), and 898 cm−1 (amorphous cellulose). The analysis of these spectra in terms of percent modifications of each treated sample relative to the control sample (non-pretreated) and the weight losses after pretreatment is shown in Table 2.

It is possible to estimate the degree of degradation of the substrate through the weight loss of the lignocellulosic biomass after cultivation [16]. The species that promoted significantly higher weight loss than the other species was P. albidus 88F-13 (40.9 ± 0 0.7%). The species P. pulmonarius PS2001, T. villosa 82I6, P. sanguineus OU04 and PR32, promoted statistically equivalent weight loss. M. palmivorus VE111 presented significantly lower weight loss (19.9 ± 2.3%) than that observed in pretreatments with the other strains. Weight losses are obviously associated with the growth of each fungus and are the result of the transformation of plant biomass into fungal biomass and CO2 generation [2].

Decreases were observed in all FTIR bands analyzed after pretreatment; however, the modifications in the different bands were different between the biological pretreatments. Only S. commune VE07, which also presented a minor degree of weight loss, had null reduction values for all bands. This species probably consumed small amounts of biomass components, which was not possible to be detect by FTIR (Table 2).

The 1515 cm−1 band, related to the aromatic skeletal vibrations in lignin, showed the most pronounced decrease, indicating that lignin degradation occurred in all pretreatments, except for S. commune VE07. T. villosa 82I6, P. pulmonarius PS2001, P. albidus 88F-13, P. sanguineus PR32, and OU04 presented the largest reductions in this band and were statistically the same (reduction around 30%). Reductions in the 1427 cm−1 band (syringyl and guaiacyl condensed nuclei) corroborate the suggestion that there was a reduction in the amount of lignin present in the biomass. P. sanguineus PR32 presented a stronger reduction in this band compared to the other tested species (Table 2).

Decreases in the bands at 898 cm−1 (amorphous cellulose) and 1098 cm−1 (crystalline cellulose) were clear indications of the degradation of cellulose. The reduction in these bands was especially pronounced in the pretreatment performed with P. sanguineus PR32, which presented values superior to all species tested, followed by P. albidus 88F-13. In the band at 1375 cm−1 (cellulose and hemicellulose), again P. sanguineus PR32 resulted in the greatest reduction. It should be highlighted that cellulose degradation is considered a disadvantage in the process, since the sugars required in the hydrolysis step are provided by this fraction of the biomass; thus, the consumption of cellulose will result in a decrease in productivity (Table 2).

It was also observed that the strains P. sanguineus OU04 and P. sanguineus PR32 presented differences in substrate degradation. While P. sanguineus PR32 strain promoted a high reduction in all bands analyzed by FTIR, P. sanguineus OUO4 strain promoted a considerable reduction in the lignin bands, a minor reduction in the hemicellulose band, and null reduction in the cellulose bands (Table 2). This differential degradation can be attributed to the differences between the metabolisms of the strains, such as the secretion of different enzymatic complexes. This demonstrates the importance of selecting different isolates of the same species.

The degradation of lignin by basidiomycetes is associated with variable levels of sugar consumption, obtained from holocellulose hydrolysis for growth requirements. For this reason, it is important to achieve a state of balance between both pathways. When selecting a basidiomycete for biological pretreatment, both parameters should be considered, since they represent a significant effect on the economics of the process. The best results will be those in which the reduction of lignin is the highest with the lowest sugar consumption, in a shorter period of time [48].

It is worth mentioning that the species T. villosa 82I6 and P. pulmonarius PS2001 presented favorable proportions between the consumption of cellulose, hemicellulose, and lignin. In other words, they presented high reductions in lignin bands and low reductions in holocellulose bands. According to Lee et al. [49], this demonstrates that the system of hydrolytic enzymes secreted by these microorganisms did not efficiently degrade the holocellulose present in the biomass. As discussed earlier in Fig. 2, these species showed low FPA and low β-glucosidase, endoglucanase, and xylanase activities.

The data obtained by FTIR are corroborated by the biomass characterization data (Table 3), where it is verified that reductions in insoluble lignin. The species that promoted significantly higher mass loss than the other species was P. albidus 88F-13 (40.9 ± 0.7%). The strains P. pulmonarius PS2001, T. villosa 82I6 and P. sanguineus OU04, and P. sanguineus PR32 promoted statistically equal mass loss. M. palmivorus VE111 showed significantly lower mass loss (19.9 ± 2.%3) than observed in pretreatments with the other species. Mass losses are obviously associated with the growth of each fungus and are the result of the transformation of plant biomass into fungal biomass and CO2 generation [2].

Regarding the control sample, there were no significant differences in the percentages of lignin and holocellulose after 49 days of biological pretreatment by the tested species. It was observed for all biological pretreatments, except for the one carried out with the species S. commune VE07, an increase in the percentage of acid-soluble lignin after the biological pretreatment, when compared to the control. Furthermore, there was a decrease in the insoluble lignin content, except for pretreatments performed with S. commune VE07 and M. palmivorus VE111. Lee et al. [49] observed this relationship between the levels of soluble and insoluble lignin in biological pretreatments of Pinus carried out with the species Ceriporia lacerata, Stereum hirsutum, and Polyporus brumalis. The insoluble lignin content was probably reduced due to the action of enzymes produced by the fungi, which promoted the decomposition of lignin to low molecular weight phenolic compounds, which also promoted an increase in the acid-soluble lignin content.

Microscopic analysis

Scanning electron microscopy of the sugarcane bagasse was performed to verify the structural changes caused after 49 days of biological pretreatment (Supplementary material). The control sample (untreated) showed more ordered structures and some pores on the order of 1 μm. After pretreatment, the structures were modified, and the biomass was covered with fungal mycelia, resulting in fiber detachment and the appearance of larger pores and cracks in some cases. In pretreatments with the species P. sanguineus PR32 and P. sanguineus OU04 and P. pulmonarius PS2001 and P. albidus 88F-13, it was observed that the sugarcane bagasse was totally enveloped by the fungal mycelium. In the pretreatment with T. villosa 82I6, the biomass modification was more evident, in which, besides the presence of mycelia, disorganization of the structure of the biomass, cracks, and an increase in the surface pore size (to about 6 μm).

Castoldi et al. [2] observed the formation of pores on the surface of eucalyptus sawdust pretreated with P. pulmonarius, Trametes sp., and Ganoderma lucidum. These structural changes in pretreated samples may favor cellulose exposure. The appearance of pores results in a greater available surface area and is generally considered an indication of increases in the accessibility of cellulose to enzymatic attack.

Enzymatic hydrolysis of pretreated sugarcane bagasse

The sugarcane bagasse pretreated with macromycetes was used in enzymatic hydrolysis assays in order to evaluate possible alterations in the release of sugars. In biomass hydrolyses pretreated with P. sanguineus OU04 and P. sanguineus PR32 strains, glucose yields were null. For the pretreatments performed with the other species, after 24 h of hydrolysis, the digestibility of the cellulose present in the pretreated sugarcane bagasse for 49 days was shown (Fig. 3). Digestibility could represent the conversion yield of the raw material into fermentable sugars [16]. The digestibility of cellulose is the percentage of glucose released during enzymatic hydrolysis in relation to the theoretical maximum present in the biomass [48]. The chemical composition of sugarcane bagasse used in these experiments was 1.7 ± 0.6% extractable components, 33.9 ± 1.2% cellulose, 15.2 ± 1.4% hemicellulose, 7.9 ± 0.6% soluble lignin, 21.1 ± 0.5% insoluble lignin, and 5.9 ± 1.8% ash.

It was observed that M. palmivorus VE111 treatment caused a decrease in digestibility (3.5 ± 0.7%) in relation to the control (12.9 ± 2.4%). P. pulmonarius PS2001 presented similar digestibility to the control (12.8 ± 8.0%), while P. albidus 88F-13, S. commune VE07, and T. villosa 82I6 species increased this parameter to 15.7 ± 1.8%, 15.5 ± 2.0%, and 22.8 ± 1.2%, respectively. It is worth mentioning that the species that promoted the greatest increase in digestibility, T. villosa 82I6, was the one that caused the greatest reduction in the percentage of total lignin present in the biomass (Fig. 3).

In Fig. 4, sugar and glucose release graphs are shown over time during the enzymatic hydrolysis of pretreated samples at different time points (7 to 49 days). The graphs refer to the pretreatments performed with the species that presented digestibility equal to or greater than the control. With regard to the hydrolysis of sugarcane bagasse pretreated with S. commune VE07, it was observed that both the release of reducing sugars and glucose formation were lower than the control.

Reducing sugars (RS) and glucose released by dry biomass mass during the enzymatic hydrolysis of sugarcane bagasse samples after different periods of biological pretreatment with A, B Schizophyllum commune VE07, C, D Pleurotus pulmonarius PS2001, E, F Pleurotus albidus 88F-13, and G, H Trametes villosa 82I6

In the hydrolysis of sugarcane bagasse pretreated with P. albidus 88-F13 and P. pulmonarius PS2001, in the first 21 and 14 days of pretreatment, respectively, a reduction in the release of reducing sugars was observed in relation to the control (Fig. 4 E and C). The same behavior was observed for glucose release in samples treated for up to, respectively, 35 and 21 days (Fig. 4 F and D). Only with longer periods of pretreatment was there an increase in the release of reducing sugars, including glucose, when compared to the control. It is likely that, in the first days of biological pretreatment, these strains consumed the accessible polysaccharides of the biomass, without the liberation of biomass deconstruction enzymes.

It is interesting that, in the pretreatment with T. villosa 82I6, an increase in the release of reducing sugars (Fig. 4G) and glucose (Fig. 4H) was observed in relation to the control, from the first days of biological pretreatment.

It is noteworthy that, for all pretreatments, the time of the enzymatic deconstruction process could be decreased from 24 to 12 h, since after the initial period there was no increase in sugar release. In addition, it was observed that the amount of glucose released during the enzymatic hydrolysis process was practically half of the reducing sugars released during the same period of time.

Figure 5 shows the analysis of glucose release in 24 h of enzymatic hydrolysis from samples pretreated biologically for different periods of time. In the enzymatic hydrolysis carried out with sugarcane bagasse pretreated with P. albidus 88F-13, it was observed that, in the samples pretreated for 42 and 49 days, glucose release was statistically equal to the control (48.5 ± 2.38 mg/g), i.e., 45.4 ± 2.6 and 56.7 ± 1.7 mg/g, respectively. However, there was a trend toward increased glucose uptake with increasing pretreatment time, which may indicate the need for longer periods of pretreatment time (Fig. 5A) or the use of a higher inocula concentration. Samples pretreated with P. pulmonarius PS2001 obtained statistically higher amounts of glucose were obtained in samples with pretreatment times of 35, 42, and 49 days (68.4 ± 0.7, 76.3 ± 1.6, and 76.5 ± 2.1 mg/g) (Fig. 5B). In the pretreatment with T. villosa 82I6, it was observed that samples collected at 21, 28, and 49 days released amounts of glucose statistically superior to the control (70.9 ± 8.3, 77.8 ± 5.8, and 77.6 ± 4.2 mg/g) (Fig. 5C).

Glucose released after 24 h of enzymatic hydrolysis of sugarcane bagasse after different periods of biological pretreatment with Pleurotus albidus 88F-13 (A); Pleurotus pulmonarius PS2001 (B), and Trametes villosa 82I6 (C). Values (averages) with the same letters do not differ significantly by the Tukey test (p > 0.05)

It should be emphasized that decreasing the process time is one of the factors that interferes in the productivity and final cost of a product. Decreasing pretreatment time is the main challenge for this area. Thus, among the strains that proved to be efficient in the biological pretreatment, T. villosa 82I6 stood out among the tested species, since from day 21 of cultivation it promoted greater release of glucose and reducing sugars from sugarcane bagasse, in relation to the control. However, this time possibly could be shortened if more concentrated inocula were employed.

Fermentation

The evaluation of ethanol production is necessary to quantify the process final performance. Since samples pretreated with T. villosa 82I6 presented better results in the hydrolysis stage, the hydrolysates of samples pretreated with this strain were fermented using the CAT-1 strain of Saccharomyces cerevisiae. Figure 6 shows the concentrations of sugars (glucose and xylose) and the concentration of ethanol over 24 h of alcoholic fermentation of the sugarcane bagasse hydrolysates pretreated with T. villosa 82I6 at different times.

Evaluating the pretreated samples, it was observed that the initial amount of sugars as well as the concentration of ethanol reached in all pretreated samples was higher than in the control (Fig. 6A). It was also found that, under all conditions, total glucose uptake occurred during the first 4 h of fermentation. Decreases in the glucose concentration coincide with increases in the ethanol concentration. The xylose content remained constant throughout the fermentation process in all the samples, since the yeast used is not able to metabolize this sugar. Regarding the amount of available xylose, values around 1 mg/mL were observed in all conditions.

Table 4 shows the maximum ethanol yield from biomass. From the hydrolyzate of the control sample, a maximum yield of 10.1 ± 0.8 mg/g was obtained. That is, for each gram of biomass used, 10.1 ± 0.8 mg of ethanol was obtained. The samples pretreated for 7, 14, 21, 35, and 42 days presented ethanol yields statistically equal to the control. Samples pretreated for 28 and 49 days showed significantly higher ethanol yields, corroborating the data shown in Fig. 3C, in which it was observed that the glucose obtained in the hydrolysis of samples pretreated for 28 and 49 days was superior to the control. Based on this result, there was a positive influence of biological pretreatment on the subsequent stages of the process.

A disadvantage of the biological pretreatments mentioned in the literature is the long time for this type of pre-treatment, but as the biomass is never used all at the same time, being stored, this pre-treatment can be carried out at this moment; therefore, even faster than other processes the same goal. There are still limitations for scaling for real scale applications, mainly because they are aerobic microorganisms, although they demand low oxygen concentrations. Thus, it is necessary to arrange the biomass in layers, leaving space for air circulation, something that is already common in spaces destined to the storage of different types of biomass.

Conclusion

Biological pretreatment of sugarcane bagasse by T. villosa 82I6 resulted in the selective degradation of lignin, facilitating the enzymatic hydrolysis of cellulose. The data obtained showed that T. villosa 82I6 is suitable to increase sugar recoveries from sugarcane bagasse improving significantly ethanol production. These results indicate the possibility of using biological pretreatment as a possible and environmentally correct alternative in the production of second-generation ethanol. Among the future challenges for feasibility are the scaling up and carrying out of this step during biomass storage, to eliminate the disadvantage of long periods for carrying out this type of pretreatment.

Data availability

Data available on request from the authors: the data that support the finding of this study are available from the corresponding author, on request.

References

Basso V, Machado JC, da Silva Lédo FJ et al (2014) Different elephant grass (Pennisetum purpureum) accessions as substrates for enzyme production for the hydrolysis of lignocellulosic materials. Biomass Bioenerg 71:155–161. https://doi.org/10.1016/j.biombioe.2014.10.011

Castoldi R, Bracht A, de Morais GR et al (2014) Biological pretreatment of Eucalyptus grandis sawdust with white-rot fungi: Study of degradation patterns and saccharification kinetics. Chem Eng J 258:240–246. https://doi.org/10.1016/j.cej.2014.07.090

Novello M, Vilasboa J, Schneider WDH et al (2014) Enzymes for second generation ethanol: Exploring new strategies for the use of xylose. RSC Adv 4:21361–21368. https://doi.org/10.1039/c4ra00909f

Akyol Ç, Ince O, Bozan M et al (2019) Biological pretreatment with Trametes versicolor to enhance methane production from lignocellulosic biomass: a metagenomic approach. Ind Crops Prod 140:111659. https://doi.org/10.1016/J.INDCROP.2019.111659

Scholl AL, Menegol D, Pitarelo AP et al (2015) Elephant grass (Pennisetum purpureum Schum.) pretreated via steam explosion as a carbon source for cellulases and xylanases in submerged cultivation. Ind Crops Prod 70:280–291. https://doi.org/10.1016/J.INDCROP.2015.03.056

Camassola M, Dillon AJP (2010) Cellulases and xylanases production by Penicillium echinulatum grown on sugar cane bagasse in solid-state fermentation. Appl Biochem Biotechnol 162:1889–1900. https://doi.org/10.1007/s12010-010-8967-3

Araújo M, Renata DA (2021) Production chain of first—generation sugarcane bioethanol : characterization and value-added application of wastes. BioEnergy Res. https://doi.org/10.1007/s12155-021-10301-4

Demirbaş A (2005) Estimating of structural composition of wood and non-wood biomass samples. Energ Sources 27:761–767. https://doi.org/10.1080/00908310490450971

Schneider WDH, Dillon AJP, Camassola M (2020) Lignin nanoparticles enter the scene: a promising versatile green tool for multiple applications. Biotechnol Adv 101676.https://doi.org/10.1016/j.biotechadv.2020.107685

Balat M, Balat H, Öz C (2008) Progress in bioethanol processing. Prog Energy Combust Sci 34:551–573. https://doi.org/10.1016/j.pecs.2007.11.001

Rajendran K, Drielak E, Sudarshan Varma V et al (2018) Updates on the pretreatment of lignocellulosic feedstocks for bioenergy production—a review. Biomass Convers Biorefinery 8:471–483. https://doi.org/10.1007/s13399-017-0269-3

Antonio F, Antunes F, Rajan K et al (2021) Sustainable second-generation ethanol production from switchgrass biomass via co-fermentation of pentoses and hexoses using novel wild yeasts. BioEnergy Res. https://doi.org/10.1007/s12155-021-10302-3

Yamakawa CK, Qin F, Mussatto SI (2018) Advances and opportunities in biomass conversion technologies and biorefineries for the development of a bio-based economy. Biomass Bioenerg 119:54–60. https://doi.org/10.1016/j.biombioe.2018.09.007

Camassola M, Dillon AJP (2009) Biological pretreatment of sugar cane bagasse for the production of cellulases and xylanases by Penicillium echinulatum. Ind Crops Prod 29:642–647. https://doi.org/10.1016/J.INDCROP.2008.09.008

Bezerra TL, Ragauskas AJ (2016) A review of sugarcane bagasse for second-generation bioethanol and biopower production. Biofuels, Bioprod Biorefining 10:634–647. https://doi.org/10.1002/bbb

Salvachúa D, Prieto A, López-Abelairas M et al (2011) Fungal pretreatment: an alternative in second-generation ethanol from wheat straw. Bioresour Technol 102:7500–7506. https://doi.org/10.1016/j.biortech.2011.05.027

Alvira P, Tomás-Pejó E, Ballesteros M, Negro MJ (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour Technol 101:4851–4861. https://doi.org/10.1016/j.biortech.2009.11.093

Guo GN, Cai B, Li R et al (2019) Enhancement of saccharification and ethanol conversion from tobacco stalks by chemical pretreatment. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-019-00478-2

Gupta A, Verma JP (2015) Sustainable bio-ethanol production from agro-residues: a review. Renew Sustain Energy Rev 41:550–567. https://doi.org/10.1016/j.rser.2014.08.032

Singh P, Suman A, Tiwari P et al (2008) Biological pretreatment of sugarcane trash for its conversion to fermentable sugars. World J Microbiol Biotechnol 24:667–673. https://doi.org/10.1007/s11274-007-9522-4

Dal Picolli T, Regalin Aver K, Claudete Fontana R, Camassola M (2018) High-performance of Agaricus blazei fungus for the biological pretreatment of elephant grass. Biotechnol Prog 34:42–50. https://doi.org/10.1002/btpr.2529

Bugg TDH, Williamson JJ, Rashid GMM (2020) Bacterial enzymes for lignin depolymerisation: new biocatalysts for generation of renewable chemicals from biomass. Curr Opin Chem Biol 55:26–33. https://doi.org/10.1016/j.cbpa.2019.11.007

Schneider WDH, Fontana RC, Baudel HM et al (2020) Lignin degradation and detoxification of eucalyptus wastes by on-site manufacturing fungal enzymes to enhance second-generation ethanol yield. Appl Energ 262:114493. https://doi.org/10.1016/J.APENERGY.2020.114493

Sánchez C (2009) Lignocellulosic residues: biodegradation and bioconversion by fungi. Biotechnol Adv 27:185–194. https://doi.org/10.1016/j.biotechadv.2008.11.001

Gambato G, Todescato K, Pavão EM et al (2016) Evaluation of productivity and antioxidant profile of solid-state cultivated macrofungi Pleurotus albidus and Pycnoporus sanguineus. Bioresour Technol 207:46–51. https://doi.org/10.1016/J.BIORTECH.2016.01.121

Camassola M, da Rosa LO, Calloni R et al (2013) Secretion of laccase and manganese peroxidase by Pleurotus strains cultivate in solid-state using Pinus spp. sawdust. Braz J Microbiol 44:207–213. https://doi.org/10.1590/S1517-83822013005000006

Schneider WDH, Fontana RC, Mendonça S et al (2018) High level production of laccases and peroxidases from the newly isolated white-rot basidiomycete Marasmiellus palmivorus VE111 in a stirred-tank bioreactor in response to different carbon and nitrogen sources. Process Biochem 69:1–11. https://doi.org/10.1016/J.PROCBIO.2018.03.005

Heinzkill M, Bech L, Halkier T et al (1998) Characterization of laccases and peroxidases from wood-rotting fungi (family Coprinaceae). Appl Environ Microbiol 64:1601–1606. https://doi.org/10.1016/0038-0717(90)90187-5

Kuwahara M, Glenn JK, Morgan MA, Gold MH (1984) Separation and characterization of two extracelluar H2O2-dependent oxidases from ligninolytic cultures of Phanerochaete chrysosporium. FEBS Lett 169:247–250. https://doi.org/10.1016/0014-5793(84)80327-0

Bailey MJ, Biely P, Poutanen K (1992) Interlaboratory testing of methods for assay of xylanase activity. J Biotechnol 23:257–270. https://doi.org/10.1016/0168-1656(92)90074-J

Ghose TK (1987) Measurement of cellulase activities. Pure Appl Chem 59:695–702. https://doi.org/10.1351/pac198759050695

Camassola M, Dillon JPA (2012) Cellulase determination: modifications to make the filter paper assay easy, fast, practical and efficient. J Anal Bioanal Tech 01:10–13. https://doi.org/10.4172/scientificreports.125

Daroit D, Simonetti A, Hertz P, Brandelli A (2008) Purification and characterization of an extracellular beta-glucosidase from Monascus purpureus. J Microbiol Biotechnol 18:933–941

Scholl AL, Menegol D, Pitarelo AP et al (2015) Ethanol production from sugars obtained during enzymatic hydrolysis of elephant grass (Pennisetum purpureum, Schum.) pretreated by steam explosion. Bioresour Technol 192:228–237. https://doi.org/10.1016/j.biortech.2015.05.065

Menegol D, Fontana RC, Dillon AJP, Camassola M (2016) Second-generation ethanol production from elephant grass at high total solids. Bioresour Technol 211:280–290. https://doi.org/10.1016/j.biortech.2016.03.098

Scholl AL, Menegol D, Pitarelo AP et al (2015) Elephant grass pretreated by steam explosion for inducing secretion of cellulases and xylanases by Penicillium echinulatum S1M29 solid-state cultivation. Ind Crops Prod 77:97–107. https://doi.org/10.1016/j.indcrop.2015.08.051

Pérez V, de Troya MT, Martínez AT et al (1993) In vitro decay of Aextoxicon punctatum and Fagus sylvatica woods by white and brown-rot fungi. Wood Sci Technol 27:295–307. https://doi.org/10.1007/BF00195308

Gonçalves AR, Esposito E, Benar P (1998) Evaluation of Panus tigrinus in the delignification of sugarcane bagasse by FTIR-PCA and pulp properties. J Biotechnol 66:177–185. https://doi.org/10.1016/S0168-1656(98)00147-3

Dillon AJP, Camassola M, Henriques JAP et al (2008) Generation of recombinants strains to cellulases production by protoplast fusion between Penicillium echinulatum and Trichoderma harzianum. Enzyme Microb Technol 43:403–409. https://doi.org/10.1016/j.enzmictec.2008.07.009

Schneider WDH, dos Reis L, Fontana RC et al (2018) Exploring strategies for the use of glycerol in the production of cellulases and xylanases, and the use of these enzymes in the hydrolysis of lignocellulosic biomass. Ind Crops Prod 122:114–118. https://doi.org/10.1016/J.INDCROP.2018.05.067

Camassola M, Dillon AJP (2007) Effect of methylxanthines on production of cellulases by Penicillium echinulatum. J Appl Microbiol 102:478–485. https://doi.org/10.1111/j.1365-2672.2006.03098.x

Stoffel F, Santana WdeO, Gregolon JGN et al (2019) Production of edible mycoprotein using agroindustrial wastes: Influence on nutritional, chemical and biological properties. Innov Food Sci Emerg Technol 58:102227. https://doi.org/10.1016/J.IFSET.2019.102227

Sindhu R, Binod P, Pandey A (2016) Biological pretreatment of lignocellulosic biomass - An overview. Bioresour Technol 199:76–82. https://doi.org/10.1016/j.biortech.2015.08.030

Binod P, Janu KU, Sindhu R, Pandey A (2011) Hydrolysis of lignocellulosic biomass for bioethanol production, 1st ed. Elsevier Inc

Schneider WDH, BolanõLosada C, Moldes D et al (2019) A sustainable approach of enzymatic grafting on eucalyptus globulus wood by laccase from the newly isolated white-rot basidiomycete Marasmiellus palmivorus VE111. ACS Sustain Chem Eng 7:13418–13424. https://doi.org/10.1021/acssuschemeng.9b02770

Lynd LR, Laser MS, Bransby D et al (2008) How biotech can ransformation biofuels. Nat Biotechnol 26:169–172. https://doi.org/10.1038/nbt0208-169

Leisola M, Pastinen O, DDA (2012) Lignin—Designed Randomness Matti. Biocomplexity 1–11. https://doi.org/10.5048/BIO-C.2012.3

García-Torreiro M, López-Abelairas M, Lu-Chau TA, Lema JM (2016) Fungal pretreatment of agricultural residues for bioethanol production. Ind Crops Prod 89:486–492. https://doi.org/10.1016/j.indcrop.2016.05.036

Lee J-W, Gwak K-S, Park J-Y et al (2007) Biological pretreatment of softwood Pinus densiflora by three white rot fungi. J Microbiol 45:485–491

Acknowledgements

We would like to thank Dr. Luiz Humberto Gomes of Luiz de Queiroz College of Agriculture (ESALQ), University of São Paulo, Piracicaba, SP for the kind donation of Saccharomyces cerevisiae strain CAT-1 and Professor George Jackson de Moraes Rocha for the kind delivery of sugarcane bagasse.

Funding

This research was supported by grants from CAPES (3255/2013) and the National Council for Scientific and Technological Development (CNPq) (472153/2013–7). Marli Camassola is a recipient of a CNPq Research Fellowship.

Author information

Authors and Affiliations

Contributions

Conceptualization and design, MC; methodology, CH, RCF, and MC; investigation, CH and RCF; writing-original draft preparation, CH and MC; writing-review and editing, CH, FGS, and MC; administrative and technical support, and obtaining of funding: MC.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable for this study.

Consent for publication

Informed consent was obtained from all individual participants included in the study.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Hartmann, C., Fontana, R.C., de Siqueira, F.G. et al. Fungal pretreatment of sugarcane bagasse: a green pathway to improve saccharification and ethanol production. Bioenerg. Res. 15, 1130–1143 (2022). https://doi.org/10.1007/s12155-021-10329-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-021-10329-6