Abstract

Economic and social development around the world has contributed to increased energy demands, which have strained the energy supply chain. The global energy matrix depends on the exploitation of fossil fuels, which are responsible for disastrous social, political, and environmental impacts. This situation has led to the need for technological advances in the development of new sources of safe, renewable, and sustainable energy production. In recent years, biomass has gained importance among emerging sources of energy production due to its abundance and renewable nature. Therefore, this study reviews the availability and physicochemical properties of unexplored Amazonian biomass sources, which, in principle, neither compete with food production nor have disastrous environmental impacts on the Amazon forest. This review also focuses on thermochemical conversion methods for possible application of the biomasses under study to produce electricity for geographically isolated communities in the Amazon, whose electricity comes from generators powered by diesel oil, a nonrenewable and relatively expensive resource. The information provided in this article is important for the formulation of alternative and renewable energy government policies for the Amazon region, in addition to presenting a scientific study of the main biomass available in the region, including thermochemical characteristics for energy conversion.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Society has become increasingly dependent on energy to conduct its basic activities related to education, health, entertainment, transport, and food, as well as its more complex tasks, such as industrial production. Population growth and economic and social development are strong contributors to the increase in energy consumption, especially in developing countries. This situation has led to the need for technological advances in the development of new sources of energy production. Currently, the burning of petroleum, natural gas, and coal accounts for approximately 81.4% of the world’s overall primary energy matrix, whereas only 9.7% of this energy originates from biomass and waste. The remainder is provided by nuclear energy (4.9%), hydroelectric energy (2.5%), geothermal energy, solar energy, and wind energy; the geothermal, solar, and wind energy together account for approximately 1.5% [1, 2].

Despite the increase in demand for new energy sources, the world’s energy matrix remains largely dependent on fossil fuels, which are to blame for disastrous social, political, and environmental impacts. One of the most relevant impacts is the uncontrolled emission of CO2, which leads to the intensification of global climate change. Most countries are now revising their power generation policies for the future with a tendency for increased inclusion of clean and renewable fuels. Over the past few years, biomass has gained importance among the emerging sources of energy production due to its abundance and renewable nature [3]. Complete replacement of coal by biomass for the generation of heat and electricity could reduce CO2 emissions by an estimated 44% [4].

However, when biomass is directly used as biofuel, it faces several serious problems, such as high moisture content, heterogeneous composition, low calorific value, and highly variable composition and properties. Therefore, to overcome the aforementioned obstacles and use biomass as biofuels, it must be subjected to thermochemical conversion processes such as torrefaction, pyrolysis, combustion, and gasification [5].

The USA and the European Union are pioneers in the use of biomass for energy purposes, where corn (kernels of Zea mays L. and subspecies) and beets (roots/tubers of Beta vulgaris L. and subspecies) are the sources of bioethanol. In Brazil, sugarcane (Saccharum officinarum L. stalks) is the most common source for the production of bioethanol [6]. An estimated 5 billion t of residues result from bioethanol production alone each year worldwide. These residues are promising sources for further production of second-generation biofuel [7]. According to one estimate, if all agricultural waste was converted into energy, it would meet approximately 64% of the world’s energy needs and would have the most significant contribution from biomass energy [8, 9]. However, several technological, processing, and economic problems remain, such as producing enough waste to supply the plants, the lack of biomass pretreatment technologies, and the costs of transporting the biomass.

Although large volumes of waste result from activities such as the production of bioethanol, only a small part of this residual material is destined for energy production. Significant sources worldwide include rice husks and sugarcane bagasse. Rice husks can be converted into fuel using thermochemical processes. Among the various thermochemical processes, the fast pyrolysis process is the most commonly used in the production of bio-oil, and the yield in percent by weight of feedstock varies from 30 to 70% for bio-oil, 15 to 50% for solid char, and 15 to 20% for gas [10]. Sugarcane bagasse mainly utilizes fuel for the generation of electricity to power bioethanol mills [11]. However, the electrical efficiency of the combustion process is four times lower than that of the application of biomass in the gasification process [12]. In Brazil, 91.5% of sugarcane bagasse generated was designed for use as solid biofuel in energy cogeneration. There are also reports of research using bagasse as feedstock for pyrolysis processes to obtain activated carbon and in gasification for syngas production [13].

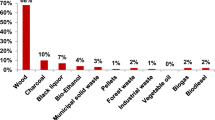

In the Brazilian matrix, hydroelectric plants provide 65.2% of the overall energy production. Thermal energy is the second largest component in Brazil’s matrix, with 17.1% supplied by fossil fuels, 8% by biomass, 6.8% by wind energy, 2.5% by thermonuclear plants, and only 0.13% solar energy [14], as demonstrated in Fig. 1. The diversification of the energy matrix is partly a consequence of the lack of investment in new hydroelectric plants and partly to avoid security problems related to the use of a single energy resource, which can impact the energy supply during long periods of drought. During this period, the electricity supply was mainly supplied by thermoelectric power plants powered by fossil fuels and biomass. It is noteworthy that the use of biomass to generate energy remains inexpressive in the current scenario [15].

Most of the main hydroelectric plants are not geographically close to the main consumption centers; therefore, the supply of electricity necessary to supply the entire Brazilian territory is distributed through the National Interconnected System (SIN), which interconnects all of the large plants. Only 3.4% of the country’s energy production capacity is outside the SIN in small isolated systems, mainly in the Amazon region. Many of these isolated systems have precarious access to energy due in part to efforts to keep the forest well-preserved [16].

Although the Brazilian Amazon region has approximately 45% hydroelectric potential, the State of Amazonas, where the main river in the Amazon basin is located, differs from the remainder of Brazil in its generation of energy because a large part of its energy does not come from hydroelectric plants. The state of Amazonas has only the Balbina hydroelectric plant, which is located on the Uatumã River, an affluent of the Amazon River, and it has the capacity to produce 250 MW of renewable energy, which is insufficient to supply the energy demand of the capital Manaus [17]. The reason is that the installation and operation of transmission lines for the generation of electricity from hydroelectric plants in the state of Amazonas are disadvantaged by the region’s topography, which includes little slope in river areas, and consequently, low hydroelectric potential; in addition, there is damage to aquatic and terrestrial biodiversity, the dispossession of indigenous villages, and high emissions of greenhouse gases, such as nitrous oxide (N2O), carbon dioxide (CO2), and mainly methane (CH4), due to the abundant presence of organic matter and high temperature, which favors decomposition [18, 19].

The state capital of Amazonas, Manaus, is part of the national energy distribution system; however, part of the capital’s electricity is supplied by thermal plants fueled with fossil fuels. The 95 isolated systems in the interior of the state range from small communities with a population of 15 inhabitants to larger cities with approximately 100,000 inhabitants. Currently, the current system utilizes isolated electrical systems that predominantly use fossil fuels in generators, which shows high costs related to operation and maintenance and fuel distribution logistics [20, 21]. However, in the region, there has been one change in the type of fuel used to generate thermal energy. The inauguration of the Urucu-Coari-Manaus gas pipeline has allowed the use of natural gas to help meet the energy demands of the metropolitan region of Manaus [21]. Although natural gas is a more economically viable energy source than diesel fuel, it is as challenging to install gas pipelines as it is to install power transmission lines across the Amazon. These difficulties enhance the attractiveness of power generation systems that run on renewable resources found on site. Power generation systems of this type present themselves as an option for the universalization of electricity in the country, and because they use the natural resources available on site to obtain primary energy, their operation implies less impact on the environment [22].

Therefore, there are studies that indicate the use of biomass discarded from plantations and/or agro-industrial residues as fuel for the generation of electric energy [23]. There are many Amazonian biomass sources. An important source is seeds [22] from the acai palm (Euterpe oleracea Mart.) fruit, which is part of the local diet and is consumed today on a large scale in Brazil and elsewhere. The processing of acai fruit generates thousands of tons of waste that has potential use in the production of electricity [24]. Another residue with potential for energy production is the Brazil nut (Bertholletia excelsa Bonpl.) shell [25]. After acai, it is the second most harvested, non-timber forest product in northern Brazil [26]. Other relatively unexplored sources of biomass exist that represent waste in sufficient volume to be converted into energy using several thermochemical processes and that originate from locally consumed native Amazonian fruits.

The objective of this review is to present the availability and physicochemical properties of unexplored Amazon biomass residues that in principle do not compete with food production or represent disastrous environmental impacts for the Amazon forest. This review also focuses on thermochemical conversion methods for possible application of the biomasses under study to produce electricity to serve geographically isolated communities in the Amazon. The information provided by this article is an important aid for the creation of governmental policies for alternative and renewable energy for the Amazon region, as well as introducing a scientific study of the main biomass available in the region and of its thermochemical characteristics for application in thermal processes of energy conversion.

We present this review article in 6 sections. After this introduction, the next section addresses the energy potential of Amazonian biomasses, with emphasis on their production and residues for later application in thermochemical conversion processes. Section 3 highlights the characteristics of thermochemical biomass conversion processes. The fourth section presents the energy potential of Amazonian biomasses already studied by approximate analysis (moisture levels, volatile matter, fixed carbon, and ash) and the highest heating value (HHV). Section 5 outlines the energy perspectives and challenges to be faced in the use of these biomasses as an energy source. Section 6 gives the conclusions of the survey.

Assessment of Biomass Energy Potential in the Amazon Region

Chemicals or fuels produced by lignocellulosic biomass from agricultural and forest residues are ecologically sound. These chemicals represent sustainable sources for the production of heat, energy, and fuels. Although the combustion of biomass emits CO2, the quantity generated is equivalent to the amount of this gas removed from the atmosphere during the development of the plant through photosynthesis; therefore, CO2 equilibrium occurs. The use of biomass can reduce the emission of SO2 and NOx gases, since biomass has a low amount of sulfur and nitrogen when compared to many fossil fuels [27].

Lignocellulosic biomass is typically composed of three main building blocks: cellulose, hemicellulose, and lignin. Cellulose is the most abundant natural biopolymer and consists of d-glucose monomers that form polymeric chains. It makes up plant cell walls together with hemicellulose and lignin and corresponds to approximately 40–55% by weight (wt%) of most biomass [28]. Hemicellulose has a structure based on heterogeneous groups of branched polysaccharides. It is the second most abundant component in biomass, ranging from 15 to 35 wt%, and it acts as a glue to hold cellulose and lignin together [29]. Cellulose and hemicellulose are responsible for the volatile matter in biomass. Lignin is formed from directly linked hydroxyl- and methoxy-substituted phenylpropane units. Lignin is present in the outer layer of fibers and is responsible for making the cell wall resistant to mechanical and biological degradation, receiving the name fixed carbon of biomass. The percentage of lignin varies from 18 to 35% by weight in lignocellulosic biomass [30].

The physicochemical properties of some types of biomass allow their use as renewable energy sources, providing promising alternatives for the energetic sector worldwide. In total, 62 countries generate electricity from biomass. In the USA alone, the annual supply of agricultural and forestry biomass residues is 1.3 billion tons, which is enough to replace more than 30% of the current transportation fuel use. With this amount, the USA leads 26% of the world production of renewable energy from biomass residues, followed by Germany with 15%, Brazil and Japan with 8% each, and the UK with 5% [31].

Brazil has a predominantly renewable energy matrix composed of hydroelectric (63%), wind (9.0%), biomass (8%), and solar (2%) technology that together represent 82% of the country’s power generation capacity [32]. Despite this accomplishment, further studies are needed to prepare the various regions of the country for future technological challenges, especially regarding the use of the type of biomass available for energy production while considering the peculiarities of each state and region in the Brazilian Federation.

Machado et al. [3] evaluated the energy potential of five biomass residues: banana (Musa spp.) pseudostem, cashew (Anacardium occidentale L.) nut shell, babassu (Orbignya speciosa) coconut shell, mango (Mangifera indica) pruning, and flower stalks found in northeastern Brazil to explore the viability of production of combustible briquettes from these materials. The higher heating value (HHV) was approximately 17 MJ kg−1 for babassu coconut shell and mango pruning, which is consistent with values observed in other studies. The energy potential of these biomasses is sufficient and could reduce environmental and social impacts caused by the severe extraction of wood for the production of charcoal and firewood in the interior of the State of Ceará. In another work, Ignacio et al. [33] studied the thermal properties of cultivated Eucalyptus urosemente with the objective of converting it into fuel for boilers and demonstrated its importance as biomass in southeastern Brazil. The residue from eucalyptus production was also used as a raw material in the gasification process. The combustible gas composition of eucalyptus chip gasification was predominantly CO (20%), followed by H2 (11%), CO2 (9%), and CH4 (9%), and the mean HHV of the gas was 7 MJ Nm−3. In this same work, the composition of the fuel gas was evaluated using waste from coffee production, such as coffee husks and coffee wood. Brazil is the largest coffee producer in the world and concentrates 80% of production in the Southeast region, generating a large volume of waste with potential for energy production for the region. The combustible gases produced were mostly CH4 (15%) for coffee husks and CO (14%) for coffee wood [34].

There is an abundance of biomass or biomass residues available in Brazil that have the potential to contribute to society’s demand for energy. Solarin and Bello [35] demonstrated the possibility of replacing fossil fuels with biomass in Brazil. Thus, it is important to know the biomass residues that are available in each Brazilian region to continuously supply energy conversion units to facilitate sustainable development. Thus, it is important to have knowledge of the biomass residues that are available in each Brazilian region for the production of energy to facilitate sustainable development. This knowledge guarantees the conservation of forest species and, consequently, identifies regional peculiarities while at the same time minimizing the dependence on fossil fuels.

A unique feature of the Amazon region is its many isolated, riverine communities. The main characteristics of these local communities are (1) a reduced and decentralized consumer market, in which kilometers of cables are needed to supply a single dwelling, due to the vast territorial dispersion; (2) difficult access, which is predominantly done by boats or aircraft, generating costs based on the transport of fossil fuel by river; (3) the prohibition of passing on various operating costs to the tariff, due to the low level of income in local communities; and (4) the increase in technical losses in the generation and distribution systems, leading to significant financial losses. These specific characteristics make it difficult to access basic daily services such as health, education, and public services, among others. Unfortunately, these communities lack decentralized and individualized energy generation, given the costs of transmission and the distribution of energy. Therefore, specific studies that facilitate the use of its natural resources for the generation of its own energy are fundamental. Information obtained through studies such as these is relevant because in the future, it will be necessary to replace the use of energy from fossil fuels [36, 37].

A study conducted in 2018 showed that there are 70 non-wood native biomass sources that are available in extractive reserves in the Amazon that can be used as a renewable source for bioenergy production to serve the isolated communities located in these reserves [38]. These communities are accessed by rivers, and the main source of energy used is fossil fuels; the fuel is often transported by rivers, which makes the energy supply limited in periods of drought in the region’s rivers. However, the authors did not investigate the physicochemical properties and thermochemical processes necessary to apply biomass as an energy source. This approach would hinder the development of specific projects and the generation of data and information sufficient to provide an environment for discussion and evaluation, together with the evaluating bodies, on the use of Amazonian biomass for energy generation in the region. Based on this research, our study investigated the physicochemical characteristics of the main biomasses found in the Amazon region, with emphasis on those produced in greater quantities in the states of Amazonas and Pará, Brazil, and there are already studies recognizing them as having potential for the generation of energy (Fig. 2).

In 2018, an estimated 220 kt of acai fruit were consumed in the state of Amazonas and Pará alone, which represents approximately 176 kt of acai seeds (80% residue from the total processed fruit) [39, 40]. This waste often ends up simply discarded or dumped directly onto the streets. This problem causes environmental and health risks for the population in addition to compromising the government budget due to the allocation of resources for cleaning sidewalks, streets, and riverbanks/beaches in cities and towns. An economical and environmentally friendly alternative would be to use this resource for the production of renewable energy. Another interesting material for power generation is the shell of Brazil nut since it is an abundant byproduct and generates a large amount of waste. It is estimated that approximately 34 kt were produced in the state of Pará alone, of which 90% of the fruit is considered to be waste (fruit pods or shells and nut shells) [39, 41].

Cupuacu fruit has a number of different uses, mainly not only for food purposes, but also in traditional medicine and cosmetics. The largest producer of the fruit is the state of Pará, with a production of approximately 28 kt in 2018 [42]. Production generates a large volume of husk and seed waste (~ 30% of the weight of the fruit), and while seeds can be eaten, there are no reports of the reuse of shell residues [43, 44].

Tucuma is a foodstuff used in culinary applications and is found in local markets. The pulp has applications in the preparation of ice cream, sweets, and as an ingredient in sandwiches. In 2017, 5 kt of fruit pulp were produced [28], of which 38% of this total consisted of endocarp. Although studies show that tucuma can be fully utilized, in practice, the endocarp is normally taken to garbage dumps [45, 46].

The inaja fruit is native to the northern region of Brazil. Its orange pulp is eaten fresh or cooked or can be transformed into wine. Its palm hearts are components of animal feed. An extraction of its seeds provides edible oil. The endocarp has no common use and has potential in power generation. Of an estimated 143 kg of harvested fruit, 61.5 kg (43%) is waste [47].

Buriti palm fruit has economic potential since it provides edible oil that is used in culinary applications and in the cosmetics industry. It is rich in monounsaturated fatty acids and natural antioxidants. In 2018, 497 t of this fruit were produced [39], of which 199 t (40%) were seeds that did not have an adequate destination [48]. Guarana is native to the Amazon region and is mainly used in soft drinks. In Brazil, from 2007 to 2017, the average annual production of this fruit was 4.3 kt. Beverage industries consumed approximately 70% of the total production. At the end of the industrial process, the seed is a waste byproduct. It normally returns to the environment after composting for use as a fertilizer in the soil. Another alternative is its use for power generation purposes [49].

Cocoa fruit and coconut are other fruits that are in great demand in Brazil and that are grown and consumed in the northern region and deserve to be highlighted in this study, since they also generate a large amount of waste. Today, Brazil is the seventh largest cocoa producer in the world, and the states of Bahia and Pará are the largest producers of cocoa and coconuts, respectively [50].

The participation of the state of Pará in the national cocoa scenario went from 18% in 2005 to 53% in 2018. In 2019, Pará maintained its leadership in Brazilian cocoa production. Of the 253 kt of this fruit produced in Brazil, Pará State accounted for 135 kt. Eighty percent of this weight is residual pod husks [49, 51]. The production of coconuts is also noteworthy in northern Brazil, where the states of Amazonas and Pará alone produced 178 kt of this fruit in 2019. Usually discarded, the fibrous part represents ~ 85% of the total weight of the fruit or 142 kt of waste. This circumstance means that each coconut consumed generates a pound and a half of waste [52].

Figure 3 represents the production of each fruit and the resulting residual biomass in the states of Amazonas and Pará, which are the largest fruit producers. It is possible to observe that in most cases, the weight of the waste exceeds that of the part used. This circumstance can contribute to the promotion of sustainable development in rural areas and underdeveloped regions from the generation of energy via the use of this waste.

The graph shows the percentage of fruit used and the amount of waste produced after processing in the states of Amazonas and Pará. These data were calculated based on the values described in the “Assessment of Biomass Energy Potential in the Amazon Region” section for the years 2017, 2018, and 2019 (assessment of biomass energy potential in the Amazon region)

Biomass Conversion Technology in the Amazon

The main technologies available to convert biomass into energy are biochemical and thermochemical. Biochemical processes involve anaerobic bacterial digestion, while thermochemical processes usually refer to the decomposition of organic matter at elevated temperatures to produce gas, thermal energy, and fuel oil. Generally, thermochemical conversion technologies involve combustion, torrefaction, pyrolysis, and gasification, as depicted in Fig. 4. The main differences among these three heat treatment methods are the operating temperature and the design of the process, which are mainly influenced by the type of raw material [53].

Conventional or direct combustion is a thermochemical process that is generally used to convert chemical energy into mechanical energy, electricity, and heat, which are commonly used in the processing industry; however, the release of atmospheric pollutants such as NO and CO2 must be accounted for [54]. Due to the increase in environmental pollution, this method is not viable for emerging countries such as Brazil, but it is applied in advanced countries such as China, Malaysia, and the USA with the main objective of minimizing the excessive volume of waste, condensing it by up to 90% from the production of electricity and heat. However, for the process to be effective, some characteristics must be observed, such as the types of fuel and fuel properties, process conditions, particle size, air flow rate, fuel moisture, increased undecaying organic matter, and higher heat value [55, 56].

The torrefaction process involves the heating of biomass at a temperature range of 200–300 °C in an inert environment for up to 60 min. This process is also called mild pyrolysis, because it operates at a relatively low temperature. The main objective of this technique is to promote the pretreatment of biomass from the production of briquettes or torrefied pellets to improve its homogeneity, heating value, and grinding and to reduce its moisture content and low-weight organic volatile components. These goals are similar to those of carbonization, which produces charcoal, but with an important difference, in that carbonization does not retain as much energy from the biomass and, therefore, produces low energy yield [57]. The briquettes obtained in the torrefaction process are resistant to biodegradation, and because they have properties comparable to coal, they can be used as an alternative for charcoal/coal for domestic heating and improve the energy potential of biomass in combustion, pyrolysis, and gasification processes [58].

Pyrolysis is another thermochemical conversion method; in this process, biomass is heated to 300–800 °C in the absence of air or oxygen to produce solid fuels (coal, biochar, or biocoal), liquids (bio-oil), and sygas. The amount produced during the process depends on the heating rate, the resistance time, the process temperature, and the lignocellulosic composition of the residue. Generally, the pyrolysis process is classified into three types: slow pyrolysis, intermediate pyrolysis, and fast pyrolysis. In slow pyrolysis (reaction temperature less than 450 °C), biochar is the main product, and its yield is directly related to the presence of ash and lignin present in biomass. In contrast, fast pyrolysis (reaction temperature between 450 and 800 °C) produces bio-oil, which can replace fuel oil in any static heating or electricity generation application [59]. Intermediate pyrolysis takes place in the temperature range of 300–500 °C, and compared to fast pyrolysis, the liquid products obtained from intermediate pyrolysis have low tar yield and viscosity [60].

During the pyrolysis process of lignocellulosic biomass, the main chemical components (extractive, holocellulose, and lignin) decompose individually. Up to 100 °C, the extractives are eliminated. Holocellulose (a combination of hemicellulose and cellulose) degrades in two stages. The first stage of mass loss is related to the decomposition of hemicellulose at a temperature of 240–290 °C, and the second mass loss event refers to the decomposition of cellulose in the temperature range of 320–360 °C. Lignin decomposes in the last stage of mass loss (above 500 °C). The interaction between the components determines the product distribution in the bio-oil [61, 62].

The gasification process consists of heating the biomass to high temperatures (> 800 °C) and obtaining syngas as a product, which is composed mainly of combustible gases CO and H2, certain amounts of CO2 and CH4, and small amounts of aliphatic hydrocarbons, benzene, toluene, and tars (in addition to CO2 and H2O), which can be used in internal combustion engines and turbines to generate electricity [13]. Gasification is the most commonly used thermochemical conversion process in developed countries such as Germany, the USA, Norway, the UK, Iceland, and Japan. The attraction of this technique is the lower production of CO2 during the process when compared to the combustion process. However, when comparing the benefits of the gasification and pyrolysis process, the fuel formed from the pyrolysis of biomass is desirable, because it has a greater volumetric heat content and low transport cost, a consequence of the easy storage of the fuel [60, 63].

Fundamental studies on each type of biomass are needed to assess its value as a raw material in thermochemical conversion processes, for example, the study of thermal properties and chemical composition. In addition to the estimate of annual production needed to supply the capacity of the biomass plants, there is the cost of harvesting, the cost of transporting the biomass to the site of the plant, the required pretreatment, and the ways of distributing and marketing the energy generated. Based on local research, knowledge of energy conversion technologies and the help of current legislation, an initial diagnosis can be made for the implementation of a thermal plant that uses biomass as fuel [64]. The biomass supply chain for renewable energy generation is composed of a series of sequential steps, which include availability, logistics, and raw material preprocessing; thermochemical conversion technologies; and, finally, distribution and final use of the renewable fuel (Fig. 5) [65].

The Brazilian Amazon region requires electricity for 270 municipalities that are part of the so-called isolated systems and, therefore, are not connected to the National Interconnected System (SIN). Electricity in these regions is produced mainly by 265 thermal plants, of which 97% run on diesel or fuel oil. The remaining plants use natural gas, biomass, or photovoltaic energy. Of this total, 170 thermoelectric plants supply only the capital of the state of Amazonas. In 2018, the gross power generation capacity of thermoelectric plants in the Brazilian Amazon was more than 8,725,332 MWh [32].

The limited use of biomass as an energy source to meet the energy demand of at least a part of the capital of the State of Amazonas and its various isolated systems drives research in experimental studies in the literature that address the perspective of energy production from Amazon biomass. Based on these studies, government policies favor the development of pilot plant projects powered by biomass as a more convenient and economical option than the generation of electricity using diesel, in these isolated communities [66].

Macedo et al. [22] proposed the development of a water steam microscale plant to generate electricity from the burning of 204 kg of biomass with 500 W of power. The thermal system consists of a combination of heat and electricity, whose objective is to meet the energy supply in isolated communities in the Amazon region. Pinheiro et al. [67] presented a proposal for the implementation of a small power plant with a steam system generated from the direct firing of the residues from the local sawmill and broom factory. The plant installed in the community of Santo Antônio, located in the State of Pará, Brazil, has a specific consumption of approximately 6 kg of biomass/kWh, which requires 300 kg per hour of biomass to meet a demand of 50 kW. The energy produced is capable of supplying 36 households, a school, two churches, and kilns of broom factories.

Sánchez et al. [68] described the project of a biomass plant, which was used as fuel for biomass burning from a local saw located on Marajó Island in the state of Pará, Brazil. The operation and maintenance of the whole system, which includes energy generation, transformation, and distribution, is performed by a community cooperative. The biomass plant provides 200 kW of energy, of which 150 kW is intended for an ice factory that will serve local fishing and a vegetable oil factory that benefits local species from the forest. The remaining capacity (50 kW) is distributed to schools, community centers, and residential demand. The investment in installing the biomass plant was valued at USD 382,350.00 and provides an average operating and maintenance cost of USD 0.26 per kWh. In the work by Sánchez et al. [68], the use of Amazonian biomass as solid fuel in the gasification process was also presented. The biomass gasificator used cupuacu bark residue and acai seed residue. The cupuacu seed biomass gasifier generated 20 kW to power supplied to 90 households in an isolated community of Timbó, in the state of Amazonas, thus replacing up to 80% of the diesel consumed by the generator engine. Meanwhile, the acai seed biomass gasifier generated 80 kW, which was distributed for the production of acai fruit processing, for energy generation in schools, churches, and households in the community of São Francisco do Paroá, in the state of Amazonas.

In another study, Itai et al. [69] evaluated the utilization of acai seeds in gasification systems as an alternative for the production of electricity in isolated communities in the Amazon. Combining the experimental and numerical results, it can be concluded that the designed cylindrical gasifier had an efficiency of 200 kW and produced clean and tar-free gases from the acai seed gasification process. Pessoa et al. [70] reported the use of waste from the acai processing industry as biomass from a gasifier for power generation in local communities in the state of Pará. The energy generated in the gasification process was quantified at 26 kWe and generates an estimated monthly revenue of USD 460 per worker/community resident. In addition, the charcoal resulting from this process was activated and successfully used in the treatment of effluents from textile industries in the Amazon region. Table 1 summarizes the works cited above on the use of and products of biomasses in terms of biorefinery for energy generation in isolated communities in the Amazon region.

Sato et al. [71] showed that acai seeds also have great potential for the production of biochar, and their addition to soil can result in environmental, economic, and social benefits. The research indicated that the application of biochar in nutrient-poor and degraded soils improves its texture, acidity, and fertility. Reis et al. [72] studied the combustion properties of five Amazonian biomasses: Brazil nut shell, acai seed, cupuacu shell, cocoa shell, and coconut shell, which have potential for use in bioenergy. Lira et al. [73] studied the feasibility of using rapid pyrolysis to convert tucumã seeds into bio-oil and biochar. The bio-oil produced included several compounds of interest to the chemical and pharmaceutical industry, such as guaiacol. The maximum bio-oil yield was 60% by weight, with a high heating value (HHV) of 31 MJ kg−1. Compared to other pyrolysis products, biochar has the potential to be used as a soil corrective agent, and the product gases can be used to provide the energy needed for the process.

In another study, which involved the use of tucumã residue for conversion into biochar, Cruz et al. [56] characterized three parts of the tucumã fruit: almonds, stones, and tucumã seeds. The HHV values obtained for almonds (27.0 MJ kg−1), for stones (20.0 MJ kg−1), and for the tucumã seeds (25.0 MJ kg−1) are close to the HHV value of vegetable coal (≈ 25.0–33.0 MJ kg−1). With the obtained data, it was possible to predict the energetic viability and applicability of the tucumã biomass in thermochemical conversion processes through combustion or any other types of reactors and/or industrial processes. Matos et al. [74] described the use of agro-industrial waste of the Amazon region, such as cocoa husks, cupuaçu, açaí kernels, piquiá, babassu, bacuri, and tucumã, to produce energy from the gasification process. Incomplete combustion produces a synthesis gas with sufficient calorific power to feed engines and to produce electricity. Another form of biomass use is through biodiesel, obtained from palm oil and babassu oil, as an additive or supplement in internal combustion engines, generator groups, or thermal plants that use diesel or automotive oil, which can be used for power generation in isolated communities of the Amazon. This step, in turn, would contribute to the improvement of the quality of life of the inhabitants of the most isolated region in the country.

As seen in the studies described above, biomass is a sustainable energy alternative for reducing CO2 emissions from the burning of fossil fuels because it is a carbon–neutral source. However, the use of biomass resources for energy production begins with an economic feasibility study. Considering the costs involves identification of the ideal biomass to be explored, in other words, the biomass amount needed to provide a given energy demand that would be supplied by a given fossil fuel amount; the best method for cultivation, harvesting, storage, and energy equivalence expresses, for example, the amount of biomass needed to replace 1 t of oil equivalent. It is also necessary for people in the community to be trained to operate and perform minor maintenance on the electrical system, as well as to manage independently and continue the project after implementation. Such care must be taken because transport, logistics, and the considerable distances found in the Amazon region are inherent obstacles to the completion and maintenance of biomass thermoelectric plants in these most isolated regions of the country [73].

Combustion Properties of Unexplored Amazon Biomass Sources

As previously mentioned, biomass has favorable characteristics for energy production when compared to fossil fuels, especially with regard to the emission of CO2 into the atmosphere. However, for the selection of thermochemical conversion processes from biomass to energy, it is essential to have knowledge of the physicochemical properties, which mainly consist of data on the moisture content, volatile matter content, fixed carbon content, ash, and higher heat value. However, to enable the correct destination of biomass for energy, it is necessary to characterize it, which consists mainly of determining the moisture content, the volatile matter content, the fixed carbon content, and the ash content. These analyses are fundamental parameters for classifying fuel from biomass since these physicochemical properties (or lack thereof) directly influence the calculation of the superior heating power [75].

To apply biomass residue in the thermochemical processes of combustion, torrefaction, pyrolysis, and gasification, it is recommended that the material has a moisture content below 20%. For humidity values above this limit, part of the energy generated during the process will be redirected to vaporize the water, thus reducing the amount of heat produced during the thermochemical processing. There are also negative implications when using biomass with a high moisture content in these conversion processes due to milling, transport, drying, storage, handling, microbiological safety, and reduced combustion capacity [76, 77]. To solve the problem of high moisture content in biomass, it is subjected to the torrefaction process, which removes moisture through dehydration, and dry biomass can be applied in energy conversion processes without the loss of heating value. According to published moisture content data for Amazonian biomasses, namely, buriti seed [48], guarana seed [49], tucuma seed [56], Brazil nut shell, cupuacu shell [72], acai seed, coconut husk [78], and cocoa pod husk [79], all biomasses reported here have results for moisture contents below 13%, which makes them attractive for applications in energy conversion processes.

Volatile matter and fixed carbon are two important parameters that explain fuel properties. Biomass with high volatile matter is suitable for the thermochemical conversion process of combustion and bio-oil production. Theoretically, the high volatile matter content makes the raw material more reactive, facilitating ignition at a low temperature. However, rapid volatilization is not favorable to the roasting process due to the formation of undesirable products, such as tar and smoke [58]. The literature reports biomass Buriti seeds [48] with a volatile matter content of 85%, the highest value found among the biomasses presented here. Since Buriti seed has a higher volatile matter than coal, it can have a significantly lower ignition temperature and is therefore attractive for combustion and pyrolysis processes [80].

The fixed carbon content is the nonvolatile fraction of the biomass. It controls the combustion reaction after removing the volatile matter content and is one of the parameters with the greatest influence on the calorific value of the biomass [60]. This parameter also directly reflects the production of biochar, because biomass with higher fixed carbon will produce a greater amount of biochar. If the biomass does not have a high fixed carbon content, it can be subjected to the torrefaction process before being applied in the combustion, pyrolysis, and gasification processes, since roasting increases the fixed carbon content while reducing the volatile matter and moisture. In the literature, the Amazonian biomass with the highest amount of fixed carbon is the Brazil nut shell [72], which has 38% fixed carbon.

Inorganic compounds are present as ash in the biomass feedstock. According to Ozyuguran et al. [81], the expected ash content for lignocellulosic biomass is between 0.1 and 16%. Only the cocoa pod husk sample (8%) [80] had a high ash content, although it was still acceptable; the other samples were between 0.2 and 8%. A high percentage of ash is a serious problem for a fuel because it can cause problems such as equipment corrosion, scale, clogging, and slag [82].

Of all the parameters shown thus far, the higher heating value (HHV) is one of the most important indicators of fuel quality. HHV expresses the maximum amount of energy that can be released when biomass is subjected to thermochemical conversion processes. The literature shows that the HHV of agricultural residues is generally in the range of 15 to 20 MJ kg−1, which is much lower than coal, which ranges from 22 to 35 MJ kg−1 [83]. The samples of Amazonian biomass residues presented [48, 49, 56, 72, 78, 79] in our study are between 18 and 22 MJ kg−1. The HHV values of Amazonian biomasses presented in the study are similar to the HHV values of bio-oil and biochar prepared from the lignocellulosic biomass pyrolysis process reported in the literature [60]. For the use of lignocellulosic biomass in gasification and combustion processes, HHV values of 20 MJ kg−1 are recommended [84].

Along with the composition of the raw material, knowledge of the decomposition behavior of biomass is also important to define which raw material will obtain the highest yield in biochar, bio-oil, and sygas in thermochemical conversion processes. This type of study is conducted through thermogravimetric analysis and differential scanning calorimetry and is mainly applied in pyrolysis and gasification technology. In the literature, there are kinetic studies of Amazonian biomass pyrolysis [85,86,87], which provide study parameters for the development of pyrolysis reactors and pilot thermoelectric power plants powered by biochar and bio-oil obtained from local biomass.

The bio-oil obtained from biomass pyrolysis can be used to heat turbines and engines to generate electricity and heat ovens and boilers. Bio-oil applications are not limited to generating electricity and heat. Many chemicals used in industry can be extracted from bio-oil, such as phenols used in the food, pharmaceutical, and paint industries and volatile organic acids used in the pharmaceutical, fertilizer, and food industries. Biochar can be used as a low-grade fuel in the adsorption of metal ions from wastewater and for the production of thermal energy [88].

Energy Perspectives and Challenges to be Faced

The isolated communities of the Amazon region with low population density demand less electricity, and for this reason, isolated electrical systems supplied with diesel oil are used, which presents high costs related to operation and maintenance and fuel distribution logistics. Among all resources available for the use of renewable energy, biomass is abundant and prominent at most sites. Therefore, to boost the emergence of thermal plants that use biomass as fuel, it is necessary to discover the thermal properties of regional biomasses. To boost the emergence of thermoelectric plants that use biomass as fuel, it is necessary to know the thermal properties of regional biomass.

The greatest cost involved in generating energy using a biomass thermal plant is the transport of biomass to the plant, since it is impractical to transport biomasses over long distances. Therefore, it is necessary for the plant to be installed in these communities and for biomass to be available on site. In addition to the operational cost of transport, biomass can suffer microbial decomposition due to the long storage and transport time to the plant. To reduce these additional costs with the biomass supply chain, it is suggested to pretreat the biomass by producing briquettes or torrefied pellets. Torrefied biomass is usually denser in energy and volume, more brittle, hydrophobic, and homogeneous, since the seasonality of biomass must be accounted for and since the plant’s supply can be made by combining available biomass [89].

The estimated costs of applying the torrefaction technology indicate a total capital investment of 34 €/ton of product (1.9 €/GJ); this value was estimated for a biomass with a moisture content below 25%. The production cost was increased to 50 €/ton of product (2.6 €/GJ) when applying a raw material with a moisture content of 50% [58]. In another study, the cost of the torrefied pellet production plant was estimated to be 7.03 US$/GJ [90]. Thus, the importance of studying the physicochemical properties of biomass for the proper selection of thermochemical conversion processes or the need for pretreatment before application in the process is highlighted.

The study of tomato peel pyrolysis made it possible to estimate the economic analysis of the implementation of a plant based on bio-oil obtained from tomato peel residue. The capital cost includes the supply to the plant, the operating cost, the energy consumption (heater coil, pumps, and chiller) and the residual value. These expenses were estimated at 6 €/kWh [91]. Another study evaluated the economic feasibility of a fast pyrolysis biorefinery with blended pine residue and switchgrass in southeastern USA with a different supply chain design [92].

Marató et al. [93] investigated the techno-economics of installing an electricity-generating plant based on the combustion of agricultural biomass residues from the harvest of sugarcane, soybean, corn, rice, sorghum, and sunflower. The cost components evaluated were the costs of harvesting biomass from the fields, baling, transporting, storing, nutrient replacement, and capital cost for the plant, totaling an estimated value of $71.6/MWh to supply a power plant with a capacity of 300 MW.

Cervi et al. [94] evaluated the environmental potential of biomass residue sugarcane straw and eucalyptus harvest and the techno-economic potential of biojet fuel production in Brazil. The environmental potential of biomass residues ranges from 70 Mt in 2015 to 102 Mt in 2030. These quantities can generate a techno-economic potential of biojet fuel that ranges from 0.45 EJ in 2015 (46 US$/GJ–65 US$/GJ) to 0.67 EJ in 2030 (19 US$/GJ–65 US$/GJ). By 2030, several biojet fuel production routes might be competitive with fossil aviation fuel prices. The northeast and southeast regions have the greatest potential due to the large volume of agricultural waste generated from the grain industry and ethanol production.

The study developed by Nogueira et al. [95] presented a techno-economic evaluation of the production of electricity from vinasse biogas obtained in a sugar and alcohol plant in the state of Paraná, Brazil. For the author, the costs involved in creating any power generation unit based on biogas depend entirely on the size of the plant, the adapted technology, and the labor costs. For the produced waste capacity, an energy generation system with an installed capacity of 3.1 MW was implemented. It was estimated that each 1 MWh of energy produced would cost US$ 2,122,115.38.

Silva et al. [96] presented in their study an analysis of the economic and energy analysis of rice husk energy production on a regional and national scale in Brazil. Electricity costs averaged 112.2 USD/MWh, generating an electrical energy potential of 497 MW (3,318,102 MWh/year). In more optimistic scenarios, the viable energy potential of this biomass in Brazil can exceed 2.5 TWh/year, which represents approximately 5% of the country’s total bioenergy production. These results demonstrate that energy generation from rice husks can be an important resource to increase bioenergy generation in Brazil. This trend was especially pronounced in the southern region, where rice production is more concentrated. In addition to the generated energy in the south region, it can supply the raw material for rice husks in the form of briquettes, facilitating its storage and transport to other regions of the country.

Several authors have researched the potential for energy generation from rice husks around the world. Anshar et al. [97] estimated the power generation potential of a steam plant fueled with rice husks. The available capacity of the plants is approximately 5664 MW, with an electric energy potential of approximately 49,622 GWh/year. This potential is equivalent to 50% of the electricity needed to supply coal fuel to plants in Indonesia. Silveira et al. [98] presented the potential for generating methane and synthesis gas produced from the gasification of rice husk residue. The methane produced is considered competitive in relation to other fuels, since 1 m3 of methane corresponds energetically to 1.25 to 1.43 kWh of electricity, 1.5 m3 of liquefied petroleum gas (LPG), and approximately 0.55 L of diesel oil. The synthesis gas had a potential of 14 MJ/kg, reaching up to 16 MJ/kg, and is used in the generation of heat and energy. Based on this information, methane and synthesis gas are widely viable in relation to the energy supply required by the grain processing industries in southern Brazil, and thus, they can become self-sufficient, with the possibility of generating energy up to 77 MWh.

As noted in the above studies, there are many techno-economic viability studies for the implementation of biomass-based pilot plants all over the world, including in Brazil. In particular, in the Amazon region, studies, research, and pilot projects for biomass-based power plants for the generation of electricity in various isolated systems have been exhaustively developed and implemented. However, the region still needs incentives and infrastructure to install these plants in more isolated regions, since studies clearly point out the potential of Amazonian biomass residues to generate electricity. The goal is to nondestructively take advantage of natural resources to enable the development of the local population. In addition, the use of this waste generated in these locations would promote a positive gain for the region’s socioeconomic development, generating direct and indirect jobs that require less qualification and can be filled by the local population.

The main challenges and barriers for the generation of electric energy from the conversion of waste into energy are related to regulatory barriers, institutional barriers, and technological barriers. Regulatory barriers make it difficult for agencies to develop technologies and techniques that are vital for supplying the production chain of biomass-based plants. In addition, companies that benefit from the Amazonian fruit and are consequently the generators of a large volume of waste have been facing problems in gaining governmental support to convert the waste generated in the industrial process into fuels. Institutional barriers are related to the creation of updated infrastructure for the biomass supply chain. The basic premise for managing the biomass supply chain in Amazonian communities must be that each community develops its own energy, according to its specific characteristics and potential. The supply of electricity must be the result of a clear and long-term commitment between local actions and the conservation of natural resources, with concrete and direct benefits for the local population, such as an increase in the quality of life evidenced in aspects such as health and education. The last challenge is related to the technological barriers available to convert biomass into reusable energy without loss of biodiversity, climate change, or other ecological problems [99].

Biomass is a renewable source that has clearly demonstrated its value for energy production; however, there is still room for significant improvement. It is noteworthy that in other regions of the country, such as the Southeast, for example, there are independent biomass plants that mainly use sugarcane bagasse as an energy source. Other regions also have thermoelectric plants that use local biomass, and there is no reason for the Amazon not to follow this trend.

Conclusions

This study investigated the different raw materials that are commonly found in the Amazon region, such as buriti, guarana, Brazil nut, cupuacu, acai, coconut, tucuma, inaja, and cocoa, as well as the residues generated from the fruit pulp or vegetable oil processing industry. One of the many possibilities that has been observed in this paper is focused on the energetic potential of the residues when applied in thermochemical processes. Amazonian waste has different physicochemical properties that are favorable for use as fuel, which demonstrates its great potential for energy generation. The application of Amazonian biomass in individual projects on a microgrid to meet the demand for electricity in isolated communities has been shown in several studies throughout the text. It was essential to know the physicochemical properties, which mainly consist of data on the moisture content, volatile matter content, fixed carbon content, ash content, and higher heat value. It was observed that there are residues produced in sufficient quantity to meet the electricity demand of isolated communities in the Amazon, but they must be explored for future applications and that thermochemical processes also must be improved and new technologies developed.

Data Availability

All of the data are available with the corresponding author and can be provided on request.

References

Safarian S, Unnþorsson R, Richter C (2019) A review of biomass gasification modelling. Renew Sustain Energ Rev 110:378–391. https://doi.org/10.1016/j.rser.2019.05.003

Ghasemian S, Faridzad A, Abbaszadeh P, Taklif A, Ghasemi A, Hafezi R (2020) An overview of global energy scenarios by 2040: identifying the driving forces using cross-impact analysis method. Int J Environ Sci Technol. https://doi.org/10.1007/s13762-020-02738-5

Machado YL, Ponte MR, Gadelha AMT, Costa AE Jr, Malveira JQ, Mazzetto SE, Rios MAS (2018) A thermogravimetric analysis of biomass wastes from the northeast region of Brazil as fuels for energy recovery. Energ Source Part A 41:1557–1572. https://doi.org/10.1080/15567036.2018.1549132

Mohamed U, Zhao Y-J, Yi Q, Shi S-J, Wei G-Q, Nimmo W (2021) Evaluation of life cycle energy, economy and CO2 emissions for biomass chemical looping gasification to power generation. Renew Energy 176:366–387. https://doi.org/10.1016/j.renene.2021.05.067

Ong HC, Chen W-H, Singh Y, Gan YY, Chen C-Y, Show PL (2020) A state-of-the-art review on thermochemical conversion of biomass for biofuel production: a TG-FTIR approach. Energ Convers Manage 209:112634. https://doi.org/10.1016/j.enconman.2020.112634

Zhang L, Bai W (2021) Sustainability of crop-based biodiesel for transportation in China: barrier analysis and life cycle ecological footprint calculations. Technol Forecast Soc Change 164:120526. https://doi.org/10.1016/j.techfore.2020.120526

Soares J, Demeke MM, Velde MV, Foulquié-Moreno MR, Kerstens D, Sels BF, Verplaetse A, Fernandes AAR, Thevelein JM, Fernandes PMB (2017) Fed-batch production of green coconut hydrolysates for high-gravity second-generation bioethanol fermentation with cellulosic yeast. Bioresour Technol 244:234–242. https://doi.org/10.1016/j.biortech.2017.07.140

Kamani MH, Eş I, Lorenzo JM, Remize F, Roselló-Soto E, Barba FJ, Clark J, Khaneghah AM (2019) Advances in plant materials, food by-products, and algae conversion into biofuels: use of environmentally friendly technologies. Green Chem 21:3213–3231. https://doi.org/10.1039/C8GC03860K

Sarkar N, Ghosh SK, Bannerjee S, Aikat K (2012) Bioethanol production from agricultural wastes: an overview. Renew Energ 37:19–27. https://doi.org/10.1016/j.renene.2011.06.045

Gautam N, Chaurasia A (2020) Study on kinetics and bio-oil production from rice husk, rice straw, bamboo, sugarcane bagasse and neem bark in a fixed-bed pyrolysis process. Energy 190:116434. https://doi.org/10.1016/j.energy.2019.116434

Milão RFD, Carminati HB, Araújo OQF, Medeiros JL (2019) Thermodynamic, financial and resource assessments of a large-scale sugarcane-biorefinery: prelude of full bioenergy carbon capture and storage scenario. Renew Sustain Energ Rev 113:109251. https://doi.org/10.1016/j.rser.2019.109251

Raheem A, Zhao M, Dastyar W, Channa AQ, Ji G, Zhang Y (2019) Parametric gasification process of sugarcane bagasse for syngas production. Int J Hydrogen Energ 44(31):16234–16247. https://doi.org/10.1016/j.ijhydene.2019.04.127

Nicodème T, Berchem T, Jacquet N, Richel A (2018) Thermochemical conversion of sugar industry by-products to biofuels. Renew Sustain Energ Rev 88:151–159. https://doi.org/10.1016/j.rser.2018.02.037

ANEEL, National Electric Energy Agency. <www.aneel.gov.br/> (accessed December/2020)

Velloso MFA, Martins FR, Pereira EB (2019) Case study for hybrid power generation combining hydro-and photovoltaic energy resources in the Brazilian semiarid region. Clean Technol Environ Policy 1(5):941–952. https://doi.org/10.1007/s10098-019-01685-1

Teixeira ACR, Silva DL, Machado Neto LVB, Diniz ASAC, Sodré JR (2015) A review on electric vehicles and their interaction with smart grids: the case of Brazil. Clean Technol Envir Policy 17:841–857. https://doi.org/10.1007/s10098-014-0865

Winemille KO, McIntyre PB, Castello L, Fluet-Chouinard E, Giarrizzo T, Nam S, Sáenz L (2016) Balancing hydropower and biodiversity in the Amazon, Congo, and Mekong. Science 351:128–129. https://doi.org/10.1126/science.aac7082

Lessa ACR, dos Santos MA, Maddock JEL, dos Santos BC (2015) Emissions of greenhouse gases in terrestrial areas pre-existing to hydroelectric plant reservoirs in the Amazon: the case of Belo Monte hydroelectric plant. Renew Sustain Energy Rev 51:1728–1736. https://doi.org/10.1016/j.rser.2015.07.067

Anderson EP, Jenkins CN, Heilpern S, Maldonado-Ocampo JA, Carvajal-Vallejos FM, Encalada AC, Tedesco PA (2018) Fragmentation of Andes-to-Amazon connectivity by hydropower dams. Sci Adv 4(1):1642. https://doi.org/10.1126/sciadv.aao1642

Energy research company. <www.epe.gov.br/> (accessed April/2020).

Almeida CF, Maciel VG, Tsambe M, Cybis LFA (2017) Environmental assessment of a bi-fuel thermal power plant in an isolated power system in the Brazilian Amazon region. J Clean Prod 154:41–50. https://doi.org/10.1016/j.jclepro.2017.03.209

Macedo WN, Monteiro LG, Corgozinho IM, Macêdo EM, Rendeiro G, Braga W, Bacha L (2016) Biomass based microturbine system for electricity generation for isolated communities in amazon region. Renew Energy 91:323–333. https://doi.org/10.1016/j.renene.2016.01.063

Silva CMS, Carneiro ACO, Vital BR, Figueiró CG, Fialho LF, Magalhães MA, Carvalho AG, Cândido WL (2018) Biomass torrefaction for energy purposes-definitions and an overview of challenges and opportunities in Brazil. Renew Sustain Energ Rev 82:2426–2432. https://doi.org/10.1016/j.rser.2017.08.095

Alves JLF, Silva JCG, Domenico MD, Galdino WVA, Andersen SLF, Alves RF, Sena RF (2021) Exploring açaí seed (Euterpe oleracea) pyrolysis using multi-component kinetics and thermodynamics assessment towards its bioenergy potential. Bioenerg Res 14:209–225. https://doi.org/10.1007/s12155-020-10175-y

Souza CDR, Silva KC (2021) Energy potential of waste from Brazil nut (Bertholletia excelsa H.B.K.) for production of activated carbon. Res Soc Dev 10(2):e53310212698. https://doi.org/10.33448/rsd-v10i2.12698

Scoles R, Gribel R (2015) Human influence on the regeneration of the Brazil nut tree (Bertholletia excelsa Bonpl., Lecythidaceae) at Capanã Grande Lake, Manicoré, Amazonas. Brazil Hum Ecol 43:843–854. https://doi.org/10.1007/s10745-015-9795-4

Maciel-Silva FW, Mussatto SI, Forster-Carneiro T (2019) Integration of subcritical water pretreatment and anaerobic digestion technologies for valorization of açai processing industries residues. J Clean Prod 228:1131–1142. https://doi.org/10.1016/j.jclepro.2019.04.362

Manzato L, Rabelo LCA, Souza SM, Silva CG, Sanches EA, Rabelo D, Mariuba LAM, Simonsen J (2017) New approach for extraction of cellulose from tucumã’s endocarp and its structural characterization. J Mol Struct 1143:229–234. https://doi.org/10.1016/j.molstruc.2017.04.088

Hazeena SH, Sindhu R, Pandey A, Binod P (2020) Lignocellulosic bio-refinery approach for microbial 2,3-Butanediol production. Bioresour technol 306:122873. https://doi.org/10.1016/j.biortech.2020.122873

Zhang J, Koubaa A, Xing D, Wang H, Wang Y, Liu W, Zhang Z, Wang X, Wang Q (2020) Conversion of lignocellulose into biochar and furfural through boron complexation and esterification reactions. Bioresour Technol 312:123586. https://doi.org/10.1016/j.biortech.2020.123586

Coelho RD, Lizcano JV, Barros THS, Barbosa FS, Leal DPV, Santos LC, Ribeiro NL, Fraga EF Jr, Martin DL (2019) Effect of water stress on renewable energy from sugarcane biomass. Renew Sustain Energ Rev 103:399–407. https://doi.org/10.1016/j.rser.2018.12.025

IMME, Ministry of Mines and Energy. <www.mme.gov.br/> (accessed December/2020)

Ignacio LHS, Santos PEA, Duarte CAR (2019) An experimental assessment of Eucalyptus urosemente energy potential for biomass production in Brazil. Renew Sustain Energ Rev 103:361–369. https://doi.org/10.1016/j.rser.2018.12.053

Oliveira JL, da Silva JN, Martins MA, Pereira EG (2018) Gasification of waste from coffee and eucalyptus production as an alternative source of bioenergy in Brazil. Sustain Energy Techn Assess 27:159–166. https://doi.org/10.1016/j.seta.2018.04.005

Solarin SA, Bello MO (2019) Interfuel substitution, biomass consumption, economic growth, and sustainable development: Evidence from Brazil. J Clean Prod 211:1357–1366. https://doi.org/10.1016/j.jclepro.2018.11.268

Welfle A (2017) Balancing growing global bioenergy resource demands - Brazil’s biomass potential and the availability of resource for trade. Biomass Bioenerg 105:83–95. https://doi.org/10.1016/j.biombioe.2017.06.011

Cervi WR, Lamparelli RAC, Seabra JEA, Junginger M, Hilst F (2019) Bioelectricity potential from ecologically available sugarcane straw in Brazil: a spatially explicit assessment. Biomass Bioenerg 122:391–399. https://doi.org/10.1016/j.biombioe.2019.02.001

Flores JA, Konrad O, Flores CR, Schroder NT (2018) Inventory data on Brazilian Amazon’s non-wood native biomass sources for bioenergy production. Data Brief 20:1935–1941. https://doi.org/10.1016/j.dib.2018.09.050

IBGE, Brazilian Institute of Geography and Statistics. <www.sidra.ibge.gov.br/>. (accessed January/2020)

Araujo RO, Chaar JS, Queiroz LS, Rocha Filho GN, Costa CEF, da Silva GCT, Landers R, Costa MJF, Gonçalves AAS, Souza LKC (2019) Low temperature sulfonation of acai stone biomass derived carbons as acid catalysts for esterification reactions. Energ Convers Manage 196:821–830. https://doi.org/10.1016/j.enconman.2019.06.059

Souza TNV, Vieira MGA, Silva MGC, Brasil DSB, Carvalho SML (2019) H3PO4-activated carbons produced from açai stones and Brazil nutshells: removal of basic blue 26 dye from aqueous solutions by adsorption. Environ Sci Pollut Res 26:28533–28547. https://doi.org/10.1007/s11356-019-04215-0

SEDAP, Secretariat of Agricultural Development and Fisheries of the State of Pará. <www.sedap.pa.gov.br/>. (accessed December/2020)s

Mendonça IM, Machado FL, Silva CC, Duvoisin S Jr, Takeno ML, Maia PJS, Manzato L, Freitas FA (2019) Application of calcined waste cupuaçu (Theobroma grandiflorum) seeds as a low-cost solid catalyst in soybean oil ethanolysis: statistical optimization. Energ Convers Manage 200:112095. https://doi.org/10.1016/j.enconman.2019.112095

Ramos SNM, Danzl W, Ziegleder G, Efraim P (2016) Formation of volatile compounds during cupuassu fermentation: influence of pulp concentration. Food Res Int 87:161–167. https://doi.org/10.1016/j.foodres.2016.06.025

Cantu-Jungles TM, Iacomini M, Cipriani TR, Cordeiro LMC (2017) Structural diversity of alkali-soluble polysaccharides from the fruit cell walls of tucumã (Astrocaryum aculeatum), a commelinid monocotyledon from the family Arecaceae. Plant Physiol Bioch 118:356–361. https://doi.org/10.1016/j.plaphy.2017.07.002

Mendonça IM, Paes OARL, Maia PJS, Souza MP, Almeida RA, Silva CC, Duvoisin S Jr, Freitas FA (2019) New heterogeneous catalyst for biodiesel production from waste tucumã peels (Astrocaryum aculeatum Meyer): parameters optimization study. Renew Energ 130:103–110. https://doi.org/10.1016/j.renene.2018.06.059

Anunciação PC, Giuffrida D, Murador DC, Paula Filho GX, Dugo G, Pinheiro-Sant’Ana HM, (2019) Identification and quantification of the native carotenoid composition in fruits from the Brazilian Amazon by HPLC–DAD–APCI/MS. J Food Compos Anal 83:103296. https://doi.org/10.1016/j.jfca.2019.103296

Guimarães MG, Evaristo RBW, Ghesti BACM, GF, (2021) Green energy technology from buriti (Mauritia flexuosa L. f.) for Brazilian agro-extractive communities. SN Appl Sci 3:283–296. https://doi.org/10.1007/s42452-021-04278-0

Lopes FCR, Pereira JC, Tannous K (2018) Thermal decomposition kinetics of guarana seed residue through thermogravimetric analysis under inert and oxidizing atmospheres. Bioresour Technol 270:294–302. https://doi.org/10.1016/j.biortech.2018.09.021

Tsai W-T, Jiang T-J, Lin Y-Q (2019) Conversion of de-ashed cocoa pod husk into high-surface-area microporous carbon materials by CO2 physical activation. J Mater Cycles Waste Manag 21:308–314. https://doi.org/10.1007/s10163-018-0791-9

Tsai C-H, Tsai W-T, Liu S-C, Lin Y-Q (2018) Thermochemical characterization of biochar from cocoa pod husk prepared at low pyrolysis temperature. Biomass Convers Bior 8:237–243. https://doi.org/10.1007/s13399-017-0259-5

Nunes LA, Silva MLS, Gerber JZ, Kalid RA (2020) Waste green coconut shells: diagnosis of the disposal and applications for use in other products. J Clean Prod 255:120169. https://doi.org/10.1016/j.jclepro.2020.120169

Rasheed T, Anwar MT, Ahmad N, Sher F, Khan SUD, Ahmad A, Wazeer I (2021) Valorisation and emerging perspective of biomass based waste-to-energy technologies and their socio-environmental impact: a review. J Environ Manage 287:112257. https://doi.org/10.1016/j.jenvman.2021.112257

Onga HC, Chen W-H, Farooq A, Gan YY, Lee KT, Ashokkumar V (2019) Catalytic thermochemical conversion of biomass for biofuel production: a comprehensive review. Renew Sustain Energ Rev 113:109266. https://doi.org/10.1016/j.rser.2019.109266

Lu JW, Zhang S, Hai J, Lei M (2017) Status and perspectives of municipal solid waste incineration in China: a comparison with developed regions. Waste Manage 69:170–186. https://doi.org/10.1016/j.wasman.2017.04.014

Cruz G, Silva AV, Da Silva JB, de Nazaré CR, de Souza ME (2020) Biofuels from oilseed fruits using different thermochemical processes: opportunities and challenges. Biofuel Bioprod Biorefin 14(3):696–719. https://doi.org/10.1002/bbb.2089

Fernandez A, Saffe A, Pereyra R, Mazza G, Rodriguez R (2016) Kinetic study of regional agro-industrial wastes pyrolysis using non-isothermal TGA analysis. Appl Therm Eng 106:1157–1164. https://doi.org/10.1016/j.applthermaleng.2016.06.084

Sukiran MA, Abnisa F, Daud WMAW, Bakar NA, Loh SK (2017) A review of torrefaction of oil palm solid wastes for biofuel production. Energ Convers Manag 149:101–120. https://doi.org/10.1016/j.enconman.2017.07.011

Wang D, Jiang P, Zhang H, Yuan W (2020) Biochar production and applications in agro and forestry systems: a review. Sci Total Environ 723:137775. https://doi.org/10.1016/j.scitotenv.2020.137775

Dhyani V, Bhaskar T (2018) A comprehensive review on the pyrolysis of lignocellulosic biomass. Renew Energ 129:695–716. https://doi.org/10.1016/j.renene.2017.04.035

Chang SH (2020) Rice husk and its pretreatments for bio-oil production via fast pyrolysis: a review. Bioenergy Res 13:23–42. https://doi.org/10.1007/s12155-019-10059

Raheem A, ZhaoDastyar MW, Channa AQ, Ji G, Zhang Y (2019) Parametric gasification process of sugarcane bagasse for syngas production. Int J Hydrogen Energy 44:16234–16247. https://doi.org/10.1016/j.ijhydene.2019.04.127

Wang A, Austin D, Song H (2019) Investigations of thermochemical upgrading of biomass and its model compounds: opportunities for methane utilization. Fuel 246:443–453. https://doi.org/10.1016/j.fuel.2019.03.015

Masud MH, Ananno AA, Arefn AME, Ahamed R, Das P, Joardder MUH (2019) Perspective of biomass energy conversion in Bangladesh. Clean Technol Envir Policy 21:719–731. https://doi.org/10.1007/s10098-019-01668-2

Martinez-Valencia L, Camenzind D, Wigmosta M, Garcia-Perez M, Wolcott M (2021) Biomass supply chain equipment for renewable fuels production: a review. Biomass Bioenerg 148:106054. https://doi.org/10.1016/j.biombioe.2021.106054

Andrade CS, Rosa LP, Da Silva NF (2011) Generation of electric energy in isolated rural communities in the Amazon Region a proposal for the autonomy and sustainability of the local populations. Renew Sustain Energy Rev 15(1):493–503. https://doi.org/10.1016/j.rser.2010.09.052

Pinheiro G, Rendeiro G, Pinho J, Macedo E (2012) Sustainable management model for rural electrification: case study based on biomass solid waste considering the Brazilian regulation policy. Renew Energ 37(1):379–386. https://doi.org/10.1016/j.renene.2011.07.004

Sánchez AS, Torres EA, Kalid RA (2015) Renewable energy generation for the rural electrification of isolated communities in the Amazon Region. Renew Sustain Energ Rev 49:278–290. https://doi.org/10.1016/j.rser.2015.04.075

Itai Y, Santos R, Branquinho M, Malico I, Ghesti GF, Brasil AM (2014) Numerical and experimental assessment of a downdraft gasifier for electric power in Amazon using açaí seed (Euterpe oleracea Mart.) as a fuel. Renew Energ 66:662–669. https://doi.org/10.1016/j.renene.2014.01.007

Pessôa TS, Ferreira LEL, Silva MP, Neto LMP, Nascimento BF, Fraga TJM, Jaguaribe EF, Cavalcanti JV, Sobrinh MAM (2019) Açaí waste beneficing by gasification process and its employment in the treatment of synthetic and raw textile wastewater. J Clean Prod 240:118047. https://doi.org/10.1016/j.jclepro.2019.118047

Sato MK, Lima HV, Lima HV, Costa AN, Rodrigues S, Mooney SJ, Clarke M, Pedroso AJS, Maia CMBF (2020) Biochar as a sustainable alternative to açaí waste disposal in Amazon. Brazil Process Saf Environ 139:36–46. https://doi.org/10.1016/j.psep.2020.04.001

Reis JS, Araujo RO, Lima VMR, Queiroz LS, Costa CEF, Pardauil JJR, Chaar JS, Rocha Filho GN, Souza LKC (2019) Combustion properties of potential Amazon biomass waste for use as fuel. J Therm Anal Calorim 138:3535–3539. https://doi.org/10.1007/s10973-019-08457-5

Lira CS, Berruti FM, Palmisano P, Berruti F, Briens C, Pécora AAB (2013) Fast pyrolysis of Amazon tucumã (Astrocaryum aculeatum) seeds in a bubbling fluidized bed reactor. J Anal Appl Pyrol 99:23–31. https://doi.org/10.1016/j.jaap.2012.11.005

Matos FB, Camacho JR, Rodrigues P, Guimarães SC Jr (2011) A research on the use of energy resources in the Amazon. Renew Sustain Energ Rev 15(6):3196–3206. https://doi.org/10.1016/j.rser.2011.04.012

Azam M, Jahromy SS, Raza W, Jordan C, Harasek M, Winter F (2019) Comparison of the combustion characteristics and kinetic study of coal, municipal solid waste, and refuse-derived fuel: model-fitting methods. Energy Sci Eng 7:2646–2657. https://doi.org/10.1002/ese3.450

Shah MA, Khan MNS, Kumar V (2018) Biomass residue characterizations for their potential application as biofuels. J Therm Anal Calorim 134:2137–2145. https://doi.org/10.1007/s10973-018-7560-9

Paniagua S, Prado-Guerra A, Garcia AI, Calvo LF (2019) Bioenergy derived from an organically fertilized poplar plot: overall TGA and index estimation study for combustion, gasification, and pyrolysis processes. Biomass Convers Bior 9:749–760. https://doi.org/10.1007/s13399-019-00392-7

Rambo MKD, Schmidt FL, Ferreira MMC (2015) Analysis of the lignocellulosic components of biomass residues for biorefinery opportunities. Talanta 144:696–703. https://doi.org/10.1016/j.talanta.2015.06.045

Gil MV, González-Vázquez MP, García R, Rubiera F, Pevida C (2019) Assessing the influence of biomass properties on the gasification process using multivariate data analysis. Energ Convers Manage 184:649–660. https://doi.org/10.1016/j.enconman.2019.01.093

Riaza J, Gibbibs J, Chalmers H (2017) Ignition and combustion of single particles of coal and biomass. Fuel 202:650–655. https://doi.org/10.1016/j.fuel.2017.04.011

Ozyuguran A, Yaman S (2017) Prediction of calorific value of biomass from proximate analysis. Energy Procedia 107:130–136. https://doi.org/10.1016/j.egypro.2016.12.149

Chen D, Shuang E, Liu L (2018) Analysis of pyrolysis characteristics and kinetics of sweet sorghum bagasse and cotton stalk. J Therm Anal Calorim 131:1899–1909. https://doi.org/10.1007/s10973-017-6585-9

Pathomrotsakun J, Nakason K, Kraithong W, Khemthong P, Panyapinyopol B, Pavasant P (2020) Fuel properties of biochar from torrefaction of ground coffee residue: effect of process temperature, time, and sweeping gas. Biomass Conv Bioref 10:743–753. https://doi.org/10.1007/s13399-020-00632-1

Saffe A, Fernandez A, Echegaray M, Mazza G, Rodrigues R (2019) Pyrolysis kinetics of regional agro-industrial wastes using isoconversional methods. Biofuels 10:245–257. https://doi.org/10.1080/17597269.2017.1316144

Baroni ÉG, Tannous K, Rueda-Ordóñez YJ et al (2016) The applicability of isoconversional models in estimating the kinetic parameters of biomass pyrolysis. J Therm Anal Calorim 123:909–917. https://doi.org/10.1007/s10973-015-4707-9

Santos VO, Queiroz LS, Araujo RO, Ribeiro FCP, Guimarães MN, Costa CEF, Chaar JS, Souza LKC (2020) Pyrolysis of acai seed biomass: kinetics and thermodynamic parameters using thermogravimetric analysis. Bioresour Technol Reports 12:100553. https://doi.org/10.1016/j.biteb.2020.100553

Lopes FCR, Tannous K, Rueda-Ordóñez YJ (2016) Combustion reaction kinetics of guarana seed residue applying isoconversional methods and consecutive reaction scheme. Bioresour Technol 219:392–402. https://doi.org/10.1016/j.biortech.2016.07.099

Kurji H, Valera-Medina A, Runyon J, Giles A, Pugh D, Marsh R, Valerio V (2016) Combustion characteristics of biodiesel saturated with pyrolysis oil for power generation in gas turbines. Renew Energy 99:443–451. https://doi.org/10.1016/j.renene.2016.07.036

Sarker TR, Nanda S, Dalai AK, Meda V (2021) A review of torrefaction technology for upgrading lignocellulosic biomass to solid biofuels. Bioenergy Res 1:25. https://doi.org/10.1007/s12155-020-10236-2

Chai L, Saffron CM (2016) Comparing pelletization and torrefaction depots: optimization of depot capacity and biomass moisture to determine the minimum production cost. Appl Energy 163:387–395. https://doi.org/10.1016/j.apenergy.2015.11.018

Prasad KM, Murugavelh S (2020) Experimental investigation and kinetics of tomato peel pyrolysis: performance, combustion and emission characteristics of bio-oil blends in diesel engine. J Cleaner Prod 254:120115. https://doi.org/10.1016/j.jclepro.2020.120115

Lan K, Ou L, Park S, Kelly SS, English BC, Yu TE, Larson J, Yao Y (2021) Techno-economic analysis of decentralized preprocessing systems for fast pyrolysis biorefineries with blended feedstocks in the southeastern United States. Renew Sustain Energy Rev 143:110881. https://doi.org/10.1016/j.rser.2021.110881

Morató T, Vaezi M, Kumar A (2020) Techno-economic assessment of biomass combustion technologies to generate electricity in South America: a case study for Bolivia. Renew Sustain Energy Rev 134:110154. https://doi.org/10.1016/j.rser.2020.110154