Abstract

The projections of ionic liquids as green solvents in chemical processes have increased in recent years. Ionic liquid is a versatile chemical with various applications. The aim of this review is to present a comprehensive perspective of ionic liquid for processing carbohydrate biomass by considering the recent progress in this field. Special attention is given to the application of ionic liquids for the production of 5-hydroxymethyl furfural (5-HMF) and levulinic acid (LA). Factors affecting the catalytic conversion of carbohydrate biomass in ionic liquid and the mechanisms of 5-HMF and LA production are also presented. In addition, the recyclability of the ionic liquid for carbohydrate biomass processing is discussed. The viewpoint for the application of functionalized ionic liquid as potential green solvent and catalyst is also highlighted. Future studies pertinent to carbohydrate biomass conversion in ionic liquids to 5-HMF and LA could use this review for selecting the appropriate reaction conditions required to achieve their specific goals. Besides, combination of technologies from ionic liquids and biomass processing strategies for the production of various fuels and value-added chemicals can be comprehended for applications in a lignocellulosic biorefinery.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

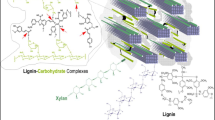

Over the past decades, fossil fuels have been the main sources for chemicals and energy production. Due to the rapid consumption in various sectors, concerns towards depletion of fossil fuel resources are increasing. Energy production from lignocellulosic biomass has several advantages compared with the conventional energy from fossil fuels such as its availability, renewable sources and carbon dioxide cycle from biomass that produce greener energy. Lignocellulosic biomass is typically composed of cellulose, hemicellulose and lignin [1]. The above-mentioned lignocellulosic biomass components can be converted into many building block chemicals have great market potential. These building blocks are useful to be converted into new bio-based chemicals with various applications including biofuels, medicinal and other high value-added compounds. In a report reviewed by US Department of Energy, several chemical compounds have been screened out as the top building blocks [2]. The compounds listed include succinic acid, fumaric acid, malic acid, 2,5-furandicarboxylic acid, 3-hydroxypropionic acid, aspartic acid, glucaric acid, glutamic acid, itaconic acid, levulinic acid, 3-hydroxybutyrolactone, glycerol, sorbitol and xylitol. Besides, the recently added to the list are para-xylene, propylene glycol, 1,3-propanediol, lactic acid, isoprene, glycerol, furfural, fatty alcohols, 1,3-butadiene, 1,4-butanediol and ethyl lactate [2, 3].

Lignocellulosic biomass can be converted to bio-based chemicals using organic and inorganic compounds as catalyst, solvent and extracting agent. Such compounds are excessively available at reasonable prices; however, the concern about their toxicity and risk of environmental pollution is of high concern. Therefore, the search for alternative compounds is steadily growing. Ionic liquids, composed of different cations and anions provide the alternatives for green catalysis and separation, due to their distinctive characteristics such as negligible vapour pressure and good solubility in both organic and inorganic materials. There has been increasing tendency for usage of ionic liquid in bio-based chemical production as catalyst or solvent. The number of published works in year 2010 to 2019 (Scopus search) involving application of ionic liquids and carbohydrate biomass processing for 5-HMF and LA productions are depicted in Fig. 1 [4]. The trend indicates that the research area has attracted significant attention from researchers globally. Even though the productions of biomass-derived building block chemicals (5-HMF and LA) in different solvents including ionic liquid, have been previously reviewed [5,6,7,8], there must be aspects in the published works that can be addressed and further described, which subsequently can contribute to literature.

Therefore, the objective of this review is to highlight the ongoing research related to catalytic conversion of carbohydrate biomass to 5-HMF and LA in ionic liquids. The overview of the functionalized ionic liquid as potential green solvent and catalyst is addressed. This review elaborates the factors affecting the 5-HMF and LA productions in ionic liquid which are (1) reaction temperature and time, (2) types of heating, (3) catalyst properties / types of catalyst, (4) catalyst loading, (5) types of feedstocks, (6) feedstock loading, (7) types of ionic liquid (8) ionic liquid loading, (9) reaction media and solvent/co-solvent and (10) water content. The mechanisms proposed for carbohydrate biomass conversion to 5-HMF and LA in ionic liquid are described, and the differences between the proposed mechanisms, taken into account the role of ionic liquid and/or catalyst towards the mechanism, are also discussed. The recyclability and reusability of ionic liquid and kinetics on carbohydrate biomass conversion to 5-HMF and LA in ionic liquid are also presented.

Biomass-Derived Platform Chemicals—5-HMF, LA and Derivatives

Platform chemicals such as 5-HMF and LA have been widely studied over the years owing to their convertibility into a large number of chemicals with applications in various areas. 5-HMF contains hydroxyl and aldehyde functional groups, while LA contains carbonyl and carboxyl group. The presence of several functional groups provides functionalities and reactivities of 5-HMF and LA which make various chemical reactions possible. The overview of 5-HMF and LA markets has been reviewed [7, 8]. 5-HMF and LA can be synthesized from hexoses, where the simplified reaction pathway is described as follows: isomerization of glucose to fructose, dehydration of fructose to 5-HMF by elimination of three water molecules, then rehydration of 5-HMF to LA, and formic acid as by-product. Alongside formic acid, small amount of acetic acid was also produced. Humins, the insoluble carbonaceous residue, can also be formed due to the polymerization and decomposition of glucose and decomposition of 5-HMF and LA [9, 10]. In addition, other valuable chemical such as lactic acid can also be produced from carbohydrate biomass conversion. Nevertheless, this review focuses on 5-HMF and LA, as the production of these two products is interrelated which is through acid-catalysed reaction, whereas the commercial production route of other product is fairly different, i.e. lactic acid is produced by microbial fermentation of carbohydrates [3].

5-HMF and LA are practically synthesized from monosaccharides, disaccharides and polysaccharides, as well as lignocellulosic biomass. The direct use of lignocellulosic biomass for 5-HMF and LA production looks more promising from the commercial point of view. In 5-HMF synthesis, the utilization of solvents could suppress unwanted side reactions and simultaneously extract more 5-HMF in order to increase the product yield [6]. The aqueous processes are preferred from an ecological and economical point of view, but unfortunately, the 5-HMF production in water is usually low. Instead, water has been regularly employed as solvent for catalytic production of LA as the presence of water will promote the rehydration of 5-HMF into LA. As reviewed elsewhere, other technologies have also been implemented for 5-HMF and LA productions, such as biphasic media, supercritical fluids and ionic liquids [6]. The application of ionic liquid for converting carbohydrate biomass to 5-HMF and LA is discussed in this review.

Various catalytic routes are applied to obtain different 5-HMF and LA derivatives with various applications. One of the 5-HMF derivatives is LA. Other 5-HMF derivatives such as 2,5-bis(hydroxymethyl)-furan can be obtained from hydrogenation of 5-HMF, which is used in the manufacturing of polyurethane foams. 2,5-dimethylfuran has gained attention as due to its superior energy density, high research octane number and ideal boiling point [11], while 2,5-furandicarboxylic acid can be used in the production of polyesters polyethylene terephthalate [12]. The LA derivatives such as δ-aminolevulinate acid is a biodegradable herbicide. LA can undergo reduction reaction to give 1,4-pentanediol, which could be used for the production of new bio polyesters. Esterification of LA with alcohols produces levulinic esters such as alkyl levulinates [13,14,15]. Alkyl levulinates show the similar properties as biodiesel and possess high potential as additives for transportation fuels. For example, ethyl levulinate is synthesized by esterification of LA with ethanol and can be used directly in a regular diesel car engine up to 5 wt% as diesel miscible biofuel [15]. Besides, LA can undergo hydrogenation to produce γ-valerolactone, which can be used as a fuel additive and solvent, and serve as a precursor of polymers [15].

Ionic Liquids for Biomass Processing

Lignocellulosic biomass is known as a potential source to produce biofuels and other bioproducts. The complex matrix of lignocellulosic biomass unfavourably obstructs its effective conversion into valuable chemical products. Thus, initial dissolution of biomass through pretreatment is an important tool for biomass conversion processes before it can be further converted to other products. The pretreatment process is to reduce the cellulose crystallinity and increase the surface area of cellulose available for the reaction, which could facilitate the conversion reaction [16, 17]. In order to be considered as an effective biomass pretreatment method, several properties should be complied: nontoxic, easy process, cost effective, low temperature process and chemically stable. A prolonged pre-treatment time could increase the possibility of the release of hazardous and toxic compounds during the process. The available pretreatment methods can be classified into physical (grinding, milling, microwave, extrusion, etc.), chemical (acid, alkaline, organic solvent), physochemical (steam explosion, liquid hot water, CO2 explosion, etc.) and biological (microorganisms) methods [1]. The review of literatures found that conventional pretreatment methods displayed several limitations such as environmental concerns, limited application ranges, and can form inhibitory products during pretreatment process which suppress further hydrolysis steps [1, 18].

In recent years, ionic liquid has been discovered and widely used for biomass pretreatment. Ionic liquids are prepared from combination of different cations and anions. The ionic liquid properties can be altered by appropriate changes of the ionic liquid structure, where it can be done by a proper selection of the cation and anion [18]. Compared with other conventional pretreatment methods, ionic liquids have high potential for energy efficient biomass pretreatment due to their tuneable properties. In addition, as cellulose is reported to be poorly soluble in conventional solvents due to its intermolecular hydrogen bonds, ionic liquids have been found to be capable of disrupting the hydrogen bonds, and making the carbohydrates more susceptible to hydrolysis [18]. Comprehensive reviews on lignocellulosic biomass pretreatment involving ionic liquid have been reported elsewhere [1, 18]. Ionic liquid can play dual-role as a solvent and catalyst for the given reaction [7]; thus, direct hydrolysis of lignocellulosic biomass incorporating ionic liquid is considered to be a promising alternative route for the production of platform chemicals such as 5-HMF and LA. However, pretreatment and hydrolysis processes incorporating ionic liquid face some constraints such as the large amount needed and exorbitantly priced ionic liquid. Since the price of ionic liquid may be an issue, practicability of ionic liquid recycling to reduce the quantity of ionic liquid used is essential. The ionic liquid recycling process for carbohydrate biomass conversion to 5-HMF and LA is elucidated in the next subtopics. The reusability is one of the main advantages of ionic liquid. It is perceivable that this recyclable property will promote the industrial application of ionic liquid.

Catalytic Processes in Ionic Liquid for 5-HMF and LA Production

In the past years, studies have been conducted on conversions of carbohydrate biomass in ionic liquids. Most of the literatures related to conversions of monosaccharides, disaccharides, polysaccharides and lignocellulosic biomass in ionic liquid have focused more on the production of 5-HMF with increasing number of studies on the production of LA.

Conversion of Monosaccharides, Disaccharides and Polysaccharides

The summary on catalytic conversions of monosaccharides, disaccharides and polysaccharides to 5-HMF and LA is given in Table 1, where ionic liquid is employed as solvent and/or catalyst with or without the presence of co-catalyst and co-solvent. Monosaccharides such as glucose and fructose are the most extensively used feedstocks for 5-HMF and LA production in ionic liquids. Disaccharides, sucrose, maltose and cellobiose, consist of two monosaccharides linked by glycoside bond, have been widely employed in the hydrolysis process containing ionic liquid. This indicates dissolution ability of ionic liquid towards disaccharides for generation of 5-HMF and LA. Hydrolysis of polysaccharides such as cellulose, inulin and starch have also been carried out in ionic liquids. Along with the presence of catalyst, ionic liquid has the ability to cleave the hydrogen bonding in polysaccharide. The bond between linkage of polysaccharide and ionic liquid was stronger than the bond between polysaccharide chain with solvent such as water and methanol [19, 21]. This stronger bond has enhanced the dissolution of lignocellulosic biomass in ionic liquid, thus boosting the catalytic processes. In addition, electron donating anion from ionic liquid could distort the hydrogen bond in the crystalline cellulose [49]. The distortion changes the cellulose structure from crystalline to amorphous, and enhancing the overall hydrolysis process. Further discussion on the effect of different types of feedstocks is given in the next section.

In order to obtain an optimum yield, the optimum reaction condition for different substrates is different. For example, glucose needed longer reaction time and higher reaction temperature to generate similar yield as fructose. This is due to the stable glucose structure and glucose need to be isomerised into fructose before it can be dehydrated into 5-HMF. Discussion on the effect of reaction temperature and reaction time are elaborated in the next section. The selection of ionic liquid for 5-HMF and LA is normally based on the types of cation and anion. For instance, ionic liquid with imidazolium cation gives a good 5-HMF yield while other cations generated less, while halide anion such as Cl− and Br− not only act as a nucleophile, but also as a base mediator that promote the conversion of glucose into 5-HMF [38, 48]. In addition, the poor catalytic activity of ionic liquid was attributed to the strong basicity and nucleophilicity of the anion, such as Oac− [38, 48, 57]. Several trends were observed on the effect of alkyl chain length towards 5-HMF production. Few studies suggested that increasing in alkyl chain length was not favourable for high 5-HMF yield in imidazolium-based ionic liquid with boric acid and germanium(IV) chloride as catalysts [19, 36]. On the contrary, alkyl chain length of imidazolium increased the 5-HMF yield using lanthanide as catalyst. The effect of different types of ionic liquids are further discussed in the next section.

Transition-metals have been known as favourable catalysts for 5-HMF and LA productions. Since they are able to prompt high yields of 5-HMF and LA under short reaction time, many studies have incorporated metal salts with ionic liquid (Table 1). Different metal salts may give different effect on the reaction, probably due to the anion effect. For instance, metal salts with larger size of the anion presenting more steric hindrance for the coordination between glucose and the catalyst [19]. An anion with more nucleophilic characteristic led to a stronger interaction between the ions which could inhibit the interaction between glucose and the catalyst, thus less competent for 5-HMF production [19]. Chromium chlorides were found to be an effective catalyst for the conversion of glucose, which might be attributed to the strong Lewis acidity of chromium. Details on the effect of chromium chlorides and other metal halides on conversion of carbohydrate biomass in ionic liquids are given in the next section. Normally, ionic liquid used for catalytic conversion of carbohydrates to 5-HMF and LA is a room temperature ionic liquid. The ionic liquid is in the liquid form during the reaction. To date, solid acid catalysts based ionic liquid have been synthesized by combination of ionic liquid with other materials for 5-HMF and LA productions [58,59,60]. For example, heteropolyacid-ionic liquid catalysts showed good performance for LA production from conversions of glucose, cellulose and starch [58, 59]. In other study, 5-HMF was obtained from fructose conversion in DMSO catalysed by heteropolyacid immobilized ionic liquid catalyst [60]. The catalyst contained Brønsted acidity from the heteropolyacid part, which favours dehydration of cellulose [60]. Further study on heteropolyacid-ionic liquid catalyst is recommended by introducing Lewis acid, in order to promote isomerization of glucose to fructose before dehydration reaction to produce 5-HMF and LA. Other types of solid acid catalyst and their effect on carbohydrate biomass conversion to 5-HMF and LA in ionic liquid are further emphasized in the next section. The discussion includes the effect of types of acidity as well as the effect of catalyst mesoporosity.

Reaction media also played roles in conversion of carbohydrate biomass to 5-HMF and LA in ionic liquid. As water is one of the products from 5-HMF formation that could promote rehydration reaction to produce LA, some compounds were used to restrain the rehydration reaction and emphasis on 5-HMF formation. For example, co-solvents such as DMSO and MIBK were added in the reaction system to increase 5-HMF yield and selectivity as well as inhibited the formation of LA and humins [21, 29, 61, 62]. Since water has a negative effect on 5-HMF production, studies have been conducted to study the effect of water content in the reaction [63,64,65,66]. A detailed discussion on the effect of co-solvent and water content on conversion of carbohydrate biomass in ionic liquid is given in the next section.

Hydrolysis of Lignocellulosic Biomass

Table 2 summarizes the hydrolysis of lignocellulosic biomass to 5-HMF and LA in ionic liquids, where several studies reported the potential of metal halides as catalyst in ionic liquid system for the conversion of lignocellulosic biomass as the combination of metal halides with ionic liquid show good performance for the reaction. In the lignocellulosic biomass conversion, ionic liquid is required for the initial fractionation process of the biomass structure, and as a source of active site for transformation of sugars to 5-HMF and LA. The effect HCl in [OMIM][Cl] for 5-HMF production from raw acorn biomass and chicory root has been explored [67, 68], where the good activity of HCl is due to proton from the HCl acted as a mediator and attacking the glycosidic oxygen in the cellulose compound. The interaction between H+ and cation and anion of ionic liquid would assist the hydrolysis reaction and consequently promote the 5-HMF production [67, 68]. The effect of several chromium halides on 5-HMF production was investigated for acorn biomass conversion in [OMIM][Cl] [67]. It was confirmed that the difference in the catalytic activity of chromium halides may resulted from the different coordination ability of the halogen groups with the Cr centre. More discussion on the effect of different metal halides are given in the next section.

The effect of CrCl2 has been reported for conversions of girasol tuber, potato tuber and chicory root in [OMIM][Cl] [68, 69]. The 5-HMF yield from conversion of potato tuber increased with the presence of CrCl2. However, CrCl2 did not act as a superior catalyst for 5-HMF production from chicory root [68]. It is presumed that the action of CrCl2 on 5-HMF production may be reliant on the types of feedstocks involved. The similar process was conducted for conversions of switchgrass and comfrey in [BMIM][Cl] and [EMIM][Cl], in the presence CrCl3 and CuCl2 as catalysts [72]. The conversions of pine wood, rice straw, castor leaves and wheat straw in ionic liquid have been conducted under conventional heating and microwave irradiation [71]. Direct conversion of biomass in ionic liquid with the presence of metal halide under microwave irradiation has improved the 5-HMF yield and reduced the reaction time [71]. The use of microwave irradiation was also reported for the conversion of castor leaves and wheat straw to 5-HMF in ionic liquid [73, 74]. Besides, probe sonication assisted [BMIM][Cl] catalysed by CrCl3 for 5-HMF production from bamboo has been reported [17]. The effect of heating methods including conventional heating and microwave irradiation, as well as the principle behind the sonication process on 5-HMF production in ionic liquid is further discussed in the next subtopic.

The catalytic production of LA in ionic liquids from lignocellulosic biomass has also been reported, where the reactions were catalysed by the presence of metal halides modified HY zeolite in [EMIM][Cl] and [BMIM][Br] [49, 76]. Ionic liquid media have disrupted the covalent linkages in biomass feedstocks and dissolved the holocellulose. The dissolved holocellulose is accessible for the chemical transformation to produce LA in the presence of catalyst [49]. For lignocellulosic biomass conversion to 5-HMF and LA, untreated and treated lignocellulosic biomass were introduced in the ionic liquid reaction systems. Some of the biomass were extracted using HCl before being converted to 5-HMF [68, 69], and some were subjected to ball mill [17]. The increasing trend in the 5-HMF yield from the pre-treated biomass is possibly contributed by the size reduction and decrease in crystallinity of feedstocks which facilitate the conversion reaction.

The application of co-solvent has been reported for the conversion of biomass to 5-HMF and LA in ionic liquids [67,68,69,70, 73, 75, 77]. The presence of co-solvent such as iso-propanol, ethyl acetate and MIBK is believed to promote 5-HMF production and inhibit other side reactions, while the presence of co-solvent such as water is to promote the rehydration for LA production. Further explanation on the effect of co-solvent on conversion of carbohydrate biomass in ionic liquid is given in the next section. Several studies also provide a simple practice for the hydrolysis of lignocellulosic biomass to produce monosaccharides for further applications. These biomasses contain a large amount of holocellulose which can be fractionated to release sugars. After completion of biomass dissolution in ionic liquid, the β-1,4-glycosidic bonds of cellulose dissolved in the ionic liquid can be easily attacked by the active sites of the catalyst present in the system, which promotes the hydrolysis process. The main product from the hydrolysis of lignocellulosic biomass, i.e. reducing sugar, can be further converted into a wide range of important chemicals including 5-HMF and LA [72, 78, 79].

Functionalized Ionic Liquid for Carbohydrate Biomass Conversion to 5-HMF and LA

It is a fact that ionic liquids are attracting extensive attention due to their possibility to be modified based on the requirements of a particular application. To date, functionalized ionic liquids, prepared through the inclusion of different types of functional groups on the cation and anion, show enormous potential in various processes. Commonly, functionalized ionic liquid is synthesized to give an ionic liquid with acid site. The example of ionic liquids with this property include sulfonic acid (SO3H) and hydrogen sulfate (HSO4) functionalized ionic liquids. Over the years, functionalized ionic liquids have been employed in various applications including in the catalytic conversion of carbohydrate biomass to 5-HMF and LA (Table 3). Alkyl methylimidazolium-based ionic liquids containing SO3H group on the cation and HSO4 group on the anion have been widely applied for carbohydrate biomass conversions.

The good performance of functionalized ionic liquid due to its high acidity were reported by various studies on 5-HMF and LA productions [9, 90, 104, 115,116,117,118]. Acidic ionic liquids with functional groups, –SO3H, –COOH and –OH, gave better performance in glucose conversion to LA as compared with the non-functionalized ionic liquids such as [BMIM][Cl] and [BMIM][BF4] [117]. The same trend on comparison with [BMIM][Cl] was obtained from fructose conversion to 5-HMF in ionic liquids with 1-methyl-3-(3-sulfopropyl)-imidazolium cation and different anions: 4-methylbenzenesulfonate, hydrogen sulfate and chloride [118]. A study explored the use of protic ionic liquid, triethylammmonium hydrogen sulfate, towards biomass conversion to LA [109]. A comparison on the effectiveness of protic and aprotic ionic liquid, [BMIM][Cl] was performed for cellulosic biomass conversion [113]. In contrast to [BMIM][Cl], the hydrogen sulfate-based protic ionic liquid, [Et3NH][HSO4], showed better activity for 5-HMF and LA productions [113]. Cellulose conversion to LA under microwave assisted reaction using 1-methyl-3-(3-sulfopropyl) imidazolium based ionic liquids ([C3SO3Hmim]) with different anions (HSO4, CH3SO3, H2PO4) was explored [119]. The highest LA yield was obtained using ionic liquid with HSO4 anion due to its high acidity. The activity of –SO3H functionalized Brønsted acidic ionic liquids with different anions and cations were studied for mushroom conversion to 5-HMF [120]. It was found that the main factors affecting the catalytic activity of the ionic liquids include their proton donating ability and acidity [120]. Liu et al. [107] have employed [C3SO3Hmim]HSO4 for LA production from rice straw, where similar interpretation was disclosed on relationship between acidity of the ionic liquid and the hydrogen bonding ability of anions towards LA production. In cellulose decomposition using [C3SO3Hmim]-based ionic liquids, the highest LA yield was achieved in the presence of [C3SO3Hmim]Cl even though its acidity is lower than [C3SO3Hmim]HSO4 [66]. The same trend was also reported in other study [90].

Eminov et al. [85] conducted a study on conversion of fructose to 5-HMF using a combination of CrCl3.6H2O and [BMIM][HSO4]. The mildly acidic proton located at anion of the ionic liquid is suitable for dehydration of fructose to 5-HMF, where it is likely to act as co-catalyst and solvent for the reaction. As reported by Zhou et al. [112], the same ionic liquid was employed for conversion of bamboo shoot shell to LA. The activity of 1-(4-sulfonic acid)butyl-3-methyl imidazolium hydrogen sulfate ([BSMim]HSO4) was examined for cellulose hydrolysis in MIBK in the presence of metal chlorides as co-catalyst, where 5-HMF was obtained as main product [62, 78, 103]. The presence of metal chlorides acted as Lewis acid sites promote the dehydration reaction for 5-HMF production, while the SO3H functionalized ionic liquid played a role as Brønsted acid sites for dissolution of cellulose. Shen et al. [104] investigated the role of [BSMim]HSO4 for one-pot synthesis of LA from cellulose. The combination of InCl3 with [BSMim]HSO4 showed lower activity for LA production. The opposite trend of results with other studies suggested that the metal chlorides promote the dehydration of sugars to 5-HMF, but not for rehydration of 5-HMF to LA [104]. Liu et al. [101] have reported the application of various acidic ionic liquids combined with different metal salts to catalyse cellobiose conversion to LA in one pot reaction. The study disclosed that catalytic activity of the ionic liquid was originated from its double acid sites: Brønsted and Lewis.

A mixture of LA and ethyl levulinate were produced from cellulose conversion in aqueous ethanol medium catalysed by a Brønsted acidic functionalized ionic liquid: 1-(1-propylsulfonic)-3-methylimidazolium chloride [65]. The reaction was conducted under aqueous medium due to the important role of water in cellulose hydrolysis and for subsequent LA production. Meanwhile, ethanol acted as solvent as well as reactant for LA esterification to ethyl levulinate. Besides, oil palm empty fruit bunch and mesocarp fibre biomass were employed for LA and ethyl levulinate productions via two-steps sequential one-pot reaction, which are depolymerization and esterification in water and ethanol medium, respectively [110, 121]. The reactions were performed in the presence of Brønsted-Lewis acidic ionic liquid, InCl3-[HMIM][HSO4], which made up of InCl3 and 1-methylimidazolium hydrogen sulfate. In other study, N-methyl-2-pyrrolidonium methyl sulfonate ([HNMP][CH3SO3]) was combined with [BMIM][Cl] for fructose conversion in ethanol [98], with 5-HMF as the major product produced. Besides, binary mixture containing [HNMP][CH3SO3] and [BMIM][Cl] was explored for fructose conversion to 5-HMF [86].

Most of studies reported on 5-HMF and LA productions from carbohydrate biomass featured monocationic ionic liquids, while the use of dicationic/tricationic ionic liquid was less explored [92, 111, 114, 122,123,124,125,126,127]. Several types of polyethylene glycol bridged geminal dicationic ionic liquids based on diphenylammonium/imidazolium cations were synthesized and were employed in fructose dehydration to 5-HMF [126]. Khan et al. [124] have introduced dicationic ionic liquids containing 1,1-Bis(3-methylimidazolium-1-yl) butylene ([C4(Mim)2]) cation for cellulose conversion to LA. Among the synthesized ionic liquid, [C4(Mim)2][2(HSO4)(H2SO4)2] gave the highest LA yield due to its higher acidity coming from the anion. The same ionic liquid was also applied for bamboo biomass conversion to LA [111]. In other study, monocationic and dicationic ionic liquids with HSO4¯ anion were synthesized and compared for rice husk conversion to LA in probe sonication system [114]. Recently, tricationic ionic liquid, glycerol-tri (3-methylimidazolium) trimesylate ([GLY(mim)3][OMs]3), was introduced for dehydration of fructose, sucrose and glucose [95]. It was presumed that the hydrogen bond formed between mesylate anion and nitrogen-containing tri(imidazolium) cation is beneficial to sugar dissolution for 5-HMF production.

The incorporation of transition metals into functionalized ionic liquids have been introduced for 5-HMF and LA productions. The immobilization of Cr3+ with SO3H-polymeric functionalized ionic liquid effectively catalyse 5-HMF production in DMSO [89], while lower 5-HMF yield was obtained when CrCl3.6H2O was used as catalyst under the same catalytic process. In another study, the polymeric ionic liquid-supported metals were applied for glucose conversion to 5-HMF [96]. Among the ionic liquids investigated, poly(3-butyl-1-vinylimidazolium chloride), P[BVIM][Cl], was found to be the most effective. By combining with CrCl2 and Et2AlCl, the metallate complexes P[BVIM]Cl[CrCl2] and P[BVIM]Cl[Et2AlCl] were formed, respectively, and tested for selective cellulose conversion to 5-HMF [96]. The pyridinium-based dicationic ionic liquid with tetrachloronickelate (II) anion, [C6(Mpy)2][NiCl4]2−, reported high 5-HMF production from fructose dehydration in DMSO [92]. In addition, [SMIM][FeCl4] was synthesized by immobilizing FeCl3 into 1-sulfonic acid-3-methyl imidazolium chloride ([SMIM][Cl]) for glucose and oil palm fronds conversions to LA [64, 108]. CrCl3 was added to 1-(3-sulfonic acid) propane-3-methylimidazole hydrosulfate to form Cr([PSMIM]HSO4)3 for degradation of cellulose in [BMIM][Cl] [102]. In other study, [SO3H-BMIM]Cl/AlCl3 was employed for 5-HMF production from disaccharides and polysaccharides conversions [100]. From the studies, the presence of both Lewis and Brønsted acid sites from the metal chlorides and SO3H functional groups have promoted the 5-HMF and LA productions [100, 102].

The hydroxy-functionalized ionic liquid, 1-hydroxyethyl-3-methyl imidazolium tetrafluoroborate ([C2OHMIM][BF4]), exhibited excellence activity for fructose conversion to 5-HMF in DMSO [61], suggested the presence of BF4− and hydroxy substituents in the imidazole ring promoted the dehydration reaction. The same ionic liquid was used for sucrose and cellobiose conversions to 5-HMF in DMSO [99]. Functionalized ionic liquids with different anion, [C2OHMIM][Cl], and different cation, [EMIM][BF4], were applied for glucose dehydration but resulted in very low 5-HMF yield. It is presumed that both hydroxy and BF4− groups play important roles in the reaction. The Lewis acid site from BF4− is known to promote the isomerization of glucose to fructose, while the basic character of hydroxy group could enhance the transformation between glucose and fructose [61]. Meanwhile, carboxy-functionalized ionic liquid, 1-carboxymethyl-3-methyl imidazolium chloride ([HO2CMMIM][Cl]), was introduced for efficient 5-HMF production from fructose [82]. Later, a study was conducted on glucose conversion to 5-HMF in heterogeneous catalytic system consisting of [HO2CMMIm]Cl and ZrOCl2 [97]. Li et al. [88] have synthesized proline functionalized ionic liquids: proline chlorate and proline bisulfate for catalytic conversion of fructose to 5-HMF in water reaction system. The proline functionalized ionic liquids were effective for fructose conversion to 5-HMF due to the presence of carboxylic group in the ionic liquid structure [88].

Other functionalized ionic liquids prepared to catalyse 5-HMF and LA productions include heteropolyacid-based ionic liquids [58,59,60, 93], metal chlorides-silica–immobilized ionic liquids [87, 128] and biochar sulfonic acid-derived ionic liquid [129]. The heteropolyacid-based functionalized ionic liquids were synthesized by combining ionic liquid with different heteropolyacid. The performance of heteropolyacid-based functionalized ionic liquids for carbohydrate biomass conversion was much better compared with the heteropolyacids, since the presence of Brønsted acidity, which originated from the heteropolyacid favours the dehydration reaction, while the ionic liquid promoted the dissolution of feedstock [58,59,60, 93]. The homogeneous metal chloride/ionic liquid was immobilized to silica composite, MCM-41 and SBA-15, to give heterogeneous catalysts for 5-HMF production [87, 128]. Meanwhile, study by Zhang et al. [129] disclosed the synthesis of fluorine-anion containing biochar sulfonic acid-derived ionic liquids. The biochar contributed to the acid sites of the ionic liquid, while the fluorine-anion containing ionic liquid improved the stability of SO3H groups.

The effectiveness of functionalized ionic liquids for carbohydrate biomass conversion to 5-HMF and LA is subjected to several factors such as the ionic liquids’ structure which is the types of anions and cations, the Brønsted and Lewis acids amount and strength, as well as the coordination of the ions with substrates during the reactions. The ionic liquid with bifunctional properties is imperative specifically for cellulose degradation to 5-HMF and LA, where the bifunctional refers to the ability of the ionic liquid to dissolve the cellulose structure and promoting the glucose dehydration to 5-HMF and subsequent rehydration of 5-HMF to LA. Generally, the effect of reaction conditions on 5-HMF and LA production using functionalized ionic liquids was also studied. The varied reaction parameters include reaction temperature, reaction time, ionic liquid loading, feedstock loading, as well as water content. The effect of these parameters on 5-HMF and LA production using the functionalized ionic liquid rendered the same trend as non-functionalized ionic liquids. Detailed on the effect of reaction conditions as well as the types of ionic liquids towards the reaction processes is discussed in the later subtopic.

Factors Affecting the Catalytic Processes in Ionic Liquid

Reaction Temperature and Time

Reaction temperature and time are two important factors affecting the carbohydrate biomass conversion to 5-HMF and LA. These two factors also affect kinetics, selectivity and activity of catalyst. The application of ionic liquid reduces the temperature required for dehydration of monosaccharides compared with aqueous and other organic solvents [122, 130]. Generally, reaction involving heterogenous catalyst in ionic liquid require higher temperature and longer time compared with homogeneous catalyst. This is because reactants must come to the surface of catalyst and react with the catalytic sites, and resulting products must diffuse away from the catalyst [55]. A sufficient reaction time is critical for achieving adequate mass transportation in the heterogeneous reactions. For better discussion in this review, reaction temperatures are categorized into several groups: room temperature, low (below 100 °C), medium (100 to 150 °C) and high temperature (above 150 °C). The circumstances of the effect of reaction temperature and time can be deduced as follows: at higher temperature and prolonged time, the initially produced 5-HMF is not stable which caused self- or cross-polymerization of 5-HMF and leads to formation of insoluble humins, as well as conversion of 5-HMF to LA and formic acid [9, 10, 80, 89, 92, 123, 131]. The presence of humins in the reaction mixture is difficult to be identified and quantified. Nevertheless, these could be confirmed by the colour change of reaction-ended mixture from orange to brown, even to black [132].

The dehydration of fructose was carried out at room temperature in [BMIM][Cl] catalysed by GeCl4 [133]. The reaction proceeded smoothly, with 70% 5-HMF yield obtained at prolonged time of 12 h. Other employed ionic liquids include [BMIM][Oac] and [BMIM][BF6]. Fructose conversion at room temperature was also investigated using binary mixture of [HNMP][CH3SO3] and [BMIM][Cl], with 5-HMF yield up to 88% in 5 h [86]. Besides, binary mixture was applied for 5-HMF production from fructose in ethanol solvent [98]. The 5-HMF yield obtained from the reaction was up to 89% in 6 h. The reaction rate at room temperature was slower than that at higher temperature; thus, a long reaction time was necessary to obtain high 5-HMF yield. Nevertheless, shorter times were reported for fructose, glucose and sucrose conversions at room temperature in ionic liquid mixtures catalysed by solid acid catalysts [134, 135]. The mixture of [BMIM][Cl]/[BMIM][BF4] yielded high 5-HMF yield up to 56% in 3 h [135].

Low temperature was generally employed for fructose conversion since no crucial step like isomerization is needed. Studies reported the optimum temperature of 70–75 °C for fructose conversion to 5-HMF in unsymmetrical dicationic ionic liquid [136] and in [BMIM][Cl] catalysed by acidic ion exchange resin [57]; optimum temperature of 80 °C for fructose conversion to 5-HMF in [BMIM][Cl] catalysed by HCl [24], in [BMIM][Cl] catalysed by heteropolyacid [28], in [BMIM][Cl] catalysed by yeast derived carbonaceous catalyst [10] and in [PSMBIM][HSO4]-DMSO [9]; and optimum temperature of 90 °C for fructose conversion to 5-HMF in proline-derived ionic liquid-water [88]. In addition, higher temperature of 95 °C was reported to obtain the optimum LA yield from fructose conversion in [BMIM-SO3H]HSO4 aqueous mixture [91]. It is suggested that as fructose conversion performed at low temperature (80 °C), the 5-HMF produced is stable; thus, the reaction could be sustained for a longer period, providing an opportunity to employ high fructose loading [24]. At higher reaction temperature (100 °C), the 5-HMF yield started to decrease [57, 136] and colour of the reaction mixture turned darker [136]. On the other hand, 5-HMF yield significantly increased at elevated temperature up to 100 °C as compared with reaction conducted at 60–80 °C [27, 63]. Several studies demonstrated 100 °C as the optimum temperature for fructose conversion to 5-HMF in ionic liquid systems such as [AMIM][Cl]-DMF [25], [ClC2MIM][Cl]-water [63], ionic liquid-based polyoxometalate salt-DMSO [93], [BMIM][HSO4] catalysed by CrCl3 [85] and [BMIM][Cl] catalysed by lignosulfonic acid [27]. The formation of by-products from fructose dehydration performed at relatively low temperature was observed but negligible [25, 130, 136]. The 5-HMF yield kept increasing with prolonged time, as the reaction proceeded at low temperature of 70 °C [88, 136]. Higher temperature ~ 100 °C was beneficial for fructose conversion to 5-HMF at shorter time [27, 57, 85, 88, 93]. Increasing reaction temperature not only accelerates the dehydration reaction but also speeds up the side reactions such as polycondensation of 5-HMF. This can be verified as the 5-HMF yield decreases faster at 100 °C than that at 75 °C with prolonging time [57].

The low feedstock conversion at low temperature indicates insufficient activation energy for the reaction to proceed. Generally, conversions of carbohydrate biomass in ionic liquid were conducted at medium temperature range (100–150 °C). The reported optimum temperature for fructose conversion in ionic liquid was in the range of 110 to 120 °C as in several studies involving reaction systems [HO2CMMIm][Cl]-isopropanol [82], [BMIM][Cl] catalysed by sulfated zirconia [137], [BMIM][Cl] catalysed by solid base catalyst [138], polyethylene glycol functionalized dicationic acidic ionic liquid-DMSO [123], [BMIM][Cl] catalysed by IrCl3 [21], [BMIM][Cl[catalysed by SBA-15-SO3H [20], [CMIM][Cl]-DMSO [80], Cr3+ immobilized SO3H functionalized solid polymeric ionic liquid [89] and pyridinium-based dicationic ionic-DMSO [92]. The selectivity and 5-HMF yield were reported to continuously decrease as reaction time becomes longer [21, 92]. Other than significant degradation of 5-HMF at higher temperature and longer time, the loss of active compounds and destroy of catalysts could occur over high temperature. This condition is anticipated for fructose conversion in [BMIM][Cl] catalysed by acidic ion exchange resin and SBA-15-SO3H [20, 57].

Increasing temperature not only increase the product yield, but also shorten the time needed to reach the optimum yield. This trend has been acquired for glucose conversions at medium temperature range in [BMIM][Cl] catalysed by Cr3+ modified ion exchange resin [131], in [BMIM][Cl] catalysed by 12-tungstophosphoric acid/boric acid [38], in [BMIM][C] catalysed by GeCl4 [19], in [BMIM][Cl catalysed by CrCl3/boric acid [41] and in [BMIM][Cl]–DMSO catalysed by bentonite-Cr [132]. The similar trend was also observed for sucrose conversions to 5-HMF in pyridinium-based dicationic ionic liquid catalysed by CrCl2 [122], and cellulose conversion catalysed by ionic liquid-heteropoly acid catalyst in MIBK-water [58]. In cellulose conversion reaction, the limit of 5-HMF production at medium temperature (~ 120 °C) was due to slow reaction rate, caused by low solubility and breakdown of the polysaccharide in the ionic liquid [51]. Meanwhile, at higher temperature (~ 170 °C), high 5-HMF yield was attained at much shorter time. Nevertheless, the formation of humins was very high and unavoidable, which caused 5-HMF yield dropped significantly after only a short period [51]. The optimum conversion of glucose to LA using [SMIM][FeCl4] was attained at temperature of 150 °C [64]. Low glucose conversion rate was observed at low temperature compared with the conversion at higher temperature, which deduced that at elevated temperature, atoms donate or receive electrons more easily thus increasing the chemical reaction rate [64]. Increasing temperature can decrease viscosity of reaction system and subsequently accelerate the mass transfer rate which facilitated the cellulose degradation [102, 104, 139, 140]. A range of low to medium temperatures from 80 to 120 °C were tested for cellulose and bamboo biomass conversions to LA catalysed by Brønsted acidic dicationic ionic liquid [111, 124]. The results demonstrated that the LA yield from cellulose increased when temperature increased from 80 to 100 °C, then decreased when the temperature was over 100 °C. It is suggested that LA is unstable at high temperature in the acidic condition, thus caused the decreased in LA yield.

Reactions conducted at high temperature (above 150 °C) were reported for conversions of monosaccharides, disaccharides and polysaccharides. Conversion of fructose in [BMIM][OH]-DMSO required high temperature of 160 °C and prolonged time of 8 h [141]. The demanded high temperature and prolonged time was possibly due to the application of alkaline ionic liquid [BMIM][OH]. The effect of types of ionic liquid is discussed in the following section. When the temperature was elevated to 160 °C for glucose conversion catalysed by carbonaceous catalyst in [BMIM][Cl], the optimum 5-HMF yield was achieved at only 15 min as compared with 140 min at 120 °C [26]. The same trend was reported for cellulose hydrolysis in [BMIM][Cl]-DMSO catalysed by AlCl3 and γ-AlOOH [50, 53]. By further increasing the temperature to 180 °C, the reaction only required 3 h to obtain the maximum 5-HMF yield compared with 9 h at 150 °C [50]. In other study on glucose dehydration catalysed by silica-supported ionic liquid layer in water, glucose conversion at 150 °C continuously increasing after 2 h reaction while the 5-HMF yield remained constant [128]. The maximum 5-HMF yield was achieved at 160 °C from sucrose conversion in [EMIM][Br] catalysed by tyrosine then the 5-HMF yield significantly declined at 180 °C [33]. For the conversion of chitosan, the optimum temperature of 180 °C was chosen when the reaction conducted in [MIM][HSO4] aqueous solution [105] and [HMIM][HSO4]–FeCl2 aqueous solution [106]. The decrease of 5-HMF yield as reaction temperature vary from 130 to 140 to 200–220 °C was likely due to rehydration reaction in aqueous systems occurring at higher temperature [105, 106].

In LA production from glucose in [BSO3HMIm][HSO4]-water, increased in reaction temperature and time has increased the rate of glucose conversion and product yield [90]. The same trend was observed for cellulose and chitosan conversions to LA, when temperature ranging from 140 to 180 °C and reaction time from 30 to 210 min in [BSO3HMIm][HSO4]-water system [90], and when temperature ranging from 160 to 180 °C and reaction time from 30 to 180 min in [C3SO3Hmim]HSO4-water system [142]. In SO3H functionalized ionic liquid system, the maximum glucose conversion and LA yield was achieved at 155 °C and 5 h [117]. At temperatures > 165 °C and > 180 °C for glucose and chitosan conversion, respectively, LA yield further decreased due the formation of humins [117, 142]. Ren et al. [66] suggested that cellulose conversion in [C3SO3HMIM][HSO4]-water for LA formation was favoured at higher temperature during short time or prolonged time at lower temperature [66]. At temperatures 130–150 °C, LA yield was low for cellulose conversion catalysed by 1-(1-propylsulfonic)-3-methylimidazolium chloride in water-ethanol medium [65]. Gradual increase in temperature resulted in increase of LA yield, with the optimum temperature of 170 °C, while 5-HMF yield decreased at temperature beyond 150 °C. In cellobiose conversion catalysed by [HSO3-(CH2)3-mim]Cl-FeCl3, with increasing temperature from 160 to 180 °C, the LA yield increased, while glucose and 5-HMF yield decreased [101]. Higher temperature was beneficial for LA production due to decreased of viscosity and increased of reaction rate.

Types of Heating

The types of heating methods applied for the preparation of 5-HMF and LA include convective-conductive heating and microwave irradiation, either in the presence of ionic liquids or not. The microwave heating has gained more attention in organic synthesis due to its main advantages: high heating efficiency and shorter reaction time [71]. ‘Energy efficiency’ is one of the principles of green chemistry. This principle needs to be applied to save time and reduce energy consumption. A significant energy saving can be anticipated by the use of microwave energy compared with the conventional heating mode. Microwave-assisted reaction containing ionic liquid can be heated up more rapidly and effectively than other heating methods as ionic liquid consisted of anions and cations which has excellent microwave irradiation conductivity [74]. The microwave-assisted reaction avoided the drawbacks resulted from conventional oil bath heating such as partly overheating [31, 71]. It is suggested that microwave-assisted reaction decrease the activation energy or increase in the pre-exponential factor in the Arrhenius [71, 73, 143, 144].

There were extensive studies on the carbohydrate biomass conversion in ionic liquid using microwave heating system. In general, the studies revealed that microwave irradiation provides a more effective conversion for 5-HMF production than a conventional oil bath and electrical heating. Under microwave irradiation, conversion of fructose in [BMIM][Cl] afforded 5-HMF yield up to 97% within 3 min in the absence of catalyst [143]. Glucose conversion catalysed by ClCl3 in [BMIM][Cl] gave 71% 5-HMF yield in 30 s, which is ~ 48% higher than oil-bath heating [144]. In addition, higher 5-HMF yield (47.8%) was obtained from glucose conversion in [BMIM][Cl] using ZrCl4 under microwave irradiation in 3.5 min, compared with oil bath heating reaction; 12.4% 5-HMF yield at 220 °C for 3.5 min [30]. Under microwave irradiation, several studies have reported on hydrolysis of cellulose to 5-HMF in [BMIM][Cl] catalysed by different catalysts such as CrCl3/LiCl, CrCl3 AlCl3 and ZrCl4 [30, 56, 74, 144]. Besides, the combination of SO3H-functionalized ionic liquid and microwave irradiation provides efficient approach for cellulose conversion to LA under aqueous condition [119]. Conversion of lignocellulosic biomass to 5-HMF in ionic liquid under microwave irradiation have been previously conducted. They include conversion of castor leaves catalysed by CuCl2 in [BMIM][Cl], conversion of untreated wheat straw catalysed by CrCl3/LiCl in [BMIM][Cl] and conversion of corn stalk, rice straw and pipe wood catalysed by CrCl3 in [BMIM][Cl] [71, 73].

The combination of [BMIM][Cl], catalyst and microwave irradiation generated synergistic effect for efficient conversion of carbohydrate biomass to 5-HMF [29, 56, 74, 75, 144]. The presence of [BMIM][Cl] provides complete dissolution of polysaccharide and disaccharides, thus leaves the saccharides chains accessible to chemical transformation. It is implied that [BMIM][Cl] has excellent dielectric property for transforming microwave into heat [31, 71, 143]. Under microwave irradiation, alternating electric field promote the vibrational motion of ions and leads to the internal heating [71]. Due to the microwave effect, as reaction in ionic liquid had almost pure ionic condition, the reaction is heated up quickly, volumetrically and simultaneously. By this, the synergistic effect of ionic liquid and microwave irradiation circumvented partly overheating resulted from conventional heating [71, 143]. Other than convective–conductive heating and microwave irradiation heating system, probe sonication has been previously applied for carbohydrate biomass conversions to 5-HMF and LA. For instance, conversions of glucose, cellulose, bamboo, rice husk to 5-HMF catalysed by CrCl3 in [BMIM][Cl], and to LA in a dicationic ionic liquid [17, 114], and conversions of fructose, glucose and sucrose to 5-HMF catalysed by solid catalysts such as zeolites and acidic resins in ionic liquid mixtures [134, 135]. Compared with the conventional heating technique, the use of ultrasonic irradiation probe reduced the reaction time from hours to minutes. Within less than 10 min, 43%, 31% and 13% of 5-HMF yields were obtained from glucose, cellulose and bamboo, respectively [17]. In addition, a good increase in 5-HMF yield was obtained at a significantly lower reaction temperature of 25 °C in contrast to 90 °C for conventional heating [135].

Catalyst Properties/Types of Catalyst

It is apparent that different catalysts have diverse effects on conversion of carbohydrate biomass to 5-HMF and LA in ionic liquids. The trend of feedstock conversion and products yield and selectivity are interrelated to the catalyst properties. In conversion of carbohydrate biomass, acidic sites, Brønsted and Lewis, are required and played different roles in 5-HMF and LA productions. The hydrolysis of cellulose to glucose was mainly due to the Brønsted acid sites and dehydration of fructose to 5-HMF [145]. The Lewis acid sites favour the isomerization of glucose into fructose, whereas the combination of Brønsted and Lewis acidity favour the dehydration-rehydration reaction [101, 145]. Nevertheless, Lewis acid sites can also decrease the LA production by catalysing the decomposition of glucose and reaction between glucose and furfural to form humins [146]. Several homogeneous catalysts which are strong mineral acids, HCl, HNO3 and H2SO4, were equally effective for 5-HMF production from fructose conversion in [BMIM][Cl] [24]. Besides, organic acids such as maleic acid and acetic acid also catalysed the reaction effectively.

Metal halides, acted as Lewis acid, have been extensively used for productions of 5-HMF and LA in ionic liquids. The most common metal halides used were chromium chlorides: CrCl3 and CrCl2. Other than CrCl3 and CrCl2, CrBr3 and CrF3 were also employed to scrutinize their effect on 5-HMF production from acorn biomass conversion in [OMIM][Cl] [67]. Among them, CrCl2 was the most effective for 5-HMF production, whereas CrF3 gave the lowest 5-HMF yield. The results suggested that the catalytic activity was varied with the type of halide. The promotion effect was higher in chloro-halide groups than in other halides groups, which might be resulted from stronger coordination ability of chloro-group with chromium centre compared with bromo and fluoro-groups [67]. Other studies which have employed CrCl3 and CrCl2 include glucose conversion in [BMIM][Cl] [40], sucrose conversion in pyridinium based-dicationic ionic liquid, [C10(Epy)2]2Br− [122] and cellulose conversion in [BMIM][Cl] and [BMIM][Cl]/toluene [52, 139, 140, 147]. For cellulose conversion in [BMIM][Cl], other metal chlorides were also tested such as CuCl2, SnCl4, WCl6, FeCl3, TiOSO4, ZnCl2 and MgCl2 [52, 139, 147]. The results showed that both CuCl2 and WCl6 have good ability to degrade cellulose, but the degradation products are unstable [139]. Meanwhile, SnCl4 showed poor performance possibly because SnCl4 is easily converted into Sn(OH)4 in the reaction [139]. However, in other study, SnCl4 showed good performance as high 5-HMF yield was attained from monosaccharides and disaccharides conversion [148]. Other metal halides were opted for 5-HMF production in ionic liquid due to their advantages compared with CrCl2 or CrCl3, which were reported to possess toxicity and polluting characteristics [103]. In search of a possibly more environmentally feasible process, conversion of glucose in [BMIM][Cl] and [EMIM][Cl] using ZrCl4 and Yb(Otf)3 as catalysts were explored [30, 39]. Besides, InCl3 was used for cellulose conversion in [C3SO3HMIM][HSO4] and biomass conversion in [HMIM][HSO4], due to its properties such as low toxicity, air and water compatibility, operational simplicity and ability to suppress side reactions in acid-sensitive substrates [103, 110, 121]. In addition, Lewis acid Fe2(SO4)3 is considered as a non-toxic and inexpensive catalyst, and has been incorporated for 5-HMF production in [BMIM][Cl] from hardwood and softwood pulp conversions [77].

It was reported that trivalent metal chlorides showed higher activity than divalent metal chlorides on glucose conversion in [BMIM][Cl]-DMSO [50]. The 5-HMF yield decreased as different metal chlorides used in the following order AlCl3 > CrCl3 > FeCl3 > ZnCl2 > MnCl2 > CuCl2. In addition, AlCl3 was used as catalyst for conversion of starch to 5-HMF in [BMIM][Cl]-DMSO under microwave-assisted reaction [56]. In [BMIM][Cl], fructose conversion was conducted in the presence of various metal halides including ScCl3, IrCl3 and AuCl3 [21, 31]. Several germanium salts, GeCl4, Ge(Oet)4 and GeBr2, were tested for glucose conversion in [BMIM][Cl] [19]. Ge(Oet)4 was less competent for 5-HMF production, which may be explained by the anion effect. Besides, the preliminary testing indicated that GeCl4 was a superior catalyst compared with other metal halides. Metal salts such as iron salts, cobalt salts and manganese salts have been employed for conversion of cellulose to 5-HMF in 1-(4-sulfonic acid) butyl-3-methylimidazolium hydrogen sulfate [62, 78, 149]. Among the metal salts used, the promoting effect on 5-HMF yield was remarkable for FeSO4 and FeCl2, CoSO4, Co2(SO4)3 and CoCl2 and MnSO4 and MnCl2. The similar trend between iron, cobalt and manganese salts was reported, where Fe(NO3)3, Co(NO3)2 and Mn(NO3)2 caused decreased in the conversion, suggested that nitrate anion is most unfavourable to the reaction. This can be explained as NO3− cannot directly act as single-ligand to form stable coordination compounds; thus, the formation of metal nitrate complex was difficult compared with others [62, 78, 149].

The performance of SO3H functionalized ionic liquid with different metal chlorides, FeCl3, CoCl2, NiCl2, CuCl2 and ZnCl2, have been examined for glucose conversion to LA [117]. Higher activity was obtained in the presence of NiCl2 compared with sole SO3H reaction system. The effect of metal sulfates and metal nitrates was also investigated. Among the metal sulfates, the NiSO4·6H2O-SO3H-functionalized ionic liquid system showed the highest synergistic effect on LA yield. The study showed that metal sulfates were more predominant in the reaction as compared with metal chlorides [117]. The results indicated that the Brønsted acidity of the ionic liquid is not the sole factor affecting the glucose conversion to LA. Nevertheless, different trend of results was obtained in other study on the addition of metal nitrates [62, 78, 149]. The addition of metal nitrates with SO3H functionalized ionic liquid resulted in a negative effect on LA yield. Nitrates possess strong oxidizing property and can oxidize glucose to other insoluble products [117]. A series of metal phosphates were tested for glucose conversion to 5-HMF in [EMIM][Br] [47], which SnPO exhibited high glucose conversion and 5-HMF yield. Even though previous studies showed high activity of chromium-based catalysts, CrPO showed poor performance. From the analysis, synergistic effect of SnPO and [EMIM][Br] leads to the excellent catalytic performance, where the tetra-coordinated Sn4+ sites from the catalyst were identified as the active species for isomerization of glucose into fructose [47].

A more efficient catalytic process could be achieved by pairing the catalysts, which may be due to synergetic effects between the catalyst. Studies on pairing different metal salts have been conducted for cellulose and biomass conversions in ionic liquids [67, 74]. It was found that adding metal halides to [BMIM][Cl]-CrCl3 could promote the 5-HMF yield from cellulose conversion compared with single CrCl3 as catalyst [74]. Among the paired catalyst, CrCl3/LiCl exhibited better catalytic activity than CrCl3/LaCl3 and CrCl3/LiBr. The different trend of activity possibly due to the different size of cation anion radius of the metal salts [74]. Combination of different metal chlorides with Brønsted acidic ionic liquid was examined for cellulose conversion to LA [101]. The ionic liquid system was affected by the metal chloride, and their acidity increased in the following order: CrCl3 < ZnCl2 < FeCl3. Even though CrCl3 generally resulted in high 5-HMF production, the cellobiose conversion in the presence of CrCl3 combined with Brønsted acidic ionic liquid showed poor catalytic effect [101]. It was reported that boric acid could promote formation of 5-HMF from glucose in [EMIM][Cl] [36]. The combination of boric acid with other catalysts has been applied for 5-HMF production in ionic liquids. The paired heteropolyacid and boric acid gave higher 5-HMF yield from glucose dehydration in [BMIM][Cl] compared with a single heteropolyacid or single boric acid catalyst [38]. When boric acid was paired with different heteropolyacids, H3PW12O40, H3SiW12O40 and H3PMo12O40, H3PW12O40/boric acid exhibited better catalytic activity for 5-HMF production [38]. In other study through combination of boric acid with CrCl3 for glucose conversion to 5-HMF in [BMIM][Cl], it was revealed that boric acid exhibited obvious promotion activity [41].

Several studies have reported the use of heteropolyacid-based catalyst for 5-HMF production in ionic liquid. Various heteropolyacids were applied for fructose conversion to 5-HMF in [BMIM][Cl] [28]. The reactions showed that feedstock conversion decreased in the order of the decreasing acidity of the heteropoly acid. Furthermore, all the used heteropolyacids exhibited comparable catalytic activity to H2SO4 and HCl. Ionic liquid-based polyoxometalate salts, prepared from the combination of ionic liquid with heteropolyacids were employed for fructose conversion to 5-HMF [93]. It was revealed that as using the same ionic liquid, the catalytic activity of the catalysts were in accordance with the Brønsted acidity of the heteropolyacids [93]. The similar trend was obtained using solid catalyst fabricated based on heteropolyacid immobilized ionic liquid–modified organosilica hollow nanospheres tested for fructose conversion to 5-HMF [60]. The catalyst prepared using heteropolyacid with strongest Brønsted acid strength promote the release of proton during fructose dehydration. Furthermore, the catalyst showed better performance for 5-HMF production without promoting side-reactions compared with its parent heteropolyacid catalyst [60]. Ionic liquid-based polyoxometalate catalysts prepared using molybdenum and tungsten oxides were also tested for cellulose conversion to 5-HMF [147]. The catalysts showed good activity for cellulose degradation, however, the 5-HMF yield attained was much lower than the yield obtained using CrCl3 catalyst [147].

Catalyst with large surface area could increase the catalytic activity since catalytic performance takes place on the catalyst surface. Several studies have reported that the pore size distribution of catalyst has significant influence on glucose and fructose dehydration reactions [35, 146]. Both catalyst mesoporosity and microporosity have affected the carbohydrate conversion to 5-HMF and LA. For instance, in aqueous solution, catalyst with a large mesopore size would promote the side reactions including fragmentation and polymerization, thus decreasing the LA yield [150]. Mesoporosity may enhance the diffusion of 5-HMF away from the active sites and lead to the formation of coke, thus resulted in low LA production. It is suggested that dehydration of glucose to 5-HMF and LA requires a catalyst with appropriate mesopore and micropore sizes. The sizes of relevant molecules in the production of 5-HMF and LA are presented in Fig. 2. The trend of molecule diffusion can be envisaged by comparing the catalyst pore size and the sizes of feedstock and product. For instance, the size of feedstock, such as glucose with 0.9 nm, and pore sizes of the catalysts indicated whether the conversion process happened on the outer surface or in the pore of the respective catalysts [48]. Both Lewis and Brønsted acids played roles for conversion of carbohydrate biomass to 5-HMF and LA, and a good balance between the acid site density and the acid site strength is an important factor [48, 151]. Therefore, catalyst mesoporosity and ratio of Lewis and Brønsted acid sites must be scrutinized in order to maximize the 5-HMF and LA production. The acidity of catalysts can be determined by temperature-programmed desorption of ammonia (NH3-TPD). The acid sites based on desorption temperature can be classified as weak acid (< 250 °C), medium acid (250–350 °C) and strong acid (> 350 °C). The NH3-TPD provides general information on the amount and strength distribution of acid sites, while FTIR spectroscopy of pyridine adsorption elucidated the nature of acid sites: Brønsted or Lewis type.

Comparison of molecular dimensions of typical feedstock and product involved in 5-HMF and LA production. Adapted with permission from [150]

The activity of several zeolite and modified zeolite catalysts was examined for 5-HMF production in ionic liquids [32, 40, 45, 46, 48]. It was depicted that glucose conversion to 5-HMF was greatly influenced by the Si/Al ratio, which affected the acid site density and strength of the catalyst. Zeolite with higher Si/Al ratio demonstrated less acid site density and stronger acid site strength. A good balance between the acid site density and the acid site strength is necessary for 5-HMF production [32, 45, 48]. In another study, chromium-loaded zeolite showed better 5-HMF production from glucose in [BMIM][Cl], compared with bare zeolites, USY, Beta and ZSM-5 zeolite [45]. This is due to USY zeolite possessed higher Si/Al ratio than Cr-USY zeolite, thus showed less 5-HMF yield [45]. In addition, modified mordenite and modified KL zeolite were used for glucose and fructose conversions in [BMIM][Br], respectively [32, 46]. The modified catalyst with moderate Si/Al ratio and high Brønsted acid sites possessed high catalytic activity in the ionic liquid reaction system. The study suggested the quick adsorption and strong interaction of ionic liquid with zeolite [46]. This condition hindered the diffusion of the products thus enhanced the role of zeolite mesoporosity on the catalytic activity when the reaction was carried out in ionic liquid solution.

It was found that acidity and pore structure of ion exchange resins showed prominent effect on fructose conversion to 5-HMF in [BMIM][Cl] [57, 131]. It was interpreted that the catalyst with large surface area applies more active sites, while large pore diameter allows the quick access of sugars molecule to the inner of the particular catalysts. A catalyst with strong adsorptive property is suitable for 5-HMF production since the adsorption of water produced from the dehydration of sugars can be done in order to avoid the further rehydration of 5-HMF to LA [57]. Besides, according to the characteristics of the catalysts, resins with sulfonic acid group possessed stronger acidity than resins with carboxyl group, thus showed better catalytic performance for fructose conversion to 5-HMF [57]. This statement was supported by study on conversion of glucose to 5-HMF in [BMIM][Cl] catalysed by ion-exchanged resin modified by CrCl3 [131]. Macroporous strong-acidic ion exchanged resin exhibits better catalytic activity due to the larger surface area, stronger acidity and large number of macrospores [131]. The same rules of acid site density and strength and pore structure also applied for other solid catalysts such as mesoporous SBA-15-based catalysts, modified activated carbon, mesoporous titania and zirconia nanoparticles for 5-HMF production in ionic liquid [20, 55, 128, 152, 153]. The 5-HMF yield from fructose conversion in [BMIM][Cl] using SBA-15-SO3H as catalyst (SBA-15 functionalized with propylsulfonic acid) was comparable with 5-HMF yield using H2SO4 as catalyst [20]. From the findings, the catalytic performance of SBA-15-SO3H depended on both sulfonic group content and mesoporous structure.

In a study on cellulose conversion in [BMIM][Cl] catalysed by modified activated carbon, the results indicate that the presence of functional group attached on the catalyst increases the pore size thus increasing the number of active sites which helps in fast cellulose hydrolysis to 5-HMF [153]. In heterogeneous catalytic reactions, reactants must come to the surface of the catalyst and react with the catalytic sites, and the resulting products must diffuse away from the catalyst for the next reactant. Mesoporous titania and zirconia nanoparticles (MTN and MZrN) were prepared as catalyst for cellulose conversion in [EMIM][Cl] [55]. The difference in catalytic activity for 5-HMF production of these two catalysts was suggested due to their specific surface area and acidic properties, since the pore size and particle size of the catalysts were similar [55]. The MZrN-based catalyst exhibited three different acidic strengths, according to NH3-TPD profile, while MTN-based catalyst exhibited only one acidic strength. Therefore, it was concluded that the higher production of 5-HMF using MZrN-based catalyst was attributed to the stronger acid strength [55].

As many studies reported on the use of metal salts for 5-HMF production in ionic liquids, studies have been conducted on the synthesis of metal salts exchanged catalyst to give a heterogeneous catalyst for the respective reaction. For instance, fructose conversion to 5-HMF catalysed by pyridinium based dicationic ionic liquids as catalyst [92]. It was implied that the reaction system would be more preferable than many other Lewis acid catalysed system as the ionic liquid contained transition metal complexes [92]. Metal salt-bentonite–exchanged catalysts were prepared and used for glucose conversion to 5-HMF in [BMIM][Cl]-DMSO [132]. Due to the high Lewis acidity of Cr3+, the catalytic activity of Bentonite-Cr increased significantly. Furthermore, the 5-HMF yield using Bentonite-Cr was comparable than that of the homogenous catalyst CrCl3, with added advantages of easy separation and recycling [132]. In addition, bentonite-Cr and montmorillonite-Cr were prepared and employed as catalyst for fructose conversion in [BMIM][Cl] [44]. Shorter reaction time was recorded to give highest 5-HMF yield in the presence of bentonite-Cr catalyst for [BMIM][Cl] reaction system [44] compared with the [BMIM][Cl]-DMSO as reported in different study [132].

The effect of different metal ions, including Cu2+, Mo5+, Fe3+, Mg2+, Al3+, Cr2+ and Cr3+ used for modification of ion exchanged resin catalyst, was investigated for glucose conversion to 5-HMF in [BMIM][Cl] [131]. More than 60% 5-HMF yield was achieved in the presence of ion-exchanged resins modified with Cr2+ and Cr3+, whereas less than 20% 5-HMF yield was obtained using other ions modified catalyst. The result was in agreement with previous study which found that chromic salts can promote the isomerization of glucose to fructose, whereas other metal salts can only improve the mutarotation of a-glucopyranose anomer to b-glucopyranose anomer [131]. A series of metal (Cu) substituted aluminophosphate molecular sieves displayed excellent performance as catalyst for fructose conversion to 5-HMF in [BMIM][Br] [35]. The catalyst with higher surface area, pore volume, and stronger acidity gave higher 5-HMF yield, highlighted the effect of acidity and porosity towards the reaction [35]. Heterogeneous catalysts were prepared by immobilizing homogeneous metal chloride/[EMIM][Cl] to mesoporous structure SBA-15 [128], and immobilizing Cr3+ to SO3H-functionalized solid polymeric ionic liquid [89] for 5-HMF production from glucose and fructose, respectively. Several metal chlorides were used which CrCl2/[EMIM][Cl] immobilized on SBA-15 showed the highest activity [128]. In addition, the strong acid sites of SO3H groups together with CrCl3 in the bulk of functionalized solid polymeric ionic liquid played the roles as active centers for the dehydration reaction [89]. The activity of Brønsted and Lewis acid polymeric catalysts was tested for cellulose conversion in [BMIM][Cl] [145]. The Brønsted acid sites were obtained by ion-exchanged while the Lewis acid sites were obtained through adsorption of Cr3+ [145]. The results of this study signified that the Brønsted acidic sites to be more effective in hydrolysis of cellulose to glucose and dehydration of fructose to 5-HMF, whereas Lewis acidic sites to be more effective in glucose-to-fructose isomerization [145].

Aluminium-containing catalyst with high Lewis acidity and low Brønsted acidity was employed to convert glucose to 5-HMF in [EMIM][Br] [42]. The oxide catalyst, Al2O3-b-0.05, was prepared by alkaline and acid treatments, which led to the increase of pore volume and average pore size, and slight decrease of specific surface area. The NH3-TPD indicated that the number of acidic sites decreased after the treatments. In addition, the combined NH3-TPD and pyridine adsorption revealed that the mild alkaline treatment is effective to block most Brønsted acid sites and weak Lewis acid sites, thus leading to the high Lewis acidity and low Brønsted acidity of the catalyst. As compared with [EMIM][Br]/Al2O3-b-0.05 heterogeneous system, the activity of homogeneous AlCl3 in [EMIM][Br] was also investigated for glucose conversion to 5-HMF. From the analysis, the optimum 5-HMF yield of the homogeneous [EMIM][Br]/AlCl3 was apparently lower than the heterogeneous [EMIM][Br]/Al2O3-b-0.05 owing to the severe side-reactions in the homogeneous system [42]. The hydrothermal stability of Al2O3 was reported to be low; thus, one of its precursor, boehmite (γ-AlOOH) with high hydrothermal stability, was prepared and employed for cellulose conversion in [BMIM][Cl]-DMSO [53]. The γ-AlOOH acted as a Lewis acid catalyst with existence of mesopores and relatively uniform distribution of pore size, exhibited excellent catalytic effects in the degradation of cellulose to 5-HMF [53].

The role of Brønsted and Lewis acid sites on conversion of polysaccharides to 5-HMF was examined on conversion of chitosan by various Brønsted-Lewis acidic ionic liquids [106]. The study was conducted using ionic liquids with different metal salts as the Lewis acid component, where ionic liquid with FeCl2 showed the best performance. Acid–chromic chloride bi-functionalized catalysts were employed in conversion of cellulose to 5-HMF in ionic liquids such as [EMIM][Cl] and [BMIM][Cl] [54, 154]. The catalysts were prepared by grafting SO3H and Cr(III) onto the surface of treated attapulgite (ATP) and halloysite nanotubes (HNTs). The grafting of SO3H and Cr(III) can be assigned to Brønsted and Lewis acidic sites of the catalyst, respectively [154]. The HNTs–SO3H–Cr(III) catalyst contained larger amounts of SO3H and Cr(III) compared with ATP–SO3H–Cr(III) catalyst, which results in better catalytic performance. The acidic features of the catalysts determined by NH3–TPD were categorized into weak, medium and strong acid. Meanwhile, an acid base catalyst was fabricated by grafting acid and base, i.e. –SO3H and –NH2 groups on carbon nanotubes and further functionalized with Cr(III) species for further enhancement of acidity. Co-existed base and Lewis acid sites were found to promote glucose isomerization to fructose, and Brønsted acid sites direct the dehydration of fructose to 5-HMF [54].

Biomass-derived carbonaceous catalysts have been extensively studied. They were typically prepared by carbonisation and sulfonation process. Lignin-derived acid catalysts were used for fructose and glucose conversion to 5-HMF in [BMIM][Cl] and [BMIM][Cl]-DMSO [27, 29]. The full solubilization of the sulfonated lignin in [BMIM][Cl] results in an acidic solution, which was suitable as reaction media for 5-HMF production. The NH3-TPD desorption profile of the catalyst showed a major peak at around 100 °C, which assigned to Brønsted acid sites from the sulfonic acid [29]. Other than lignin, solid acid catalysts containing –SO3H, –COOH and phenolic –OH groups were prepared from cellulose, glucose or starch, for glucose conversion to 5-HMF in [BMIM][Cl] [26]. The study showed the synergic effect of –SO3H, –COOH and phenolic –OH groups for glucose conversion to 5-HMF in [BMIM][Cl][26]. In addition, carbonaceous catalyst was also prepared from carbonisation and sulfonation of yeast cells for 5-HMF production in [BMIM][Cl]. The obtained carbonaceous catalyst exhibited high catalytic activity suggesting that –SO3H groups served as active sites [10]. Besides, biochar modified catalyst was prepared through pyrolysis of corn stalk, and subsequently employed for 5-HMF production in [AMIM][Cl]-isopropanol reaction system [70]. The biochar modified catalyst possess appropriate components to effectively promote the degradation of lignocellulosic content [70].

It was known glucose conversion to 5-HMF reaction process consisted of isomerization and dehydration steps, which acid catalyst, Brønsted and Lewis, was generally employed. Alkaline/base catalysts have also been employed for glucose conversion to 5-HMF. It was found that the increase of the alkalinity of catalyst or catalytic system would effectively improve the isomerization of glucose into fructose [54, 138, 155]. A study was conducted on glucose conversion to 5-HMF in [BMIM][Cl]-DMSO catalysed by a simple base catalyst, ammonium aluminium carbonate hydroxide (NH4Al(OH2)CO3) [138]. The study indicated the catalytic activity primarily arise from the catalyst, while [BMIM][Cl] and DMSO were acted as the solvent to dissolve glucose and products [138]. Furthermore, the use of basic bone char and acidic ionic liquid [C3SO3HMIM][HSO4] combination shows a synergistic effect on increasing 5-HMF selectivity from glucose conversion [155]. The mesoporous bone char catalyst was synthesized using cattle bone powder and its basicity was examined by CO2-TPD, which exhibits medium and strong basic sites [155].

Catalyst Loading