Abstract

The increasing demand for biosimilar monoclonal antibodies (mAbs) has prompted the development of stable high-producing cell lines while simultaneously decreasing the time required for screening. Existing platforms have proven inefficient, resulting in inconsistencies in yields, growth characteristics, and quality features in the final mAb products. Selecting a suitable expression host, designing an effective gene expression system, developing a streamlined cell line generation approach, optimizing culture conditions, and defining scaling-up and purification strategies are all critical steps in the production of recombinant proteins, particularly monoclonal antibodies, in mammalian cells. As a result, an active area of study is dedicated to expression and optimizing recombinant protein production. This review explores recent breakthroughs and approaches targeted at accelerating cell line development to attain efficiency and consistency in the synthesis of therapeutic proteins, specifically monoclonal antibodies. The primary goal is to bridge the gap between rising demand and consistent, high-quality mAb production, thereby benefiting the healthcare and pharmaceutical industries.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The treatment of severe and chronic diseases has undergone a radical change with the introduction of targeted biologics, mainly monoclonal antibodies (mAbs). These medications have significantly changed how diseases including cancer (with monoclonal antibodies), autoimmune diseases, diabetes (with human insulin), and anemia (with replacements such as erythropoietin) are treated [1, 2]. The extensive range of diagnostic and therapeutic applications of antibodies, especially monoclonal antibodies and their derivatives, including antibody–drug conjugates, Fc-fusion proteins, and antibody fragments, are well known. Antibodies such as pembrolizumab (Keytruda) and nivolumab (Opdivo) have attracted a lot of interest in the field of cancer immunotherapy. A total of 119 therapeutic mAbs—including two diagnostic mAbs—have been approved in the USA since the first therapeutic mAb, muromonab-CD3, was approved in 1992 [3]. Remarkably, a large number of these approvals go outside indications related to cancer, demonstrating the remarkable efficacy of antibodies as therapies for a variety of illnesses.

The approval of antibodies for non-cancer illnesses, like treating HIV infections (Ibalizumab) and preventing migraines (erenumab, galcanezumab, fremanezumab), demonstrates further diversification. Furthermore, the US FDA has approved four mAbs for the treatment of HIV infection, prevention of respiratory syncytial virus, and inhalational anthrax. A good example of this is Adalimumab (Humira), which is the world’s bestseller medication in 2018 and is given subcutaneously as a biological disease modifier. It plays a crucial role in the treatment of rheumatoid arthritis and other persistent, life-threatening diseases mediated by TNFα. [4, 5]

Cell line development (CLD), as depicted in Fig. 1, is a fundamental step of the overall product development involving the engineering of cell lines with a primary to produce recombinant therapeutic proteins. This involves the use of an expression vector, comprising of regulatory elements, such as promoters, enhancers, selection marker genes, as well as codon-optimized gene of interest (GOI). Expression of GOI is strongly influenced by these regulatory elements as well as signal sequences located upstream of the genes. Along with these, the host cell to be used is another crucial aspect of CLD. Various mammalian cell lines are used as hosts for large-scale therapeutic protein production. These include rodent cell lines like NS0, SP2/0, Chinese hamster Ovary (CHO) cell line, and human cell lines like HEK-293. The CHO cell line is the gold standard expression system for manufacturing biosimilars since these cells facilitate accurate glycosylation in mAbs and have established a track record for their regulatory acceptance. Along with this, the growth of the CHO cells is scalable in suspension culture, using chemically defined media. Thus, considerable advances have been made in upstream process development for enhancing the mAb yields and to obtain products with appropriate PTMs necessary for protein function and stability [6, 7]. The initial step in the CLD process is the construction of the expression vector containing the GOI and subsequently transfecting this expression vector into the host cell line. The transfection method used can be selected from a variety of options, such as the cationic polymers, electroporation, or nucleofection. Overall, CLD is a complex process that presents challenges, like the need to maintain high yields of mAbs, having quality and structural attributes comparable to the innovator mAb. Advancements in cell biology, biochemistry, and bioengineering have revolutionized the process of producing therapeutic proteins from mammalian cells. The existing biologics utilize commercially available platforms for generating dedicated cell lines for therapeutic protein production. However, the current platforms have limitations in terms of growth characteristics, inconsistent yields, and quality attributes [8]. The biopharmaceutical industry is, therefore, continuously seeking to develop newer, more efficient approaches to overcome these challenges and enhance the production capacity of therapeutic proteins. It becomes clear as we work our way through the complex web of developments, possibilities, and obstacles in CHO cell line generation that the path from efficiency to yield is characterized by a dynamic interaction of scientific creativity, technical prowess, and regulatory compliance.

Producing mAbs using mammalian cells involves several critical steps that are essential to ensure the efficiency and consistency of these proteins. These include designing an effective gene expression system, selecting a suitable expression host, developing a streamlined approach for cell line generation, and optimizing culture conditions. This review uniquely highlights how advancements in each of these areas, both individually and collectively, contributes to accelerating the efficiency and consistency in the production of therapeutic proteins, specifically the mAbs. Additionally, this review provides a deeper understanding of how the CHO cell line development has evolved from a more traditional approach to a collection of sophisticated techniques, for enhancing the mAb yield and quality. Furthermore, novel approaches are crucial for optimizing expression vectors, host cells (genomics to proteomics and metabolomics) and the cell line development process. These approaches play a key role in achieving large-scale, high-density cell cultures, boosting gene delivery tactics. optimizing downstream recovery and analytical methods for improved efficacy and economical yield. Integration of the advancements discussed in this review will enable streamlined cell line development and thus, translation of innovative research into therapeutic products. Researchers can investigate novel approaches to design cell lines, integrate principles of synthetic biology, and create platforms with improved adaptability and productivity to produce commercially viable therapeutic proteins.

Vector Engineering Strategies

The development of cell lines is significantly altered by the field of vector engineering, which is essential for the precise regulation and improvement of host cell gene expression. In this complex procedure, vectors—vehicles for delivering and expressing genes of interest in the desired cells—are strategically modified and designed. The modification of vector elements, such as promoters, enhancers, and chromatin-modifying elements, can enhance the expression of the gene of interest and improve the efficiency of gene transfer as well as signal sequences essential for protein secretion, as shown in Fig. 2 [6].

Advances in vector engineering have revolutionized the field of cell line development, enabling researchers to express and study genes in various systems and facilitate the development of gene therapies for various diseases. In this article, we have discussed the recent advancements in vector engineering and their applications in cell line development, with a particular emphasis on the production of therapeutic proteins.

The alteration of promoter and enhancer elements is one of the tenets of vector engineering. These components play a crucial role in determining how genes are translated into RNA and then into proteins. Choosing the right promoter is an essential step in obtaining high and consistent transgene expression. Promoters play a key role in the synthesis and processing of the signals that control transcription initiation. A variety of promoters are used, including eukaryotic heterologous promoters, like phosphoglycerate kinase 1 (PGK), human elongation factor-1 alpha (EF-1), and human ubiquitin C (UBC), as well as viral heterologous promoters like cytomegalovirus immediate early (CMV-IE) and Simian Virus 40 (SV40). hCMVp, a human CMV major immediate-early enhancer/promoter, is frequently used because it is effective at promoting transgenic expression [9,10,11]. The SV40 enhancer was the first cis-acting element to be discovered, and it has been demonstrated to significantly boost transcription rates with both, homologous and heterologous promoters [12]. RSVp was shown to have the second highest expression rate (92%), after hCMVp (100%), when utilized for episomal transient transgene expression in CHO cells, in a comparative study [9]. Although viral promoters are commonly used for expression of recombinant proteins, they are susceptible to epigenetic silencing due to methylation of DNA, thereby resulting in reduced expression [13].

A desirable alternative to viral promoters is provided by endogenous promoters like the Chinese hamster elongation factor-1 (CHEF-1) promoter. The risk of silence and stress reactions associated with viral promoters is decreased by the fact that these promoters are derived from genes that are normally present in the host cells. The concepts of synthetic biology have also led to the emergence of synthetic promoters, which offer innovative and adaptable transcriptional regulation. For example, the super core promoter SCP1 combines components from several sources to greatly boost transcription rates [14].

Cumate gene switches, which use cumate-sensitive operon sequences (the cymene operon of Pseudomonas putida) and work similarly to the Tet-On/Tet-Off system, are one of the most newly developed mammalian-inducible systems. In serum-free CHO cells, cumate gene switch has been studied for transitional gene expression based on adeno- or lentiviral vectors. Depending on the product, the LV/CHO system yielded transient transgene expression with an ON/OFF induction ratio of 6–74 (six-fold for a mAb and 74-fold for an anticoagulant, erythropoietin), making it advantageous when the prompt production of relatively tiny protein quantities is required. The cumate gene-switch technology can be modified for fed-batch culture [15]. CHOBRI/rcTA, a recently described cumate-inducible stable CHO cell line, allowed the reproducible synthesis of up to 350 mg/L of a recombinant antibody and 940 mg/L of a recombinant Fc protein [16]. A similar study was also performed by Poulain et al. and it demonstrates that the cumate gene switch is a good platform for stable clone formation and encourages the wider use of inducible systems for scale biologic production in CHO cells [17]. The crucial benefit of inducible systems is the effective independence of cell culture growth and production phases. Cells that are free of the metabolic stress provided by the recombinant protein production grow and divide more quickly, resulting in a higher cell density. Although inducible promoters have widespread scope in the production of biologics, there are limitations in the use of toxic inducers that affect the cell health and productivity.

Chromatin-Modifying Elements to Improve Transgene Transcriptions

Along with elements, such as promoters and enhancers, the expression of GOI depends on the integration site in the host chromosome. Random integration can result in unpredictable results affecting expression of GOI as well as endogenous gene function [18]. To overcome this position effect a variety of chromatin-modifying elements (CMEs) have been described in a mammalian expression system resulting in boosting the yield of a heterologous product. These can be classified into 1. those that actively alter chromatin into a transcriptionally open state (ubiquitously acting chromatin opening elements [UCOEs] and locus control regions [LCRs] and 2. those that prevent heterochromatin marks from spreading into regions of euchromatin-forming boundaries between chromosomal domains (insulators, stabilizing anti-repressor [STAR] elements, scaffold, or matrix attachment regions [S/MARs].

Ubiquitously acting Chromatin-Opening Elements (UCOEs) are sequences that keep chromatin open, resulting in consistent, high-level transgenic expression, as shown in Fig. 3 [19]. These UCOEs have methylation-free CpG islands surrounded by divergently transcribed promoters, similar to how housekeeping genes are regulated. Upstream integration of UCOEs has been found to boost expression levels and resist gene silencing. Nematpour et al. evaluated and concluded that the use of UCOEs along with the with heavy chains greatly increased the level and stability of mAb expression, resulting in more stable cell lines with higher outputs [20]. Doan et al. improved the expression of anti-TNFα mAbs by the CHO-DG44 cells by employing a vector construct incorporating UCOE in combination with DHFR (to improve productivity through gene amplification) [21]. These studies clearly highlight the role of UCOEs in enhancing the transgene expression, thereby proving to be a good option for commercial production of mAbs.

Ubiquitously acting Chromatin-Opening Elements (UCOE): Chromatin-modifying elements such as UCOE protect GOI from epigenetic silencing, thereby maintaining the genes in an open state for transcription to occur. (i) The incoming GOI integrated at a heterochromatin region of the genome is silenced through covalent modification like methylation of cytosine in DNA. This leads to silencing of the genes and productivity loss over time. (ii) The incorporation of UCOE upstream to the gene cassette generates open chromatin regions resisting silencing. This maintains an integration-independent state of GOI, hence improving the productivity for longer time

The other group of CME include S/MARs which are AT-rich entities that enable DNA attachment and higher-order loop creation. They have a high affinity for binding to nuclear matrix or scaffold, in vitro [22]. In silico studies have linked the existence of nucleosome positioning motifs and binding sites for numerous TFs to the capacity of MARs to boost transgene output [23]. S/MAR protected a transgene against epigenetic silencing by generating a distinctive chromosomal domain at the integration site when it was inserted before the promoter in control of GOI. Human-globin, interferon, and chicken lysozyme 50 region MARs have been described and successfully used to boost transgene output in stably transfected CHO cells. In comparison to UCOEs, MAR activity appeared to be less prevalent [24]. Although managing MARs can be unpredictable due to their huge size and poorly understood mode of action, more research will undoubtedly lead to a better understanding.

The use of other chromatin-modifying elements, such as insulators and Stabilizing Anti-Repressor (STARs), has not increased transgene expression considerably. Although early reports indicated that these elements were quite effective and promising, the system was never fully implemented in the industry. While some of these elements have shown promise in early research, their full potential is still being explored. The effects of these elements vary depending on several parameters, such as the integration site, the host cell line, as well as the characteristics of the GoI.

Several techniques are used to optimize gene expression for the synthesis of therapeutic proteins. Although strong natural viral promoters are frequently employed to achieve elevated expression levels, synthetic promoter libraries accurately regulate transcription strength. Both viral and mammalian heterologous promoters are susceptible to transcriptional suppression, thus explaining the reason why endogenous CHO promoters like CHEF-1α are an advantageous substitute. Growth and production stages can be separated as a result of induced systems, like Tet-On or cumate gene switches. Furthermore, it is imperative to guarantee expression stability, accomplished by components, like MARs and UCOEs, which function at the epigenetic level to sustain a transcriptionally permissive chromatin state throughout extended cultivation. Chromatin-modifying elements will probably be used in more advanced ways in future.

Codon Optimization and Use of Signal Sequences

Codon optimization describes methods for boosting the expression of proteins from a GOI by exploiting synonymous mutations [25]. Codon optimization for gene expression is crucial due to the varying abundance of transfer RNA in different cells and the impacts it has on mRNA stability and secondary structures created by the transcripts [26]. Using the empirical method of DNA shuffling, early attempts at codon optimization for gene expression increased the production of green fluorescent protein (GFP) in CHO cells by 42-fold. With a better understanding of the mammalian cells, more logical methods of codon optimization are now available and a technique known as codon adaptive indices is used to rate how well optimized for expression of a gene may be [27]. Recent proteomic research about CHO cells involved a thorough evaluation of codon utilization. Proline, threonine, aspartate, and cysteine were found to prefer specific codons more than others [28]. Improvements in mAb expression, ranging between 1.5 and fourfold, were observed in CHO and human cells using optimization based on codon use [26, 29]. Several studies claim that codon optimization primarily increases the mRNA levels.

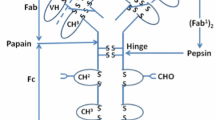

Human IgG antibodies are composed of two identical heavy chains (HCs) and two identical light chains (LCs). To transport the HC and LC protein complexes into the ER for correct folding, assembly, and post-translational modification, the HC and LC need the right signal peptides. When compared to employing a native IgG LC signal peptide, a signal peptide produced using human albumin more than doubled the average specific productivity of a stable mAb-producing CHO cell mini pool to over 40 pg/cell/day [30]. A two-fold increase in pertuzumab production was demonstrated in CHO cells through codon optimization and the choice of suitable signal peptides [31].

To summarize, vector engineering is a multifaceted and dynamically expanding field that propels cell line creation forward. Researchers can obtain optimal gene expression and protein production in host cells by methodically tweaking vector elements. This has vast applications in research, biotechnology, and medicine, allowing for the synthesis of therapeutic proteins, study into gene function, and the development of novel gene treatments. Vector engineering will play an increasingly important role in creating the landscape of molecular biology and biotechnology as the discipline advances.

Host Cell Engineering

CHO cells are a preferred choice for the production of biosimilars and other therapeutic proteins in the biopharmaceutical industry due to their mammalian nature, facilitating proper protein folding and glycosylation as well as efficient scalability in suspension culture. However, the production of biopharmaceuticals using Chinese hamster ovary (CHO) cells faces significant challenges due to the escalating demand for therapeutic proteins [32]. To meet these demands, researchers have turned to innovative strategies in cell engineering. These strategies often involve manipulating the activity of specific genes within the CHO cells to achieve desirable outcomes, such as enhanced protein expression and improved cell viability. This is achieved through techniques like overexpression of certain genes, CRISPR-Cas-mediated knockout, which involves silencing specific genes, or knockdown, which involves reducing the expression of particular gene products.

CHO cell variants have been developed that outperform their parent cell lines in multiple critical aspects. These include heightened growth rates, increased resistance to apoptosis (programmed cell death), improved metabolic activity, enhanced productivity in terms of protein synthesis, and the ability to tailor recombinant proteins with specific glycosylation patterns. Moreover, recent advancements have led to the creation of suspension cell lines, which are more convenient to manage and can be more effectively scaled up for large-scale production. This section focuses on developments in host cell engineering through genome modifications resulting in improved recombinant protein production.

Engineering Cell Death

Cell death triggers the accumulation of metabolites and disruptions in stress, leading to imbalances in cell culture and bioprocess yields. Additionally, cell death introduces proteases, causing product instability and enzymes hindering desired product synthesis. Insufficient nutrients in the culture medium prompt cellular deprivation, inducing autophagy in host cells. Manipulating genes controlling apoptosis and autophagy offers a way to extend culture sustainability, as detailed in Tables 1, 2, and 3. Enhancing cell viability through mammalian cell engineering targets apoptosis and autophagy genes, as shown in Fig. 4. Increasing the expression of particular B-cell family (BCF) proteins like BCL-2 and BCL-XL increases cell viability by inhibiting apoptosis triggers. BCL-2-related genes also counteract physiological stress in various cell lines, boosting monoclonal antibody (mAb) production, and cell lifespan [33].

Strategies for prevent apoptotic engineering: Genetic modification to prevent apoptosis/autophagy targets either to knock out/ repress pro-apoptotic genes or overexpress anti-apoptotic genes. (i) Transfection of host cells with GOI leads to producer cell line with a growth and productivity profile. (ii) This growth and productivity profile is enhanced when genetically engineered host cell is used for production. These engineered host cell line has been subjected to genetic manipulation using tools such as CRISPR/Cas9 and siRNA to prevent or delay apoptosis thereby maintaining the cell health for longer period of time during production

SIRT6 is a stress-responsive protein that regulates DNA repair and genome integrity and plays a key role in cellular survival and lifespan. Hashemi et al. engineered CHO-K1 cells to overexpress SIRT6 stably, assessing its impact on apoptosis-related genes and monoclonal antibody (mAb) production. Remarkably, SIRT6-engineered cells displayed increased BCL-2 mRNA levels and reduced caspase-3 and Bax mRNA expression compared to parental CHO-K1 cells. This coincided with higher cell viability and reduced apoptotic progression. Moreover, IgG1 mAb titers significantly improved by 1.7- and 2.8-fold during transient and stable expression in the SIRT6-engineered clone [34].

It is well known that the application of siRNA to silence pro-apoptotic proteins FADD, Alg-2, and REQUIEM enhances CHO cell culture density and productivity [35]. A recent study by MacDonald et al. employed CRISPR‐Cas9 technology to engineer combinatorial knockouts (KOs) of crucial effector proteins from the BCL‐2 family—Bak1, Bax, and Bok. The study found that Bak1 and Bax exhibit synergistic anti-apoptotic properties, while the absence of Bok had minimal impact. Loss of Bak1 and Bax contributed to a delay and attenuation in cell death progression, revealing their significance in CHO cell cultures’ performance [36]. Similar results were shown by Rahimi et al., where disrupting Bax resulted in prolonged cell viability and increased proliferation rate in engineered clones. Bax protein expression reduction in manipulated cells led to enhanced stress-induced apoptosis tolerance, resistance to the apoptosis inducer, oleuropein, and significantly elevated recombinant protein production levels [37].

Autophagy, a significant cellular process for restoring equilibrium during stress, influences protein expression dynamics. Knocking out ULK1, a key player in autophagy initiation, led to a three-fold protein expression enhancement in stable Cripto-Fc-producing cells. These findings underscore the complex interplay between autophagy, protein expression, and cellular homeostasis, highlighting the potential for targeted interventions to optimize cellular machinery for improved protein production [38].

These studies show how modulating apoptosis and autophagy pathways are crucial because of the complex interplay between factors that cause cell death, metabolic imbalances, and product instability. Furthermore, the connection between autophagy, the kinetics of protein expression, and cellular homeostasis provides the basis for targeted therapies, having enormous potential for optimizing cellular processes for higher mAb production.

Engineering Host Cell Metabolic Pathways

The metabolic activities of host cells yield various waste products, which can hinder cell growth and affect product yields. Increased glucose and glutamine uptake rates lead to lactate and ammonia accumulation, hampering cell proliferation and product production. Studies have revealed that controlling glucose and glutamine levels in the culture medium can prevent the build-up of these harmful metabolites. A significant portion of inhibitory waste products in CHO cell cultures arises from the breakdown of amino acids. In a study by Mulukutla et al. engineered CHO cells in fed-batch cultures that were designed to reduce the production of specific amino acid metabolites. This was achieved by targeting pathways related to phenylalanine-tyrosine and branched chain amino acids. Overexpression of under-expressed genes in the phenylalanine-tyrosine pathway decreased inhibitory by-products. In the branched chain amino acid catabolic pathway, knocking out the gene BCAT1 eliminated problematic metabolite production, leading to improved cell growth and productivity in fed-batch cultures [39].

Strategically engineering the metabolic pathways within the host cells has emerged as an effective method to reduce the production and accumulation of undesirable waste metabolites. The relevant genes orchestrating these effects are carefully detailed in Tables 1, 2, and 3, outlining the effectiveness of their modifications.

Lactate dehydrogenase (LDH) is pivotal in converting pyruvate to lactate, driven by the NADH/NAD + coenzyme pair. LDH has been identified as a target for manipulation in host cells using techniques, such as loss of function mutation. Single allele knockout of the LDHA gene in CHO cells induced a metabolic state with reduced lactate production and increased recombinant protein production, as shown in Fig. 5 [40]. Ley et al. utilized CRISPR-Cas9 genome editing to modify genes across nine distinct amino acid catabolic pathways. This led to noticeable reductions in specific lactate and ammonium secretion by perturbing single amino acid catabolic genes. These changes coincided with increased growth rates and integral viable cell density. Significant reductions in ammonium (up to 26%) and lactate production (up to 22%) were observed, underscoring the potential of targeted gene disruptions, particularly Hpd and Gad2, to fine-tune cellular performance in antibody production scenarios [41].

Regulation of Lactate metabolism in host cell. Reducing lactate formation during fed-batch in mammalian cells is one of the effective metabolic engineering techniques used. (i) Generation of lactic acid from pyruvate using LDH leads to acidification of the culture medium as well as increased oxidative stress leading to cell death. (ii) Knockdown of LDH gene reduces lactate levels and reactive oxygen species (ROS) generation, maintaining cell viability during longer time in fed-batch culture

Optimization efforts have also targeted transport proteins responsible for glucose and glutamine uptake. The downregulation of the membrane-bound glucose transporter GLUT5 through RNA interference (RNAi) by Wlaschin and colleagues reduced glucose consumption and mitigated lactate and ammonia build-up. Enhancing proteins crucial to host cell metabolism has been linked to improved culture viability and higher product yields, as discussed in detail in Table 1.

Furthermore, researchers have explored alternate metabolic pathways beyond the tricarboxylic acid (TCA) cycle. For instance, CHO cells producing tissue plasminogen activator (tPA) were engineered by modifying a key step in galactose metabolism to limit lactate synthesis. This involved enhancing the expression of galactokinase (Galk1), which improved biomass and product synthesis. CHO-Galk1 cells exhibited enhanced glycolytic flux for glucose and galactose growth phases, enabling them to thrive on galactose as the primary carbon source. While lactate production decreased, metabolic adjustments were noted, emphasizing the need for further improvements for optimal galactose metabolism and nutrient utilization [42]. In another study, Tang et al. demonstrated that deleting the pyruvate kinase muscle (PKM) gene, responsible for converting phosphoenolpyruvate (PEP) to pyruvate, reduced lactate secretion in Chinese hamster ovary (CHO) cells. The knockout of pyruvate kinase muscle isoforms 1 and 2 (PKM-KO) and isoform-1 (PKM1-KO) led to altered glucose consumption, amino acid metabolism, reduced lactate secretion, and higher IgG titers compared to wild-type cells [43].

The manipulation of host cell metabolism has emerged as a potent strategy in CHO CLD. By modulating specific gene expressions, notable advancements have been achieved in the development of CHO cells. These modifications hold promise for augmenting cell viability and elevating the immunoglobulin Ig titer, with a simultaneous reduction in cell mortality. A central emphasis lies in mitigating the generation of lactate and ammonia within the culture milieu. Furthermore, transitions toward alternate metabolic pathways, while deviating from the TCA cycle, have been explored to optimize the cellular metabolic framework. These cumulative tactics underscore the efficacy of metabolic engineering in tailoring CHO cells to achieve heightened performance and amplified Ig production.

Engineering Cell Cycle

Modifying the way mammalian cell lines grow and divide, particularly those crucial for producing monoclonal antibodies (mAbs), offers a pathway to increase cell density and yield. Engineered cell lines depict a high growth rate that in turn cause nutrient scarcity, accumulation of toxic metabolites, and oxygen depletion. This is prevalently seen in batch cultures causing rapid decrease in cell density. To address these issues, strategic interventions are used to balance growth and product formation. Key proteins in these strategies are cell cycle inhibitors, like p21CIP1 and p27KIP1, which play a critical role in stopping cell division after DNA damage. Another protein, interferon regulatory factor-1 (IRF-1), can be targeted to slow down cell growth and increase the production of IgG antibodies [44].

The focus is on enhancing the genes that regulate cell proliferation and viability. Table 1 provides a list of these genes along with their impacts. Co-expressing checkpoint proteins in the cell cycle, such as cyclin-dependent kinase-like 3 and cytochrome c oxidase subunit 15, notably increases the maximum viable cell density [45]. Similar improvements have been seen when the c-myc gene is overexpressed in CHO cells, resulting in a significant 70% increase in cell density [46].

Decoupling cell growth from biotherapeutic production has emerged as an increasingly favored strategy in the biopharma sector, particularly for difficult-to-express products. The typical approach involves cultivating cells to a high density without concurrent recombinant protein production (referred to as the growth phase). Subsequently, the expression of the recombinant protein is triggered, and cell proliferation is arrested (the production phase). This is commonly achieved by combining an inducible gene expression system with a strategy to control proliferation. The separation of growth and production phases optimizes the allocation of cellular resources, enhancing both growth characteristics and the production of challenging proteins. [16]

However, current methods for controlling mammalian cell proliferation rely on temperature shifts and chemical agents [47]. These approaches interact with numerous non-proliferation pathways, leading to variable effects on product quality and culture viability. In contrast, synthetic biology presents an alternative approach that strategically targets proliferation pathways to arrest cell growth. Surprisingly, these synthetic biology techniques have not been extensively utilized. Targeting cell proliferation control represents a potential solution for arresting cell proliferation specifically at the G1 phase, characterized by larger cells and elevated ribosomal protein S6 levels, all while preserving product quality. The orderly progression through the cell cycle relies on the controlled activation, degradation, and synthesis of various cell cycle regulators [44].

Synthetic biology’s potential in separating growth and production in mammalian cells has found partial realization in “purity by design” cell lines. The initiation of a caffeine-inducible mammalian protein kinase R effectively halts the translation of non-product proteins, with the additional safeguard of a viral IRES sequence ensuring the protection of recombinant protein production. Despite these advancements, the achievable titer is constrained as translation from IRES sequences lacks access to the complete ribosomal machinery [48].

Engineering Glycosylation

Producing therapeutic antibodies in mammalian cells involves a complex process that includes various modifications, one of which is glycosylation. Glycosylation patterns are crucial in determining the behavior and efficacy of monoclonal antibodies (mAbs) within the human body. These patterns influence critical factors such as the antibodies’ longevity in the bloodstream, their potential to elicit immune responses, and their ability to perform their intended functions effectively. Abnormal glycosylation patterns can lead to immune reactions and a decrease in mAb effectiveness, making it essential to address this issue in biopharmaceutical production.

Researchers are actively exploring strategies to fine-tune glycosylation patterns in therapeutic antibodies. One approach involves manipulating specific genes to induce glycosylation patterns more closely resembling those found in humans. These targeted gene manipulations, as highlighted in Table 1, hold the potential to produce mAbs with glycosylation patterns that mirror the human equivalent, thereby improving their compatibility and effectiveness when administered to patients.

An alternative strategy focuses on controlling the N-glycosylation pathway to enhance the glycan structures on recombinant antibodies. By orchestrating this pathway, researchers have achieved remarkable improvements in the glycosylation patterns of antibodies, which can contribute to better therapeutic outcomes. Conversely, another avenue involves suppressing specific glycosylation pathways within host cells. This manipulation allows for the production of mAbs with customized glycosylation patterns, addressing the concern of inappropriate glycosylation and enhancing the therapeutic potential of these antibodies. Examples of such targeted gene knockouts, such as MGNT and MGAT1, have demonstrated the feasibility of this approach in Chinese hamster ovary (CHO) cells [49]. Genes targeted for the production of monoclonal antibodies with tailored glycosylation patterns have been enlisted in Tables 2 and 3 along with the mode of intervention used, gene knockout, or knockdown.

In recent studies, novel genetic engineering techniques like CRISPR-Cas-mediated gene intervention have emerged as powerful tools for altering glycosylation patterns in mAbs. Shen et al. harnessed the potential of CRISPR‐Cas13d technology to precisely control the expression of genes related to glycosylation, metabolism, apoptosis, and other crucial cellular processes in CHO cells. This technique substantially reduced IgG fucosylation and effectively suppressed more than 90% of FUT8 gene expression [50]. In another study by Yang, Wang et al. created CHO cell lines with a FUT8 gene knockout using CRISPR-Cas9 mediation. This gene knockout not only influenced core protein fucosylation but also had broader impacts on various glycosylation mechanisms, leading to alterations in the relative abundance of protein glycosylation profiles [51].

Furthermore, researchers have explored the modulation of glycosylation pathways to optimize antibody glycoform profiles. In a study by Prabhu et al., glycoform profiles of recombinant IgG were modified by strategically knocking down genes associated with glycosylation pathways. This approach resulted in the inhibition of UDP-Gal and GDP-Fuc production, critical molecules in glycosylation. Interestingly, the engineered cell line relied on a salvage pathway, adjusting glycosylation levels by manipulating extracellular galactose and fucose levels. This innovative approach allows for the production of glycoengineered proteins with specific glycosylation profiles for enhanced biological activity and targeted therapeutic applications [52].

Moreover, exploring specific sialic acid residues on mAbs, such as N‐glycolylneuraminic acid (NGNA), has shed light on the potential benefits of overexpressing specific genes. Fischer et al. conducted a study involving the CMAH gene, which has been linked to NGNA sialylation. By modifying the CMAH gene locus, they successfully increased NGNA sialylation levels. This alteration was meticulously performed, involving the creation of a catalytically inactive version of the CMAH protein, leading to enhanced NGNA sialylation on the surface glycoprotein of the engineered cells. This breakthrough suggests designing antibodies with modified sialylation patterns, potentially enhancing their therapeutic properties [53].

These advances in host cell engineering have accelerated the biopharmaceutical industry toward more efficient and dependable manufacturing processes. Researchers have boosted cell survival and protein expression by understanding and altering complex biological pathways. They have also discovered unique methods for manipulating glycosylation patterns, a crucial factor in the effectiveness of therapeutic interventions. Modern methods like CRISPR-Cas-mediated gene editing can make changes that are even more precise and targeted. These advancements not only solve issues with product stability and scalability but also open the door to customizing particular product features to satisfy various therapeutic needs. Host cell engineering is positioned to be a key player in determining the direction of biopharmaceutical development as the field continues to expand.

Selection and Amplification

Following transfection with the appropriate expression plasmid(s), a production host cell line is being subjected to selection pressure to produce stable cell pool with the genomic integration of expression vector. Several techniques have been developed to select for the selection as well as amplification of particular chromosomal genes [54]. This gene amplification can be used to produce substantially higher yields of any specific gene product than through traditional gene transfer alone, by co-introducing a gene that can be selected for gene amplification along with a non-selectable GOI.

DHFR-Based Platform

The use of DHFR expression vectors in combination with CHO cells defective in DHFR is the most popular method for gene transfer and amplification. Since CHO cells are well suited for producing proteins, they have been used to create several proteins having high commercial values. The dihydrofolate reductase (DHFR) and glutamine synthetase (GS) selection/amplification platforms have been generally employed for stable and homogenous mAb production [55]. DHFR-positive transformants are isolated after recipient cells are transfected with expression vectors, encoding both the desired proteins and DHFR. Populations of transformed cells are then chosen for growing levels of resistance to the DHFR inhibitor, methotrexate (MTX). MTX-resistant cells with elevated DHFR protein levels and amplified copies of the DHFR genes can be isolated using this method. Due to their near physical proximity, DHFR and the GOI are co-amplified. This technique for enabling protein overexpression has been very effective and is still the most popular co-transfer and co-amplification method used to date [56].

The multiple tandem vector repetitions that are produced as a result of amplification, however, can be unstable, making it laborious and time consuming and decreasing output over time [57]. Attenuating the expression of the DHFR selectable marker is an alternative strategy to raising gene copy numbers to improve transgene transcription. Only the cells from locations with the highest transcriptional activity survive the selection. In a study by Naddafi et al., the DHFR selection marker with the phiC31 integrase technology was used to create a high-expressing plasmid that can be employed in investigations to express Blinatumomab in CHO-DG44 cells and anticipated its use [58]. In a parallel investigation by Min et al., methotrexate-mediated gene amplification was combined with site-specific integration to develop high-producer rCHO cell lines. This hybrid cell line development approach has the potential to improve protein production efficiency and yield in CHO cells, which are commonly employed in biopharmaceutical manufacturing.

GS-Based Platform

The glutamate synthetase (GS) selection method has also been popularly used in CHO cells. Glutamate synthetase, which catalyzes the transformation of glutamate to glutamine, is encoded by the GS gene. Since glutamine is a necessary amino acid, cells cannot develop in glutamine-free media without GS expression. However, CHO cells typically express GS in glutamine-free medium. Thus, the competitive inhibitor MSX must be included in the cell culture medium to be able to employ GS as a selectable marker. By including MSX, it is ensured that only cells that express the GS selectable marker in the plasmid vector and thus produce greater amounts of GS will be able to survive under the selective conditions [59, 60]. Engineering of cell lines and optimization of transfection and selection processes have been the main areas of emphasis for improving the selection strength of the GS gene. It was demonstrated that knockout of the endogenous GS genes in CHO cells, using the zinc finger nuclease (ZFN) technology, resulted in multiple cell lines with higher sensitivity to MSX selection and resulted in a six-fold increase in the frequency of high producers for a recombinant mAb, increasing the effectiveness of the cell line development and clone screening procedure [61, 62]. The strength of selection can be effectively increased while using the same concentration of MSX by suppressing the endogenous GS gene expression and by boosting the glutamine content in the cell culture medium before transfection [63].

There are multiple rounds of amplification required for both techniques after transfection, even though they use different metabolic pathways (nucleotide metabolism for DHFR and glutamine metabolism for GS) [64]. Consequently, the use of toxic chemicals and specialized media requires expensive and time-consuming development. Amplification of the vector and resulting cell line takes a longer time with the DHFR platform, as compared to the GS platform, due to multiple rounds of amplification using analogues (MTX or MSX), as depicted in Fig. 3. At the University of Edinburgh, a new expression system called OSCAR™ was created [65]. This system was dependent on minigene vectors that were partially disabled and encoded for the enzyme, hypoxanthine phosphoribosyltransferase (HPRT), which was required for purine synthesis via the typical cellular salvage route. [65, 66] When one of these minigenes and a GOI were transfected into HPRT-deficient mammalian cells, the cells were cultivated in a selective hypoxanthine aminopterin thymidine (HAT) medium that prevented de novo purine synthesis. As a result, the salvage route using a disabled HPRT enzyme became essential for cell survival [65]. Since this enzyme is required in high concentrations for cell survival, the OSCAR™ system selected and amplified the GOI in a single step, in a shorter duration than the conventional DHFR and GS systems. In comparison to conventional systems, OSCAR™ created cells with seven-fold higher steady expression yields at a seven-fold reduced cost of materials due to the absence of special medium and hazardous substances, thus rendering it an expedient technology [65]. Although OSCAR™ is a new technology, further investigations are required to determine whether it may be applied to a wider cell and media types, as well its performance in bioreactors [67].

Post-selection and amplification of producing population of transfectants, this pool of cells (generated either via selection through DHFR or GS platform) is subjected to single-cell cloning to generate monoclonal population (Fig. 6).

DHFR/MTX and GS/MSX selection and amplification system: The DHFR gene vector (having adjacent GOI) is amplified using MTX, an analogue of folate necessary for de novo synthesis of purines and pyrimidines. The MTX concentration is gradually increased from 10 nanoMolar (nM) to 1000 nM and, multiple rounds of amplification are needed requiring more time for the cell line to be established (12–14 weeks of DHFR amplification). In GS-MSX system, MSX is used as an analogue of glutamate and a precursor to glutamine (essential amino acid) for augmenting the amplification of GOI. Here, the time needed to establish the selected pool is comparatively lesser since 25 to 50 (µM) MTX concentration is used and not as many rounds of amplification is needed as in case of DHFR-MTX amplification

High-Throughput Selection and Screening Systems

The transfectant population is considered to be a pool of cells since it is a heterologous mixture of cells which significantly differ in the number and location of the transfected gene cassette. This contributes to cell population with varied genetic and phenotypic characteristic affecting the product quality and stability. Also, difference in growth rate and metabolic profile would substantially impact the product profile. Hence, there is a need to establish production cell lines which are phenotypically and genetically identical. Also, regulatory guidelines state that the production cell line has to be monoclonal and originate from a single progenitor cell. Therefore, single-cell isolation and clone screening systems are crucial tools in biotechnology and biopharmaceutical industries, for identifying and selecting high-quality cell lines. These systems allow researchers to isolate individual cells, clone them, and then screen them for desirable traits, such as high productivity or protein quality. Limiting dilution is one of the earliest and most widely used single-cell isolation methods. This method involves serial dilution of cells until individual cells are isolated and grown into clonal populations. While limiting dilution (LD) is a low-throughput technique, it is a valuable and reliable method for single-cell isolation and clone selection. However, it is advisable to carry out two rounds of LD to ensure monoclonality due to the tendency of the cells to clump together and most importantly, the manual nature of the technique [68]. Fluorescence-activated cell sorting (FACS) is another widely used single-cell isolation method that utilizes fluorescent labeling and automated sorting of cells [69]. FACS enables high-throughput single-cell isolation and has been used for various applications, such as sorting stem cells and immune cells. The ClonePix system is a high-throughput single-cell isolation and clone screening system that uses image-based technology. The system can pick individual cells and distribute them into microplates, allowing for efficient screening and analysis of multiple clones simultaneously [70]. Other high-throughput systems that use image-based technology to isolate and screen single cells include video imaging plate systems (VIPS) [71], cellcelector [72], and single-cell printer [73]. These systems can dispense individual cells into multi-well plates, allowing for high-throughput clone screening. Josephides et al. reported the use of Cyto-Mine Single-Cell Analysis and Monoclonality Assurance System which employs picodroplet technology to screen millions of droplets allowing analysis of individual cells and dispensing single cells in an automated fashion [74]. These high-throughput technologies are preferred over traditional methods and offer higher precision and accuracy in single-cell selection, leading to improved clonality and reproducibility. Also, these automated solutions offer documentation assisting in regulatory compliance and traceability of results ensuring quality in the clone development.

Transfection Strategies

One of the crucial factors in the development of a product cell line is the strategy employed for delivering the desired expression vectors into the host cells. This depends on factors, such as the type of the host cell line, the product type along with its yield, and importantly regulatory compliance. Transfection strategies include reagent-based methods that employ cationic lipids, diethylamino ethyl (DEAE)-dextran polyethylenimine, calcium-phosphate, and cationic polymers- or their dendrimer-mediated delivery, virus-mediated delivery and instrument-based delivery methods, like electroporation and microinjection, etc.[75, 76] The non-viral delivery techniques have gained popularity for recombinant protein production as they have been approved by regulatory agencies for the production of proteins for human administration [77].

The preliminary DNA delivery techniques, calcium–phosphate precipitation, and DEAE-dextran are very affordable but are frequently associated with poor transfection effectiveness and high levels of cytotoxicity [78, 79]. Cationic polymers, such as polyethylenimines (PEI), are frequently used, economical, non-cytotoxic reagents, and may be scaled up to hundreds of liters and result in almost 100% transfection efficiency [80,81,82]. Commercially available reagents like jetPEI® have been frequently used by the biopharmaceutical industries for large-scale production of therapeutic proteins using HEK 293 and CHO cell platforms. PEI, however, is incompatible with some components of the growth media [81].

Another well-accepted method for introducing foreign DNA into host cells is electroporation or electric field-mediated permeabilization, which involves the exposure of cells to brief electric pulses that create transient holes in the cell membranes [83]. Under optimum electric field intensities, pulse lengths, buffer conductivities, waveforms, and pulse number, this method offers high transfection efficiency, high cell vitality, ease of use, and applicability to diverse cell types, without altering the biological structure or function of host cells. According to reports, methods for microfluidic electro-permeabilization, in which cells undergo electroporation as they pass through an electric field chamber, allow for large-scale transfection using devices like the MaxCyte VLX® scalable transfection system [84, 85].

Nucleofection is a major advance over the conventional electroporation approach that allows direct DNA transmission into the nucleus by electric field and solution combinations that are cell type specific [86]. Amaxa developed a patented commercial electroporation system known as Nucleofection™, which is currently owned by Lonza. Several patented cell-specific buffers are meant to maximize transfection while minimizing cell death. Due to the Nucleofector’s ability to transfect a variety of challenging-to-transfect cells, the Nucleofection™ technology has become quite popular among researchers.

Process Optimization

Optimum production of biologics using mammalian cell cultures significantly relies on medium and feed optimization (as shown in Fig. 7), as these processes play a crucial role in enhancing cell growth and protein production [87]. There have been several advances in feed and medium optimization for enhancing the yields of biologics. For example, dynamic feeding manner and feed optimization, using computer bio-simulations (‘Digital Twins’), as well as genome-scale flux analysis of metabolic pathways for optimizing media compositions are some of the advanced techniques that have been developed [88]. Saldanha et al. used a partial least squares model to identify the key components that increased mAb productivity. It was deduced that while the concentrations of TCA cycle intermediates and several vitamins had a significant impact on the stationary phase when mAb production was at its peak, the initial concentrations of several amino acids, pyruvic acid, and pyridoxine influenced early cell growth [89]. Detailed knowledge of how cells respond to various media constituent elements, feeding approaches gas exchange, and other parameters is necessary for effective media development and optimization processes [90].

Media and feed optimization can be performed using different techniques, such as the design of experiments (DoE), which is a statistical method for designing and analysing experiments. Mora et al. developed a DoE framework for identifying efficient feeding strategies, which helped to reduce the operational hands-on time and improved the overall workstream efficiency [91]. This approach could significantly reduce the time and resources required for media optimization, while also providing a robust and reproducible method for achieving optimal productivity [92]. There are many types of bioreactors available today, such as cell culture bags, G-Rex flasks, rocking motion bioreactors, stirred flasks and stirred tank bioreactors, and hollow-fiber bioreactors. These bioreactors are used for different purposes, such as for manufacturing biotherapeutics for scalable and versatile manufacturing processes[93] and fed-batch and batch cell culture. Furthermore, there have been efforts in the development of GMP bioreactors that are focused on closed and fully automated point-of-care (POC) systems. Automated, scalable, affordable, and GMP-compliant bioreactors are required for the manufacturing of biologics or adoptive cell treatments [94]. In recent years, single-use bioreactors have become the preferred choice for the production of biologics. These consist of disposable bags instead of culture vessels. In this case, the bioreactor is associated with a plastic lining that is enclosed in a more durable construction and comes into contact with the cells and the medium [95]. Single-use bioreactors consist of stainless-steel bodies lined with bioreactor bags, assemblies, and other accessories for applications, such as bioproduction, process development, and research and development [96]. These bags and assemblies are disposed of after a single use. Process parameter optimization is an essential step in the development of mammalian cell lines for producing therapeutic products. This involves optimization of parameters such as temperature, pH, dissolved oxygen concentration, and agitation rate to ensure the production of high-quality therapeutic proteins. There have been several advances in process parameter optimization in biologics manufacturing. For example, digital biomanufacturing is undergoing most of the same advances as in digital manufacturing [97]. To ensure that a biomanufacturing process is under control, a continued process variable monitoring program for a biologic product entails routine data collection related to critical process parameters (CPPs) and critical quality attributes (CQAs), as well as pre-processing, analysis, and evaluation of the data [98]. Modern technologies like AI and machine learning are promising tools for improving bioprocesses and advancing the biotechnology industry. They can be used to optimize bioprocess parameters, monitor and control bioreactors, and predict product yields and quality. Machine learning algorithms can analyze large datasets to identify patterns and relationships between variables, allowing for more accurate predictions and control strategies. AI-based control systems can adjust the process in real time to optimize productivity and minimize variability. Examples of such control strategies include Open Loop Control, Proportional Integral/Proportional Integral Derivative (PI/PID) Control, Cascade Control, Model Predictive Control, Neural Network and Fuzzy Logic-Based Control. [99, 100] Along with process control, these strategies can also be used to predict product quality profiles. Recently, Athanasios et al. developed a hybrid modeling framework to predict antibody glycosylation using commonly generated extracellular measurements. This framework combines nucleotide sugar donor fluxes computed by a stoichiometric model of central Chinese Hamster Ovary cell metabolism with an artificial neural network to accurately compute antibody glycan distribution profiles. The framework was tested in three independent fed-batch experiments and demonstrated an error rate of only 0.27%. This platform has potential applications in process control, cell line selection, and metabolic engineering [101]. Since cutting-edge biopharmaceuticals including virus-like particles, exosomes, cell, and gene therapies, along with recombinant proteins and peptides lack any platform production approach, there is a pressing need for intensified and quicker product development procedures [102]. As long as design space constraints are complied with, this method enables optimization or modification of a manufacturing process. Along with the optimization of medium and process parameters, their real-time monitoring is necessary for better control during manufacturing. With more sophisticated analytical methods, cyber-physical systems, and sophisticated interrogation tools being available in recent years, real-time tracking of biopharmaceutical development processes has substantially advanced [103]. Many sensors for bioprocess monitoring have been available over decades, while new ones, especially spectrometric sensors, are making their way into cell culture bioprocesses [104]. To monitor bioprocesses, the utility of several spectroscopic techniques, including ultraviolet–visible (UV–Vis), near-infrared (NIR), mid-infrared (MIR), dielectric spectroscopy, Raman spectroscopy, and fluorescent spectroscopy, has been explored [105]. For instance, Geetanjali et al. created a Fourier transform near-infrared spectroscopy (FT-NIR)-based measurement approach for all 20 amino acids, glucose, lactate, and trastuzumab concentrations in CHO cell culture [106]. These recent developments have given rise to several unique techniques or strategies for biomanufacturing evaluation.

Conclusion and Future Prospects

In conclusion, monoclonal antibody production in CHO cells has seen significant advancements in recent years due to continuous developments in vector engineering, CHO host cell engineering, selection and amplification strategies, transfection strategies, transcription factor engineering, and media optimization. Vector engineering has enabled the creation of more efficient vectors that can produce higher protein yields and control gene expression more precisely. Click or tap here to enter text.Additionally, CHO host cell engineering has advanced the production of antibodies with more desirable glycosylation patterns, leading to better clinical outcomes. The use of selection and amplification strategies such as glutamine synthetase amplification and methotrexate selection has resulted in the selection of high-yielding cell lines with stable protein production. Furthermore, transfection strategies have also evolved to improve gene transfer efficiency and protein expression levels, with the use of electroporation and nucleofection. Transcription factor engineering has emerged as a promising strategy for enhancing protein expression levels by targeting transcriptional regulatory pathways. Moreover, media optimization has played a crucial role in maximizing cell growth and protein production, with the development of chemically defined media and the optimization of nutrient and supplement concentrations. Overall, these advancements in vector engineering, CHO host cell engineering, selection and amplification strategies, transfection strategies, transcription factor engineering, and media optimization have contributed to the successful production of monoclonal antibodies at a large scale, leading to the development of several important biopharmaceuticals. Further research and innovation in these areas will continue to enhance the efficiency, efficiency, safety, and efficacy of monoclonal antibody production, driving progress in the field of biopharmaceuticals. The success of monoclonal antibody production in CHO cells depends on careful optimization and testing of each step, which requires expertise in molecular biology, cell biology, and bioprocessing.

Looking ahead, the future of cell line development for CHO cells in monoclonal antibody production is very promising. The incorporation of novel technologies such as machine learning, artificial intelligence and automation will likely play a more significant role in optimizing cell lines and accelerating biomanufacturing processes. One potential future direction is the use of single-cell omics technologies, such as single-cell transcriptomics and proteomics, to better understand cellular heterogeneity and identify key factors that contribute to optimal cell line performance. This could lead to the development of new methods for selecting the best performing cells and optimizing bioprocesses. Another potential area of development is the use of synthetic biology approaches to design and engineer cells with specific functions and properties, such as enhanced protein secretion, increased cell viability, and improved stress tolerance. These advancements could potentially lead to the development of entirely new types of cell lines that can produce biologics with improved properties and reduced costs. Overall, the continued advancement of cell line development for CHO cells in monoclonal antibody production is essential for meeting the increasing demand for biopharmaceuticals and improving patient outcomes. The integration of new technologies and approaches will likely play a critical role in achieving this goal and driving the future of biomanufacturing.

Data availability

No datasets were generated or analysed during the current study.

References

Lu, R.-M., Hwang, Y.-C., Liu, I.-J., Lee, C.-C., Tsai, H.-Z., Li, H.-J., & Wu, H.-C. (2020). Development of therapeutic antibodies for the treatment of diseases. Journal of Biomedical Science, 27, 1.

Castelli, M. S., McGonigle, P., & Hornby, P. J. (2019). The pharmacology and therapeutic applications of monoclonal antibodies. Pharmacology Research & Perspectives, 7, e00535.

Cai, H.H. Therapeutic Monoclonal Antibodies Approved by FDA in 2020.

Lyu, X., Zhao, Q., Hui, J., Wang, T., Lin, M., Wang, K., Zhang, J., Shentu, J., Dalby, P. A., Zhang, H., & Liu, B. (2022). The global landscape of approved antibody therapies. Antib. Ther., 5, 233–257.

Kaplon, H., & Reichert, J. M. (2019). Antibodies to watch in 2019. mAbs, 11, 219–238.

Dumont, J., Euwart, D., Mei, B., Estes, S., & Kshirsagar, R. (2016). Human cell lines for biopharmaceutical manufacturing: History, status, and future perspectives. Critical Reviews in Biotechnology, 36, 1110–1122.

Li, W., Fan, Z., Lin, Y., & Wang, T.-Y. (2021). Serum-free medium for recombinant protein expression in chinese hamster ovary cells. Frontiers in Bioengineering and Biotechnology. https://doi.org/10.3389/fbioe.2021.646363

Tihanyi, B., & Nyitray, L. (2020). Recent advances in CHO cell line development for recombinant protein production. Drug Discovery Today: Technologies, 38, 25–34.

Wang, X.-Y., Zhang, J.-H., Zhang, X., Sun, Q.-L., Zhao, C.-P., & Wang, T.-Y. (2016). Impact of different promoters on episomal vectors harbouring characteristic motifs of matrix attachment regions. Science and Reports, 6, 26446.

Brown, A. J., Sweeney, B., Mainwaring, D. O., & James, D. C. (2014). Synthetic promoters for CHO cell engineering. Biotechnology and Bioengineering, 111, 1638–1647.

Ho, S. C., Yeo, J. H., Fang, S. G., & Yang, Y. (2015). Impact of using different promoters and matrix attachment regions on recombinant protein expression level and stability in stably transfected CHO cells. Molecular Biotechnology, 57, 138–144.

Voss, S. D., Schlokat, U., & Gruss, P. (1986). The role of enhancers in the regulation of cell-type-specific transcriptional control. Trends in Biochemical Sciences, 11, 287–289.

Zúñiga, R. A., Gutiérrez-González, M., Collazo, N., Sotelo, P. H., Ribeiro, C. H., Altamirano, C., Lorenzo, C., Aguillón, J. C., & Molina, M. C. (2019). Development of a new promoter to avoid the silencing of genes in the production of recombinant antibodies in chinese hamster ovary cells. Journal of Biological Engineering, 13, 59.

Even, D. Y., Kedmi, A., Basch-Barzilay, S., Ideses, D., Tikotzki, R., Shir-Shapira, H., Shefi, O., & Juven-Gershon, T. (2016). Engineered promoters for potent transient overexpression. PLoS ONE, 11, e0148918.

Sheikholeslami, Z., Jolicoeur, M., & Henry, O. (2014). Elucidating the effects of postinduction glutamine feeding on the growth and productivity of CHO cells. Biotechnology Progress, 30, 535–546.

Poulain, A., Perret, S., Malenfant, F., Mullick, A., Massie, B., & Durocher, Y. (2017). Rapid protein production from stable CHO cell pools using plasmid vector and the cumate gene-switch. Journal of Biotechnology, 255, 16–27.

Poulain, A., Mullick, A., Massie, B., & Durocher, Y. (2019). Reducing recombinant protein expression during CHO pool selection enhances frequency of high-producing cells. Journal of Biotechnology, 296, 32–41.

Castan, A., Schulz, P., Wenger, T., & Fischer, S. (2018). Chapter 7 - Cell Line Development. In G. Jagschies, E. Lindskog, K. Łącki, & P. Galliher (Eds.), Biopharmaceutical processing (pp. 131–146). Elsevier.

del Refugio Rocha-Pizaña, M., Ascencio-Favela, G., Soto-García, B. M., de la Luz Martinez-Fierro, M., & Alvarez, M. M. (2017). Evaluation of changes in promoters, use of UCOES and chain order to improve the antibody production in CHO cells. Protein Expression and Purification, 132, 108–115.

Nematpour, F., Mahboudi, F., Vaziri, B., Khalaj, V., Ahmadi, S., Ahmadi, M., Ebadat, S., & Davami, F. (2017). Evaluating the expression profile and stability of different UCOE containing vector combinations in mAb-producing CHO cells. BMC Biotechnology, 17, 18.

Doan, C. C., Ho, N. Q. C., Nguyen, T. T., Nguyen, T. P. T., Do, D. G., Hoang, N. S., & Le, T. L. (2022). Enhancement of anti-TNFα monoclonal antibody production in CHO cells through the use of UCOE and DHFR elements in vector construction and the optimization of cell culture media. Preparative Biochemistry & Biotechnology, 52, 452–470.

Zhang, J.-H., Zhang, J.-H., Wang, X.-Y., Xu, D.-H., & Wang, T.-Y. (2020). Distance effect characteristic of the matrix attachment region increases recombinant protein expression in Chinese hamster ovary cells. Biotechnology Letters, 42, 187–196.

Girod, P.-A., Nguyen, D.-Q., Calabrese, D., Puttini, S., Grandjean, M., Martinet, D., Regamey, A., Saugy, D., Beckmann, J. S., Bucher, P., & Mermod, N. (2007). Genome-wide prediction of matrix attachment regions that increase gene expression in mammalian cells. Nature Methods, 4, 747–753.

Saunders, F., Sweeney, B., Antoniou, M. N., Stephens, P., & Cain, K. (2015). Chromatin function modifying elements in an industrial antibody production platform - comparison of UCOE, MAR, STAR and cHS4 elements. PLoS ONE, 10, e0120096.

Ayyar, B. V., Arora, S., & Ravi, S. S. (2017). Optimizing antibody expression: the nuts and bolts. Methods, 116, 51–62.

Hung, F., Deng, L., Ravnikar, P., Condon, R., Li, B., Do, L., Saha, D., Tsao, Y.-S., Merchant, A., Liu, Z., & Shi, S. (2010). mRNA stability and antibody production in CHO cells: Improvement through gene optimization. Biotechnology Journal, 5, 393–401.

Angov, E. (2011). Codon usage: Nature’s roadmap to expression and folding of proteins. Biotechnology Journal, 6, 650–659.

Baycin-Hizal, D., Tabb, D. L., Chaerkady, R., Chen, L., Lewis, N. E., Nagarajan, H., Sarkaria, V., Kumar, A., Wolozny, D., Colao, J., Jacobson, E., Tian, Y., O’Meally, R. N., Krag, S. S., Cole, R. N., Palsson, B. O., Zhang, H., & Betenbaugh, M. (2012). Proteomic analysis of chinese hamster ovary cells. Journal of Proteome Research, 11, 5265–5276.

Kalwy, S., Rance, J., & Young, R. (2006). Toward more efficient protein expression. Molecular Biotechnology, 34, 151–156.

Kober, L., Zehe, C., & Bode, J. (2013). Optimized signal peptides for the development of high expressing CHO cell lines. Biotechnology and Bioengineering, 110, 1164–1173.

Ramezani, A., Mahmoudi Maymand, E., Yazdanpanah-Samani, M., Hosseini, A., Toghraie, F. S., & Ghaderi, A. (2017). Improving Pertuzumab production by gene optimization and proper signal peptide selection. Protein Expression and Purification, 135, 24–32.

Zhou, Q., Zhang, Y., Lu, X., Wang, C., Pei, X., Lu, Y., Cao, C., Xu, C., & Zhang, B. (2021). Stable overexpression of mutated PTEN in Chinese hamster ovary cells enhances their performance and therapeutic antibody production. Biotechnology Journal, 16, 2000623.

Dogan, A. A., & Dufva, M. (2023). Heterogenous morphogenesis of Caco-2 cells reveals that flow induces three-dimensional growth and maturation at high initial seeding cell densities. Biotechnology and Bioengineering, 120, 1667–1677.

Hashemi, N., Tabatabaee, S. H., Shams, F., Rahimpour, A., Kazemi, B., Rajabibazl, M., & Ranjbari, J. (2023). Overexpression of SIRT6 alleviates apoptosis and enhances cell viability and monoclonal antibody expression in CHO-K1 cells. Molecular Biology Reports, 50, 6019–6027.

Wong, D. C. F., Wong, K. T. K., Nissom, P. M., Heng, C. K., & Yap, M. G. S. (2006). Targeting early apoptotic genes in batch and fed-batch CHO cell cultures. Biotechnology and Bioengineering, 95, 350–361.

MacDonald, M. A., Barry, C., Groves, T., Martínez, V. S., Gray, P. P., Baker, K., Shave, E., Mahler, S., Munro, T., Marcellin, E., & Nielsen, L. K. (2022). Modeling apoptosis resistance in CHO cells with CRISPR-mediated knockouts of Bak1, Bax, and Bok. Biotechnology and Bioengineering, 119, 1380–1391.

Rahimi, A., Karimipoor, M., Mahdian, R., Alipour, A., Hosseini, S., Mohammadi, M., Kaghazian, H., Abbasi, A., Shahsavarani, H., & Shokrgozar, M. A. (2023). Efficient CRISPR/Cas9-mediated BAX gene ablation in CHO cells to impair apoptosis and enhance recombinant protein production. Iranian Journal of Biotechnology, 21, e3388.

Thalén, N., J. Hicks, M. Lundqvist, A. Backmark, S. Engberg, C. Raynoschek, J. Gunnarsson, A.-L. Volk, R. Roth, and J. Rockberg (2021) ULK1 knockout cell line downregulates autophagy, upregulates recombinant transcript and improves protein secretion.

Mulukutla, B. C., Mitchell, J., Geoffroy, P., Harrington, C., Krishnan, M., Kalomeris, T., Morris, C., Zhang, L., Pegman, P., & Hiller, G. W. (2019). Metabolic engineering of Chinese hamster ovary cells towards reduced biosynthesis and accumulation of novel growth inhibitors in fed-batch cultures. Metabolic Engineering, 54, 54–68.

An LDHa single allele CHO cell mutant exhibits altered metabolic state and enhanced culture performance - Wilkens - 2019 - Journal of Chemical Technology & Biotechnology - Wiley Online Library[Online]. Available: https://onlinelibrary.wiley.com/doi/full/https://doi.org/10.1002/jctb.5906. [Accessed: 15-Sep-2023].

Ley, D., Pereira, S., Pedersen, L. E., Arnsdorf, J., Hefzi, H., Davy, A. M., Ha, T. K., Wulff, T., Kildegaard, H. F., & Andersen, M. R. (2019). Reprogramming AA catabolism in CHO cells with CRISPR/Cas9 genome editing improves cell growth and reduces byproduct secretion. Metabolic Engineering, 56, 120–129.

Jiménez, N., Martínez, V. S., & Gerdtzen, Z. P. (2019). Engineering CHO cells galactose metabolism to reduce lactate synthesis. Biotechnology Letters, 41, 779–788.

Tang, D., Sandoval, W., Liu, P., Lam, C., Snedecor, B., & Misaghi, S. (2021). Preventing pyruvate kinase muscle expression in Chinese hamster ovary cells curbs lactogenic behavior by altering glycolysis, gating pyruvate generation, and increasing pyruvate flux into the TCA cycle. Biotechnology Progress, 37, e3193.

Donaldson, J. S., Dale, M. P., & Rosser, S. J. (2021). Decoupling growth and protein production in CHO cells: A targeted approach. Frontiers in Bioengineering and Biotechnology. https://doi.org/10.3389/fbioe.2021.658325

Jaluria, P., Betenbaugh, M., Konstantopoulos, K., & Shiloach, J. (2007). Enhancement of cell proliferation in various mammalian cell lines by gene insertion of a cyclin-dependent kinase homolog. BMC Biotechnology, 7, 71.

Kuystermans, D., & Al-Rubeai, M. (2009). cMyc increases cell number through uncoupling of cell division from cell size in CHO cells. BMC Biotechnology, 9, 76.

Hong, J. K., Lee, S. M., Kim, K.-Y., & Lee, G. M. (2014). Effect of sodium butyrate on the assembly, charge variants, and galactosylation of antibody produced in recombinant Chinese hamster ovary cells. Applied Microbiology and Biotechnology, 98, 5417–5425.

Bojar, D., Fuhrer, T., & Fussenegger, M. (2019). Purity by design: Reducing impurities in bioproduction by stimulus-controlled global translational downregulation of non-product proteins. Metabolic Engineering, 52, 110–123.

Zhong, X., Cooley, C., Seth, N., Juo, Z. S., Presman, E., Resendes, N., Kumar, R., Allen, M., Mosyak, L., Stahl, M., Somers, W., & Kriz, R. (2012). Engineering novel Lec1 glycosylation mutants in CHO-DUKX cells: Molecular insights and effector modulation of N-acetylglucosaminyltransferase I. Biotechnology and Bioengineering, 109, 1723–1734.

Shen, C.-C., Lin, M.-W., Nguyen, B. K. T., Chang, C.-W., Shih, J.-R., Nguyen, M. T. T., Chang, Y.-H., & Hu, Y.-C. (2020). CRISPR-Cas13d for gene knockdown and engineering of CHO cells. ACS Synthetic Biology, 9, 2808–2818.

Yang, G., Wang, Q., Chen, L., Betenbaugh, M. J., & Zhang, H. (2021). Glycoproteomic characterization of FUT8 Knock-Out CHO cells reveals roles of FUT8 in the glycosylation. Frontiers in Chemistry, 9, 755238.

Prabhu, A., Shanmugam, D., & Gadgil, M. (2022). Engineering nucleotide sugar synthesis pathways for independent and simultaneous modulation of N-glycan galactosylation and fucosylation in CHO cells. Metabolic Engineering, 74, 61–71.

Fischer, S., Mathias, S., Stadermann, A., Yang, S., Schmieder, V., Zeh, N., Schmidt, N., Richter, P., Wright, S., Zimmermann, E., Ley, Y., van der Meer, J., Hartsch, T., Bernloehr, C., Otte, K., Bradl, H., Gamer, M., & Schulz, P. (2022). Loss of a newly discovered microRNA in Chinese hamster ovary cells leads to upregulation of N-glycolylneuraminic acid sialylation on monoclonal antibodies. Biotechnology and Bioengineering, 119, 832–844.

Kellems, R. E. (1991). Gene amplification in mammalian cells: Strategies for protein production. Current Opinion in Biotechnology, 2, 723–729.

Zhang, J.-H., Shan, L.-L., Liang, F., Du, C.-Y., & Li, J.-J. (2022). Strategies and considerations for improving recombinant antibody production and quality in Chinese hamster ovary cells. Frontiers in Bioengineering and Biotechnology. https://doi.org/10.3389/fbioe.2022.856049

Sharker, S. M., & Rahman, A. (2021). A review on the current methods of Chinese hamster ovary (CHO) cells cultivation for the production of therapeutic protein. Current Drug Discovery Technologies., 18, 354–364.

Chusainow, J., Yang, Y. S., Yeo, J. H. M., Toh, P. C., Asvadi, P., Wong, N. S. C., & Yap, M. G. S. (2009). A study of monoclonal antibody-producing CHO cell lines: What makes a stable high producer? Biotechnology and Bioengineering, 102, 1182–1196.

Naddafi, F., Davami, F., Tabarzad, M., Barkhordari, F., & Shirazi, F. H. (2019). Construction of a mammalian IRES-based expression vector to amplify a bispecific antibody; blinatumomab. Iran. J. Pharm. Res. IJPR, 18, 2117–2123.

Jostock, T., & Knopf, H.-P. (2012). Mammalian stable expression of biotherapeutics. Methods and Protocols, 899, 227–238.

Lin, P.-C., Chan, K. F., Kiess, I. A., Tan, J., Shahreel, W., Wong, S.-Y., & Song, Z. (2019). Attenuated glutamine synthetase as a selection marker in CHO cells to efficiently isolate highly productive stable cells for the production of antibodies and other biologics. mAbs, 11, 965–976.

Fan, L., Kadura, I., Krebs, L. E., Hatfield, C. C., Shaw, M. M., & Frye, C. C. (2012). Improving the efficiency of CHO cell line generation using glutamine synthetase gene knockout cells. Biotechnology and Bioengineering, 109, 1007–1015.

Srila, W., Baumann, M., Riedl, M., Rangnoi, K., Borth, N., & Yamabhai, M. (2023). Glutamine synthetase (GS) knockout (KO) using CRISPR/Cpf1 diversely enhances selection efficiency of CHO cells expressing therapeutic antibodies. Science and Reports, 13, 10473.

Zhu, J., & Hatton, D. (2018). New mammalian expression systems. Advances in Biochemical Engineering/Biotechnology, 165, 9–50.

Wurm, F. M. (2004). Production of recombinant protein therapeutics in cultivated mammalian cells. Nature Biotechnology, 22, 1393–1398.

Melton, D. W., Ketchen, A. M., Kind, A. J., McEwan, C., Paisley, D., & Selfridge, J. (2001). A one-step gene amplification system for use in cultured mammalian cells and transgenic animals. Transgenic Research, 10, 133–142.

Barnes, L. M., Bentley, C. M., & Dickson, A. J. (2001). Characterization of the stability of recombinant protein production in the GS-NS0 expression system. Biotechnology and Bioengineering, 73, 261–270.