Abstract

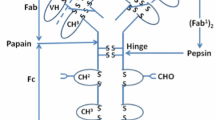

As biopharmaceutical companies have optimized cell line and production culture process development, titers of recombinant antibodies have risen steadily to 3–8 g/L for fed-batch mammalian cultures at production scales of 10 kL or larger. Most new antibody products are produced from Chinese Hamster Ovary (CHO) cell lines, and there are relatively few alternative production hosts under active evaluation. Many companies have adopted a strategy of using the same production cell line for early clinical phases as well as commercial production, which reduces the risk of product comparability issues during the development lifecycle. Product quality and consistency expectations rest on the platform knowledge of the CHO host cell line and processes used for the production of many licensed antibodies. The lack of impact of low-level product variants common to this platform on product safety and efficacy also builds on the established commercial history of recombinant antibodies, which dates back to 1997.

Efforts to increase titers further will likely yield diminishing returns. Very few products would benefit significantly from a titer greater than 8 g/L; in many cases, a downstream processing bottleneck would preclude full recovery from production-scale bioreactors for high titer processes. The benefits of a process platform based on standard fed-batch production culture include predictable scale-up, process transfer, and production within a company’s manufacturing network or at a contract manufacturing organization. Furthermore, the confidence in an established platform provides key support towards regulatory flexibility (e.g., design space) for license applications following a quality-by-design strategy.

These factors suggest that novel technologies for antibody production may not provide a substantial return on investment. What, then, should be the focus of future process development efforts for companies that choose to launch antibody products using their current platform? This review proposes key focus areas in an effort to continually improve process consistency, assure acceptable product quality, and establish appropriate process parameter limits to enable flexible manufacturing options.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

- Cell culture production

- CHO platform

- CHO technology

- Continuous processing

- Innovation

- Mabs

- Mammalian cell technology

- Monoclonal antibodies, Perfusion

1 Introduction

Industrial mammalian cell culture technology used for the production of recombinant protein therapeutics was established in 1987 with the licensure of recombinant tissue plasminogen activator. Since that landmark, mammalian cell culture has become the production methodology of choice for most biopharmaceutical products. The growing success of antibody-based therapies has driven advances in process technology and production facility design and management, with concomitant reductions in the cost of goods and improved process reliability. With novel protein products becoming a larger fraction of the product pipeline in many companies, continued cost pressures for innovator companies, and the introduction of biosimilar products, it is important to consider where to invest process development resources into innovative technologies.

2 Current Platform Cell Culture Production Processes

2.1 Cell Line Development

Chinese Hamster Ovary (CHO) cells are the most common choice of cell line for the production of recombinant protein therapeutics. They are generally capable of high productivity, demonstrate consistently good growth phenotypes, can be adapted to chemically-defined media, and typically do not generate product variants whose post-translational modifications present a concern for product safety.

Prior to 2010, many companies developed an improved cell line to be used for pivotal clinical trials and commercial production, replacing the cell line used for initial clinical trials. Now, it is more common to use the same cell line for all clinical phases leading to commercialization. This single cycle of cell line development is a much more efficient development strategy, provided the initial cell line is sufficiently productive and product quality is acceptable. Improvements in expression vector design combined with screening technologies allowing the examination of thousands of clones has led to high and consistent titers; for recombinant antibodies, it is typical to achieve titers of 3–8 g/L from initial cell lines using standardized media and process conditions. This optimizes speed to the clinic and simplifies the development lifecycle, as there are fewer issues of product comparability arising from cell line changes during clinical development.

The optimization of expression vectors continues to yield improvements in titers, while selection markers remain relatively standardized. These improvements can be employed efficiently within typical platform process media and conditions.

One area of general interest is the use of targeted integration for production cell line generation. By constructing a parental cell line with a “hot spot” identified for the integration of heterologous product genes through gene swapping technology such as Cre-lox [1, 2] or other techniques, it is possible to generate a productive cell line with one (or very few) gene copies consistently and quickly. This offers the potential for improvements over the established technique of random integration of multiple copies throughout the CHO genome. Evidence presented at conferences has indicated there would likely be reduced sequence variants, improved stability of expression, and more consistent expression and growth phenotypes from product to product. Several companies are implementing targeted integration for Current Good Manufacturing Practice (cGMP) cell lines, and this is one example of a recent innovation in cell culture technology that may have broad applicability. It is noteworthy that this technology has been in various stages of feasibility and subsequent optimization for over a decade in some laboratories, which gives a sense of how the complexity of major changes in cell culture technology can give rise to relatively long implementation phases.

However, issues with the long-term stability of production expression remain a complication for some cell lines. Occasionally, gene expression may be very stable, even for seed cultures that are carried in repeated passaging for over 100 generations. Other cell lines may show an expression decline of 50% or more in similar time frames. The mechanism of decline may be traced in many cases to loss of copy number, but not always. The ability to predict which cell lines will display instability, and which will not, is currently not understood. The outcome of extended culturing on product expression levels is typically the sole determinant of a cell line’s stability. This results in either a lengthy aging study prior to selection of the final clone, living with the consequences, or switching cell lines if an unstable phenotype is observed later in development.

Recent health authority feedback has emphasized assurance that production cell lines are derived under appropriate conditions, which strengthens the confidence that a single clone is present at the time of cell deposition. The driver for this feedback presumably is concern over the potential for shifts in product quality attributes over time if the line was not clonally derived. Companies have generally responded by either implementing two rounds of limiting-dilution cloning into the production cell isolation approach or validating image analysis to provide assurance of a single cell being present in the isolation well during a single round of limiting-dilution cloning. Industry has also provided feedback on the importance and value of process and product data demonstrating consistency over the typically expected range of cell age employed in the manufacturing process [3, 4].

The impact of high-throughput screening for bioreactor conditions and media optimization enables further improvements in yield and consistency as larger regions of bioreactor and medium operation spaces are evaluated [5, 6]. With a high degree of miniaturization comes the challenges of defining a high-fidelity model of a production bioreactor, including pH control, aeration strategies, and culture feeding management. Although these miniature reactors are not necessarily intended to be qualified scale-down models sufficient for process characterization or validation, key differences could give rise to confounded conclusions influencing the selection of the optimal production clone.

2.2 Production Bioreactors and Facilities

The design basis for suspension mammalian cell production cultures primarily relies on stirred tank bioreactors (although airlift bioreactors are in use). These bioreactors have changed relatively little since the establishment of deep-tank CHO bioreactor technology in the 1980s. Of the three primary modes of bioreactor management (batch, fed-batch, and perfusion), fed-batch cultures are the most common. Feeding strategies can vary from bolus to continuous with one or multiple feed solutions; feeding on demand occurs with feedback control loops or simpler prespecified feeding schedules. Feeds can include nutrient concentrates, glucose, trace elements and vitamins, or other media components. The flexibility of this simple process design combined with the many parameters available for the optimization of product titer and quality have resulted in it being the workhorse in the biotechnology industry today, with the demonstrated capability of high titers, consistent product quality, scalability, and ready transfer to multiple facilities, including contract manufacturing organizations (CMOs).

Mammalian cell production bioreactors range in size from 25,000 L down to hundreds of liters depending on the production scale required for commercial and clinical supply demands. Small-scale laboratory bioreactors used in process development, characterization, and validation studies are often 2–5 L in volume. This 10,000-fold scaling factor is a key advantage for conventional stirred tank bioreactors, enabling many experimental conditions to be tested efficiently, including complex statistically designed experiments. The scale-up/scale-down heuristics and principles are now well-established (although they may vary slightly from company to company or between bioreactor types). Many companies have transferred multiple processes from small-scale clinical to large-scale commercial facilities, between plants in their commercial network, or to CMOs (one or multiple sites). The body of knowledge used to assess the risks, complications, and solutions needed for scale-up and technology transfer for stirred tank fed-batch bioreactor processes is quite extensive. The track record of successes speaks both to the robustness of this core bioprocess technology and the accumulated wisdom of nearly three decades of experience [7, 8].

One recent advance in the field of bioreactor design is the development of disposable (single-use) bioreactors that are capable of cultivating cells similarly to the stainless steel vessels, with highly consistent behavior for nearly all key performance indicators. The differences in the methods of agitation and mixing are one obvious difference, but these differences have not proven to be a significant complication in most cases. The production scale of the disposable reactor can reach 2 kL (recently, a 3.5-kL disposable bioreactor was launched by one company), but it is unlikely to ever reach the volumes of many common large-scale commercial facilities (10–25 kL). Complications have been observed with the low-molecular-weight leachables from the bioreactor polymer film(s) slowing or halting cell growth. However, improved supplier understanding of bag film chemistries combined with rigorous control and testing of vendor-initiated changes should fully prevent this problem from recurring [9,10,11]). These systems have made significant inroads into clinical or small-scale (often dedicated to a single product) commercial production.

A common facility design for a very large-scale commercial plant employs one or two seed trains, a few inoculum trains, and four to eight production bioreactors, all serving one purification train downstream. Additional flexibility is gained if appropriate segregation and the number of seed and inoculum trains enables concurrent cultivation of two different cell lines; in this case, a second purification train would be needed to process the harvests. The ratio of bioreactors to purification trains may limit the duration of the production culture or vice versa, with a typical production culture duration for antibody production being 10–16 days. These are highly efficient and productive facilities for the commercial production of large volumes of therapeutic proteins. The production of two or more products is key to maximizing plant utilization; it encourages platform processes that minimize downtime due to equipment swaps or significant re-programming of controllers. With disposable bioreactors and liquid handling equipment, facility designs can be freed of some of the requirements for facilities supporting stainless steel bioreactors. Utilities for clean steam, clean in place (CIP), sterilization in place (SIP), or water for injection may be reduced or even eliminated, greatly reducing the complexity of equipment, piping, and facility layout. These “factories of the future” will have reduced footprints and can be built and brought online faster than conventional stainless steel facilities.

In the past 20 years, biotechnology manufacturers using mammalian cell production systems have begun to implement additional virus barriers as business risk mitigation to ensure a continued supply of product as well as the freedom to operate a facility. Cases of viral contamination have occurred in clinical or commercial facilities, some of which have led to extended periods of time for remediation and resumption of manufacturing [12,13,14]. High-temperature short-time (HTST) heat treatment of media is used in many facilities and has been proven effective [15]. Although other techniques have also been employed as barriers for some raw materials that are incompatible with heat treatment, such as gamma irradiation for serum and virus retentive filtration for lipids solubilized in alcohols, HTST is used for the bulk of viral barrier applications in commercial processes (see [16] by Shiratori and Kiss on virus barriers). The use of animal-derived raw materials for new cGMP antibody production processes is rare. Avoiding their use in any stage of preclinical and clinical development reduces the risks of adventitious agent contamination or product quality changes in the development lifecycle.

2.3 Media and Feeding Strategies

Cell culture media formulations may be developed in-house or selected from several suppliers of media for cGMP use. The optimal formulations of seed, inoculum, production, and feed media are key to ensuring consistent product quality and high titer processes. Chemically-defined media are now commonplace and are replacing complex media, including hydrolysates.

The use of a chemically-defined medium allows for much greater understanding of the effects of specific media components on both process performance and product quality. The refinement and optimization of amino acid ratios (e.g., cysteine/cystine, asp/asn/gly/gln) and absolute levels is now possible in the absence of interference from hydrolysate or serum contributions via peptides and uncharacterized levels of trace metal forms. This allows for targeted studies that can better control metabolic behavior consistency. On the other hand, the absence of potentially significant quantities of trace metals from complex materials requires a much broader understanding of the importance of these trace metals on cell growth, metabolic responses, and product quality. Additionally, metal impurities in other raw materials may significantly impact the total levels in meaningful ways and must be accounted for in medium formulation designs. Formulations are often blended based on platform knowledge in designing feeds that can further boost performance. The improvement know-how around component impact influences the feeding strategy development for modulating product quality attributes, including preventing misincorporation, excessive proline amidation, or trisulfide formation [17,18,19,20,21].

2.4 Harvest

For very large-scale (≥1 kL) mammalian cell cultures, disc-stack centrifuges dominate for the initial cell removal step of the harvest operation. Non-hermetically sealed centrifuges that are successfully used for many industrial applications, including microbial cell separation, can cause significant mammalian cell disruption due to the energy dissipation associated with the air-liquid interfaces. To avoid this type of cell disruption (lysis), the associated debris, and other potential issues that can arise, most companies employ either hydrohermetic or fully hermetic centrifuges.

As biotechnology companies developed improved cell culture processes that delivered improved growth and viability profiles and higher antibody titers, it was discovered that cell lysis during the harvest operation released reducing enzymes and energy sources that could trigger a catastrophic antibody disulfide bond reduction event [22,23,24]. This behavior was experienced and reported by multiple companies. Mitigations for preventing antibody reduction were developed, including control of the dissolved oxygen level in the harvested cell culture fluid (HCCF) by sparging air to prevent the establishment of reducing conditions. Depending on the specific cell culture process and the levels of reducing power present at harvest, varying amounts of air sparging may occur. Assessment of product stability in the presence of air sparging of the HCCF has generally shown minimal impact with antibody molecules, but other novel formats susceptible to disulfide bond reduction may require other mitigations.

For existing large-scale facilities, the retrofitting of non-hermetic centrifuges to hydrohermetic units may be possible at reasonable costs and downtime. Given the numerous observations of antibody reduction across multiple companies, it is highly recommended that new facilities employ fully hermetic centrifuges for mitigation purposes.

Clarification (often by depth filtration) and sterilizing-grade filtration of centrate fluids is a standardized operation to deliver low turbidity and low bioburden to harvest pool storage prior to initiating purification operations.

2.5 Downstream Processing Limitations

Each combination of a product’s unique downstream process and the intended manufacturing facility has a limit in its downstream processing train, where higher titers cannot be completely recovered. Typical downstream bottlenecks include in-process pool tank volumes, buffer make-up volumes, or chromatographic or ultrafiltration capacities. Some simple process fixes include the use of isocratic flow-through chromatography steps instead of product bind/elute steps or single-pass tangential flow filtration to provide modest concentration of in-process pools. With an assessment of facility fit limitation during Phase III process development, antibody titers as high as 6–8 g/L can often be processed in existing facilities without substantial equipment retrofit. These high titers, combined with demonstrated production bioreactor scales of 10–25 kL, suggest that (except for unusual products with multi-ton scale annual demands) there may be no substantial benefit to pushing titers higher than this purification bottleneck, particularly if it requires the development of novel downstream processing unit operations to handle the increased mass from the cell culture process.

2.6 Summary of the State of the Art

The state of the art of industrial mammalian cell culture for cGMP production of therapeutic proteins has arrived at a rather mature production technology base [25]. The majority of active companies in this sector have converged on fed-batch cultures in large bioreactors, and a network of CMOs supporting this design are available for development or contract production for clinical or commercial supply. The capacity and cost of goods for production with existing very large-scale facilities is also quite favorable because economies of scale combined with multiproduct operations can optimize plant utilization. This leads to the following question: What new innovations are needed for the future of mammalian cell culture production technology, whether for monoclonal antibodies or other recombinant protein products?

3 Key Focus Areas for the Current Process Platform

The following areas offer significant opportunities for investment in process knowledge, product quality, process consistency, and robust operations in clinical and commercial production.

3.1 Raw Material Variability and Sourcing

Process consistency is a key objective for commercial production. One known source of cell culture process perturbations is the raw materials, which can have minor (or occasionally major) impacts on a cell culture process. Complex and undefined medium components may be one source of variability. However, even chemically-defined media may be prone to uncontrolled variations arising from the composition of trace components, which may vary from media lot to lot, particularly as a result of impurities in another raw material. A well-designed medium will dampen this variability, typically by adding the trace components as a specified raw material themselves. One specific example is with low levels of essential trace elements (e.g., metals), which may have subtle effects on product glycans arising from their role as co-factors for glycosyltransferases [26]. Even simple and commonly used raw materials can affect process performance. For example, some polymeric shear protectants have been shown to suffer from lot-to-lot variations in protective function, resulting in variations in cell viability or the extent of cell growth and subsequent titers [27].

If raw materials can influence product quality or process performance, it is worth investigating the root cause and considering actions that can return the process to stable operations with the highest product quality capability offered by a mean-centered and consistent critical quality attribute (CQA) output. These actions could be implemented using a design space if there are other process parameters that also influence the quality attribute that is drifting. Alternatively, basal or feed media can be supplemented with the variable components, either to a consistent level that factors in the contribution of each raw material lot or to a level high enough to minimize the impact of media lot variation.

In one case study, a depth filter used as a pre-filter for a cell culture medium was determined to be leaching manganese into the filtered medium. This contribution to the total manganese in the culture medium was originally unknown, yet its fraction of the total manganese influenced the resultant antibody glycan profile. When the filter manufacturer made a change to the source of diatomaceous earth used in the filter matrix, the amount of leached manganese was significantly reduced, and a shift in the antibody glycan profile resulted. Once the root cause was determined to be this “absence” of the inadvertently supplemented manganese, the medium formulation was adjusted to restore the total manganese levels to the historical levels, and the glycan profile was restored.

Although disposable bioreactors and media storage bags are not a raw material used in media formulations, they can have an influence on cell growth or product expression due to leachables. There have been examples of serious impact to cell growth after media storage in bags, which was exacerbated by gamma irradiation prior to use [9,10,11]. This issue was resolved by the disposable bag supplier after identification of the component and mechanism of toxicity. This is another cautionary case study that should be kept in mind after vendor-initiated changes of disposable materials that contact cells or media.

Dual sourcing of cell culture raw materials such as media or key media components (e.g., hydrolysates) can be a valuable risk mitigation strategy to guard against supply interruption or uncontrolled variability. Media formulations that are primarily defined chemicals should be easily sourced from two or more vendors. However, the subtle impacts of blending, handling, storage, or environmental exposure may alter the levels of trace or slightly reactive compounds (thiol compounds, iron, etc.) or influence media stability, which may only be revealed upon second sourcing or scale-up [28,29,30].

A solid understanding of potential raw material lot variation impacts at the time of a product licensure application is a key element of a cell culture license application. These experimental study designs and interpretations can be complicated, but very informative, in evaluating process consistency and potential commercial performance.

3.2 Advanced Process Controls and Facility Management Across a Network of Production Sites

Several companies and CMOs manage a network of cell culture production facilities for multiple commercial products. Differences in equipment and facility design are frequently encountered as networks grow by acquisition or are expanded long after the first sites are licensed. The alignment of process controls and bioreactor management (e.g., pH, aeration) can be complicated because the subtleties of online or offline calibration may differ from site to site, emphasizing the benefits of standardization around best practices.

Process monitoring and cross-site comparisons of processes running in multiple plants provide an opportunity for continued advancements in process knowledge. When raw material variation affects process performance, a multiple-site network data review can provide critical information quickly to jumpstart root cause analysis. Common-cause investigations (when appropriately coordinated and executed) can accelerate corrective action and prevention compared to single-site production.

Advanced statistical analysis methods, such as multivariate analysis (MVA) [31], have become more readily available to biotechnology process scientists and engineers at affordable costs and with user-friendly interfaces. They should continue to be exploited for the value they can bring in advancing process understanding. In many situations, mechanistic models are simply unavailable to interpret process performance, and MVA approaches may be the only practical approach available. In addition, the use of advanced process controls can provide improved process consistency and performance while also enhancing process knowledge that can be leveraged across processes. Further development of strategies for improved control of glycosylation profiles will be needed given the continued learning about the importance of glycan structures on the biological activity of some antibodies and recombinant proteins [32, 33]. Additional examples of such advanced controls include the use of online Raman spectroscopy to estimate nutrient and/or waste product concentrations as well as institute closed-loop actions to better manage metabolism [34, 35]. Such online sensing solutions should be pursued further, including consideration for the prediction of product concentration and product quality attributes in addition to the aforementioned metabolic profiles.

3.3 Process Parameter Control Ranges and Targets

At the time of a commercial license application, process characterization studies will have identified critical process parameters and established acceptable process parameter control ranges for the cell culture unit operations [36]. The definition of criticality is based on a parameter’s impact on product quality, rather than on key performance indicators such as titer or cell density. There may be opportunities for optimizing a process by moving one or more parameter targets within acceptable ranges. This is the concept behind a design space as envisioned by the International Conference on Harmonization Q8 [37], which enables post-licensure movement of multiple parameter targets without requiring regulatory approval. Commercial processes have now been approved with a design space [38], and descriptions of how they may be established have been described [39]. One opportunity for future cell culture license applications is to establish sufficiently wide parameter ranges to enable operational flexibility, process robustness in light of raw material variability and equipment design differences between sites, and optimization of process performance. Of course, sufficient attention must be paid to the appropriate qualification of the scale-down models used to generate the data supporting the claimed process ranges [40, 41].

In some cases, the tuning of process parameters within an acceptable range can have a significant impact. It is not uncommon to have production culture pH or temperature targets demonstrably influence cell metabolism, including the production or consumption of lactate. The means of aerating the culture with blends of air and oxygen, sparger geometry, and agitation rate may also affect metabolism and titer through variations in the ventilation, or stripping, of carbon dioxide from the production bioreactor. These and other parameters represent fine control elements that are worth studying in development, commercial production, and between facilities in a network.

The types of flexibility in key parameters that would benefit manufacturing within a design space include pH, temperature, culture duration, limit of in vitro cell age, feeding strategies, simple vs. complex process control strategies, and parameter excursion studies that cover temporary deviations in some control parameters. Individual plants in a network or at a CMO may have different preferences for targets of some of these process control elements, and establishing wider multivariate ranges at the time of licensure could be quite valuable in supporting commercial production over the long term.

Products in the pipeline will also benefit from the use of a consistent process platform, if applicable, building on knowledge from process characterization and commercial production using very similar processes. Although every cell line and product are unique, many elements and learnings established from the initial licensure of a platform process will inform subsequent products’ risk assessment, enabling streamlining and simplification of the final licensure phase of product development.

3.4 Novel Product Formats

Novel protein constructs or formats are becoming a larger fraction of the pipeline of many biopharmaceutical companies. These include bispecific antibodies, receptor fusion proteins, antibody-drug conjugates with site-specific toxin loading, or antibody cytokine fusions. Most of these products fit into the current cell culture production platforms with no required modifications. There may be some adjustments needed in media components or bioreactor parameters based on unique product quality considerations posed by either novel product variants or product-related impurities. In general, the cell culture process platform used for antibody production is an excellent starting point for process development for novel product formats, offering a rapid entry into Phase I clinical studies and a platform knowledge base that informs subsequent Phase III development and commercialization.

4 New Process Technologies: A Cautionary Note

Novel process technologies that are a radical shift from the established platform process design described above are being considered in academic and industrial laboratories, with some larger-scale implementations. Although there are certainly innovations and increased process understanding needed for the current platform process, there needs to be a balance between the investment placed in “revolutionary” versus “evolutionary” process technologies. Major shifts in a production basis would carry many uncertainties regarding scale-up, robustness, production costs, and development timelines, among others. In some cases, the magnitude of the rewards is also uncertain and may be overestimated as being critical for future competitive markets (it is unlikely that the cost of goods sold [COGS] of recombinant protein therapeutics will be a determinant of a competitive market). Are investments in many of the new technologies under evaluation warranted? What problem(s) are they solving or creating? The history of bioprocess technology over the last 30 years indicates that many novel technologies burst onto the scene, then faded as the challenges of implementation were faced.

4.1 Perfusion Culture

Perfusion culture is an active area of investigation, as well as some controversy. Perfusion cell cultures use a cell retention device (centrifuge, spin filter, filter or inclined settler) to retain cells in the bioreactor during the inoculum or production phases. In some recent advances, the product is also retained in the bioreactor through the use of an ultrafilter [33, 51, 52]. A number of perfusion processes for biopharmaceuticals have been licensed, accounting for a small proportion (<10%) of all commercial mammalian cell culture processes [42]. In most of these cases, the product is an enzyme, blood factor, or other product that may exhibit instabilities when exposed to extended fed-batch culture conditions (i.e., residence time).

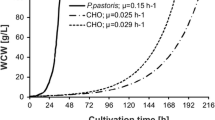

Many companies that ran perfusion cultures for early products in their portfolios moved away from perfusion to fed-batch for antibody processes. However, for a few companies, an installed production base using perfusion has been an important driver to continue this basis for pipeline programs. Recently, there has been renewed enthusiasm toward the further evaluation of perfusion cultures. This appears to be driven by two factors: (1) the potential to combine perfusion with a disposable bioreactor to drive process intensification and maximize plant productivity, and (2) the ability to enable a fully continuous production train when coupled with a continuous downstream process (see the next section).

There are potential advantages to perfusion processes [43, 44]. Often, the volumetric productivity (g/L/day) from a perfusion-based production bioreactor is higher than fed-batch operations, thus allowing a reduction in some aspects of the production plant size and necessary capital. Because scaling up perfusion bioreactors beyond 1 kL is difficult due to limits of the cell retention device, “scaling out” with multiple suites or facilities is sometimes claimed as an advantage. This comes at the loss of economies of scale, but potentially with shorter lead times to build out increased capacity.

Although there are claims that continuous cell culture processes will have more consistent product quality, there is little evidence in the published literature that this is the case. Benchmarking highlights experiences with commercial perfusion processes that have had quality attributes drift with extended cell age, requiring the pooling of multiple harvests to maintain product consistency. Other complications include elevated contamination rates for some cell retention devices, a slow approach to steady state, and raw material impacts on many batches produced over several months with complex batch genealogy. Many issues in manufacturing (e.g., technical failure, deviations, microbial contaminations) cause an immediate impact on productivity because troubleshooting and maintenance cannot be performed between batches as with conventional processing. Finally, extended culture durations lead to longer development, characterization, and validation cycles, as well as greater expenses and the generation of less knowledge in understanding the process.

In addition, the portability of perfusion processes to CMOs may be lacking if surge capacity is needed. Although the use of smaller-volume bioreactors enables perfusion operations with disposable bioreactors, they still require large-volume tanks for feed media and harvest operations. Many plants are not set up for this type of operation and lack the specialized equipment needed for cell retention and continuous harvest. Very high cell densities in perfusion cultures may push the limits of oxygen transfer and process control in disposable bioreactors. A significant capital investment would be needed to convert or build continuous processing capacity for multiple plants in existing facilities. Indeed, authors have cautioned against pursuing this type of platform change for companies that have established large-scale fed-batch infrastructure [45, 52].

4.2 Fully Continuous Processes

Fully continuous processing for biologics drug substance production would require the previously described continuous (i.e., perfusion) cell culture, as well as a downstream processing train (simulated moving bed or countercurrent chromatography with no process pool hold tanks) that is capable of producing a purified drug substance from a continuous cell culture harvest. Today, the products made by perfusion cell culture use batch purification operations.

For highly unstable proteins, a perfusion culture plus low-temperature purification trains have been a common processing solution; a continuous downstream train is not automatically required for these products. Other potential advantages have been claimed, including a reduction in plant footprints, open ballroom facility design, compatibility with disposables, benefits of a fully automated process, and improved product consistency.

Continuous purification processes are neither well established, scalable, transportable, nor particularly valuable when coupled with perfusion culture [46]. Simulated moving bed or countercurrent chromatography using three to six (or more) columns per step are the most advanced of the continuous options. However, to our knowledge, they have yet to be scaled up or used for the cGMP production of proteins. Furthermore, they may have limited utility for multicomponent separations.

In some cases, there may be value to “connected” processes, where only two unit operations are run in series without a pool tank. A virus filtration step could be connected to the outlet of a flow-through chromatographic step, for example, if there were facility fit limitations for a four-column process needed for a nonstandard antibody-like product. Another example would be in-line concentration using single-pass tangential flow membranes. However, these are not fully continuous processes as envisioned by some.

Although the combination of a perfusion cell culture process and a continuous purification train would be a technological tour-de-force, it is not clear what problem it would solve (or what advantage it would bring) to the existing innovator facility networks or large-scale CMOs. The perfusion culture complications listed previously still exist, and the scale-up and validation of totally novel purification unit operations/equipment is no small feat. Connecting the two would present real and significant engineering, control, and quality assurance challenges. Complex, interacting control loops require significant automation and monitoring to prevent scheduling issues when process upsets occur. Furthermore, the debugging of many novel unit operations would require a significant investment prior to clinical production, let alone licensure/inspection and commercial operation. This added complexity can translate into increased failure rates, as up to six chromatography columns run as a simulated moving bed for each of three process steps (18 columns, not 3) will likely have a higher overall failure rate than batch downstream processing. In addition, managing the ensuing interruptions would be a significant challenge to the entire production train.

Note that some of the advantages of continuous processing for small-molecule active pharmaceutical ingredient (API) synthesis or drug product (DP) tableting (reduced solvent usage, near-infrared radiation monitoring of API production, use of small plug flow reactors) are sometimes mentioned in the literature, but they have little relevance to biologics. In some cases, comments from regulatory authorities speak broadly on the advantages of continuous processing, but they do not differentiate between proteins and small molecules.

The current platform for mammalian cell-derived products is durable, predictable, cost-effective, and efficient. Claims about the superior performance of fully continuous processing are, at this point, aspirational. Given that, what is the benefit of perfusion cell culture coupled to a batch downstream? This was the design basis that several companies had established in the past, but generally moved away from.

4.3 Novel Production Hosts

New mammalian cell hosts would bring significant hurdles for implementation compared to the more established CHO cell. For several decades, investments have been made into alternate production hosts such as transgenic animals, plants, yeast strains with engineered glycosylation pathways, and human cell lines (such as the PER.C6 line). Despite these efforts, very few products have been launched with totally novel hosts in the last decade.

If the host under development were uniquely enabling of certain product quality attributes that could not be effectively produced or controlled using conventional cell lines, that may be a driver for an alternate host, as in the case of specifically tailored glycoforms produced from engineered yeast strains. Otherwise, an alternate host is unlikely to have a significant impact on COGs, especially at very large scale of production. In the ton-per year processing, the downstream processing costs are a much larger fraction of the overall COGs than the cell culture or upstream costs [47]. Therefore, reducing the upstream costs through the use of an alternate host with reduced cost compared to CHO cell culture would have diminishing effects on the COGs.

Even a well-established production host like Escherichia coli (licensed for the production of the first recombinant protein therapeutic, Humulin, in 1982) is chosen primarily for production of niche smaller non-glycosylated proteins such as hormones, cytokines, or antibody fragments, despite the capabilities to express complex, correctly-folded multi-subunit disulfide-bonded proteins to high concentration in the periplasm [48]. The production COGs of antibodies produced in CHO using existing technology is estimated to be as low as $20–30 per gram [25]. Although the COGs of insulin produced by E. coli or yeast would be lower, much of the benefit is derived from the very large scale of production; at a more modest production scale of less than 1 ton of product per year, there might not be much difference in the COGs of the two hosts (in part because the downstream processing train for intracellular E. coli proteins has more unit operations and lower yield than purification trains isolating a secreted product from CHO cells). The common perception that mammalian cell-derived proteins are inherently more expensive to produce than microbially-derived proteins is not always true.

4.4 Biosimilars

The development, licensure, and marketing of biosimilar products is an emerging opportunity for many companies planning to enter this competitive space in the decade ahead. The ability to match all of the innovator’s product attributes within the innovator’s historical product ranges presents a challenge. Some firms are seeking to solve this problem with an innovative approach to complex process control strategies in order to maintain CQAs within the innovator’s goalposts [49], including feedback bioreactor control using process analytical technology (PAT) techniques. If the innovator’s product was made by fed-batch culture, would production using a fundamentally different process technology (e.g., continuous culture) make matching innovator CQAs difficult? Although this may be a problem that can be solved by extensive process development, it would seem that a biosimilar manufacturing process that matches the innovator’s production process would likely have a simpler path forward in matching product quality attributes.

The development of the commercial cell line for biosimilars would likely follow a conventional state-of-the-art effort, including a single cycle of cell line development (with the initial and pivotal clinical trials using the same cell line), high throughput screening (where enabled) of cell lines for appropriate product quality and optimal titer, and, of course, typically the selection of the same host cell line as the innovator product.

Although there certainly will be pricing pressures in a competitive biosimilars market, is it likely that production technology will ever dictate the outcome in the market? This scenario is sometimes raised as a motivation to evaluate new process technologies (including fully continuous processing). However, if the sale prices of the biosimilars drop so low that production costs become a key differentiator in the marketplace, it is unlikely that those biosimilar products will offer a significant return on investment.

It is not yet clear whether the biosimilars market will have any lasting impact on bioprocess technology through the use of novel or innovative processes, or whether conventional processes will continue to be favored by biosimilar companies.

4.5 Harvest

As mentioned previously, the development and implementation of single-use bioreactor systems has been established in the biotechnology industry. For certain product volumes, single-use systems for clinical and commercial production may make sense given the reduced plant startup time that is possible, along with the potential to significantly reduce the requirement for support utilities such as SIP and CIP. One unit operation that has been slow to efficiently align with the vision of disposable systems is the harvest operation.

With single-use production bioreactor volumes in the 1–2 kL range and high cell densities utilized to drive multi-gram per liter titers, harvest unit operations have often continued to rely on centrifugation for efficient cell removal prior to final filtration. This approach presents challenges because single-use bioreactors cannot be pressurized to drive flow to the centrifuge, requiring either use of a feed pump or transfer of the bioreactor contents to a fixed vessel that can be pressurized as the centrifuge feed source. The former approach exposes cells to potentially high and disruptive energy dissipation rates, whereas the latter negates the cleaning benefit of the single-use bioreactor. Either approach based on centrifugation triggers the need for equipment (centrifuge, etc.) cleaning operations, which then prevent the approach to a utility-lite facility that is the vision of single-use processing. Accordingly, development of single-use centrifugation systems/interfaces or other cell removal devices is an area where further innovation is appropriate. This type of technological approach is briefly described in [50].

In the interests of pursuing the utility-lite facility vision for single-use technologies, some companies have eliminated the centrifuge as the initial cell removal step and opted for a purely filtration harvest approach. The challenge with this approach is in identifying the initial filtration technology. Companies have pursued the use of depth filtration for cell removal and initial clarification. However, at these 1–2 kL scales of operation with high-density cultures, one must choose between an extremely large depth filtration area that has a large footprint and is costly or a more moderately sized depth filtration operation that can take as long as 24 h to harvest a batch. One potential approach to improving the filterability of pre-harvest cell culture fluid is that of flocculation of the cells and cell debris. Many flocculants tend to result in acidic conditions, which can cause product damage due to proteolysis. In addition, large amounts of polymeric flocculants and flocs may be a disposal issue, let alone a handling challenge. Accordingly, the non-centrifuge harvest approach is an area that would benefit from further innovation.

5 Conclusion

The current state of the art for industrial mammalian cell cultures has matured to a consensus platform of fed-batch operations at production scales up to 25 kL. The broad use of chemically-defined media and an improved understanding of media formulation and the influence of critical components have enabled more precise control of product quality and improved process consistency. With titers of 6–8 g/L or higher, 100-kg batches are possible with low COGs and very high production capacities. This combination of factors is a very attractive process design basis, with a long development history, a growing understanding of the causes of process variation, and experience with scale-up and facility transfer. Under what scenario is a more intensified process worth the additional investment and risk? There are several areas where further investment in the current process platform will likely provide significant returns. These focus areas will continue to improve this platform to ensure speed to clinic, efficient process development, streamlined process characterization, and validation of reliable and transportable commercial processes.

References

Nagy A (2000) Cre recombinase: the universal reagent for genome tailoring. Genesis 26:99–109

Zhang L, Inniss M, Han S, Moffat M, Jones H, Zhang B, Cox W, Rance J, Young R (2015) Recombinase-mediated cassette exchange (RMCE) for monoclonal antibody expression in the commercially relevant CHOK1SV cell line. Biotechnol Prog 31(6):1645–1656

Evans K, Albanetti T, Venkat R, Schoner R, Savery J, Miro-Quesada G, Rahan B, Groves C (2015) Assurance of monoclonality in one round of cloning through cell sorting for single cell deposition coupled with high resolution cell imaging. Biotechnol Prog 31(5):1172–1179

Frye C, Deshpande R, Estes S, Francissen K, Joly J, Lubiniecki A, Munro T, Russell R, Wang T, Anderson K (2016) Industry view on the relative importance of “clonality” of biopharmaceutical-producing cell lines. Biologicals 44(2):117–122

Chen A, Chitta R, Chang D, Amanullah A (2009) Twenty-four well plate miniature bioreactor systems as a scale-down model for cell culture process development. Biotechnol Bioeng 102(1):148–160

Rouiller Y, Perilleux A, Collet N, Jordan M, Stettler M, Broly H (2013) A high-throughput media design approach for high performance mammalian fed-batch cultures. MAbs 5(3):501–511

Goochee C (2002) The role of a process development group in biopharmaceutical process startup. Cytotechnology 38:63–76

Pohlscheidt M, Corrales M, Charaniya S, Fallon E, Bruch M, Jenzsch M, Sieblist C (2013) Avoiding pitfalls during technology transfer of cell culture manufacturing processes in the pharmaceutical industry—mitigating risk and optimizing performance. Pharm Outsourcing 14:34–48

Hammond M, Marghitoiu L, Lee H, Perez L, Rogers G, Nashed-Samuel Y, Nunn H, Kline S (2014) A cytotoxic leachable compound from single-use bioprocess equipment that causes poor cell growth performance. Biotechnol Prog 30(2):332–337

Horvath B, Tsang V, Lin W, Dai X-P, Kunas K, Frank G (2013) A generic growth test method for improving quality control of disposables in industrial cell culture. BioPharm Int 12(6):34–41

Wood J, Mahajan E, Shiratori M (2013) Strategy for selecting disposable bags for cell culture media applications based on a root-cause investigation. Biotechnol Prog 29(6):1535–1549

Garnick R (1996) Experience with viral contamination in cell culture. Dev Biol Stand 88:49–56

Moody M, Alves W, Varghese J, Khan F (2011) Mouse minute virus (MMV) contamination—a case study: detection, root cause determination, and corrective actions. PDA J Pharm Sci Technol 65(6):580–588

Skrine J (2011) A biotech production facility contamination case study—minute mouse virus. PDA J Pharm Sci Technol 65(6):599–611

Kiss R (2011) Practicing safe cell culture: applied process designs for minimizing virus contamination risk. PDA J Pharm Sci Technol 65(6):715–729

Shiratori M, Kiss R (2017) Risk mitigation in preventing adventitious agent contamination of mammalian cell cultures. Adv Biochem Eng Biotechnol. https://doi.org/10.1007/10_2017_38

Gramer M (2013) Product quality considerations for mammalian cell culture process development and manufacturing. In: Zhou W, Kantardjieff A (eds) Mammalian cell cultures for biologics manufacturing. Advances in biochemical engineering/biotechnology, vol 139. Springer, Berlin

Hossler P, McDermott S, Racicot C, Fann J (2013) Improvement of mammalian cell culture performance through surfactant enabled concentrated feed media. Biotechnol Prog 29(4):1023–1033

Luo J, Zhang J, Ren D, Tsai WL, Li F, Amanullah A, Hudson T (2012) Probing of C-terminal lysine variation in a recombinant monoclonal antibody production using Chinese hamster ovary cells with chemically defined media. Biotechnol Bioeng 109(9):2306–2315

Vijayasankaran N, Varma S, Yang Y, Mun M, Arevalo S, Gawlitzek M, Swartz T, Lim A, Li F, Zhang B, Meier S, Kiss R (2013) Effect of cell culture medium components on color of formulated monoclonal antibody drug substance. Biotechnol Prog 29(5):1270–1277

Yuk I (2014) Effects of copper on CHO cells: insights from gene expression analyses. Biotechnol Prog 30(2):429–442

Kao Y-H, Hewitt D, Trexler-Schmidt M, Laird M (2010) Mechanism of antibody reduction in cell culture production processes. Biotechnol Bioeng 107(4):622–632

Mun M, Khoo S, Do Minh A, Dvornicky J, Trexler-Schmidt M, Kao Y-H, Laird M (2015) Air sparging for prevention of antibody disulfide bond reduction in harvested CHO cell culture fluid. Biotechnol Bioeng 112(4):734–742

Trexler-Schmidt M, Sargis S, Chiu J, Sze-Khoo S, Mun M, Kao Y-H, Laird M (2010) Identification and prevention of antibody disulfide bond reduction during cell culture manufacturing. Biotechnol Bioeng 106(3):452–461

Kelley B (2009) Industrialization of mAb production technology: the bioprocessing industry at a crossroads. MAbs 1(5):443–452

Hossler P, Khattak S, Jian Z (2009) Optimal and consistent protein glycosylation in mammalian cell culture. Glycobiology 19(9):936–949

Peng H, Ali A, Lanan M, Hughes E, Wiltberger K, Guan B, Prajapati S, Hu W (2016) Mechanism investigation for poloxamer 188 raw material variation in cell culture. Biotechnol Prog 32(3):767–775

Gilbert A, Huang Y-M, Ryll T (2014) Identifying and eliminating cell culture process variability. Pharm Bioprocess 2(6):519–534

Kolwyck D (2013) How defined is chemically defined medium? IBC’s biopharmaceutical development and production week, Huntington Beach, CA, February 2013

Toro A, Colon J, Melendez-Colon V, Rivera J (2010) Changes in raw material sources from suppliers: determining their impact on customers’ biopharmaceutical manufacturing operations. Bioprocess Int 2010:50–55

Kirdar A, Green K, Rathore A (2008) Application of multivariate data analysis for identification and successful resolution of a root cause for a bioprocessing application. Biotechnol Prog 24(3):720–726

Shi H, Goudar C (2014) Recent advances in the understanding of biological implications and modulation methodologies of monoclonal antibody N-linked high mannose glycans. Biotechnol Bioeng 111(10):1907–1919

Zupke C, Brady L, Slade P, Clark P, Caspary R, Livinston B, Taylor L, Bigham K, Morris A, Bailey R (2015) Real-time product attribute control to manufacture antibodies with defined N-linked glycan levels. Biotechnol Prog 31:1433–1441

Berry B, Moretto J, Matthews J, Smelko J, Wiltberger K (2015) Cross-scale predictive modeling of CHO cell culture growth and metabolites using Raman spectroscopy and multivariate analysis. Biotechnol Prog 31(2):566–577

Matthews T, Berry B, Smelko J, Moretto J, Moore B, Wiltberger K (2016) Closed loop control of lactate concentration in mammalian cell culture by Raman spectroscopy leads to improved cell density, viability, and biopharmaceutical protein production. Biotechnol Bioeng 113(11):2416–2124

Tai M, Ly A, Leung I, Nayar G (2015) Efficient high-throughput biological process characterization: definitive screening design with the ambr250 bioreactor system. Biotechnol Prog 31(5):1388–1395

ICH International Conference on Harmonization Q8, Pharmaceutical Development (2009)

Luciani F, Galluzzo S, Gaggioli A, Kruse N, Venneugues P, Schneider C, Pini C, Melchiorri D (2015) Implementing quality by design for biotech products: are regulators on track? MAbs 7(3):451–455

Hakemeyer C, McKnight N, St. John R, Meier S, Trexler-Schmidt M, Kelley B, Zettl F, Puskeiler R, Kleinjans A, Lim F, Wurth C (2016) Process characterization and design space definition. Biologicals 44(5):306–318

Janakiraman V, Kwiatkowski C, Kshirsagar R, Ryll T, Huang Y-M (2015) Application of high-throughput mini-bioreactor system for systematic scale-down modeling, process characterization, and control strategy development. Biotechnol Prog 31(6):1623–1632

Rameez S, Mostafa S, Miller C, Shukla A (2014) High-throughput miniaturized bioreactors for cell culture process development: reproducibility, scalability, and control. Biotechnol Prog 30(3):718–727

Goudar C, Chen C, Le H (2015) Biopharmaceuticals—continuous processing in upstream operations. Chemical Engineering Progress, New York

Croughan MS, Konstantinov KB, Cooney C (2015) The future of industrial bioprocessing: batch or continuous? Biotechnol Bioeng 112(4):648–651

Hernandez R (2015) Continuous manufacturing: a changing processing paradigm. BioPharm Int 28(4):20–27

Farid SS, Pollock J, Ho SV (2014) Evaluating the economic and operational feasibility of continuous processes for monoclonal antibodies. Continuous processing in pharmaceutical manufacturing. Wiley, Weinheim, pp 433–456

Zydney A (2016) Continuous downstream processing for high value biological products: a review. Biotechnol Bioeng 113(3):465–475

Jagschies G (2012) Changing upstream development to improve the downstream process and the overall yield and product quality, IBC life sciences conference, monoclonal antibody development & production, San Diego

Simmons L, Reilly D, Klimowski L, Raju T, Meng G, Sims P, Hong K, Shields R, Damico L, Rancatore P, Yansura D (2002) Expression of full-length immunoglobulins in Escherischia coli: rapid and efficient production of aglycosylated antibodies. J Immunol Methods 263(1–2):133–147

Grampp G, Ramanan S (2013) Managing unexpected events in the manufacturing of biologic medicines. BioDrugs 27(4):305–316

Turner R, Joseph A, Titchener-Hooker N, Bender J (2016) Manufacturing of proteins and antibodies: chapter downstream processing technologies—harvest operations. Adv Biochem Eng Biotechnol. https://doi.org/10.1007/10_2016_54

Smelko J, Wiltberger K, Hickman E, Morris B, Blackburn T, Ryll T (2011) Performance of high intensity fed-batch mammalian cell cultures in disposable bioreactor systems. Biotechnol Prog 27(5):1358–1364

Yang W, Minklera D, Kshirsagar R, Ryll T, Huang Y-M (2016) Concentrated fed-batch cell culture increases manufacturing capacity without additional volumetric capacity. J Biotechnol 217:1–11

Acknowledgements

Numerous technical staff at Genentech and Roche have contributed over the years to the collective platform process and the understanding of its capabilities, its historical challenges, and the opportunities for future improvements briefly summarized in this chapter. In addition, further acknowledgement is warranted to the many individuals and companies within the biotechnology industry that have driven the advances responsible for making the mammalian cell culture processes for antibody production the highly productive systems they are today.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this chapter

Cite this chapter

Kelley, B., Kiss, R., Laird, M. (2018). A Different Perspective: How Much Innovation Is Really Needed for Monoclonal Antibody Production Using Mammalian Cell Technology?. In: Kiss, B., Gottschalk, U., Pohlscheidt, M. (eds) New Bioprocessing Strategies: Development and Manufacturing of Recombinant Antibodies and Proteins. Advances in Biochemical Engineering/Biotechnology, vol 165. Springer, Cham. https://doi.org/10.1007/10_2018_59

Download citation

DOI: https://doi.org/10.1007/10_2018_59

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-97108-7

Online ISBN: 978-3-319-97110-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)