Abstract

A thermostable, alkaline rhamnogalacturonan lyase (RG lyase) CtRGLf, of family 11 polysaccharide lyase from Clostridium thermocellum was cloned, expressed, purified and biochemically characterised. Both, the full-length CtRGLf (80 kDa) protein and its truncated derivative CtRGL (63.9 kDa) were expressed as soluble proteins and displayed maximum activity against rhamnogalacturonan I (RG I). CtRGLf showed maximum activity at 70 °C, while CtRGL at 60 °C. Both enzymes showed maximum activity at pH 8.5. CtRGLf and CtRGL do not show higher activity on substrates with high β-d-galactopyranose (d-Galp) substitution, this catalytic property deviates from that of some earlier characterised RG lyases which prefer substrates with high d-Galp substitution. The enzyme activity of CtRGLf and CtRGL was enhanced by 1.5 and 1.3 fold, respectively, in the presence of 3 mM of Ca2+ ions. The TLC analysis of the degraded products of RG I, released by the action of CtRGLf and CtRGL revealed the production of RG oligosaccharides as major products confirming their endolytic activity.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The major components of plant cell wall are the polysaccharides that assemble to form a network. These polysaccharides are mainly cellulose, hemicellulose, and pectin. The plant cell wall is able to fulfil its structural role by providing strength and protection to the cell due to the presence of cellulose and hemicellulose [1]. The plant cell wall also has a functional role in cell–cell adhesion, cell signalling, wall porosity, pollen tube growth, leaf abscission and the pectin component of cell wall has been credited to play these roles [2]. Structural role of pectin in promoting upright growth of plants has also been reported [3]. Pectin is predominantly localised in the primary cell wall of all higher plants, gymnosperms, pteridophytes and bryophytes [4]. The principal components of pectin are homogalacturonan (HG) and the substituted HG: Rhamnogalacturonan I (RG I) and Rhamnogalacturonan II (RG II). Xylogalacturonans and Apiogalacturonans are other less abundant substituted HG [ 2 ]. Homogalacturonan is a homopolymer of α-(1 → 4) linked d-galactopyranosyluronic acid (d-GalpA) residues which may be methylated at C-6. RG I is composed of a main chain of alternating l-rhamnopyranosyl (l-Rhap) and d-GalpA residues. The repeating monomeric unit is a disaccharide [→4)-α-d-GalpA-(1 → 2)-α-l-Rhap-(1→]. 20–80 % of l-Rhap residues are substituted with individual, linear or branched chains of l-arabinofuranosyl (l-Araf) and d-Galp. The side chains of RG I may be substituted with l-fucose or d-glucuronic acid (GlcA) [4]. RG I has been demonstrated to be crucial for normal development of periderm in potato [5]. Transgenic potato plants that expressed RG I cleaving enzyme developed morphological abnormalities like swelling of periderm cells. RG II main chain contrary to the name is also composed of α-(1 → 4) linked d-GalpA with l-Rhap residues as substitutions apart from 12 other different monosaccharide residues [4].

Degradation of plant cell wall makes a reservoir of nutrients available for recycling. Nature has bestowed a diverse group of microorganisms with enzymes to breakdown the plant cell wall polysaccharides [6, 7]. When pectin comes under microbial attack, both glycoside hydrolases and polysaccharide lyases are recruited. Glycoside hydrolases cleave the glycosidic bonds via an acid–base catalysis mechanism [9]. Polysaccharide lyases cleave their substrates via a β-elimination mechanism, generating in the residue at the non-reducing end of the product a double bond between C-4 and C-5 [10]. Glycoside hydrolases and polysaccharide lyases have been classified into different families based on sequence similarity [11]. Many of the plant cell wall polysaccharide degrading enzymes are modular in nature and have one or more specialised substrate-binding module(s) referred to as carbohydrate-binding module(s) (CBM) in addition to a catalytic module.

Enzymes that can bring about deconstruction of plant cell wall polysaccharides are of key importance in conversion of lignocellulosic biomass into bioethanol and in production of prebiotics [12, 13]. The pectinases are one such class of industrial enzymes that are used in paper mills, textile industries, coffee and tea fermentations, treatment of feedstock for biofuel production and recovery of valuable products of plant origin like essential oils [14]. Some organisms are better at cleaving the recalcitrant structural polysaccharides of plant cell wall than others especially the anaerobic microorganisms which probably under selection pressure from the environment have evolved to possess highly efficient enzyme systems [15]. C. thermocellum is an anaerobic, thermophilic bacterium which presented to the researchers a new meaning of enzyme modularity and concerted enzyme action when the multi-enzyme complex referred to as cellulosome was first observed in it [16]. The cellulosomal complex has also been reported from other microorganisms [17]. Several studies focussing on cellulase and hemicellulases from this bacterium, which are more efficient than those from fungal origin, have been undertaken for bioethanol production [18, 19]. Despite never disappointing researchers in their search for cellulases and hemicellulases, pectin degrading enzymes of C. thermocellum are still to be characterised. The members of family 11 polysaccharide lyase (PL11) characterised earlier are rhamnogalacturonan lyases (RG lyases) from Bacillus subtilis, Clostridium cellulolyticum, Cellvibrio japonicus and Bacillus licheniformis [6–8, 20]. In the present study, cloning, expression and biochemical characterisation of a putative cellulosomal, family 11 PL enzyme (CtRGLf) has been reported. CtRGLf comprises a RG Lyase catalytic module, designated as CtRGL and an associated putative family 35 CBM (Fig. 1a). CtRGLf endolytically cleaves RG I component of pectin. To our knowledge this is the first modular RG lyase reported from C. thermocellum and is a new family 11 polysaccharide lyase member.

a Molecular architecture of protein CtRGLf showing modular structure with a CBM35 module towards the N-terminal connected to the catalytic module, CtRGL via a linker sequence. b Expression and purification of CtRGLf analysed on SDS-PAGE gel (12 %, w/v); lane M—Molecular mass marker (14.3–97.4 kDa, Genei), lane 1—uninduced E. coli (DE3) BL21 cells, lane 2—induced E. coli (DE3) BL21 cells, lane 3—cell pellet after sonication, lane 4—cell free extract, lane 5—purified protein and c Expression and purification of CtRGL analysed on SDS-PAGE gel (12 %, w/v); lane M—molecular mass marker (10-200 kDa, Fermentas), lane 1—uninduced E. coli (DE3) pLysS cells, lane 2—induced E. coli (DE3) pLysS cells, lane 3—cell pellet after sonication, lane 4—cell free extract, lane 5—purified protein

Materials and Methods

Sequence Analysis of CtRGLf

The amino acid sequence of CtRGLf (locus tag Cthe_0246) from C. thermocellum was accessed from the CAZy database (http://www.cazy.org/). The sequence with GenBank accession number: ABN51485.1 is classified as a family 11 PL according to the classification developed by Lombard et al. [ 11 ]. The sequence was subjected to BLAST analysis. The ‘PDB’ database was chosen for BLAST (http://www.rcsb.org/pdb/home/home.do). Conserved Domains Database was referred to determine the expanse of domains (http://www.ncbi.nlm.nih.gov/cdd/). The subcellular localisation of CtRGLf was predicted using PSORT server (http://psort.hgc.jp/form.html).

Genomic DNA, Vector and Bacterial Strains

The genomic DNA of C. thermocellum ATCC 27405 was procured from DSMZ, Germany. The pET28a (+) (Novagen) expression vector was used for cloning and expression of PCR products. Escherichia coli DH5α cells (Novagen) were used as host for amplification of recombinant plasmids. E. coli BL21 (DE3) (Novagen) and E. coli (pLysS) (DE3) (Novagen) were used as host for expression of proteins.

Cloning of Full-Length CtRGLf and Truncated Derivative CtRGL

The nucleotide sequences of full-length family 11 PL from C. thermocellum, CtRGLf, and its truncated derivative, CtRGL were amplified using 0.025 U/µl of Taq DNA polymerase (Bioline, UK). The 50 µl PCR reactions contained 0.45 µM each of forward and reverse primers, 1.5 mM MgCl2 and 2 mM dNTPs. The sequences of the forward primer and the reverse primer used for the amplification of gene encoding CtRGLf were FP1: 5′-CGGCTAGCACGAGATATCAGGCTGAGG-3′ and RP1: 5′-CCCTCGAGTTACGGCACAAGGTAAATATTTGG-3′. The reverse primer for amplification of gene encoding CtRGL was same as that for CtRGLf, while the sequence of the forward primer was FP2: 5′-CGGCTAGCATGGAGAGCTGGACAGAG-3′. The forward and reverse primers contained NheI and XhoI restriction sites (underlined), respectively. The PCR conditions used were initial denaturation at 94 °C for 4 min and 94 °C for 30 s, 49 °C for 60 s, 72 °C for 60 s for a total of 30 cycles followed by final extension at 72 °C for 10 min on a thermal cycler (TAKARA Bio, Japan). The PCR products were separated on 0.8 % (w/v) agarose gel. The DNA fragments encoding CtRGLf (2136 bp) and CtRGL (1686 bp) were excised from the gel and purified using GenElute kit (Sigma Chemical Company, USA). The purified PCR products and pET28a (+) expression vector were digested with NheI and XhoI restriction enzymes (Promega, USA). The restriction enzymes digested PCR products and the vector were ligated by T4 DNA ligase (Promega, USA). The ligation reaction mixtures were transformed into E. coli DH5α cells for plasmid DNA amplification. The positive clones were confirmed by restriction digestion of the isolated plasmid DNA.

Expression of Recombinant Proteins and Culture Conditions

E. coli BL21 (DE3) cells were used as host for expression of CtRGLf and were aerobically cultured in 600 ml LB medium supplemented with kanamycin (50 µg/ml) at 37 °C, 180 rpm. CtRGL was expressed in E. coli BL21 (DE3) pLysS cells, which were aerobically cultured in 600 ml Terrific Broth supplemented with chloramphenicol (34 µg/ml) and kanamycin (50 µg/ml) incubated at 37 °C and 180 rpm [21]. After the cell growth reached mid exponential phase (A 600 = 0.6), the cells were cooled to 16 °C and then isopropyl-β-d-thiogalactopyranoside (IPTG) was added at a final concentration of 1 mM and further incubated at 16 °C and 180 rpm for 20 h.

Purification of Recombinant Proteins

The E. coli cells (600 ml culture) harbouring the plasmids containing genes encoding CtRGLf and CtRGL after IPTG induction were harvested by centrifugation at 9000×g, 4 °C for 10 min. The cell pellet was washed with 50 mM Tris–HCl buffer (pH 8.5) containing 100 mM NaCl and 50 mM imidazole, re-suspended in the same buffer. The re-suspended cells were subjected to ultra-sonication (Sonics, Vibra cell) for 8–12 min (5 s on and 15 s off pulse; 33 % amplitude), and the lysed cells were centrifuged at 20,000×g, 4 °C for 50 min. The supernatant (cell free extract) obtained after centrifugation was filtered through 0.45 µm membrane and applied to 1 ml Ni2+ ion chelating immobilised ion affinity chromatography (IMAC) column (HiTrap, GE Healthcare, USA). The column was pre-equilibrated with 50 mM Tris–HCl buffer (pH 8.5) containing 100 mM NaCl and 50 mM imidazole. Both CtRGLf and CtRGL contained a stretch of six histidine residue tag at N-terminal and were eluted with a linear gradient of imidazole (0–500 mM) in 50 mM of Tris–HCl buffer (pH 8.5) containing 100 mM NaCl. The purified CtRGLf and CtRGL enzymes were dialysed against 50 mM Tris–HCl buffer (pH 8.5) with several changes.

Enzyme Activity Assay

One ml reaction mixture containing 0.15 % (w/v) substrate dissolved in 50 mM of Tris–HCl buffer (pH 8.5) and 3 mM CaCl2 and the recombinant enzyme was incubated at 60 °C for 5 min. After incubation, the reaction mixture was kept on ice for 5 min to stop the reaction and then centrifuged at 13,000×g and the supernatant was used to measure the absorbance. The enzyme activity was assayed by monitoring the formation of Δ4,5 unsaturated d-GalpA residue at the non-reducing end of the cleaved substrate by measuring its absorbance at 235 nm (A 235) on a UV–Visible spectrophotometer (Gene-Quant, GE Healthcare, USA). One unit of enzyme activity was defined as the amount of enzyme required to produce 1 µmol of product per minute. The enzyme activity was calculated using the known molar coefficient of 4600 M−1 for Δ4,5 unsaturated d-GalpA [22].

Substrate Specificity

The substrate specificity of CtRGLf and CtRGL was investigated using various pectic substrates (1 %, w/v) viz. rhamnogalacturonan from soybean (RGS), rhamnogalacturonan from potato (RGP), pectic galactan from lupin (PGL), galactan from potato (GP), polygalacturonic acid (PGA) and pectin (25 % methyl-esterified) under optimised conditions. CtRGLf or CtRGL was incubated with substrate in 50 mM Tris–HCl buffer (pH 8.5) containing 3 mM CaCl2 for 5 min at optimum temperature and the A235 was recorded as mentioned in previous section. RGS, RGP, PGL and GP were purchased from Megazyme, Ireland. PGA and pectin (25 % methyl-esterified) were purchased from Sigma-Aldrich Corporation, USA.

Biochemical Characterisation

The optimum pH for the activity CtRGLf or CtRGL was determined by incubating the enzymes with 0.15 % (w/v) RGS at 60 °C for 5 min in different buffers containing 3 mM CaCl2: 50 mM MES (pH 6.0), 50 mM Tris–HCl (pH 7.0–9.0), 50 mM Glycine-NaOH (pH 10.0) and 50 mM CAPS (pH 11.0). The A235 was measured and the enzyme activity was calculated. To determine the optimum temperature for the activity of CtRGLf or CtRGL, the enzymes were incubated at different temperatures ranging from 30 to 100 °C in 50 mM Tris–HCl buffer (pH 8.5) containing 0.15 % (w/v) RGS and 3 mM CaCl2. The A 235 was measured and the enzyme activity was calculated as described earlier. The effect of temperature on stability of CtRGLf and CtRGL was determined by incubating the enzymes in Tris–HCl buffer (pH 8.5) at different temperatures ranging from 30 to 100 °C for 30 min followed by determination of activity at respective optimum temperatures. The kinetic parameters of CtRGLf and CtRGL were determined by assaying their activity against different concentrations of substrates under the optimised conditions of temperature and pH. The effect of various metal ions on the activity of CtRGLf or CtRGL was determined by pre-treating them with 10 mM EDTA at 25 °C for 60 min to remove any bound divalent metal ion, followed by buffer exchange to 50 mM Tris–HCl (pH 8.5). The activity was measured in the presence of CaCl2, MgCl2, MnCl2 or CoCl2 at a final concentration of 3 mM. The effect of Ca2+ ions on the activity of CtRGLf and CtRGL was determined by varying the CaCl2 concentration from 0 to 8 mM in the reaction mixture.

Thin-Layer Chromatography Analysis of CtRGLf- and CtRGL-Treated RGS

The mode of action of CtRGLf and CtRGL on RGS was determined by analysing the degradation products formed at different time intervals using thin-layer chromatography. Separate reaction mixtures (1 ml) of CtRGLf and CtRGL were set that contained 0.15 % (w/v) RGS and 3 mM CaCl2 in 50 mM Tris–HCl buffer (pH 8.5). A separate reaction was set for each time interval (0, 5, 15, 30 min, 1, 12 and 24 h). The large undigested polysaccharide molecules were precipitated by adding 2 volumes of absolute ethanol followed by centrifugation at 13,000×g for 10 min. The supernatant (1 ml) containing enzyme-degraded products of RGS was collected in separate microcentrifuge tubes and concentrated to 20 µl by incubating at 60 °C for 16 h. The concentrated sample (1 µl) was applied as a spot on a TLC plate (Merck, Germany) that was later developed in a solution containing 1-butanol, acetic acid and water in 5:2:3 ratio. The TLC plates were stained by diphenylamine-aniline-phosphoric acid reagent (1 ml 37.5 % HCl, 2 ml aniline, 10 ml 85 % H3PO4, 100 ml ethyl acetate and 2 g diphenylamine) and visualised after incubating at 80 °C for 30 min [23].

Results and Discussion

Sequence Analysis of CtRGLf

The amino acid sequence with locus tag Cthe_0246 from C. thermocellum in the CAZy database was found to be a part of 2461 bp long ORF. A prokaryotic ribosome-binding site (GGAGG) was identified 8 bp upstream of the putative translational start codon. BLAST analysis revealed the modular structure of the protein represented by the amino acid sequence in the form of three distinct domains. The N-terminal cleavage site of the signal peptide was predicted between Ala25 and Gly26 by SignalP 3.0 server (http://www.cbs.dtu.dk/services/SignalP-3.0/), which was same as that predicted using rules of Perlman and Halvorson (1983) [24]. Towards the N-terminal, downstream of the signal peptide a stretch of 20 amino acids showed similarity to Dockerin I from C. thermocellum (Fig. 1a). The second module spanning from amino acids residue 109–232 was identified to be a putative family 35 CBM as it showed similarity to an already characterised CBMs from C. thermocellum. Towards C-terminal, the catalytic module ranging from amino acid residue 259–820 exhibited 62 and 59 % sequence identity with two RG Lyases YesW and YesX, respectively, from B. subtilis [6]. A schematic representation of the molecular architecture of CtRGLf presented in Fig. 1a shows that the N-terminal putative Dockerin I module is connected to the putative CBM35 module which is in turn connected to a (RG lyase module (catalytic domain) via a small linker sequences. The interaction between enzymes borne Dockerin modules and the Cohesin modules of a scaffold protein gives rise to the cellulosomal complex [15]. The presence of a putative Dockerin I at N-terminal and the subcellular localisation score predicted by PSORT server indicated that the protein encoded by sequence Cthe_0246 (CtRGLf is a derivative of Cthe_0246 without the N-terminal Dockerin I) is an extracellular enzyme and probably integrates as a component of the C. thermocellum cellulosome.

Purification of Recombinant CtRGLf and CtRGL

The recombinant CtRGLf and CtRGL expressed as soluble proteins and after purification displayed homogeneous single bands on 12 % SDS-PAGE gels (Fig. 1b, c). The molecular masses of the recombinant CtRGLf and CtRGL including the N-terminal histidine tag were calculated to be 80.2 and 63.9 kDa, respectively, which are in close agreement with those observed on SDS-PAGE gels. The purification folds of CtRGLf and CtRGL were 21 and 37, respectively. The activity yields of CtRGLf and CtRGL were 17 and 1.8 %, respectively (Table 1). CtRGL showed a tendency to form inclusion bodies resulting in a low activity yield which was also reported for RG lyase, Rgl11Y from C. cellulolyticum [7].

Substrate Specificity of CtRGLf and CtRGL

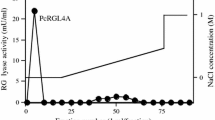

The β-elimination reaction mechanism of CtRGLf and CtRGL was confirmed by the increase in the absorbance at 235 nm, when the enzymes were incubated with their substrate RGS, which is due to the formation of double bond in the d-GalpA residue at the newly formed non-reducing end. Both CtRGLf and CtRGL displayed high activity against two RGs (RGS and RGP) and moderate activity against pectic galactan (PGL). Both the enzymes showed low activity against PGA and pectin (25 % methyl-esterified) (Table 2). CtRGLf and CtRGL were primarily active against rhamnogalacturonans but they could also cleave the homogalacturonan component of pectin. It may be easy to comprehend that the low activities of CtRGLf and CtRGL against PGL may be due to the low content of l-Rhap and d-GalpA residues present in this substrate when compared to both RGs (RGS and RGP). However, it is noteworthy that this catalytic property of CtRGLf and CtRGL is in stark contrast to that of some other RG lyases, Rgl11Y and Rgl11A from C. cellulolyticum and P. cellulosa, respectively [7, 8]. Rgl11A and Rgl11Y displayed higher activity on PGP, despite its low l-Rhap and d-GalpA contents. This highlights the role of β-d-galactopyranose (d-Galp) substitutions for their enhanced activity on PGP as it is highly substituted with d-Galp residues [7, 8]. All these substrates contain RG I main chain, but differ in the percentage of d-Galp residues in their side chains. PGL and PGP contain around 74 and 87 % d-Galp, respectively, while RGP and RGS contain only 20 % d-Galp. Very recently, another RG lyase belonging to PL family 4, PcRGL4A from Penicillium chrysogenum has been reported which too does not preferentially degrades substrates with higher d-Galp substitution [25].

Biochemical Properties of CtRGLf and CtRGL

The optimum temperature for the activity of CtRGLf was 70 °C, whereas for CtRGL it was 60 °C (Fig. 2a). Optimum pH for the activity of both CtRGLf and CtRGL was 8.5 (Fig. 2b), similar to other RG lyases from B. subtilis, C. cellulolyticum, C. japonicus and B. licheniformis [6–8, 20]. CtRGLf was more thermostable than CtRGL as it retained 90 % of its activity after incubation at 60 °C for 30 min, whereas CtRGL showed only 45 % of its activity obtained under optimised assay conditions (Fig. 2c). The higher thermal stability of CtRGLf may be attributed to the presence of CBM35. A Family 13 CBM has also been recently reported to provide thermostability to its associate catalytic module [26]. The K m values of CtRGLf and CtRGL with RGS were similar, 4.8 mg/ml and 5.1 mg/ml, respectively (Table 2). This indicated that CtRGL, the truncated form of CtRGLf can cleave RGS, independently even in the absence of CBM. The k cat values of CtRGLf and CtRGL against RGS were 21 and 7 s−1, respectively (Table 2). The lower k cat value of CtRGL may be attributed to the low activity yield obtained (Table 1) which might have been due to the formation of inclusion bodies as mentioned in “Purification of recombinant CtRGLf and CtRGL ” section. Structural determination of RG lyases from B. subtilis established an important role of calcium ions for enzyme catalysis [27]. The sequence analysis of CtRGLf revealed the presence of conserved Ca2+ ions binding amino acid residues. Therefore, the effect of divalent metal ions on the activity of CtRGLf and CtRGL was analysed after the treatment with 10 mM EDTA which completely abolished the enzyme activity (Table 3). These results highlighted the important role of divalent metal ions on the activity of CtRGLf and CtRGL. In the absence of any metal ion CtRGLf and CtRGL showed 6.5 and 4.4 U/mg, respectively, which were 67 and 77 %, respectively, of their activities in the presence of 3 mM Ca2+ ions. Among the various metal ions tested, Ca2+ ions (3 mM) were able to restore the enzyme activity of EDTA-treated CtRGLf and CtRGL up to 45 and 35 %, respectively, when compared with the activity of EDTA-untreated enzymes in the presence of 3 mM Ca2+ (Table 3). However, Mn2+ ions (3 mM) resulted in higher reactivation than Ca2+ ions (3 mM), restoring the enzyme activity of EDTA-treated CtRGLf and CtRGL up to 96 and 77 %, respectively. Ochiai et al. have also reported that Mn2+ ions were more potent than Ca2+ ions in restoring the activity of EDTA-treated two RG lyases from B. subtilis [6].

a Effect of temperature on activity of CtRGLf and CtRGL. The activity at 70 °C for CtRGLf and activity at 60 °C for CtRGL was taken as 100 %, b effect of pH on activity of CtRGLf and CtRGL. The activities of both CtRGLf and CtRGL at pH 8.5 were taken as 100 %, c thermal stability of CtRGLf and CtRGL. The activity of the enzymes incubated at 4 °C was taken as 100 %

Two different types of RG lyases have been reported, the first which do not have an absolute requirement of calcium ions and show optimum activity at acidic pH and the second which requires calcium ions and show optimum activity at basic pH. RG lyase from Erwinia chrysanthemi is active in acidic pH and does not depend on Ca2+ ions for its activity [28]. RG lyases from B. subtilis, C. cellulolyticum, C. japonicas and B. licheniformis are active in alkaline pH and require Ca2+ ions [6, 7, 20]. CtRGLf and CtRGL were optimally active at alkaline pH and required Ca2+ ions for their activity (Fig. 3). The activities of CtRGLf and CtRGL were enhanced by 1.5 and 1.3 fold, respectively, by 3 mM Ca2+ ions.

Thin-Layer Chromatography Analysis of CtRGLf- and CtRGL-Treated RGS

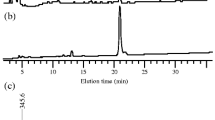

The profiles of time-dependent enzymatic degradation of RGS by CtRGLf and CtRGL, analysed by TLC, are shown in Fig. 4. It has been reported earlier that the smallest possible reaction product generated by the activity of a RG lyase on RG I is unsaturated RG disaccharide whose mobility is similar to that of d-GalpA [6]. All the samples of both CtRGLf and CtRGL collected at different time periods over 24 h displayed the products of variable sizes, appearing as discrete spots with much less mobility than d-GalpA on the TLC plate. This suggested that both CtRGLf and CtRGL cleave the substrate endolytically and produced oligosaccharides larger than the unsaturated RG disaccharide as the major products. This type of substrate cleavage pattern was also displayed by an endo- RG lyase (YesW) from B. subtilis [6]. ATP-binding cassette (ABC) transporters are trans-membrane proteins involved in metabolite translocation across the cell membrane [29]. Owing to the presence of the gene encoding a putative ABC transporter downstream of the ORF encoding CtRGLf, it may be speculated that the oligosaccharides produced by CtRGLf are taken up by C. thermocellum cells. However, till date, the existence of any pathway or enzymes which might metabolise these oligosaccharides is not known for C. thermocellum. The pectin and pectic oligosaccharides have been reported to show anti-proliferative effects on the human colonic adenocarcinoma cell line HT29 [30]. The RGI component of potato was reported to inhibit the proliferation of HT29 colon cancer cells [31]. The RG oligosaccharides produced by action of CtRGLf may be studied for therapeutic applications. Besides reporting a novel thermophilic RG lyase, this study presents cues to the potential of C. thermocellum to degrade RGI component of pectin and reinforces its versatility as a degrader of the plant biomass which is critical for recycling the nutrients in the ecosystem.

References

Vincken, J. P., Schols, H. A., & Oomen, R. J. (2003). If homogalacturonan were a side chain of rhamnogalacturonan I. Implications for cell wall architecture. Plant Physiology, 132, 1781–1789.

Ridley, B. L., O’Neill, M. A., & Mohnen, D. (2001). Pectins: structure, biosynthesis, and oligogalacturonide-related signalling. Phytochemistry, 57, 929–967.

Matsunaga, T., Ishii, T., & Matsumoto, S. (2004). Occurrence of the primary cell wall polysaccharide rhamnogalacturonan II in pteridophytes, lycophytes and bryophytes. Implications for the evolution of vascular plants. Plant Physiology, 134, 339–351.

O’Neill, M. A., Warrenfeltz, D., & Kates, K. (1996). Rhamnogalacturonan-II, a pectic polysaccharide in the walls of growing plant cell, forms a dimer that is covalently cross-linked by borate ester in vitro conditions for the formation and hydrolysis of the dimer. Journal of Biological Chemistry, 271, 22923–22930.

Oomen, R. J., Doeswijk, V. H., & Bush, M. S. (2002). In muro fragmentation of the rhamnogalacturonan I backbone in potato (Solanum tuberosum L.) results in a reduction and altered location of the galactan and arabinan side-chains and abnormal periderm development. Plant J, 30, 403–413.

Ochiai, A., Itoh, T., & Kawamata, A. (2007). Plant cell wall degradation by saprophytic Bacillus subtilis strains: gene clusters responsible for rhamnogalacturonande polymerization. Applied and Environment Microbiology, 73, 3803–3813.

Pages, S., Valette, O., & Abdou, L. (2003). A rhamnogalacturonan lyase in the Clostridium cellulolyticum cellulosome. Journal of Bacteriology, 185, 4727–4733.

McKie, V. A., Vincken, J. P., & Voragen, A. G. (2001). A new family of rhamnogalacturonan lyases contains an enzyme that binds to cellulose. Biochemical Journal, 355, 167–177.

Koshland, D. E. (1953). Stereochemistry and the mechanism of enzymatic reactions. Biological Reviews, 28, 416–436.

Moran, F. S., Nasuno, S., & Starr, M. P. (1968). Extracellular and intracellular polygalacturonic acid trans-eliminase of Erwinia carotovora. Archives of Biochemistry and Biophysics, 123, 298–306.

Lombard, V., Golaconda, R. H., & Drula, E. (2014). The Carbohydrate-active enzymes database (CAZy) in 2013. Nucleic Acids Research, 42, D490–D495.

Koukiekolo, R., Cho, H. Y., & Kosugi, A. (2005). Degradation of corn fibre by Clostridium cellulovorans cellulases and hemicellulases and contribution of scaffolding protein CbpA. Applied and Environment Microbiology, 71, 3504–3511.

Aachary, A. A., & Prapulla, S. G. (2011). Xylooligosaccharides (XOS) as an emerging prebiotic: microbial synthesis, utilization, structural characterization, bioactive properties, and applications. Comprehensive Reviews in Food Science and Food Safety, 10, 2–16.

Kashyap, D. R., Vohra, P. K., & Tewari, R. (2001). Application of pectinases in the commercial sector: a review. Bioresource Technology, 77, 215–227.

Fontes, C. M., & Gilbert, H. J. (2010). Cellulosomes: highly efficient nanomachines designed to deconstruct plant cell wall complex carbohydrates. Annual Review of Biochemistry, 79, 655–681.

Lamed, R., Setter, E., & Bayer, E. A. (1983). Characterization of a cellulose-binding, cellulase-containing complex in Clostridium thermocellum. Journal of Bacteriology, 156, 828–836.

Bayer, E. A., Morag, E., & Lamed, R. (1994). The cellulosome- a treasure-trove for biotechnology. Trends in Biotechnology, 12, 379–386.

Das, S. P., Ravindran, R., & Ahmed, S. (2012). Bioethanol production involving recombinant C. thermocellum hydrolytic hemicellulase and fermentative microbes. Applied Biochemistry and Biotechnology, 167, 1475–1488.

Anbar, M., Gul, O., & Lamed, R. (2012). Improved thermostability of Clostridium thermocellum endoglucanase Cel8A by using consensus-guided mutagenesis. Applied and Environmental Microbiology, 78, 3458–3464.

Silva, I. R., Jers, C., & Otten, H. (2014). Design of thermostable rhamnogalacturonan lyase mutants from Bacillus licheniformis by combination of targeted single point mutations. Applied Microbiology and Biotechnology, 98, 4521–4531.

Tartof, K. D., & Hobbs, C. A. (1987). Improved media for growing plasmid and cosmid clones. Bethesda Research Laboratories Focus, 9, 12.

Tanabe, H., Kobayashi, Y., Matuo, Y., Nishi, N., & Wada, F. (1984). Isolation and Fundamental Properties of endo-Pectate Lyase pl-Isozymes from Erwinia carotovora. Agricultural and Biological Chemistry, 48(8), 2113–2120.

Zhang, Z., Xiao, Z., & Linhardt, R. J. (2009). Thin layer chromatography for the separation and analysis of acidic carbohydrates. Journal of Liquid Chromatography & Related Technologies, 32, 1711–1732.

Perlman, D., & Halvorson, H. O. (1983). A putative signal peptidase recognition site and sequence in eukaryotic and prokaryotic signal peptides. Journal of Molecular Biology, 167, 391–409.

Iwai, M., Yamada, H., Ikemoto, T., Matsumoto, S., Fujiwara, D., Takenaka, S., & Sakamoto, T. (2015). Biochemical characterization and overexpression of an endo-rhamnogalacturonan lyase from Penicillium chrysogenum. Molecular Biotechnology, 57(6), 539–548.

Li, S., Yang, X., Bao, M., Wu, Y., Yu, W., & Han, F. (2015). Family 13 carbohydrate-binding module of alginate lyase from Agarivorans sp. L11 enhances its catalytic efficiency and thermostability, and alters its substrate preference and product distribution. FEMS microbiology letters, 362(10), fnv054.

Ochiai, A., Itoh, T., Mikami, B., Hashimoto, W., & Murata, K. (2009). Structural determinants responsible for substrate recognition and mode of action in family 11 polysaccharide lyases. Journal of Biological Chemistry, 284(15), 10181–10189.

Laatu, M., & Condemine, G. (2003). Rhamnogalacturonate lyase RhiE is secreted by the out system in Erwinia chrysanthemi. Journal of Bacteriology, 185, 1642–1649.

Ames, G. L., Mimura, C. S., & Shyamala, V. (1990). Bacterial periplasmic permeases belong to a family of transport proteins operating from Escherichia coli to human: traffic ATPases. FEMS Microbiology Reviews, 6(4), 429–446.

Olano, E., Rimbach, G. H., Gibson, G. R., & Rastall, R. A. (2002). Pectin and pectic-oligosaccharides induce apoptosis in in vitro human colonic adenocarcinoma cells. Anticancer Research, 23(1A), 341–346.

Cheng, H., Zhang, Z., & Leng, J. (2013). The inhibitory effects and mechanisms of rhamnogalacturonan I pectin from potato on HT-29 colon cancer cell proliferation and cell cycle progression. International Journal of Food Science and Nutrition, 64, 36–43.

Acknowledgments

The authors thank Department of Science and Technology, Ministry of Science and Technology, New Delhi, Govt. of India and Fundação para a Ciência e a Tecnologia, Portugal for Indo-Portugal joint project grant (INT/Portugal/P-14/2013). Fellowship provided by Ministry of Human Resource Development, Govt. of India to AD is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Dhillon, A., Fernandes, V.O., Dias, F.M.V. et al. A New Member of Family 11 Polysaccharide Lyase, Rhamnogalacturonan Lyase (CtRGLf) from Clostridium thermocellum . Mol Biotechnol 58, 232–240 (2016). https://doi.org/10.1007/s12033-016-9921-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12033-016-9921-6